ECU CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1618 of 2339

(28) Obtain helper and/or transmission jack.

Secure transmission jack to transaxle assembly.

(29) Remove upper mount bracket from transaxle

(Fig. 14).

(30) Remove remaining transaxle bellhousing-to-

engine bolts.

(31) Remove transaxle assembly from vehicle.

DISASSEMBLY

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement) or replaced, it is neces-

sary to perform the PCM/TCM Quick Learn Proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/POWERTRAIN/TRANSMIS-

SION CONTROL MODULE - STANDARD PROCE-

DURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

(1) Remove input and output speed sensors.

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts.

(3) Remove solenoid/pressure switch assembly and

gasket (Fig. 15).(4) Remove oil pan-to-case bolts (Fig. 16).

(5) Remove oil pan (Fig. 17).

Fig. 15 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 16 Remove Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 17 Remove Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPARTATF RTV (MS-GF41)

3 - OIL FILTER

RS41TE AUTOMATIC TRANSAXLE21 - 157

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1657 of 2339

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 159).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 159).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 160). Torque horizontal bolt to

102 N´m (75 ft. lbs.).(12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(13) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N´m (75 ft. lbs.).

(17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(18) Install and connect crank position sensor (if

equipped).

(19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162).

(21) Connect transmission range sensor connector

(Fig. 162).

(22) Connect input and output speed sensor con-

nectors (Fig. 162).

(23) Remove plugs and connect transaxle oil cooler

lines. (Refer to 7 - COOLING/TRANSMISSION -

STANDARD PROCEDURE)

(24) Remove plug and Install fluid level indicator/

tube assembly.

Fig. 158 Solenoid Pack-to-Transaxle Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 159 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 196 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1695 of 2339

(9) Disconnect gear shift cable from gear shift

lever (Fig. 212).

(10) Remove gear shift cable from column bracket

(Fig. 212).

(11) Disengage grommet from dash panel (Fig.

213) and remove gear shift cable from inside vehicle.INSTALLATION

(1) Fish gear shift cable dash panel opening into

engine compartment and secure grommet (Fig. 214).

(2) Install gear shift cable through column bracket

(Fig. 215) until audible ªclickº is heard.

(3) Connect gear shift cable to gear shift lever (Fig.

215).

Fig. 212 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

Fig. 213 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

Fig. 214 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

Fig. 215 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

21 - 234 41TE AUTOMATIC TRANSAXLERS

GEAR SHIFT CABLE (Continued)

Page 1741 of 2339

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 329). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)

Fig. 329 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

21 - 280 41TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

Page 1753 of 2339

(5) Install check balls into position as shown in

(Fig. 360). If necessary, secure them with petrolatum

or transmission assembly gel for assembly ease.

(6) Install thermal valve into transfer plate (Fig.

361).

Fig. 360 Ball Check Location

1 - (#4) BALL CHECK LOCATION

2 - (#2) BALL CHECK LOCATION

3 - RETAINER4 - (#3) BALL CHECK LOCATION

5 - LOW/REVERSE SWITCH VALVE

6 - T/C LIMIT VALVE

Fig. 361 Install Thermal Valve

1 - THERMAL VALVE

21 - 292 41TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 1765 of 2339

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

(2) Remove the 5 wheel mounting nuts from the

studs.

(3) Remove the tire and wheel from the hub.

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

(1) Raise the vehicle so the tire and wheel assem-

bly clears ground level.

(2) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 12).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(3) Grasp the wheel cover at the edges in line with

the remaining installed wheel mounting nuts and

pull straight outward from the wheel. This will pop

the wheel cover retaining tabs over the two remain-

ing wheel nuts, removing the wheel cover from the

vehicle.

(4) Remove the two remaining wheel mounting

nuts from the hub's studs.

(5) Remove the wheel and tire from the hub.

INSTALLATION

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

(2) Loosely install all 5 wheel mounting nuts.

Lightly snug the wheel nuts, then progressively

tighten them in the proper sequence (Fig. 13).

Tighten wheel mounting nuts to 135 N´m (100 ft.

lbs.).

