wiring CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 457 of 2339

that axis may have an open, short or be incorrectly

connected. Check the wiring to that axis (module to

motor). Repair any wiring problems and retry that

axis. Refer to the appropriate wiring information for

complete circuit schematic or connector pin-out infor-

mation.

SEAT SWITCH

DESCRIPTION

Vehicles equipped with a driver side power seat

utilize an eight-way power seat switch. Vehicles

equipped with a passenger side power seat utilize a

four-way power seat switch. These power seat

switches features two knobs ganged together on the

outboard seat cushion side shield (Fig. 2).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS AND TESTING

DRIVER SEAT SWITCH

(1) Remove the power seat switch, (Refer to 8 -

ELECTRICAL/POWER SEATS/DRIVER SEAT

SWITCH - REMOVAL).

(2) Using an ohmmeter, check pin #1 of the power

seat switch wire harness connector for continuity to

ground. It should be present. If OK, go to Step 3. If

not OK, repair the open ground circuit as required.

(3) Using a voltmeter, check pin #5 of the power

seat switch wire harness connector for battery cur-

rent. It should be present. If OK, go to Step 4. If not

OK, repair the open voltage supply circuit as

required.

(4) Using an ohmmeter, test the power seat switch

for continuity, refer to SEAT SWITCH CONTINUITY

TEST TABLE (Fig. 3). If continuity is not present as

indicated, replace the power seat switch.

Fig. 2 POWER SEAT SWITCH LOCATION

1 - POWER SEAT SWITCH

2 - SEAT CUSHION SIDE SHIELD

8N - 34 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

Page 463 of 2339

POWER SLIDING DOOR SYSTEM

TABLE OF CONTENTS

page page

POWER SLIDING DOOR SYSTEM

DESCRIPTION.........................40

OPERATION...........................41

DIAGNOSIS AND TESTING

POWER SLIDING DOOR SYSTEM........42

STANDARD PROCEDURE

POWER SLIDING DOOR LEARN CYCLE....48

PUSH-PIN GROMMET REPLACEMENT.....48

POWER SLIDING DOOR ADJUSTMENT....49

LATCH

DESCRIPTION.........................49

OPERATION...........................49

REMOVAL.............................49

INSTALLATION.........................50

SLIDING DOOR MOTOR

DESCRIPTION.........................51

OPERATION...........................51

REMOVAL.............................51

INSTALLATION.........................51

FULL OPEN SWITCH

DESCRIPTION.........................52

OPERATION...........................52

B-PILLAR SWITCH

DESCRIPTION.........................52OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................52

LOWER DRIVE UNIT

DESCRIPTION.........................53

OPERATION...........................53

REMOVAL.............................53

INSTALLATION.........................54

FLEX DRIVE

DESCRIPTION.........................55

OPERATION...........................55

REMOVAL.............................55

INSTALLATION.........................56

LOWER DRIVE UNIT TRACK & RACK

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL.............................57

INSTALLATION.........................58

WIRING HARNESS

DESCRIPTION.........................59

OPERATION...........................59

REMOVAL.............................59

INSTALLATION.........................59

POWER SLIDING DOOR

SYSTEM

DESCRIPTION

Some vehicles are equipped with a power sliding

door system. Vehicles may be equipped with only a

right side power sliding door or a right and left side

power sliding doors. The components of the power

sliding door system are:

²Door motor assembly

²Latch assembly

²Sliding door control module

²Lower drive unit assembly

²Flex drive assembly

²Wire harness and track

²Lower drive unit track and rack assembly

²Full open switch

²B-pillar switch

²Overhead console switch

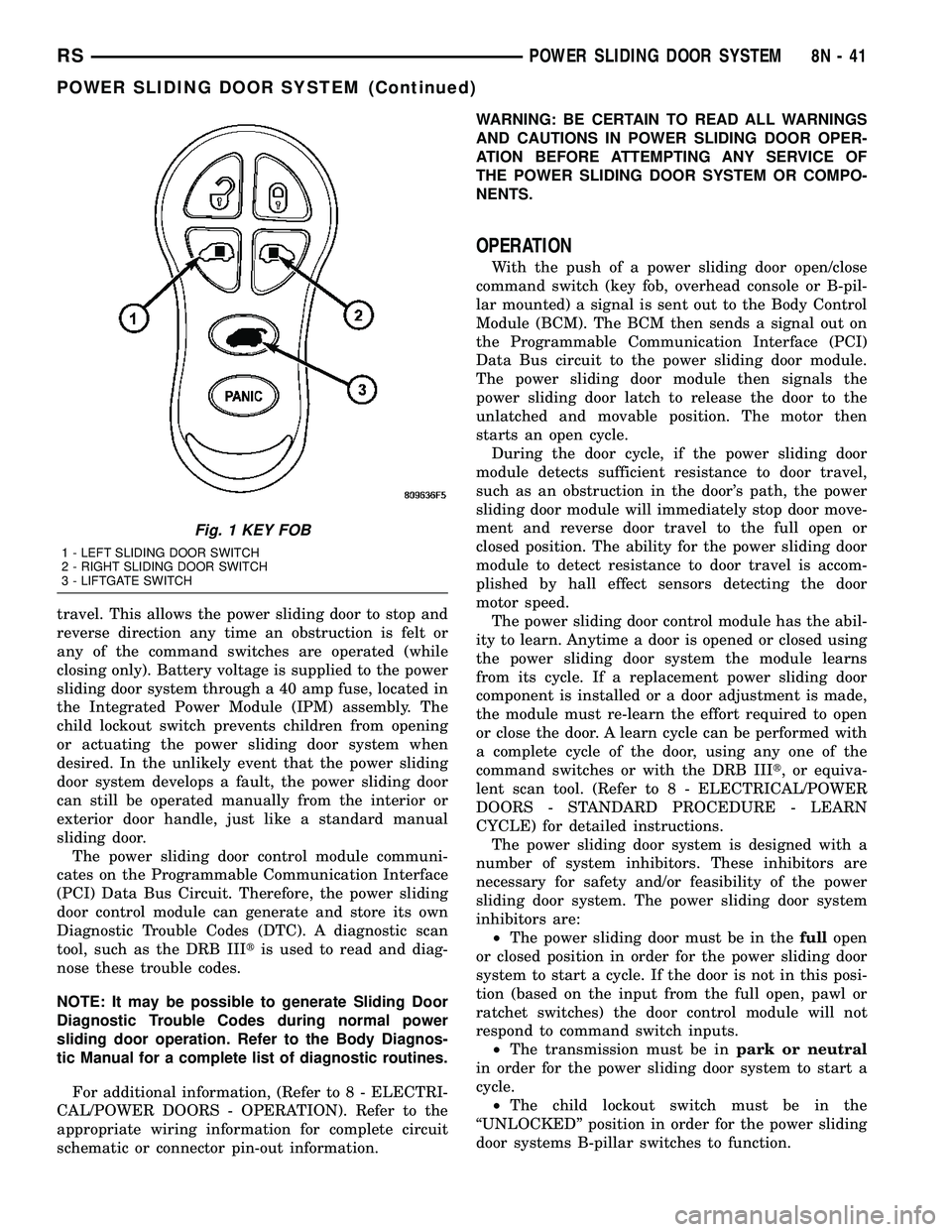

²Key fob switches (Fig. 1)

²Pawl switch

²Ratchet switch

²Child lockout and handle switchesEach power sliding door has its own door control

module, located in the center of the door behind the

door trim panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/DOOR CONTROL

MODULE - DESCRIPTION) The power sliding door

motor is located in the front portion of the door, on

the inner door panel sheet metal. The latch assembly

is located in the rear of the power sliding door, near

the body line. The lower drive unit is attached to the

lower door hinge. The flex drive assembly connects

the door motor to the lower drive unit. The wire har-

ness and track and the lower drive unit track are vis-

ible with the door open in the lower door sill area.

The power sliding door full open switch is located

under the lower drive unit and is part of the hold

open latch assembly. The pawl, ratchet, handle and

child lockout switches are all located on the power

sliding door latch assembly. The B-pillar switch is an

open and close command switch located on the inte-

rior B-pillar trim. The overhead console switch, is an

open and close command switch located in the vehi-

cle's overhead console.

