key CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 309 of 2177

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

REMOTE SWITCHES

DESCRIPTION

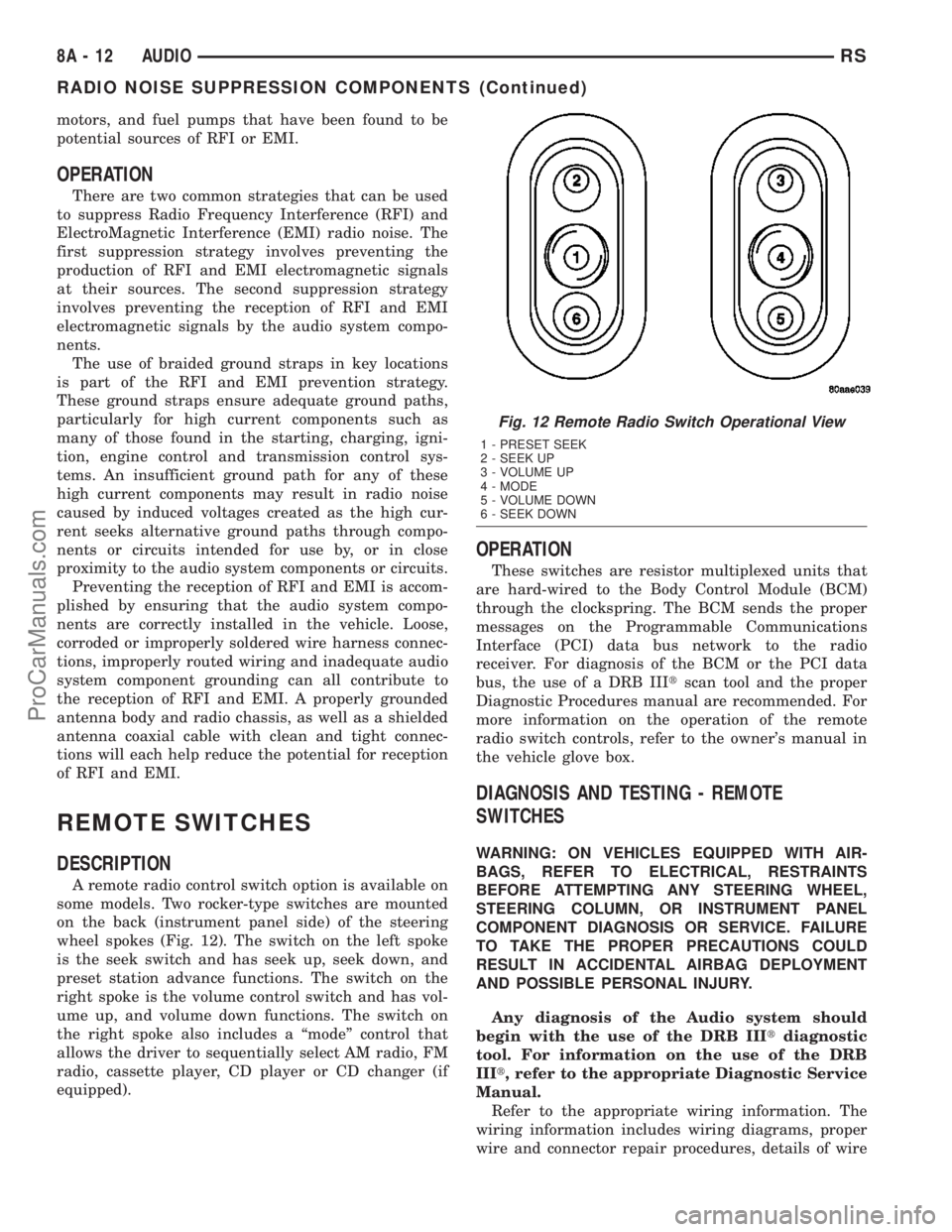

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 12). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

Fig. 12 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 12 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

ProCarManuals.com

Page 314 of 2177

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1WARNING.............................1

DIAGNOSIS AND TESTING - CHIME SYSTEM . . 1

CHIME/BUZZER

DESCRIPTION

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

²Low/High Tire Pressure

²Service Tire Pressure Monitor (TPM)

HIGH SPEED WARNING - EXPORT

The chime will sound, acting as a warning to the

driver that the vehicle speed has exceeded 120 3

kph (75 2 mph).

