fuse CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2197 of 2339

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) or

the front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 2208 of 2339

DISTRIBUTION DUCT

REMOVAL

(1) Remove the trim from the right quarter inner

panel and the right D pillaR (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

REMOVAL).

(2) Slide the rear distribution duct upwards far

enough to disengage it from the outlet at the top of

the rear HVAC housing (Fig. 2).

(3) While pulling the lower end of the rear distri-

bution duct away from the rear HVAC housing out-

let, disengage the upper end of the distribution duct

from the headliner duct.

(4) Remove the rea distribution duct from the

vehicle.

INSTALLATION

(1) Align the upper end of the rear distribution

duct to the headliner duct.

(2) Slide the upper end of the rear distribution

duct onto the headliner duct far enough to align the

lower end of the duct with the outlet at the top of the

rear HVAC housing.

(3) Slide the rear distribution duct downwards far

enough to engage it onto the outlet at the top of the

rear HVAC housing.

(4) Reinstall the trim onto the right quarter inner

panel and the right D pillar (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

INSTALLATION).

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft. The blower motor

and wheel are located near the top of the rear HVAC

housing in the passenger compartment behind the

right rear wheel house. The rear HVAC housing must

be removed from the vehicle to access the blower

motor for service. The blower motor and blower

motor wheel are a factory balanced unit and cannot

be adjusted or repaired. If faulty or damaged, the

blower motor and blower wheel must be replaced as

a unit.

OPERATION

On models equipped with the Manual Temperature

Control (MTC) system, the rear blower motor will

operate only whenever the ignition switch is in the

On position, the front blower control switch is in any

position except Off and the rear blower control switch

on the front A/C-heater control is in any position

except Off. On models equipped with the Automatic

Temperature Control (ATC) system, the blower motor

will operate whenever the ignition switch is in the

On position, the A/C-heater control power is turned

on and the rear blower control switch on the front

A/C-heater control is in any position except Off. The

rear blower motor can only be turned off by turning

off the rear system at the front A/C-heater control.

The rear blower motor receives battery current

whenever the rear blower motor relay is energized.

The rear blower motor relay output circuit is pro-

tected by a fuse in the Integrated Power Module

(IPM) located in the engine compartment near the

battery. In the MTC system, the rear blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the rear blower

motor speed is controlled by an electronic blower

motor power module, which uses a pulse width mod-

ulated input from the ATC control module and feed-

back from the rear blower motor to regulate the

blower motor ground path it provides. The rear

blower motor and wheel are used to control the veloc-

ity of air moving through the rear HVAC housing.

The rear blower motor controls the velocity of the air

flowing through the rear HVAC housing by spinning

the blower wheel within the housing at the selected

speed or, in the ATC system, at the selected or pro-

grammed speed.

Fig. 2 Rear Distribution Duct

1 - HEADLINER DUCT

2 - REAR DISTRIBUTION DUCT

3 - REAR HVAC HOUSING OUTLET

RSDISTRIBUTION - REAR24-57

Page 2209 of 2339

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 2316 of 2339

FRONT WIPER/WASHER SWITCH -DIAGNOSIS AND TESTING ..............8R-2

FRONT-WHEEL-DRIVE - INSTALLATION ....2-36

FRONT-WHEEL-DRIVE - REMOVAL ........2-36

FUEL CORRECTION OR ADAPTIVE MEMORIES, OPERATION ...............14-24

FUEL DELIVERY SYSTEM - DIAGNOSIS AND TESTING ........................ 14-2

FUEL DOSING PUMP - DESCRIPTION ....24-117

FUEL DOSING PUMP - INSTALLATION . . . 24-117

FUEL DOSING PUMP - OPERATION .....24-117

FUEL DOSING PUMP - REMOVAL .......24-117

FUEL ENGINE OIL - DESCRIPTION, FLEXIBLE .............................0-3

FUEL FILL DOOR - INSTALLATION .......23-52

FUEL FILL DOOR - REMOVAL ...........23-52

FUEL FILL DOOR BLOCKER LATCH - INSTALLATION ....................... 23-53

FUEL FILL DOOR BLOCKER LATCH - REMOVAL .......................... 23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - INSTALLATION ..............23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - REMOVAL .................23-53

FUEL FILL DOOR BLOCKER LOCKOUT LINK - INSTALLATION .................23-54

FUEL FILL DOOR BLOCKER LOCKOUT LINK - REMOVAL ..................... 23-54

FUEL FILLER CAP - DESCRIPTION .......25-13

FUEL FILLER CAP - OPERATION .........25-13

FUEL INJECTOR - DESCRIPTION .........14-30

FUEL INJECTOR - OPERATION ..........14-31

FUEL LEVEL SENDING UNIT / SENSOR - DESCRIPTION ........................ 14-5

FUEL LEVEL SENDING UNIT / SENSOR - INSTALLATION ........................ 14-6

FUEL LEVEL SENDING UNIT / SENSOR - OPERATION .......................... 14-5

FUEL LEVEL SENDING UNIT / SENSOR - REMOVAL ........................... 14-5

FUEL LINES/HOSES AND CLAMPS - DESCRIPTION ........................ 14-7

FUEL PRESSURE GAUGE - STANDARD PROCEDURE ......................... 14-3

FUEL PRESSURE REGULATOR - INSTALLATION ........................ 14-7

FUEL PRESSURE REGULATOR - OPERATION .......................... 14-7

FUEL PRESSURE REGULATOR - REMOVAL ........................... 14-7

FUEL PUMP - DESCRIPTION .............14-8

FUEL PUMP - OPERATION ..............14-8

FUEL PUMP MODULE - DESCRIPTION .....14-8

FUEL PUMP MODULE - OPERATION .......14-9

FUEL PUMP RELAY - DESCRIPTION ......14-32

FUEL PUMP RELAY - OPERATION ........14-32

FUEL REQUIREMENTS - DESCRIPTION ......0-4

FUEL REQUIREMENTS - DIESEL ENGINE - DESCRIPTION ........................0-6

FUEL, SPECIAL TOOLS ............14-27,14-4

FUEL SYSTEM PRESSURE RELEASE PROCEDURE - STANDARD

PROCEDURE ......................... 14-2

FUEL SYSTEM PRESSURE, SPECIFICATIONS ...................... 14-4

FUEL TANK - DESCRIPTION ............14-12

FUEL TANK - OPERATION ..............14-12

FUEL TANK - STANDARD PROCEDURE, DRAINING ........................... 14-2

FUEL TANK FILLER TUBE - INSTALLATION ....................... 14-17

FUEL TANK FILLER TUBE - REMOVAL ....14-16

FULL OPEN SWITCH - DESCRIPTION ....8N-11,

8N-52

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD ...........8W-97-3

FUSE - OPERATION, IOD .............8W-97-3

FUSES POWERING SEVERAL LOADS - STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON ......8W-01-10

