maintenance CHRYSLER CARAVAN 2003 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 239 of 2177

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 92 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 264 of 2177

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 6) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

For cooling system capacity, (Refer to LUBRICATION

& MAINTENANCE/FLUID CAPACITIES - SPECIFI-

CATIONS).

Fill coolant recovery/reserve container (Fig. 6) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 6). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the recovery/reserve container (Fig. 6). The

coolant level should be between the MIN and MAX

marks.

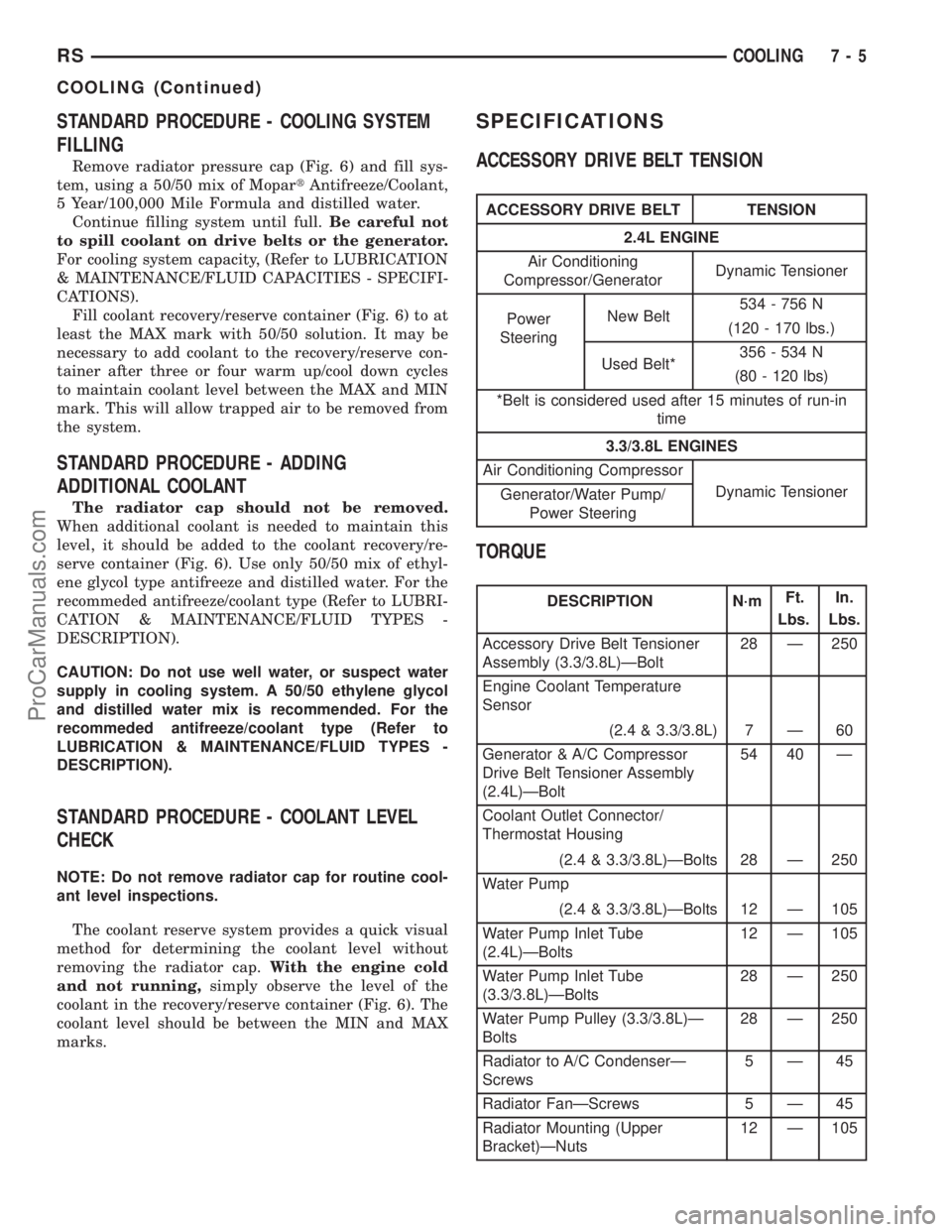

SPECIFICATIONS

ACCESSORY DRIVE BELT TENSION

ACCESSORY DRIVE BELT TENSION

2.4L ENGINE

Air Conditioning

Compressor/GeneratorDynamic Tensioner

Power

SteeringNew Belt534 - 756 N

(120 - 170 lbs.)

