towing CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 14 of 2177

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION..........................1

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND

LUBRICANTS.........................1

DESCRIPTION - ENGINE COOLANT........3

DESCRIPTION - FLEXIBLE FUEL ENGINE

OIL .................................3

DESCRIPTION - TRANSMISSION FLUID.....4

DESCRIPTION - FUEL REQUIREMENTS.....4

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................6

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................6FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES.......6

FLUID FILL/CHECK LOCATIONS

DESCRIPTION..........................7

LUBRICATION POINTS

DESCRIPTION..........................7

MAINTENANCE SCHEDULES

DESCRIPTION..........................7

HOISTING

STANDARD PROCEDURE - HOISTING.......15

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING...15

TOWING

STANDARD PROCEDURE - TOWING........17

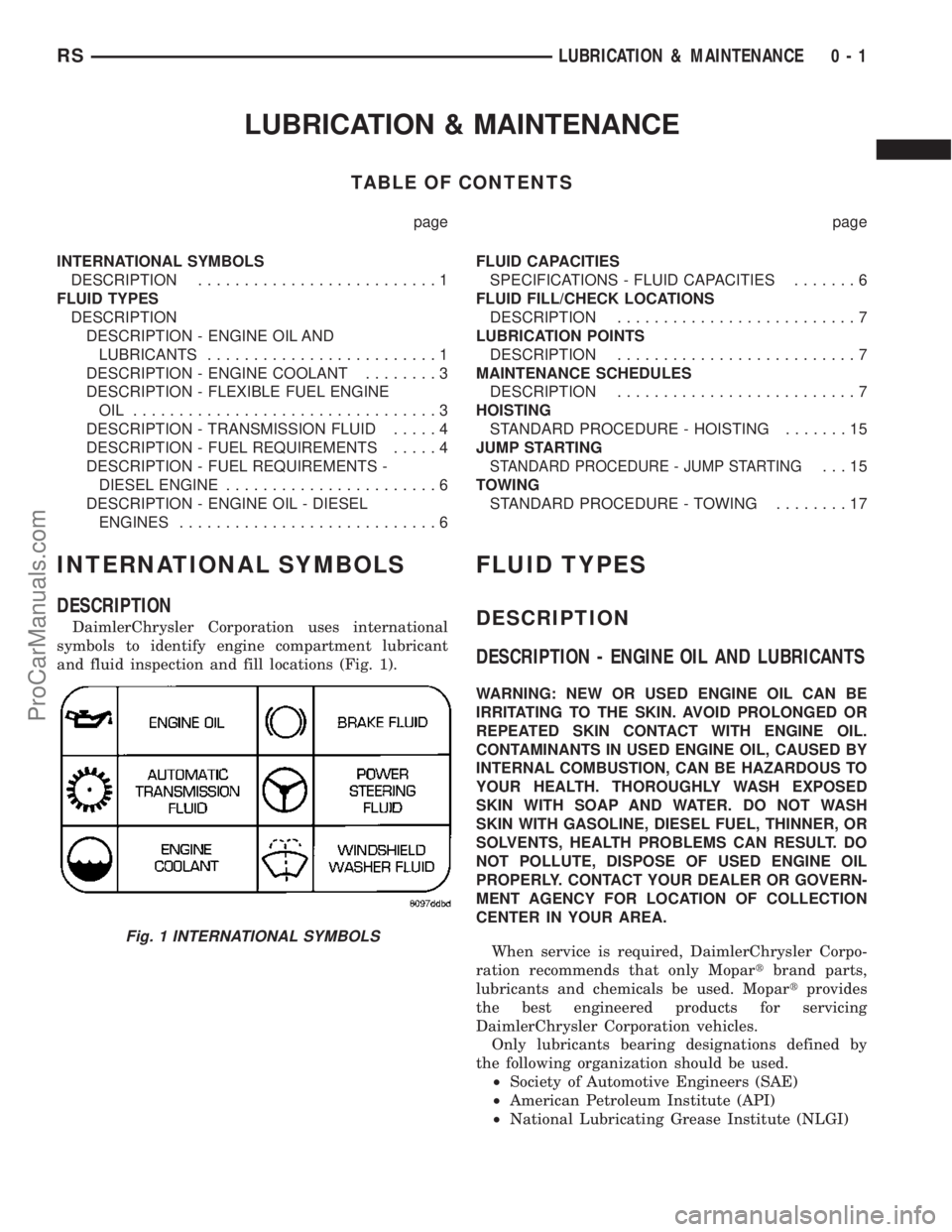

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND LUBRICANTS

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopartprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Only lubricants bearing designations defined by

the following organization should be used.

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API)

²National Lubricating Grease Institute (NLGI)

Fig. 1 INTERNATIONAL SYMBOLS

RSLUBRICATION & MAINTENANCE0-1

ProCarManuals.com

Page 20 of 2177

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill point locations are located in

each applicable service manual section.

LUBRICATION POINTS

DESCRIPTION

Lubrication point locations are located in each

applicable Sections.

MAINTENANCE SCHEDULES

DESCRIPTION

Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É

F).L

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a

fully warmed engine is shut off. Checking the oil level

while the vehicle is on level ground will improve the

accuracy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the automatic transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval

shown on Schedule ªAº 10 000 km (6,000 miles) or

every other interval shown on Schedule ªBº 10 000

km (6,000 miles).

SCHEDULE ªBº

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

Change the automatic transmission fluid and filter

every 77 000 km (48,000 miles) if the vehicle is usu-

ally operated under one or more of the conditions

marked with anL.

²

Day or night temperatures are below 0É C (32É F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C

(90É F).L

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.

