remote control CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 301 of 2177

CONDITION POSSIBLE CAUSE CORRECTION

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FREE FROM THESE

CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

ANTENNA BODY AND CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

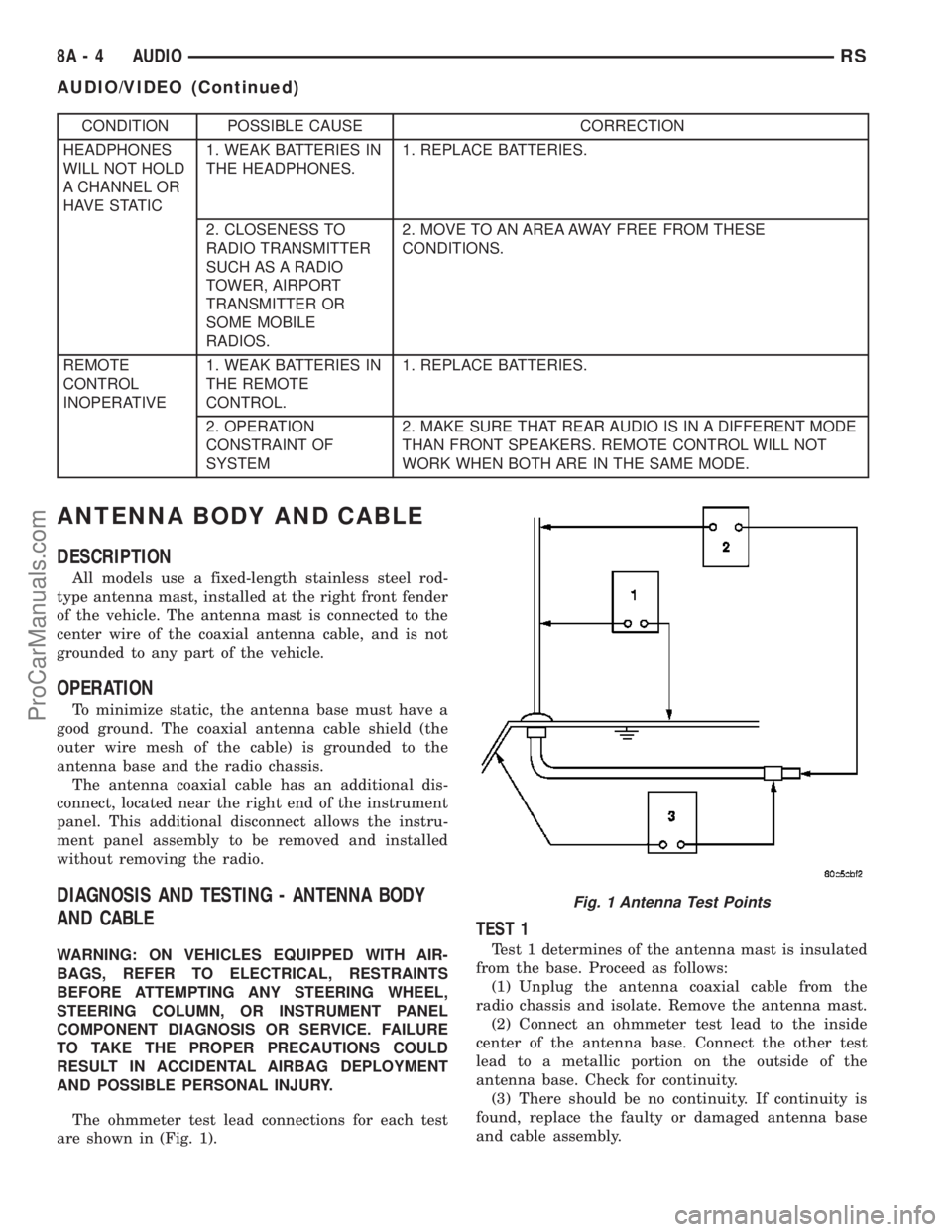

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 1 Antenna Test Points

8A - 4 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com

Page 304 of 2177

DIAGNOSIS AND TESTING - ANTENNA MODULE - EXPORT

CONDITION POSSIBLE CAUSES CORRECTION

NO AM RECEPTION,

WEAK FM RECEPTION1. Antenna module to antenna

connector open or disconnected.1. Repair open, reconnect

antenna module connector to

glass mounted antenna.

