maintenance CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1735 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehicle

in a brightly lit area. From inside the darkened lug-

gage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage com-

partment. If light is visible through a normally sealed

location, water could enter through the opening.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 2 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1787 of 2177

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 14). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install radiator sight shield.

(10) Install hood prop rod.

(11) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(12) Install bolts attaching hood latch to cross-

member. Tighten bolts to 13.5 N´m (10 ft. lbs.)

torque.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 15).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

15).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 16).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 17).

Fig. 15 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 16 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

23 - 54 EXTERIORRS

GRILLE OPENING REINFORCEMENT (Continued)

ProCarManuals.com

Page 2129 of 2177

VAPOR CANISTER

DESCRIPTION

There are 2 EVAP canisters on the vehicle. The

vacuum and vapor tubes connect to the top of the

canister. It is a charcoal canister (Fig. 15) or (Fig.

16).

OPERATION

All vehicles use a maintenance free, evaporative

(EVAP) canister. Fuel tank vapors vent into the can-

ister. The canister temporarily holds the fuel vapors

until intake manifold vacuum draws them into the

combustion chamber. The Powertrain Control Module

(PCM) purges the canister through the proportional

purge solenoid. The PCM purges the canister at pre-

determined intervals and engine conditions.

Purge Free Cells

Purge-free memory cells are used to identify the

fuel vapor content of the evaporative canister. Since

the evaporative canister is not purged 100% of the

time, the PCM stores information about the evapora-

tive canister's vapor content in a memory cell.

The purge-free cells are constructed similar to cer-

tain purge-normal cells. The purge-free cells can be

monitored by the DRB IIItScan Tool. The only dif-

ference between the purge-free cells and normal

adaptive cells is that in purge-free, the purge is com-

pletely turned off. This gives the PCM the ability to

compare purge and purge-free operation.

REMOVAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the 2 hoses (Fig. 15).

(3) Remove bolt.

(4) Pull canister rearward to remove.

Fig. 15 FRONT EVAP CANISTER

1 - Front EVAP Canister

2 - Vent Valve

Fig. 16 REAR EVAP CANISTER

1 - Rear EVAP Canister

2 - Front EVAP Canister

3 - Vent Valve

25 - 18 EVAPORATIVE EMISSIONSRS

ProCarManuals.com

Page 2158 of 2177

LIFTGATE MOTOR - OPERATION.........8N-15

LIFTGATE MOTOR - REMOVAL..........8N-15

LIFTGATE SIDE - INSTALLATION.........23-43

LIFTGATE SIDE - REMOVAL............23-43

LIFTGATE SILL PLATE - INSTALLATION . . . 23-77

LIFTGATE SILL PLATE - REMOVAL.......23-77

LIFTGATE SPOILER - INSTALLATION......23-41

LIFTGATE SPOILER - REMOVAL.........23-41

LIFTGATE SYSTEM - DESCRIPTION,

POWER.............................8N-2

LIFTGATE SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LIFTGATE SYSTEM - OPERATION,

