wiper size CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1265 of 2177

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

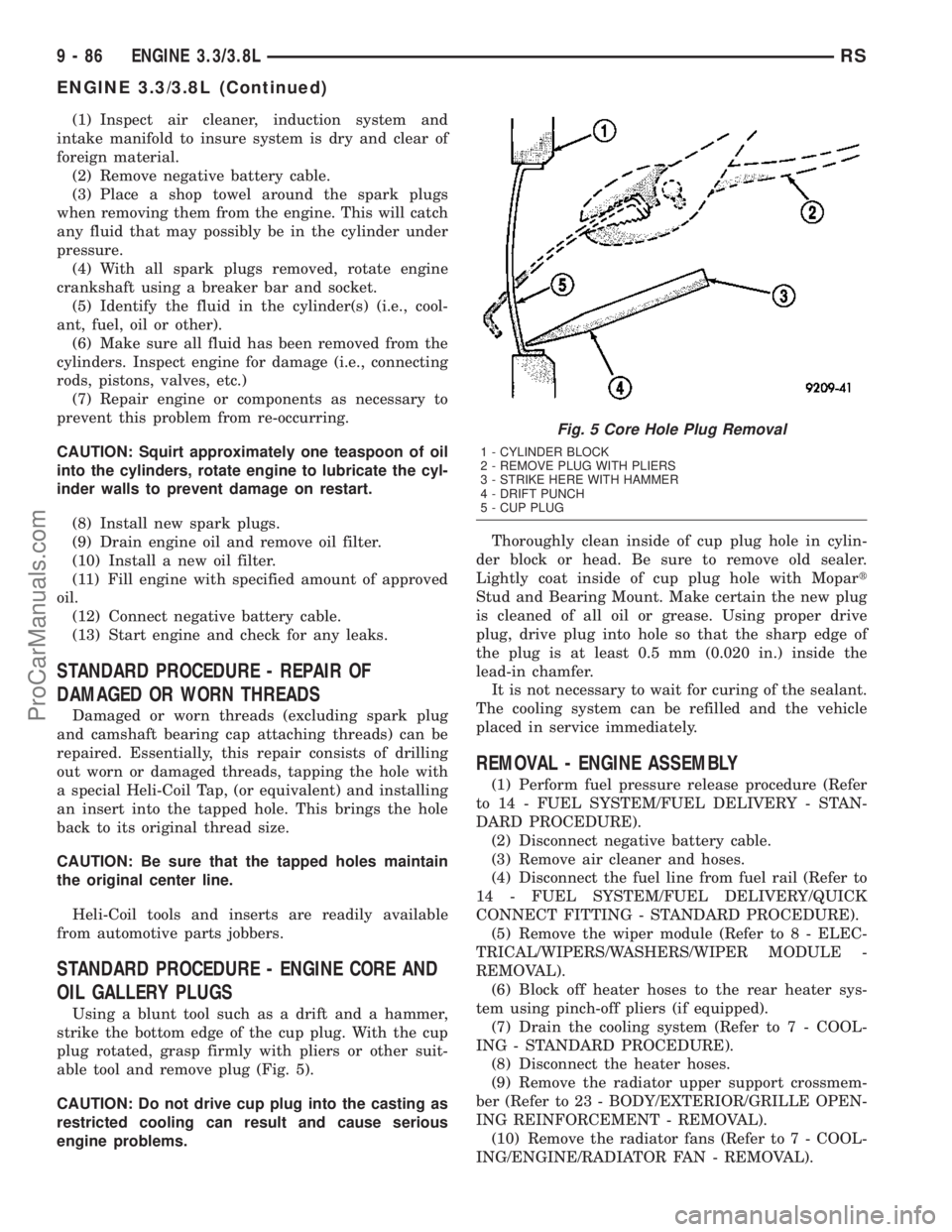

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 5).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE).

(2) Disconnect negative battery cable.

(3) Remove air cleaner and hoses.

(4) Disconnect the fuel line from fuel rail (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE).

(5) Remove the wiper module (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(6) Block off heater hoses to the rear heater sys-

tem using pinch-off pliers (if equipped).

(7) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(8) Disconnect the heater hoses.

(9) Remove the radiator upper support crossmem-

ber (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - REMOVAL).

(10) Remove the radiator fans (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

Fig. 5 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 86 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1270 of 2177

(47) Connect the radiator upper hose.

(48) Connect the heater hoses. Remove pinch-off

pliers from the rear heater hoses (if equipped).

(49) Install the radiator upper support crossmem-

ber (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION).

(50) Install the wiper module (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(51) Connect the fuel line to fuel rail (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

STANDARD PROCEDURE).

(52) Install the air cleaner and hoses.