FWD - FOLD-IN-FLOOR SEATING - INSTALLATION ........................ 2-45

FWD - FOLD-IN-FLOOR SEATING - REMOVAL ........................... 2-45

FWD - INSTALLATION ..................2-45

FWD - INSTALLATION, REAR WHEEL SPEED SENSOR ....................... 5-93

FWD - INSTALLATION, SPRING ...........2-42FWD - REMOVAL

...................... 2-45

FWD - REMOVAL, REAR WHEEL SPEED SENSOR ............................ 5-93

FWD - REMOVAL, SPRING ..............2-40

GALLERY PLUGS - STANDARD PROCEDURE, ENGINE CORE AND OIL . 9-10,9-88

GAP AND FLUSH MEASUREMENTS - SPECIFICATIONS .................... 23-177

GAP, SPECIFICATIONS - WHEEL SPEED SENSOR AIR ......................... 5-91

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-139

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-138

GASKET - DIAGNOSIS AND TESTING, CYLINDER HEAD ................. 9-102,9-25

GASKET SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE ....9-11,9-87

GASKETS AND SEALERS, STANDARD PROCEDURE - FORM-IN-PLACE ......9-11,9-86

GAUGE - STANDARD PROCEDURE, FUEL PRESSURE .......................... 14-3

GEAR - DESCRIPTION .................19-26

GEAR - INSTALLATION, LHD ............19-31

GEAR - INSTALLATION, RHD ............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION, LIFT ............................... 8N-17

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT .....8N-16

GEAR - OPERATION .................... 19-26

GEAR - REMOVAL, LHD ...............19-26

GEAR - REMOVAL, RHD ...............19-29

GEAR SHIFT CABLE - INSTALLATION ....21-234

GEAR SHIFT CABLE - REMOVAL . . . 21-233,21-84

GEAR, SPECIAL TOOLS - POWER STEERING .......................... 19-34

GEARSHIFT CABLE ADJUSTMENT, ADJUSTMENTS ..................... 21-235

GEARTRAIN - DESCRIPTION, PLANETARY .................. 21-112,21-263

GEARTRAIN - OPERATION, PLANETARY . 21-112, 21-263

GENERAL - WARNINGS .............8W-01-7

GENERAL DIAGNOSIS - DIAGNOSIS AND TESTING, 4XTE TRANSAXLE .......21-149,21-5

GENERATOR - DESCRIPTION ...........8F-24

GENERATOR - OPERATION .............8F-24

GENERATOR DECOUPLER PULLEY - DESCRIPTION ....................... 8F-28

GENERATOR DECOUPLER PULLEY - DIAGNOSIS AND TESTING ..............8F-28

GENERATOR DECOUPLER PULLEY - INSTALLATION ....................... 8F-29

GENERATOR DECOUPLER PULLEY - OPERATION ......................... 8F-28

GENERATOR DECOUPLER PULLEY - REMOVAL .......................... 8F-29

GENERATOR, SPECIFICATIONS ..........8F-23

GLASS - DESCRIPTION, HEATED .........8G-1

GLASS - INSTALLATION, DOOR .........23-17

GLASS - INSTALLATION, LIFTGATE ......23-164

GLASS - INSTALLATION, SLIDING DOOR . 23-163

GLASS - OPERATION, HEATED ...........8G-2

GLASS - REMOVAL, DOOR .............23-16

GLASS - REMOVAL, LIFTGATE .........23-164

GLASS - REMOVAL, SLIDING DOOR .....23-163

GLASS INTEGRAL ANTENNA - EXPORT - DESCRIPTION, QUARTER ..............8A-13

GLASS INTEGRAL ANTENNA - EXPORT - OPERATION, QUARTER ................8A-13

GLASS INTEGRAL ANTENNA, EXPORT - QUARTER .......................... 8A-13

GLASS PANEL - INSTALLATION ........23-173

GLASS PANEL - REMOVAL ............23-173

GLASS PANEL ADJUSTMENT, ADJUSTMENTS - SUNROOF ...........23-173

GLASS RUN WEATHERSTRIP - INSTALLATION, FRONT DOOR ..........23-166

GLASS RUN WEATHERSTRIP - REMOVAL, FRONT DOOR .............23-166

GLASS-OUTSIDE REARVIEW MIRROR - INSTALLATION ....................... 23-61

GLASS-OUTSIDE REARVIEW MIRROR - REMOVAL .......................... 23-61

GLOVE BOX - INSTALLATION ...........23-66

GLOVE BOX - REMOVAL ...............23-66GLOVE BOX LAMP SWITCH -

INSTALLATION ....................... 8L-22

GLOVE BOX LAMP SWITCH - REMOVAL . . 8L-22

GLOVE BOX LATCH - INSTALLATION .....23-66

GLOVE BOX LATCH - REMOVAL .........23-66

GLOVE BOX LATCH STRIKER - INSTALLATION ....................... 23-66

GLOVE BOX LATCH STRIKER - REMOVAL . 23-66

GRID REPAIR PROCEDURE, STANDARD PROCEDURE ......................... 8G-5

GRILLE - DESCRIPTION ...............23-55

GRILLE - INSTALLATION ...............23-55

GRILLE - INSTALLATION, COWL .........23-50

GRILLE - REMOVAL ..................23-55

GRILLE - REMOVAL, COWL ............23-50

GROCERY BAG RETAINER - INSTALLATION, PLASTIC ..............23-149

GROCERY BAG RETAINER - REMOVAL, PLASTIC .......................... 23-149

GROMMET REPLACEMENT, STANDARD PROCEDURE - PUSH-PIN ..............8N-48

GROUND - OPERATION, PCM ...........8E-14

GROUND - STANDARD PROCEDURE, TESTING FOR A SHORT TO ..........8W-01-9

GROUND AND SPLICE INFORMATION - DESCRIPTION, CONNECTOR ..........8W-01-7

GROUND ON FUSES POWERING SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W -01-10

GUIDE - INSTALLATION, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE - REMOVAL, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - ASSEMBLY, CALIPER ....5-25

