coolant CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 285 of 2177

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not recom-

mended. Damage may occur to radiator or drain-

cock.

NOTE: It is not necessary to remove draincock dur-

ing a routine coolant drain.

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Open the draincock by turning it counterclock-

wise until it stops.

(3) Turn the draincock back (clockwise) 1/8 turn.

(4) Pull the draincock (Fig. 16) from the radiator

tank.

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

(3) Tighten the draincock by turning clockwise

until it stops.(4) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

RADIATOR PRESSURE CAP

DESCRIPTION

The cooling system pressure cap is located on the

radiator. The cap construction includes; stainless

steel swivel top, rubber seals, and retainer, main

spring, and a spring loaded valve (Fig. 17).

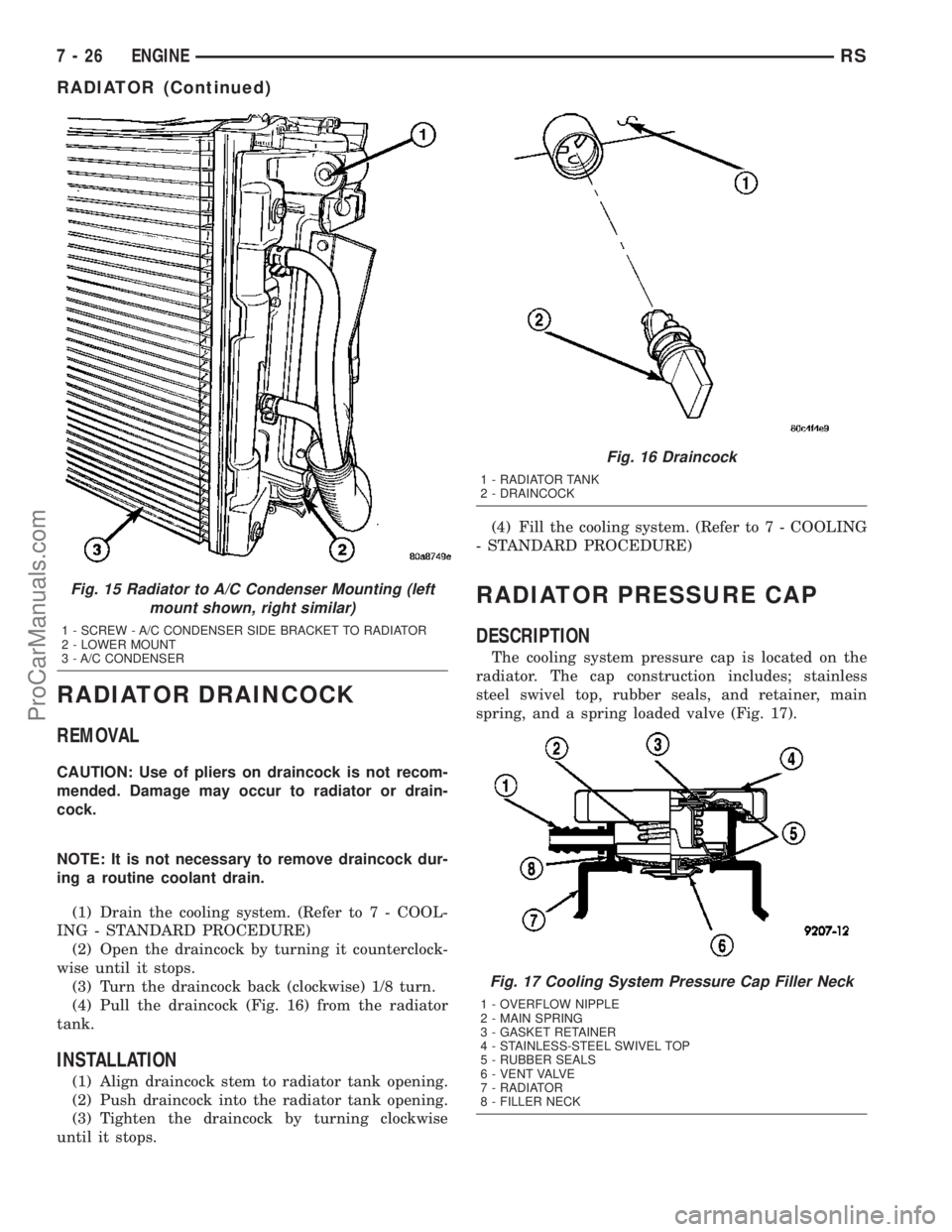

Fig. 15 Radiator to A/C Condenser Mounting (left

mount shown, right similar)

1 - SCREW - A/C CONDENSER SIDE BRACKET TO RADIATOR

2 - LOWER MOUNT

3 - A/C CONDENSER

Fig. 16 Draincock

1 - RADIATOR TANK

2 - DRAINCOCK

Fig. 17 Cooling System Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

7 - 26 ENGINERS

RADIATOR (Continued)

ProCarManuals.com

Page 286 of 2177

OPERATION

The cooling system is equipped with a pressure cap

that releases excessive pressure; maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is also a vent valve in the center of the cap.

This valve also opens when coolant is cooling and

contracting, allowing the coolant to return to cooling

system from coolant reserve system tank by vacuum

through a connecting hose.If valve is stuck shut,

or the coolant recovery hose is pinched, the

radiator hoses will be collapsed on cool down.

