key CHRYSLER CARAVAN 2005 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2270 of 2339

NOTE: Verify that there is more than 1/8 of a tank of

fuel in the vehicle's fuel tank before performing this

procedure. Add fuel, if necessary.

NOTE: Failure to prime the dosing pump after drain-

ing the supplemental cabin fuel line will prevent

cabin heater activation during the first attempt to

start the cabin heater. This will also set a diagnostic

trouble code (DTC) in the cabin heater control's

memory. Do not perform the Dosing Pump Priming

procedure if an attempt was made to start the cabin

heater without priming the dosing pump first. This

will put excess fuel in the cabin heater and cause

smoke to emit from the cabin heater exhaust pipe

when cabin heater activation occurs.

(7) Connect the DRBIIItscan tool to the diagnos-

tic link connector.

(8) Turn the ignition to the ON position.

NOTE: Do not activate the dosing pump prime more

than one time. This will put excess fuel in the sup-

plemental cabin heater and cause smoke to emit

from the cabin heater exhaust pipe when cabin

heater activation occurs.

NOTE: A clicking noise heard coming from the dos-

ing pump indicates that the pump is operational.

(9) With the DRBIIItscan tool in Cabin Heater,

select System Tests and Dosing Pump Prime. Allow

the dosing pump to run for the full 45 second cycle

time. When the 45 second cycle is complete, press

Page Back on the DRBIIItscan tool key pad to exit

the Dosing Pump Prime. The Dosing Pump Priming

procedure is now complete.

HEATER HOSES

REMOVAL

(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

NOTE: Complete removal of the supplemental cabin

heater from vehicle is not required, lowering the

cabin heater allows easier access to coolant line

clamps.(3) Lower the supplemental cabin heater from the

vehicle (Refer to 24 - HEATING & AIR CONDITION-

ING/CABIN HEATER/HEATER UNIT - REMOVAL).

(4) Remove the clamps from both flexible coolant

line ends.

NOTE: It is recommended that both flexible cabin

heater coolant lines be replaced if either cabin

heater coolant line is damaged.

(5) Remove both coolant lines from vehicle.

INSTALLATION

(1) Install both flexible coolant lines to the supple-

mental cabin heater and install the clamps.

(2) Install the flexible coolant lines to the coolant

pipes and install the clamps.

(3) Install the supplemental cabin heater into the

vehicle (Refer to 24 - HEATING & AIR CONDITION-

ING/CABIN HEATER/HEATER UNIT - INSTALLA-

TION).

(4) Lower the vehicle.

(5) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(6) Verify operation of the supplemental cabin

heater.

HEATER PIPES

REMOVAL

WARNING: ALLOW THE ENGINE COOLING SYSTEM

TO COOL COMPLETELY BEFORE REMOVING RADI-

ATOR CAP OR DRAINING THE ENGINE COOLING

SYSTEM. PERSONAL INJURY MAY RESULT IF THE

ENGINE COOLING SYSTEM IS OPENED WHILE

ENGINE COOLANT IS HOT AND UNDER PRES-

SURE.

NOTE: Steel heater lines from engine compartment

to the supplemental cabin heater are part of an

assembly that includes the air intake pipe. If the

cabin heater lines or air intake pipe require removal

or replacement the entire cabin heater assembly

will require removal or replacement.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(2) Remove clamps from both the EGR cooler and

the lower heater port. Separate hoses from the mat-

ing plumbing port (Fig. 6).

RSCABIN HEATER24 - 119

FUEL LINE (Continued)

Page 2277 of 2339

OXYGEN SENSOR HEATER MONITOR (SBEC)

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

heater fault MUST be repaired first. After the O2S

fault is repaired, verify that the heater circuit is

operating correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested directly. The

sensor output is used to test the heater by isolating

the effect of the heater element on the O2S output

voltage from the other effects. The resistance is nor-

mally between 100 ohms and 4.5 megaohms. When

oxygen sensor temperature increases, the resistance

in the internal circuit decreases. The PCM sends a 5

volts biased signal through the oxygen sensors to

ground this monitoring circuit. As the temperature

increases, resistance decreases and the PCM detects

a lower voltage at the reference signal. Inversely, as

the temperature decreases, the resistance increases

and the PCM detects a higher voltage at the refer-

ence signal. The O2S circuit is monitored for a drop

in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle, after the 2nd failure.Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

Pending ConditionsÐThere are not conditions or

situations that prompt conflict or suspension of test-

ing. The oxygen sensor heater test is not run pending

resolution of MIL illumination due to oxygen sensor

failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a high oxygen

condition, there is an abundance of oxygen in the

exhaust gas. A functioning converter would store this

oxygen so it can use it for the oxidation of HC and

CO. As the converter absorbs the oxygen, there will

be a lack of oxygen downstream of the converter. The

output of the downstream O2S will indicate limited

activity in this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

25 - 4 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2299 of 2339

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a good trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the thirdgood trip) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MIL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes.

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire. (MIL Off)

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire. (MIL Off)

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault. (MIL On)

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire. Catalyst damage misfire is a

2 trip MIL. The MIL flashes on the first trip when

catalyst damage misfire levels are present. (MIL On)

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-ditions Window is when engine RPM is within 375

RPM and load is within 20% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a scan tool.

Erasing the DTC with the scan tool erases all OBD

II information. The scan tool automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Global Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on scan tool)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Global Good Trip

To increment a Global Good Trip, the Oxygen sen-

sor and Catalyst efficiency monitors must have run

and passed, and 2 minutes of engine run time.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

25 - 26 ON-BOARD DIAGNOSTICSRS

TASK MANAGER (Continued)

Page 2308 of 2339

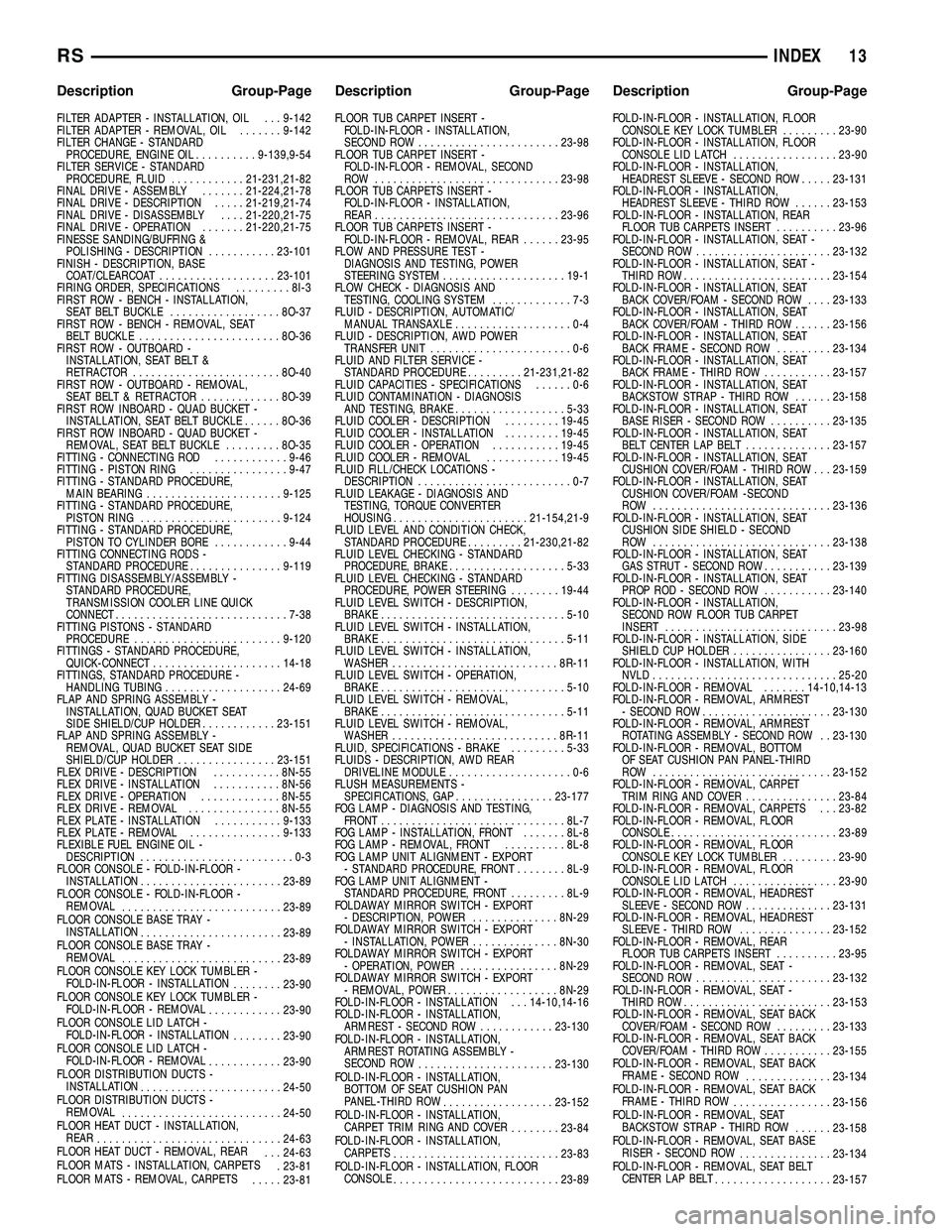

CHIRP PREFERENCE - STANDARDPROCEDURE, HORN .................. 8N-24

CIRCUIT, DIAGNOSIS AND TESTING - AMBIENT TEMPERATURE SENSOR ......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT RESISTANCE TEST - DIAGNOSIS AND TESTING, FEED ........8F-35