2. Coax open or disconnected. 2. Repair open, reconnect coax.

3. No battery power at antenna

module.3. Check fuse. if okay, repair

open in battery voltage circuit.

NO AM OR FM

RECEPTION1. Coax disconnected at radio. 1. Reconnect coax.

2. Coax shorted to ground. 2. Repair or Replace coax

WEAK OR NO AM/FM

RECEPTION1. Antenna Module faulty. 1. Substitute known good

module. If reception improves,

Antenna Module was faulty.

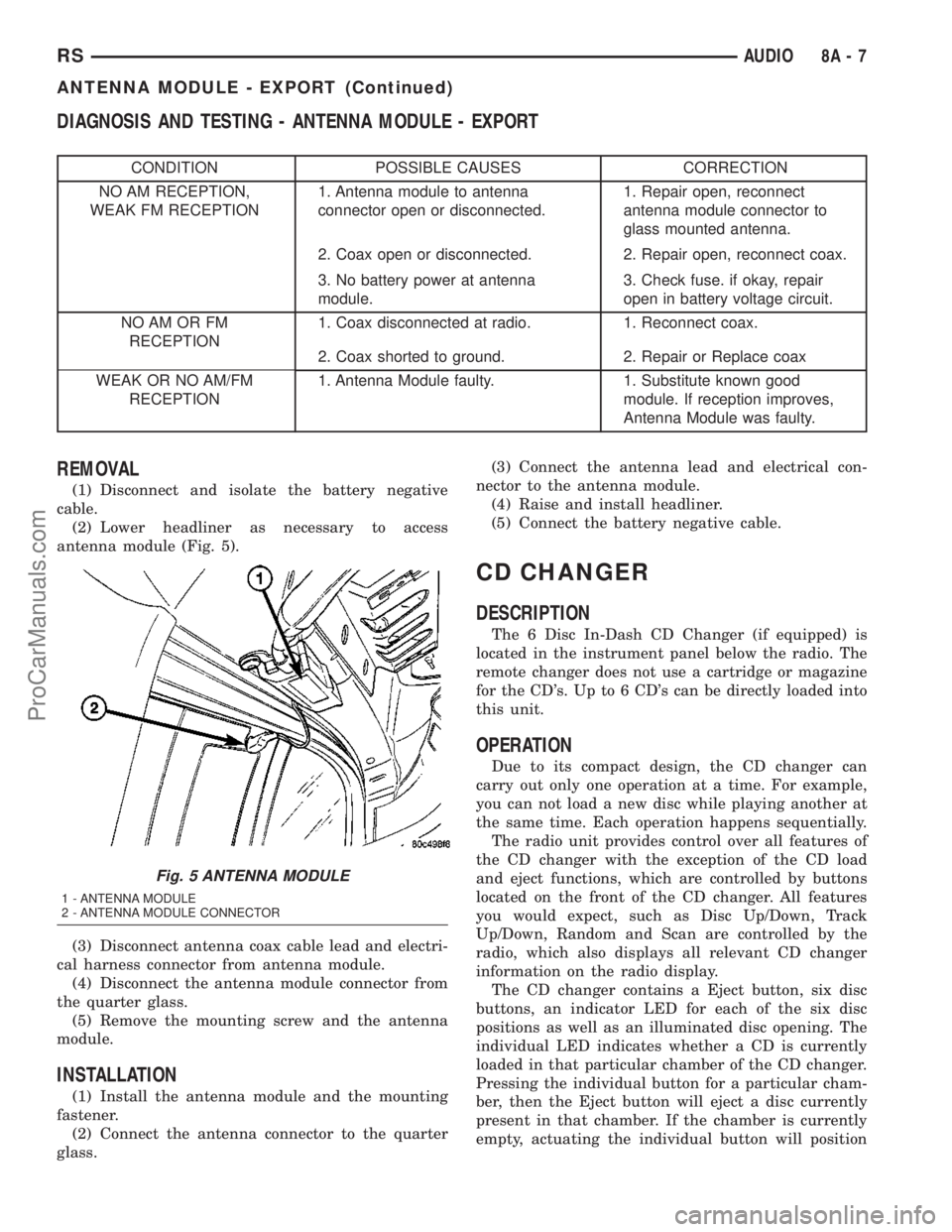

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Lower headliner as necessary to access

antenna module (Fig. 5).