Used Belt*356 - 534 N

(80 - 120 lbs)

*Belt is considered used after 15 minutes of run-in

time

3.3/3.8L ENGINES

Air Conditioning Compressor

Dynamic Tensioner

Generator/Water Pump/

Power Steering

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Accessory Drive Belt Tensioner

Assembly (3.3/3.8L)ÐBolt28 Ð 250

Engine Coolant Temperature

Sensor

(2.4 & 3.3/3.8L) 7 Ð 60

Generator & A/C Compressor

Drive Belt Tensioner Assembly

(2.4L)ÐBolt54 40 Ð

Coolant Outlet Connector/

Thermostat Housing

(2.4 & 3.3/3.8L)ÐBolts 28 Ð 250

Water Pump

(2.4 & 3.3/3.8L)ÐBolts 12 Ð 105

Water Pump Inlet Tube

(2.4L)ÐBolts12 Ð 105

Water Pump Inlet Tube

(3.3/3.8L)ÐBolts28 Ð 250

Water Pump Pulley (3.3/3.8L)Ð

Bolts28 Ð 250

Radiator to A/C CondenserÐ

Screws5Ð45

Radiator FanÐScrews 5 Ð 45

Radiator Mounting (Upper

Bracket)ÐNuts12 Ð 105

RSCOOLING7-5

COOLING (Continued)

ProCarManuals.com

Page 277 of 2177

CLEANING

Drain cooling system and refill with clean water.

Refer to drain and fill procedures in this section. Run

engine with radiator cap installed until upper radia-

tor hose is hot. Stop engine and drain water from

system. If water is dirty; fill, run, and drain system

again, until water runs clear. Refill cooling system

with a 50/50 mixture of the recommended ethylene

glycol and distilled water (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - DESCRIPTION).

INSPECTION

After performing a cleaning/flush procedure,

inspect all hoses, clamps and connections for deterio-

ration and leaks. Inspect radiator and heater core for

leaks.

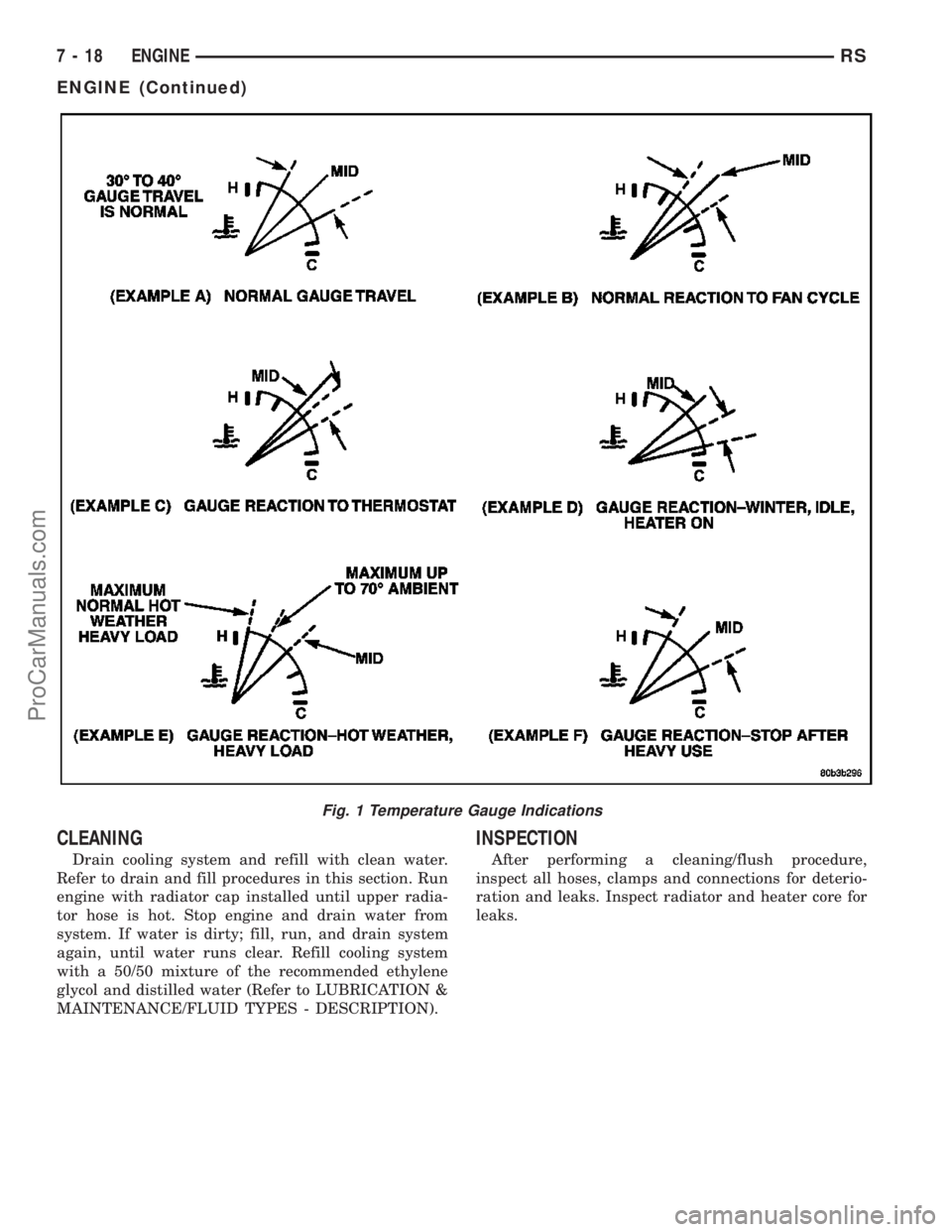

Fig. 1 Temperature Gauge Indications

7 - 18 ENGINERS

ENGINE (Continued)

ProCarManuals.com

Page 278 of 2177

COOLANT

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may resultin premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -46ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer (Special Tool 8286)(Refer to 7 -

COOLING - SPECIAL TOOLS) will test the amount

of glycol in a coolant mixture by measuring the

amount a beam of light bends as it passes through

the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is not rec-

ommended.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAIN-

TENANCE SCHEDULES - DESCRIPTION).