CIRCUIT TEST - DIAGNOSIS AND TESTING, CONTROL .................. 8F-33

CIRCUIT TEST - DIAGNOSIS AND TESTING, FEED ...................... 8F-36

CIRCUITS AND VALVES - OPERATION, HYDRAULIC .......................... 5-95

CIRCUITS, DESCRIPTION - NON- MONITORED ......................... 25-5

CLAMP - STANDARD PROCEDURE, HOSES .............................. 14-7

CLAMPS - DESCRIPTION, FUEL LINES/HOSES ........................ 14-7

CLAMPS - DESCRIPTION, HOSE ...........7-1

CLAMPS - OPERATION, HOSE .............7-2

CLASSIFICATION MODULE - DESCRIPTION, OCCUPANT .............8O-25

CLASSIFICATION MODULE - INSTALLATION, OCCUPANT ............8O-26

CLASSIFICATION MODULE - OPERATION, OCCUPANT ......................... 8O-25

CLASSIFICATION MODULE - REMOVAL, OCCUPANT ......................... 8O-26

CLEARANCE - STANDARD PROCEDURE, MEASURING CONNECTING ROD

BEARING ............................ 9-123

CLEARANCE USING PLASTIGAGE - STANDARD PROCEDURE, MEASURING

BEARING ........................ 9-12,9-86

CLOCKSPRING - DESCRIPTION .........8O-10

CLOCKSPRING - INSTALLATION .........8O-12

CLOCKSPRING - OPERATION ...........8O-11

CLOCKSPRING - REMOVAL ............8O-12

CLOCKSPRING CENTERING - STANDARD PROCEDURE ........................ 8O-11

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT .....8J-1

CLUSTER BEZEL - INSTALLATION ........23-65

CLUSTER BEZEL - REMOVAL ...........23-65

CLUSTER DIAGNOSIS - DIAGNOSIS AND TESTING ............................ 8J-3

CLUSTER ILLUMINATION LAMPS - INSTALLATION ....................... 8L-21

CLUSTER ILLUMINATION LAMPS - REMOVAL .......................... 8L-21

CLUSTER LENS - INSTALLATION ........8J-11

CLUSTER LENS - REMOVAL ............8J-11

CLUTCH AIR PRESSURE TESTS - DIAGNOSIS AND TESTING ........21-153,21-8

CLUTCH ASSEMBLY - ASSEMBLY, INPUT ....................... 21-246,21-95

CLUTCH ASSEMBLY - DISASSEMBLY, INPUT ....................... 21-237,21-86

CLUTCH BREAK-IN, STANDARD PROCEDURE - A/C ................... 24-15

CLUTCH COIL, DIAGNOSIS AND TESTING - A/C COMPRESSOR .................. 24-14

CLUTCH INSPECTION, STANDARD PROCEDURE ........................ 24-15

CLUTCH RELAY - DESCRIPTION, A/C COMPRESSOR ....................... 24-18

CLUTCH RELAY - INSTALLATION, A/C COMPRESSOR ....................... 24-19

CLUTCH RELAY - OPERATION, A/C COMPRESSOR ....................... 24-18

CLUTCH RELAY - REMOVAL, A/C COMPRESSOR ....................... 24-19

CLUTCH/COIL - DESCRIPTION, A/C COMPRESSOR ....................... 24-13

CLUTCH/COIL - OPERATION, A/C COMPRESSOR ....................... 24-13

CLUTCHES - DESCRIPTION, DRIVING . . . 21-219,

21-74

CLUTCHES - DESCRIPTION, HOLDING . . . 21-236,

21-86

CLUTCHES - OPERATION, DRIVING .....21-219,

21-74

CLUTCHES - OPERATION, HOLDING ....21-236,

21-86

COAT/CLEARCOAT FINISH - DESCRIPTION, BASE .................23-101CODE - DESCRIPTION, PAINT

..........23-101

CODE CHARTS - SPECIFICATIONS, COLOR ............................ 23-100

CODES - STANDARD PROCEDURE, OBTAINING DIAGNOSTIC TROUBLE ......8E-15

CODES, STANDARD PROCEDURE - ERASING TRANSMITTER ..............8M-12

CODES, STANDARD PROCEDURE - SETTING TRANSMITTER ..............8M-12

COIL - DESCRIPTION, IGNITION ..........8I-6

COIL - OPERATION, IGNITION ............8I-6

COIL, DIAGNOSIS AND TESTING - A/C COMPRESSOR CLUTCH ...............24-14

COLLAR - INSTALLATION, STRUCTURAL . . . 9-49

COLLAR - REMOVAL, STRUCTURAL .......9-49

COLOR CODE CHARTS - SPECIFICATIONS .................... 23-100

COLUMN - DESCRIPTION, STEERING .....19-10

COLUMN - DIAGNOSIS AND TESTING, STEERING .......................... 19-11

COLUMN COVER - INSTALLATION, LOWER STEERING ................... 23-74

COLUMN COVER - INSTALLATION, OVER STEERING .......................... 23-76

COLUMN COVER - REMOVAL, LOWER STEERING .......................... 23-74

COLUMN COVER - REMOVAL, OVER STEERING .......................... 23-76

COLUMN FASTENER TORQUE, SPECIFICATIONS ..................... 19-17

COMBUSTION PRESSURE LEAKAGE TEST - DIAGNOSIS AND TESTING,

CYLINDER ........................ 9-85,9-9

COMMUNICATION RECEIVE - PCM INPUT - OPERATION, DATA BUS ..............8E-14

COMMUNICATIONS INTERFACE (PCI) BUS, OPERATION - PROGRAMMABLE ....14-25

COMPASS CALIBRATION, STANDARD PROCEDURE ......................... 8M-4

COMPASS DEMAGNETIZING, STANDARD PROCEDURE ......................... 8M-5

COMPASS MINI-TRIP COMPUTER, DIAGNOSIS AND TESTING .............8M-10

COMPASS VARIATION ADJUSTMENT, STANDARD PROCEDURE ...............8M-5

COMPASS/MINI-TRIP COMPUTER - DESCRIPTION ....................... 8M-10

COMPASS/MINI-TRIP COMPUTER - OPERATION ........................ 8M-10

COMPRESSION PRESSURE TEST - DIAGNOSIS AND TESTING, CYLINDER . . 9-85,9-9

COMPRESSOR CLUTCH COIL, DIAGNOSIS AND TESTING - A/ C.........24-14

COMPRESSOR CLUTCH RELAY - DESCRIPTION, A/C ................... 24-18

COMPRESSOR CLUTCH RELAY - INSTALLATION, A/C ................... 24-19

COMPRESSOR CLUTCH RELAY - OPERATION, A/C ..................... 24-18

COMPRESSOR CLUTCH RELAY - REMOVAL, A/C ...................... 24-19

COMPRESSOR CLUTCH/COIL - DESCRIPTION, A/C ................... 24-13

COMPRESSOR CLUTCH/COIL - OPERATION, A/C ..................... 24-13

COMPRESSOR, DESCRIPTION - A/C ......24-72

COMPRESSOR, INSTALLATION - A/C .....24-74

COMPRESSOR MOUNTING BRACKET, 2.4L ENGINE - A/C ..............24-74,24-75

COMPRESSOR NOISE DIAGNOSIS, DIAGNOSIS AND TESTING - A/C .........24-72

COMPRESSOR, OPERATION - A/C ........24-72

COMPRESSOR, REMOVAL - A/C .........24-73

COMPUTER - DESCRIPTION, COMPASS/ MINI-TRIP ......................... 8M-10

COMPUTER - OPERATION, COMPASS/ MINI-TRIP ......................... 8M-10

COMPUTER, DIAGNOSIS AND TESTING - COMPASS MINI-TRIP .................8M-10

CONCENTRATION TESTING - DIAGNOSIS AND TESTING, COOLANT ...............7-19

CONDENSER - DESCRIPTION, A/C .......24-75

CONDENSER - OPERATION, A/C .........24-75

CONDITION CHECK, STANDARD PROCEDURE - FLUID LEVEL ......21-230,21-82

CONDITIONER, DESCRIPTION - HEATER AND AIR ............................ 24-1CONDITIONER, OPERATION - HEATER

AND AIR ............................ 24-4

CONNECT FITTING DISASSEMBLY/ ASSEMBLY - STANDARD PROCEDURE,

TRANSMISSION COOLER LINE QUICK .....7-38

CONNECTING ROD - DESCRIPTION, PISTON ........................ 9-119,9-44

CONNECTING ROD - INSTALLATION, PISTON ............................. 9-45

CONNECTING ROD - REMOVAL, PISTON . . . 9-44

CONNECTING ROD BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING .............9-123

CONNECTING ROD, FITTING .............9-46

CONNECTING RODS - STANDARD PROCEDURE, FITTING .................9-119

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-6

CONNECTOR - INSTALLATION .......8W-01-11

CONNECTOR - OPERATION, DATA LINK ....8E-6

CONNECTOR - REMOVAL ...........8W-01-11

CONNECTOR, GROUND AND SPLICE INFORMATION - DESCRIPTION ........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION - DESCRIPTION ....................8W -91-1

CONSOLE - DESCRIPTION, OVERHEAD ....8M-2

CONSOLE - FOLD-IN-FLOOR - INSTALLATION, FLOOR ................23-89

CONSOLE - FOLD-IN-FLOOR - REMOVAL, FLOOR ............................. 23-89

CONSOLE - INSTALLATION, LOWER ......23-73

CONSOLE - REMOVAL, LOWER ..........23-73

CONSOLE BASE TRAY - INSTALLATION, FLOOR ............................. 23-89

CONSOLE BASE TRAY - REMOVAL, FLOOR ............................. 23-89

CONSOLE, DIAGNOSIS AND TESTING - OVERHEAD .......................... 8M-3

CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION,

FLOOR ............................. 23-90

CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR .....23-90

CONSOLE LAMP - INSTALLATION, CENTER ............................ 8L-21

CONSOLE LAMP - REMOVAL, CENTER ....8L-21

CONSOLE LAMP SWITCH - INSTALLATION, CENTER ...............8L-21

CONSOLE LAMP SWITCH - REMOVAL, CENTER ............................ 8L-21

CONSOLE LID LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR ................23-90

CONSOLE LID LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR .................... 23-90

CONSOLE, SPECIAL TOOLS - OVERHEAD . . 8M-7

CONTAINER - DESCRIPTION, COOLANT RECOVERY .......................... 7-20

CONTAINER - INSTALLATION, COOLANT RECOVERY .......................... 7-20

CONTAINER - OPERATION, COOLANT RECOVERY .......................... 7-20

CONTAINER - REMOVAL, COOLANT RECOVERY .......................... 7-20

CONTAMINATION - DIAGNOSIS AND TESTING, BRAKE FLUID ................5-33

CONTINUITY - STANDARD PROCEDURE, TESTING .........................8W -01-9

CONTROL (4 SPEED EATX ONLY) - OPERATION, INTERACTIVE SPEED ........8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-12

