bolt pattern CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 49 of 2177

CAUTION: When installing hub and bearing into

steering knuckle, be careful not to damage the

bearing seal (Fig. 7) on the outer C/V joint.

(1) Install hub and bearing onto stub axle and into

steering knuckle until squarely seated on the face of

the steering knuckle.

(2) Install the 4 hub and bearing mounting bolts

from the rear of the knuckle. Equally tighten all 4

mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front ofsteering knuckle. Tighten mounting bolts to a torque

of 65 N´m (45 ft. lbs.)

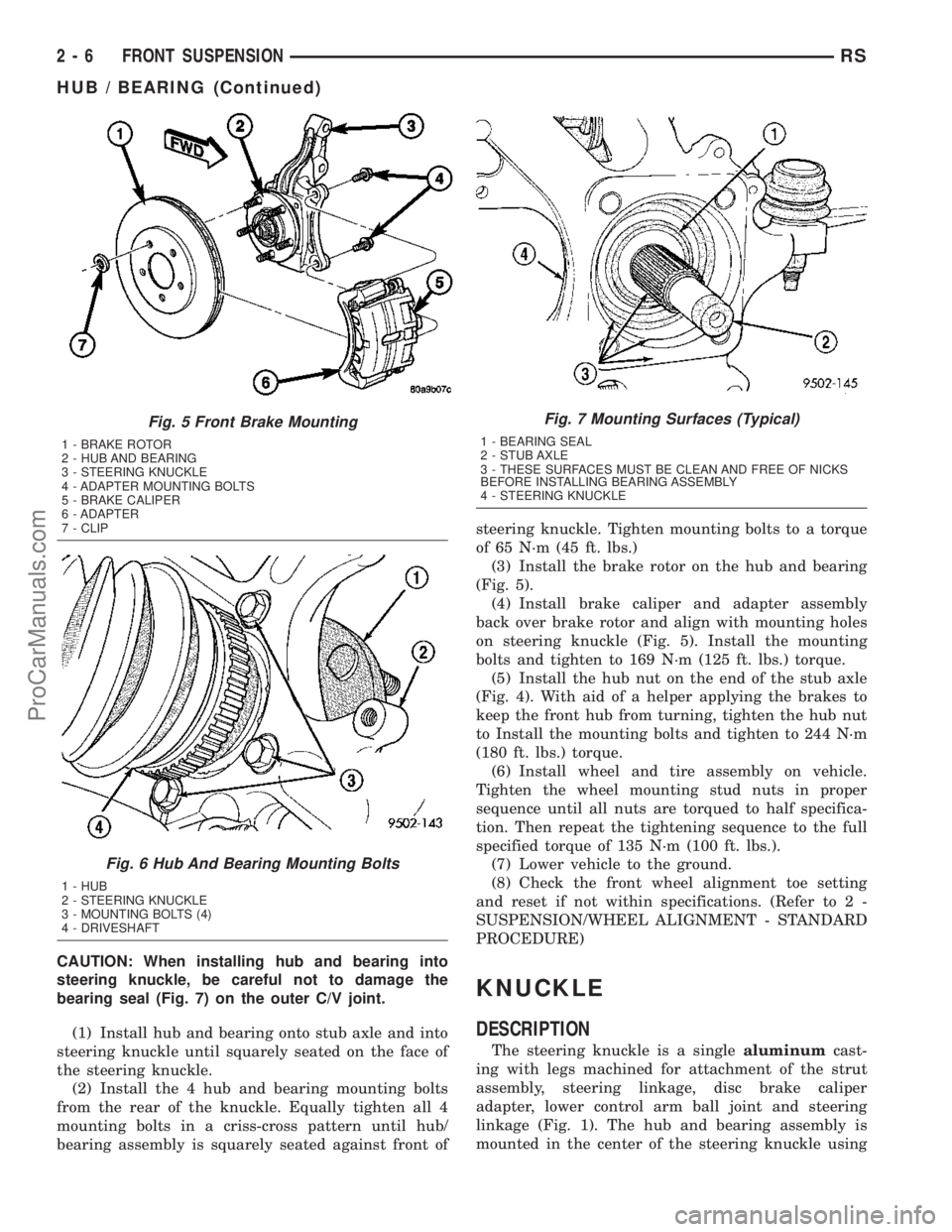

(3) Install the brake rotor on the hub and bearing

(Fig. 5).