COOLANT RECOVERY

CONTAINER

DESCRIPTION

The coolant recovery/reserve system container is

mounted in the engine compartment (Fig. 2). The

container is made of plastic.

OPERATION

The coolant recovery system works with the radia-

tor pressure cap to use thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. Provides a convenient and safe method

RSENGINE7-19

ProCarManuals.com

Page 341 of 2177

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermowrap- The battery thermow-

rap insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedure, see the owner's manual in

the vehicle glove box. Optionally, refer to the Lubri-

cation and Maintenance section of this manual for

the recommended battery maintenance schedules and

for the proper battery jump starting procedure. While

battery charging can be considered a maintenance

procedure, the battery charging procedure and

related information are located later in this section of

this service manual. This was done because the bat-

tery must be fully-charged before any battery system

diagnosis or testing procedures can be performed.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. Refer to

Charging System for the proper charging system on-

board diagnostic test procedures.

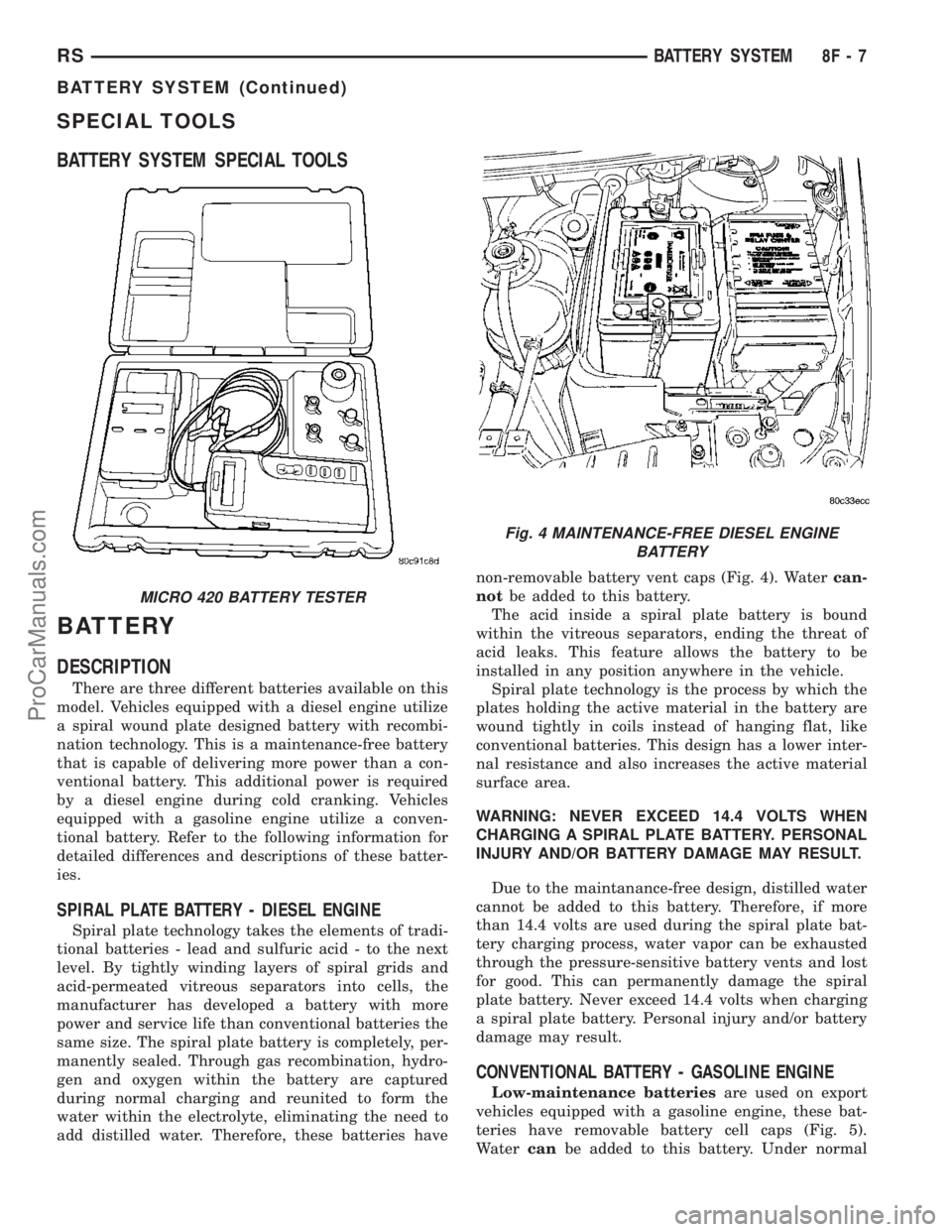

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery system tester is

designed to help the dealership technicians diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a vehicle. If the instruction manual is not

available refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

8F - 2 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

ProCarManuals.com

Page 344 of 2177

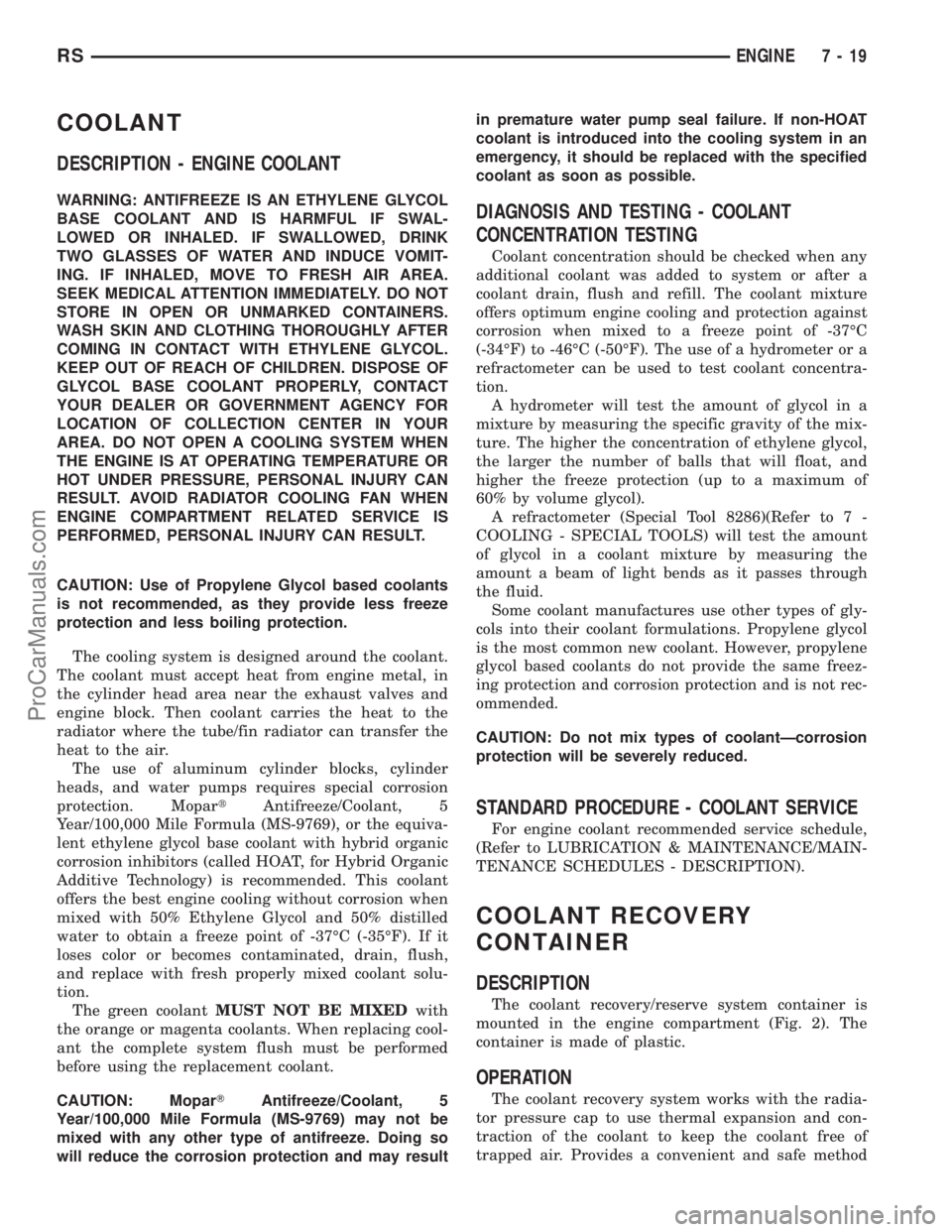

CLEANING

The following information details the recommended

cleaning procedures for the battery and related com-

ponents. In addition to the maintenance schedules

found in this service manual and the owner's man-

ual, it is recommended that these procedures be per-

formed any time the battery or related components

must be removed for vehicle service.

(1) Clean the battery cable terminal clamps of all

corrosion. Remove any corrosion using a wire brush

or a post and terminal cleaning tool, and a sodium

bicarbonate (baking soda) and warm water cleaning

solution (Fig. 1).

(2) Clean the battery tray and battery holddown

hardware of all corrosion. Remove any corrosion

using a wire brush and a sodium bicarbonate (baking

soda) and warm water cleaning solution. Paint any

exposed bare metal.