CONTROL ARM - INSPECTION, LOWER ....2-14

CONTROL ARM - INSTALLATION, LOWER . . 2-15

CONTROL ARM - OPERATION, LOWER .....2-12

CONTROL ARM - REMOVAL, LOWER ......2-12

CONTROL ARM (REAR BUSHING - HYDRO) - ASSEMBLY, LOWER ...........2-15

CONTROL ARM (REAR BUSHING - HYDRO) - DISASSEMBLY, LOWER ........2-13

CONTROL ARM (REAR BUSHING - STANDARD) - ASSEMBLY, LOWER ........2-14

CONTROL ARM (REAR BUSHING - STANDARD) - DISASSEMBLY, LOWER .....2-13

CONTROL CABLE - INSTALLATION, THROTTLE .......................... 14-40

CONTROL CABLE - REMOVAL, THROTTLE .......................... 14-40

CONTROL CALIBRATION, STANDARD PROCEDURE - A/C-HEATER .............24-19

RS INDEX7

Description Group-Page Description Group-Page Description Group-Page

Page 2310 of 2339

COVER - RIGHT - INSTALLATION,CYLINDER HEAD ..................... 9-106

COVER - RIGHT - REMOVAL, CYLINDER HEAD .............................. 9-106

COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT

BACK ............................. 23-133

COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT

BACK ............................. 23-133

COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT

BACK ............................. 23-156

COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT

CUSHION .......................... 23-159

COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT

BACK ............................. 23-155

COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT

CUSHION .......................... 23-159

COVER/FOAM -SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT

CUSHION .......................... 23-136

COVER/FOAM -SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT

CUSHION .......................... 23-136

COVER(S) - DESCRIPTION, CYLINDER HEAD .............................. 9-105

COVER(S) - INSTALLATION, TIMING BELT ............................... 9-64

COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION, SEAT BACK

HINGE ............................ 23-146

COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT BACK HINGE. . . 23-146

COVER(S) - REMOVAL, TIMING BELT ......9-63

COWL GRILLE - INSTALLATION .........23-50

COWL GRILLE - REMOVAL .............23-50

COWL TRIM - INSTALLATION ...........23-88

COWL TRIM - REMOVAL ...............23-88

C-PILLAR - INSTALLATION, SEAT BELT HEIGHT ADJUSTE R-BOR............. 8O-38

C-PILLAR - REMOVAL, SEAT BELT HEIGHT ADJUSTE R-BOR............. 8O-38

C-PILLAR TRIM - INSTALLATION ........23-88

C-PILLAR TRIM - REMOVAL ............23-88

CRADLE CROSSMEMBER - DESCRIPTION, FRONT .................13-14

CRADLE CROSSMEMBER THREAD REPAIR - DESCRIPTION, FRONT .........13-14

CRANK - INSTALLATION, WINDOW .......23-21

CRANK - REMOVAL, WINDOW ..........23-21

CRANKSHAFT - INSPECTION .............9-38

CRANKSHAFT - INSTALLATION ...........9-39

CRANKSHAFT - REMOVAL ..............9-37

CRANKSHAFT END PLAY - STANDARD PROCEDURE ......................... 9-37

CRANKSHAFT END PLAY - STANDARD PROCEDURE, MEASURING .............9-128

CRANKSHAFT MAIN BEARINGS - INSTALLATION ....................... 9-127

CRANKSHAFT MAIN BEARINGS - REMOVAL .......................... 9-127

CRANKSHAFT OIL SEAL - FRONT - INSTALLATION ................... 9-130,9-42

CRANKSHAFT OIL SEAL - FRONT - REMOVAL ...................... 9-130,9-41

CRANKSHAFT OIL SEAL - REAR - INSTALLATION ................... 9-131,9-42

CRANKSHAFT OIL SEAL - REAR - REMOVAL ...................... 9-131,9-42

CRANKSHAFT POSITION SENSOR - DESCRIPTION ....................... 14-29

CRANKSHAFT POSITION SENSOR - OPERATION ......................... 14-29

CRANKSHAFT POSITION SENSOR - REMOVAL .......................... 14-30

CRANKSHAFT REAR OIL SEAL RETAINER - INSTALLATION ..................... 9-132

CRANKSHAFT REAR OIL SEAL RETAINER - REMOVAL ......................... 9-132

CRANKSHAFT SPROCKET - INSTALLATION ................... 9-160,9-67

CRANKSHAFT SPROCKET - REMOVAL ....9-159,

9-66 CROSSBAR - INSTALLATION, LUGGAGE

RACK .............................. 23-59

CROSSBAR - REMOVAL, LUGGAGE RACK . 23-58

CROSSMEMBER - DESCRIPTION, FRONT CRADLE ............................ 13-14

CROSSMEMBER - INSTALLATION, UPPER RADIATOR .................... 23-56

CROSSMEMBER - REMOVAL, UPPER RADIATOR .......................... 23-56

CROSSMEMBER MOUNT BUSHINGS - INSTALLATION, FRONT ................13-17

CROSSMEMBER MOUNT BUSHINGS - REMOVAL, FRONT .................... 13-17

CROSSMEMBER THREAD REPAIR - DESCRIPTION, FRONT CRADLE .........13-14

CROSS-OVER PIPE - 3.3/3.8L - INSTALLATION ........................ 11-6

CROSS-OVER PIPE - 3.3/3.8L - REMOVAL ........................... 11-6

CUP HOLDER - FOLD-IN-FLOOR - INSTALLATION, SIDE SHIELD ..........23-160

CUP HOLDER - FOLD-IN-FLOOR - REMOVAL, SIDE SHIELD ..............23-160

CUP HOLDER - INSTALLATION ..........23-65

CUP HOLDER - INSTALLATION, QUAD BUCKET SEAT SIDE SHIELD - NO .......23-143

CUP HOLDER - REMOVAL ..............23-65

CUP HOLDER - REMOVAL, QUAD BUCKET SEAT SIDE SHIELD - NO .......23-143

CURB HEIGHT MEASUREMENT - STANDARD PROCEDURE ................2-55

CURTAIN AIRBAG - DESCRIPTION .......8O-12

CURTAIN AIRBAG - INSTALLATION .......8O-16

CURTAIN AIRBAG - OPERATION .........8O-13

CURTAIN AIRBAG - REMOVAL ..........8O-14

CUSHION - INSTALLATION, FRONT SEAT . 23-118

CUSHION - INSTALLATION, QUAD SEAT . . 23-141

CUSHION - INSTALLATION, STABILIZER BAR.................................2-4

CUSHION - OCS - INSTALLATION, FRONT SEAT ............................. 23-120

CUSHION - OCS - REMOVAL, FRONT SEAT ............................. 23-119

CUSHION - REMOVAL, FRONT SEAT .....23-117

CUSHION - REMOVAL, QUAD SEAT .....23-141

CUSHION - REMOVAL, STABILIZER BAR ....2-4

CUSHION COVER - QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION, SEAT . . . 23-144

CUSHION COVER - QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT .......23-144

CUSHION COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-159

CUSHION COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-159

CUSHION COVER/FOAM -SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-136

CUSHION COVER/FOAM -SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-136

CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR - INSTALLATION,

BOTTOM OF SEAT ................... 23-152

CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR - REMOVAL, BOTTOM

OF SEAT........................... 23-152

CUSHION SIDE COVER - INSTALLATION, FRONT SEAT ....................... 23-121

CUSHION SIDE COVER - OCS - INSTALLATION, FRONT SEAT ..........23-122

CUSHION SIDE COVER - OCS - REMOVAL, FRONT SEAT ..............23-121

CUSHION SIDE COVER - REMOVAL, FRONT SEAT ....................... 23-120

CUSHION SIDE SHIELD - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION,

SEAT ............................. 23-138

CUSHION SIDE SHIELD - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ....23-138