Software technology has enabled the power sliding

door control module to detect resistance to door

8N - 40 POWER SLIDING DOOR SYSTEMRS

Page 464 of 2339

travel. This allows the power sliding door to stop and

reverse direction any time an obstruction is felt or

any of the command switches are operated (while

closing only). Battery voltage is supplied to the power

sliding door system through a 40 amp fuse, located in

the Integrated Power Module (IPM) assembly. The

child lockout switch prevents children from opening

or actuating the power sliding door system when

desired. In the unlikely event that the power sliding

door system develops a fault, the power sliding door

can still be operated manually from the interior or

exterior door handle, just like a standard manual

sliding door.

The power sliding door control module communi-

cates on the Programmable Communication Interface

(PCI) Data Bus Circuit. Therefore, the power sliding

door control module can generate and store its own

Diagnostic Trouble Codes (DTC). A diagnostic scan

tool, such as the DRB IIItis used to read and diag-

nose these trouble codes.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). Refer to the

appropriate wiring information for complete circuit

schematic or connector pin-out information.WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

THE POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the Programmable Communication Interface (PCI)

Data Bus circuit to the power sliding door module.

The power sliding door module then signals the

power sliding door latch to release the door to the

unlatched and movable position. The motor then

starts an open cycle.

During the door cycle, if the power sliding door

module detects sufficient resistance to door travel,

such as an obstruction in the door's path, the power

sliding door module will immediately stop door move-

ment and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors detecting the door

motor speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a complete cycle of the door, using any one of the

command switches or with the DRB IIIt, or equiva-

lent scan tool. (Refer to 8 - ELECTRICAL/POWER

DOORS - STANDARD PROCEDURE - LEARN

CYCLE) for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. The power sliding door system

inhibitors are:

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The transmission must be inpark or neutral

in order for the power sliding door system to start a

cycle.

²The child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR SWITCH

2 - RIGHT SLIDING DOOR SWITCH

3 - LIFTGATE SWITCH

RSPOWER SLIDING DOOR SYSTEM8N-41

POWER SLIDING DOOR SYSTEM (Continued)

Page 466 of 2339

POWER SLIDING DOOR SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

Door opens unexpectedly Inoperative sliding door control module

or Body Control Module (BCM)Disconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, Refer to the Body Diagnostic

Manual for detailed procedures

Inoperative latch assembly Check wiring/cable connections

Check for trouble codes, replace latch if

necessary

Inoperative open/close command

switchCheck for shorted or defective switch

Inoperative striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Door will not open manually

using inside handleThe child lock out switch is in the

9LOCKED9positionEnsure the child lock out switch is in the

9UNLOCKED9position

Inoperative inside handle assembly

Check for broken inside handle

assembly

Check cable connections at latch and

handle assembly.

Check for binds or kinks in cable.

Check for foreign matter preventing the

operation of handle assembly

Replace the handle if necessary

Inoperative latch assembly Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Replace latch if necessary

Inoperative inside handle cable

assemblyCheck cable for binding

Check cable for broken condition

Replace the cable, if necessary

Binding or sticking of components Check for foreign matter preventing the

operation of door

Establish location of binding

Replace necessary components

Door will not open manually

using outside handleInoperative outside handle assembly Check for broken outside handle assembly

Check cable connections at latch and handle

assembly.

Check for binds or kinks in cable.

RSPOWER SLIDING DOOR SYSTEM8N-43

POWER SLIDING DOOR SYSTEM (Continued)

Page 468 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Power loss during power

door operationWiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Low battery voltage Charge battery

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative drive assembly Remove lower drive unit and check for no

drive condition

No latching in primary and/or

secondary positionsInoperative inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Inoperative latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Door seal force too high Inspect seals for damage, mis-assembly,

foreign matter. (Refer to 8 - ELECTRICAL/

POWER DOORS - STANDARD

PROCEDURE) for door adjustment

procedure and specifications in the Body

section of the service manual for

specifications

Inoperative drive assembly Remove lower drive unit and check for no

drive condition

Inoperative striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Latch will not fully release

from primary positionInoperative latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

RSPOWER SLIDING DOOR SYSTEM8N-45

POWER SLIDING DOOR SYSTEM (Continued)

Page 469 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Inoperative fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism.

