wheel CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1 of 2177

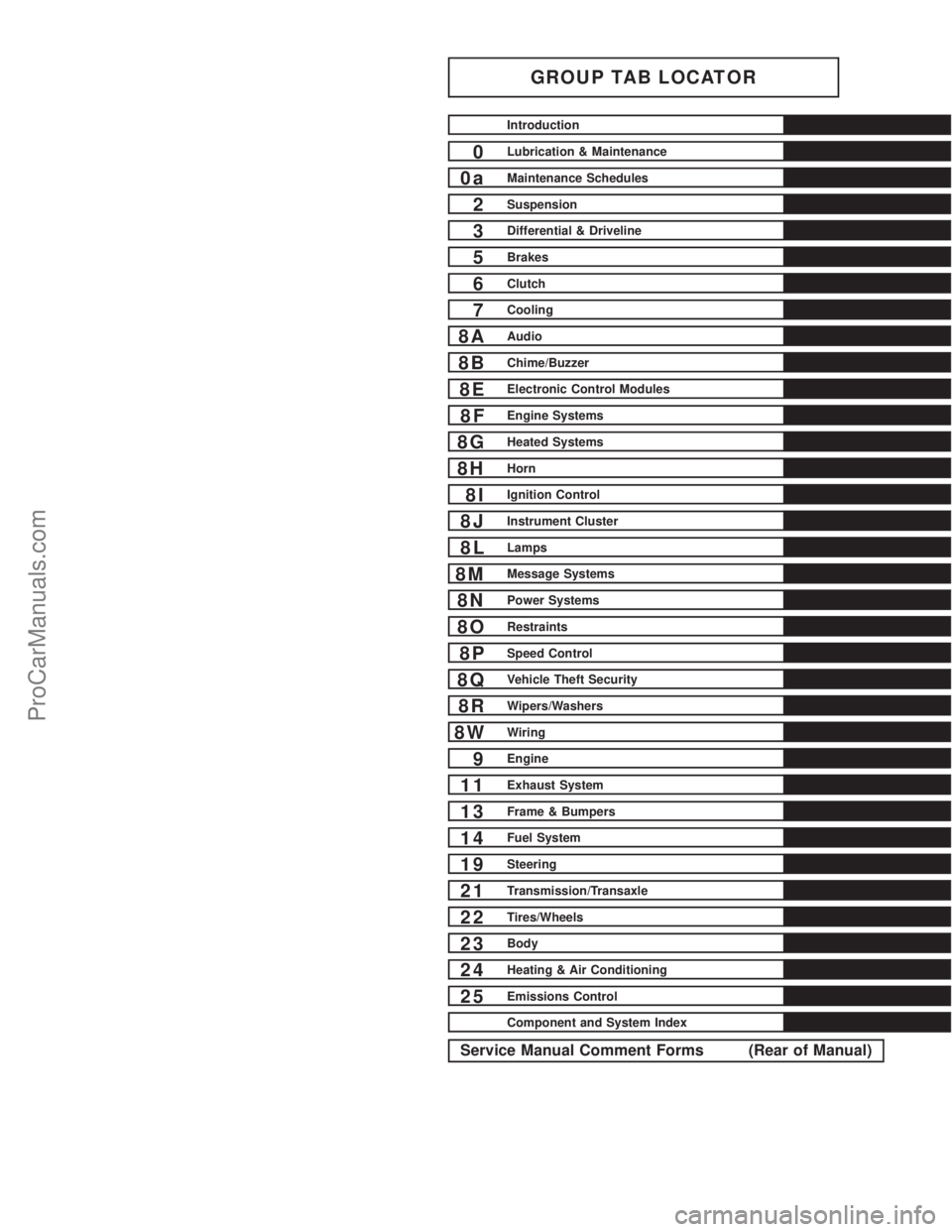

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

0aMaintenance Schedules

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission/Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

ProCarManuals.com

Page 3 of 2177

AW D

²C = Chrysler

²D = Dodge

DIGIT 21

Price Class

²H = Highline

²L = Lowline

²P = Premium

²S = Luxury

²X = Premium

DIGITS 22 AND 23

Body Type

²52 = Short Wheel Base

²53 = Long Wheel Base

BODY CODE PLATE LINE 2

DIGITS 1, 2 AND 3

Paint Procedure

DIGIT 4

Open Space

DIGITS 5 THROUGH 7

Primary Paint (Refer to 23 - BODY/PAINT - SPEC-

IFICATIONS).

DIGIT 8 AND 9

Open Space

DIGITS 10 THROUGH 12

Secondary Paint

DIGIT 13 AND 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engine Code

²EDZ = 2.4L 4 cyl. 16-Valve DOHC Gasoline

(MPI)

²EGA = 3.3L 6 cyl. Gasoline (SMPI)

²EGH = 3.8L 6 cyl. Gasoline (SMPI)

²EGM = 3.3L 6 cyl. Ethanol Flexible Fuel

²ENJ = 2.5L 4 cyl. 16-Valve Turbo Diesel

DIGIT 23

Open Space

BODY CODE PLATE LINE 1

DIGITS 1, 2, AND 3

Transaxle Codes

²DGC = 31TH 3-Speed Automatic Transaxle

²DGL = 41AE/TE 4-Speed Electronic Automatic

²DDR = T850 5-Speed Manual Transaxle

DIGIT 4

Open Space

DIGIT 5

Market Code

²C = Canada

²B = International

²M = Mexico

²U = United States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehicle Identification Number

²Refer to Vehicle Identification Number (VIN)

paragraph for proper breakdown of VIN code.