(3) If the removed battery is to be reinstalled,

clean the outside of the battery case and the top

cover with a sodium bicarbonate (baking soda) and

warm water cleaning solution using a stiff bristle

parts cleaning brush to remove any acid film (Fig. 2).

Rinse the battery with clean water. Ensure that the

cleaning solution does not enter the battery cells

through the vent holes. If the battery is being

replaced, refer to Battery System Specifications for

the factory-installed battery specifications. Confirm

that the replacement battery is the correct size and

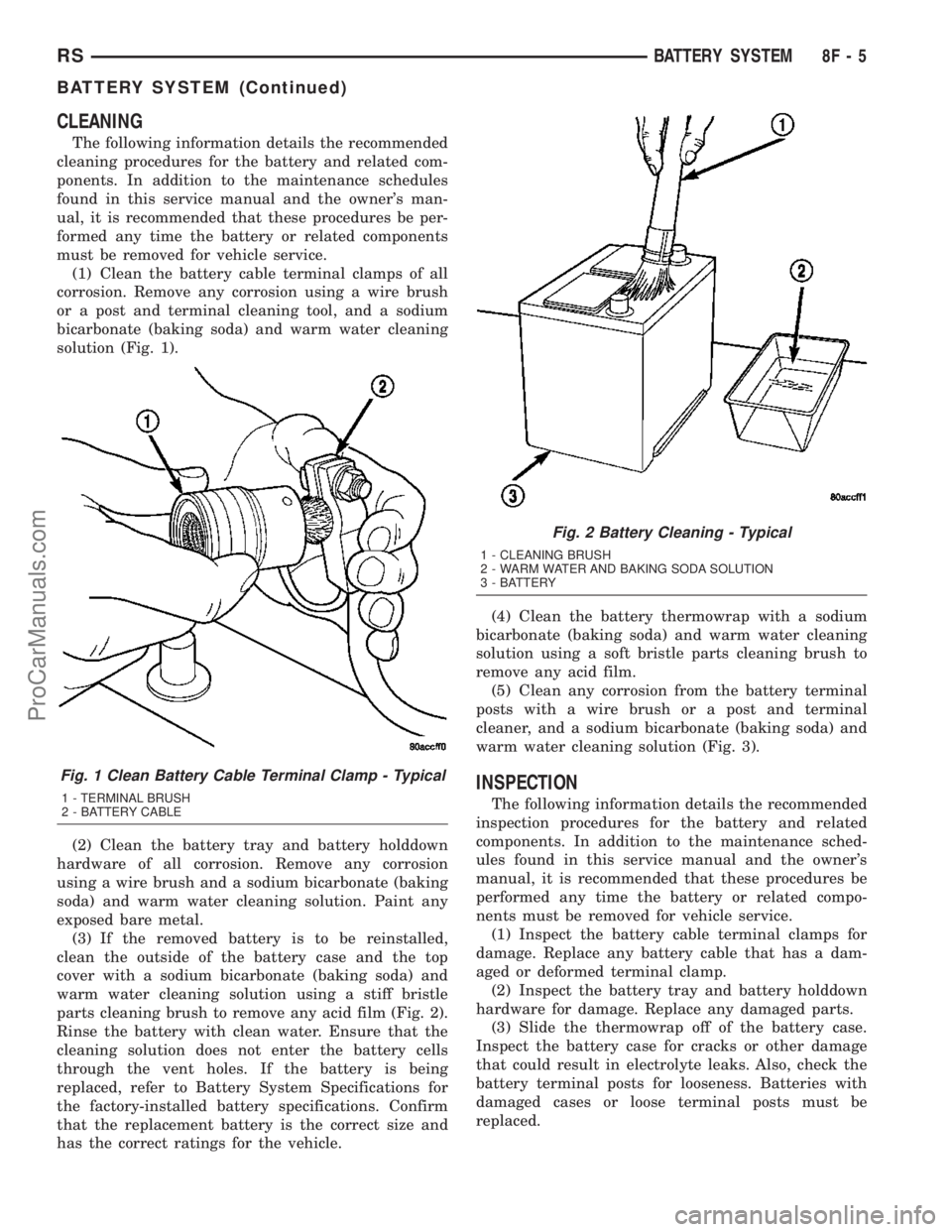

has the correct ratings for the vehicle.(4) Clean the battery thermowrap with a sodium

bicarbonate (baking soda) and warm water cleaning

solution using a soft bristle parts cleaning brush to

remove any acid film.

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermowrap off of the battery case.

Inspect the battery case for cracks or other damage

that could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced.

