brake sensor CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1117 of 2177

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Body Control Module C3 BK/WT Under Left Instrument Panel 40, 41

Body Control Module C4 BK/GY Under Left Instrument Panel 19, 20, 29

Body Control Module C5 BK Under Left Instrument Panel 19, 20, 29

Boost Pressure Sensor (Diesel) BK Top Left of Engine N/S

Brake Fuid Level Switch BK On Master Cylinder 6

Brake Lamp Switch BK At Top Of Brake Pedal 40, 41

Brake Transmission Shift

Interlock Solenoid (EATX)BK Near Steering Column 19, 20, 21, 30

C100 BK Left Fender Shield 5, 11

C101 LTGY Left Fender Shield 5

C102 (2.4L) BK Top Front of Engine 11

C102 (3.3/3.8L) BK At Fuel Rail 17

C103 (Diesel) BK Left Side Engine Compartment 5

C106 (Export) BK Near Left Headlamp Leveling Motor N/S

C107 (Export) BK Near Right Headlamp Leveling

MotorN/S

C110 (2.4L) BK Left Front Engine 11

C111 (2.4L) BK Left Front Engine 11

C200 GY Left Side Instrument Panel 19, 20, 29, 40, 41

C201 YL Left Side Instrument Panel 19, 20, 29, 40, 41

C202 GY Right Side Instrument Panel A/C

Heatrer Unit19, 23, 28

C203 (United Kingdom) WT Right Side of Instrument Panel N/S

C204 Rear of Radio 49

C300 (LHD) BK Left Front Door Lower 35, 42

C300 (RHD) BK Right Front Door Lower N/S

C301 LTGY Left Front Door Upper 35, 42

C302 LTGY Right Front Door Upper 8, 38, 43

C303 (LHD) BK Right Front Door Lower 8, 43

C303 (RHD) BK Left Front Door Lower 38, 43

C304 YL Left Wire Track Seat to Body 31

C305 GY Left Wire Track Seat to Body 31

C306 YL Right Wire Track Seat to Body 32

C307 GY Right Wire Track Seat to Body 32

C308 BL Left Rear Sliding Door 39

C309 GN Right Rear Sliding Door 31, 32, 38

C310 BK At Front Console 33

C311 GY Rear A/C Switch N/S

C312 GY At Dome Lamp 32, 38, 49

C313 BK At Rear Console 33

C314 BK Left Side Liftgate 48

C315 BK Right Side Liftgate 48

C316 BK Wire Track to Sliding Door N/S

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1118 of 2177

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C317 BK Right Sliding Door 31

C318 (Trailer Tow) BK Left Quarter N/S

C319 Left Side Liftgate N/S

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 BK On Seat Harness to Body 31

C324 BK Left Sliding Door N/S

C325 BK Right Sliding Door 31

C326 YL At Driver Side Airbag N/S

C327 YL At Passenger Side Airbag N/S

C328 Front of Left Quarter 46

C329 (Diesel) BK Near Fuel Tank 33

C330 (Diesel) LTGY Left Rear Engine Compartment N/S

C331 (Diesel) BK Left Rear Engine Compartment N/S

Cabin Heater RHD) At Heater N/S

Cabin Heater Assist C1 (Diesel) BK Top of Engine 15, 16

Cabin Heater Assist C2 (Diesel) BK Top of Engine 15, 16

Camshaft Position Sensor (Gas) BK Rear of Cylinder Head

Right Side of Engine11

Camshaft Position Sensor

(Diesel)BK Rear of Cylinder Head 15, 16

CD Changer Behind CD Changer N/S

Center Dome Lamp GY At Lamp N/S

Center High Mounted Stop Lamp BK At Lamp 48

Clockspring - C1 WT Steering Column 19, 20, 21, 22, 30

Clockspring - C2 YL Steering Column 19, 20, 21, 22, 30

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 BK Steering Column N/S

Clockspring - C5 YL Steering Column N/S

Clutch Pedal Interlock Switch

(Diesel)RD At Switch/Driver Side 41

Clutch Pedal Upstop Switch

(Diesel)BK At Switch/Driver Side 41

Controller Anti-Lock Brake BK Right Side of Engine Compartment 11, 16, 17, 18

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 15

Crankshaft Position Sensor

(Diesel)BK Rear of Engine 16

Crankshaft Position Sensor (Gas) BK Rear of Engine 13, 17

Data Link Connector WT Lower Instrument Panel Near

Steering Column40, 41

Dosing Pump BK Top of Engine N/S

Driver Airbag Squib1 BN Steering Column N/S

Driver Airbag Squib2 BK Steering Column N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1126 of 2177