Refer to the proper Body Diagnostic Procedures

manual for further description of chimes.

OPERATION

Refer to the proper Body Diagnostic Procedures

manual for complete chime/buzzer operation and con-

ditions for operation.

HIGH SPEED WARNING - EXPORT

When the vehicle speed sensor sees 120 3kph

(75 2 mph), it sends a PCI data bus message to the

Body Control Module (BCM). The BCM then turns on

the chime to let the driver know that the vehicle has

reached a speed greater than 120 3kph(75 2

mph). This audible message will continue until the

vehicle is slowed below the predetermined speed.

WARNING

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

DIAGNOSIS AND TESTING - CHIME SYSTEM

Refer to the proper Body Diagnostic Procedures

manual for complete Diagnosis and Testing of the

Chime System.

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVER'S SEAT BELT IS NOT BUCKLED.

(1) Using a DRB llltscan tool, actuate chime

(BCM actuates).

(2) Using a voltmeter, check for voltage:

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

RSCHIME/BUZZER8B-1

ProCarManuals.com

Page 315 of 2177

(3) Check drivers seat belt buckle switch input

(from Occupant Restraint Controller (ORC) for a

closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Verify Programmable Communication Interface

(PCI) data bus communication between ORC and

BCM.

NO FASTEN SEAT BELT LAMP WHEN IGNITION

SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage at the clus-

ter connector:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE CONTINUES

FOR MORE THAN 10 SECONDS AFTER SEAT

BELTS ARE FASTENED AND DRIVER'S DOOR IS

CLOSED.

Refer to the proper Body Diagnostic Procedures

manual.

NO TONE WHEN PARK OR HEADLAMPS ARE ON

AND DRIVER'S DOOR IS OPEN.

Make sure ignition is in lock position with the key

removed.

(1) Check the BCM DTC's and BCM sensors to

verify the door is open. Repair as necessary.

(2) Actuate Chime (BCM actuates).

(3) Inspect BCM connectors and wires for proper

connection.

(4) Measure with a voltmeter the voltage (12v) on

BCM connector (PX2) pin 34 with harness connected.

(5) Check BCM sensors to verify headlamp switch

position.

8B - 2 CHIME/BUZZERRS

CHIME/BUZZER (Continued)

ProCarManuals.com

Page 316 of 2177

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................2

BODY CONTROL MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................5

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................6

INSTALLATION..........................6

DATA LINK CONNECTOR

DESCRIPTION..........................6

OPERATION............................7

FRONT CONTROL MODULE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................7

REMOVAL.............................8

INSTALLATION..........................8

HEATED SEAT MODULE

DESCRIPTION..........................8

OPERATION............................9

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE.............................9

REMOVAL.............................9

INSTALLATION.........................10

MEMORY SEAT/MIRROR MODULE

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE................10

REMOVAL.............................10

INSTALLATION.........................10

POWER LIFTGATE CONTROL MODULE

DESCRIPTION.........................10

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION........................11OPERATION - SENSOR RETURN - PCM