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - DISASSEMBLY,

CALIPER ............................ 5-24

GUIDE PINS (TRW BRAKES) - INSTALLATION, DISC BRAKE CALIPER .....5-32

GUIDE PINS (TRW BRAKES) - REMOVAL, DISC BRAKE CALIPER .................. 5-31

HALF SHAFT - DIAGNOSIS AND TESTING . . . 3-1

HALF SHAFT - FRONT - DESCRIPTION ......3-1

HALF SHAFT - FRONT - INSTALLATION .....3-4

HALF SHAFT - FRONT - REMOVAL .........3-2

HALF SHAFT - FRONT - SPECIFICATIONS ....3-6

HANDLE - INSTALLATION, ASSIST .......23-79

HANDLE - INSTALLATION, EXTERIOR ....23-22,

23-40

HANDLE - INSTALLATION, INSIDE LATCH . . 23-34

HANDLE - INSTALLATION, OUTSIDE ......23-36

HANDLE - INSTALLATION, RECLINER ....23-108

HANDLE - REMOVAL, ASSIST ...........23-79

HANDLE - REMOVAL, EXTERIOR . . . 23-21,23-40

HANDLE - REMOVAL, INSIDE LATCH .....23-34

HANDLE - REMOVAL, OUTSIDE .........23-35

HANDLE - REMOVAL, RECLINER .......23-108

HANDLE ACTUATOR - INSTALLATION, INSIDE ............................. 23-27

HANDLE ACTUATOR - REMOVAL, INSIDE . . 23-27

HANDLE CABLE - INSTALLATION, INSIDE . . 23-38

HANDLE CABLE - INSTALLATION, OUTSIDE ........................... 23-37

HANDLE CABLE - REMOVAL, INSIDE .....23-37

HANDLE CABLE - REMOVAL, OUTSIDE ....23-37

HANDLE SWITCH - DESCRIPTION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - INSTALLATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - OPERATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - REMOVAL, EXTERIOR . 8N-10

HANDLING AIRBAGS - STANDARD PROCEDURE ......................... 8O-6

HANDLING TUBING AND FITTINGS, STANDARD PROCEDURE ...............24-69

HANDS FREE MODULE - INSTALLATION ....8T-3

HANDS FREE MODULE - REMOVAL .......8T-3

HARNESS - DESCRIPTION, WIRING ......8N-59

HARNESS - DIAGNOSIS AND TESTING, WIRING ..........................8W -01-7

HARNESS - INSTALLATION, WIRING .....8N-59

HARNESS - OPERATION, WIRING ........8N-59

HARNESS - REMOVAL, WIRING .........8N-59

HCU (HYDRAULIC CONTROL UNIT) - DESCRIPTION ....................... 5-100

RS INDEX15

Description Group-Page Description Group-Page Description Group-Page

Page 2319 of 2339

INTERMEDIATE - INSTALLATION, CABLE- PARKING BRAKE ..................... 5-69

INTERMEDIATE - REMOVAL, CABLE - PARKING BRAKE ...................... 5-69

INTERNATIONAL SYMBOLS - DESCRIPTION .........................0-1

INTRODUCTION - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-3,9-78

IOD FUSE - DESCRIPTION ...........8W-97-3

IOD FUSE - OPERATION .............8W-97-3

JOINT - DESCRIPTION, LOWER BALL ......2-10

JOINT - DIAGNOSIS AND TESTING, LOWER BALL ........................ 2-10

JOINT - OPERATION, LOWER BALL .......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-60

JOINT MOLDING - REMOVAL, ROOF ......23-60

JOUNCE BUMPER - DESCRIPTION ........2-35

JOUNCE BUMPER - OPERATION ..........2-35

JUMP STARTING - STANDARD PROCEDURE ......................... 0-25

JUNCTION BLOCK - DESCRIPTION, NON-ABS ............................ 5-33

JUNCTION BLOCK - INSTALLATION, NON-ABS ............................ 5-34

JUNCTION BLOCK - OPERATION, NON-ABS ............................ 5-33

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-34

KEY - DESCRIPTION, TRANSPONDER .....8Q-6

KEY - OPERATION, TRANSPONDER .......8Q-6

KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

KEY REMOTE ENTRY MODULE - DESCRIPTION, SENTRY ................8Q-3

KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY .......8Q-5

KEY REMOTE ENTRY MODULE - INSTALLATION, SENTRY ................8Q-6

KEY REMOTE ENTRY MODULE - OPERATION, SENTRY .................. 8Q-4

KEY REMOTE ENTRY MODULE - REMOVAL, SENTRY ................... 8Q-6

KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY .......8Q-3

KEYLESS ENTRY TRANSMITTER, DIAGNOSIS AND TESTING .............8N-24

KEYLESS ENTRY TRANSMITTER PROGRAMMING - STANDARD

PROCEDURE, REMOTE ................8N-24

KEY/LOCK CYLINDER - DESCRIPTION ....19-20

KEY/LOCK CYLINDER - INSTALLATION ....19-20

KEY/LOCK CYLINDER - OPERATION ......19-20

KEY/LOCK CYLINDER - REMOVAL .......19-20

KNEE - INSTALLATION, BLOCKER- INFLATABLE ......................... 23-75

KNEE - REMOVAL, BLOCKER- INFLATABLE ......................... 23-75

KNEE BLOCKER AIRBAG - DESCRIPTION . . 8O-22

KNEE BLOCKER AIRBAG - INSTALLATION . 8O-23

KNEE BLOCKER AIRBAG - OPERATION . . . 8O-22

KNEE BLOCKER AIRBAG - REMOVAL .....8O-23

KNOB - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

KNOB - REMOVAL, SEAT BELT HEIGHT ADJUSTER ......................... 8O-38

KNOCK SENSOR - DESCRIPTION ..........8I-8

KNOCK SENSOR - OPERATION ...........8I-8

KNUCKLE - DESCRIPTION ................2-6

KNUCKLE - INSPECTION, STEERING ........2-9

KNUCKLE - INSTALLATION, STEERING ......2-9

KNUCKLE - OPERATION .................2-7

KNUCKLE - REMOVAL, STEERING .........2-7

LABEL, DESCRIPTION - VEHICLE EMISSION CONTROL INFORMATION .......25-1

LAMP - DESCRIPTION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - DIAGNOSIS AND TESTING, FRONT FOG .......................... 8L-7

LAMP - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP - INSTALLATION, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - INSTALLATION, COURTESY ......8L-21