(3) Lower the vehicle.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

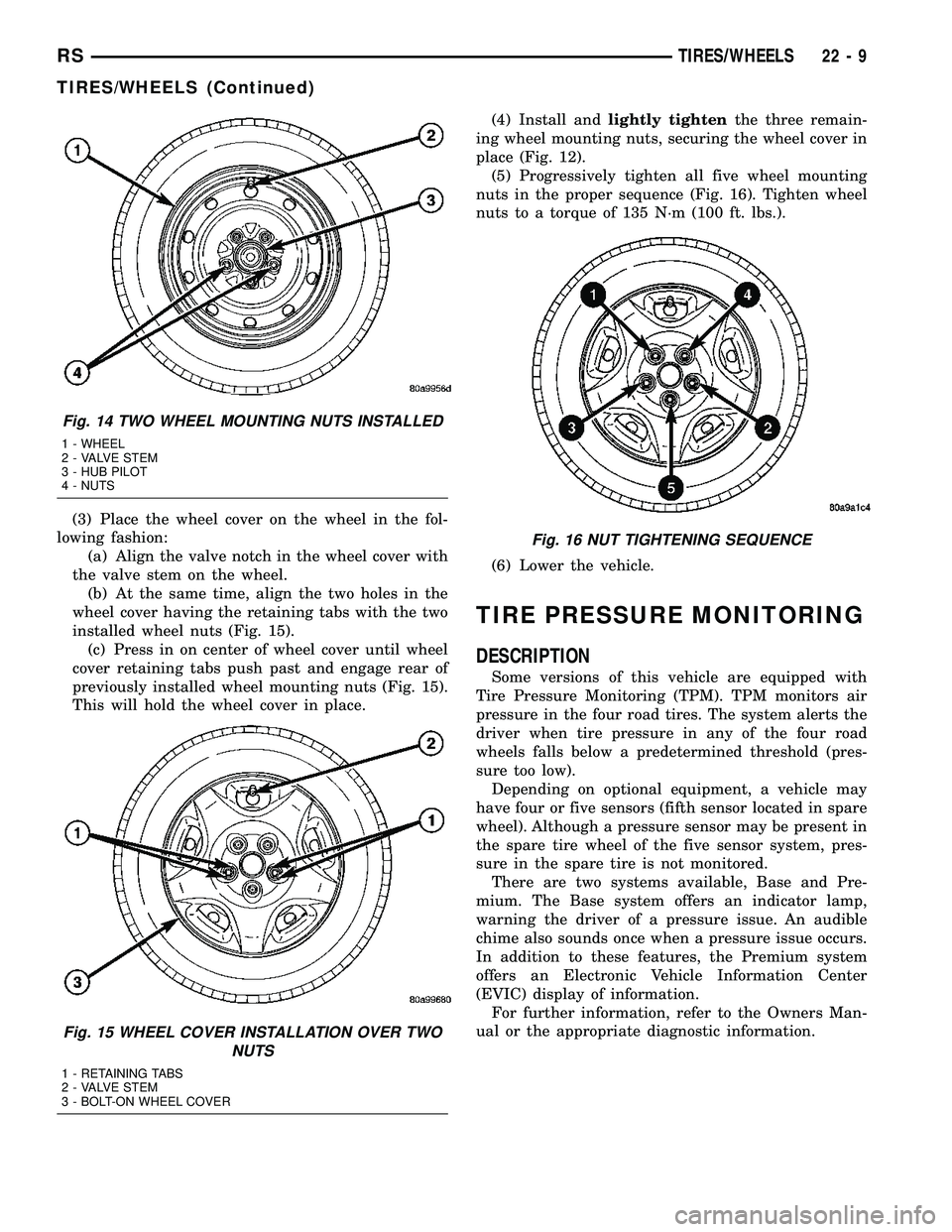

NOTE: Wheel mounting nuts must be installed on

the studs as shown (Fig. 14) to allow proper instal-

lation of the wheel cover.

(2) Using the valve stem as an index placed at the

12 O'clock position, install andlightly tightentwo

wheel mounting nuts on the studs located at the 4

O'clock and 8 O'clock positions as shown (Fig. 14).