IF TWO BODY CODE PLATES ARE REQUIRED

The last code shown on either plate will be fol-

lowed by END. When two plates are required, the

last code space on the first plate will indicate (CTD)

When a second plate is required, the first four

spaces of each line will not be used due to overlap of

the plates.

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

2 INTRODUCTIONRS

BODY CODE PLATE (Continued)

ProCarManuals.com

Page 11 of 2177

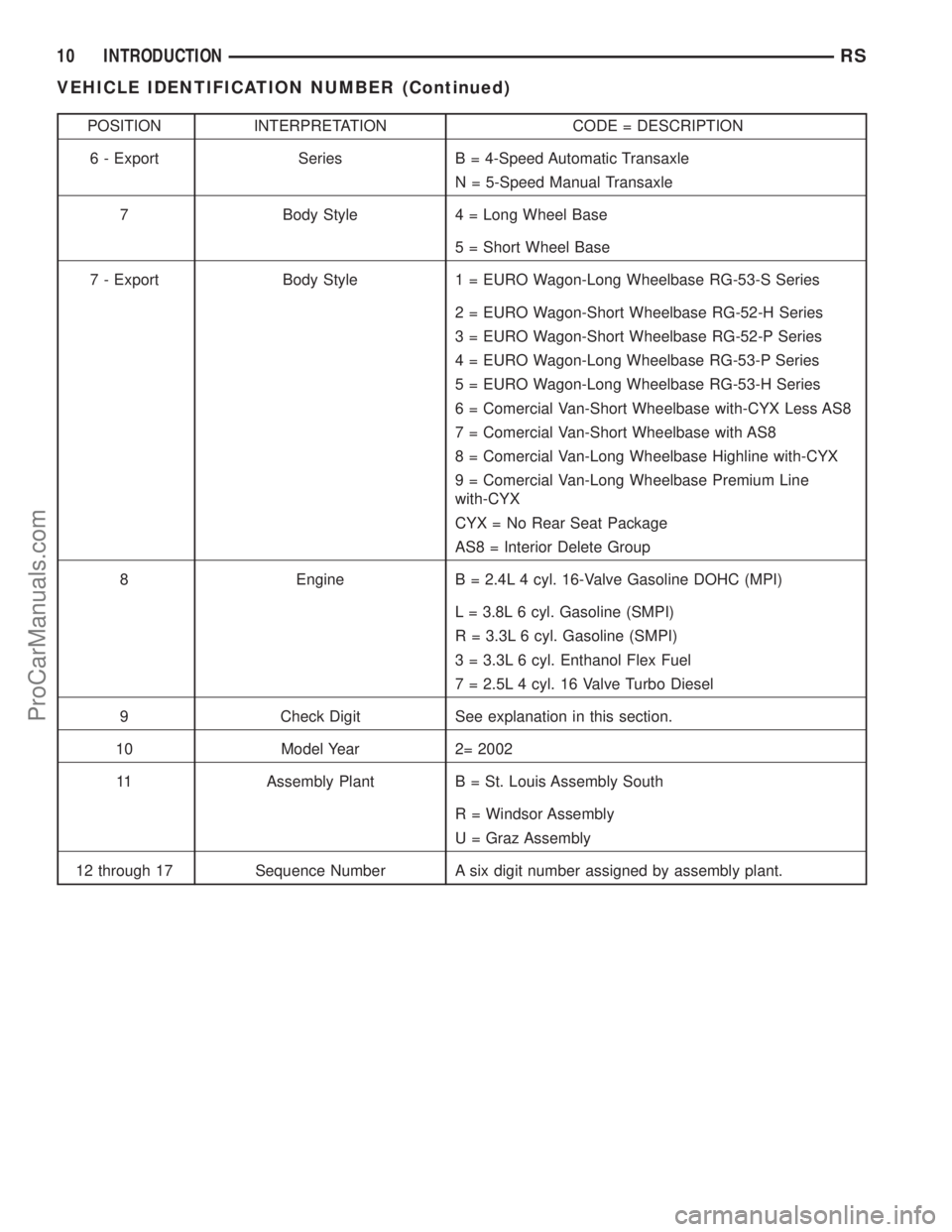

POSITION INTERPRETATION CODE = DESCRIPTION

6 - Export Series B = 4-Speed Automatic Transaxle

N = 5-Speed Manual Transaxle

7 Body Style 4 = Long Wheel Base

5 = Short Wheel Base

7 - Export Body Style 1 = EURO Wagon-Long Wheelbase RG-53-S Series

2 = EURO Wagon-Short Wheelbase RG-52-H Series

3 = EURO Wagon-Short Wheelbase RG-52-P Series

4 = EURO Wagon-Long Wheelbase RG-53-P Series

5 = EURO Wagon-Long Wheelbase RG-53-H Series

6 = Comercial Van-Short Wheelbase with-CYX Less AS8

7 = Comercial Van-Short Wheelbase with AS8

8 = Comercial Van-Long Wheelbase Highline with-CYX

9 = Comercial Van-Long Wheelbase Premium Line

with-CYX

CYX = No Rear Seat Package

AS8 = Interior Delete Group

8 Engine B = 2.4L 4 cyl. 16-Valve Gasoline DOHC (MPI)

L = 3.8L 6 cyl. Gasoline (SMPI)

R = 3.3L 6 cyl. Gasoline (SMPI)

3 = 3.3L 6 cyl. Enthanol Flex Fuel

7 = 2.5L 4 cyl. 16 Valve Turbo Diesel

9 Check Digit See explanation in this section.

10 Model Year 2= 2002

11 Assembly Plant B = St. Louis Assembly South

R = Windsor Assembly

U = Graz Assembly

12 through 17 Sequence Number A six digit number assigned by assembly plant.