CV BOOT - INNER - INSTALLATION ........3-7

CV BOOT - INNER - REMOVAL ............3-6

CV BOOT - OUTER - INSTALLATION .......3-11

CV BOOT - OUTER - REMOVAL ...........3-10

CYCLE, STANDARD PROCEDURE - POWER LIFTGATE LEARN ...............8N-8

CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR LEARN .........8N-48

CYLINDER - DESCRIPTION, KEY/LOCK ....19-20

CYLINDER - DESCRIPTION, STANDARD 4 . . . 8I-9

CYLINDER - INSTALLATION, KEY/LOCK . . . 19-20CYLINDER - INSTALLATION, LOCK . . 23-19,23-42

CYLINDER - INSTALLATION, SUPPORT

....23-43

CYLINDER - OPERATION, KEY/LOCK ......19-20

CYLINDER - REMOVAL, KEY/LOCK .......19-20

CYLINDER - REMOVAL, LOCK ......23-19,23-42

CYLINDER - REMOVAL, SUPPORT .......23-42

CYLINDER BLEEDING - STANDARD PROCEDURE, MASTER .................5-36

CYLINDER BORE FITTING - STANDARD PROCEDURE, PISTON TO ...............9-44

CYLINDER BORE HONING - STANDARD PROCEDURE .................... 9-115,9-36

CYLINDER COMBUSTION PRESSURE LEAKAGE TEST - DIAGNOSIS AND

TESTING ......................... 9-85,9-9

CYLINDER COMPRESSION PRESSURE TEST - DIAGNOSIS AND TESTING .....9-85,9-9

CYLINDER (FLUID RESERVOIR) - ASSEMBLY, MASTER ................... 5-39

CYLINDER (FLUID RESERVOIR) - DISASSEMBLY, MASTER ................5-38

CYLINDER HEAD - CLEANING .......9-103,9-26

CYLINDER HEAD - DESCRIPTION ....9-102,9-25

CYLINDER HEAD - INSPECTION .....9-104,9-27

CYLINDER HEAD - INSTALLATION . . . 9-104,9-27

CYLINDER HEAD - REMOVAL .......9-103,9-26

CYLINDER HEAD COVER - CLEANING ......9-31

CYLINDER HEAD COVER - INSPECTION ....9-31

CYLINDER HEAD COVER - INSTALLATION ......................... 9-32

CYLINDER HEAD COVER - LEFT - INSTALLATION ....................... 9-107

CYLINDER HEAD COVER - LEFT - REMOVAL .......................... 9-107

CYLINDER HEAD COVER - REMOVAL ......9-31

CYLINDER HEAD COVER - RIGHT - INSTALLATION ....................... 9-106

CYLINDER HEAD COVER - RIGHT - REMOVAL .......................... 9-106

CYLINDER HEAD COVER(S) - DESCRIPTION ....................... 9-105

CYLINDER HEAD GASKET - DIAGNOSIS AND TESTING ................... 9-102,9-25

CYLINDER HEAD OFF - INSTALLATION . . . 9-111, 9-33

CYLINDER HEAD OFF - REMOVAL . . . 9-109,9-33

CYLINDER HEAD ON - INSTALLATION ....9-111,

9-33

CYLINDER HEAD ON - REMOVAL ....9-111,9-33

CYLINDER LOCK SWITCH - EXPORT - DESCRIPTION, DOOR .................8N-22

CYLINDER LOCK SWITCH - EXPORT - OPERATION, DOOR ................... 8N-22

CYLINDER LOCK SWITCH, EXPORT - DOOR ............................. 8N-22

CYLINDERS - INSPECTION, WHEEL .......5-62

CYLINDERS - INSTALLATION, WHEEL .....5-62

CYLINDERS - REMOVAL, WHEEL .........5-62

DAMAGED OR WORN THREADS - STANDARD PROCEDURE, REPAIR OF . . 9-10,9-88

DAMPER - INSTALLATION, VIBRATION . . . 9-132, 9-49

DAMPER - REMOVAL, VIBRATION . . . 9-132,9-48

DATA BUS COMMUNICATION RECEIVE - PCM INPUT - OPERATION ..............8E-14

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-6

DATA LINK CONNECTOR - OPERATION .....8E-6

DAY / NIGHT MIRROR - DESCRIPTION, AUTOMATIC ........................ 8N-28

DAY / NIGHT MIRROR - OPERATION, AUTOMATIC ........................ 8N-28

DAY / NIGHT MIRROR, DIAGNOSIS AND TESTING - AUTOMATIC ................8N-28

DEAERATION - DIAGNOSIS AND TESTING, COOLING SYSTEM .............7-4

DECOUPLER PULLEY - DESCRIPTION, GENERATOR ........................ 8F-28

DECOUPLER PULLEY - DIAGNOSIS AND TESTING, GENERATOR ................8F-28

DECOUPLER PULLEY - INSTALLATION, GENERATOR ........................ 8F-29

DECOUPLER PULLEY - OPERATION, GENERATOR ........................ 8F-28

DECOUPLER PULLEY - REMOVAL, GENERATOR ........................ 8F-29

DEFINITION, DESCRIPTION - TRIP ........25-1

DEFLECTOR - INSTALLATION, WIND .....23-174

DEFLECTOR - REMOVAL, WIND ........23-174

RS INDEX9

Description Group-Page Description Group-Page Description Group-Page

Page 2313 of 2339

ENGINE OIL PRESSURE - DIAGNOSISAND TESTING, CHECKING ...............9-53

ENGINE, SPECIAL TOOLS - 2.4L ..........9-21

ENGINE, SPECIAL TOOLS - 3.3/3.8L .......9-98

ENGINE, SPECIFICATIONS - 3.3/3.8L ......9-93

ENGINE SPEED SENSOR - DESCRIPTION . . 14-30

ENGINE SPEED SENSOR - OPERATION ....14-30

ENGINE, STANDARD PROCEDURE - HYDROSTATIC LOCKED .............9-10,9-87

ENGINES - DESCRIPTION, ENGINE OIL - DIESEL ..............................0-6

ENGINES - EXPORT - DESCRIPTION, DIESEL ............................. 0-21

ENGINES, INSTALLATION - 2.4L/3.3L/ 3.8L ............................... 24-77

ENGINES, INSTALLATION - 2.5L/2.8L DIESEL ............................ 24-78

ENGINES, REMOVAL - 2.4L/3.3L/3.8L .....24-76

ENGINES, REMOVAL - 2.5L/2.8L DIESEL . . 24-77

ENTRY MODULE - DESCRIPTION, SENTRY KEY REMOTE .................8Q-3

ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY KEY REMOTE .........8Q-5

ENTRY MODULE - INSTALLATION, SENTRY KEY REMOTE .................8Q-6

ENTRY MODULE - OPERATION, SENTRY KEY REMOTE ........................ 8Q-4

ENTRY MODULE - REMOVAL, SENTRY KEY REMOTE ........................ 8Q-6

ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY KEY REMOTE .........8Q-3

ENTRY TRANSMITTER, DIAGNOSIS AND TESTING - KEYLESS .................. 8N-24

ENTRY TRANSMITTER PROGRAMMING - STANDARD PROCEDURE, REMOTE

KEYLESS ........................... 8N-24

EQUIPMENT, STANDARD PROCEDURE - REFRIGERANT SYSTEM SERVICE ........24-69

ERASING TRANSMITTER CODES, STANDARD PROCEDURE ..............8M-12

EVACUATE, STANDARD PROCEDURE - REFRIGERANT SYSTEM ...............24-70

EVAP CANISTER - INSTALLATION, REAR . . 25-21

EVAP CANISTER - REMOVAL, REAR ......25-20

EVAPORATION CONTROL SYSTEM - OPERATION ......................... 25-11

EVAPORATOR - DESCRIPTION, A/C . 24-80,24-98

EVAPORATOR - INSTALLATION, A/C ......24-81

EVAPORATOR - OPERATION, A/C . . . 24-80,24-98

EVAPORATOR - REMOVAL, A/C ..........24-81

EVAPORATOR, INSTALLATION - REAR A/C............................... 24-100

EVAPORATOR LINE EXTENSION, INSTALLATION - REAR A/C ............24-100

EVAPORATOR LINE EXTENSION, REMOVAL - REAR A/C .................24-99

EVAPORATOR, REMOVAL - REAR A/C .....24-98

EVAPORATOR TEMPERATURE SENSOR - DESCRIPTION ....................... 24-26

EVAPORATOR TEMPERATURE SENSOR - OPERATION ......................... 24-27

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-13

EVAP/PURGE SOLENOID - INSTALLATION . 25-13

EVAP/PURGE SOLENOID - OPERATION ....25-13

EVAP/PURGE SOLENOID - REMOVAL .....25-13

EXCESSIVE EXHAUST SYSTEM NOISE - DIAGNOSIS AND TESTING ..............11-2

EXHAUST MANIFOLD - CLEANING ........9-63

EXHAUST MANIFOLD - INSPECTION .......9-63

EXHAUST MANIFOLD - INSTALLATION .....9-63

EXHAUST MANIFOLD - LEFT - CLEANING . . 9-154

EXHAUST MANIFOLD - LEFT - INSPECTION ........................ 9-155

EXHAUST MANIFOLD - LEFT - INSTALLATION ....................... 9-155

EXHAUST MANIFOLD - LEFT - REMOVAL . . 9-154

EXHAUST MANIFOLD - REMOVAL .........9-63

EXHAUST MANIFOLD - RIGHT - CLEANING .......................... 9-153

EXHAUST MANIFOLD - RIGHT - INSPECTION ........................ 9-153

EXHAUST MANIFOLD - RIGHT - INSTALLATION ....................... 9-153

EXHAUST MANIFOLD - RIGHT - REMOVAL .......................... 9-152

EXHAUST SYSTEM - DESCRIPTION .......11-1

EXHAUST SYSTEM NOISE - DIAGNOSIS AND TESTING, EXCESSIVE ..............11-2EXHAUST SYSTEM RESTRICTION CHECK

- DIAGNOSIS AND TESTING .............11-2

EXHAUST SYSTEM, SPECIAL TOOLS ......11-4

EXHAUST TUBE - INSTALLATION .......24-116

EXHAUST TUBE - REMOVAL ...........24-116

EXHAUSTER - DESCRIPTION, REAR QUARTER PANEL/FENDER AIR ..........23-59

EXHAUSTER - INSTALLATION, REAR QUARTER PANEL/FENDER AIR ..........23-60

EXHAUSTER - REMOVAL, REAR QUARTER PANEL/FENDER AIR ..........23-59

EXPANSION VALVE - DESCRIPTION ......24-81

EXPANSION VALVE - DESCRIPTION, A/C . 24-100

EXPANSION VALVE - OPERATION ........24-81

EXPANSION VALVE - OPERATION, A/C . . . 24-100

EXPANSION VALVE, DIAGNOSIS AND TESTING - FRONT A/C .................24-82

EXPANSION VALVE, DIAGNOSIS AND TESTING - REAR A/C .................24-101

EXPORT - ANTENNA MODULE ..........8A-10

EXPORT - BRAKE ROTOR ...............5-60

EXPORT - DESCRIPTION ................5-63

EXPORT - DESCRIPTION ................0-13

EXPORT - DESCRIPTION ................2-10

EXPORT - DESCRIPTION, ANTENNA MODULE ........................... 8A-10

EXPORT - DESCRIPTION, DIESEL ENGINES ............................ 0-21

EXPORT - DESCRIPTION, DOOR CYLINDER LOCK SWITCH ...............8N-22

EXPORT - DESCRIPTION, POWER FOLDAWAY MIRROR SWITCH ..........8N-29

EXPORT - DESCRIPTION, QUARTER GLASS INTEGRAL ANTENNA ............8A-13

EXPORT - DOOR CYLINDER LOCK SWITCH ............................ 8N-22

EXPORT - INSTALLATION ...............5-68

EXPORT - INSTALLATION ...............2-11

EXPORT - INSTALLATION, HEADLAMP UNIT .............................. 8L-17

EXPORT - INSTALLATION, HOOD AJAR SWITCH ............................ 8Q-3

EXPORT - INSTALLATION, POWER FOLDAWAY MIRROR SWITCH ..........8N-30

EXPORT - OPERATION, ANTENNA MODULE ........................... 8A-10

EXPORT - OPERATION, DOOR CYLINDER LOCK SWITCH ....................... 8N-22

EXPORT - OPERATION, POWER FOLDAWAY MIRROR SWITCH ..........8N-29

EXPORT - OPERATION, QUARTER GLASS INTEGRAL ANTENNA .................. 8A-13

EXPORT - QUARTER GLASS INTEGRAL ANTENNA .......................... 8A-13