Fig. 12 NUTS SECURING WHEEL COVER

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 13 Tightening Sequence

22 - 8 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

Page 1766 of 2339

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

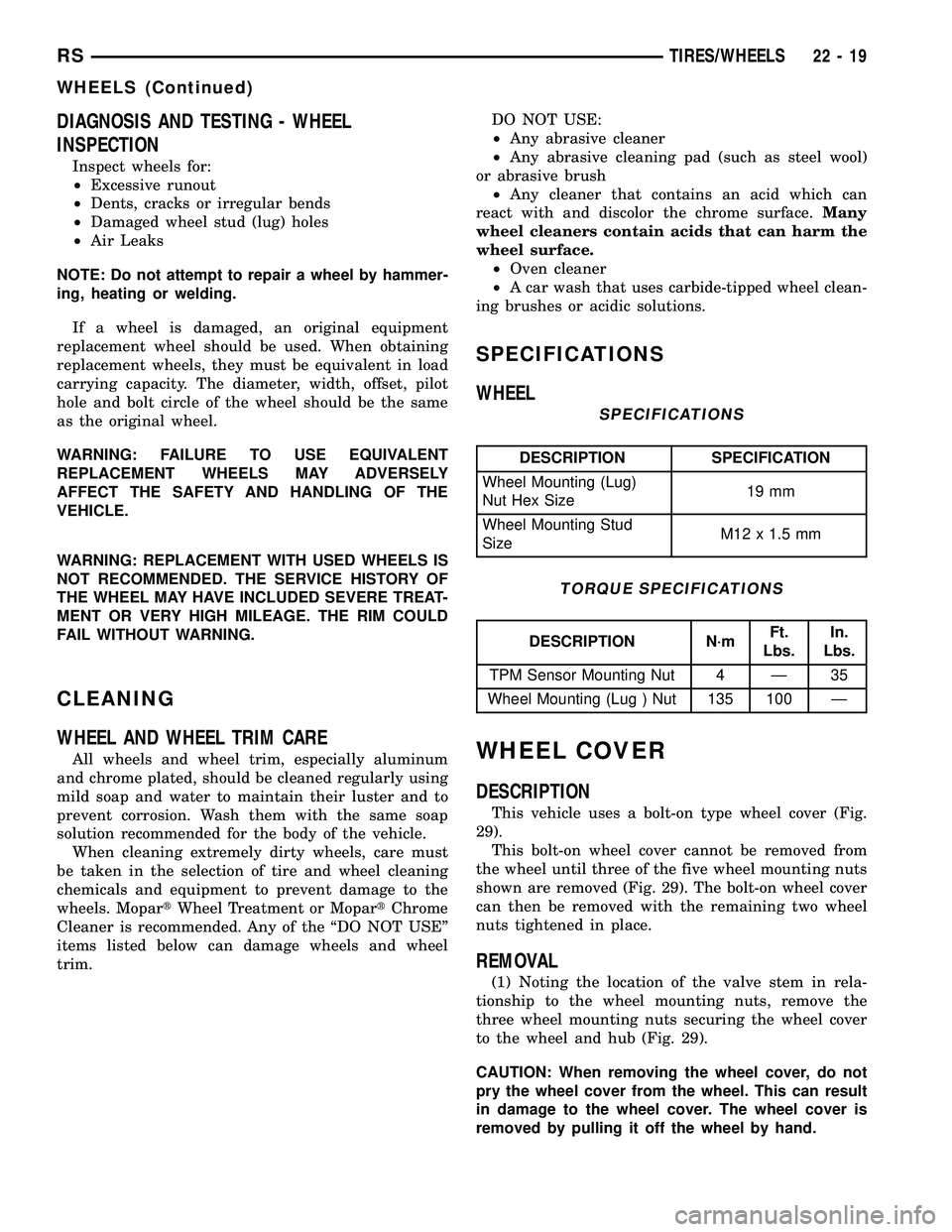

This will hold the wheel cover in place.(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with

Tire Pressure Monitoring (TPM). TPM monitors air

pressure in the four road tires. The system alerts the

driver when tire pressure in any of the four road

wheels falls below a predetermined threshold (pres-

sure too low).

Depending on optional equipment, a vehicle may

have four or five sensors (fifth sensor located in spare

wheel). Although a pressure sensor may be present in

the spare tire wheel of the five sensor system, pres-

sure in the spare tire is not monitored.