10 INTRODUCTIONRS

VEHICLE IDENTIFICATION NUMBER (Continued)

ProCarManuals.com

Page 16 of 2177

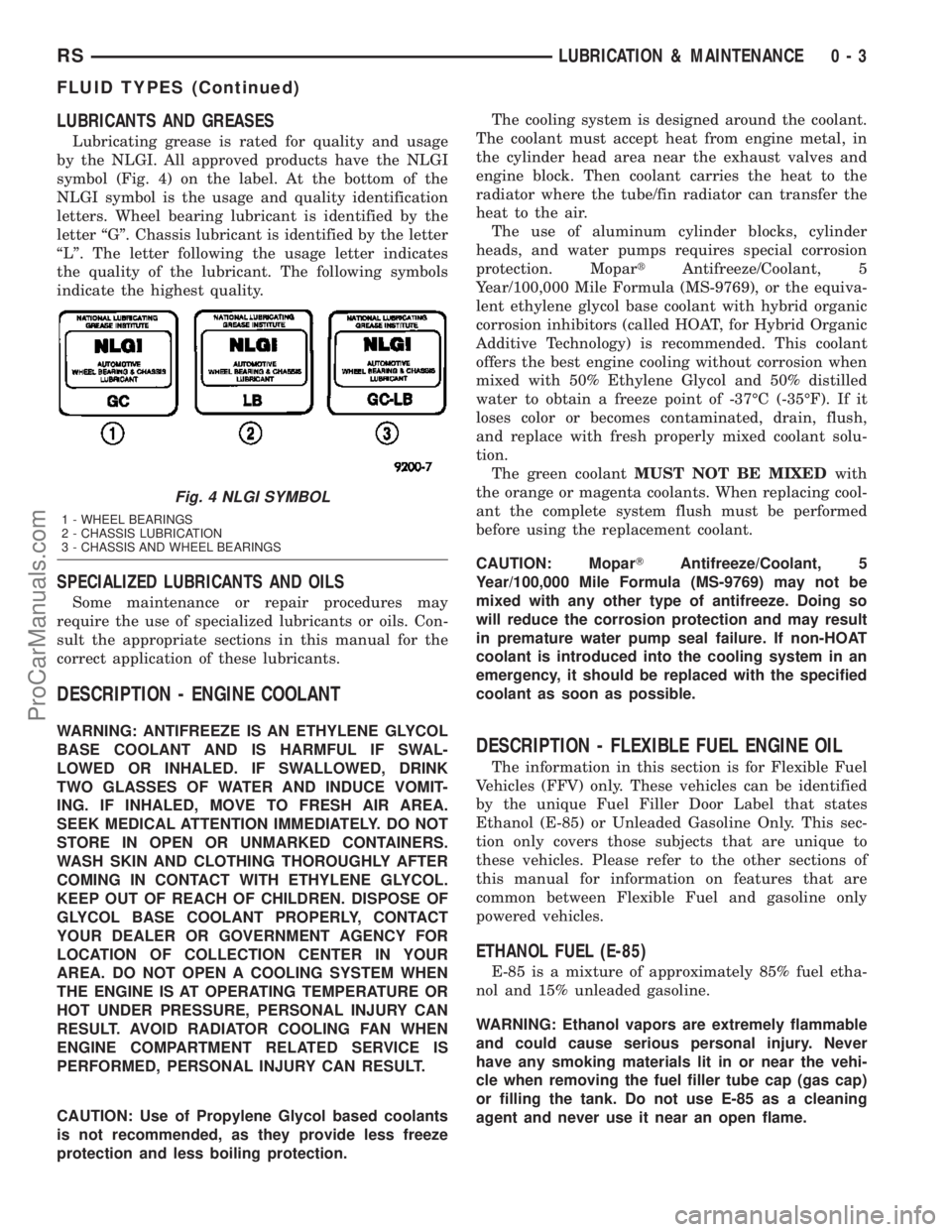

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 4) on the label. At the bottom of the

NLGI symbol is the usage and quality identification

letters. Wheel bearing lubricant is identified by the

letter ªGº. Chassis lubricant is identified by the letter

ªLº. The letter following the usage letter indicates

the quality of the lubricant. The following symbols

indicate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.