INPUT..............................15

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT.................15

OPERATION - IGNITION SENSE - PCM

INPUT..............................15

OPERATION - PCM GROUND............15

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM

OUTPUT - SBEC CONTROLLER..........15

OPERATION - 5 VOLT SUPPLY - PCM

OUTPUT............................15

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES..........15

STANDARD PROCEDURE - PINION

FACTOR SETTING.....................15

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE........................16

REMOVAL

REMOVAL - SBEC CONTROLLER.........16

REMOVAL - NGC CONTROLLER..........17

INSTALLATION

INSTALLATION - SBEC CONTROLLER.....17

INSTALLATION.......................17

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................19

SLIDING DOOR CONTROL MODULE

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................20

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................20

OPERATION...........................20

STANDARD PROCEDURE

STANDARD PROCEDURE - PINION

FACTOR SETTING.....................23

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE........................23

REMOVAL.............................23

INSTALLATION.........................24

RSELECTRONIC CONTROL MODULES8E-1

ProCarManuals.com

Page 317 of 2177

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM for a failed driver,

control circuit or ground circuit, be sure to check

the related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM driver/control circuit failures are caused

by internal component failures (i.e. relay and sole-

noids) and shorted circuits (i.e. pull-ups, drivers

and switched circuits). These failures are difficult to

detect when a double fault has occurred and only

one DTC has set.

When a PCM (SBEC) and the SKIM are replaced

at the same time perform the following steps in

order:

(1) Program the new PCM (SBEC)

(2) Program the new SKIM

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (SBEC)

The SKIS Secret Key is an ID code that is unique

to each SKIM. This code is programmed and stored

in the SKIM, PCM and transponder chip (ignition

keys). When replacing the PCM it is necessary to

program the secret key into the new PCM using the

DRB III. Perform the following steps to program the

secret key into the PCM.

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition to the RUN

position for one hour then enter the correct PIN.

(Ensure all accessories are turned off. Also monitor

the battery state and connect a battery charger if

necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.(8) The DRB III will ask, Is odometer reading

between XX and XX? Select the YES or NO button on

the DRB III. If NO is selected, the DRB III will read,

Enter odometer Reading

the odometer reading from the Instrument Panel and

press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, the SKIM must be replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle keys will need to be replaced

and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

If ignition key programming is unsuccessful, the

DRB III will display one of the following messages:

Programming Not Attempted - The DRB III

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

Programming Key Failed (Possible Used Key From

Wrong Vehicle) - SKIM is unable to program key due

to one of the following:

²faulty ignition key transponder

²ignition key is programmed to another vehicle.

8 Keys Already Learned, Programming Not Done -

SKIM transponder ID memory is full.