There are two systems available, Base and Pre-

mium. The Base system offers an indicator lamp,

warning the driver of a pressure issue. An audible

chime also sounds once when a pressure issue occurs.

In addition to these features, the Premium system

offers an Electronic Vehicle Information Center

(EVIC) display of information.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

Page 1776 of 2339

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive runout

²Dents, cracks or irregular bends

²Damaged wheel stud (lug) holes

²Air Leaks

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged, an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they must be equivalent in load

carrying capacity. The diameter, width, offset, pilot

hole and bolt circle of the wheel should be the same

as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE.

WARNING: REPLACEMENT WITH USED WHEELS IS

NOT RECOMMENDED. THE SERVICE HISTORY OF

THE WHEEL MAY HAVE INCLUDED SEVERE TREAT-

MENT OR VERY HIGH MILEAGE. THE RIM COULD

FAIL WITHOUT WARNING.

CLEANING

WHEEL AND WHEEL TRIM CARE

All wheels and wheel trim, especially aluminum

and chrome plated, should be cleaned regularly using

mild soap and water to maintain their luster and to

prevent corrosion. Wash them with the same soap

solution recommended for the body of the vehicle.

When cleaning extremely dirty wheels, care must

be taken in the selection of tire and wheel cleaning

chemicals and equipment to prevent damage to the

wheels. MopartWheel Treatment or MopartChrome

Cleaner is recommended. Any of the ªDO NOT USEº

items listed below can damage wheels and wheel

trim.DO NOT USE:

²Any abrasive cleaner

²Any abrasive cleaning pad (such as steel wool)

or abrasive brush

²Any cleaner that contains an acid which can

react with and discolor the chrome surface.Many

wheel cleaners contain acids that can harm the

wheel surface.

²Oven cleaner

²A car wash that uses carbide-tipped wheel clean-

ing brushes or acidic solutions.