(3) Disconnect antenna coax cable lead and electri-

cal harness connector from antenna module.

(4) Disconnect the antenna module connector from

the quarter glass.

(5) Remove the mounting screw and the antenna

module.

INSTALLATION

(1) Install the antenna module and the mounting

fastener.

(2) Connect the antenna connector to the quarter

glass.(3) Connect the antenna lead and electrical con-

nector to the antenna module.

(4) Raise and install headliner.

(5) Connect the battery negative cable.

CD CHANGER

DESCRIPTION

The 6 Disc In-Dash CD Changer (if equipped) is

located in the instrument panel below the radio. The

remote changer does not use a cartridge or magazine

for the CD's. Up to 6 CD's can be directly loaded into

this unit.

OPERATION

Due to its compact design, the CD changer can

carry out only one operation at a time. For example,

you can not load a new disc while playing another at

the same time. Each operation happens sequentially.

The radio unit provides control over all features of

the CD changer with the exception of the CD load

and eject functions, which are controlled by buttons

located on the front of the CD changer. All features

you would expect, such as Disc Up/Down, Track

Up/Down, Random and Scan are controlled by the

radio, which also displays all relevant CD changer

information on the radio display.

The CD changer contains a Eject button, six disc

buttons, an indicator LED for each of the six disc

positions as well as an illuminated disc opening. The

individual LED indicates whether a CD is currently

loaded in that particular chamber of the CD changer.

Pressing the individual button for a particular cham-

ber, then the Eject button will eject a disc currently

present in that chamber. If the chamber is currently

empty, actuating the individual button will position

Fig. 5 ANTENNA MODULE

1 - ANTENNA MODULE

2 - ANTENNA MODULE CONNECTOR

RSAUDIO8A-7

ANTENNA MODULE - EXPORT (Continued)

ProCarManuals.com

Page 307 of 2177

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include:

²AM/FM/cassette/CD (RAZ sales code)

²AM/FM/CD with CD changer control (RBK sales

code)

²AM/FM/cassette with CD changer control fea-

ture (RBB sales code)

²AM/FM/cassette/CD with rear audio (RBU sales

code)

All factory-installed radio receivers can communi-

cate on the Programmable Communications Interface

(PCI) data bus network. All factory-installed receiv-

ers are stereo Electronically Tuned Radios (ETR) and

include an electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

8A - 10 AUDIORS

QUARTER GLASS INTEGRAL ANTENNA - EXPORT (Continued)