LAMP - INSTALLATION, DOME/CARGO ....8L-22

LAMP - INSTALLATION, FRONT FOG .......8L-8

LAMP - INSTALLATION, LICENSE ........8L-17

LAMP - INSTALLATION, LIFTGATE .......8L-22 LAMP - INSTALLATION, PARK/TURN

SIGNAL ............................ 8L-18

LAMP - INSTALLATION, READING ........8L-23

LAMP - INSTALLATION, TAIL ...........8L-19

LAMP - INSTALLATION, VANITY .........8L-24

LAMP - OPERATION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - REMOVAL, CENTER CONSOLE ....8L-21

LAMP - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - REMOVAL, COURTESY ..........8L-21

LAMP - REMOVAL, DOME/CARGO .......8L-22

LAMP - REMOVAL, FRONT FOG ..........8L-8

LAMP - REMOVAL, LICENSE ............8L-17

LAMP - REMOVAL, LIFTGATE ...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING ...........8L-22

LAMP - REMOVAL, TAIL ...............8L-18

LAMP - REMOVAL, VANITY .............8L-24

LAMP SWITCH - DESCRIPTION, BRAKE ....8L-4

LAMP SWITCH - DIAGNOSIS AND TESTING, BRAKE ...................... 8L-4

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - INSTALLATION, GLOVE BOX ............................... 8L-22

LAMP SWITCH - OPERATION, BRAKE ......8L-4

LAMP SWITCH - REMOVAL, BRAKE .......8L-5

LAMP SWITCH - REMOVAL, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP .................8L-6

LAMP UNIT - INSTALLATION, TAIL .......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP UNIT - REMOVAL, TAIL ...........8L-19

LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG .....8L-9

LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG ...............8L-9

LAMPS - INSTALLATION, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS - REMOVAL, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS, SPECIFICATIONS - EXTERIOR .....8L-3

LAMPS, SPECIFICATIONS - INTERIOR ....8L-20

LAMPS/LIGHTING - EXTERIOR - DESCRIPTION ........................ 8L-2

LAMPS/LIGHTING - EXTERIOR - OPERATION .......................... 8L-2

LAMPS/LIGHTING - EXTERIOR - WARNING ........................... 8L-3

LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER .....23-157

LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER .................. 23-157

LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND TESTING, HYDRAULIC ....9-34

LASH ADJUSTERS - INSTALLATION, HYDRAULIC .......................... 9-35

LASH ADJUSTERS - REMOVAL, HYDRAULIC .......................... 9-35

LATCH - DESCRIPTION ...........8N-12,8N-49

LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID ....23-90

LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID .................23-90

LATCH - INSTALLATION .....23-18,23-41,23-63

LATCH - INSTALLATION ..........8N-13,8N-50

LATCH - INSTALLATION, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH - INSTALLATION, GLOVE BOX .....23-66

LATCH - INSTALLATION, HOLD OPEN .....23-25

LATCH / LOCK ASSEMBLY - INSTALLATION ....................... 23-27

LATCH / LOCK ASSEMBLY - REMOVAL ....23-26

LATCH - OPERATION ............8N-12,8N-49

LATCH - REMOVAL .........23-18,23-41,23-63

LATCH - REMOVAL ..............8N-12,8N-49

LATCH - REMOVAL, FUEL FILL DOOR BLOCKER ........................... 23-53

LATCH - REMOVAL, GLOVE BOX .........23-66

LATCH - REMOVAL, HOLD OPEN ........23-25

LATCH ACTUATOR - DESCRIPTION ......8N-13

LATCH ACTUATOR - INSTALLATION ......8N-14

LATCH ACTUATOR - OPERATION ........8N-13 LATCH ACTUATOR - REMOVAL

..........8N-13

LATCH CABLE - INSTALLATION, HOLD OPEN .............................. 23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE .....23-34

LATCH LOCKING LINK - INSTALLATION, SEAT RISER ........................ 23-151

LATCH LOCKING LINK - REMOVAL, SEAT RISER ............................ 23-151

LATCH RELEASE CABLE - INSTALLATION . . 23-64

LATCH RELEASE CABLE - REMOVAL .....23-63

LATCH STRIKER - INSTALLATION . . 23-19,23-42, 23-64

LATCH STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-53

LATCH STRIKER - INSTALLATION, GLOVE BOX ............................... 23-66

LATCH STRIKER - INSTALLATION, HOLD OPEN .............................. 23-26

LATCH STRIKER - INSTALLATION, REAR . . 23-29

LATCH STRIKER - REMOVAL . 23-19,23-41,23-64

LATCH STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH STRIKER - REMOVAL, GLOVE BOX ............................... 23-66

LATCH STRIKER - REMOVAL, HOLD OPEN .............................. 23-26

LATCH STRIKER - REMOVAL, REAR ......23-29

LEAD - DIAGNOSIS AND TESTING, TIRE/VEHICLE ......................... 22-14

LEAF SPRING FRONT - INSTALLATION, BUSHING ............................ 2-30

LEAF SPRING FRONT - REMOVAL, BUSHING ............................ 2-29

LEAK DETECTION ASSY - INSTALLATION, NATURAL VAC ....................... 25-14

LEAK DETECTION ASSY - REMOVAL, NATURAL VAC ....................... 25-14

LEAK DETECTION PUMP - INSTALLATION . 25-15

LEAK DETECTION PUMP - REMOVAL .....25-15

LEAK INSPECTION - DIAGNOSIS AND TESTING, ENGINE OIL ...............9-8,9-84

LEAK REPAIRING - STANDARD PROCEDURE, TIRE ................... 22-17

LEAK TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM .....................7-2

LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER HOUSING FLUID . . 21-154, 21-9

LEAKAGE TEST - DIAGNOSIS AND TESTING, CYLINDER COMBUSTION

PRESSURE ....................... 9-85,9-9

LEAKS - DIAGNOSIS AND TESTING, INTAKE MANIFOLD ...............9-147,9-60

LEAKS, DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM ...............24-67

LEAKS, DIAGNOSIS AND TESTING - WATER ............................. 23-1

LEARN CYCLE, STANDARD PROCEDURE - POWER LIFTGATE ................... 8N-8

LEARN CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR ..............8N-48