(4) Install brake caliper and adapter assembly

back over brake rotor and align with mounting holes

on steering knuckle (Fig. 5). Install the mounting

bolts and tighten to 169 N´m (125 ft. lbs.) torque.

(5) Install the hub nut on the end of the stub axle

(Fig. 4). With aid of a helper applying the brakes to

keep the front hub from turning, tighten the hub nut

to Install the mounting bolts and tighten to 244 N´m

(180 ft. lbs.) torque.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

(8) Check the front wheel alignment toe setting

and reset if not within specifications. (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

KNUCKLE

DESCRIPTION

The steering knuckle is a singlealuminumcast-

ing with legs machined for attachment of the strut

assembly, steering linkage, disc brake caliper

adapter, lower control arm ball joint and steering

linkage (Fig. 1). The hub and bearing assembly is

mounted in the center of the steering knuckle using

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 6 Hub And Bearing Mounting Bolts

1 - HUB

2 - STEERING KNUCKLE

3 - MOUNTING BOLTS (4)

4 - DRIVESHAFT

Fig. 7 Mounting Surfaces (Typical)

1 - BEARING SEAL

2 - STUB AXLE

3 - THESE SURFACES MUST BE CLEAN AND FREE OF NICKS

BEFORE INSTALLING BEARING ASSEMBLY

4 - STEERING KNUCKLE

2 - 6 FRONT SUSPENSIONRS

HUB / BEARING (Continued)

ProCarManuals.com

Page 76 of 2177

NOTE: If equipped with antilock brakes, make sure

wheel speed sensor stays clean and dry as it is

installed into the hub and bearing cap.

(4) If the vehicle is equipped with antilock brakes,

perform the following:

(a) If metal sensor retaining clip is not in the

neutral installed position on hub and bearing cap,

install from the bottom, if necessary, and push clip

upward until it snaps into position.

(b) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch

in the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining

clip.

(c) Install secondary (yellow) retaining clip over

wheel speed sensor head and engage the tabs on

each side (Fig. 8).

(5) Install brake drum or disc brake rotor and

brake caliper. (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/DRUM - INSTALLATION)(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTOR -

INSTALLATION)

(6) Install wheel and tire (Refer to 22 - TIRES/

WHEELS - INSTALLATION). Tighten the wheel

nuts in the proper sequence to a torque of 135 N´m

(100 ft. lbs.).

(7) Adjust the rear brakes as necessary. (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS)

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

brakes.