ProCarManuals.com

Page 309 of 2177

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

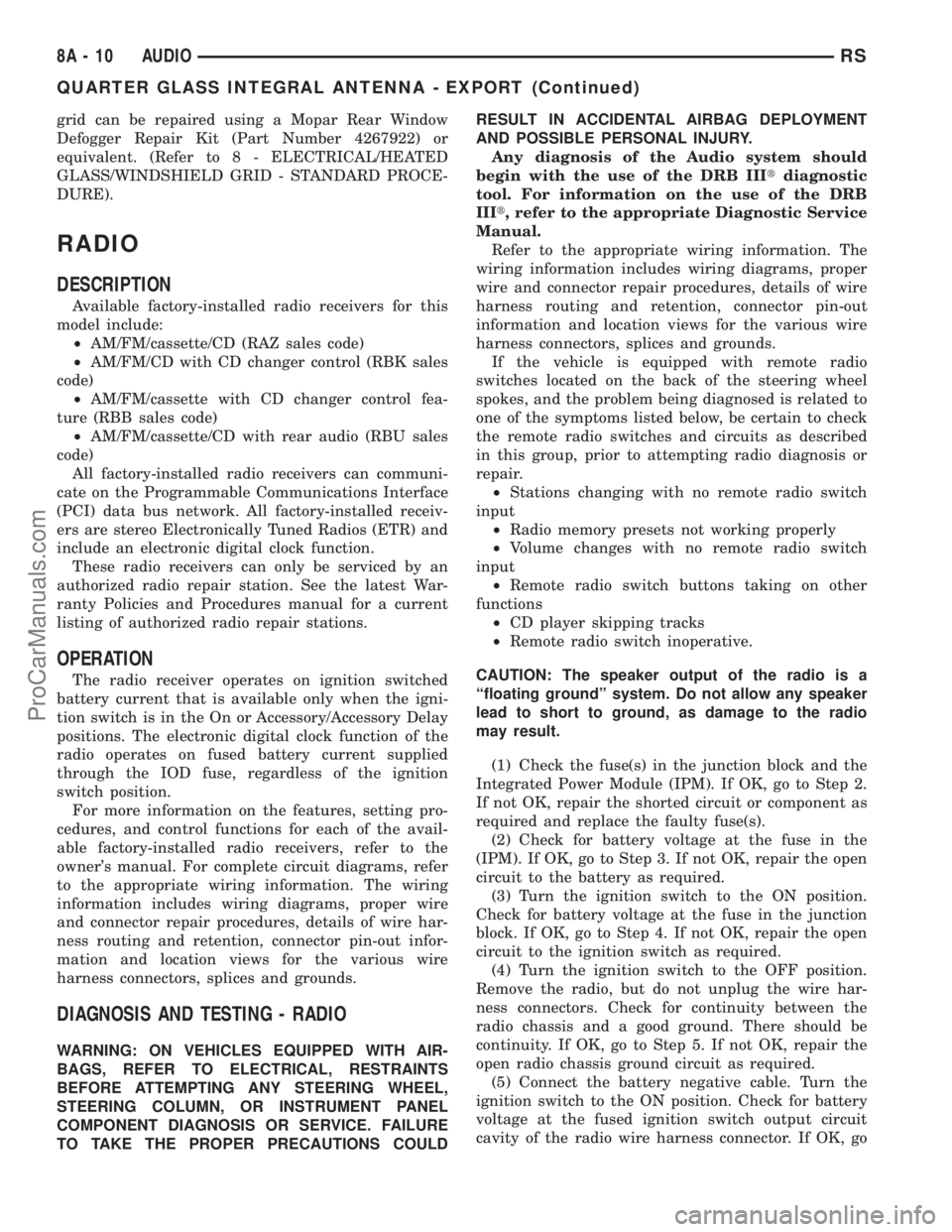

REMOTE SWITCHES

DESCRIPTION

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 12). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

Fig. 12 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 12 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

ProCarManuals.com

Page 310 of 2177

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the airbag system capac-

itor to discharge before further service.