8E - 2 ELECTRONIC CONTROL MODULESRS

ProCarManuals.com

Page 318 of 2177

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 319 of 2177

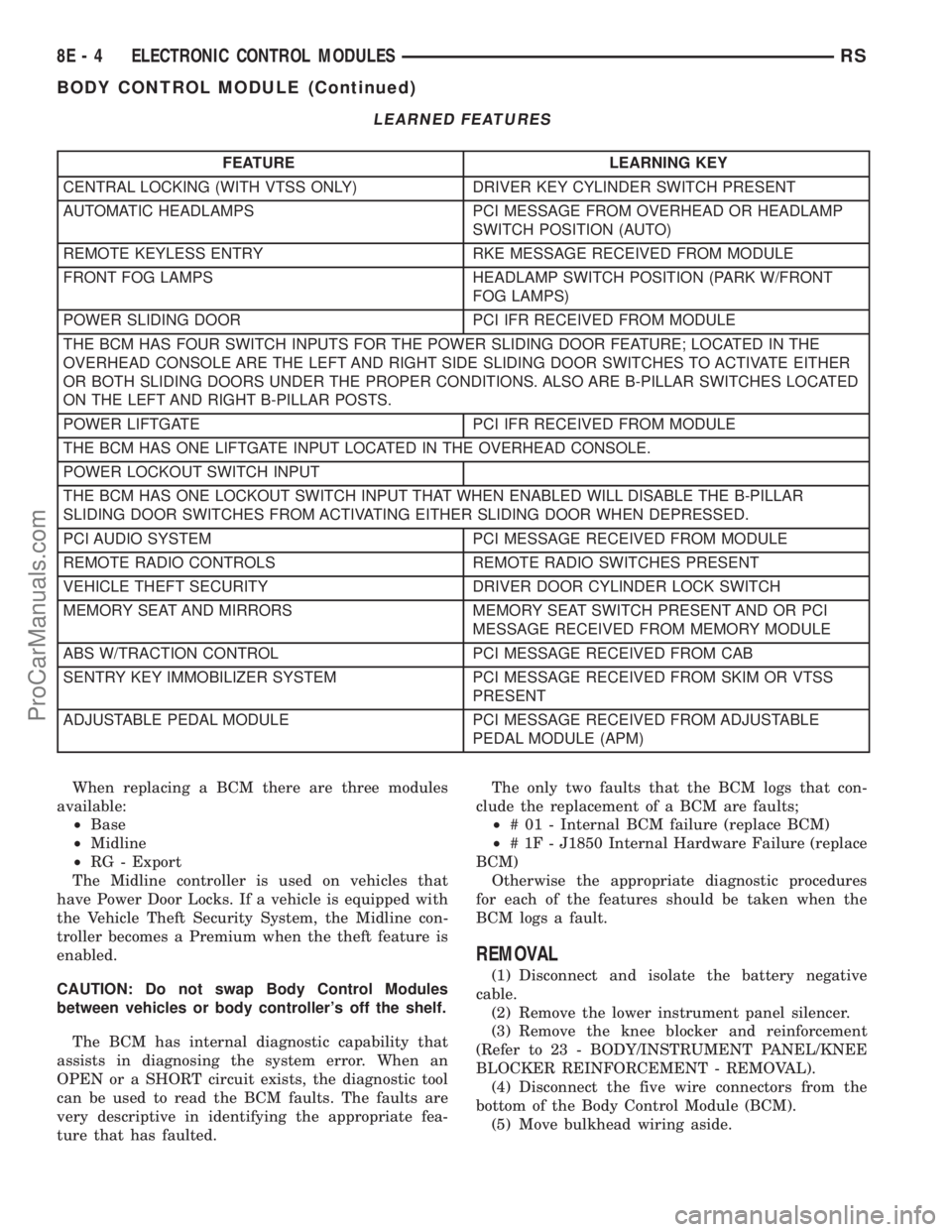

LEARNED FEATURES

FEATURE LEARNING KEY

CENTRAL LOCKING (WITH VTSS ONLY) DRIVER KEY CYLINDER SWITCH PRESENT

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY RKE MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY DRIVER DOOR CYLINDER LOCK SWITCH

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

When replacing a BCM there are three modules

available:

²Base

²Midline

²RG - Export

The Midline controller is used on vehicles that

have Power Door Locks. If a vehicle is equipped with

the Vehicle Theft Security System, the Midline con-

troller becomes a Premium when the theft feature is

enabled.

CAUTION: Do not swap Body Control Modules

between vehicles or body controller's off the shelf.

The BCM has internal diagnostic capability that

assists in diagnosing the system error. When an

OPEN or a SHORT circuit exists, the diagnostic tool

can be used to read the BCM faults. The faults are

very descriptive in identifying the appropriate fea-

ture that has faulted.The only two faults that the BCM logs that con-

clude the replacement of a BCM are faults;

²# 01 - Internal BCM failure (replace BCM)

²# 1F - J1850 Internal Hardware Failure (replace

BCM)

Otherwise the appropriate diagnostic procedures

for each of the features should be taken when the

BCM logs a fault.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower instrument panel silencer.

(3) Remove the knee blocker and reinforcement

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER REINFORCEMENT - REMOVAL).

(4) Disconnect the five wire connectors from the

bottom of the Body Control Module (BCM).

(5) Move bulkhead wiring aside.