LEARN PROCEDURE - STANDARD PROCEDURE, QUICK .................. 8E-15

LENS - INSTALLATION, CLUSTER ........8J-11

LENS - REMOVAL, CLUSTER ............8J-11

LEVEL AND CONDITION CHECK, STANDARD PROCEDURE - FLUID . . 21-230,21-82

LEVEL CHECK - STANDARD PROCEDURE, COOLANT .................7-4

LEVEL CHECK - STANDARD PROCEDURE, ENGINE OIL ..............9-140

LEVEL CHECK, STANDARD PROCEDURE - ENGINE OIL ........................ 9-54

LEVEL CHECKING - STANDARD PROCEDURE, BRAKE FLUID .............5-33

LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID . . . 19-44

LEVEL SENDING UNIT / SENSOR - DESCRIPTION, FUEL ................... 14-5

LEVEL SENDING UNIT / SENSOR - INSTALLATION, FUEL .................. 14-6

LEVEL SENDING UNIT / SENSOR - OPERATION, FUEL ..................... 14-5

LEVEL SENDING UNIT / SENSOR - REMOVAL, FUEL ...................... 14-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2325 of 2339

POWER MODULE - INSTALLATION,INTEGRATED ......................8W -97-2

POWER MODULE - OPERATION, INTEGRATED ......................8W -97-2

POWER MODULE - REAR BLOWER MOTOR - DESCRIPTION ...............24-40

POWER MODULE - REAR BLOWER MOTOR - INSTALLATION ...............24-41

POWER MODULE - REAR BLOWER MOTOR - OPERATION .................24-40

POWER MODULE - REAR BLOWER MOTOR - REMOVAL .................. 24-41

POWER MODULE - REMOVAL, INTEGRATED ......................8W -97-2

POWER OUTLET - DESCRIPTION ......8W-97-3

POWER OUTLET - DIAGNOSIS & TESTING .........................8W -97-3

POWER OUTLET - OPERATION ........8W-97-3

POWER SEAT SYSTEM, DESCRIPTION ....8N-31

POWER SEAT SYSTEM, DIAGNOSIS AND TESTING ........................... 8N-33

POWER SEAT SYSTEM, OPERATION .....8N-32

POWER SEAT TRACK - DESCRIPTION ....8N-37

POWER SEAT TRACK - OPERATION ......8N-38

POWER SEAT TRACK, DIAGNOSIS AND TESTING ........................... 8N-38

POWER SLIDING DOOR ADJUSTMENT, STANDARD PROCEDURE ..............8N-49

POWER SLIDING DOOR LEARN CYCLE, STANDARD PROCEDURE ..............8N-48

POWER SLIDING DOOR SYSTEM - DESCRIPTION ........................ 8N-40

POWER SLIDING DOOR SYSTEM - OPERATION ......................... 8N-41

POWER SLIDING DOOR SYSTEM, DIAGNOSIS AND TESTING .............8N-42

POWER STEERING BELT TENSION - STANDARD PROCEDURE, CHECKING .......7-8

POWER STEERING FASTENER TORQUE, SPECIFICATIONS ...................... 19-9

POWER STEERING FLUID LEVEL CHECKING - STANDARD PROCEDURE ....19-44

POWER STEERING GEAR, SPECIAL TOOLS ............................. 19-34

POWER STEERING PUMP INITIAL OPERATION - STANDARD PROCEDURE . . . 19-37

POWER STEERING PUMP, SPECIAL TOOLS ............................. 19-44

POWER STEERING, SPECIAL TOOLS ......19-9

POWER STEERING SYSTEM - DESCRIPTION ........................ 19-1

POWER STEERING SYSTEM - OPERATION .......................... 19-1

POWER STEERING SYSTEM FLOW AND PRESSURE TEST - DIAGNOSIS AND

TESTING ............................ 19-1

POWER TRANSFER UNIT FLUID - DESCRIPTION, AWD ....................0-6

POWER WINDOWS - DESCRIPTION ......8N-61

POWER WINDOWS - OPERATION ........8N-61

POWER WINDOWS, DIAGNOSIS AND TESTING ........................... 8N-61

POWERING SEVERAL LOADS - STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-10

PRELOAD - ADJUSTMENT, DIFFERENTIAL BEARING ..............21-228

PRELOAD MEASUREMENT AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL BEARING ...............21-79