POWER.............................8N-3

LIMITS - DESCRIPTION, HIGH AND LOW . . . 25-8

LINE - INSTALLATION, DISCHARGE......24-69

LINE - INSTALLATION, FUEL...........24-110

LINE - INSTALLATION, LIQUID..........24-82

LINE - INSTALLATION, SUCTION . . . 24-102,24-91

LINE - REMOVAL, DISCHARGE..........24-68

LINE - REMOVAL, FUEL...............24-109

LINE - REMOVAL, LIQUID..............24-80

LINE - REMOVAL, SUCTION......24-101,24-90

LINE AND TERMINAL REPAIR -

STANDARD PROCEDURE, GRID..........8G-3

LINE EXTENSION - INSTALLATION,

EVAPORATOR.......................24-96

LINE EXTENSION - REMOVAL,

EVAPORATOR.......................24-95

LINE REPAIR REAR - STANDARD

PROCEDURE, GRID....................8G-2

LINES - DESCRIPTION, OIL COOLER.....9-138

LINES - DESCRIPTION, UNDERBODY....24-103

LINES - INSTALLATION, OIL COOLER.....9-138

LINES - INSTALLATION, REAR AIR

CONDITIONING.....................24-105

LINES - INSTALLATION, REAR HEATER . . 24-105

LINES - INSTALLATION, TRANSMISSION

OIL COOLER.........................7-38

LINES - OPERATION, OIL COOLER.......9-138

LINES - OPERATION, UNDERBODY......24-103

LINES - REMOVAL, OIL COOLER........9-138

LINES - REMOVAL, REAR AIR

CONDITIONING.....................24-104

LINES - REMOVAL, REAR HEATER......24-104

LINES - REMOVAL, TRANSMISSION OIL

COOLER.............................7-38

LINES/HOSES AND CLAMPS -

DESCRIPTION, FUEL...................14-6

LINING - INSPECTION, REAR DRUM

BRAKE SHOE.........................5-22

LINK - DESCRIPTION, TRD............21-249

LINK - INSTALLATION, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-53

LINK - OPERATION, TRD..............21-249

LINK - REMOVAL, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-52

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-6

LINK CONNECTOR - OPERATION, DATA....8E-7

LINK ROD - DESCRIPTION, LIFT GEAR . . . 8N-16

LINK ROD - INSTALLATION, LIFT GEAR . . . 8N-16

LINK ROD - OPERATION, LIFT GEAR.....8N-16

LINK ROD - REMOVAL, LIFT GEAR.......8N-16

LINKAGE - INSTALLATION, WIPER.......8R-18

LINKAGE - REMOVAL, WIPER...........8R-17

LIQUID LINE - INSTALLATION...........24-82

LIQUID LINE - REMOVAL

..............24-80

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL

.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE

...................8W-91-1

LOCATIONS - DESCRIPTION, FLUID

FILL/CHECK

...........................0-7

LOCATIONS - SPECIFICATIONS, BODY

SEALING

..........................23-127

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE

..............23-153

LOCATIONS - SPECIFICATIONS, WELD

. . . 23-161

LOCK ASSEMBLY - INSTALLATION,

LATCH

.............................23-27

LOCK ASSEMBLY - REMOVAL, LATCH

....23-26

LOCK CYLINDER - INSTALLATION

. . 23-20,23-41

LOCK CYLINDER - REMOVAL

......23-19,23-41

LOCK CYLINDER HOUSING -

INSTALLATION

.......................19-19

LOCK CYLINDER HOUSING - REMOVAL

. . . 19-17LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR.....................8N-41

LOCK MOTOR - INSTALLATION, SLIDING

DOOR.............................8N-44

LOCK MOTOR - REMOVAL, SLIDING

DOOR.............................8N-44

LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR.....................8N-41

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER............8N-40

LOCK SWITCH - INSTALLATION, DOOR . . . 8N-42

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER..........................8N-41

LOCK SWITCH - OPERATION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - REMOVAL, DOOR.......8N-42