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

TPM Sensor Mounting Nut 4 Ð 35

Wheel Mounting (Lug ) Nut 135 100 Ð

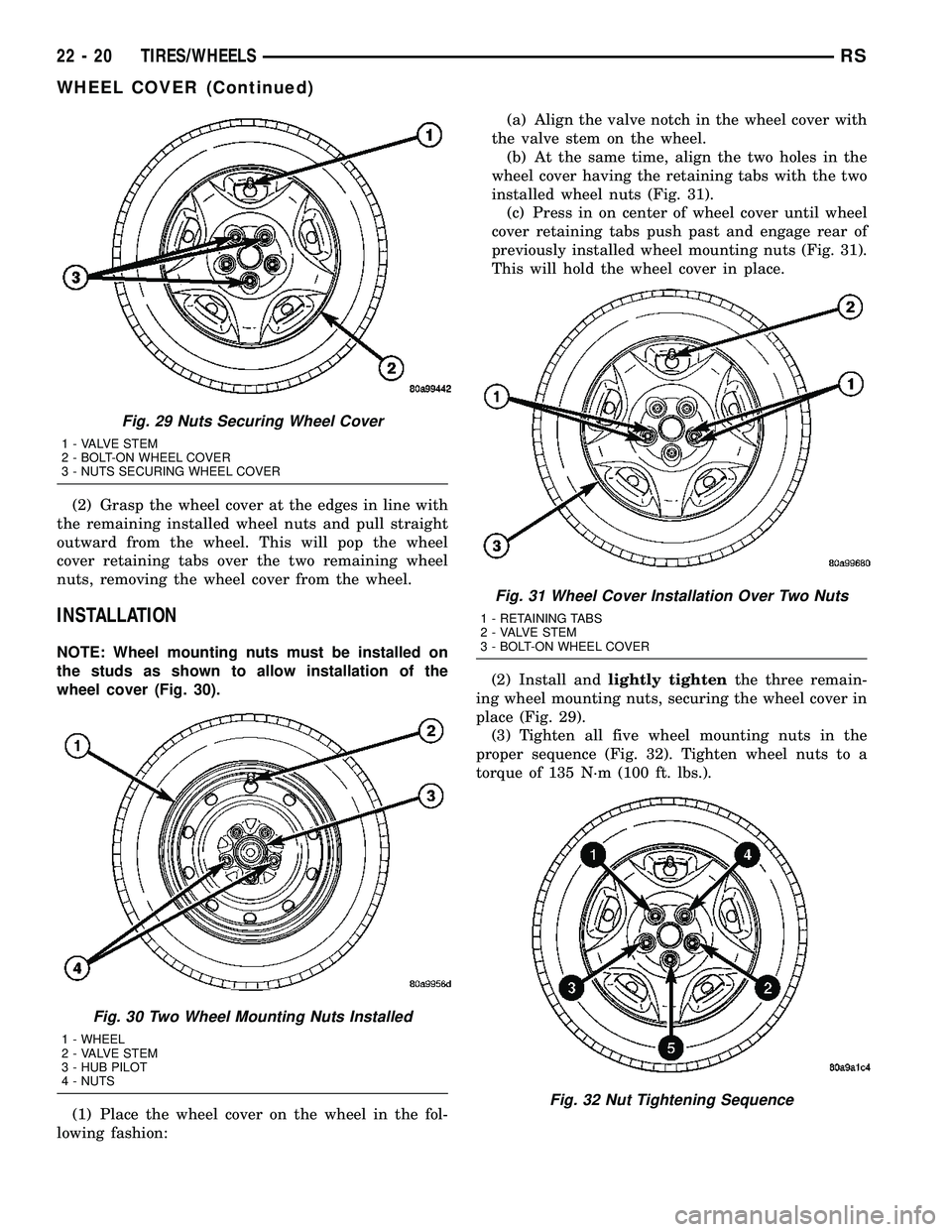

WHEEL COVER

DESCRIPTION

This vehicle uses a bolt-on type wheel cover (Fig.

29).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 29). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 29).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

RSTIRES/WHEELS22-19

WHEELS (Continued)

Page 1777 of 2339

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 30).

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 31).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 31).

This will hold the wheel cover in place.

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 29).

(3) Tighten all five wheel mounting nuts in the

proper sequence (Fig. 32). Tighten wheel nuts to a

torque of 135 N´m (100 ft. lbs.).

Fig. 29 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 30 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 31 Wheel Cover Installation Over Two Nuts

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 32 Nut Tightening Sequence

22 - 20 TIRES/WHEELSRS

WHEEL COVER (Continued)