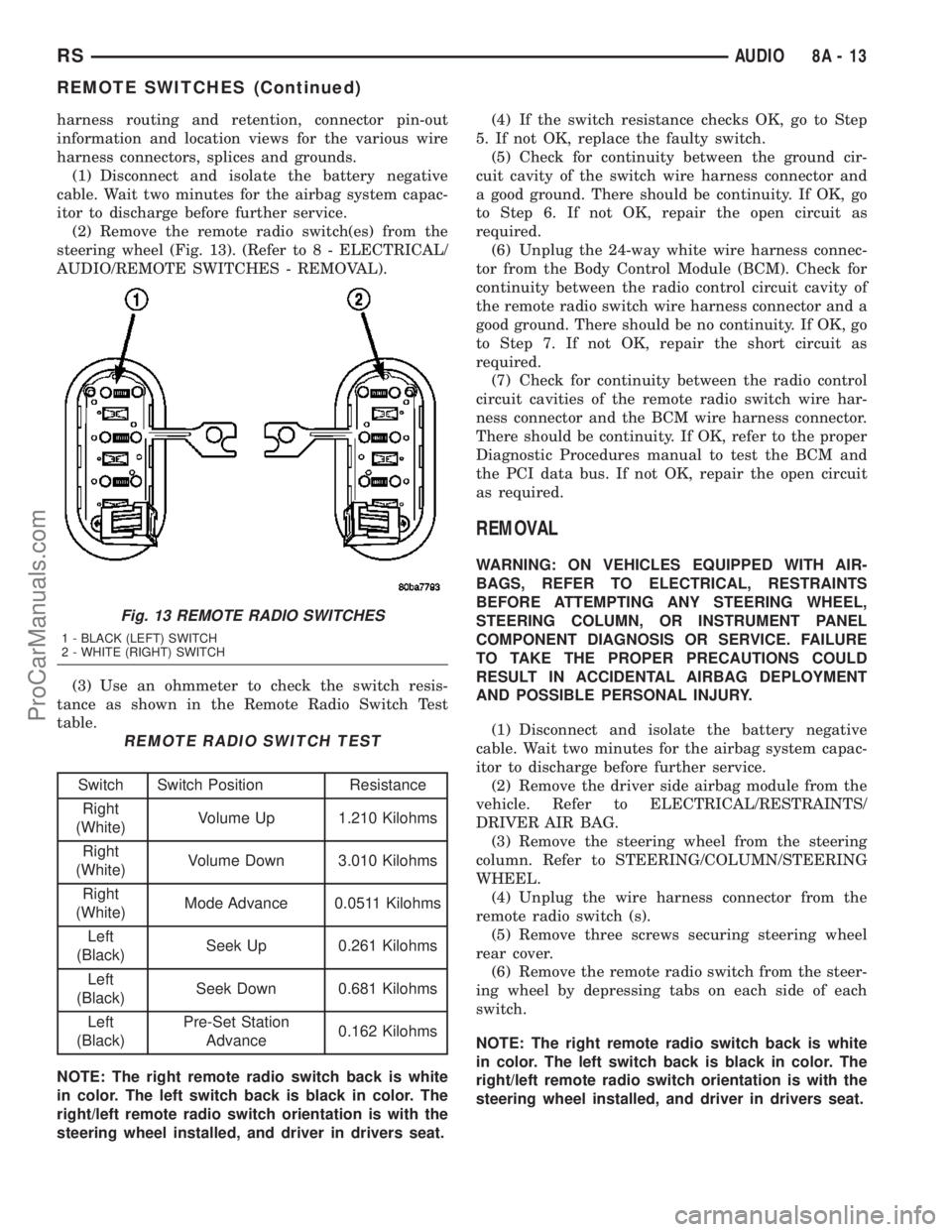

(2) Remove the remote radio switch(es) from the

steering wheel (Fig. 13). (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table.

REMOTE RADIO SWITCH TEST

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.(4) If the switch resistance checks OK, go to Step

5. If not OK, replace the faulty switch.

(5) Check for continuity between the ground cir-

cuit cavity of the switch wire harness connector and

a good ground. There should be continuity. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Unplug the 24-way white wire harness connec-

tor from the Body Control Module (BCM). Check for

continuity between the radio control circuit cavity of

the remote radio switch wire harness connector and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the short circuit as

required.

(7) Check for continuity between the radio control

circuit cavities of the remote radio switch wire har-

ness connector and the BCM wire harness connector.

There should be continuity. If OK, refer to the proper

Diagnostic Procedures manual to test the BCM and

the PCI data bus. If not OK, repair the open circuit

as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the airbag system capac-

itor to discharge before further service.

(2) Remove the driver side airbag module from the

vehicle. Refer to ELECTRICAL/RESTRAINTS/

DRIVER AIR BAG.

(3) Remove the steering wheel from the steering

column. Refer to STEERING/COLUMN/STEERING

WHEEL.

(4) Unplug the wire harness connector from the

remote radio switch (s).

(5) Remove three screws securing steering wheel

rear cover.

(6) Remove the remote radio switch from the steer-

ing wheel by depressing tabs on each side of each

switch.

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

Fig. 13 REMOTE RADIO SWITCHES

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

RSAUDIO8A-13

REMOTE SWITCHES (Continued)

ProCarManuals.com

Page 311 of 2177

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Install three screws securing steering wheel

rear cover.

(3) Connect the wire harness to the remote radio

switch.

(4) Install the steering wheel. Refer to STEERING/

COLUMN/STEERING WHEEL.

(5) Install the driver side airbag module. Refer to

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG.

(6) Connect the battery negative cable.

SPEAKER

DIAGNOSIS AND TESTING - SPEAKER

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speakerlead to short to ground, as damage to the radio

may result.

(1) If all speakers are inoperative, check the radio

fuses in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 3.

(3) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. Remove the radio receiver.

(4) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(5) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

D-PILLAR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 14).

(8) Disconnect the wire harness connector from the

speaker.

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel. (Refer to 23

- BODY/DOOR - FRONT/TRIM PANEL - REMOV-

AL).