ALL-WHEEL-DRIVE VEHICLES

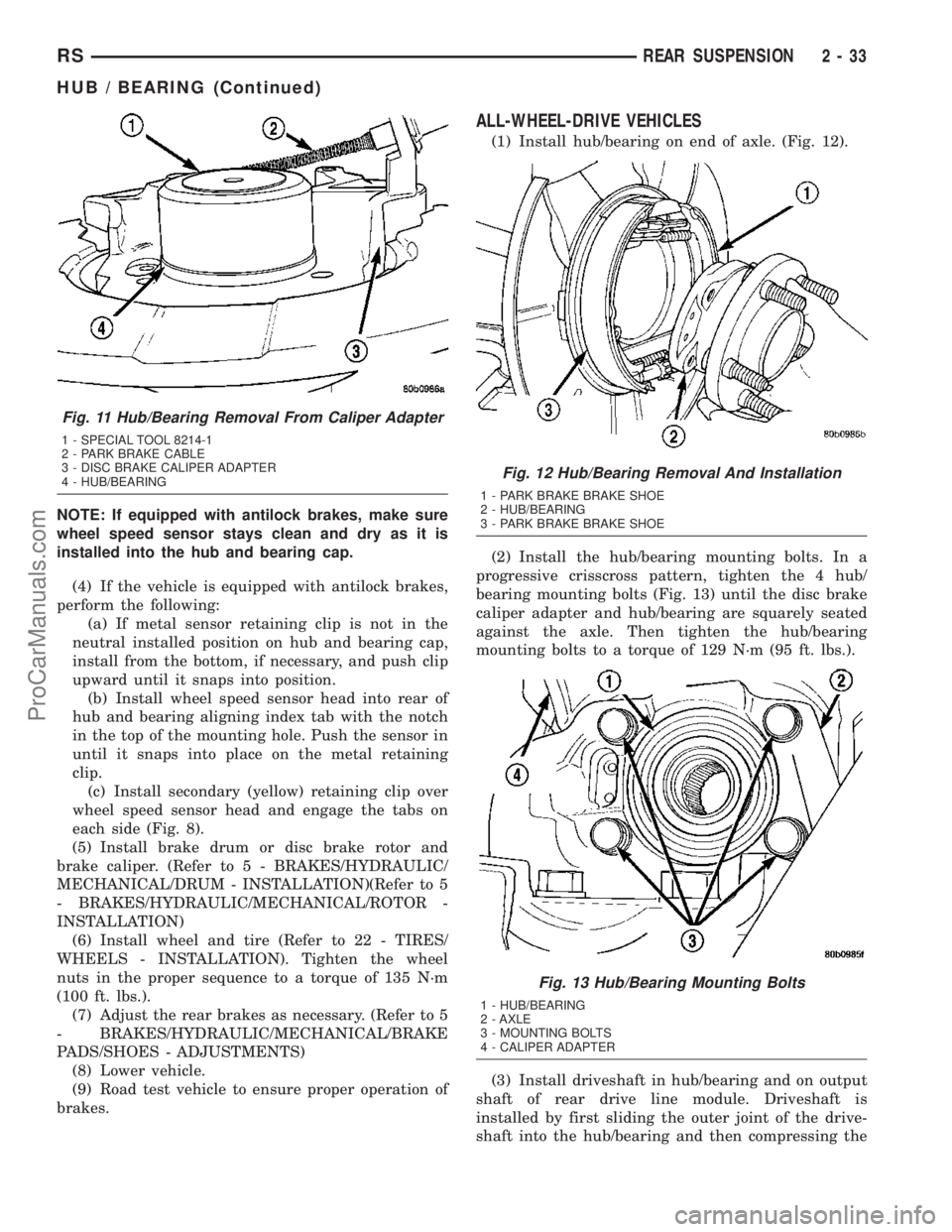

(1) Install hub/bearing on end of axle. (Fig. 12).

(2) Install the hub/bearing mounting bolts. In a

progressive crisscross pattern, tighten the 4 hub/

bearing mounting bolts (Fig. 13) until the disc brake

caliper adapter and hub/bearing are squarely seated

against the axle. Then tighten the hub/bearing

mounting bolts to a torque of 129 N´m (95 ft. lbs.).

(3) Install driveshaft in hub/bearing and on output

shaft of rear drive line module. Driveshaft is

installed by first sliding the outer joint of the drive-

shaft into the hub/bearing and then compressing the

Fig. 11 Hub/Bearing Removal From Caliper Adapter

1 - SPECIAL TOOL 8214-1

2 - PARK BRAKE CABLE

3 - DISC BRAKE CALIPER ADAPTER

4 - HUB/BEARING

Fig. 12 Hub/Bearing Removal And Installation

1 - PARK BRAKE BRAKE SHOE

2 - HUB/BEARING

3 - PARK BRAKE BRAKE SHOE

Fig. 13 Hub/Bearing Mounting Bolts

1 - HUB/BEARING

2 - AXLE

3 - MOUNTING BOLTS

4 - CALIPER ADAPTER

RSREAR SUSPENSION2-33

HUB / BEARING (Continued)