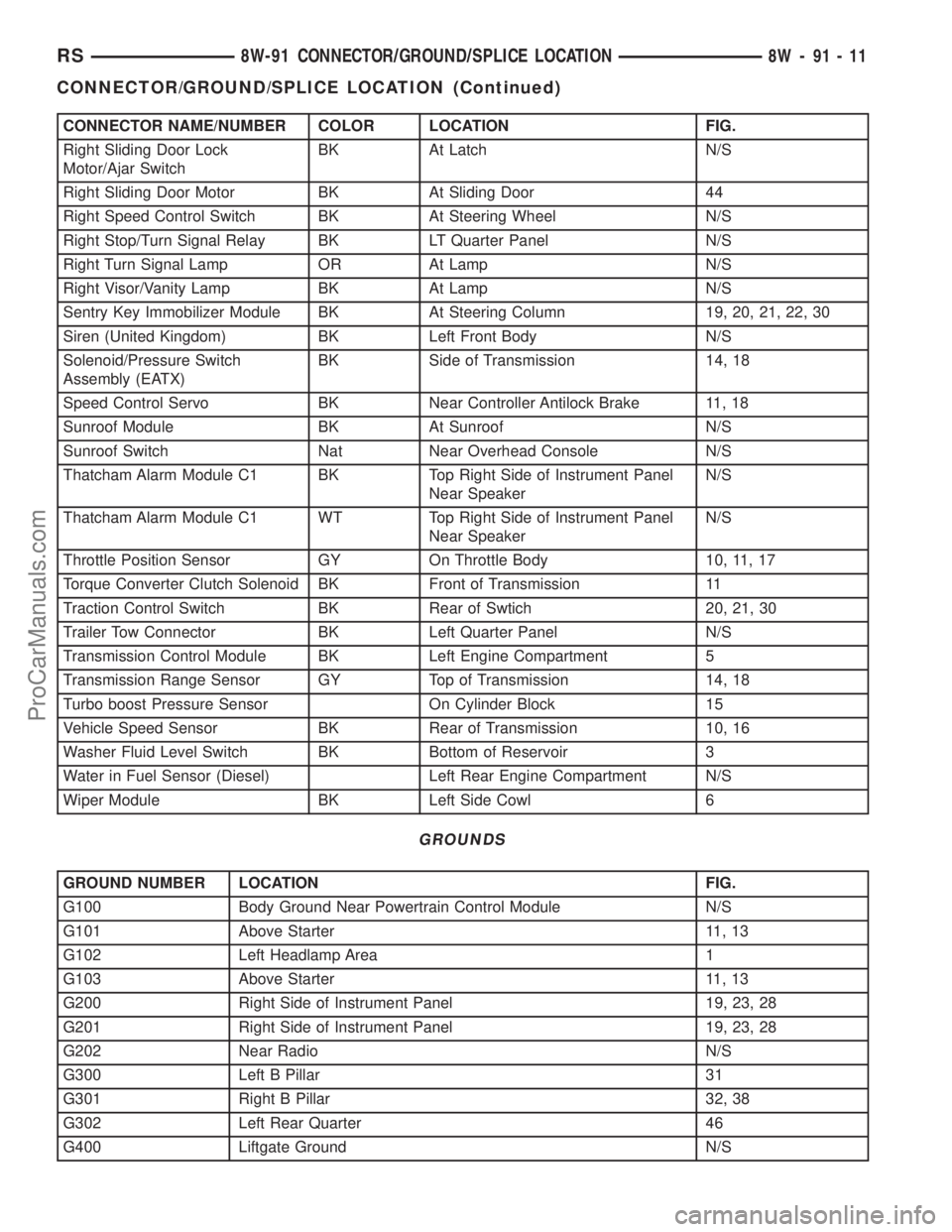

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Sliding Door Lock

Motor/Ajar SwitchBK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 44

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Immobilizer Module BK At Steering Column 19, 20, 21, 22, 30