EXPORT - REMOVAL ................... 5-67

EXPORT - REMOVAL ................... 2-11

EXPORT - REMOVAL, HEADLAMP UNIT . . . 8L-17

EXPORT - REMOVAL, HOOD AJAR SWITCH ............................ 8Q-3

EXPORT - REMOVAL, POWER FOLDAWAY MIRROR SWITCH ..........8N-29

EXPORT - STANDARD PROCEDURE, FRONT FOG LAMP UNIT ALIGNMENT ......8L-9

EXPORT - STANDARD PROCEDURE, HEADLAMP UNIT ALIGNMENT ..........8L-15

EXTENSION, INSTALLATION - REAR A/C EVAPORATOR LINE .................. 24-100

EXTENSION, REMOVAL - REAR A/C EVAPORATOR LINE ................... 24-99

EXTENSION TRIM - INSTALLATION, A-PILLAR LOWER .................... 23-79

EXTENSION TRIM - REMOVAL, A-PILLAR LOWER ............................ 23-79

EXTERIOR - DESCRIPTION, LAMPS/ LIGHTING ........................... 8L-2

EXTERIOR - OPERATION, LAMPS/ LIGHTING ........................... 8L-2

EXTERIOR - WARNING, LAMPS/ LIGHTING ........................... 8L-3

EXTERIOR HANDLE - INSTALLATION .....23-22,

23-40

EXTERIOR HANDLE - REMOVAL ....23-21,23-40

EXTERIOR HANDLE SWITCH - DESCRIPTION ....................... 8N-10

EXTERIOR HANDLE SWITCH - INSTALLATION ...................... 8N-10

EXTERIOR HANDLE SWITCH - OPERATION ......................... 8N-10EXTERIOR HANDLE SWITCH - REMOVAL . . 8N-10

EXTERIOR LAMPS, SPECIFICATIONS

......8L-3

EXTERIOR NAME PLATES - ADHESIVE ATTACHED - INSTALLATION ............23-51

EXTERIOR NAME PLATES - ADHESIVE ATTACHED - REMOVAL ................23-51

EXTERIOR NAME PLATES - TAPE ATTACHED - INSTALLATION ............23-51

EXTERIOR NAME PLATES - TAPE ATTACHED - REMOVAL ................23-51

FACTOR SETTING - STANDARD PROCEDURE, PINION .................8E-15

FAILED PARK SWITCH - DIAGNOSIS AND TESTING ............................ 8R-2

FAN - DESCRIPTION, RADIATOR ..........7-29

FAN - INSTALLATION, RADIATOR .........7-30

FAN - OPERATION, RADIATOR ...........7-29

FAN - REMOVAL, RADIATOR .............7-30

FAN MOTOR - DIAGNOSIS AND TESTING, RADIATOR ................... 7-30

FAN RELAY - DESCRIPTION, RADIATOR ....7-31

FAN RELAY - INSTALLATION, RADIATOR . . . 7-31

FAN RELAY - OPERATION, RADIATOR ......7-31

FAN RELAY - REMOVAL, RADIATOR .......7-31

FASCIA - INSTALLATION, FRONT .........13-1

FASCIA - INSTALLATION, REAR ..........13-4

FASCIA - REMOVAL, FRONT .............13-1

FASCIA - REMOVAL, REAR ..............13-4

FASCIA - SCUFF PAD - INSTALLATION, REAR ............................... 13-5

FASCIA - SCUFF PAD - REMOVAL, REAR . . . 13-5

FASTENER TORQUE, SPECIFICATIONS - ABS ................................ 5-91

FASTENER TORQUE, SPECIFICATIONS - BRAKE ...............................5-9

FASTENER TORQUE, SPECIFICATIONS - COLUMN ........................... 19-17

FASTENER TORQUE, SPECIFICATIONS - FRONT SUSPENSION ...................2-3

FASTENER TORQUE, SPECIFICATIONS - POWER STEERING .................... 19-9

FASTENER TORQUE, SPECIFICATIONS - REAR SUSPENSION ................... 2-28

FEED CIRCUIT RESISTANCE TEST - DIAGNOSIS AND TESTING ..............8F-35

FEED CIRCUIT TEST - DIAGNOSIS AND TESTING ........................... 8F-36

FENDER - INSTALLATION, FRONT ........23-52

FENDER - REMOVAL, FRONT ...........23-51

FFV REPLACEMENT PARTS - DESCRIPTION ........................ 14-2

FILL - DIAGNOSIS AND TESTING, VEHICLE DOES NOT .................. 25-17

FILL DOOR - INSTALLATION, FUEL .......23-52

FILL DOOR - REMOVAL, FUEL ..........23-52

FILL DOOR BLOCKER LATCH - INSTALLATION, FUEL .................23-53

FILL DOOR BLOCKER LATCH - REMOVAL, FUEL ..................... 23-53

FILL DOOR BLOCKER LATCH STRIKER - INSTALLATION, FUEL .................23-53

FILL DOOR BLOCKER LATCH STRIKER - REMOVAL, FUEL ..................... 23-53

FILL DOOR BLOCKER LOCKOUT LINK - INSTALLATION, FUEL .................23-54

FILL DOOR BLOCKER LOCKOUT LINK - REMOVAL, FUEL ..................... 23-54

FILL/CHECK LOCATIONS - DESCRIPTION, FLUID ...............................0-7

FILLER CAP - DESCRIPTION, FUEL .......25-13

FILLER CAP - OPERATION, FUEL ........25-13

FILLER NECK SEAL - DIAGNOSIS AND TESTING, RADIATOR CAP TO ............7-28

FILLER TUBE - INSTALLATION, FUEL TANK .............................. 14-17

FILLER TUBE - REMOVAL, FUEL TANK ....14-16

FILLING - STANDARD PROCEDURE, COOLING SYSTEM .....................7-4

FILLING, STANDARD PROCEDURE - REAR HEATER CORE .................24-102

FILTER - DESCRIPTION, AIR ............24-42

FILTER - DESCRIPTION, OIL .............9-54

FILTER - INSTALLATION, AIR ...........24-43

FILTER - INSTALLATION, INLET ..........14-17

FILTER - INSTALLATION, OIL .......9-141,9-54

FILTER - REMOVAL, AIR ...............24-42

FILTER - REMOVAL, INLET .............14-17

FILTER - REMOVAL, OIL ...........9-141,9-54

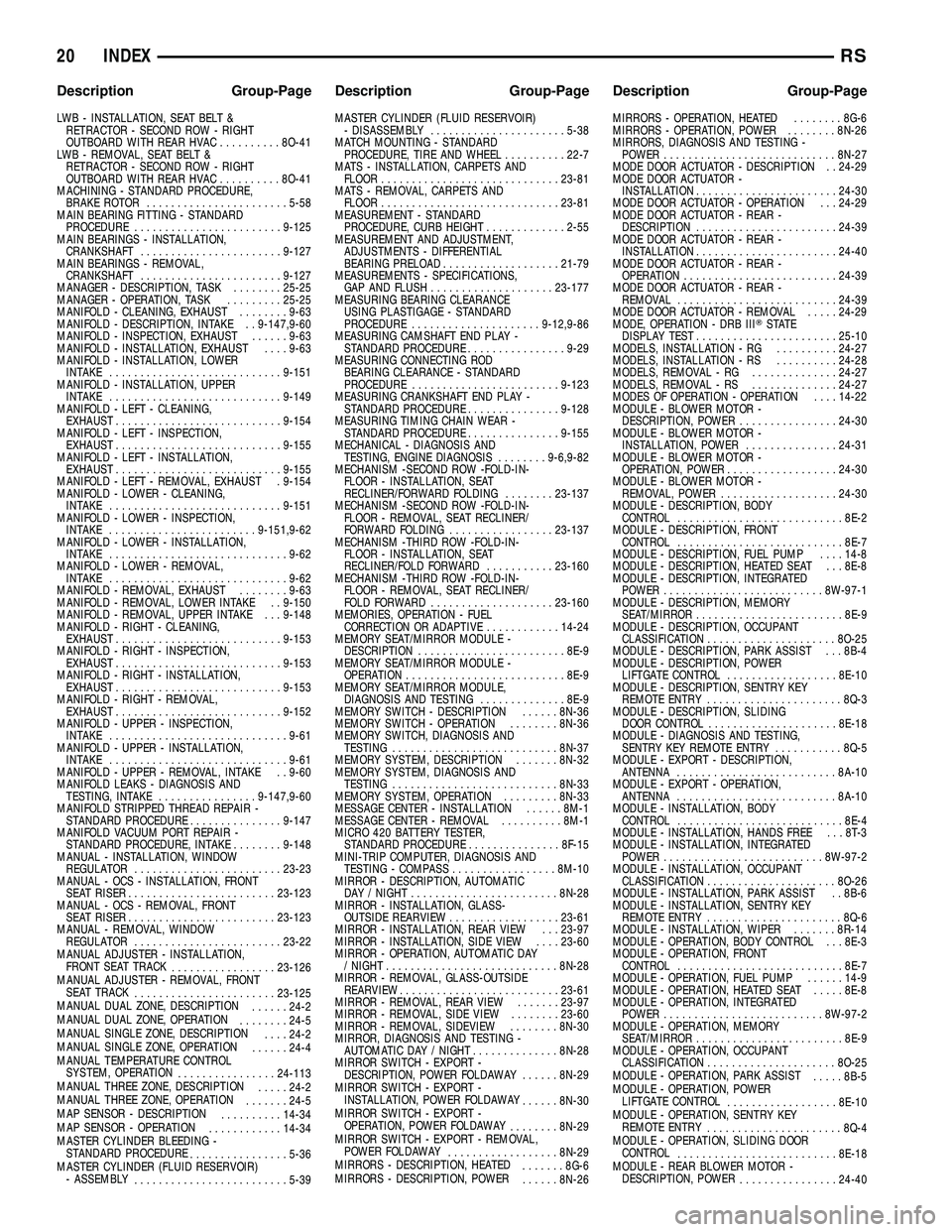

12 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2314 of 2339

FILTER ADAPTER - INSTALLATION, OIL . . . 9-142

FILTER ADAPTER - REMOVAL, OIL.......9-142

FILTER CHANGE - STANDARD PROCEDURE, ENGINE OIL ..........9-139,9-54

FILTER SERVICE - STANDARD PROCEDURE, FLUID ............21-231,21-82

FINAL DRIVE - ASSEMBLY .......21-224,21-78

FINAL DRIVE - DESCRIPTION .....21-219,21-74

FINAL DRIVE - DISASSEMBLY ....21-220,21-75

FINAL DRIVE - OPERATION .......21-220,21-75

FINESSE SANDING/BUFFING & POLISHING - DESCRIPTION ...........23-101

FINISH - DESCRIPTION, BASE COAT/CLEARCOAT ................... 23-101

FIRING ORDER, SPECIFICATIONS .........8I-3

FIRST ROW - BENCH - INSTALLATION, SEAT BELT BUCKLE .................. 8O-37

FIRST ROW - BENCH - REMOVAL, SEAT BELT BUCKLE ....................... 8O-36

FIRST ROW - OUTBOARD - INSTALLATION, SEAT BELT &

RETRACTOR ........................ 8O-40

FIRST ROW - OUTBOARD - REMOVAL, SEAT BELT & RETRACTOR .............8O-39

FIRST ROW INBOARD - QUAD BUCKET - INSTALLATION, SEAT BELT BUCKLE ......8O-36

FIRST ROW INBOARD - QUAD BUCKET - REMOVAL, SEAT BELT BUCKLE .........8O-35

FITTING - CONNECTING ROD ............9-46

FITTING - PISTON RING ................9-47

FITTING - STANDARD PROCEDURE, MAIN BEARING ...................... 9-125

FITTING - STANDARD PROCEDURE, PISTON RING ....................... 9-124

FITTING - STANDARD PROCEDURE, PISTON TO CYLINDER BORE ............9-44

FITTING CONNECTING RODS - STANDARD PROCEDURE ...............9-119

FITTING DISASSEMBLY/ASSEMBLY - STANDARD PROCEDURE,

TRANSMISSION COOLER LINE QUICK

CONNECT ............................ 7-38

FITTING PISTONS - STANDARD PROCEDURE ........................ 9-120

FITTINGS - STANDARD PROCEDURE, QUICK-CONNECT ..................... 14-18

FITTINGS, STANDARD PROCEDURE - HANDLING TUBING ................... 24-69

FLAP AND SPRING ASSEMBLY - INSTALLATION, QUAD BUCKET SEAT

SIDE SHIELD/CUP HOLDER ............23-151

FLAP AND SPRING ASSEMBLY - REMOVAL, QUAD BUCKET SEAT SIDE

SHIELD/CUP HOLDER ................23-151

FLEX DRIVE - DESCRIPTION ...........8N-55

FLEX DRIVE - INSTALLATION ...........8N-56

FLEX DRIVE - OPERATION .............8N-55

FLEX DRIVE - REMOVAL ...............8N-55

FLEX PLATE - INSTALLATION ...........9-133

FLEX PLATE - REMOVAL ...............9-133

FLEXIBLE FUEL ENGINE OIL - DESCRIPTION .........................0-3

FLOOR CONSOLE - FOLD-IN-FLOOR - INSTALLATION ....................... 23-89

FLOOR CONSOLE - FOLD-IN-FLOOR - REMOVAL .......................... 23-89

FLOOR CONSOLE BASE TRAY - INSTALLATION ....................... 23-89

FLOOR CONSOLE BASE TRAY - REMOVAL .......................... 23-89

FLOOR CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION ........23-90

FLOOR CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL ............23-90

FLOOR CONSOLE LID LATCH - FOLD-IN-FLOOR - INSTALLATION ........23-90

FLOOR CONSOLE LID LATCH - FOLD-IN-FLOOR - REMOVAL ............23-90

FLOOR DISTRIBUTION DUCTS - INSTALLATION ....................... 24-50

FLOOR DISTRIBUTION DUCTS - REMOVAL .......................... 24-50

FLOOR HEAT DUCT - INSTALLATION, REAR .............................. 24-63

FLOOR HEAT DUCT - REMOVAL, REAR . . . 24-63

FLOOR MATS - INSTALLATION, CARPETS . 23-81

FLOOR MATS - REMOVAL, CARPETS .....23-81 FLOOR TUB CARPET INSERT -

FOLD-IN-FLOOR - INSTALLATION,

SECOND ROW ....................... 23-98

FLOOR TUB CARPET INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND

ROW .............................. 23-98

FLOOR TUB CARPETS INSERT - FOLD-IN-FLOOR - INSTALLATION,

REAR .............................. 23-96

FLOOR TUB CARPETS INSERT - FOLD-IN-FLOOR - REMOVAL, REAR ......23-95

FLOW AND PRESSURE TEST - DIAGNOSIS AND TESTING, POWER

STEERING SYSTEM .................... 19-1

FLOW CHECK - DIAGNOSIS AND TESTING, COOLING SYSTEM .............7-3

FLUID - DESCRIPTION, AUTOMATIC/ MANUAL TRANSAXLE ...................0-4

FLUID - DESCRIPTION, AWD POWER TRANSFER UNIT .......................0-6

FLUID AND FILTER SERVICE - STANDARD PROCEDURE .........21-231,21-82

FLUID CAPACITIES - SPECIFICATIONS ......0-6

FLUID CONTAMINATION - DIAGNOSIS AND TESTING, BRAKE .................. 5-33

FLUID COOLER - DESCRIPTION .........19-45

FLUID COOLER - INSTALLATION .........19-45

FLUID COOLER - OPERATION ...........19-45

FLUID COOLER - REMOVAL ............19-45

FLUID FILL/CHECK LOCATIONS - DESCRIPTION .........................0-7

FLUID LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER

HOUSING ....................... 21-154,21-9

FLUID LEVEL AND CONDITION CHECK, STANDARD PROCEDURE .........21-230,21-82