ProCarManuals.com

Page 219 of 2177

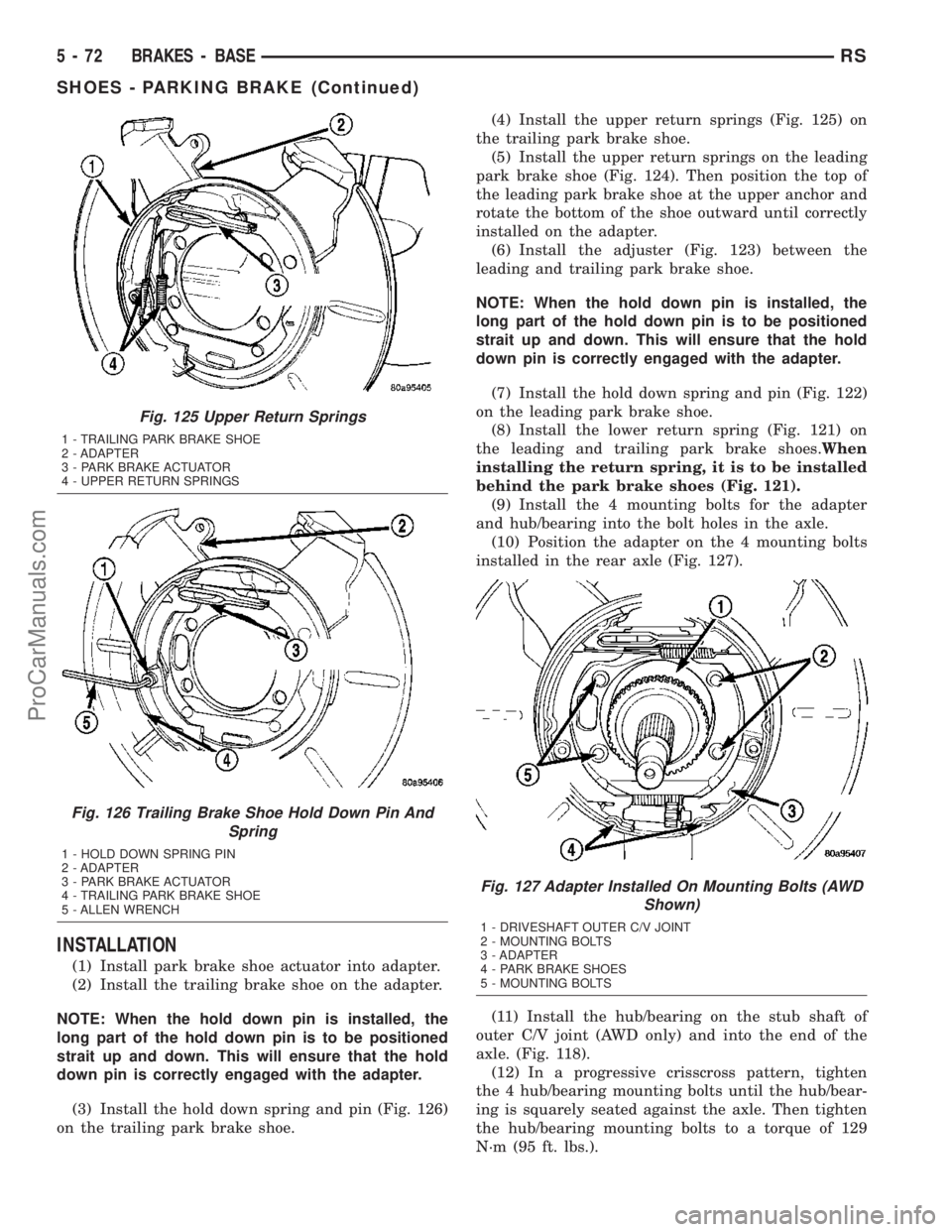

INSTALLATION

(1) Install park brake shoe actuator into adapter.

(2) Install the trailing brake shoe on the adapter.

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(3) Install the hold down spring and pin (Fig. 126)

on the trailing park brake shoe.(4) Install the upper return springs (Fig. 125) on

the trailing park brake shoe.

(5) Install the upper return springs on the leading

park brake shoe (Fig. 124). Then position the top of

the leading park brake shoe at the upper anchor and

rotate the bottom of the shoe outward until correctly

installed on the adapter.