PREPARATION - STANDARD PROCEDURE, ENGINE GASKET

SURFACE ........................ 9-11,9-87

PRESSURE - DIAGNOSIS AND TESTING, CHECKING ENGINE OIL .................9-53

PRESSURE - DIAGNOSIS AND TESTING, ENGINE OIL ......................... 9-138

PRESSURE CAP - DESCRIPTION, RADIATOR ........................... 7-27

PRESSURE CAP - OPERATION, RADIATOR ........................... 7-27

PRESSURE CAP TESTING - DIAGNOSIS AND TESTING, COOLING SYSTEM ........7-28

PRESSURE FOR HIGH SPEED OPERATION - STANDARD PROCEDURE,

TIRE ............................... 22-17

PRESSURE GAUGE - STANDARD PROCEDURE, FUEL .................... 14-3PRESSURE LEAKAGE TEST - DIAGNOSIS

AND TESTING, CYLINDER

COMBUSTION ..................... 9-85,9-9

PRESSURE MONITORING - DESCRIPTION, TIRE ................... 22-9

PRESSURE MONITORING - OPERATION, TIRE ............................... 22-10

PRESSURE REGULATOR - INSTALLATION, FUEL .................. 14-7

PRESSURE REGULATOR - OPERATION, FUEL ............................... 14-7

PRESSURE REGULATOR - REMOVAL, FUEL ............................... 14-7

PRESSURE RELEASE PROCEDURE - STANDARD PROCEDURE, FUEL

SYSTEM ............................ 14-2

PRESSURE RELIEF VALVE - INSTALLATION, OIL ................... 9-144

PRESSURE RELIEF VALVE - REMOVAL, OIL................................ 9-143

PRESSURE RELIEF VALVE, DESCRIPTION - HIGH ............................. 24-72

PRESSURE RELIEF VALVE, OPERATION - HIGH .............................. 24-72

PRESSURE SENSOR - DESCRIPTION, SEAT WEIGHT BLADDER ...............8O-43

PRESSURE SENSOR - DIAGNOSIS AND TESTING, TIRE ...................... 22-11

PRESSURE SENSOR - OPERATION, SEAT WEIGHT BLADDER ................... 8O-44

PRESSURE, SPECIFICATIONS - FUEL SYSTEM ............................ 14-4

PRESSURE SWITCH - DESCRIPTION, OIL . 9-144

PRESSURE SWITCH - INSTALLATION, OIL ........................... 9-144,9-56

PRESSURE SWITCH - OPERATION, OIL . . . 9-144

PRESSURE SWITCH - REMOVAL, OIL ....9-144,

9-56

PRESSURE TEST - DIAGNOSIS AND TESTING, CYLINDER COMPRESSION . . . 9-85,9-9

PRESSURE TEST - DIAGNOSIS AND TESTING, POWER STEERING SYSTEM

FLOW ............................... 19-1

PRESSURE TESTS - DIAGNOSIS AND TESTING, CLUTCH AIR ...........21-153,21-8

PRESSURE TESTS - DIAGNOSIS AND TESTING, HYDRAULIC ............21-150,21-6

PRESSURE TRANSDUCER - DESCRIPTION, A/C ................... 24-20

PRESSURE TRANSDUCER - OPERATION, A/C................................ 24-20

PRESSURE TRANSDUCER, DIAGNOSIS AND TESTING - A/C ................... 24-21

PRESSURES - STANDARD PROCEDURE, TIRE INFLATION ..................... 22-16

PROGRAMMABLE COMMUNICATIONS INTERFACE (PCI) BUS, OPERATION ......14-25

PROGRAMMING - STANDARD PROCEDURE, PCM/SKIM ................8E-1

PROGRAMMING - STANDARD PROCEDURE, REMOTE KEYLESS

ENTRY TRANSMITTER ................8N-24

PROGRAMMING - STANDARD PROCEDURE, TRANSPONDER ...........8Q-6

PROGRAMMING, STANDARD PROCEDURE - ELECTRONIC VEHICLE

INFORMATION CENTER ................8M-8

PROP ROD - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-140

PROP ROD - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT .............23-139