FLUID LEVEL CHECKING - STANDARD PROCEDURE, BRAKE ................... 5-33

FLUID LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING ........19-44

FLUID LEVEL SWITCH - DESCRIPTION, BRAKE .............................. 5-10

FLUID LEVEL SWITCH - INSTALLATION, BRAKE .............................. 5-11

FLUID LEVEL SWITCH - INSTALLATION, WASHER ........................... 8R-11

FLUID LEVEL SWITCH - OPERATION, BRAKE .............................. 5-10

FLUID LEVEL SWITCH - REMOVAL, BRAKE .............................. 5-11

FLUID LEVEL SWITCH - REMOVAL, WASHER ........................... 8R-11

FLUID, SPECIFICATIONS - BRAKE .........5-33

FLUIDS - DESCRIPTION, AWD REAR DRIVELINE MODULE ....................0-6

FLUSH MEASUREMENTS - SPECIFICATIONS, GAP ................23-177

FOG LAMP - DIAGNOSIS AND TESTING, FRONT .............................. 8L-7

FOG LAMP - INSTALLATION, FRONT .......8L-8

FOG LAMP - REMOVAL, FRONT ..........8L-8

FOG LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT ........8L-9

FOG LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT .........8L-9

FOLDAWAY MIRROR SWITCH - EXPORT - DESCRIPTION, POWER ..............8N-29

FOLDAWAY MIRROR SWITCH - EXPORT - INSTALLATION, POWER ..............8N-30

FOLDAWAY MIRROR SWITCH - EXPORT - OPERATION, POWER ................8N-29

FOLDAWAY MIRROR SWITCH - EXPORT - REMOVAL, POWER .................. 8N-29

FOLD-IN-FLOOR - INSTALLATION . . . 14-10,14-16

FOLD-IN-FLOOR - INSTALLATION, ARMREST - SECOND ROW ............23-130

FOLD-IN-FLOOR - INSTALLATION, ARMREST ROTATING ASSEMBLY -

SECOND ROW ...................... 23-130

FOLD-IN-FLOOR - INSTALLATION, BOTTOM OF SEAT CUSHION PAN

PANEL-THIRD ROW .................. 23-152

FOLD-IN-FLOOR - INSTALLATION, CARPET TRIM RING AND COVER ........23-84

FOLD-IN-FLOOR - INSTALLATION, CARPETS ........................... 23-83

FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........................... 23-89FOLD-IN-FLOOR - INSTALLATION, FLOOR

CONSOLE KEY LOCK TUMBLER .........23-90

FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID LATCH .................23-90

FOLD-IN-FLOOR - INSTALLATION, HEADREST SLEEVE - SECOND ROW .....23-131

FOLD-IN-FLOOR - INSTALLATION, HEADREST SLEEVE - THIRD ROW ......23-153

FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR TUB CARPETS INSERT ..........23-96

FOLD-IN-FLOOR - INSTALLATION, SEAT - SECOND ROW ...................... 23-132

FOLD-IN-FLOOR - INSTALLATION, SEAT - THIRD ROW ........................ 23-154

FOLD-IN-FLOOR - INSTALLATION, SEAT BACK COVER/FOAM - SECOND ROW ....23-133

FOLD-IN-FLOOR - INSTALLATION, SEAT BACK COVER/FOAM - THIRD ROW ......23-156

FOLD-IN-FLOOR - INSTALLATION, SEAT BACK FRAME - SECOND ROW .........23-134

FOLD-IN-FLOOR - INSTALLATION, SEAT BACK FRAME - THIRD ROW ...........23-157

FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW STRAP - THIRD ROW ......23-158

FOLD-IN-FLOOR - INSTALLATION, SEAT BASE RISER - SECOND ROW ..........23-135

FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER LAP BELT ..............23-157

FOLD-IN-FLOOR - INSTALLATION, SEAT CUSHION COVER/FOAM - THIRD ROW . . . 23-159

FOLD-IN-FLOOR - INSTALLATION, SEAT CUSHION COVER/FOAM -SECOND

ROW ............................. 23-136

FOLD-IN-FLOOR - INSTALLATION, SEAT CUSHION SIDE SHIELD - SECOND

ROW ............................. 23-138

FOLD-IN-FLOOR - INSTALLATION, SEAT GAS STRUT - SECOND ROW ...........23-139

FOLD-IN-FLOOR - INSTALLATION, SEAT PROP ROD - SECOND ROW ...........23-140

FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR TUB CARPET

INSERT ............................ 23-98

FOLD-IN-FLOOR - INSTALLATION, SIDE SHIELD CUP HOLDER ................23-160

FOLD-IN-FLOOR - INSTALLATION, WITH NVLD .............................. 25-20

FOLD-IN-FLOOR - REMOVAL .......14-10,14-13

FOLD-IN-FLOOR - REMOVAL, ARMREST - SECOND ROW ..................... 23-130

FOLD-IN-FLOOR - REMOVAL, ARMREST ROTATING ASSEMBLY - SECOND ROW . . 23-130

FOLD-IN-FLOOR - REMOVAL, BOTTOM OF SEAT CUSHION PAN PANEL-THIRD

ROW ............................. 23-152

FOLD-IN-FLOOR - REMOVAL, CARPET TRIM RING AND COVER ...............23-84

FOLD-IN-FLOOR - REMOVAL, CARPETS . . . 23-82

FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ........................... 23-89

FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE KEY LOCK TUMBLER .........23-90

FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID LATCH .................23-90

FOLD-IN-FLOOR - REMOVAL, HEADREST SLEEVE - SECOND ROW ..............23-131

FOLD-IN-FLOOR - REMOVAL, HEADREST SLEEVE - THIRD ROW ...............23-152

FOLD-IN-FLOOR - REMOVAL, REAR FLOOR TUB CARPETS INSERT ..........23-95

FOLD-IN-FLOOR - REMOVAL, SEAT - SECOND ROW ...................... 23-132

FOLD-IN-FLOOR - REMOVAL, SEAT - THIRD ROW ........................ 23-153

FOLD-IN-FLOOR - REMOVAL, SEAT BACK COVER/FOAM - SECOND ROW .........23-133

FOLD-IN-FLOOR - REMOVAL, SEAT BACK COVER/FOAM - THIRD ROW ...........23-155

FOLD-IN-FLOOR - REMOVAL, SEAT BACK FRAME - SECOND ROW ..............23-134

FOLD-IN-FLOOR - REMOVAL, SEAT BACK FRAME - THIRD ROW ................23-156

FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW STRAP - THIRD ROW ......23-158

FOLD-IN-FLOOR - REMOVAL, SEAT BASE RISER - SECOND ROW ...............23-134

FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER LAP BELT ................... 23-157

RS INDEX13

Description Group-Page Description Group-Page Description Group-Page

Page 2319 of 2339

INTERMEDIATE - INSTALLATION, CABLE- PARKING BRAKE ..................... 5-69

INTERMEDIATE - REMOVAL, CABLE - PARKING BRAKE ...................... 5-69

INTERNATIONAL SYMBOLS - DESCRIPTION .........................0-1

INTRODUCTION - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-3,9-78

IOD FUSE - DESCRIPTION ...........8W-97-3

IOD FUSE - OPERATION .............8W-97-3

JOINT - DESCRIPTION, LOWER BALL ......2-10

JOINT - DIAGNOSIS AND TESTING, LOWER BALL ........................ 2-10

JOINT - OPERATION, LOWER BALL .......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-60

JOINT MOLDING - REMOVAL, ROOF ......23-60

JOUNCE BUMPER - DESCRIPTION ........2-35

JOUNCE BUMPER - OPERATION ..........2-35

JUMP STARTING - STANDARD PROCEDURE ......................... 0-25

JUNCTION BLOCK - DESCRIPTION, NON-ABS ............................ 5-33

JUNCTION BLOCK - INSTALLATION, NON-ABS ............................ 5-34

JUNCTION BLOCK - OPERATION, NON-ABS ............................ 5-33

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-34

KEY - DESCRIPTION, TRANSPONDER .....8Q-6

KEY - OPERATION, TRANSPONDER .......8Q-6

KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

KEY REMOTE ENTRY MODULE - DESCRIPTION, SENTRY ................8Q-3

KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY .......8Q-5

KEY REMOTE ENTRY MODULE - INSTALLATION, SENTRY ................8Q-6

KEY REMOTE ENTRY MODULE - OPERATION, SENTRY .................. 8Q-4

KEY REMOTE ENTRY MODULE - REMOVAL, SENTRY ................... 8Q-6

KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY .......8Q-3

KEYLESS ENTRY TRANSMITTER, DIAGNOSIS AND TESTING .............8N-24

KEYLESS ENTRY TRANSMITTER PROGRAMMING - STANDARD

PROCEDURE, REMOTE ................8N-24

KEY/LOCK CYLINDER - DESCRIPTION ....19-20

KEY/LOCK CYLINDER - INSTALLATION ....19-20

KEY/LOCK CYLINDER - OPERATION ......19-20

KEY/LOCK CYLINDER - REMOVAL .......19-20

KNEE - INSTALLATION, BLOCKER- INFLATABLE ......................... 23-75

KNEE - REMOVAL, BLOCKER- INFLATABLE ......................... 23-75

KNEE BLOCKER AIRBAG - DESCRIPTION . . 8O-22

KNEE BLOCKER AIRBAG - INSTALLATION . 8O-23

KNEE BLOCKER AIRBAG - OPERATION . . . 8O-22

KNEE BLOCKER AIRBAG - REMOVAL .....8O-23

KNOB - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

KNOB - REMOVAL, SEAT BELT HEIGHT ADJUSTER ......................... 8O-38

KNOCK SENSOR - DESCRIPTION ..........8I-8

KNOCK SENSOR - OPERATION ...........8I-8

KNUCKLE - DESCRIPTION ................2-6

KNUCKLE - INSPECTION, STEERING ........2-9

KNUCKLE - INSTALLATION, STEERING ......2-9

KNUCKLE - OPERATION .................2-7

KNUCKLE - REMOVAL, STEERING .........2-7

LABEL, DESCRIPTION - VEHICLE EMISSION CONTROL INFORMATION .......25-1

LAMP - DESCRIPTION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - DIAGNOSIS AND TESTING, FRONT FOG .......................... 8L-7

LAMP - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP - INSTALLATION, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - INSTALLATION, COURTESY ......8L-21

LAMP - INSTALLATION, DOME/CARGO ....8L-22

LAMP - INSTALLATION, FRONT FOG .......8L-8

LAMP - INSTALLATION, LICENSE ........8L-17

LAMP - INSTALLATION, LIFTGATE .......8L-22 LAMP - INSTALLATION, PARK/TURN

SIGNAL ............................ 8L-18

LAMP - INSTALLATION, READING ........8L-23

LAMP - INSTALLATION, TAIL ...........8L-19

LAMP - INSTALLATION, VANITY .........8L-24

LAMP - OPERATION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - REMOVAL, CENTER CONSOLE ....8L-21

LAMP - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - REMOVAL, COURTESY ..........8L-21

LAMP - REMOVAL, DOME/CARGO .......8L-22

LAMP - REMOVAL, FRONT FOG ..........8L-8

LAMP - REMOVAL, LICENSE ............8L-17

LAMP - REMOVAL, LIFTGATE ...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING ...........8L-22