(6) Install the adjuster (Fig. 123) between the

leading and trailing park brake shoe.

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(7) Install the hold down spring and pin (Fig. 122)

on the leading park brake shoe.

(8) Install the lower return spring (Fig. 121) on

the leading and trailing park brake shoes.When

installing the return spring, it is to be installed

behind the park brake shoes (Fig. 121).

(9) Install the 4 mounting bolts for the adapter

and hub/bearing into the bolt holes in the axle.

(10) Position the adapter on the 4 mounting bolts

installed in the rear axle (Fig. 127).

(11) Install the hub/bearing on the stub shaft of

outer C/V joint (AWD only) and into the end of the

axle. (Fig. 118).

(12) In a progressive crisscross pattern, tighten

the 4 hub/bearing mounting bolts until the hub/bear-

ing is squarely seated against the axle. Then tighten

the hub/bearing mounting bolts to a torque of 129

N´m (95 ft. lbs.).

Fig. 125 Upper Return Springs

1 - TRAILING PARK BRAKE SHOE

2 - ADAPTER

3 - PARK BRAKE ACTUATOR

4 - UPPER RETURN SPRINGS

Fig. 126 Trailing Brake Shoe Hold Down Pin And

Spring

1 - HOLD DOWN SPRING PIN

2 - ADAPTER

3 - PARK BRAKE ACTUATOR

4 - TRAILING PARK BRAKE SHOE

5 - ALLEN WRENCH

Fig. 127 Adapter Installed On Mounting Bolts (AWD

Shown)