Siren (United Kingdom) BK Left Front Body N/S

Solenoid/Pressure Switch

Assembly (EATX)BK Side of Transmission 14, 18

Speed Control Servo BK Near Controller Antilock Brake 11, 18

Sunroof Module BK At Sunroof N/S

Sunroof Switch Nat Near Overhead Console N/S

Thatcham Alarm Module C1 BK Top Right Side of Instrument Panel

Near SpeakerN/S

Thatcham Alarm Module C1 WT Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor GY On Throttle Body 10, 11, 17

Torque Converter Clutch Solenoid BK Front of Transmission 11

Traction Control Switch BK Rear of Swtich 20, 21, 30

Trailer Tow Connector BK Left Quarter Panel N/S

Transmission Control Module BK Left Engine Compartment 5

Transmission Range Sensor GY Top of Transmission 14, 18

Turbo boost Pressure Sensor On Cylinder Block 15

Vehicle Speed Sensor BK Rear of Transmission 10, 16

Washer Fluid Level Switch BK Bottom of Reservoir 3

Water in Fuel Sensor (Diesel) Left Rear Engine Compartment N/S

Wiper Module BK Left Side Cowl 6

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 11, 13

G102 Left Headlamp Area 1

G103 Above Starter 11, 13

G200 Right Side of Instrument Panel 19, 23, 28

G201 Right Side of Instrument Panel 19, 23, 28

G202 Near Radio N/S

G300 Left B Pillar 31

G301 Right B Pillar 32, 38

G302 Left Rear Quarter 46

G400 Liftgate Ground N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1237 of 2177

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is a two piece aluminum cast-

ing (Fig. 101) that attaches to the cylinder head with

fasteners. The manifold is a long branch design to

enhance low and mid-range torque

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

INTAKE MANIFOLD - UPPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect connector from inlet air tempera-

ture sensor (Fig. 102).

(3) Disconnect air intake tube at throttle body and

remove upper air cleaner housing.

(4) Disconnect connector from throttle position

sensor (TPS) (Fig. 104).

(5) Disconnect connector from idle air control (IAC)

motor (Fig. 104).

(6)

Disconnect connector from MAP sensor (Fig. 103).

(7) Remove vacuum lines for purge solenoid and

PCV valve at intake manifold.