(53) Install new oil filter. Fill engine crankcase

with proper oil to correct level.

(54) Connect negative cable to battery.

(55) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(56) Start engine and run until operating temper-

ature is reached.

(57) Adjust transmission linkage, if necessary.

SPECIFICATIONS

3.3/3.8L ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type 60É V-6 Engine

Number of Cylinders 6

Displacement

Ð3.3L 3.3 Liters

(201 cu. in.)

Ð3.8L 3.8 Liters

(231 cu. in.)

Bore

Ð3.3L 93.0 mm

(3.66 in.)

Ð3.8L 96.0 mm

(3.779 in.)

Stroke

Ð3.3L 81.0 mm

(3.188 in.)

Ð3.8L 87.0 mm

(3.425 in.)

Compression Ratio

Ð3.3L 9.35:1

Ð3.8L 9.6:1

DESCRIPTION SPECIFICATION

Firing Order 1-2-3-4-5-6

Cylinder Number (Front

to Rear)

ÐFront Bank 2,4,6

ÐRear Bank 1,3,5

Compression PressureÐ

Minimum689.5 kPa

(100 psi)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter

(Standard)

Ð3.3L 92.993±93.007 mm

(3.661±3.6617 in.)

Ð3.8L 95.993±96.007 mm

(3.7792±3.780 in.)

Out-of-Round (Service

Limits)0.076 mm

(0.003 in.)

Taper (Service Limits) 0.051 mm

(0.002 in.)

Lifter Bore Diameter 22.980±23.010 mm

(0.905±0.906 in.)

Deck Surface Flatness

(Max.)0.1 mm

(0.004 in.)

Pistons

Piston Diameter

Ð3.3L ÐMeasured 39.8

mm (1.567 in.) from

piston top92.968±92.998 mm

(3.660±3.661 in.)

Ð3.8L ÐMeasured 33.01

mm (1.30 in.) from piston

top95.968±95.998 mm

(3.778±3.779 in.)

Clearance in Bore @

Size Location (New)-0.005±0.039 mm

(-0.0002±0.0015 in.)

Weight

Ð3.3L 362 5 grams

(12.77 0.1764 oz.)

Ð3.8L 426 5 grams

(15.03 0.1764 oz.)

Piston Pins

Type Press Fit in Rod

(Serviced as an

Assembly)

RSENGINE 3.3/3.8L9-91

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 2098 of 2177

(4) Compress insert in rear heater hose quick con-

nection and pull downward on hose.

(5) Remove (3) straps securing underbody lines.

(6) Separate and remove rear heater lines from

vehicle.

INSTALLATION

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines, while the

3.3L and 3.8L engines have unique heater return

plumbing on the engine for models with or without

an optional engine oil cooler. There are also unique

plumbing configurations at the heater core for mod-

els with or without the optional rear heater and air

conditioner. All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose toward the center of the hose being

installed. Release the clamp when it is near the cen-

ter of the hose.

(2) Grasp one end of the heater hose being

installed firmly and carefully twist the hose back and

forth while pushing it over from the barbed end of

the nipple. Repeat this procedure at the opposite end

of the hose being installed.

(3) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose over the tube or nipple. Release the

clamp when it is over the tube or nipple.

(4) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

SUCTION LINE

REMOVAL

The front air conditioner suction line includes the

low side service port on a section of tubing located

near the compressor. On models equipped with the

optional rear air conditioner, the front air conditioner

suction line also includes a suction line hose and

tube extension that connects the front suction line to

the suction line for the rear air conditioner.WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner top cover and snorkel

from the air cleaner housing located on the right side

of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the nut that secures the suction line

fitting to the top of the compressor.

(6) Disconnect the suction line fitting from the

compressor suction port.

(7) Remove the seal from the suction line fitting

and discard.

(8) Install plugs in, or tape over the opened suc-

tion line fitting and the compressor suction port.

(9) Disengage the retainer that secures the suction

line routing clip to the filter-drier mounting bracket

on the side of the right front strut tower in the

engine compartment (Fig. 7).

(10) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(11) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(12) Remove the seals from the suction line and

liquid line fittings and discard.

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) If the vehicle is equipped with the optional

rear air conditioner, go to Step 15. If the vehicle does

not have the optional rear air conditioner, go to Step

21.

(15) Raise and support the vehicle.

(16) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear

heater and air conditioner (Fig. 8).

(17) Disconnect the suction line extension fitting

from the underbody suction line fitting for the rear

air conditioner.

(18) Remove the seal from the underbody suction

line fitting and discard.

RSPLUMBING - REAR24 - 101

HEATER HOSE (Continued)

ProCarManuals.com