RSLUBRICATION & MAINTENANCE0-7

ProCarManuals.com

Page 30 of 2177

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

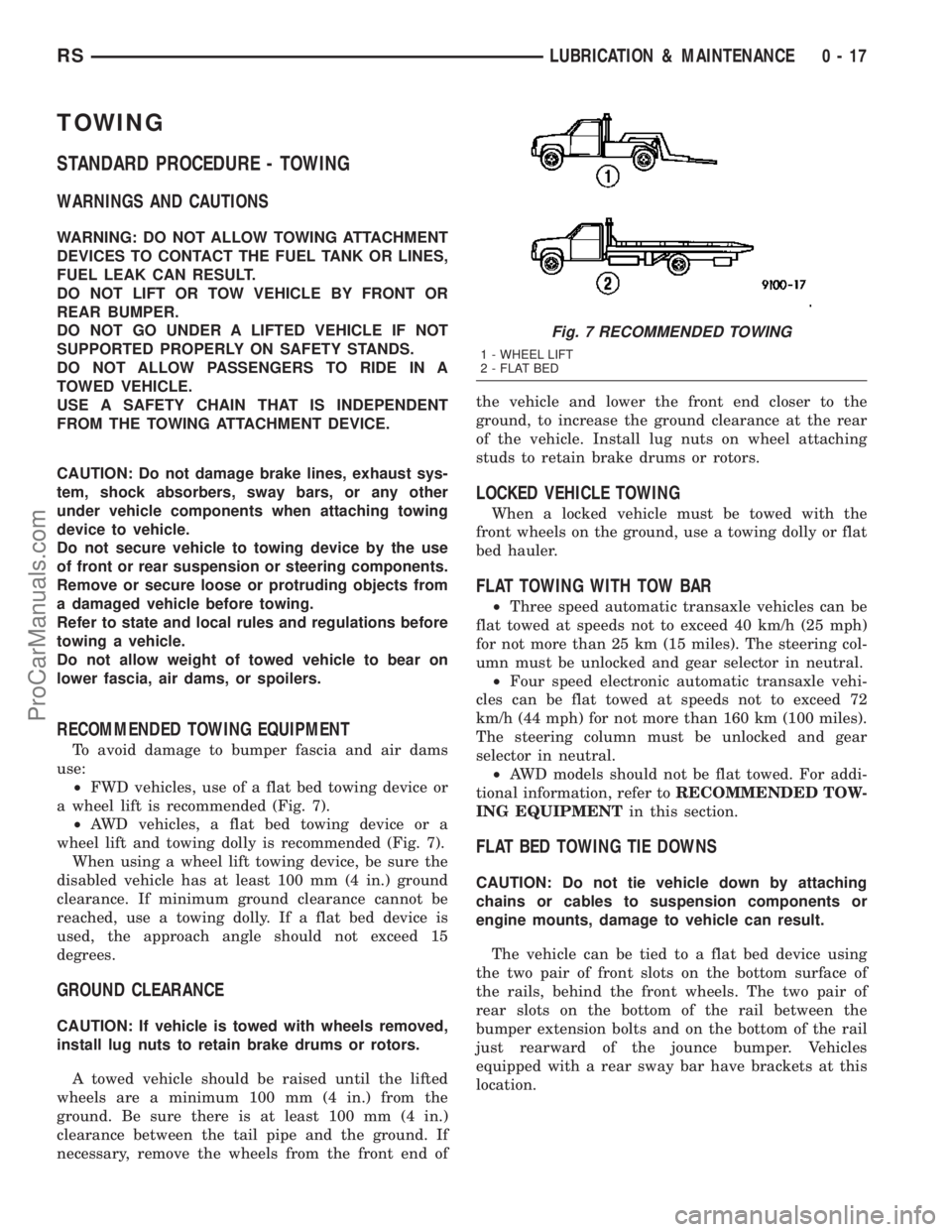

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end ofthe vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-17

ProCarManuals.com

Page 31 of 2177

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at least 10 inches road clearance

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

0 - 18 LUBRICATION & MAINTENANCERS

TOWING (Continued)