Clean the vent valve (Fig. 17) and inspect cool-

ant recovery hose routing, to ensure proper

sealing when boiling point is reached.

The gasket in the cap seals the filler neck, so that

vacuum can be maintained, allowing coolant to be

drawn back into the radiator from the reserve tank.

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP TESTING

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700 (Fig. 18). Working

the plunger, bring the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the pressure cap.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 18), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

DIAGNOSIS AND TESTING - RADIATOR CAP

TO FILLER NECK SEAL

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 19). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.

Fig. 18 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

Fig. 19 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

RSENGINE7-27

RADIATOR PRESSURE CAP (Continued)

ProCarManuals.com

Page 287 of 2177

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

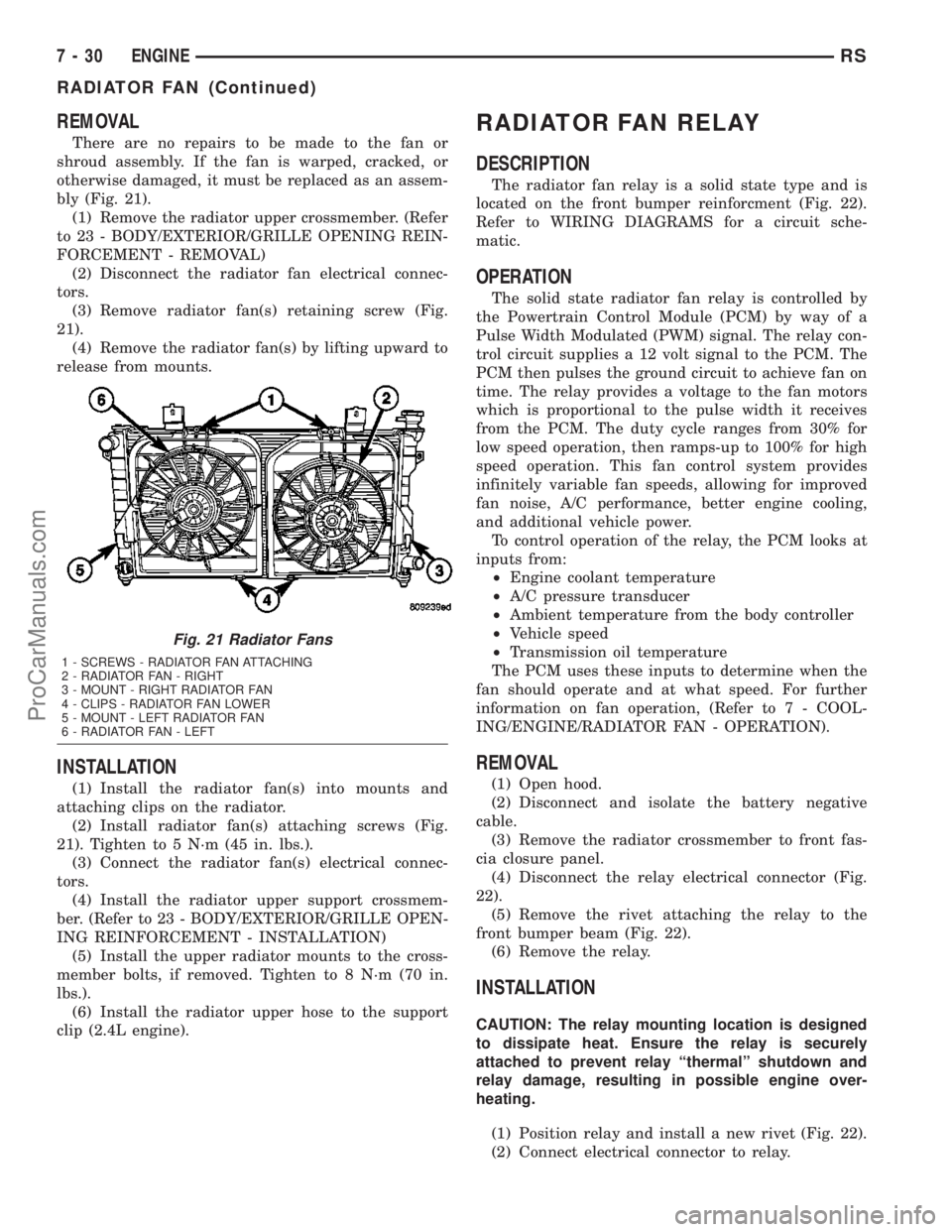

INSPECTION

Hold the cap in your hand,top side up(Fig. 20).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 21). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

Fig. 20 Cooling System Pressure Cap

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

7 - 28 ENGINERS

RADIATOR PRESSURE CAP (Continued)