LOCK SWITCH - REMOVAL, DOOR

CYLINDER..........................8N-41

LOCKED ENGINE - STANDARD

PROCEDURE, HYDROSTATIC.........9-10,9-85

LOCK/LATCH - INSTALLATION, UNDER

SEAT STORAGE BIN.................23-104

LOCK/LATCH - REMOVAL, UNDER SEAT

STORAGE BIN......................23-104

LOCKOUT LINK - INSTALLATION, FUEL

FILL DOOR BLOCKER.................23-53

LOCKOUT LINK - REMOVAL, FUEL FILL

DOOR BLOCKER.....................23-52

LOCKS - DESCRIPTION, POWER........8N-38

LOCKS - OPERATION, POWER..........8N-39

LOUVER - INSTALLATION, REAR HVAC . . . 23-79

LOUVER - REMOVAL, REAR HVAC.......23-79

LOW LIMITS - DESCRIPTION, HIGH.......25-8

LOWER - CLEANING, INTAKE MANIFOLD . . 9-148

LOWER - INSPECTION, INTAKE

MANIFOLD......................9-148,9-60

LOWER - INSTALLATION, INTAKE

MANIFOLD...........................9-60

LOWER - INSTALLATION, SHROUD.......19-22

LOWER - REMOVAL, INTAKE MANIFOLD . . . 9-60

LOWER - REMOVAL, SHROUD..........19-21

LOWER BALL JOINT - DESCRIPTION......2-10

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-10

LOWER BALL JOINT - OPERATION........2-10

LOWER CONSOLE - INSTALLATION......23-68

LOWER CONSOLE - REMOVAL..........23-68

LOWER CONTROL ARM - DESCRIPTION . . . 2-12

LOWER CONTROL ARM - INSPECTION.....2-14

LOWER CONTROL ARM - INSTALLATION . . . 2-15

LOWER CONTROL ARM - OPERATION.....2-12

LOWER CONTROL ARM - REMOVAL......2-12

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - ASSEMBLY.................2-14

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - DISASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - ASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - DISASSEMBLY...........2-13

LOWER DRIVE UNIT - DESCRIPTION.....8N-32

LOWER DRIVE UNIT - INSTALLATION....8N-33

LOWER DRIVE UNIT - OPERATION.......8N-32

LOWER DRIVE UNIT - REMOVAL

........8N-33

LOWER DRIVE UNIT TRACK & RACK -

DESCRIPTION

.......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

INSTALLATION

......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

OPERATION

.........................8N-34

LOWER DRIVE UNIT TRACK & RACK -

REMOVAL

..........................8N-34

LOWER EXTENSION TRIM -

INSTALLATION, A-PILLAR

..............23-73

LOWER EXTENSION TRIM - REMOVAL,

A-PILLAR

...........................23-73

LOWER HINGE - INSTALLATION

.........23-28

LOWER HINGE - REMOVAL

.............23-28

LOWER INSTRUMENT PANEL -

INSTALLATION

.......................23-68

LOWER INSTRUMENT PANEL -

REMOVAL

..........................23-68

LOWER INTAKE MANIFOLD -

INSTALLATION

.......................9-149

LOWER INTAKE MANIFOLD - REMOVAL

. . . 9-148LOWER STEERING COLUMN COVER -

INSTALLATION.......................23-69

LOWER STEERING COLUMN COVER -

REMOVAL..........................23-69

LOWER TRIM - INSTALLATION,

B-PILLAR...........................23-74

LOWER TRIM - REMOVAL, B-PILLAR.....23-73

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-1

LUBRICATION - DESCRIPTION......9-136,9-52

LUBRICATION - OPERATION........9-136,9-52

LUBRICATION - STANDARD PROCEDURE....2-2

LUBRICATION POINTS - DESCRIPTION......0-7

LUBRICATION, SPECIFICATIONS - BODY . . 23-12

LUGGAGE RACK CROSSBAR -

INSTALLATION.......................23-56

LUGGAGE RACK CROSSBAR - REMOVAL . . 23-55

LUGGAGE RACK RISER - INSTALLATION . . 23-55

LUGGAGE RACK RISER - REMOVAL......23-54

LUMBAR SUPPORT - INSTALLATION....23-104

LUMBAR SUPPORT - REMOVAL........23-104

LWB - INSTALLATION, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-15

LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-15

MACHINING - STANDARD PROCEDURE,

BRAKE ROTOR.......................5-53

MAIN BEARING FITTING - STANDARD

PROCEDURE..........................9-123

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT.......................9-124

MAIN BEARINGS - REMOVAL,

CRANKSHAFT.......................9-124

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-7

MANAGER - DESCRIPTION, TASK........25-24

MANAGER - OPERATION, TASK.........25-24

MANIFOLD - CLEANING, EXHAUST........9-61

MANIFOLD - DESCRIPTION, INTAKE . . 9-144,9-58

MANIFOLD - INSPECTION, EXHAUST......9-61

MANIFOLD - INSTALLATION, EXHAUST....9-61

MANIFOLD - INSTALLATION, LOWER

INTAKE ............................9-149

MANIFOLD - INSTALLATION, UPPER

INTAKE ............................9-147

MANIFOLD - LEFT - CLEANING,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSPECTION,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSTALLATION,