ProCarManuals.com

Page 32 of 2177

MAINTENANCE SCHEDULES

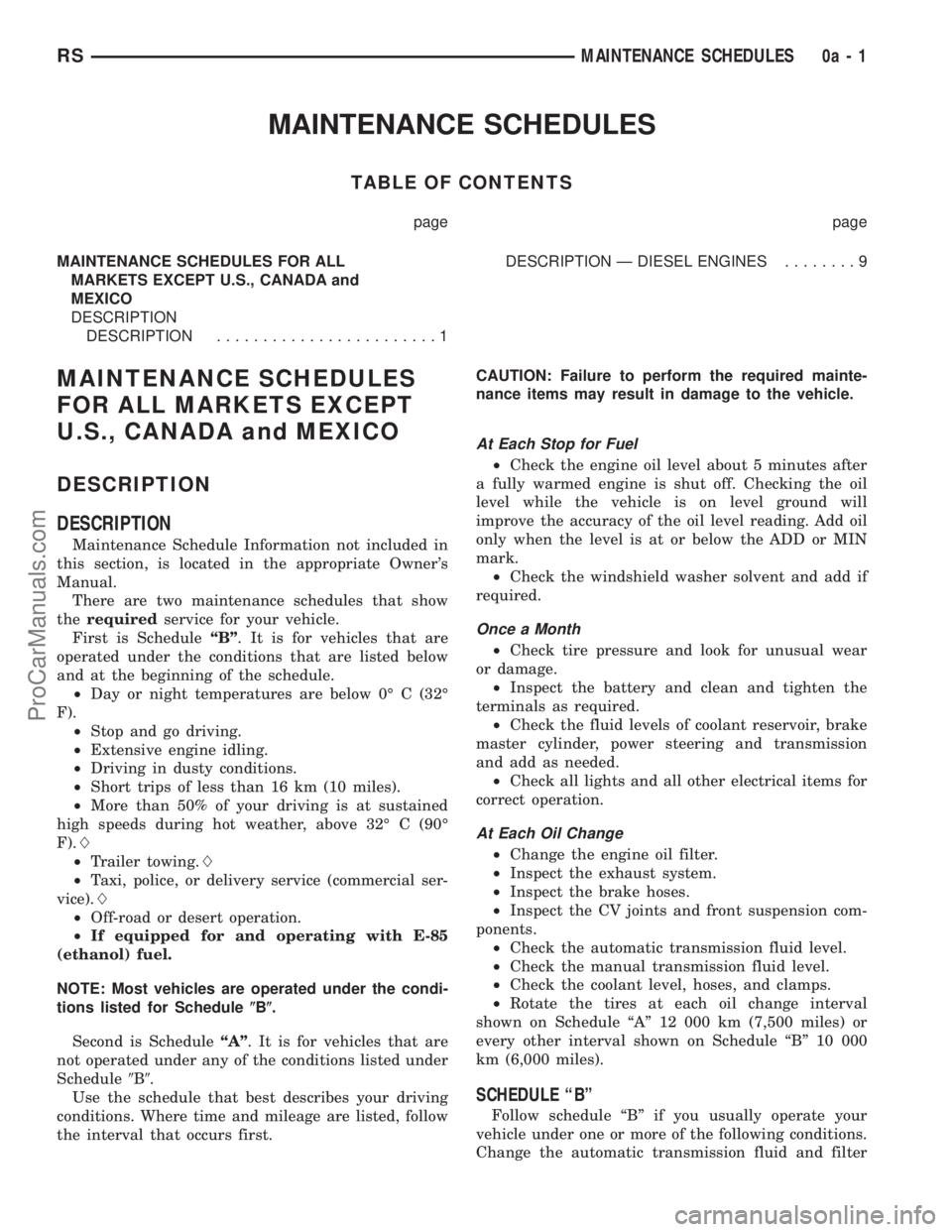

TABLE OF CONTENTS

page page

MAINTENANCE SCHEDULES FOR ALL

MARKETS EXCEPT U.S., CANADA and

MEXICO

DESCRIPTION

DESCRIPTION........................1DESCRIPTION Ð DIESEL ENGINES........9

MAINTENANCE SCHEDULES

FOR ALL MARKETS EXCEPT

U.S., CANADA and MEXICO

DESCRIPTION

DESCRIPTION

Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É

F).L

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the automatic transmission fluid level.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval

shown on Schedule ªAº 12 000 km (7,500 miles) or

every other interval shown on Schedule ªBº 10 000

km (6,000 miles).