(8) Remove vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

Fig. 101 Intake Manifold - Upper and Lower

1 - UPPER INTAKE MANIFOLD

2 - LOWER INTAKE MANIFOLD

Fig. 102 INLET AIR TEMPERATURE SENSOR - 2.4L

Fig. 103 MAP SENSOR - 2.4L

1 - MAP SENSOR

9 - 58 ENGINE 2.4LRS

ProCarManuals.com

Page 1238 of 2177

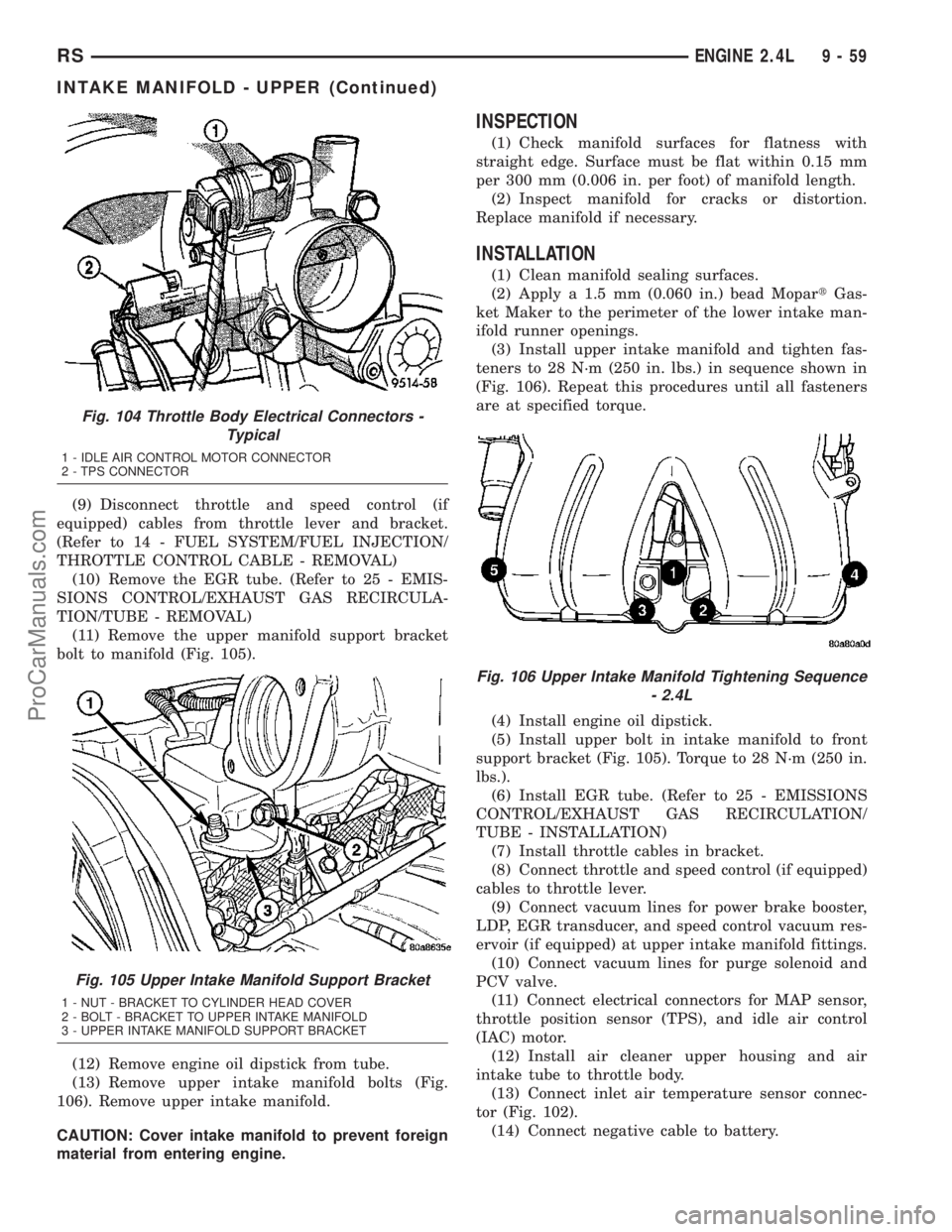

(9) Disconnect throttle and speed control (if

equipped) cables from throttle lever and bracket.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(10) Remove the EGR tube. (Refer to 25 - EMIS-

SIONS CONTROL/EXHAUST GAS RECIRCULA-

TION/TUBE - REMOVAL)

(11) Remove the upper manifold support bracket

bolt to manifold (Fig. 105).

(12) Remove engine oil dipstick from tube.

(13) Remove upper intake manifold bolts (Fig.

106). Remove upper intake manifold.

CAUTION: Cover intake manifold to prevent foreign

material from entering engine.

INSPECTION

(1) Check manifold surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (0.006 in. per foot) of manifold length.

(2) Inspect manifold for cracks or distortion.

Replace manifold if necessary.

INSTALLATION

(1) Clean manifold sealing surfaces.

(2) Apply a 1.5 mm (0.060 in.) bead MopartGas-

ket Maker to the perimeter of the lower intake man-

ifold runner openings.

(3) Install upper intake manifold and tighten fas-

teners to 28 N´m (250 in. lbs.) in sequence shown in

(Fig. 106). Repeat this procedures until all fasteners

are at specified torque.

(4) Install engine oil dipstick.

(5) Install upper bolt in intake manifold to front

support bracket (Fig. 105). Torque to 28 N´m (250 in.

lbs.).