DESCRIPTION - FLEXIBLE FUEL ENGINE OIL

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

Fig. 4 NLGI SYMBOL

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RSLUBRICATION & MAINTENANCE0-3

FLUID TYPES (Continued)

ProCarManuals.com

Page 21 of 2177

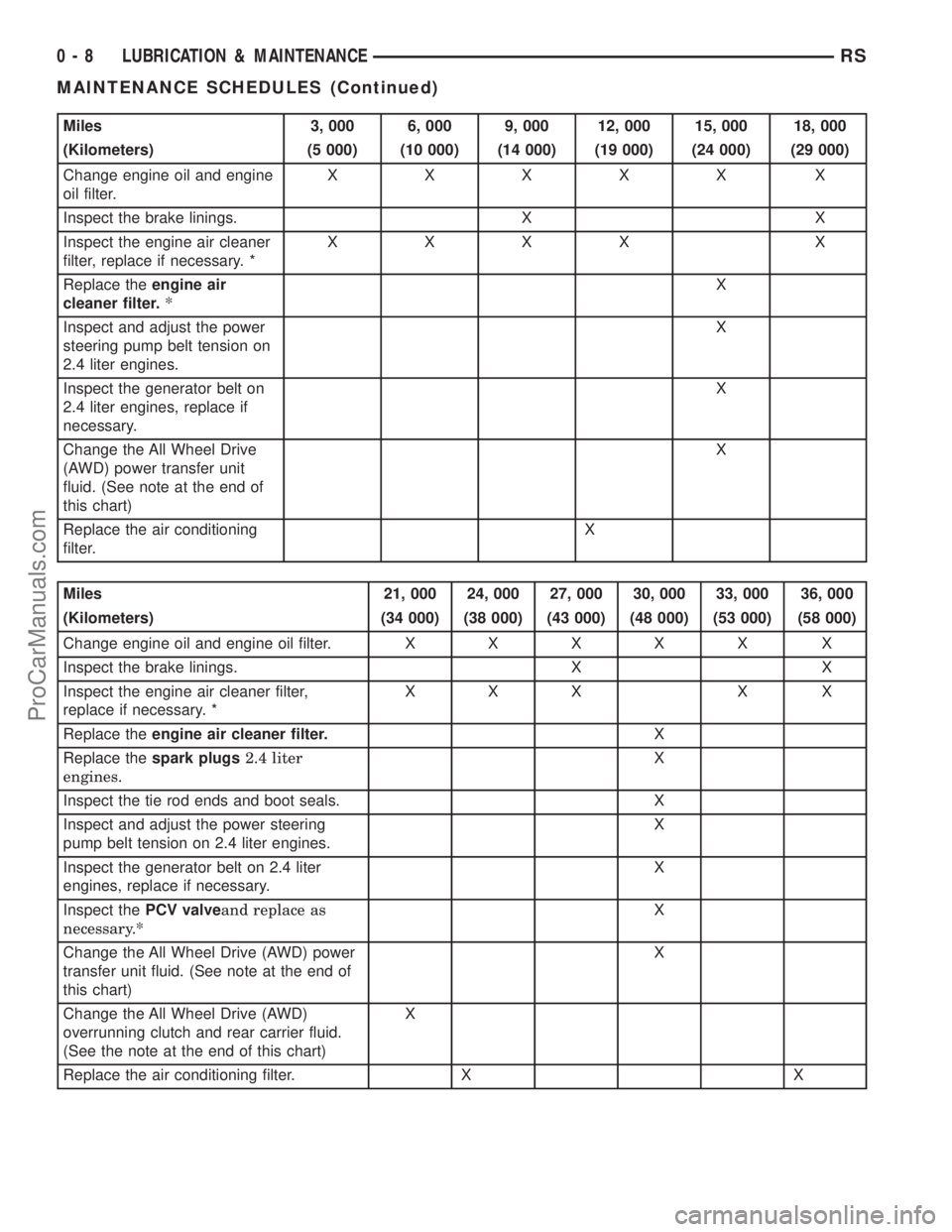

Miles 3, 000 6, 000 9, 000 12, 000 15, 000 18, 000

(Kilometers) (5 000) (10 000) (14 000) (19 000) (24 000) (29 000)

Change engine oil and engine

oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *XXXX X

Replace theengine air

cleaner filter.*X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Change the All Wheel Drive

(AWD) power transfer unit

fluid. (See note at the end of

this chart)X

Replace the air conditioning

filter.X

Miles 21, 000 24, 000 27, 000 30, 000 33, 000 36, 000

(Kilometers) (34 000) (38 000) (43 000) (48 000) (53 000) (58 000)

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter,

replace if necessary. *XXX X X

Replace theengine air cleaner filter.X

Replace thespark plugs2.4 liter

engines.X

Inspect the tie rod ends and boot seals. X

Inspect and adjust the power steering

pump belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect thePCV valveand replace as

necessary.*X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Change the All Wheel Drive (AWD)

overrunning clutch and rear carrier fluid.