EXHAUST...........................9-152

MANIFOLD - LEFT - REMOVAL, EXHAUST . 9-152

MANIFOLD - LOWER - CLEANING,

INTAKE ............................9-148

MANIFOLD - LOWER - INSPECTION,

INTAKE ........................9-148,9-60

MANIFOLD - LOWER - INSTALLATION,

INTAKE .............................9-60

MANIFOLD - LOWER - REMOVAL,

INTAKE .............................9-60

MANIFOLD - REMOVAL, EXHAUST........9-61

MANIFOLD - REMOVAL, LOWER INTAKE . . 9-148

MANIFOLD - REMOVAL, UPPER INTAKE . . . 9-145

MANIFOLD - RIGHT - CLEANING,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSPECTION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSTALLATION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - REMOVAL,

EXHAUST...........................9-150

MANIFOLD - UPPER - INSPECTION,

INTAKE .............................9-59

MANIFOLD - UPPER - INSTALLATION,

INTAKE .............................9-59

MANIFOLD - UPPER - REMOVAL, INTAKE . . 9-58

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

................9-145,9-58

MANIFOLD STRIPPED THREAD REPAIR -

STANDARD PROCEDURE

...............9-145

MANIFOLD VACUUM PORT REPAIR -

STANDARD PROCEDURE, INTAKE

........9-145

MANUAL - INSTALLATION, WINDOW

REGULATOR

........................23-23

MANUAL - REMOVAL, WINDOW

REGULATOR

........................23-23

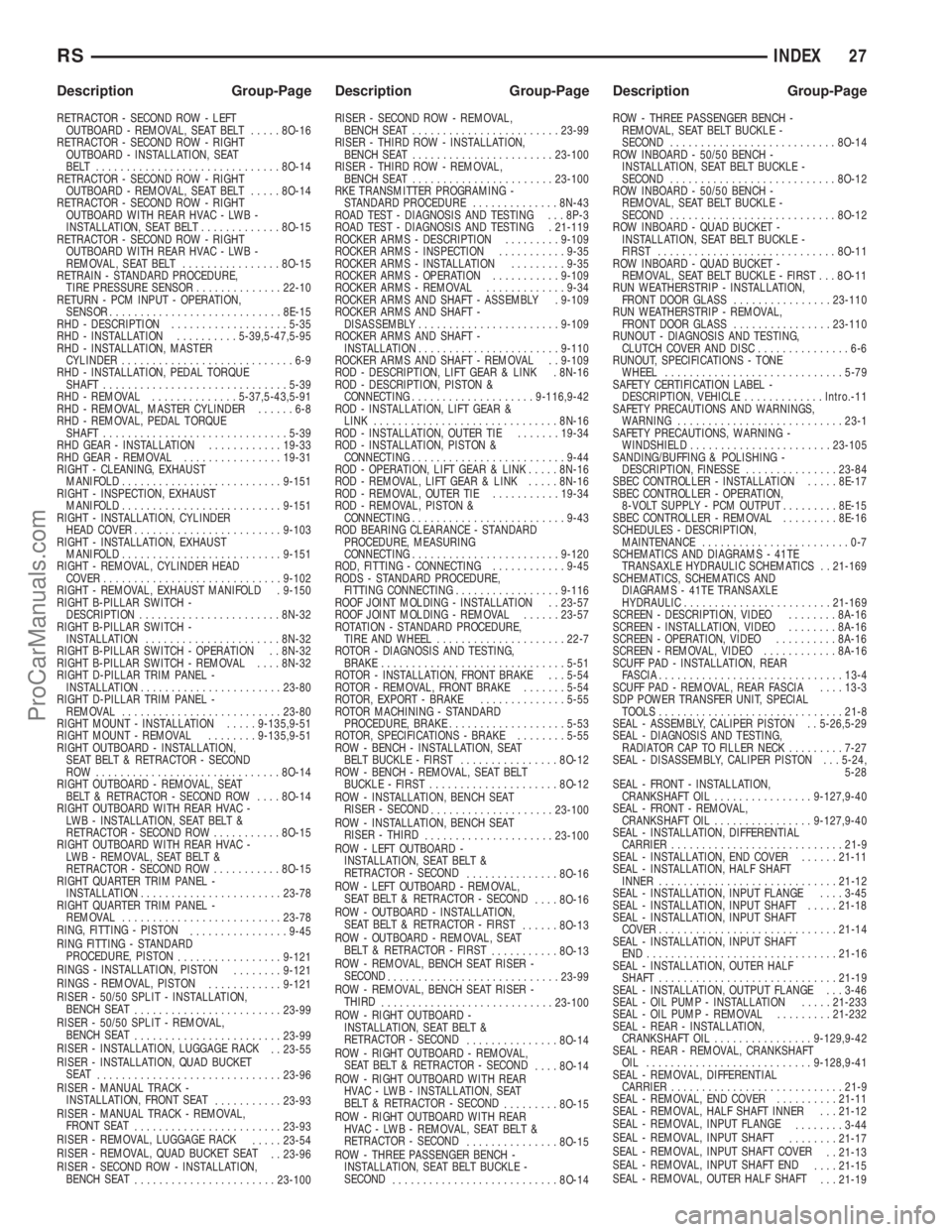

RSINDEX19

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2166 of 2177

RETRACTOR - SECOND ROW - LEFT

OUTBOARD - REMOVAL, SEAT BELT.....8O-16

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - INSTALLATION, SEAT

BELT ..............................8O-14

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - REMOVAL, SEAT BELT.....8O-14