SCHEDULE ªBº

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

Change the automatic transmission fluid and filter

RSMAINTENANCE SCHEDULES0a-1

ProCarManuals.com

Page 33 of 2177

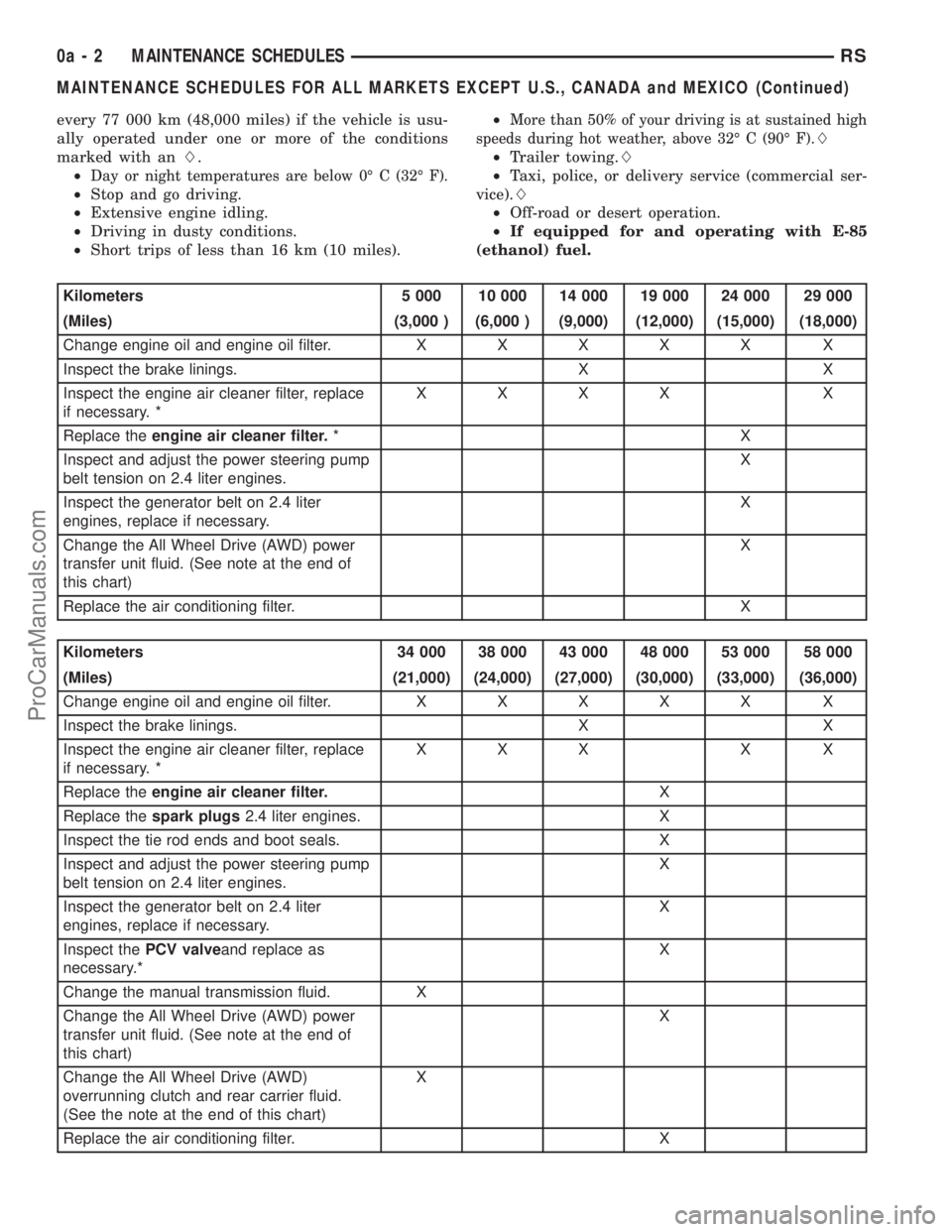

every 77 000 km (48,000 miles) if the vehicle is usu-

ally operated under one or more of the conditions

marked with anL.

²

Day or night temperatures are below 0É C (32É F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).²

More than 50% of your driving is at sustained high

speeds during hot weather, above 32É C (90É F).L

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.

Kilometers 5 000 10 000 14 000 19 000 24 000 29 000

(Miles) (3,000 ) (6,000 ) (9,000) (12,000) (15,000) (18,000)

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX X

Replace theengine air cleaner filter.*X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter. X

Kilometers 34 000 38 000 43 000 48 000 53 000 58 000

(Miles) (21,000) (24,000) (27,000) (30,000) (33,000) (36,000)

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXX X X

Replace theengine air cleaner filter.X

Replace thespark plugs2.4 liter engines. X

Inspect the tie rod ends and boot seals. X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect thePCV valveand replace as

necessary.*X

Change the manual transmission fluid. X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Change the All Wheel Drive (AWD)

overrunning clutch and rear carrier fluid.

(See the note at the end of this chart)X

Replace the air conditioning filter. X

0a - 2 MAINTENANCE SCHEDULESRS

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 40 of 2177

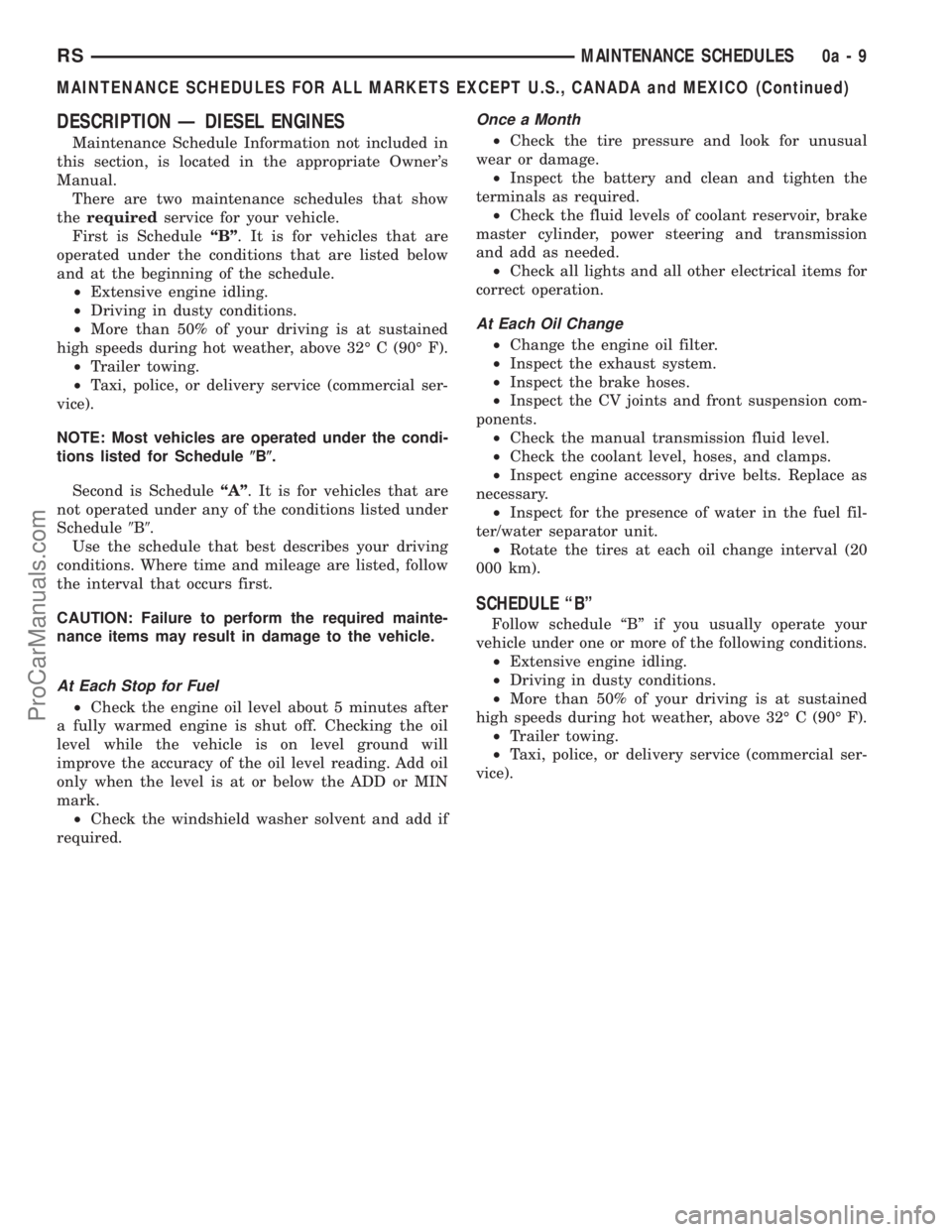

DESCRIPTION Ð DIESEL ENGINES

Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Extensive engine idling.