1 - DRIVESHAFT OUTER C/V JOINT

2 - MOUNTING BOLTS

3 - ADAPTER

4 - PARK BRAKE SHOES

5 - MOUNTING BOLTS

5 - 72 BRAKES - BASERS

SHOES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 268 of 2177

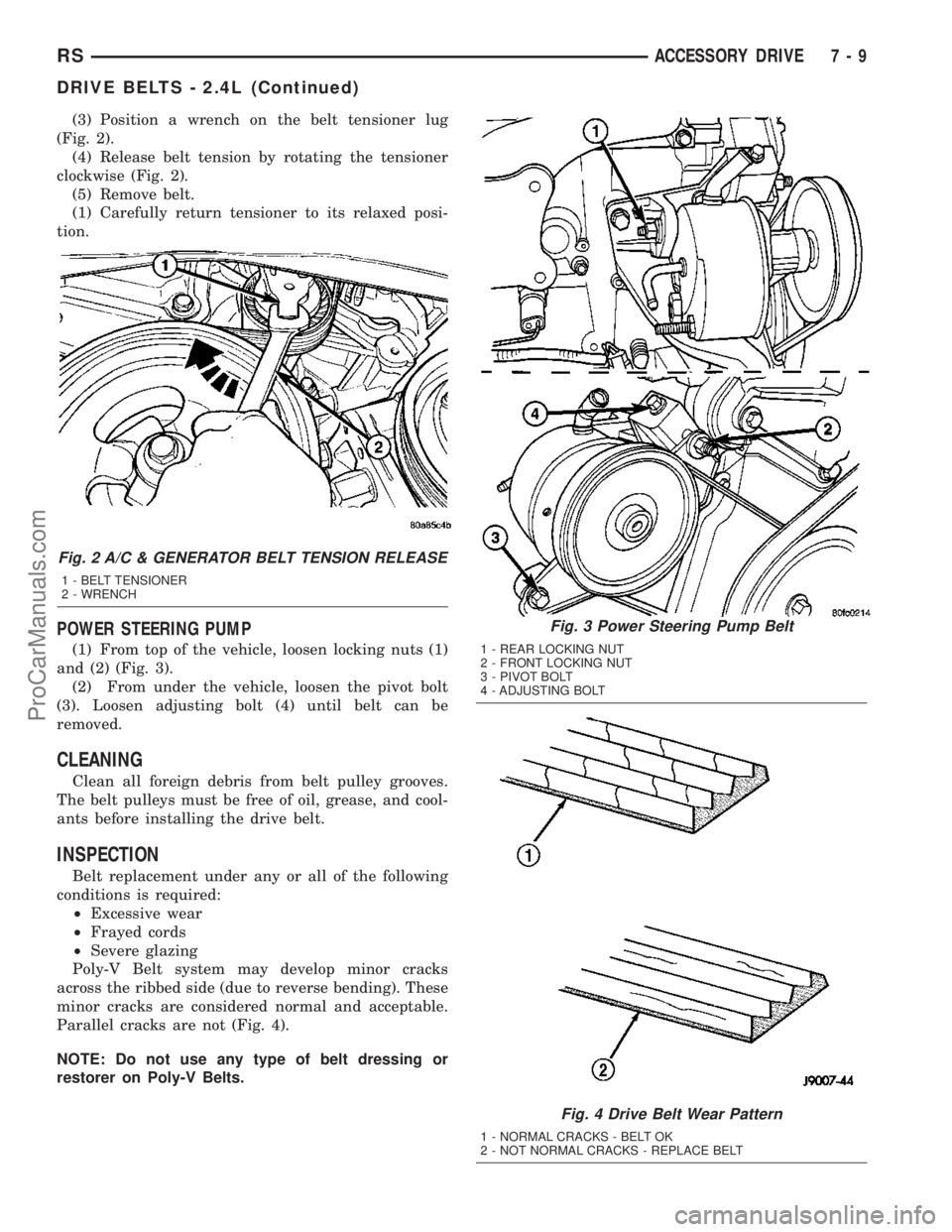

(3) Position a wrench on the belt tensioner lug

(Fig. 2).

(4) Release belt tension by rotating the tensioner

clockwise (Fig. 2).

(5) Remove belt.

(1) Carefully return tensioner to its relaxed posi-

tion.

POWER STEERING PUMP

(1) From top of the vehicle, loosen locking nuts (1)

and (2) (Fig. 3).

(2) From under the vehicle, loosen the pivot bolt

(3). Loosen adjusting bolt (4) until belt can be

removed.

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

INSPECTION

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 4).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

Fig. 2 A/C & GENERATOR BELT TENSION RELEASE

1 - BELT TENSIONER

2 - WRENCH

Fig. 3 Power Steering Pump Belt

1 - REAR LOCKING NUT

2 - FRONT LOCKING NUT

3 - PIVOT BOLT

4 - ADJUSTING BOLT

Fig. 4 Drive Belt Wear Pattern

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

RSACCESSORY DRIVE7-9

DRIVE BELTS - 2.4L (Continued)