ProCarManuals.com

Page 288 of 2177

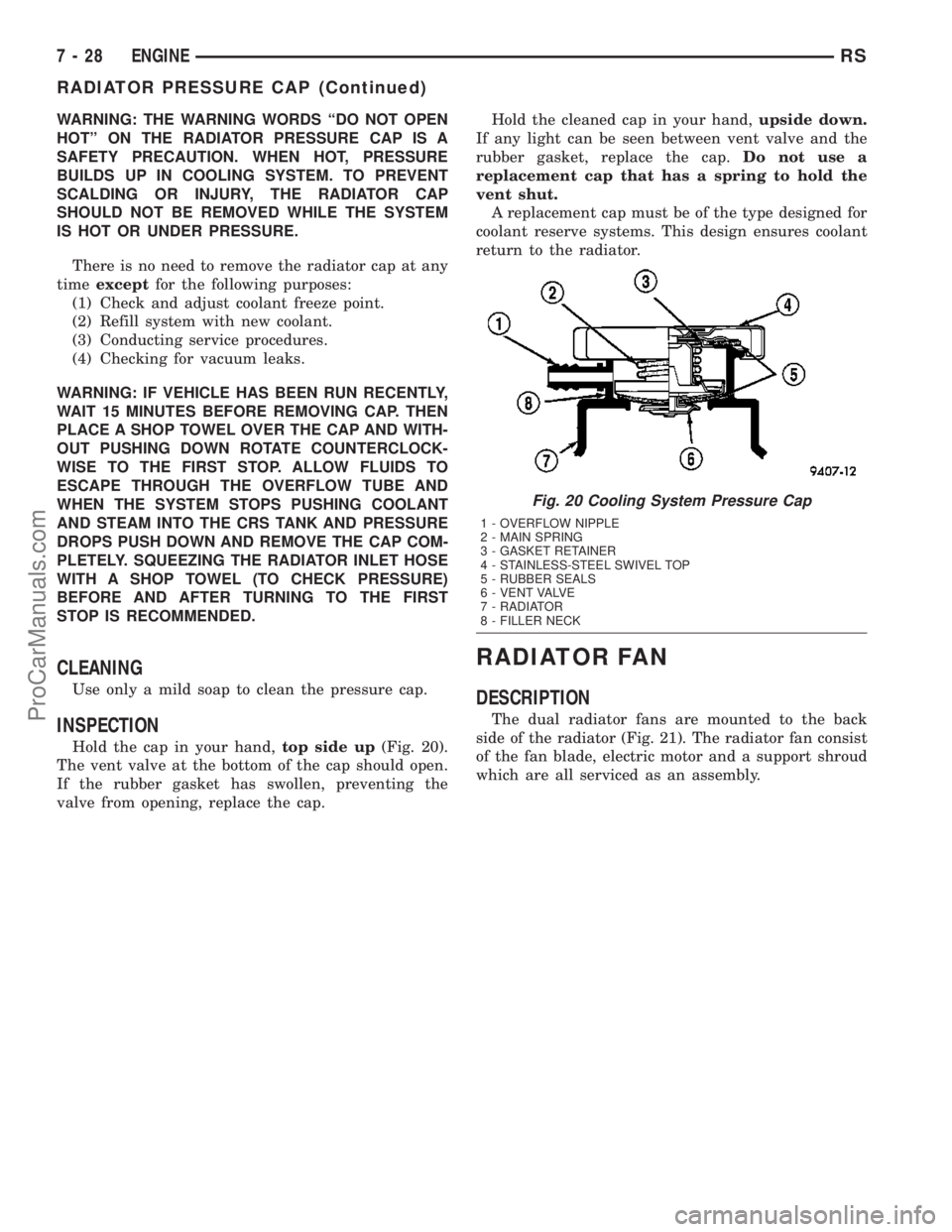

OPERATION

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE TRANSAXLE OIL

TEMPERATURE

Fan

Operation

Speeds:Initial Max Initial Max Initial Max

Fan On: 104ÉC

(220ÉF)110ÉC

(230ÉF) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%1,724 Kpa

(250 psi)2,068 Kpa

(300 psi) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%96ÉC (204ÉF) 111ÉC (232ÉF)

Fan Speed

Duty Cycles

(Ramps-up)

from 30% to

99%

Fan Off: 101ÉC

(214ÉF)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%1,710 Kpa

(248 psi)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%89ÉC (192ÉF) Fan Speed

Duty Cycles

(Ramps-down)

from 99% to

30%

DIAGNOSIS AND TESTING - RADIATOR FAN MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

RSENGINE7-29

RADIATOR FAN (Continued)