LAMP - REMOVAL, TAIL ...............8L-18

LAMP - REMOVAL, VANITY .............8L-24

LAMP SWITCH - DESCRIPTION, BRAKE ....8L-4

LAMP SWITCH - DIAGNOSIS AND TESTING, BRAKE ...................... 8L-4

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - INSTALLATION, GLOVE BOX ............................... 8L-22

LAMP SWITCH - OPERATION, BRAKE ......8L-4

LAMP SWITCH - REMOVAL, BRAKE .......8L-5

LAMP SWITCH - REMOVAL, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP .................8L-6

LAMP UNIT - INSTALLATION, TAIL .......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP UNIT - REMOVAL, TAIL ...........8L-19

LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG .....8L-9

LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG ...............8L-9

LAMPS - INSTALLATION, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS - REMOVAL, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS, SPECIFICATIONS - EXTERIOR .....8L-3

LAMPS, SPECIFICATIONS - INTERIOR ....8L-20

LAMPS/LIGHTING - EXTERIOR - DESCRIPTION ........................ 8L-2

LAMPS/LIGHTING - EXTERIOR - OPERATION .......................... 8L-2

LAMPS/LIGHTING - EXTERIOR - WARNING ........................... 8L-3

LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER .....23-157

LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER .................. 23-157

LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND TESTING, HYDRAULIC ....9-34

LASH ADJUSTERS - INSTALLATION, HYDRAULIC .......................... 9-35

LASH ADJUSTERS - REMOVAL, HYDRAULIC .......................... 9-35

LATCH - DESCRIPTION ...........8N-12,8N-49

LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID ....23-90

LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID .................23-90

LATCH - INSTALLATION .....23-18,23-41,23-63

LATCH - INSTALLATION ..........8N-13,8N-50

LATCH - INSTALLATION, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH - INSTALLATION, GLOVE BOX .....23-66

LATCH - INSTALLATION, HOLD OPEN .....23-25

LATCH / LOCK ASSEMBLY - INSTALLATION ....................... 23-27

LATCH / LOCK ASSEMBLY - REMOVAL ....23-26

LATCH - OPERATION ............8N-12,8N-49

LATCH - REMOVAL .........23-18,23-41,23-63

LATCH - REMOVAL ..............8N-12,8N-49

LATCH - REMOVAL, FUEL FILL DOOR BLOCKER ........................... 23-53

LATCH - REMOVAL, GLOVE BOX .........23-66

LATCH - REMOVAL, HOLD OPEN ........23-25

LATCH ACTUATOR - DESCRIPTION ......8N-13

LATCH ACTUATOR - INSTALLATION ......8N-14

LATCH ACTUATOR - OPERATION ........8N-13 LATCH ACTUATOR - REMOVAL

..........8N-13

LATCH CABLE - INSTALLATION, HOLD OPEN .............................. 23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE .....23-34

LATCH LOCKING LINK - INSTALLATION, SEAT RISER ........................ 23-151

LATCH LOCKING LINK - REMOVAL, SEAT RISER ............................ 23-151

LATCH RELEASE CABLE - INSTALLATION . . 23-64

LATCH RELEASE CABLE - REMOVAL .....23-63

LATCH STRIKER - INSTALLATION . . 23-19,23-42, 23-64

LATCH STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-53

LATCH STRIKER - INSTALLATION, GLOVE BOX ............................... 23-66

LATCH STRIKER - INSTALLATION, HOLD OPEN .............................. 23-26

LATCH STRIKER - INSTALLATION, REAR . . 23-29

LATCH STRIKER - REMOVAL . 23-19,23-41,23-64

LATCH STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH STRIKER - REMOVAL, GLOVE BOX ............................... 23-66

LATCH STRIKER - REMOVAL, HOLD OPEN .............................. 23-26

LATCH STRIKER - REMOVAL, REAR ......23-29

LEAD - DIAGNOSIS AND TESTING, TIRE/VEHICLE ......................... 22-14

LEAF SPRING FRONT - INSTALLATION, BUSHING ............................ 2-30

LEAF SPRING FRONT - REMOVAL, BUSHING ............................ 2-29

LEAK DETECTION ASSY - INSTALLATION, NATURAL VAC ....................... 25-14

LEAK DETECTION ASSY - REMOVAL, NATURAL VAC ....................... 25-14

LEAK DETECTION PUMP - INSTALLATION . 25-15

LEAK DETECTION PUMP - REMOVAL .....25-15

LEAK INSPECTION - DIAGNOSIS AND TESTING, ENGINE OIL ...............9-8,9-84

LEAK REPAIRING - STANDARD PROCEDURE, TIRE ................... 22-17

LEAK TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM .....................7-2

LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER HOUSING FLUID . . 21-154, 21-9

LEAKAGE TEST - DIAGNOSIS AND TESTING, CYLINDER COMBUSTION

PRESSURE ....................... 9-85,9-9

LEAKS - DIAGNOSIS AND TESTING, INTAKE MANIFOLD ...............9-147,9-60

LEAKS, DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM ...............24-67

LEAKS, DIAGNOSIS AND TESTING - WATER ............................. 23-1

LEARN CYCLE, STANDARD PROCEDURE - POWER LIFTGATE ................... 8N-8

LEARN CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR ..............8N-48