²Driving in dusty conditions.

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Inspect engine accessory drive belts. Replace as

necessary.

²Inspect for the presence of water in the fuel fil-

ter/water separator unit.

²Rotate the tires at each oil change interval (20

000 km).

SCHEDULE ªBº

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

²Extensive engine idling.

²Driving in dusty conditions.

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

RSMAINTENANCE SCHEDULES0a-9

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

ProCarManuals.com

Page 273 of 2177

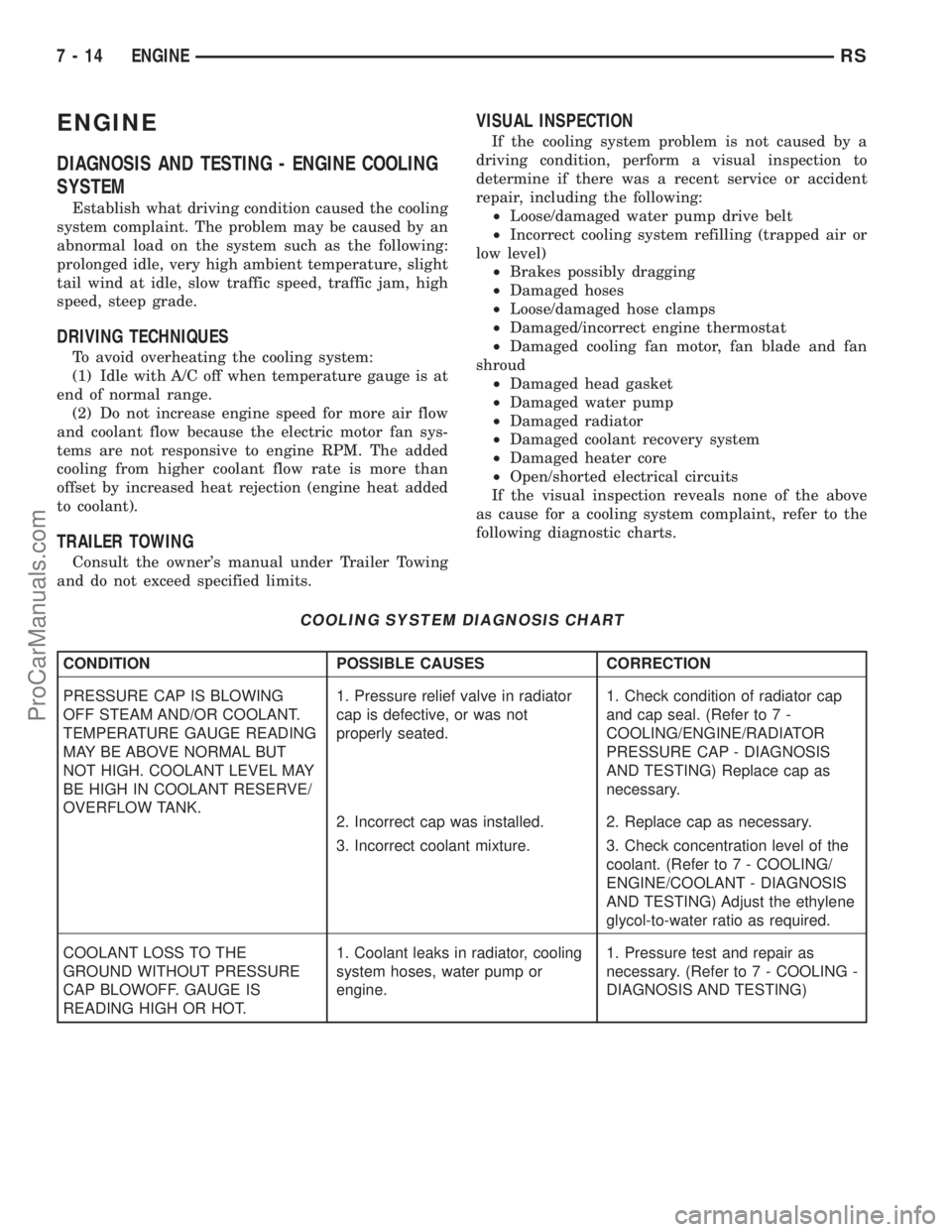

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

7 - 14 ENGINERS

ProCarManuals.com

Page 1403 of 2177

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering system

repairs. Shudder should dissipate after the vehicle

has been driven several weeks.

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note the

following. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotate

steering wheel more than one revolution in eitherdirection and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

NOTE: *** Increased low speed or stationary steer-

ing effort can be expected if the steering fluid is at

a high temperature. High fluid temperature usually

results from high engine rpm due to trailer towing,

ascending grades, or racing the engine for pro-

longed periods of time.