ProCarManuals.com

Page 289 of 2177

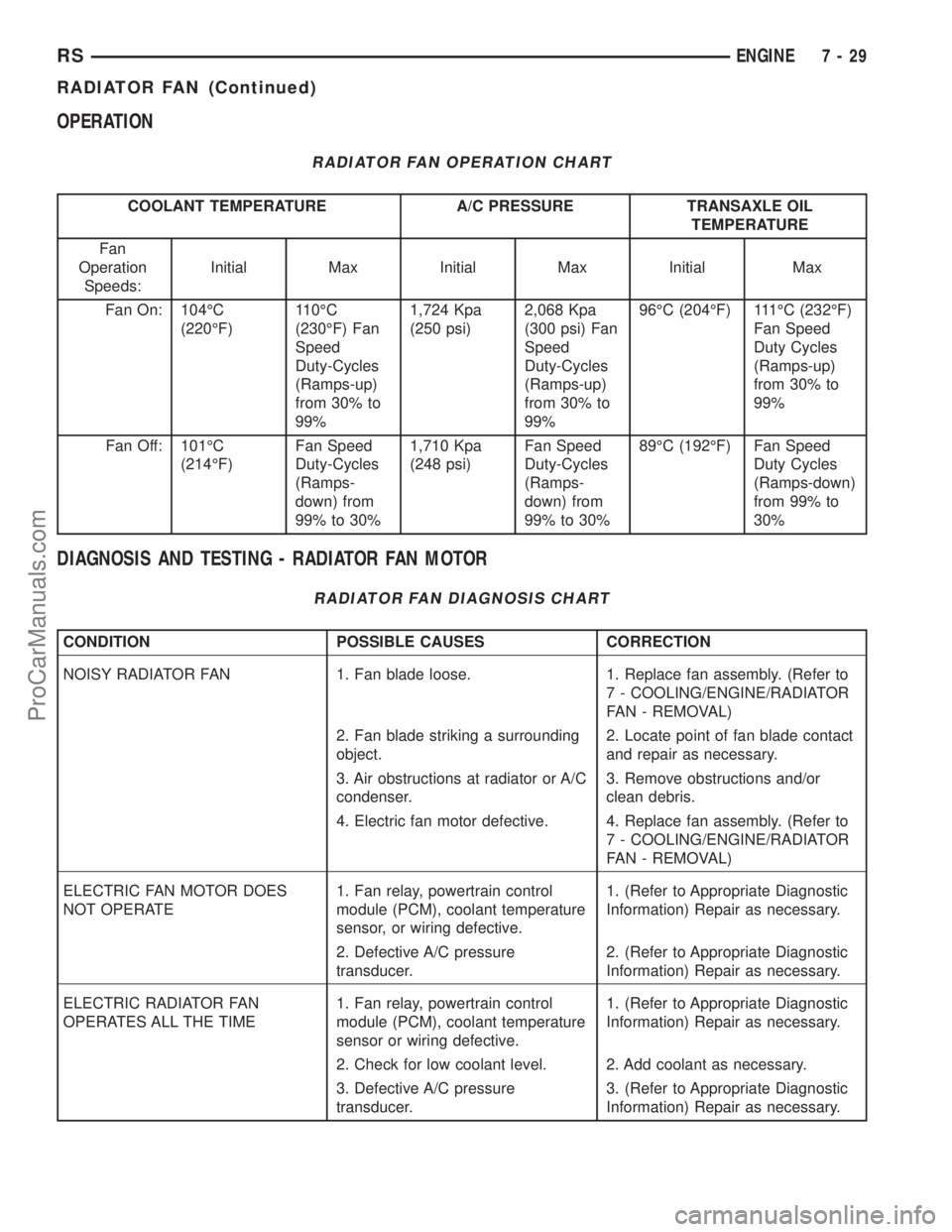

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 21).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

21).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

21). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.

(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 22).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

22).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 22).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

(1) Position relay and install a new rivet (Fig. 22).

(2) Connect electrical connector to relay.

Fig. 21 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

7 - 30 ENGINERS

RADIATOR FAN (Continued)