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

INSTALLATION, SEAT BELT.............8O-15

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

REMOVAL, SEAT BELT................8O-15

RETRAIN - STANDARD PROCEDURE,

TIRE PRESSURE SENSOR..............22-10

RETURN - PCM INPUT - OPERATION,

SENSOR............................8E-15

RHD - DESCRIPTION...................5-35

RHD - INSTALLATION..........5-39,5-47,5-95

RHD - INSTALLATION, MASTER

CYLINDER............................6-9

RHD - INSTALLATION, PEDAL TORQUE

SHAFT..............................5-39

RHD - REMOVAL..............5-37,5-43,5-91

RHD - REMOVAL, MASTER CYLINDER......6-8

RHD - REMOVAL, PEDAL TORQUE

SHAFT..............................5-39

RHD GEAR - INSTALLATION............19-33

RHD GEAR - REMOVAL................19-31

RIGHT - CLEANING, EXHAUST

MANIFOLD..........................9-151

RIGHT - INSPECTION, EXHAUST

MANIFOLD...........................9-151

RIGHT - INSTALLATION, CYLINDER

HEAD COVER........................9-103

RIGHT - INSTALLATION, EXHAUST

MANIFOLD..........................9-151

RIGHT - REMOVAL, CYLINDER HEAD

COVER.............................9-102

RIGHT - REMOVAL, EXHAUST MANIFOLD . 9-150

RIGHT B-PILLAR SWITCH -

DESCRIPTION.......................8N-32

RIGHT B-PILLAR SWITCH -

INSTALLATION......................8N-32

RIGHT B-PILLAR SWITCH - OPERATION . . 8N-32

RIGHT B-PILLAR SWITCH - REMOVAL....8N-32

RIGHT D-PILLAR TRIM PANEL -

INSTALLATION.......................23-80

RIGHT D-PILLAR TRIM PANEL -

REMOVAL..........................23-80

RIGHT MOUNT - INSTALLATION.....9-135,9-51

RIGHT MOUNT - REMOVAL........9-135,9-51

RIGHT OUTBOARD - INSTALLATION,

SEAT BELT & RETRACTOR - SECOND

ROW ..............................8O-14

RIGHT OUTBOARD - REMOVAL, SEAT

BELT & RETRACTOR - SECOND ROW....8O-14

RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT BELT &

RETRACTOR - SECOND ROW...........8O-15

RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW...........8O-15

RIGHT QUARTER TRIM PANEL -

INSTALLATION.......................23-78

RIGHT QUARTER TRIM PANEL -

REMOVAL..........................23-78

RING, FITTING - PISTON

................9-45

RING FITTING - STANDARD

PROCEDURE, PISTON

.................9-121

RINGS - INSTALLATION, PISTON

........9-121

RINGS - REMOVAL, PISTON

............9-121

RISER - 50/50 SPLIT - INSTALLATION,

BENCH SEAT

........................23-99

RISER - 50/50 SPLIT - REMOVAL,

BENCH SEAT

........................23-99

RISER - INSTALLATION, LUGGAGE RACK

. . 23-55

RISER - INSTALLATION, QUAD BUCKET

SEAT

..............................23-96

RISER - MANUAL TRACK -

INSTALLATION, FRONT SEAT

...........23-93

RISER - MANUAL TRACK - REMOVAL,

FRONT SEAT

........................23-93

RISER - REMOVAL, LUGGAGE RACK

.....23-54

RISER - REMOVAL, QUAD BUCKET SEAT

. . 23-96

RISER - SECOND ROW - INSTALLATION,

BENCH SEAT

.......................23-100RISER - SECOND ROW - REMOVAL,

BENCH SEAT........................23-99

RISER - THIRD ROW - INSTALLATION,

BENCH SEAT.......................23-100

RISER - THIRD ROW - REMOVAL,

BENCH SEAT.......................23-100

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE..............8N-43