8A - 14 AUDIORS

REMOTE SWITCHES (Continued)

ProCarManuals.com

Page 318 of 2177

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 319 of 2177

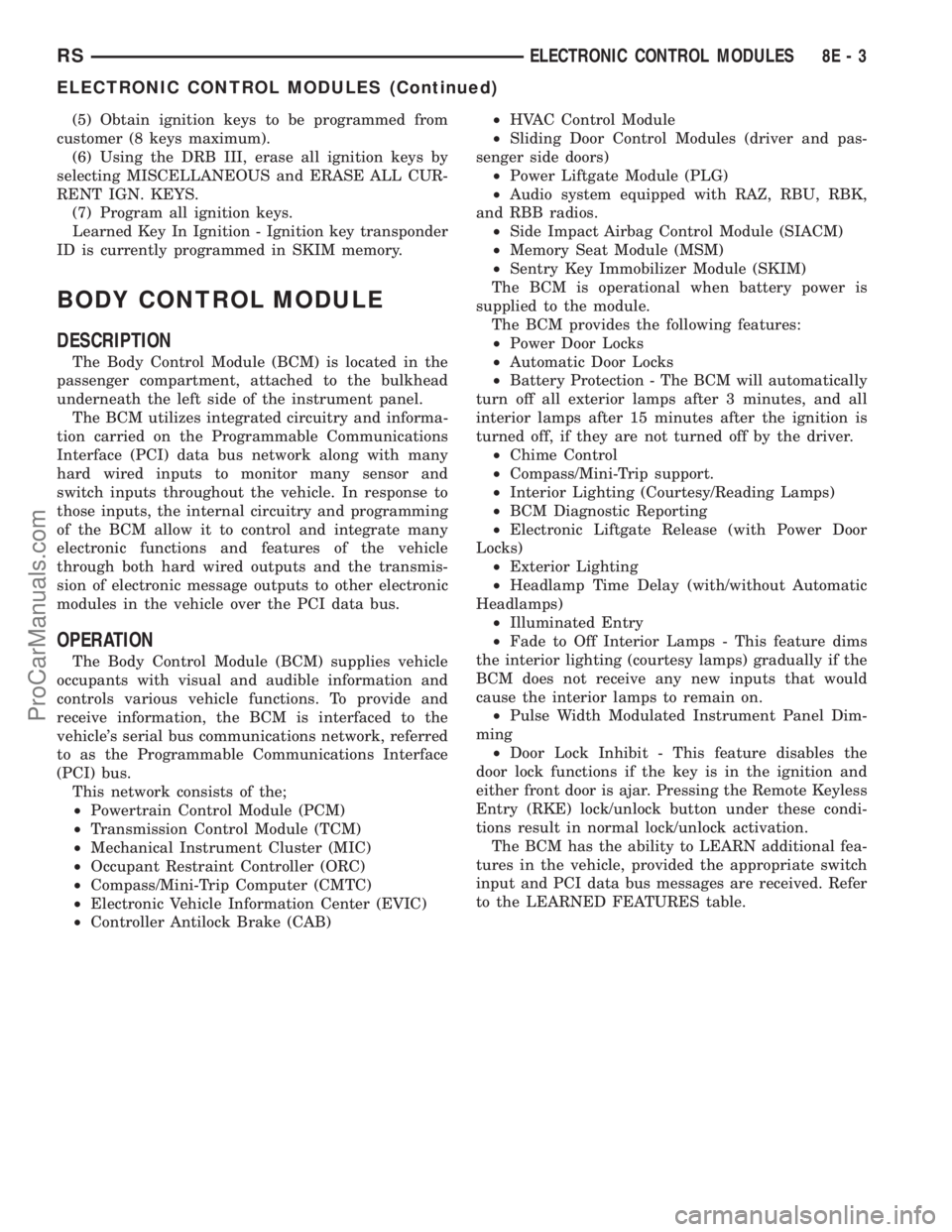

LEARNED FEATURES

FEATURE LEARNING KEY

CENTRAL LOCKING (WITH VTSS ONLY) DRIVER KEY CYLINDER SWITCH PRESENT

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY RKE MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY DRIVER DOOR CYLINDER LOCK SWITCH

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

When replacing a BCM there are three modules

available:

²Base

²Midline

²RG - Export

The Midline controller is used on vehicles that

have Power Door Locks. If a vehicle is equipped with

the Vehicle Theft Security System, the Midline con-

troller becomes a Premium when the theft feature is

enabled.