ProCarManuals.com

Page 291 of 2177

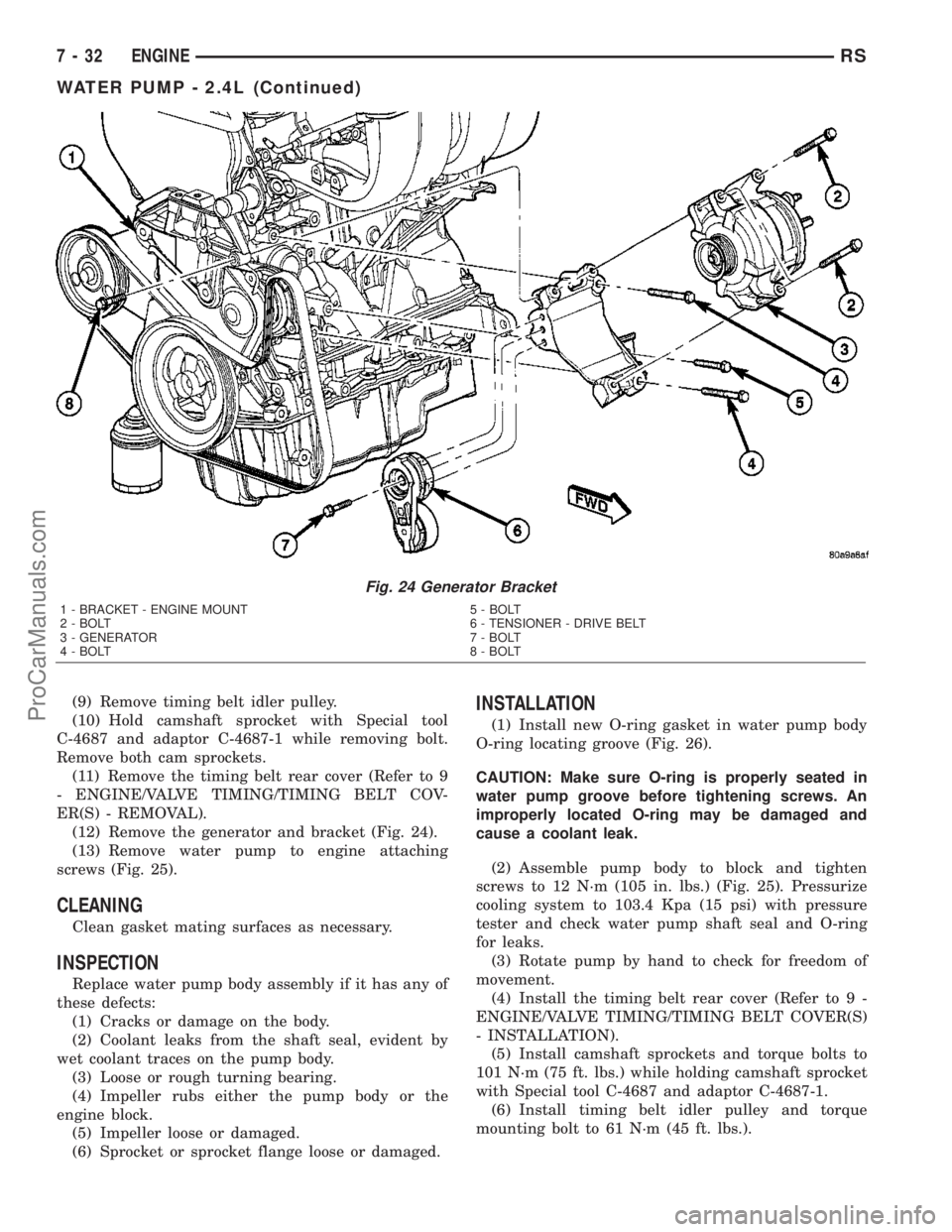

(9) Remove timing belt idler pulley.

(10) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(11) Remove the timing belt rear cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

(12) Remove the generator and bracket (Fig. 24).

(13) Remove water pump to engine attaching

screws (Fig. 25).

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

wet coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring locating groove (Fig. 26).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may be damaged and

cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 25). Pressurize

cooling system to 103.4 Kpa (15 psi) with pressure

tester and check water pump shaft seal and O-ring

for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.) while holding camshaft sprocket

with Special tool C-4687 and adaptor C-4687-1.

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

Fig. 24 Generator Bracket

1 - BRACKET - ENGINE MOUNT 5 - BOLT

2 - BOLT 6 - TENSIONER - DRIVE BELT

3 - GENERATOR 7 - BOLT

4 - BOLT 8 - BOLT

7 - 32 ENGINERS

WATER PUMP - 2.4L (Continued)