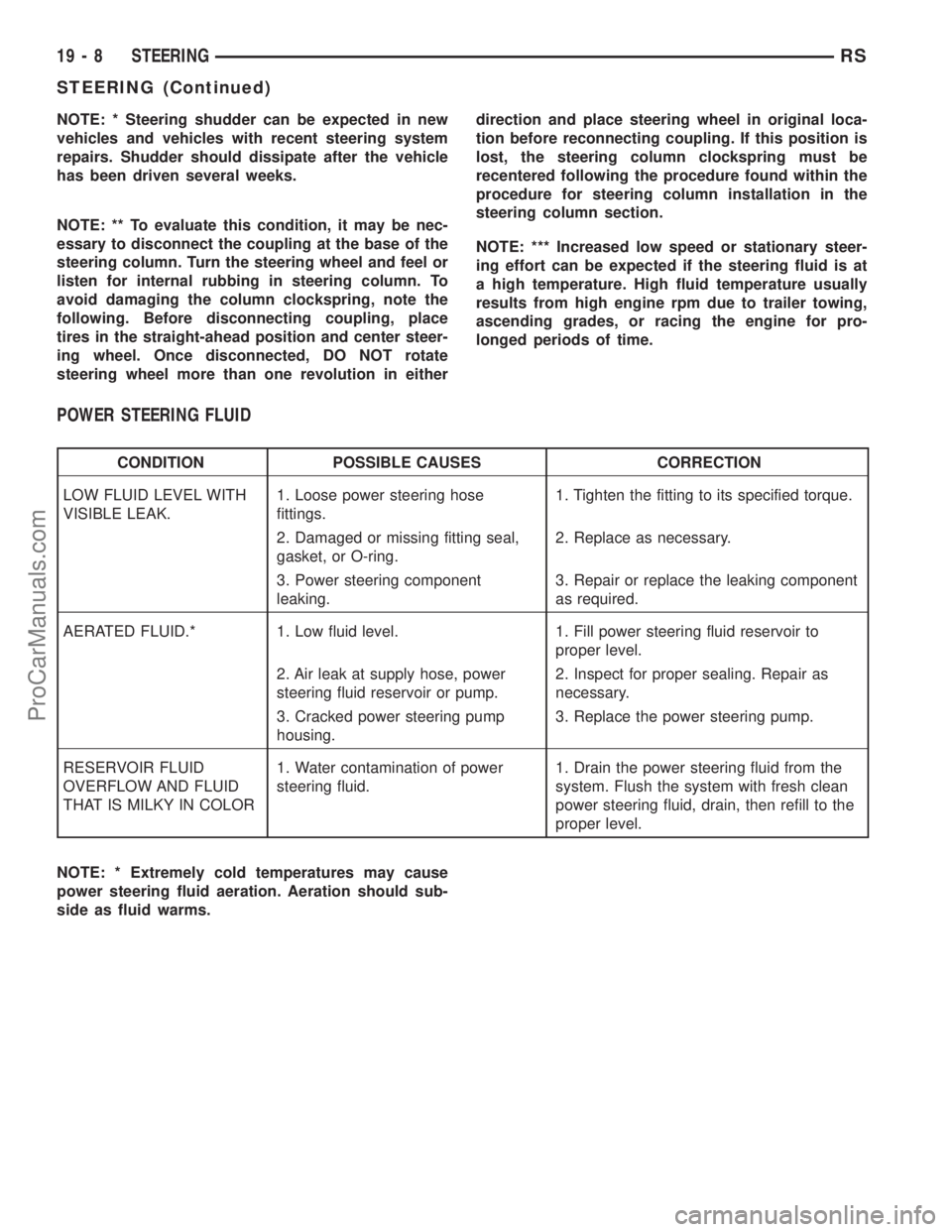

POWER STEERING FLUID

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH

VISIBLE LEAK.1. Loose power steering hose

fittings.1. Tighten the fitting to its specified torque.

2. Damaged or missing fitting seal,

gasket, or O-ring.2. Replace as necessary.

3. Power steering component

leaking.3. Repair or replace the leaking component

as required.

AERATED FLUID.* 1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level.

2. Air leak at supply hose, power

steering fluid reservoir or pump.2. Inspect for proper sealing. Repair as

necessary.

3. Cracked power steering pump

housing.3. Replace the power steering pump.

RESERVOIR FLUID

OVERFLOW AND FLUID

THAT IS MILKY IN COLOR1. Water contamination of power

steering fluid.1. Drain the power steering fluid from the

system. Flush the system with fresh clean

power steering fluid, drain, then refill to the

proper level.

NOTE: * Extremely cold temperatures may cause

power steering fluid aeration. Aeration should sub-

side as fluid warms.

19 - 8 STEERINGRS

STEERING (Continued)