(6) Install EGR tube. (Refer to 25 - EMISSIONS

CONTROL/EXHAUST GAS RECIRCULATION/

TUBE - INSTALLATION)

(7) Install throttle cables in bracket.

(8) Connect throttle and speed control (if equipped)

cables to throttle lever.

(9) Connect vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

(10) Connect vacuum lines for purge solenoid and

PCV valve.

(11) Connect electrical connectors for MAP sensor,

throttle position sensor (TPS), and idle air control

(IAC) motor.

(12) Install air cleaner upper housing and air

intake tube to throttle body.

(13) Connect inlet air temperature sensor connec-

tor (Fig. 102).

(14) Connect negative cable to battery.

Fig. 104 Throttle Body Electrical Connectors -

Typical

1 - IDLE AIR CONTROL MOTOR CONNECTOR

2 - TPS CONNECTOR

Fig. 105 Upper Intake Manifold Support Bracket

1 - NUT - BRACKET TO CYLINDER HEAD COVER

2 - BOLT - BRACKET TO UPPER INTAKE MANIFOLD

3 - UPPER INTAKE MANIFOLD SUPPORT BRACKET

Fig. 106 Upper Intake Manifold Tightening Sequence

- 2.4L

RSENGINE 2.4L9-59

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1266 of 2177

(11) Disconnect the throttle cables from the throt-

tle body.

(12) Disconnect the MAP, IAC, and TPS electrical

connectors.

(13) Disconnect the EGR transducer electrical con-

nector (if equipped).

(14) Disconnect the vacuum hoses from throttle

body.

(15) Disconnect the brake booster and speed con-

trol vacuum hoses.

(16) Disengage wire harness clip from the right

side engine mount.

(17) Remove the power steering reservoir from

mounting position and set aside.Do notdisconnect

hose.

(18) Disconnect ground strap from rear of cylinder

head.

(19) Disconnect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(20) Disconnect the fuel injector electrical harness

connector and disengage clip from support bracket.

(21) Disconnect camshaft and crankshaft position

sensor electrical connectors.

(22) Evacuate air conditioning system. Refer to 24

- HEATING & AIR CONDITIONING.

(23) Disconnect A/C compressor electrical connec-

tor.

(24) Disconnect the A/C lines from compressor.

Cover and seal all openings of hoses and compressor.

(25) Remove the radiator upper hose.

(26) Disengage electrical harness clip at transaxle

dipstick tube.

(27) Remove transaxle dipstick tube. Seal opening

using a suitable plug.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the transaxle,

damage to the inner wall of the hose will occur. To

prevent prevent potential leakage, the cooler hoses

must be cut off flush at the transaxle fitting, and a

service cooler hose splice kit must be installed

upon reassembly.

(28) Using a blade or suitable hose cutter, cut

transaxle oil cooler lines off flush with fittings. Plug

cooler lines and fittings to prevent debris from enter-

ing transaxle or cooler circuit. A service splice kit will

be installed upon reassembly.

(29) Disconnect transaxle shift linkage and electri-

cal connectors.

(30)

Raise vehicle on hoist and drain the engine oil.

(31) Remove the axle shafts. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - REMOVAL)