ProCarManuals.com

Page 293 of 2177

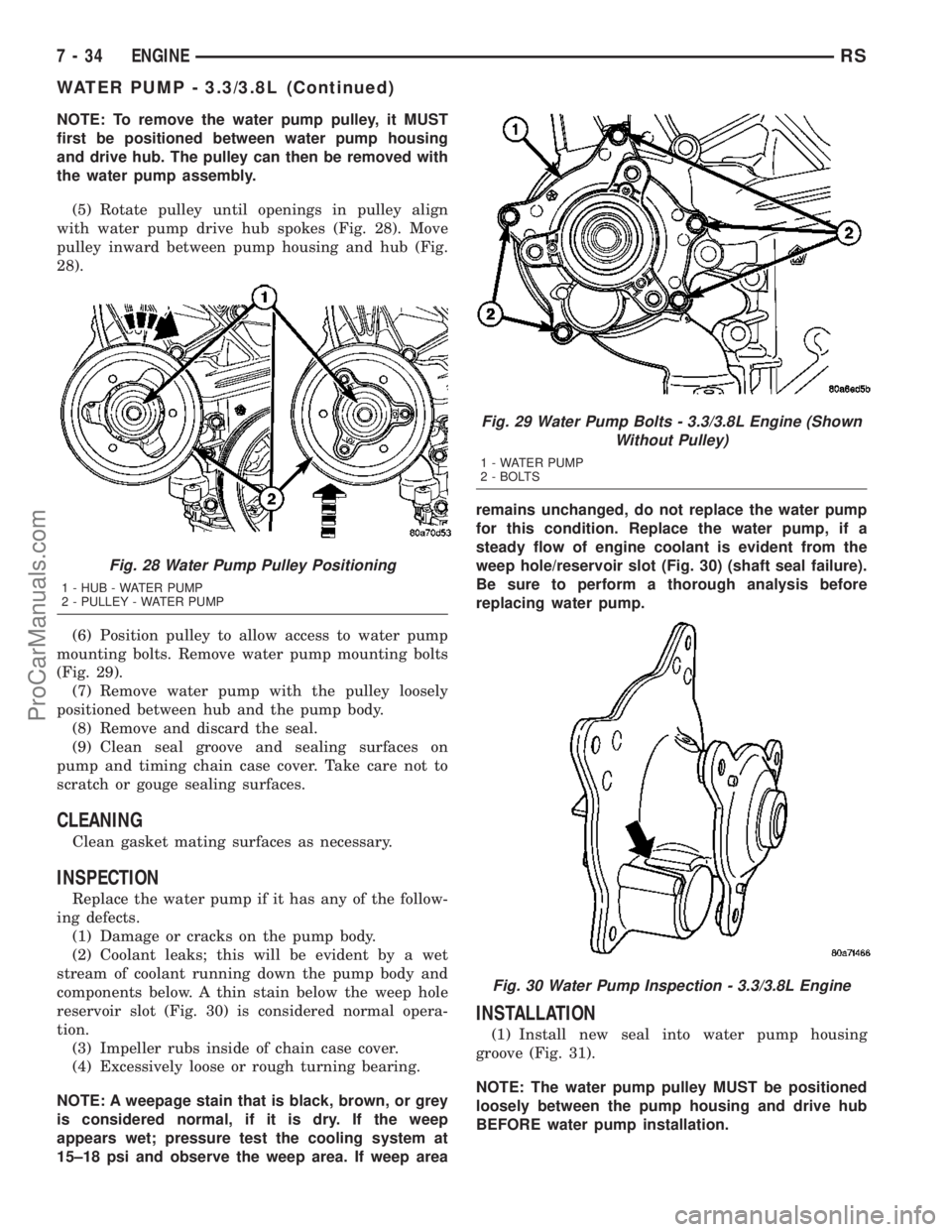

NOTE: To remove the water pump pulley, it MUST

first be positioned between water pump housing

and drive hub. The pulley can then be removed with

the water pump assembly.

(5) Rotate pulley until openings in pulley align

with water pump drive hub spokes (Fig. 28). Move

pulley inward between pump housing and hub (Fig.

28).

(6) Position pulley to allow access to water pump

mounting bolts. Remove water pump mounting bolts

(Fig. 29).

(7) Remove water pump with the pulley loosely

positioned between hub and the pump body.

(8) Remove and discard the seal.

(9) Clean seal groove and sealing surfaces on

pump and timing chain case cover. Take care not to

scratch or gouge sealing surfaces.

CLEANING

Clean gasket mating surfaces as necessary.

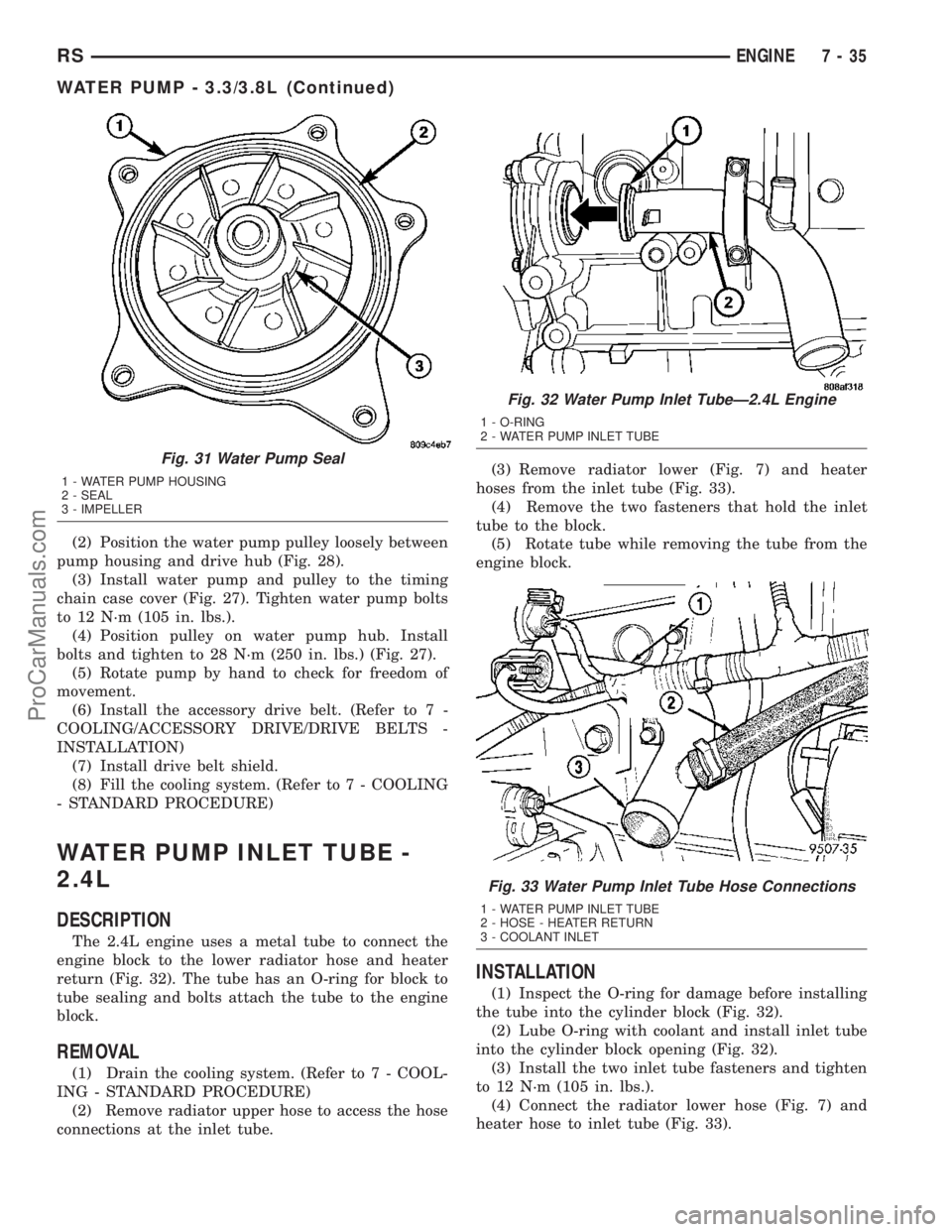

INSPECTION

Replace the water pump if it has any of the follow-

ing defects.