Fig. 1 Clean Battery Cable Terminal Clamp - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

Fig. 2 Battery Cleaning - Typical

1 - CLEANING BRUSH

2 - WARM WATER AND BAKING SODA SOLUTION

3 - BATTERY

RSBATTERY SYSTEM8F-5

BATTERY SYSTEM (Continued)

ProCarManuals.com

Page 346 of 2177

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS

BATTERY

DESCRIPTION

There are three different batteries available on this

model. Vehicles equipped with a diesel engine utilize

a spiral wound plate designed battery with recombi-

nation technology. This is a maintenance-free battery

that is capable of delivering more power than a con-

ventional battery. This additional power is required

by a diesel engine during cold cranking. Vehicles

equipped with a gasoline engine utilize a conven-

tional battery. Refer to the following information for

detailed differences and descriptions of these batter-

ies.

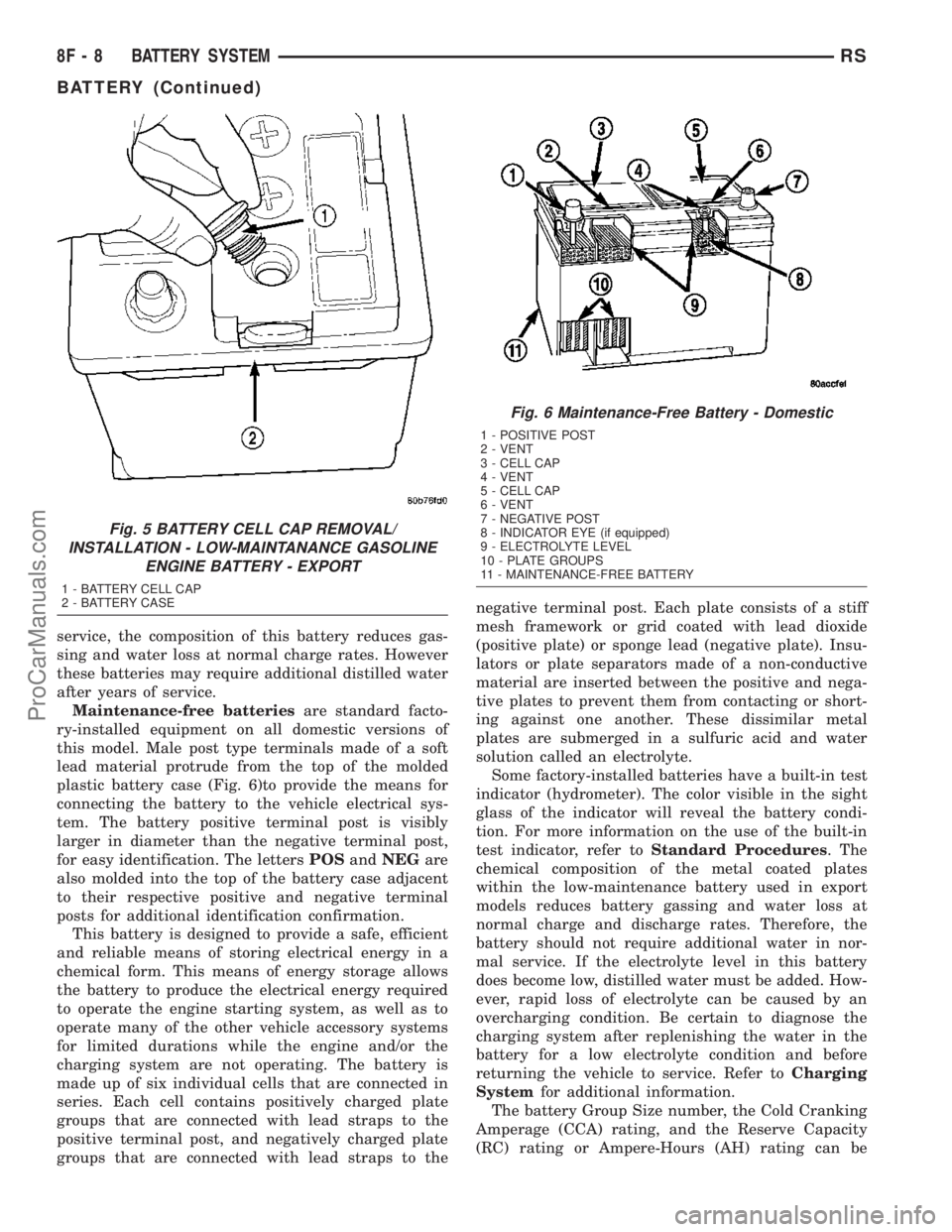

SPIRAL PLATE BATTERY - DIESEL ENGINE

Spiral plate technology takes the elements of tradi-

tional batteries - lead and sulfuric acid - to the next

level. By tightly winding layers of spiral grids and

acid-permeated vitreous separators into cells, the

manufacturer has developed a battery with more

power and service life than conventional batteries the

same size. The spiral plate battery is completely, per-

manently sealed. Through gas recombination, hydro-

gen and oxygen within the battery are captured

during normal charging and reunited to form the

water within the electrolyte, eliminating the need to

add distilled water. Therefore, these batteries havenon-removable battery vent caps (Fig. 4). Watercan-

notbe added to this battery.