(See the note at the end of this chart)X

Replace the air conditioning filter. X X

0 - 8 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 22 of 2177

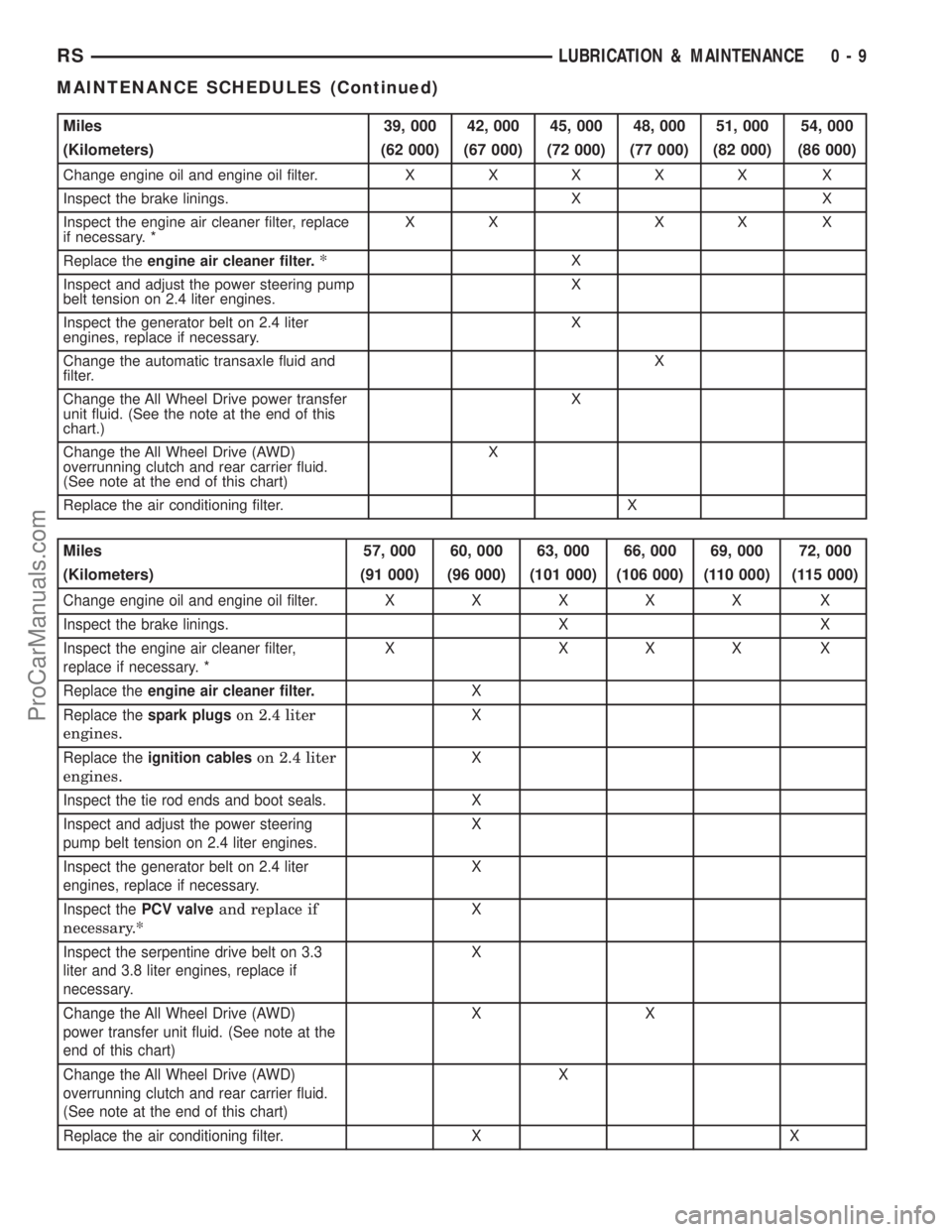

Miles 39, 000 42, 000 45, 000 48, 000 51, 000 54, 000

(Kilometers) (62 000) (67 000) (72 000) (77 000) (82 000) (86 000)

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XX XX X

Replace theengine air cleaner filter.

*X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Change the automatic transaxle fluid and

filter.X

Change the All Wheel Drive power transfer

unit fluid. (See the note at the end of this

chart.)X

Change the All Wheel Drive (AWD)

overrunning clutch and rear carrier fluid.

(See note at the end of this chart)X

Replace the air conditioning filter. X

Miles 57, 000 60, 000 63, 000 66, 000 69, 000 72, 000

(Kilometers) (91 000) (96 000) (101 000) (106 000) (110 000) (115 000)

Change engine oil and engine oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter,

replace if necessary. *X XXX X

Replace theengine air cleaner filter.X

Replace thespark plugs

on 2.4 liter

engines.X

Replace theignition cables

on 2.4 liter

engines.X

Inspect the tie rod ends and boot seals. X

Inspect and adjust the power steering

pump belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect thePCV valve

and replace if

necessary.*X

Inspect the serpentine drive belt on 3.3

liter and 3.8 liter engines, replace if

necessary.X

Change the All Wheel Drive (AWD)

power transfer unit fluid. (See note at the

end of this chart)XX

Change the All Wheel Drive (AWD)

overrunning clutch and rear carrier fluid.