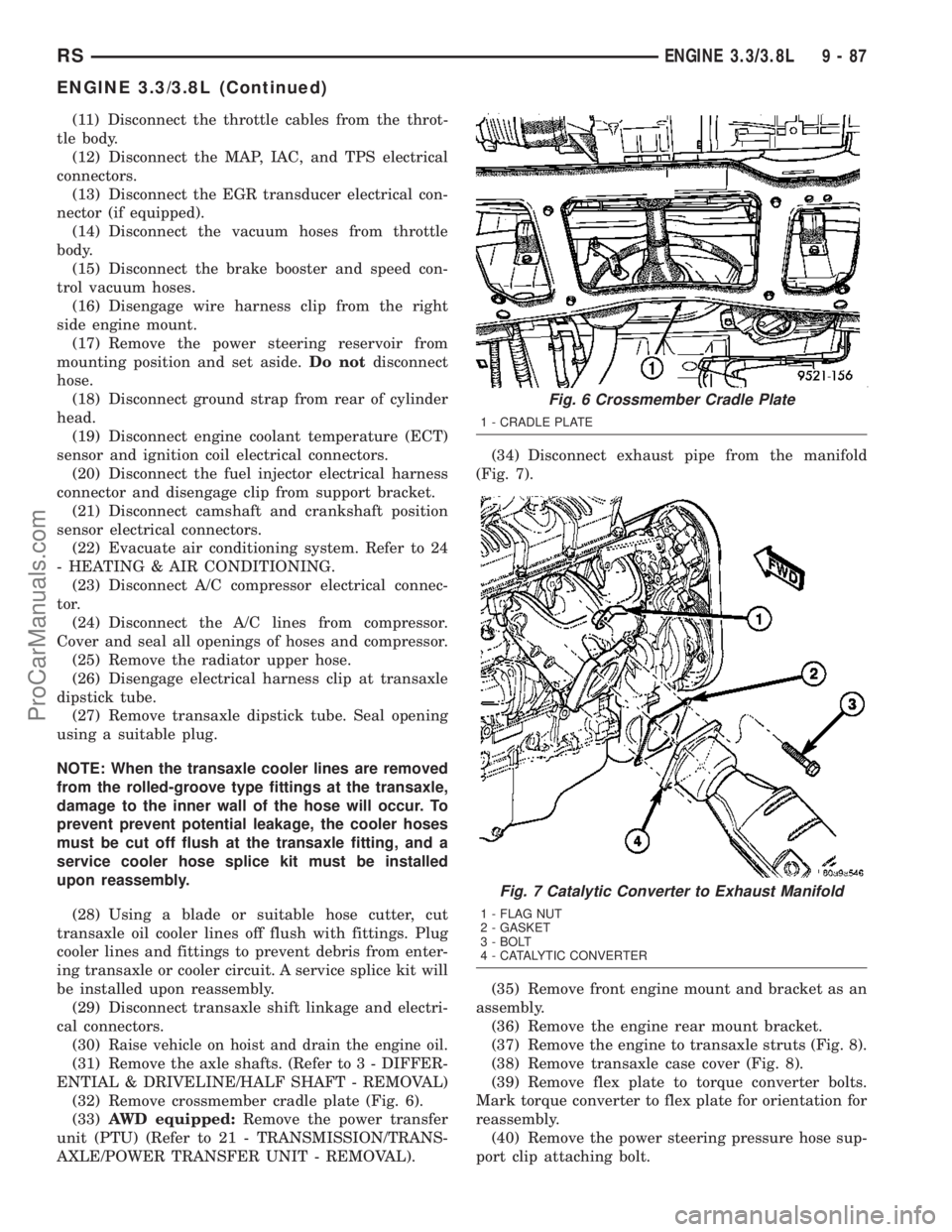

(32) Remove crossmember cradle plate (Fig. 6).

(33)AWD equipped:Remove the power transfer

unit (PTU) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/POWER TRANSFER UNIT - REMOVAL).(34) Disconnect exhaust pipe from the manifold

(Fig. 7).

(35) Remove front engine mount and bracket as an

assembly.

(36) Remove the engine rear mount bracket.

(37) Remove the engine to transaxle struts (Fig. 8).

(38) Remove transaxle case cover (Fig. 8).

(39) Remove flex plate to torque converter bolts.

Mark torque converter to flex plate for orientation for

reassembly.

(40) Remove the power steering pressure hose sup-

port clip attaching bolt.

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

RSENGINE 3.3/3.8L9-87

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1269 of 2177

(8) Install the generator and wiring harness (Refer

to 8 - ELECTRICAL/CHARGING/GENERATOR -

INSTALLATION).

(9) Raise vehicle.

(10) Attach wiring harness support clip to the

engine oil dipstick tube.

(11) Connect oil pressure switch electrical connec-

tor.

(12) Install the A/C compressor.

(13) Install the water pump pulley.

(14) Connect the radiator lower hose.(15) Install the accessory drive belt and splash

shield (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - INSTALLATION).

(16) Connect the engine block heater electrical con-

nector (if equipped).

(17) Connect the knock sensor electrical connector

(3.8L only).