ProCarManuals.com

Page 2173 of 2177

TOP PAD ASSEMBLY - REMOVAL,

INSTRUMENT PANEL..................23-70

TORQUES, SPECIFICATIONS............8F-33

TOUCH-UP - DESCRIPTION, PAINTED.....23-84

TOWING - STANDARD PROCEDURE.......0-17

TPM - CAUTION, SENSOR..............22-10

TPM - DESCRIPTION, SENSOR..........22-10

TPM - INSTALLATION, SENSOR.........22-12

TPM - OPERATION, SENSOR............22-10

TPM - REMOVAL, SENSOR.............22-11

TRACK - DESCRIPTION, DRIVER POWER

SEAT ..............................8N-58

TRACK - DESCRIPTION, PASSENGER

POWER SEAT.......................8N-59

TRACK - DIAGNOSIS AND TESTING,

DRIVER POWER SEAT................8N-58

TRACK - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-60

TRACK - INSTALLATION, BENCH SEAT . . . 23-102

TRACK - INSTALLATION, DRIVER POWER

SEAT ..............................8N-59

TRACK - INSTALLATION, FRONT SEAT

RISER - MANUAL....................23-93

TRACK - INSTALLATION, PASSENGER

POWER SEAT.......................8N-61

TRACK - OPERATION, DRIVER POWER

SEAT ..............................8N-58

TRACK - OPERATION, PASSENGER

POWER SEAT.......................8N-60

TRACK & RACK - DESCRIPTION, LOWER

DRIVE UNIT..........................8N-34

TRACK & RACK - INSTALLATION,

LOWER DRIVE UNIT..................8N-34

TRACK & RACK - OPERATION, LOWER

DRIVE UNIT........................8N-34

TRACK & RACK - REMOVAL, LOWER

DRIVE UNIT........................8N-34

TRACK - REAR COVER - INSTALLATION,

FRONT SEAT........................23-95

TRACK - REAR COVER - REMOVAL,

FRONT SEAT........................23-95

TRACK - REMOVAL, BENCH SEAT.......23-102

TRACK - REMOVAL, DRIVER POWER

SEAT ..............................8N-59

TRACK - REMOVAL, FRONT SEAT RISER

- MANUAL..........................23-93

TRACK - REMOVAL, PASSENGER POWER

SEAT ..............................8N-61

TRACK BAR - DESCRIPTION.............2-44

TRACK BAR - INSTALLATION............2-45

TRACK BAR - OPERATION...............2-44

TRACK BAR - REMOVAL................2-44

TRACK MANUAL ADJUSTER -

INSTALLATION, FRONT SEAT...........23-94

TRACK MANUAL ADJUSTER - REMOVAL,

FRONT SEAT........................23-94

TRACK POWER ADJUSTER -

INSTALLATION, FRONT SEAT...........23-94

TRACK POWER ADJUSTER - REMOVAL,

FRONT SEAT........................23-94

TRACTION CONTROL SWITCH -

DIAGNOSIS AND TESTING..............5-82

TRACTION CONTROL SYSTEM -

DESCRIPTION........................5-76

TRACTION CONTROL SYSTEM -

OPERATION..........................5-77

TRANSAXLE - ASSEMBLY, T850 MANUAL

. 21-42

TRANSAXLE - DESCRIPTION, 41TE

AUTOMATIC

........................21-117

TRANSAXLE - DESCRIPTION, T850

MANUAL

...........................21-21

TRANSAXLE - DISASSEMBLY, T850

MANUAL

...........................21-35

TRANSAXLE - INSTALLATION, T850

MANUAL

...........................21-51

TRANSAXLE - OPERATION, 41TE

AUTOMATIC

........................21-119

TRANSAXLE - OPERATION, T850

MANUAL

...........................21-24

TRANSAXLE - REMOVAL, T850 MANUAL

. . 21-31

TRANSAXLE - SPECIAL TOOLS, T850

.......6-6

TRANSAXLE - SPECIAL TOOLS, T850

.....21-58

TRANSAXLE - SPECIFICATIONS, 41TE

. . . 21-181

TRANSAXLE - SPECIFICATIONS, T850

MANUAL

...........................21-56

TRANSAXLE GENERAL DIAGNOSIS -

DIAGNOSIS AND TESTING, 41TE

.......21-119TRANSAXLE HYDRAULIC SCHEMATICS,

SCHEMATICS AND DIAGRAMS - 41TE . . . 21-169

TRANSAXLE, SPECIAL TOOLS - 41TE

AUTOMATIC........................21-183

TRANSDUCER - DESCRIPTION, A/C

PRESSURE.........................24-10

TRANSDUCER - DIAGNOSIS AND

TESTING, A/C PRESSURE..............24-10

TRANSDUCER - INSTALLATION, A/C

PRESSURE.........................24-11

TRANSDUCER - OPERATION, A/C

PRESSURE.........................24-10

TRANSDUCER - REMOVAL, A/C

PRESSURE.........................24-10

TRANSFER UNIT - DESCRIPTION,

POWER.............................21-1

TRANSFER UNIT - OPERATION, POWER....21-3

TRANSFER UNIT, SPECIAL TOOLS - SDP

POWER.............................21-8

TRANSMISSION CONTROL MODULE -

DESCRIPTION.......................8E-20

TRANSMISSION CONTROL MODULE -

OPERATION.........................8E-20

TRANSMISSION CONTROL RELAY -

DESCRIPTION......................21-247

TRANSMISSION CONTROL RELAY -

OPERATION........................21-248

TRANSMISSION FLUID - DESCRIPTION.....0-4

TRANSMISSION OIL COOLER -

DESCRIPTION........................7-37

TRANSMISSION OIL COOLER -

INSPECTION.........................7-37

TRANSMISSION OIL COOLER -

INSTALLATION........................7-37

TRANSMISSION OIL COOLER -

REMOVAL...........................7-37

TRANSMISSION OIL COOLER LINES -

INSTALLATION........................7-38

TRANSMISSION OIL COOLER LINES -

REMOVAL...........................7-38

TRANSMISSION RANGE SENSOR -

DESCRIPTION......................21-248

TRANSMISSION RANGE SENSOR -

INSTALLATION......................21-249

TRANSMISSION RANGE SENSOR -

OPERATION........................21-248