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or overhead

console switch does not

operate power sliding doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Inoperative latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Inoperative BCM Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Inoperative key fob Verify inoperative key fob by trying other key

fob functions

Replace key fob battery

Reprogram key fob

Replace key fob if necessary

Inoperative sliding door control module Disconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage, replace

assembly

8N - 46 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 470 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative hold open latch striker Replace hold open latch striker, if necessary

High inside/outside opening

effortInoperative latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Binding or sticking of components Establish location of binding and replace

necessary components

Door continues to cinch

closed during power modeInoperative latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Door continues to open

during power mode (runaway

motor)Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative drive assembly Remove lower drive unit and check for no

drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door opens very slowly Inoperative door motor assembly Check wire/cable connections

Replace motor assembly, if necessary

RSPOWER SLIDING DOOR SYSTEM8N-47

POWER SLIDING DOOR SYSTEM (Continued)

Page 482 of 2339

WIRING HARNESS

DESCRIPTION

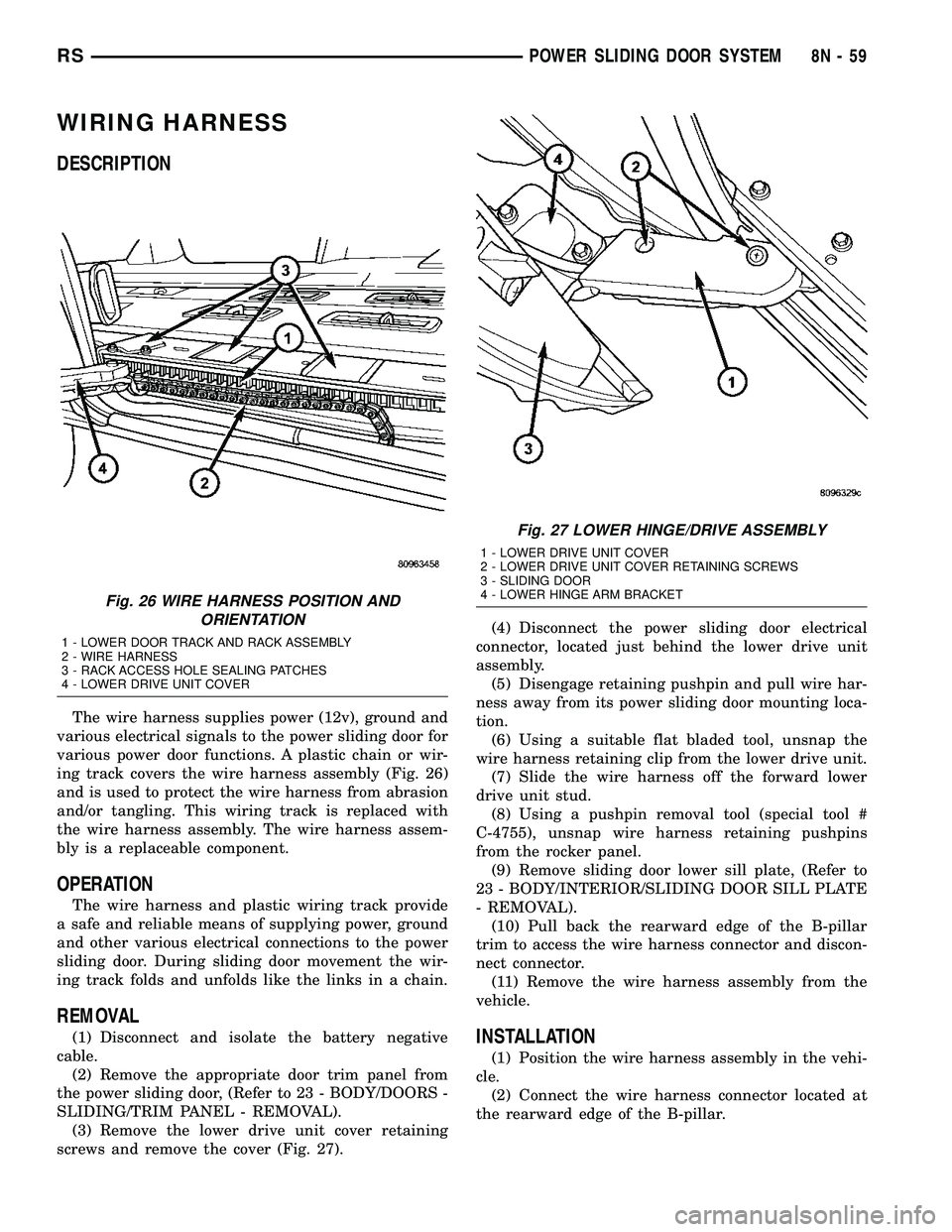

The wire harness supplies power (12v), ground and

various electrical signals to the power sliding door for

various power door functions. A plastic chain or wir-

ing track covers the wire harness assembly (Fig. 26)