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-3

ROAD TEST - DIAGNOSIS AND TESTING . 21-119

ROCKER ARMS - DESCRIPTION.........9-109

ROCKER ARMS - INSPECTION...........9-35

ROCKER ARMS - INSTALLATION.........9-35

ROCKER ARMS - OPERATION...........9-109

ROCKER ARMS - REMOVAL.............9-34

ROCKER ARMS AND SHAFT - ASSEMBLY . 9-109

ROCKER ARMS AND SHAFT -

DISASSEMBLY.......................9-109

ROCKER ARMS AND SHAFT -

INSTALLATION.......................9-110

ROCKER ARMS AND SHAFT - REMOVAL . . 9-109

ROD - DESCRIPTION, LIFT GEAR & LINK . 8N-16

ROD - DESCRIPTION, PISTON &

CONNECTING....................9-116,9-42

ROD - INSTALLATION, LIFT GEAR &

LINK..............................8N-16

ROD - INSTALLATION, OUTER TIE.......19-34

ROD - INSTALLATION, PISTON &

CONNECTING.........................9-44

ROD - OPERATION, LIFT GEAR & LINK.....8N-16

ROD - REMOVAL, LIFT GEAR & LINK.....8N-16

ROD - REMOVAL, OUTER TIE...........19-34

ROD - REMOVAL, PISTON &

CONNECTING.........................9-43

ROD BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING

CONNECTING........................9-120

ROD, FITTING - CONNECTING............9-45

RODS - STANDARD PROCEDURE,

FITTING CONNECTING.................9-116

ROOF JOINT MOLDING - INSTALLATION . . 23-57

ROOF JOINT MOLDING - REMOVAL......23-57

ROTATION - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-7

ROTOR - DIAGNOSIS AND TESTING,

BRAKE..............................5-51

ROTOR - INSTALLATION, FRONT BRAKE . . . 5-54

ROTOR - REMOVAL, FRONT BRAKE.......5-54

ROTOR, EXPORT - BRAKE..............5-55

ROTOR MACHINING - STANDARD

PROCEDURE, BRAKE...................5-53

ROTOR, SPECIFICATIONS - BRAKE........5-55

ROW - BENCH - INSTALLATION, SEAT

BELT BUCKLE - FIRST................8O-12

ROW - BENCH - REMOVAL, SEAT BELT

BUCKLE - FIRST.....................8O-12

ROW - INSTALLATION, BENCH SEAT

RISER - SECOND

....................23-100

ROW - INSTALLATION, BENCH SEAT

RISER - THIRD

.....................23-100

ROW - LEFT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR - SECOND

...............8O-16

ROW - LEFT OUTBOARD - REMOVAL,

SEAT BELT & RETRACTOR - SECOND

....8O-16

ROW - OUTBOARD - INSTALLATION,

SEAT BELT & RETRACTOR - FIRST

......8O-13

ROW - OUTBOARD - REMOVAL, SEAT

BELT & RETRACTOR - FIRST

...........8O-13

ROW - REMOVAL, BENCH SEAT RISER -

SECOND

............................23-99

ROW - REMOVAL, BENCH SEAT RISER -

THIRD

............................23-100

ROW - RIGHT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR - SECOND

...............8O-14

ROW - RIGHT OUTBOARD - REMOVAL,

SEAT BELT & RETRACTOR - SECOND

....8O-14

ROW - RIGHT OUTBOARD WITH REAR

HVAC - LWB - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND

.........8O-15

ROW - RIGHT OUTBOARD WITH REAR

HVAC - LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND

...............8O-15

ROW - THREE PASSENGER BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND

...........................8O-14ROW - THREE PASSENGER BENCH -

REMOVAL, SEAT BELT BUCKLE -

SECOND...........................8O-14

ROW INBOARD - 50/50 BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND...........................8O-12