PROPORTIONING - DESCRIPTION, ELECTRONIC VARIABLE BRAKE ..........5-88

PROPORTIONING - OPERATION, ELECTRONIC VARIABLE BRAKE ..........5-89

PROPORTIONING VALVE (HEIGHT SENSING) - DESCRIPTION ..............5-53

PROPORTIONING VALVE (HEIGHT SENSING) - DIAGNOSIS AND TESTING .....5-54

PROPORTIONING VALVE (HEIGHT SENSING) - INSTALLATION ..............5-55

PROPORTIONING VALVE (HEIGHT SENSING) - OPERATION ................5-53

PROPORTIONING VALVE (HEIGHT SENSING) - REMOVAL .................5-55

PULLEY - DESCRIPTION, GENERATOR DECOUPLER ........................ 8F-28PULLEY - DIAGNOSIS AND TESTING,

GENERATOR DECOUPLER ..............8F-28

PULLEY - INSTALLATION, GENERATOR DECOUPLER ........................ 8F-29

PULLEY - INSTALLATION, TIMING BELT TENSIONER .......................... 9-70

PULLEY - OPERATION, GENERATOR DECOUPLER ........................ 8F-28

PULLEY - REMOVAL, GENERATOR DECOUPLER ........................ 8F-29

PULLEY - REMOVAL, TIMING BELT TENSIONER .......................... 9-69

PUMP - 2.4L - CLEANING, WATER ........7-32

PUMP - 2.4L - DESCRIPTION, WATER .....7-32

PUMP - 2.4L - INSPECTION, WATER ......7-32

PUMP - 2.4L - INSTALLATION, WATER .....7-32

PUMP - 2.4L - REMOVAL, WATER ........7-32

PUMP - 3.3/3.8L - CLEANING, WATER .....7-35

PUMP - 3.3/3.8L - DESCRIPTION, WATER ............................. 7-34

PUMP - 3.3/3.8L - INSPECTION, WATER . . . 7-35

PUMP - 3.3/3.8L - INSTALLATION, WATER ............................. 7-35

PUMP - 3.3/3.8L - REMOVAL, WATER .....7-34

PUMP - ASSEMBLY, OIL ...........9-146,9-58

PUMP - ASSEMBLY, OIL ........21-112,21-263

PUMP - CLEANING, OIL ...........9-145,9-57

PUMP - DESCRIPTION, FUEL ............14-8

PUMP - DESCRIPTION, FUEL DOSING . . . 24-117

PUMP - DESCRIPTION, OIL .............9-144

PUMP - DESCRIPTION, OIL ......21-110,21-261

PUMP - DISASSEMBLY, OIL ........9-145,9-57

PUMP - DISASSEMBLY, OIL .....21-110,21-261

PUMP - INSPECTION, OIL ..........9-145,9-58

PUMP - INSTALLATION, FUEL DOSING . . . 24-117

PUMP - INSTALLATION, LEAK DETECTION ......................... 25-15

PUMP - INSTALLATION, OIL ........9-146,9-59

PUMP - INSTALLATION, SEAL - OIL ....21-113,

21-264

PUMP - OPERATION, FUEL ..............14-8

PUMP - OPERATION, FUEL DOSING .....24-117

PUMP - OPERATION, OIL .......21-110,21-261

PUMP - REMOVAL, FUEL DOSING ......24-117

PUMP - REMOVAL, LEAK DETECTION ....25-15

PUMP - REMOVAL, OIL ............9-144,9-56

PUMP - REMOVAL, SEAL - OIL . . . 21-113,21-264

PUMP (2.4L ENGINE) - INSTALLATION ....19-43

PUMP (2.4L ENGINE) - REMOVAL .......19-38

PUMP (2.4L/3.3L/3.8L ENGINE) - DESCRIPTION ....................... 19-36

PUMP (3.3L/3.8L ENGINE) - INSTALLATION ....................... 19-43

PUMP (3.3L/3.8L ENGINE) - REMOVAL . . . 19-40

PUMP (DIESEL) - DESCRIPTION .........19-37

PUMP (DIESEL) - INSTALLATION ........19-43

PUMP (DIESEL) - REMOVAL ............19-41

PUMP INITIAL OPERATION - STANDARD PROCEDURE, POWER STEERING ........19-37

PUMP INLET TUBE - 2.4L - DESCRIPTION, WATER .................7-36

PUMP INLET TUBE - 2.4L - INSTALLATION, WATER .................7-36

PUMP INLET TUBE - 2.4L - REMOVAL, WATER ............................. 7-36

PUMP INLET TUBE - 3.3/3.8L - INSTALLATION, WATER .................7-37

PUMP INLET TUBE - 3.3/3.8L - REMOVAL, WATER .................... 7-37

PUMP MODULE - DESCRIPTION, FUEL ....14-8

PUMP MODULE - OPERATION, FUEL ......14-9

PUMP MOTOR - INSTALLATION, WASHER ........................... 8R-12

PUMP MOTOR - REMOVAL, WASHER ....8R-12

PUMP (PULLEY) - ASSEMBLY ..........19-42

PUMP (PULLEY) - DISASSEMBLY ........19-41

PUMP RELAY - DESCRIPTION, FUEL .....14-32

PUMP RELAY - OPERATION, FUEL .......14-32

PUMP, SPECIAL TOOLS - POWER STEERING .......................... 19-44

PUSH-PIN GROMMET REPLACEMENT, STANDARD PROCEDURE ..............8N-48

PUSHRODS - DESCRIPTION ............9-112

PUSHRODS - OPERATION ..............9-112

QUAD BUCKET - INSTALLATION, BUCKET SEAT BACK ........................ 23-141

QUAD BUCKET - INSTALLATION, SEAT BELT BUCKLE - FIRST ROW INBOARD ....8O-36

24 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2330 of 2339

SENSOR - OPERATION, BATTERYTEMPERATURE ...................... 8F-24

SENSOR - OPERATION, BELT TENSION ....8O-9

SENSOR - OPERATION, CAMSHAFT POSITION ............................ 8I-4

SENSOR - OPERATION, CRANKSHAFT POSITION .......................... 14-29

SENSOR - OPERATION, ENGINE SPEED . . . 14-30

SENSOR - OPERATION, EVAPORATOR TEMPERATURE ...................... 24-27

SENSOR - OPERATION, FUEL LEVEL SENDING UNIT ....................... 14-5

SENSOR - OPERATION, HEATED SEAT ....8G-13

SENSOR - OPERATION, INFRARED TEMPERATURE ...................... 24-28

SENSOR - OPERATION, KNOCK ...........8I-8

SENSOR - OPERATION, MAP ...........14-34

SENSOR - OPERATION, O2 .............14-36

SENSOR - OPERATION, PARK ASSIST .....8B-6

SENSOR - OPERATION, PINCH ..........8N-17

SENSOR - OPERATION, SEAT WEIGHT BLADDER & PRESSURE ...............8O-44

SENSOR - OPERATION, THROTTLE POSITION .......................... 14-41

SENSOR - OPERATION, TRANSMISSION RANGE ...................... 21-131,21-282

SENSOR - OUTPUT - DESCRIPTION, SPEED ...................... 21-122,21-273

SENSOR - OUTPUT - INSTALLATION, SPEED ...................... 21-123,21-274

SENSOR - OUTPUT - OPERATION, SPEED ...................... 21-122,21-273

SENSOR - OUTPUT - REMOVAL, SPEED . 21-123, 21-274

SENSOR - REMOVAL, BATTERY TEMPERATURE ...................... 8F-24

SENSOR - REMOVAL, CRANKSHAFT POSITION .......................... 14-30

SENSOR - REMOVAL, FRONT WHEEL SPEED .............................. 5-91

SENSOR - REMOVAL, FUEL LEVEL SENDING UNIT ....................... 14-5

SENSOR - REMOVAL, IMPACT ..........8O-19

SENSOR - REMOVAL, PARK ASSIST ......8B-6

SENSOR - REMOVAL, PINCH ...........8N-18

SENSOR - REMOVAL, TRANSMISSION RANGE ...................... 21-131,21-282

SENSOR - SPECIFICATIONS, BATTERY TEMPERATURE ...................... 8F-23

SENSOR - TPM - CAUTION .............22-11

SENSOR - TPM - DESCRIPTION .........22-10

SENSOR - TPM - INSTALLATION ........22-11

SENSOR - TPM - OPERATION ...........22-10

SENSOR - TPM - REMOVAL ............22-11

SENSOR AIR GAP, SPECIFICATIONS - WHEEL SPEED ........................ 5-91

SENSOR CIRCUIT, DIAGNOSIS AND TESTING - AMBIENT TEMPERATURE .....8M-12

SENSOR, DIAGNOSIS AND TESTING - AMBIENT TEMPERATURE ..............8M-12

SENSOR, DIAGNOSIS AND TESTING - HEATED SEAT ....................... 8G-13

SENSOR RETURN - PCM INPUT - OPERATION ......................... 8E-14

SENTRY KEY REMOTE ENTRY MODULE - DESCRIPTION ........................ 8Q-3

SENTRY KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING ..............8Q-5

SENTRY KEY REMOTE ENTRY MODULE - INSTALLATION ....................... 8Q-6

SENTRY KEY REMOTE ENTRY MODULE - OPERATION .......................... 8Q-4

SENTRY KEY REMOTE ENTRY MODULE - REMOVAL ........................... 8Q-6

SENTRY KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING ..............8Q-3