Page 1778 of 2339

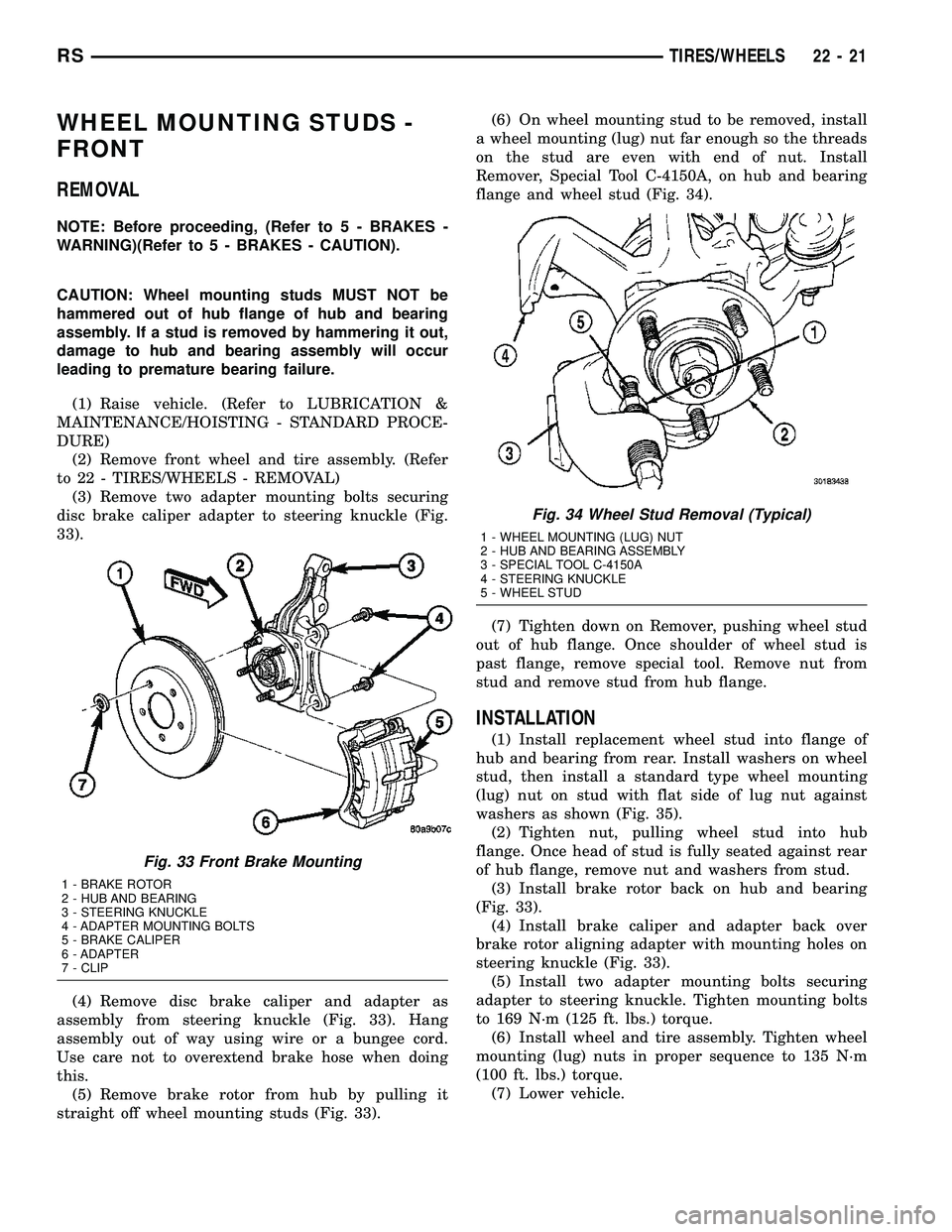

WHEEL MOUNTING STUDS -

FRONT

REMOVAL

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION).

CAUTION: Wheel mounting studs MUST NOT be

hammered out of hub flange of hub and bearing

assembly. If a stud is removed by hammering it out,

damage to hub and bearing assembly will occur

leading to premature bearing failure.

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly. (Refer

to 22 - TIRES/WHEELS - REMOVAL)

(3) Remove two adapter mounting bolts securing

disc brake caliper adapter to steering knuckle (Fig.

33).

(4) Remove disc brake caliper and adapter as

assembly from steering knuckle (Fig. 33). Hang

assembly out of way using wire or a bungee cord.

Use care not to overextend brake hose when doing

this.

(5) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 33).(6) On wheel mounting stud to be removed, install

a wheel mounting (lug) nut far enough so the threads

on the stud are even with end of nut. Install

Remover, Special Tool C-4150A, on hub and bearing

flange and wheel stud (Fig. 34).

(7) Tighten down on Remover, pushing wheel stud

out of hub flange. Once shoulder of wheel stud is

past flange, remove special tool. Remove nut from

stud and remove stud from hub flange.

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing from rear. Install washers on wheel

stud, then install a standard type wheel mounting

(lug) nut on stud with flat side of lug nut against

washers as shown (Fig. 35).

(2) Tighten nut, pulling wheel stud into hub

flange. Once head of stud is fully seated against rear

of hub flange, remove nut and washers from stud.

(3) Install brake rotor back on hub and bearing

(Fig. 33).

(4) Install brake caliper and adapter back over

brake rotor aligning adapter with mounting holes on

steering knuckle (Fig. 33).

(5) Install two adapter mounting bolts securing

adapter to steering knuckle. Tighten mounting bolts

to 169 N´m (125 ft. lbs.) torque.

(6) Install wheel and tire assembly. Tighten wheel

mounting (lug) nuts in proper sequence to 135 N´m

(100 ft. lbs.) torque.

(7) Lower vehicle.

Fig. 33 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 34 Wheel Stud Removal (Typical)

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - SPECIAL TOOL C-4150A

4 - STEERING KNUCKLE

5 - WHEEL STUD

RSTIRES/WHEELS22-21