(18) Install the torque converter to flex plate bolts.

(19) Install the transaxle case cover (Fig. 8).

(20) Install the powertrain struts (Fig. 8).

(21) Install the engine rear mount bracket.

(22) Install the engine front mount and bracket

assembly.

(23)AWD equipped;Install the power transfer

unit (PTU) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/POWER TRANSFER UNIT - INSTALLA-

TION).

(24) Install the axle shafts (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION).

(25) Connect exhaust pipe to manifold (Fig. 7).

(26) Install crossmember cradle plate (Fig. 6).

(27) Lower vehicle.

(28) Connect transaxle shift linkage.

(29) Connect transaxle electrical connectors.

(30) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(31) Install transaxle dipstick tube and attach

electrical harness clip.

(32) Connect the A/C lines to compressor.

(33) Connect the A/C compressor electrical connec-

tor.

(34) Evacuate and recharge A/C system.

(35) Connect crankshaft and camshaft position

sensors.

(36) Connect the fuel injector electrical harness

connector and engage clip to support bracket.

(37) Connect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(38) Connect the ground strap to rear of cylinder

head.

(39) Install power steering reservoir.

(40) Engage wire harness clip to engine right side

mount.

(41) Connect the brake booster and speed control

vacuum hoses.

(42) Connect the vacuum hoses to the throttle

body.

(43) Connect the EGR transducer electrical connec-

tor (if equipped).

(44) Connect the TPS, IAC, and MAP sensor elec-

trical connectors.

(45) Connect throttle cables to throttle body.

(46) Install the radiator fans (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

Fig. 13 Right Mount to Engine

1 - BOLT

2 - MOUNT BRACKET

3 - ENGINE RIGHT MOUNT ASSEMBLY

Fig. 14 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 90 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1324 of 2177

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

INTAKE MANIFOLD - UPPER

STANDARD PROCEDURE

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR

The composite upper intake manifold thread

bosses, if stripped out, can be repaired by utilizing a

repair screw available through Mopartparts. Repair

screws are available for the following manifold

attached components:

²MAP sensor

²Power steering reservoir

²EGR tube

²Throttle cable bracket

The repair screws require a unique tightening

torque specification from the original screw. Refer to

the following chart for specification.

DESCRIPTION TORQUE*

STRIP-OUT REPAIR SCREWS ONLY

MAP Sensor Repair

Screw4 N´m (35 in. lbs.)

Power Steering Reservoir

Repair Screw9 N´m (80 in. lbs.)

EGR Tube Attaching

Repair Screw9 N´m (80 in. lbs.)

Throttle Cable Bracket

Repair Screw9 N´m (80 in. lbs.)

*Install Slowly Using Hand Tools Only

STANDARD PROCEDURE - INTAKE MANIFOLD

VACUUM PORT REPAIR

The composite intake manifold vacuum ports can

be repaired. Although, if the manifold plenum cham-

ber is damaged or cracked, the manifold must be

replaced.

To repair a broken or damaged vacuum nipple

(port) on the composite intake manifold, perform the

following procedure:

PARTS REQUIRED TOOLS REQUIRED

´ Brass Nipple ± 1/49

O.D. x 1/89pipe thread

(LDP/Speed Control Port)´ Pipe Tap ± 1/89-18

NPT

´ Drill Bit ± 11/329

´ File/Sandpaper

´ Brass Nipple ± 1/29

O.D. x 1/49pipe thread

(Brake Booster Port)´ Pipe Tap ± 1/49-18

NPT

´ Drill Bit ± 7/169

´ File/Sandpaper

NOTE: While performing this procedure, avoid get-

ting the manifold material residue into the plenum

chamber.

(1) File or sand the remaining port back until a

flat surface is obtained (plane normal to nipple (port)

axis).

(2) Drill out the nipple (port) base using a 7/16º

(brake booster port) or 11/32º (LDP/speed control port

) drill bit (Fig. 113).

(3) Using a 1/4º±18 NPT (brake booster port) or

1/8º±18 NPT (LDP/speed control port ) pipe tap, cut

internal threads (Fig. 113). Use caution to start tap

in a axis same as original nipple.