The acid inside a spiral plate battery is bound

within the vitreous separators, ending the threat of

acid leaks. This feature allows the battery to be

installed in any position anywhere in the vehicle.

Spiral plate technology is the process by which the

plates holding the active material in the battery are

wound tightly in coils instead of hanging flat, like

conventional batteries. This design has a lower inter-

nal resistance and also increases the active material

surface area.

WARNING: NEVER EXCEED 14.4 VOLTS WHEN

CHARGING A SPIRAL PLATE BATTERY. PERSONAL

INJURY AND/OR BATTERY DAMAGE MAY RESULT.

Due to the maintanance-free design, distilled water

cannot be added to this battery. Therefore, if more

than 14.4 volts are used during the spiral plate bat-

tery charging process, water vapor can be exhausted

through the pressure-sensitive battery vents and lost

for good. This can permanently damage the spiral

plate battery. Never exceed 14.4 volts when charging

a spiral plate battery. Personal injury and/or battery

damage may result.

CONVENTIONAL BATTERY - GASOLINE ENGINE

Low-maintenance batteriesare used on export

vehicles equipped with a gasoline engine, these bat-

teries have removable battery cell caps (Fig. 5).

Watercanbe added to this battery. Under normal

MICRO 420 BATTERY TESTER

Fig. 4 MAINTENANCE-FREE DIESEL ENGINE

BATTERY

RSBATTERY SYSTEM8F-7

BATTERY SYSTEM (Continued)

ProCarManuals.com

Page 347 of 2177

service, the composition of this battery reduces gas-

sing and water loss at normal charge rates. However

these batteries may require additional distilled water

after years of service.

Maintenance-free batteriesare standard facto-

ry-installed equipment on all domestic versions of

this model. Male post type terminals made of a soft

lead material protrude from the top of the molded

plastic battery case (Fig. 6)to provide the means for

connecting the battery to the vehicle electrical sys-

tem. The battery positive terminal post is visibly

larger in diameter than the negative terminal post,

for easy identification. The lettersPOSandNEGare

also molded into the top of the battery case adjacent

to their respective positive and negative terminal

posts for additional identification confirmation.

This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or the

charging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to thenegative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer toStandard Procedures. The

chemical composition of the metal coated plates

within the low-maintenance battery used in export

models reduces battery gassing and water loss at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, distilled water must be added. How-

ever, rapid loss of electrolyte can be caused by an

overcharging condition. Be certain to diagnose the

charging system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer toCharging

Systemfor additional information.

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

Fig. 5 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTANANCE GASOLINE

ENGINE BATTERY - EXPORT

1 - BATTERY CELL CAP

2 - BATTERY CASE

Fig. 6 Maintenance-Free Battery - Domestic

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - VENT

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - INDICATOR EYE (if equipped)

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - MAINTENANCE-FREE BATTERY

8F - 8 BATTERY SYSTEMRS

BATTERY (Continued)

ProCarManuals.com

Page 353 of 2177

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(4) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Integrated Power Module (IPM), one

at a time until the amperage reading becomes very

low, or nonexistent. Refer to the appropriate wiring

information in this service manual for complete Inte-

grated Power Module fuse, circuit breaker, and cir-

cuit identification. This will isolate each circuit and

identify the circuit that is the source of the high-am-

perage IOD. If the amperage reading remains high

after removing and replacing each fuse and circuit

breaker, disconnect the wire harness from the gener-

ator. If the amperage reading now becomes very low

or nonexistent, refer to Charging System for the

proper charging system diagnosis and testing proce-

dures. After the high-amperage IOD has been cor-

rected, switch the multi-meter to progressively lower

amperage scales and, if necessary, repeat the fuse

and circuit breaker remove-and-replace process to

identify and correct all sources of excessive IOD. It is

now safe to select the lowest milliampere scale of the

multi-meter to check the low-amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(5) Allow twenty minutes for the IOD to stabilize