CAUTION: Do not swap Body Control Modules

between vehicles or body controller's off the shelf.

The BCM has internal diagnostic capability that

assists in diagnosing the system error. When an

OPEN or a SHORT circuit exists, the diagnostic tool

can be used to read the BCM faults. The faults are

very descriptive in identifying the appropriate fea-

ture that has faulted.The only two faults that the BCM logs that con-

clude the replacement of a BCM are faults;

²# 01 - Internal BCM failure (replace BCM)

²# 1F - J1850 Internal Hardware Failure (replace

BCM)

Otherwise the appropriate diagnostic procedures

for each of the features should be taken when the

BCM logs a fault.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower instrument panel silencer.

(3) Remove the knee blocker and reinforcement

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER REINFORCEMENT - REMOVAL).

(4) Disconnect the five wire connectors from the

bottom of the Body Control Module (BCM).

(5) Move bulkhead wiring aside.

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

ProCarManuals.com

Page 370 of 2177

(3) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(4) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid and from the battery positive ter-

minal to starter post for loose or corroded connec-

tions. Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter. Inspect the ring gear

teeth.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED.

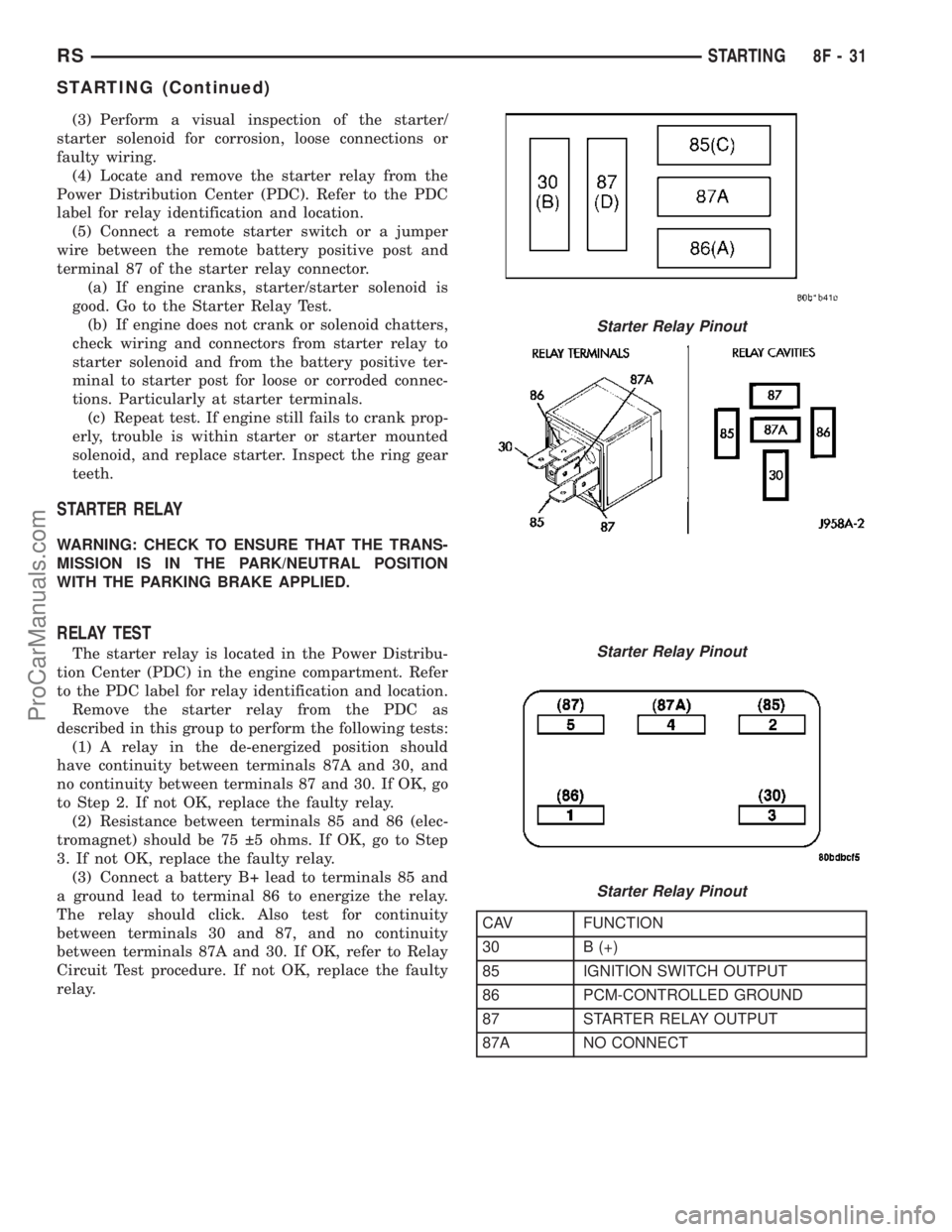

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 85 and

a ground lead to terminal 86 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

CAV FUNCTION

30 B (+)

85 IGNITION SWITCH OUTPUT

86 PCM-CONTROLLED GROUND

87 STARTER RELAY OUTPUT

87A NO CONNECT

Starter Relay Pinout

Starter Relay Pinout

Starter Relay Pinout

RSSTARTING8F-31

STARTING (Continued)

ProCarManuals.com

Page 449 of 2177

US/Mpush button to step through the zone numbers,

until the zone number for your geographic location

appears in the display.

(6) On Electronic Vehicle Information Center

(EVIC) and Compass Mini-Trip Computer (CMTC)

equipped vehicles momentarily depress and release

theRESETpush button to enter the displayed zone

number into the EVIC/CMTC module memory. On

Compass Temperature Module (CT) equipped vehicles

depress theC/Tpush button to enter the displayed

zone number into the electronic module memory.

(7) Confirm that the correct directions are now

indicated by the compass.

REMOVAL - OVERHEAD CONSOLE