ProCarManuals.com

Page 1214 of 2177

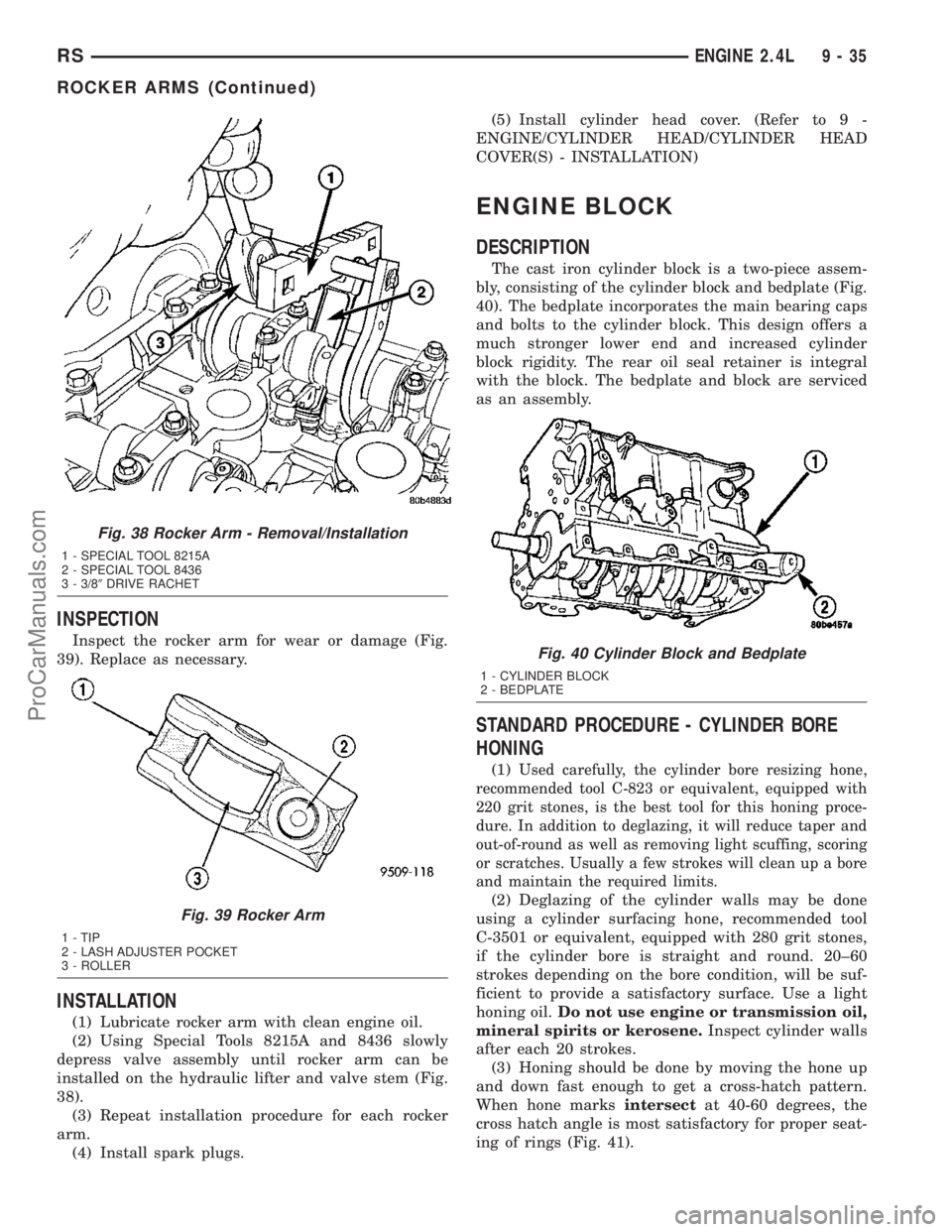

INSPECTION

Inspect the rocker arm for wear or damage (Fig.

39). Replace as necessary.

INSTALLATION

(1) Lubricate rocker arm with clean engine oil.

(2) Using Special Tools 8215A and 8436 slowly

depress valve assembly until rocker arm can be

installed on the hydraulic lifter and valve stem (Fig.

38).

(3) Repeat installation procedure for each rocker

arm.

(4) Install spark plugs.(5) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

ENGINE BLOCK

DESCRIPTION

The cast iron cylinder block is a two-piece assem-

bly, consisting of the cylinder block and bedplate (Fig.

40). The bedplate incorporates the main bearing caps

and bolts to the cylinder block. This design offers a

much stronger lower end and increased cylinder

block rigidity. The rear oil seal retainer is integral

with the block. The bedplate and block are serviced

as an assembly.

STANDARD PROCEDURE - CYLINDER BORE

HONING

(1)Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped with

220 grit stones, is the best tool for this honing proce-

dure. In addition to deglazing, it will reduce taper and

out-of-round as well as removing light scuffing, scoring

or scratches. Usually a few strokes will clean up a bore

and maintain the required limits.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Use a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.Inspect cylinder walls

after each 20 strokes.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 40-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 41).

Fig. 38 Rocker Arm - Removal/Installation

1 - SPECIAL TOOL 8215A

2 - SPECIAL TOOL 8436

3 - 3/89DRIVE RACHET

Fig. 39 Rocker Arm

1 - TIP

2 - LASH ADJUSTER POCKET

3 - ROLLER

Fig. 40 Cylinder Block and Bedplate

1 - CYLINDER BLOCK

2 - BEDPLATE

RSENGINE 2.4L9-35

ROCKER ARMS (Continued)

ProCarManuals.com