(See note at the end of this chart)X

Replace the air conditioning filter. X X

RSLUBRICATION & MAINTENANCE0-9

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 23 of 2177

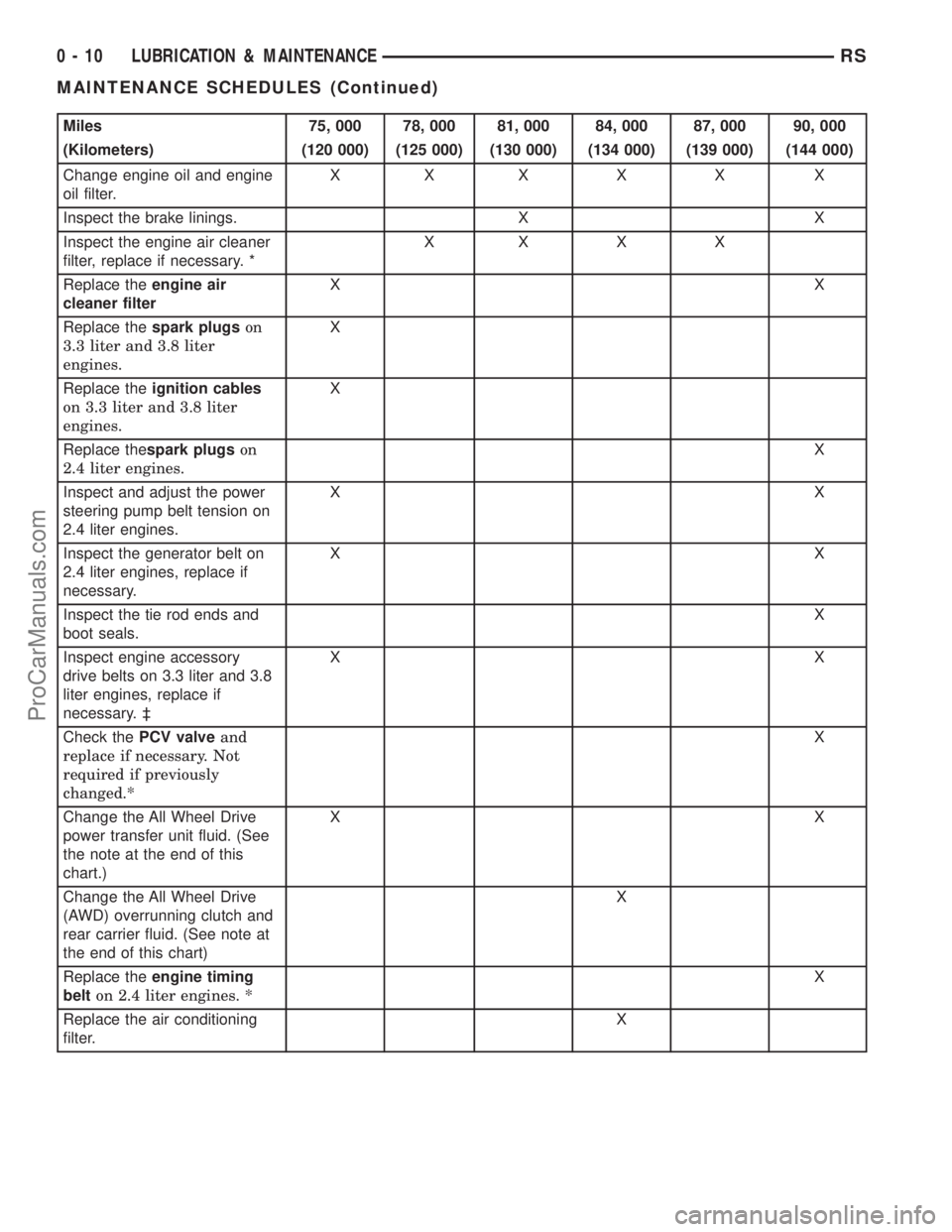

Miles 75, 000 78, 000 81, 000 84, 000 87, 000 90, 000

(Kilometers) (120 000) (125 000) (130 000) (134 000) (139 000) (144 000)