ROW INBOARD - 50/50 BENCH -

REMOVAL, SEAT BELT BUCKLE -

SECOND...........................8O-12

ROW INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST.............................8O-11

ROW INBOARD - QUAD BUCKET -

REMOVAL, SEAT BELT BUCKLE - FIRST . . . 8O-11

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS................23-110

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS................23-110

RUNOUT - DIAGNOSIS AND TESTING,

CLUTCH COVER AND DISC...............6-6

RUNOUT, SPECIFICATIONS - TONE

WHEEL.............................5-79

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE.............Intro.-11

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD.......................23-105

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE...............23-84

SBEC CONTROLLER - INSTALLATION.....8E-17

SBEC CONTROLLER - OPERATION,

8-VOLT SUPPLY - PCM OUTPUT.........8E-15

SBEC CONTROLLER - REMOVAL.........8E-16

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-7

SCHEMATICS AND DIAGRAMS - 41TE

TRANSAXLE HYDRAULIC SCHEMATICS . . 21-169

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - 41TE TRANSAXLE

HYDRAULIC........................21-169

SCREEN - DESCRIPTION, VIDEO........8A-16

SCREEN - INSTALLATION, VIDEO........8A-16

SCREEN - OPERATION, VIDEO..........8A-16

SCREEN - REMOVAL, VIDEO............8A-16

SCUFF PAD - INSTALLATION, REAR

FASCIA..............................13-4

SCUFF PAD - REMOVAL, REAR FASCIA....13-3

SDP POWER TRANSFER UNIT, SPECIAL

TOOLS..............................21-8

SEAL - ASSEMBLY, CALIPER PISTON . . 5-26,5-29

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP TO FILLER NECK.........7-27

SEAL - DISASSEMBLY, CALIPER PISTON . . . 5-24,

5-28

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL................9-127,9-40

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL................9-127,9-40

SEAL - INSTALLATION, DIFFERENTIAL

CARRIER............................21-9

SEAL - INSTALLATION, END COVER......21-11

SEAL - INSTALLATION, HALF SHAFT

INNER.............................21-12

SEAL - INSTALLATION, INPUT FLANGE....3-45

SEAL - INSTALLATION, INPUT SHAFT.....21-18

SEAL - INSTALLATION, INPUT SHAFT

COVER.............................21-14

SEAL - INSTALLATION, INPUT SHAFT

END ...............................21-16

SEAL - INSTALLATION, OUTER HALF

SHAFT.............................21-19

SEAL - INSTALLATION, OUTPUT FLANGE . . . 3-46

SEAL - OIL PUMP - INSTALLATION.....21-233

SEAL - OIL PUMP - REMOVAL.........21-232

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL................9-129,9-42

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL ...........................9-128,9-41

SEAL - REMOVAL, DIFFERENTIAL

CARRIER............................21-9

SEAL - REMOVAL, END COVER..........21-11

SEAL - REMOVAL, HALF SHAFT INNER . . . 21-12

SEAL - REMOVAL, INPUT FLANGE

........3-44

SEAL - REMOVAL, INPUT SHAFT

........21-17

SEAL - REMOVAL, INPUT SHAFT COVER

. . 21-13

SEAL - REMOVAL, INPUT SHAFT END

....21-15

SEAL - REMOVAL, OUTER HALF SHAFT

. . . 21-19

RSINDEX27

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com