and observe the multi-meter reading. The low-amper-

age IOD should not exceed twenty-five milliamperes

(0.025 ampere). If the current draw exceeds twenty-

five milliamperes, isolate each circuit using the fuse

and circuit breaker remove-and-replace process in

Step 4. The multi-meter reading will drop to within

the acceptable limit when the source of the excessive

current draw is disconnected. Repair this circuit as

required; whether a wiring short, incorrect switch

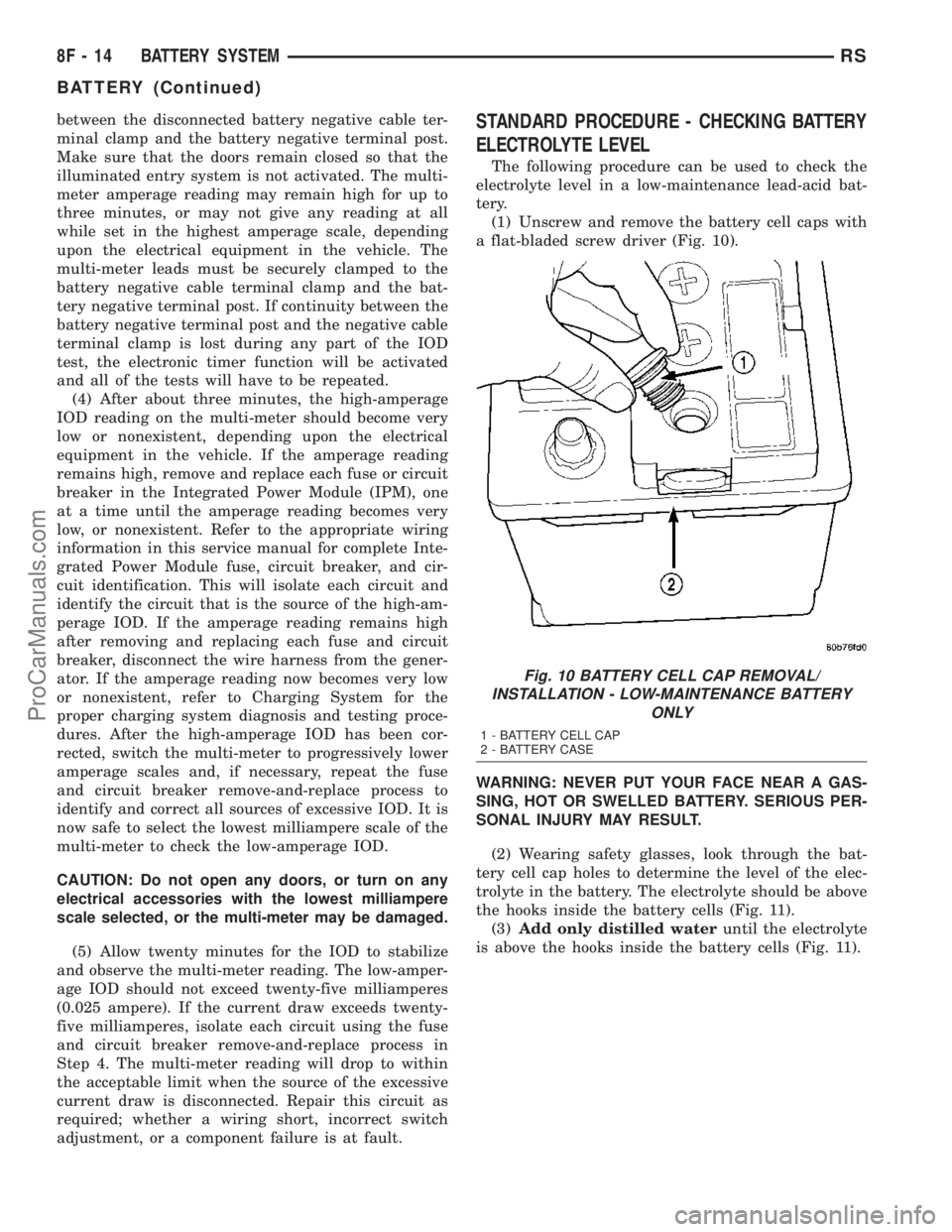

adjustment, or a component failure is at fault.STANDARD PROCEDURE - CHECKING BATTERY

ELECTROLYTE LEVEL

The following procedure can be used to check the

electrolyte level in a low-maintenance lead-acid bat-

tery.

(1) Unscrew and remove the battery cell caps with

a flat-bladed screw driver (Fig. 10).

WARNING: NEVER PUT YOUR FACE NEAR A GAS-

SING, HOT OR SWELLED BATTERY. SERIOUS PER-

SONAL INJURY MAY RESULT.

(2) Wearing safety glasses, look through the bat-

tery cell cap holes to determine the level of the elec-

trolyte in the battery. The electrolyte should be above

the hooks inside the battery cells (Fig. 11).

(3)Add only distilled wateruntil the electrolyte

is above the hooks inside the battery cells (Fig. 11).

Fig. 10 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTENANCE BATTERY

ONLY

1 - BATTERY CELL CAP

2 - BATTERY CASE

8F - 14 BATTERY SYSTEMRS

BATTERY (Continued)

ProCarManuals.com

Page 354 of 2177

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES AND SAFETY GLASSES SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY.

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.

(1) Verify that the ignition switch and all accesso-

ries are OFF.

(2) Disconnect the battery cables from the battery

posts, negative first (Fig. 12).

(3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.).

(3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 5

N´m (40 in. lbs.).

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware consists of a

molded plastic lip that is integral to the outboard

edge of the battery tray and support unit, a molded

steel hold down bracket and a single hex nut with a

coned washer.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downsin this section of this service

manual for the location of the proper battery hold

down installation procedures, including the proper

hold down fastener tightness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

Fig. 11 HOOK INSIDE BATTERY CELLS - LOW-

MAINTENANCE BATTERY ONLY

1 - TOP OF BATTERY

2 - HOOK INSIDE BATTERY CELLS

Fig. 12 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSBATTERY SYSTEM8F-15

BATTERY (Continued)

ProCarManuals.com