Change engine oil and engine

oil filter.XXXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *XXXX

Replace theengine air

cleaner filterXX

Replace thespark plugson

3.3 liter and 3.8 liter

engines.X

Replace theignition cables

on 3.3 liter and 3.8 liter

engines.X

Replace thespark plugson

2.4 liter engines.X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.XX

Inspect the generator belt on

2.4 liter engines, replace if

necessary.XX

Inspect the tie rod ends and

boot seals.X

Inspect engine accessory

drive belts on 3.3 liter and 3.8

liter engines, replace if

necessary. ³XX

Check thePCV valveand

replace if necessary. Not

required if previously

changed.*X

Change the All Wheel Drive

power transfer unit fluid. (See

the note at the end of this

chart.)XX

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See note at

the end of this chart)X

Replace theengine timing

belton 2.4 liter engines. *X

Replace the air conditioning

filter.X

0 - 10 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 24 of 2177

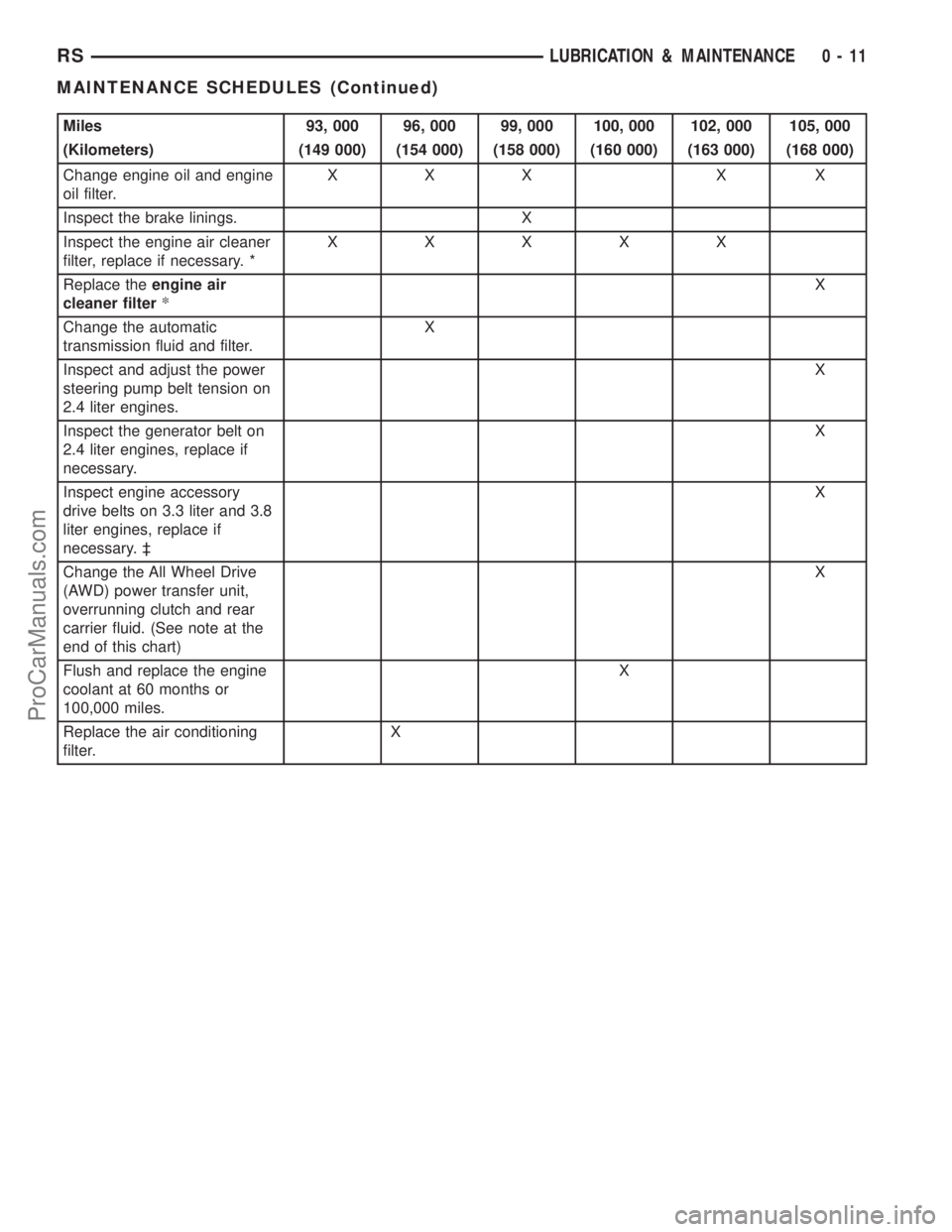

Miles 93, 000 96, 000 99, 000 100, 000 102, 000 105, 000

(Kilometers) (149 000) (154 000) (158 000) (160 000) (163 000) (168 000)

Change engine oil and engine

oil filter.XXX X X

Inspect the brake linings. X

Inspect the engine air cleaner

filter, replace if necessary. *XXXXX

Replace theengine air

cleaner filter*X

Change the automatic

transmission fluid and filter.X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect engine accessory