LEARN PROCEDURE - STANDARD PROCEDURE, QUICK .................. 8E-15

LENS - INSTALLATION, CLUSTER ........8J-11

LENS - REMOVAL, CLUSTER ............8J-11

LEVEL AND CONDITION CHECK, STANDARD PROCEDURE - FLUID . . 21-230,21-82

LEVEL CHECK - STANDARD PROCEDURE, COOLANT .................7-4

LEVEL CHECK - STANDARD PROCEDURE, ENGINE OIL ..............9-140

LEVEL CHECK, STANDARD PROCEDURE - ENGINE OIL ........................ 9-54

LEVEL CHECKING - STANDARD PROCEDURE, BRAKE FLUID .............5-33

LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID . . . 19-44

LEVEL SENDING UNIT / SENSOR - DESCRIPTION, FUEL ................... 14-5

LEVEL SENDING UNIT / SENSOR - INSTALLATION, FUEL .................. 14-6

LEVEL SENDING UNIT / SENSOR - OPERATION, FUEL ..................... 14-5

LEVEL SENDING UNIT / SENSOR - REMOVAL, FUEL ...................... 14-5

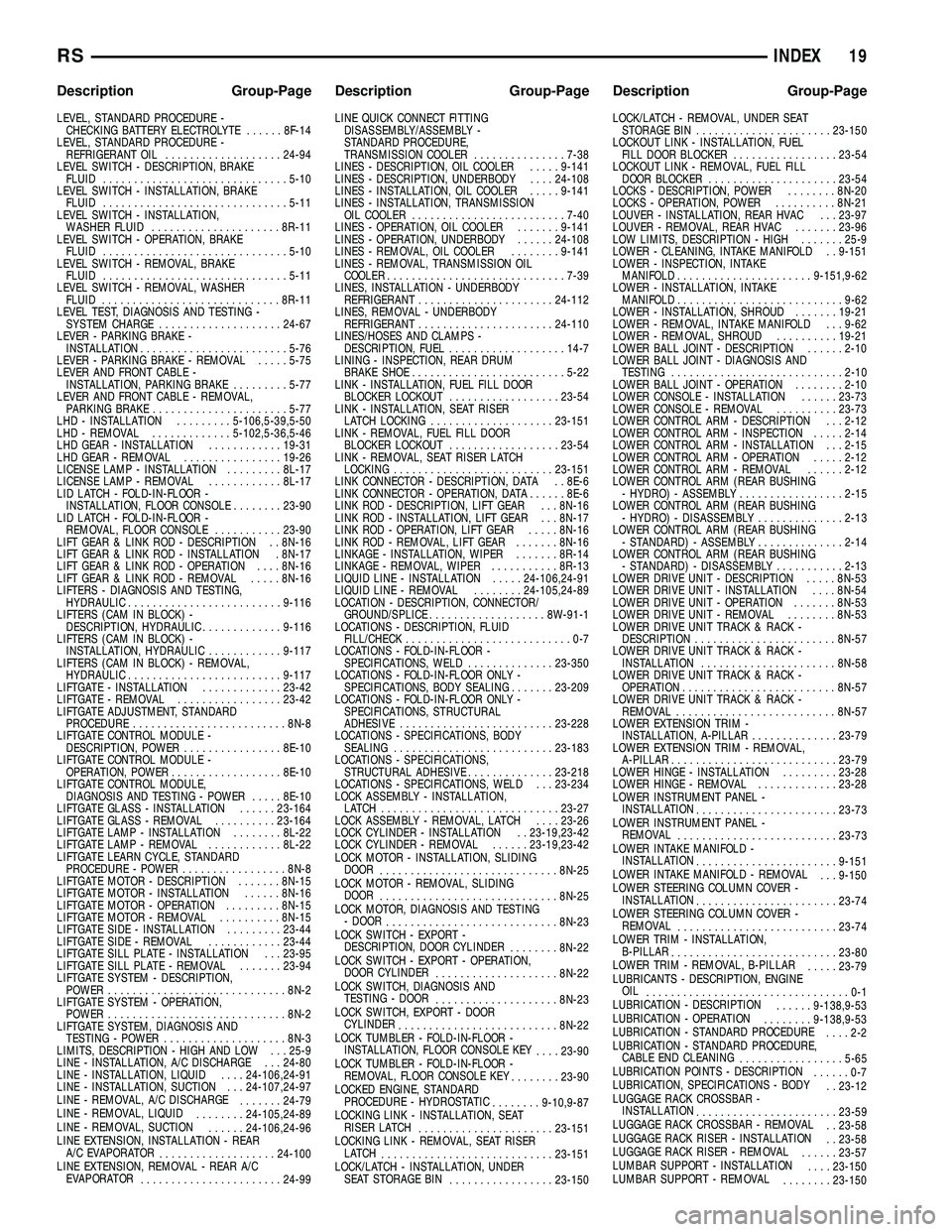

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2320 of 2339

LEVEL, STANDARD PROCEDURE -CHECKING BATTERY ELECTROLYTE ......8F-14

LEVEL, STANDARD PROCEDURE - REFRIGERANT OIL ................... 24-94

LEVEL SWITCH - DESCRIPTION, BRAKE FLUID .............................. 5-10

LEVEL SWITCH - INSTALLATION, BRAKE FLUID .............................. 5-11

LEVEL SWITCH - INSTALLATION, WASHER FLUID ..................... 8R-11

LEVEL SWITCH - OPERATION, BRAKE FLUID .............................. 5-10

LEVEL SWITCH - REMOVAL, BRAKE FLUID .............................. 5-11

LEVEL SWITCH - REMOVAL, WASHER FLUID ............................. 8R-11

LEVEL TEST, DIAGNOSIS AND TESTING - SYSTEM CHARGE .................... 24-67

LEVER - PARKING BRAKE - INSTALLATION ........................ 5-76

LEVER - PARKING BRAKE - REMOVAL .....5-75

LEVER AND FRONT CABLE - INSTALLATION, PARKING BRAKE .........5-77

LEVER AND FRONT CABLE - REMOVAL, PARKING BRAKE ...................... 5-77

LHD - INSTALLATION .........5-106,5-39,5-50

LHD - REMOVAL .............5-102,5-36,5-46

LHD GEAR - INSTALLATION ............19-31

LHD GEAR - REMOVAL ................19-26

LICENSE LAMP - INSTALLATION .........8L-17

LICENSE LAMP - REMOVAL ............8L-17

LID LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

LID LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

LIFT GEAR & LINK ROD - DESCRIPTION . . 8N-16

LIFT GEAR & LINK ROD - INSTALLATION . 8N-17

LIFT GEAR & LINK ROD - OPERATION ....8N-16

LIFT GEAR & LINK ROD - REMOVAL .....8N-16

LIFTERS - DIAGNOSIS AND TESTING, HYDRAULIC ......................... 9-116

LIFTERS (CAM IN BLOCK) - DESCRIPTION, HYDRAULIC .............9-116

LIFTERS (CAM IN BLOCK) - INSTALLATION, HYDRAULIC ............9-117

LIFTERS (CAM IN BLOCK) - REMOVAL, HYDRAULIC ......................... 9-117

LIFTGATE - INSTALLATION .............23-42

LIFTGATE - REMOVAL .................23-42

LIFTGATE ADJUSTMENT, STANDARD PROCEDURE ......................... 8N-8

LIFTGATE CONTROL MODULE - DESCRIPTION, POWER ................8E-10

LIFTGATE CONTROL MODULE - OPERATION, POWER .................. 8E-10

LIFTGATE CONTROL MODULE, DIAGNOSIS AND TESTING - POWER .....8E-10

LIFTGATE GLASS - INSTALLATION ......23-164

LIFTGATE GLASS - REMOVAL ..........23-164

LIFTGATE LAMP - INSTALLATION ........8L-22

LIFTGATE LAMP - REMOVAL ............8L-22

LIFTGATE LEARN CYCLE, STANDARD PROCEDURE - POWER .................8N-8

LIFTGATE MOTOR - DESCRIPTION .......8N-15

LIFTGATE MOTOR - INSTALLATION ......8N-16

LIFTGATE MOTOR - OPERATION .........8N-15

LIFTGATE MOTOR - REMOVAL ..........8N-15

LIFTGATE SIDE - INSTALLATION .........23-44

LIFTGATE SIDE - REMOVAL ............23-44

LIFTGATE SILL PLATE - INSTALLATION . . . 23-95

LIFTGATE SILL PLATE - REMOVAL .......23-94

LIFTGATE SYSTEM - DESCRIPTION, POWER ............................. 8N-2

LIFTGATE SYSTEM - OPERATION, POWER ............................. 8N-2

LIFTGATE SYSTEM, DIAGNOSIS AND TESTING - POWER .................... 8N-3

LIMITS, DESCRIPTION - HIGH AND LOW . . . 25-9

LINE - INSTALLATION, A/C DISCHARGE . . . 24-80

LINE - INSTALLATION, LIQUID ....24-106,24-91

LINE - INSTALLATION, SUCTION . . . 24-107,24-97

LINE - REMOVAL, A/C DISCHARGE .......24-79

LINE - REMOVAL, LIQUID ........24-105,24-89

LINE - REMOVAL, SUCTION ......24-106,24-96

LINE EXTENSION, INSTALLATION - REAR A/C EVAPORATOR ................... 24-100

LINE EXTENSION, REMOVAL - REAR A/C EVAPORATOR ....................... 24-99LINE QUICK CONNECT FITTING

DISASSEMBLY/ASSEMBLY -

STANDARD PROCEDURE,

TRANSMISSION COOLER ...............7-38

LINES - DESCRIPTION, OIL COOLER .....9-141

LINES - DESCRIPTION, UNDERBODY ....24-108

LINES - INSTALLATION, OIL COOLER .....9-141

LINES - INSTALLATION, TRANSMISSION OIL COOLER ......................... 7-40

LINES - OPERATION, OIL COOLER .......9-141

LINES - OPERATION, UNDERBODY ......24-108

LINES - REMOVAL, OIL COOLER ........9-141

LINES - REMOVAL, TRANSMISSION OIL COOLER ............................. 7-39

LINES, INSTALLATION - UNDERBODY REFRIGERANT ...................... 24-112

LINES, REMOVAL - UNDERBODY REFRIGERANT ...................... 24-110

LINES/HOSES AND CLAMPS - DESCRIPTION, FUEL ................... 14-7

LINING - INSPECTION, REAR DRUM BRAKE SHOE ......................... 5-22

LINK - INSTALLATION, FUEL FILL DOOR BLOCKER LOCKOUT .................. 23-54

LINK - INSTALLATION, SEAT RISER LATCH LOCKING .................... 23-151

LINK - REMOVAL, FUEL FILL DOOR BLOCKER LOCKOUT .................. 23-54

LINK - REMOVAL, SEAT RISER LATCH LOCKING .......................... 23-151

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-6

LINK CONNECTOR - OPERATION, DATA ......8E-6

LINK ROD - DESCRIPTION, LIFT GEAR . . . 8N-16

LINK ROD - INSTALLATION, LIFT GEAR . . . 8N-17

LINK ROD - OPERATION, LIFT GEAR .....8N-16

LINK ROD - REMOVAL, LIFT GEAR .......8N-16

LINKAGE - INSTALLATION, WIPER .......8R-14

LINKAGE - REMOVAL, WIPER ...........8R-13

LIQUID LINE - INSTALLATION .....24-106,24-91

LIQUID LINE - REMOVAL ........24-105,24-89

LOCATION - DESCRIPTION, CONNECTOR/ GROUND/SPLICE ...................8W -91-1

LOCATIONS - DESCRIPTION, FLUID FILL/CHECK ...........................0-7

LOCATIONS - FOLD-IN-FLOOR - SPECIFICATIONS, WELD ..............23-350

LOCATIONS - FOLD-IN-FLOOR ONLY - SPECIFICATIONS, BODY SEALING .......23-209

LOCATIONS - FOLD-IN-FLOOR ONLY - SPECIFICATIONS, STRUCTURAL

ADHESIVE ......................... 23-228

LOCATIONS - SPECIFICATIONS, BODY SEALING .......................... 23-183

LOCATIONS - SPECIFICATIONS, STRUCTURAL ADHESIVE ..............23-218

LOCATIONS - SPECIFICATIONS, WELD . . . 23-234

LOCK ASSEMBLY - INSTALLATION, LATCH ............................. 23-27

LOCK ASSEMBLY - REMOVAL, LATCH ....23-26

LOCK CYLINDER - INSTALLATION . . 23-19,23-42

LOCK CYLINDER - REMOVAL ......23-19,23-42

LOCK MOTOR - INSTALLATION, SLIDING DOOR ............................. 8N-25

LOCK MOTOR - REMOVAL, SLIDING DOOR ............................. 8N-25

LOCK MOTOR, DIAGNOSIS AND TESTING - DOOR ............................ 8N-23

LOCK SWITCH - EXPORT - DESCRIPTION, DOOR CYLINDER ........8N-22

LOCK SWITCH - EXPORT - OPERATION, DOOR CYLINDER .................... 8N-22

LOCK SWITCH, DIAGNOSIS AND TESTING - DOOR .................... 8N-23

LOCK SWITCH, EXPORT - DOOR CYLINDER .......................... 8N-22

LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE KEY ....23-90

LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE KEY ........23-90

LOCKED ENGINE, STANDARD PROCEDURE - HYDROSTATIC ........9-10,9-87

LOCKING LINK - INSTALLATION, SEAT RISER LATCH ...................... 23-151

LOCKING LINK - REMOVAL, SEAT RISER LATCH ............................ 23-151

LOCK/LATCH - INSTALLATION, UNDER SEAT STORAGE BIN .................23-150LOCK/LATCH - REMOVAL, UNDER SEAT

STORAGE BIN ...................... 23-150

LOCKOUT LINK - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-54

LOCKOUT LINK - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-54

LOCKS - DESCRIPTION, POWER ........8N-20

LOCKS - OPERATION, POWER ..........8N-21

LOUVER - INSTALLATION, REAR HVAC . . . 23-97

LOUVER - REMOVAL, REAR HVAC .......23-96

LOW LIMITS, DESCRIPTION - HIGH .......25-9

LOWER - CLEANING, INTAKE MANIFOLD . . 9-151

LOWER - INSPECTION, INTAKE MANIFOLD ...................... 9-151,9-62

LOWER - INSTALLATION, INTAKE MANIFOLD ........................... 9-62

LOWER - INSTALLATION, SHROUD .......19-21

LOWER - REMOVAL, INTAKE MANIFOLD . . . 9-62

LOWER - REMOVAL, SHROUD ..........19-21

LOWER BALL JOINT - DESCRIPTION ......2-10

LOWER BALL JOINT - DIAGNOSIS AND TESTING ............................ 2-10

LOWER BALL JOINT - OPERATION ........2-10

LOWER CONSOLE - INSTALLATION ......23-73

LOWER CONSOLE - REMOVAL ..........23-73

LOWER CONTROL ARM - DESCRIPTION . . . 2-12

LOWER CONTROL ARM - INSPECTION .....2-14

LOWER CONTROL ARM - INSTALLATION . . . 2-15

LOWER CONTROL ARM - OPERATION .....2-12

LOWER CONTROL ARM - REMOVAL ......2-12

LOWER CONTROL ARM (REAR BUSHING - HYDRO) - ASSEMBLY .................2-15

LOWER CONTROL ARM (REAR BUSHING - HYDRO) - DISASSEMBLY ..............2-13

LOWER CONTROL ARM (REAR BUSHING - STANDARD) - ASSEMBLY ..............2-14

LOWER CONTROL ARM (REAR BUSHING - STANDARD) - DISASSEMBLY ...........2-13

LOWER DRIVE UNIT - DESCRIPTION .....8N-53

LOWER DRIVE UNIT - INSTALLATION ....8N-54

LOWER DRIVE UNIT - OPERATION .......8N-53

LOWER DRIVE UNIT - REMOVAL ........8N-53

LOWER DRIVE UNIT TRACK & RACK - DESCRIPTION ....................... 8N-57

LOWER DRIVE UNIT TRACK & RACK - INSTALLATION ...................... 8N-58

LOWER DRIVE UNIT TRACK & RACK - OPERATION ......................... 8N-57

LOWER DRIVE UNIT TRACK & RACK - REMOVAL .......................... 8N-57

LOWER EXTENSION TRIM - INSTALLATION, A-PILLAR ..............23-79

LOWER EXTENSION TRIM - REMOVAL, A-PILLAR ........................... 23-79

LOWER HINGE - INSTALLATION .........23-28

LOWER HINGE - REMOVAL .............23-28

LOWER INSTRUMENT PANEL - INSTALLATION ....................... 23-73

LOWER INSTRUMENT PANEL - REMOVAL .......................... 23-73

LOWER INTAKE MANIFOLD - INSTALLATION ....................... 9-151

LOWER INTAKE MANIFOLD - REMOVAL . . . 9-150

LOWER STEERING COLUMN COVER - INSTALLATION ....................... 23-74

LOWER STEERING COLUMN COVER - REMOVAL .......................... 23-74

LOWER TRIM - INSTALLATION, B-PILLAR ........................... 23-80

LOWER TRIM - REMOVAL, B-PILLAR .....23-79

LUBRICANTS - DESCRIPTION, ENGINE OIL .................................0-1