and is used to protect the wire harness from abrasion

and/or tangling. This wiring track is replaced with

the wire harness assembly. The wire harness assem-

bly is a replaceable component.

OPERATION

The wire harness and plastic wiring track provide

a safe and reliable means of supplying power, ground

and other various electrical connections to the power

sliding door. During sliding door movement the wir-

ing track folds and unfolds like the links in a chain.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the appropriate door trim panel from

the power sliding door, (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL).

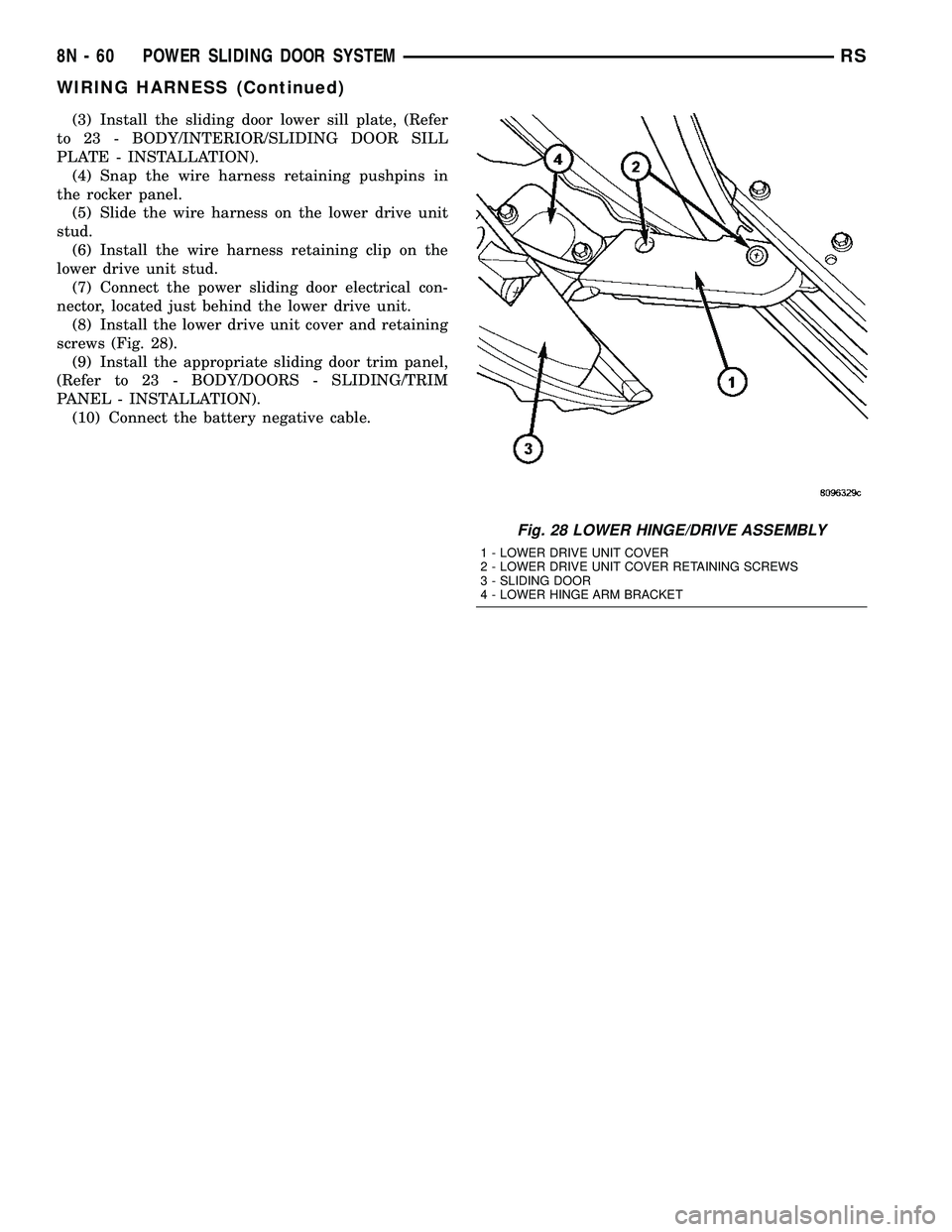

(3) Remove the lower drive unit cover retaining

screws and remove the cover (Fig. 27).(4) Disconnect the power sliding door electrical

connector, located just behind the lower drive unit

assembly.

(5) Disengage retaining pushpin and pull wire har-

ness away from its power sliding door mounting loca-

tion.

(6) Using a suitable flat bladed tool, unsnap the

wire harness retaining clip from the lower drive unit.

(7) Slide the wire harness off the forward lower

drive unit stud.

(8) Using a pushpin removal tool (special tool #

C-4755), unsnap wire harness retaining pushpins

from the rocker panel.

(9) Remove sliding door lower sill plate, (Refer to

23 - BODY/INTERIOR/SLIDING DOOR SILL PLATE

- REMOVAL).

(10) Pull back the rearward edge of the B-pillar

trim to access the wire harness connector and discon-

nect connector.

(11) Remove the wire harness assembly from the

vehicle.INSTALLATION

(1) Position the wire harness assembly in the vehi-

cle.

(2) Connect the wire harness connector located at

the rearward edge of the B-pillar.

Fig. 26 WIRE HARNESS POSITION AND

ORIENTATION

1 - LOWER DOOR TRACK AND RACK ASSEMBLY

2 - WIRE HARNESS

3 - RACK ACCESS HOLE SEALING PATCHES

4 - LOWER DRIVE UNIT COVER

Fig. 27 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

RSPOWER SLIDING DOOR SYSTEM8N-59

Page 483 of 2339

(3) Install the sliding door lower sill plate, (Refer

to 23 - BODY/INTERIOR/SLIDING DOOR SILL

PLATE - INSTALLATION).

(4) Snap the wire harness retaining pushpins in

the rocker panel.

(5) Slide the wire harness on the lower drive unit

stud.

(6) Install the wire harness retaining clip on the

lower drive unit stud.

(7) Connect the power sliding door electrical con-