TRANSMISSION RANGE SENSOR -

REMOVAL.........................21-249

TRANSMITTER - DESCRIPTION,

UNIVERSAL........................8M-10

TRANSMITTER - DIAGNOSIS AND

TESTING, KEYLESS ENTRY.............8N-42

TRANSMITTER - DIAGNOSIS AND

TESTING, UNIVERSAL................8M-10

TRANSMITTER - OPERATION,

UNIVERSAL........................8M-10

TRANSMITTER CODES - STANDARD

PROCEDURE, ERASING...............8M-11

TRANSMITTER CODES - STANDARD

PROCEDURE, SETTING................8M-11

TRANSMITTER PROGRAMING -

STANDARD PROCEDURE, RKE..........8N-43

TRANSPONDER KEY - DESCRIPTION......8Q-3

TRANSPONDER KEY - OPERATION........8Q-3

TRANSPONDER PROGRAMMING -

STANDARD PROCEDURE...............8Q-4

TRANSVERSE BRACKET - DESCRIPTION . . 8N-18

TRANSVERSE BRACKET - INSTALLATION . . 8N-18

TRANSVERSE BRACKET - OPERATION....8N-18

TRANSVERSE BRACKET - REMOVAL.....8N-18

TRAY - BRACKET ASSEMBLY -

INSTALLATION, FLOOR CONSOLE

........23-82

TRAY - BRACKET ASSEMBLY -

REMOVAL, FLOOR CONSOLE

...........23-82

TRAY - DESCRIPTION, BATTERY

.........8F-18

TRAY - INSTALLATION, BATTERY

........8F-19

TRAY - INSTALLATION, FLOOR CONSOLE

. . 23-81

TRAY - OPERATION, BATTERY

..........8F-19

TRAY - REMOVAL, BATTERY

............8F-19

TRAY - REMOVAL, FLOOR CONSOLE

.....23-81

TRD LINK - DESCRIPTION

............21-249

TRD LINK - OPERATION

..............21-249

TREAD WEAR INDICATORS - DIAGNOSIS

AND TESTING

.......................22-16

TRIM - INSTALLATION, A-PILLAR

........23-73

TRIM - INSTALLATION, A-PILLAR

LOWER EXTENSION

..................23-73TRIM - INSTALLATION, B-PILLAR

LOWER............................23-74

TRIM - INSTALLATION, B-PILLAR UPPER . . 23-74

TRIM - INSTALLATION, COWL..........23-75

TRIM - INSTALLATION, C-PILLAR........23-76

TRIM - INSTALLATION, REAR HEADER....23-79

TRIM - REMOVAL, A-PILLAR...........23-73

TRIM - REMOVAL, A-PILLAR LOWER

EXTENSION.........................23-73

TRIM - REMOVAL, B-PILLAR LOWER.....23-73

TRIM - REMOVAL, B-PILLAR UPPER.....23-74

TRIM - REMOVAL, COWL..............23-75

TRIM - REMOVAL, C-PILLAR...........23-75

TRIM - REMOVAL, REAR HEADER.......23-79

TRIM BOLSTER - INSTALLATION,

QUARTER..........................23-77

TRIM BOLSTER - REMOVAL, QUARTER . . . 23-77

TRIM COVER - INSTALLATION, DRIVER

AIRBAG.............................8O-7

TRIM COVER - REMOVAL, DRIVER

AIRBAG.............................8O-6

TRIM PANEL - INSTALLATION.....23-20,23-33,

23-43

TRIM PANEL - INSTALLATION, LEFT

D-PILLAR...........................23-77

TRIM PANEL - INSTALLATION, LEFT

QUARTER..........................23-78

TRIM PANEL - INSTALLATION, RIGHT

D-PILLAR...........................23-80

TRIM PANEL - INSTALLATION, RIGHT

QUARTER..........................23-78

TRIM PANEL - REMOVAL....23-20,23-33,23-42

TRIM PANEL - REMOVAL, LEFT

D-PILLAR...........................23-77

TRIM PANEL - REMOVAL, LEFT

QUARTER..........................23-78

TRIM PANEL - REMOVAL, RIGHT

D-PILLAR...........................23-80

TRIM PANEL - REMOVAL, RIGHT

QUARTER..........................23-78

TRIM PLATE - INSTALLATION, DOOR

SILL...............................23-76

TRIM PLATE - REMOVAL, DOOR SILL....23-76

TRIP DEFINITION - DESCRIPTION.........25-1

TROUBLE CODES - STANDARD

PROCEDURE, OBTAINING DIAGNOSTIC . . . 8E-15

TUBE - 2.4L - DESCRIPTION, WATER

PUMP INLET.........................7-35

TUBE - 2.4L - INSTALLATION, WATER

PUMP INLET.........................7-35

TUBE - 2.4L - REMOVAL, WATER PUMP

INLET...............................7-35

TUBE - 3.3/3.8L - INSTALLATION, WATER

PUMP INLET.........................7-36

TUBE - 3.3/3.8L - REMOVAL, WATER

PUMP INLET.........................7-36

TUBE - INSTALLATION, DRAIN.........23-117

TUBE - INSTALLATION, EXHAUST.......24-107

TUBE - INSTALLATION, FUEL TANK

FILLER.............................14-12

TUBE - REMOVAL, DRAIN.............23-116

TUBE - REMOVAL, EXHAUST..........24-107

TUBE - REMOVAL, FUEL TANK FILLER....14-12

TUBES - INSTALLATION, HEATER CORE

EXTENSION.........................24-77

TUBES - REMOVAL, HEATER CORE

EXTENSION

.........................24-75

TUBES AND HOSES - DESCRIPTION,

BRAKE

..............................5-14

TUBES AND HOSES - INSPECTION,

BRAKE

..............................5-14

TUBES AND HOSES - OPERATION,

BRAKE

..............................5-14

TURN SIGNAL SYSTEM - DESCRIPTION

. . . 8L-21

TURN SIGNAL SYSTEM - OPERATION

....8L-21

TURNING TORQUE - ADJUSTMENT,

DIFFERENTIAL

.......................21-69

TWO ZONE ATC - OPERATION

..........24-106

UNDER SEAT STORAGE BIN -

INSTALLATION

......................23-103

UNDER SEAT STORAGE BIN - REMOVAL

. 23-103

UNDER SEAT STORAGE BIN GUIDE -

INSTALLATION

......................23-104

UNDER SEAT STORAGE BIN GUIDE -

REMOVAL

.........................23-104

UNDER SEAT STORAGE BIN LOCK/LATCH

- INSTALLATION

....................23-104

34 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com