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

ProCarManuals.com

Page 330 of 2177

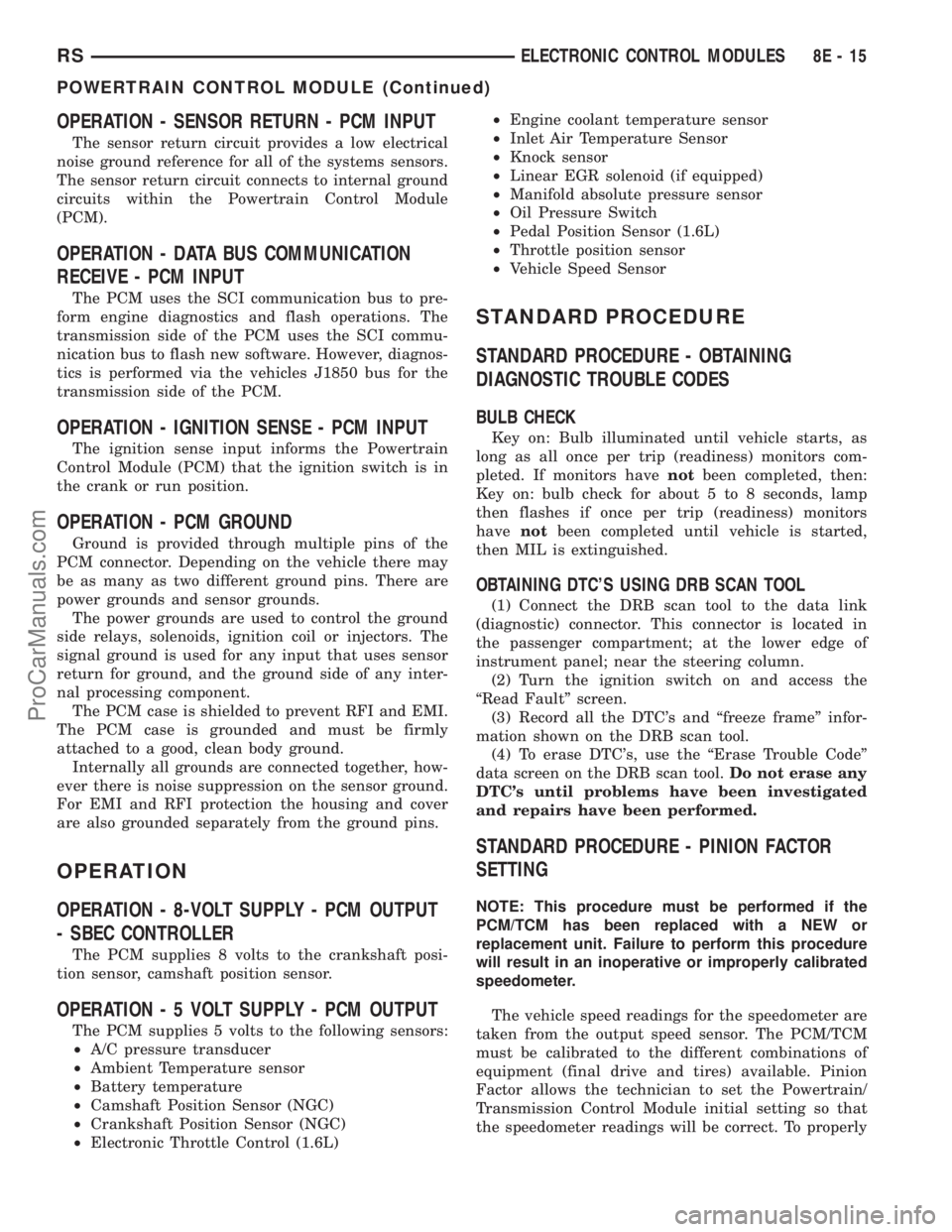

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module

(PCM).

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT

The PCM uses the SCI communication bus to pre-

form engine diagnostics and flash operations. The

transmission side of the PCM uses the SCI commu-

nication bus to flash new software. However, diagnos-

tics is performed via the vehicles J1850 bus for the

transmission side of the PCM.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as two different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side relays, solenoids, ignition coil or injectors. The

signal ground is used for any input that uses sensor

return for ground, and the ground side of any inter-

nal processing component.

The PCM case is shielded to prevent RFI and EMI.