(1) Damage or cracks on the pump body.

(2) Coolant leaks; this will be evident by a wet

stream of coolant running down the pump body and

components below. A thin stain below the weep hole

reservoir slot (Fig. 30) is considered normal opera-

tion.

(3) Impeller rubs inside of chain case cover.

(4) Excessively loose or rough turning bearing.

NOTE: A weepage stain that is black, brown, or grey

is considered normal, if it is dry. If the weep

appears wet; pressure test the cooling system at

15±18 psi and observe the weep area. If weep arearemains unchanged, do not replace the water pump

for this condition. Replace the water pump, if a

steady flow of engine coolant is evident from the

weep hole/reservoir slot (Fig. 30) (shaft seal failure).

Be sure to perform a thorough analysis before

replacing water pump.

INSTALLATION

(1) Install new seal into water pump housing

groove (Fig. 31).

NOTE: The water pump pulley MUST be positioned

loosely between the pump housing and drive hub

BEFORE water pump installation.

Fig. 28 Water Pump Pulley Positioning

1 - HUB - WATER PUMP

2 - PULLEY - WATER PUMP

Fig. 29 Water Pump Bolts - 3.3/3.8L Engine (Shown

Without Pulley)

1 - WATER PUMP

2 - BOLTS

Fig. 30 Water Pump Inspection - 3.3/3.8L Engine

7 - 34 ENGINERS

WATER PUMP - 3.3/3.8L (Continued)

ProCarManuals.com

Page 294 of 2177

(2) Position the water pump pulley loosely between

pump housing and drive hub (Fig. 28).

(3) Install water pump and pulley to the timing

chain case cover (Fig. 27). Tighten water pump bolts

to 12 N´m (105 in. lbs.).

(4) Position pulley on water pump hub. Install

bolts and tighten to 28 N´m (250 in. lbs.) (Fig. 27).

(5) Rotate pump by hand to check for freedom of

movement.

(6) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(7) Install drive belt shield.

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

WATER PUMP INLET TUBE -

2.4L

DESCRIPTION

The 2.4L engine uses a metal tube to connect the

engine block to the lower radiator hose and heater

return (Fig. 32). The tube has an O-ring for block to

tube sealing and bolts attach the tube to the engine

block.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove radiator upper hose to access the hose

connections at the inlet tube.(3) Remove radiator lower (Fig. 7) and heater

hoses from the inlet tube (Fig. 33).

(4) Remove the two fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block.

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 32).

(2) Lube O-ring with coolant and install inlet tube

into the cylinder block opening (Fig. 32).

(3) Install the two inlet tube fasteners and tighten

to 12 N´m (105 in. lbs.).

(4) Connect the radiator lower hose (Fig. 7) and

heater hose to inlet tube (Fig. 33).

Fig. 31 Water Pump Seal

1 - WATER PUMP HOUSING

2 - SEAL

3 - IMPELLER

Fig. 32 Water Pump Inlet TubeÐ2.4L Engine

1 - O-RING

2 - WATER PUMP INLET TUBE

Fig. 33 Water Pump Inlet Tube Hose Connections

1 - WATER PUMP INLET TUBE

2 - HOSE - HEATER RETURN

3 - COOLANT INLET

RSENGINE7-35

WATER PUMP - 3.3/3.8L (Continued)