nector, located just behind the lower drive unit.

(8) Install the lower drive unit cover and retaining

screws (Fig. 28).

(9) Install the appropriate sliding door trim panel,

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - INSTALLATION).

(10) Connect the battery negative cable.

Fig. 28 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

8N - 60 POWER SLIDING DOOR SYSTEMRS

WIRING HARNESS (Continued)

Page 484 of 2339

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................61

OPERATION...........................61

DIAGNOSIS AND TESTING

POWER WINDOWS....................61

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR................62

REMOVAL.............................62INSTALLATION.........................62

WINDOW MOTOR

REMOVAL.............................62

WINDOW SWITCH

DIAGNOSIS AND TESTING

WINDOW SWITCH....................63

REMOVAL.............................64

INSTALLATION.........................64

POWER WINDOWS

DESCRIPTION

The Power Window System is activated through

switches mounted on the driver and passenger door

panels.

OPERATION

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

The power window motors ground through the

master switch in the driver door by a black wire

attached to the left cowl panel. Refer to the appropri-

ate wiring information.

The power rear vent windows, if equipped, are

operated by switches mounted in the driver door

switch bezel. A separate switch is used for each win-

dow. Permanent magnet type motors connected to a

crank system are used to open and close the rear

vent windows. A battery positive and negative con-

nection to either of the two motor terminals will

cause the motor to rotate in one direction. Reversing

current through these same two connections will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING

POWER WINDOWS

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed withmotor test. Refer to the appropriate wiring informa-

tion.

(1) Remove front door trim panel and sound pad as

necessary to gain access to power window motor wire

connector, (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power window switch and bezel

assembly from the driver door. (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS/POWER WINDOW

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

RSPOWER WINDOWS8N-61