The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the housing and cover

are also grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

- SBEC CONTROLLER

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Ambient Temperature sensor

²Battery temperature

²Camshaft Position Sensor (NGC)

²Crankshaft Position Sensor (NGC)

²Electronic Throttle Control (1.6L)²Engine coolant temperature sensor

²Inlet Air Temperature Sensor

²Knock sensor

²Linear EGR solenoid (if equipped)

²Manifold absolute pressure sensor

²Oil Pressure Switch

²Pedal Position Sensor (1.6L)

²Throttle position sensor

²Vehicle Speed Sensor

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 5 to 8 seconds, lamp

then flashes if once per trip (readiness) monitors

havenotbeen completed until vehicle is started,

then MIL is extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

PCM/TCM has been replaced with a NEW or

replacement unit. Failure to perform this procedure

will result in an inoperative or improperly calibrated

speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The PCM/TCM

must be calibrated to the different combinations of

equipment (final drive and tires) available. Pinion

Factor allows the technician to set the Powertrain/

Transmission Control Module initial setting so that

the speedometer readings will be correct. To properly

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 332 of 2177

REMOVAL - NGC CONTROLLER

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a Diagnostic Trou-

ble Code (DTC) may be set. Refer to the appropriate

Powertrain Diagnostic Manual and the DRBIIItscan

tool.

(1) Turn wheels to the left.

(2) Disconnect the negative battery cable.

(3) Raise vehicle and support.

(4) Remove the left front wheel well splash shield

(Fig. 13).

(5) Unlock and disconnect the electrical connectors

(Fig. 14).

(6) Remove 3 screws from PCM to mounting

bracket.

(7) Remove the PCM.

INSTALLATION

INSTALLATION - SBEC CONTROLLER

(1) Install the PCM.

(2) Install the lower PCM mounting bolt. Tighten

bolt.

(3) Install the 2 upper PCM bracket bolts. Tighten

bolt.

(4) Install the headlamp, refer to the Lamps sec-

tion for more information.

(5) Install the 2 PCM connectors.(6) Install the battery shield, refer to the Battery

section for more information.

(7) Connect the negative battery cable.

INSTALLATION

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a diagnostic trouble

code (DTC) may be set and SKIM must be done or

car will not start if it is a SKIM equipped car. If a

SKIM car you must do a secret key transfer also.