drive belts on 3.3 liter and 3.8

liter engines, replace if

necessary. ³X

Change the All Wheel Drive

(AWD) power transfer unit,

overrunning clutch and rear

carrier fluid. (See note at the

end of this chart)X

Flush and replace the engine

coolant at 60 months or

100,000 miles.X

Replace the air conditioning

filter.X

RSLUBRICATION & MAINTENANCE0-11

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 25 of 2177

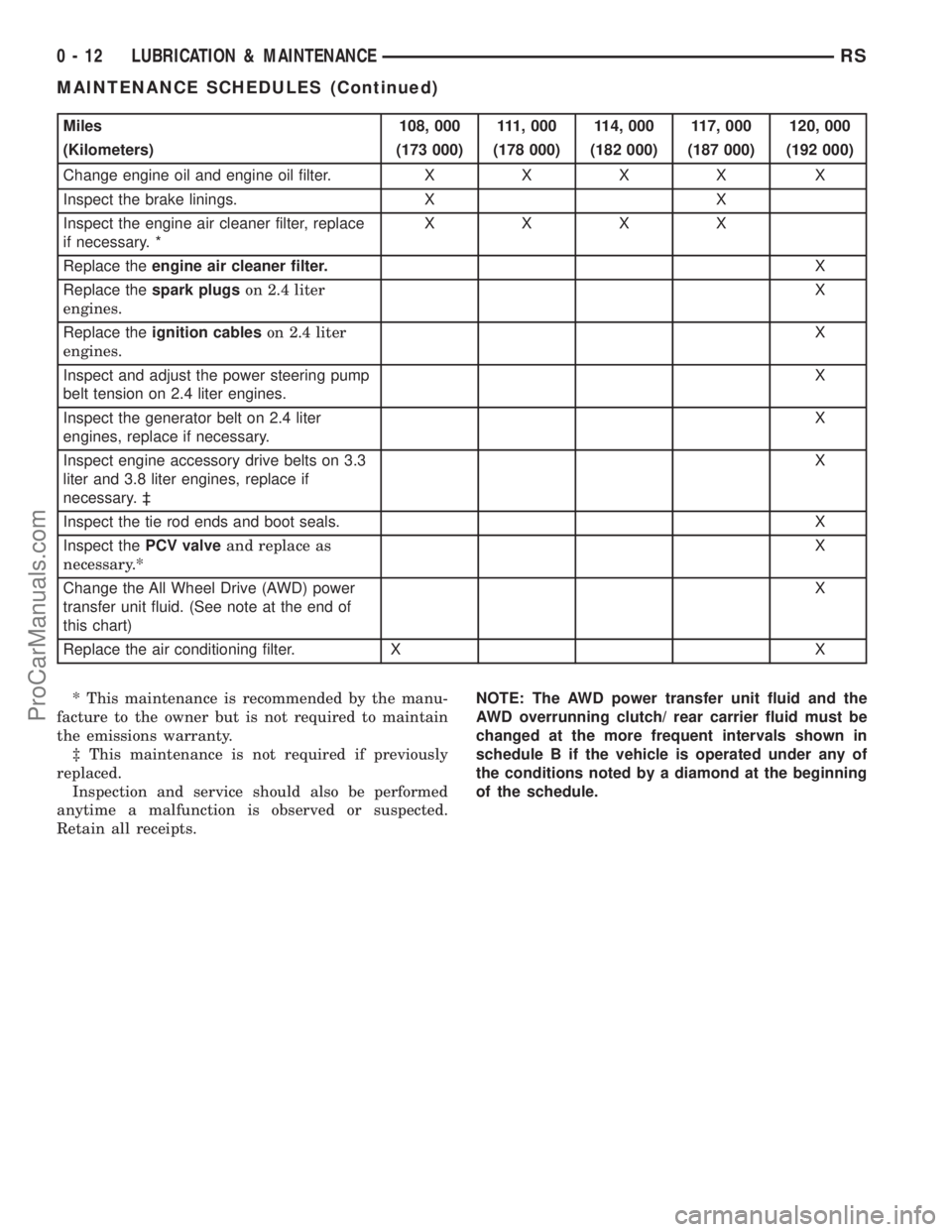

Miles 108, 000 111, 000 114, 000 117, 000 120, 000

(Kilometers) (173 000) (178 000) (182 000) (187 000) (192 000)

Change engine oil and engine oil filter.XXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter and 3.8 liter engines, replace if

necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter. X X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must be

changed at the more frequent intervals shown in

schedule B if the vehicle is operated under any of

the conditions noted by a diamond at the beginning

of the schedule.

0 - 12 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 30 of 2177

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

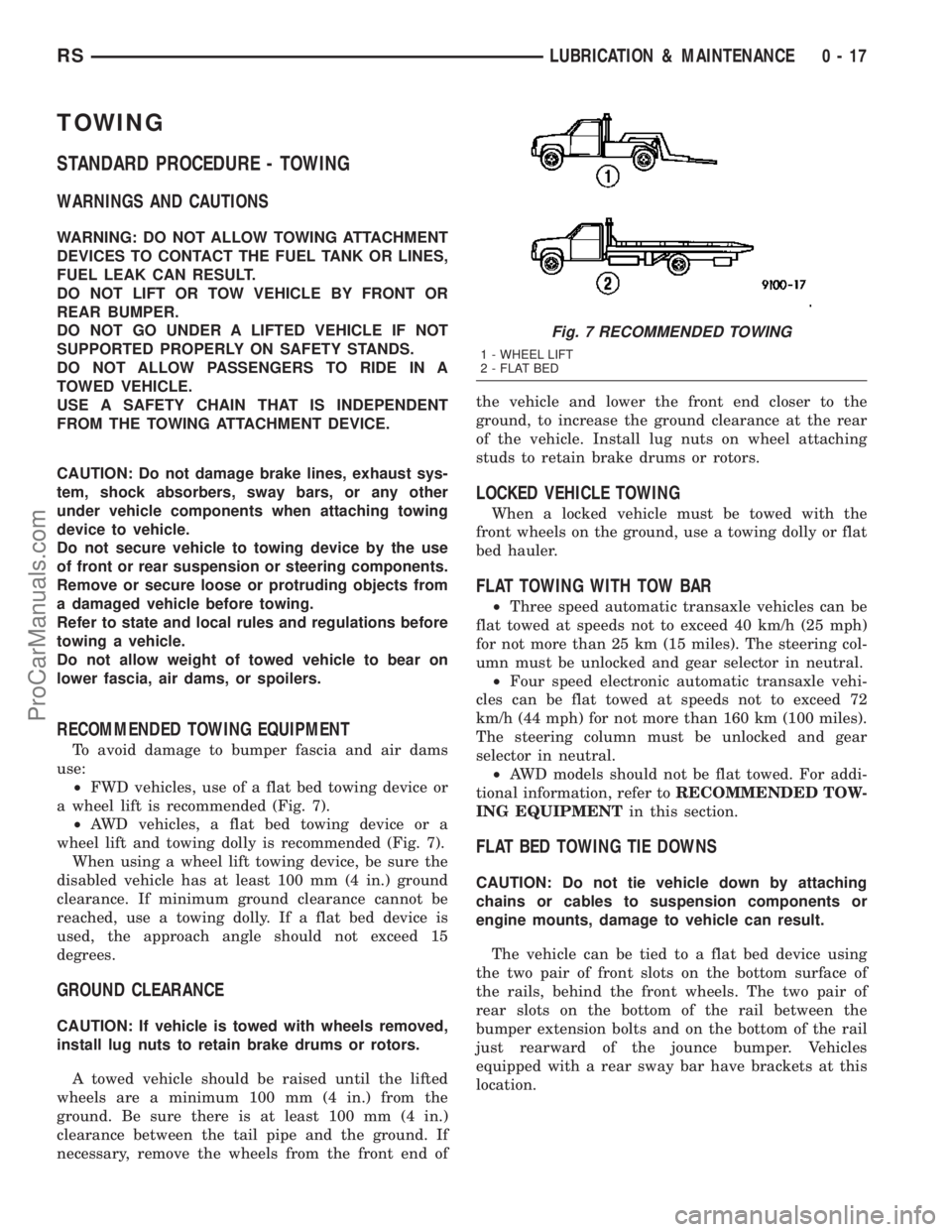

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end ofthe vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-17

ProCarManuals.com