(4) Apply MopartThread Sealant to threads of

repair nipple(s).

(5) Install repair nipple(s). Do not over torque

repair nipple(s).

REMOVAL - UPPER INTAKE MANIFOLD

(1) Disconnect battery negative cable.

(2) Disconnect inlet air temperature (IAT) sensor

electrical connector.

(3) Remove air inlet resonator to throttle body

hose assembly.

(4) Disconnect throttle and speed control cables

from throttle body (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/THROTTLE CONTROL CABLE -

REMOVAL).

(5) Disconnect make-up air hose support clip from

throttle cable bracket.

(6) Disconnect the automatic idle speed (AIS)

motor and throttle position sensor (TPS) wiring con-

nectors from throttle body.

RSENGINE 3.3/3.8L9 - 145

INTAKE MANIFOLD (Continued)

ProCarManuals.com

Page 1325 of 2177

(7) Disconnect the manifold absolute pressure

(MAP) sensor electrical connector.

(8) Disconnect the vapor purge vacuum hose from

throttle body.

(9) Disconnect the PCV hose (Fig. 114).

(10) Remove the power steering reservoir attach-

ing bolts and only loosen the nut (Fig. 115). Lift res-

ervoir up to disengage lower mount from stud. Set

reservoir aside.Do notdisconnect hose.

(11) Disconnect the brake booster and leak detec-

tion pump (LDP) hoses from intake manifold (Fig.

116).

(12) Remove intake manifold bolts and remove the

manifold (Fig. 117).

(13) Cover the lower intake manifold with a suit-

able cover while the upper manifold is removed.

(14) Clean and inspect the upper intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - CLEANING) and (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSPECTION).

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

INSPECTION

Check manifold for:

²Damage and cracks.

Fig. 113 Intake Manifold Port Repair

1 - BRAKE BOOSTER PORT = 1/49±18 NPT PIPE TAP

1 - LDP/SPEED CONTROL PORT = 1/89±18 NPT PIPE TAP

2 - DRILL BIT = 7/169BRAKE BOOSTER PORT

2 - DRILL BIT = 11/329LDP/SPEED CONTROL PORT

3 - INTAKE MANIFOLD

Fig. 114 PCV & HOSE

1 - HOSE - PCV

2 - P C V VA LV E

Fig. 115 POWER STEERING FLUID RESERVOIR

1 - POWER STEERING RESERVOIR

2 - BOLT - RESERVOIR TO MANIFOLD

3 - NUT - RESERVOIR TO COIL BRACKET

9 - 146 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1326 of 2177

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - UPPER INTAKE MANIFOLD

(1) If the following components were removed from

manifold, install and tighten to specifications:

CAUTION: The special screws used for the compos-

ite manifold attached components must be installed

slowly using hand tools only. This requirement is to

prevent the melting of material that causes stripped

threads. If threads become stripped, an oversize

repair screw is available. For more information and

procedure (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - STANDARD PROCEDURE - MAN-

IFOLD STRIPPED THREAD REPAIR).

²MAP sensor - 1.7 N´m (15 in. lbs.)

²Throttle cable bracket - 5.6 N´m (50 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

(3) Inspect manifold gasket condition. Gaskets can

be re-used, if not damaged. To replace, remove gasket

from upper manifold (Fig. 117). Position new gasket

in seal channel and press lightly in-place. Repeat

procedure for each gasket position.

(4) Position upper manifold on lower manifold (Fig.

117). Apply MopartLock & Seal Adhesive (Medium

Strength Threadlocker) to each upper intake mani-

fold bolt. Install and tighten bolts to 12 N´m (105 in.

lbs.) following torque sequence in (Fig. 118).

(5) Connect the MAP sensor electrical connector.(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 116).

Fig. 116 BRAKE BOOSTER & LDP VACUUM HOSES

1 - LDP & SPEED CONTROL VACUUM HOSE

2 - BRAKE BOOSTER VACUUM HOSE

3 - MAP SENSOR

Fig. 117 INTAKE MANIFOLD - UPPER

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

Fig. 118 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 147

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com