ProCarManuals.com

Page 321 of 2177

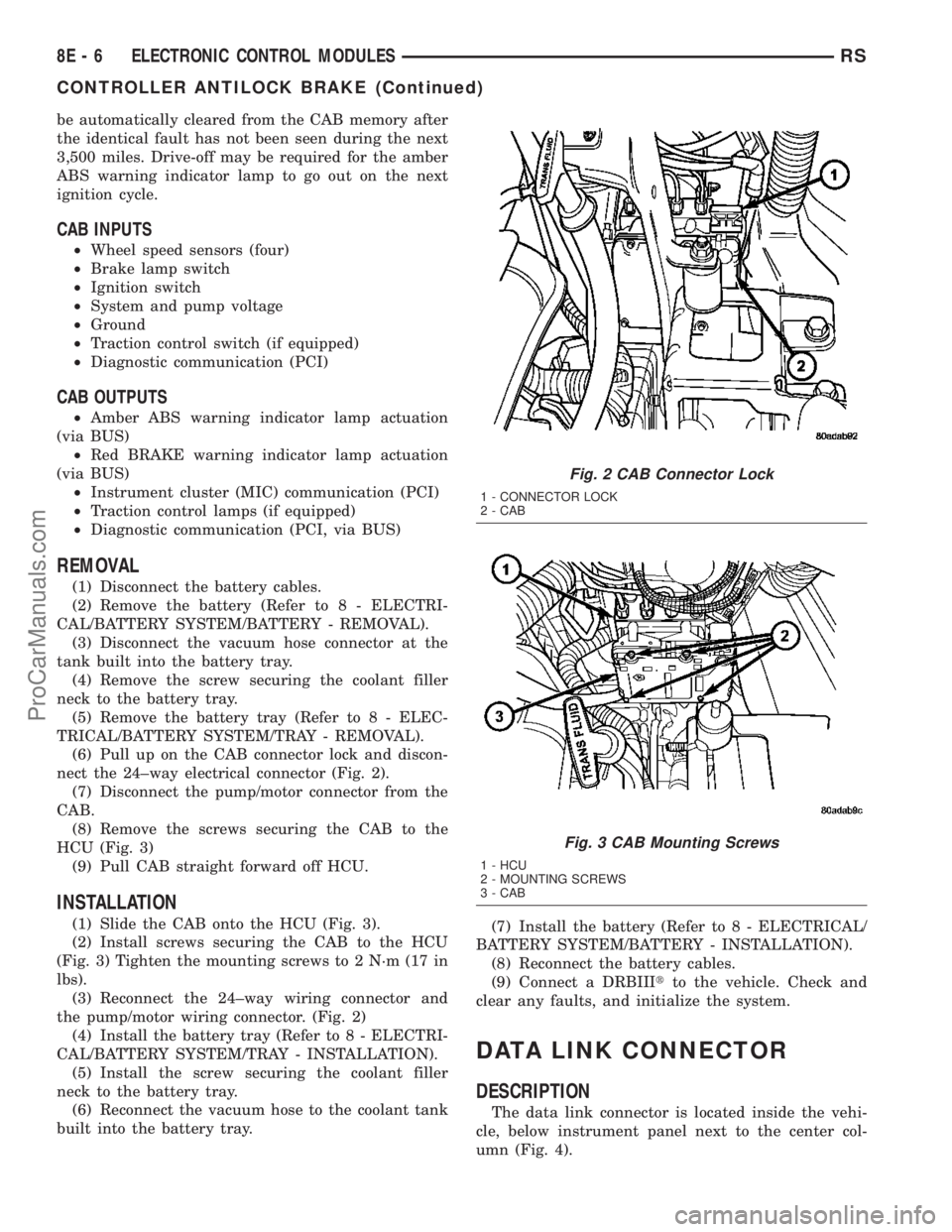

be automatically cleared from the CAB memory after

the identical fault has not been seen during the next

3,500 miles. Drive-off may be required for the amber

ABS warning indicator lamp to go out on the next

ignition cycle.

CAB INPUTS

²Wheel speed sensors (four)

²Brake lamp switch

²Ignition switch

²System and pump voltage

²Ground

²Traction control switch (if equipped)

²Diagnostic communication (PCI)

CAB OUTPUTS

²Amber ABS warning indicator lamp actuation

(via BUS)

²Red BRAKE warning indicator lamp actuation

(via BUS)

²Instrument cluster (MIC) communication (PCI)

²Traction control lamps (if equipped)

²Diagnostic communication (PCI, via BUS)

REMOVAL

(1) Disconnect the battery cables.

(2) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(3) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(4) Remove the screw securing the coolant filler

neck to the battery tray.

(5) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(6) Pull up on the CAB connector lock and discon-

nect the 24±way electrical connector (Fig. 2).

(7) Disconnect the pump/motor connector from the

CAB.

(8) Remove the screws securing the CAB to the

HCU (Fig. 3)

(9) Pull CAB straight forward off HCU.

INSTALLATION

(1) Slide the CAB onto the HCU (Fig. 3).

(2) Install screws securing the CAB to the HCU

(Fig. 3) Tighten the mounting screws to 2 N´m (17 in

lbs).

(3) Reconnect the 24±way wiring connector and

the pump/motor wiring connector. (Fig. 2)

(4) Install the battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(5) Install the screw securing the coolant filler

neck to the battery tray.

(6) Reconnect the vacuum hose to the coolant tank

built into the battery tray.(7) Install the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(8) Reconnect the battery cables.

(9) Connect a DRBIIItto the vehicle. Check and

clear any faults, and initialize the system.

DATA LINK CONNECTOR

DESCRIPTION

The data link connector is located inside the vehi-

cle, below instrument panel next to the center col-

umn (Fig. 4).

Fig. 2 CAB Connector Lock

1 - CONNECTOR LOCK

2 - CAB

Fig. 3 CAB Mounting Screws

1 - HCU

2 - MOUNTING SCREWS

3 - CAB

8E - 6 ELECTRONIC CONTROL MODULESRS

CONTROLLER ANTILOCK BRAKE (Continued)

ProCarManuals.com

Page 327 of 2177

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²Ambient temperature Sensor

²ASD Relay

²Battery Temperature Sensor (NGC)

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Torque Management Input

²Transaxle Control Module (3.3/3.8L Only)

²Transmission Control Relay (Switched B+) (2.4L

Only)

²Transmission Pressure Switches (2.4L Only)

²Transmission Temperature Sensor (2.4L Only)

²Transmission Input Shaft Speed Sensor (2.4L

Only)

²Transmission Output Shaft Speed Sensor (2.4L

Only)

²Transaxle Gear Engagement

²Vehicle Speed

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

²Torque Reduction Request

²Transmission Control Relay (2.4L Only)

²Transmission Solenoids (2.4L Only)

²Vehicle Speed

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com