NGC CONTROLLER LOCATION

Fig. 13 SPLASH SHIELD

Fig. 14 NGC CONTROLLER

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 333 of 2177

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

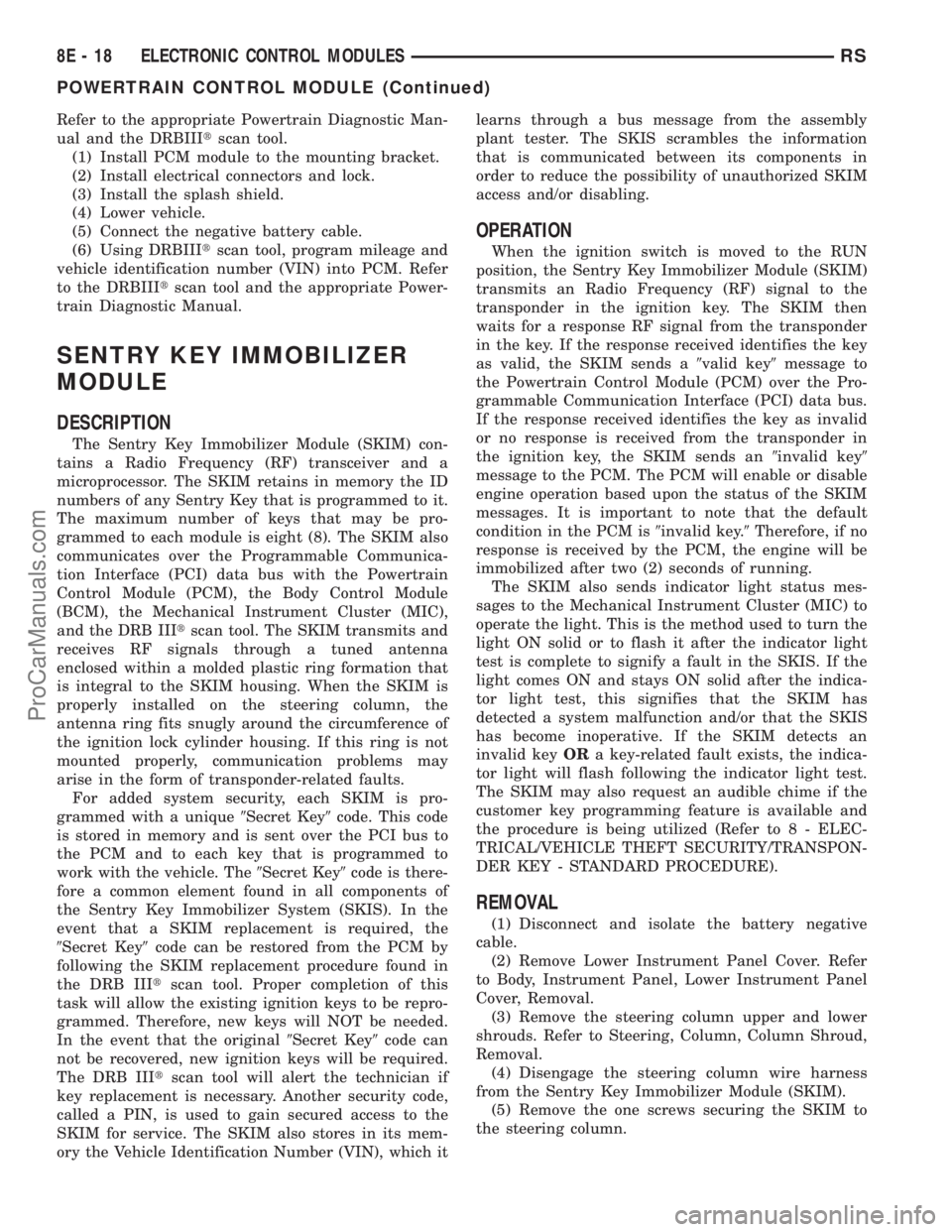

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM retains in memory the ID

numbers of any Sentry Key that is programmed to it.

The maximum number of keys that may be pro-

grammed to each module is eight (8). The SKIM also

communicates over the Programmable Communica-

tion Interface (PCI) data bus with the Powertrain

Control Module (PCM), the Body Control Module

(BCM), the Mechanical Instrument Cluster (MIC),

and the DRB IIItscan tool. The SKIM transmits and

receives RF signals through a tuned antenna

enclosed within a molded plastic ring formation that

is integral to the SKIM housing. When the SKIM is

properly installed on the steering column, the

antenna ring fits snugly around the circumference of

the ignition lock cylinder housing. If this ring is not

mounted properly, communication problems may

arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which itlearns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the Sentry Key Immobilizer Module (SKIM)

transmits an Radio Frequency (RF) signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the Powertrain Control Module (PCM) over the Pro-

grammable Communication Interface (PCI) data bus.

If the response received identifies the key as invalid

or no response is received from the transponder in

the ignition key, the SKIM sends an9invalid key9

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKIM also sends indicator light status mes-

sages to the Mechanical Instrument Cluster (MIC) to

operate the light. This is the method used to turn the

light ON solid or to flash it after the indicator light

test is complete to signify a fault in the SKIS. If the

light comes ON and stays ON solid after the indica-

tor light test, this signifies that the SKIM has

detected a system malfunction and/or that the SKIS

has become inoperative. If the SKIM detects an

invalid keyORa key-related fault exists, the indica-

tor light will flash following the indicator light test.

The SKIM may also request an audible chime if the

customer key programming feature is available and

the procedure is being utilized (Refer to 8 - ELEC-

TRICAL/VEHICLE THEFT SECURITY/TRANSPON-

DER KEY - STANDARD PROCEDURE).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com