(1) Disconnect and isolate the remote negative bat-

tery cable.

(2) Remove the overhead console retaining screw,

located in the front of console.

(3) Using your fingertips, grasp the sides of the

overhead console and pull straight down evenly to

disengage the two snap clips at the rear of the unit.

(4) Lower the overhead console far enough to

access the wire harness connectors.

(5) Disconnect the EVIC, CMTC or CT electronic

module and the reading/courtesy lamps electrical

connector.

(6) Remove the overhead console from the vehicle.

INSTALLATION

(1) Position the overhead console in the vehicle.

(2) Connect the EVIC, CMTC or CT electronic

module and the reading/courtesy lamps electrical

connector.

(3) Using your fingertips, grasp the sides of the

overhead console and push straight up evenly to

engage the two snap clips at the rear of the unit.

CAUTION: DO NOT PRESS ON THE SUNGLASS

STORAGE BIN DOOR. DAMAGE TO THE DOOR MAY

RESULT.

(4) Install the overhead console retaining screw,

located in the front of console. Torque the screw to

1.2 N´m (10 in. lbs.).

(5) Connect the remote negative battery cable.

SPECIAL TOOLS

OVERHEAD CONSOLE

ELECTRONIC VEHICLE INFO

CENTER

DESCRIPTION

The Electronic Vehicle Information Center (EVIC)

is a module located in the overhead console on some

models. The EVIC module features a large Vacuum

Fluorescent Display (VFD) screen for displaying

information, and back-lit push button switches

labeled C/T (compass/thermometer), RESET, STEP,

and MENU.

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) J1850 data bus circuit. The PCI data

bus circuit allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities.

The EVIC ªMenuº push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Refer toELECTRONIC VEHICLE INFORMA-

TION CENTER PROGRAMMINGin the Standard

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional univer-

sal transmitter transceiver, the EVIC will also dis-

play messages and an icon indicating when the

universal transmitter transceiver is being trained,

which of the three transmitter buttons is transmit-

ting, and when the transceiver is cleared.

Data input for all EVIC functions, including VFD

dimming level, is received through the J1850 PCI

data bus circuit. The EVIC module uses its internal

programming and all of its data inputs to calculate

and display the requested data. If the data displayed

is incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

DEGAUSSING TOOL #6029

8M - 6 MESSAGE SYSTEMSRS

OVERHEAD CONSOLE (Continued)

ProCarManuals.com