SERVO - DESCRIPTION .................8P-4

SERVO - INSTALLATION ................8P-4

SERVO - OPERATION ..................8P-4

SERVO - REMOVAL .................... 8P-4

SETTING - STANDARD PROCEDURE, PINION FACTOR ...................... 8E-15

SETTING TRANSMITTER CODES, STANDARD PROCEDURE ..............8M-12

SEVERAL LOADS - STANDARD PROCEDURE, TESTING FOR A SHORT

TO GROUND ON FUSES POWERING . . . 8W-01-10

SHACKLE - INSTALLATION, SPRING .......2-44 SHACKLE - REMOVAL, SPRING

..........2-44

SHAFT - ASSEMBLY, ROCKER ARMS .....9-113

SHAFT - DIAGNOSIS AND TESTING, HALF ................................3-1

SHAFT - DISASSEMBLY, ROCKER ARMS . . 9-113

SHAFT - FRONT - DESCRIPTION, HALF .....3-1

SHAFT - FRONT - INSTALLATION, HALF .....3-4

SHAFT - FRONT - REMOVAL, HALF ........3-2

SHAFT - FRONT - SPECIFICATIONS, HALF . . . 3-6

SHAFT - INSTALLATION, ROCKER ARMS . . 9-113

SHAFT - REMOVAL, ROCKER ARMS ......9-112

SHAFT - RHD - INSTALLATION, PEDAL TORQUE ............................ 5-44

SHAFT - RHD - REMOVAL, PEDAL TORQUE ............................ 5-44

SHAFTS AND CARRIER ASSEMBLY - DESCRIPTION, BALANCE ................9-71

SHAFTS AND CARRIER ASSEMBLY - INSTALLATION, BALANCE ...............9-73

SHAFTS AND CARRIER ASSEMBLY - OPERATION, BALANCE .................9-71

SHAFTS AND CARRIER ASSEMBLY - REMOVAL, BALANCE ................... 9-71

SHIELD - INSTALLATION, FRONT WHEELHOUSE SPLASH ................23-57

SHIELD - NO CUP HOLDER - INSTALLATION, QUAD BUCKET SEAT

SIDE ............................. 23-143

SHIELD - NO CUP HOLDER - REMOVAL, QUAD BUCKET SEAT SIDE ............23-143

SHIELD - REMOVAL, FRONT WHEELHOUSE SPLASH ................23-57

SHIELD - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT

CUSHION SIDE ..................... 23-138

SHIELD - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT CUSHION

SIDE ............................. 23-138

SHIELD CUP HOLDER - FOLD-IN-FLOOR - INSTALLATION, SIDE ...............23-160

SHIELD CUP HOLDER - FOLD-IN-FLOOR - REMOVAL, SIDE ................... 23-160

SHIELD/CUP HOLDER - FLAP AND SPRING ASSEMBLY - INSTALLATION,

QUAD BUCKET SEAT SIDE ............23-151

SHIELD/CUP HOLDER - FLAP AND SPRING ASSEMBLY - REMOVAL, QUAD

BUCKET SEAT SIDE .................. 23-151

SHIELD/CUP HOLDER - INSTALLATION, QUAD BUCKET SEAT SIDE ............23-142

SHIELD/CUP HOLDER - REMOVAL, QUAD BUCKET SEAT SIDE .................. 23-141

SHIELDS - DESCRIPTION, HEAT ..........11-7

SHIELDS - INSTALLATION, HEAT .........11-7

SHIELDS - OPERATION, HEAT ............11-7

SHIELDS - REMOVAL, HEAT .............11-7

SHIFT CABLE - INSTALLATION, GEAR ....21-234

SHIFT CABLE - REMOVAL, GEAR . . 21-233,21-84

SHIFT INTERLOCK SOLENOID - DESCRIPTION ................ 21-113,21-264

SHIFT INTERLOCK SOLENOID - DIAGNOSIS AND TESTING, BRAKE/

TRANSMISSION ............... 21-115,21-266

SHIFT INTERLOCK SOLENOID - INSTALLATION ................ 21-116,21-267

SHIFT INTERLOCK SOLENOID - OPERATION .................. 21-114,21-265

SHIFT INTERLOCK SOLENOID - REMOVAL ................... 21-115,21-266

SHOCK ABSORBER - DESCRIPTION .......2-36

SHOCK ABSORBER - INSTALLATION ......2-38

SHOCK ABSORBER - OPERATION .........2-36

SHOCK ABSORBER - REMOVAL ..........2-36

SHOCK ABSORBER (UPPER BUSHING) - ASSEMBLY .......................... 2-37

SHOCK ABSORBER (UPPER BUSHING) - DISASSEMBLY ........................ 2-37

SHOE LINING - INSPECTION, REAR DRUM BRAKE ........................ 5-22

SHOES - ADJUSTMENT, PARKING BRAKE . . 5-85

SHOES - ADJUSTMENT, REAR DRUM BRAKE .............................. 5-23

SHOES - CLEANING, DISC BRAKE ....5-16,5-18

SHOES - INSPECTION, DISC BRAKE . . . 5-16,5-18

SHOES - INSTALLATION, REAR DISC BRAKE .............................. 5-19

SHOES - INSTALLATION, REAR DRUM BRAKE .............................. 5-22SHOES - PARKING BRAKE -

INSTALLATION ........................ 5-84

SHOES - PARKING BRAKE - REMOVAL ....5-78

SHOES - REMOVAL, REAR DISC BRAKE ....5-17

SHOES - REMOVAL, REAR DRUM BRAKE . . 5-19

SHOES (CONTINENTAL TEVES BRAKES) - INSTALLATION, FRONT DISC BRAKE ......5-16

SHOES (CONTINENTAL TEVES BRAKES) - REMOVAL, FRONT DISC BRAKE ..........5-15

SHOES (TRW BRAKES) - INSTALLATION, FRONT DISC BRAKE ................... 5-17

SHOES (TRW BRAKES) - REMOVAL, FRONT DISC BRAKE ................... 5-15

SHORT TO GROUND - STANDARD PROCEDURE, TESTING FOR A ........8W-01-9

SHORT TO GROUND ON FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A ..........................8W -01-10

SHROUD - LOWER - INSTALLATION ......19-21

SHROUD - LOWER - REMOVAL .........19-21

SHROUD - UPPER - INSTALLATION ......19-22

SHROUD - UPPER - REMOVAL ..........19-22

SHUT DOWN RELAY - DESCRIPTION, AUTO ............................... 8I-3

SHUT DOWN RELAY - OPERATION, AUTO . . . 8I-3

SIDE - INSTALLATION, BODY ...........23-44

SIDE - INSTALLATION, LIFTGATE ........23-44

SIDE - REMOVAL, BODY ...............23-44

SIDE - REMOVAL, LIFTGATE ............23-44

SIDE COVER - INSTALLATION, FRONT SEAT CUSHION ..................... 23-121

SIDE COVER - OCS - INSTALLATION, FRONT SEAT CUSHION ...............23-122

SIDE COVER - OCS - REMOVAL, FRONT SEAT CUSHION ..................... 23-121

SIDE COVER - REMOVAL, FRONT SEAT CUSHION .......................... 23-120

SIDE MOLDINGS - INSTALLATION, BODY . . 23-46

SIDE MOLDINGS - REMOVAL, BODY .....23-45

SIDE SHIELD - NO CUP HOLDER - INSTALLATION, QUAD BUCKET SEAT ....23-143

SIDE SHIELD - NO CUP HOLDER - REMOVAL, QUAD BUCKET SEAT ........23-143

SIDE SHIELD - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT

CUSHION .......................... 23-138

SIDE SHIELD - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT

CUSHION .......................... 23-138

SIDE SHIELD CUP HOLDER - FOLD-IN- FLOOR - INSTALLATION ..............23-160

SIDE SHIELD CUP HOLDER - FOLD-IN- FLOOR - REMOVAL .................. 23-160

SIDE SHIELD/CUP HOLDER - FLAP AND SPRING ASSEMBLY - INSTALLATION,

QUAD BUCKET SEAT .................23-151

SIDE SHIELD/CUP HOLDER - FLAP AND SPRING ASSEMBLY - REMOVAL, QUAD

BUCKET SEAT ...................... 23-151

SIDE SHIELD/CUP HOLDER - INSTALLATION, QUAD BUCKET SEAT ....23-142

SIDE SHIELD/CUP HOLDER - REMOVAL, QUAD BUCKET SEAT .................23-141

SIDE VIEW MIRROR - INSTALLATION .....23-60

SIDE VIEW MIRROR - REMOVAL ........23-60

SIDEVIEW MIRROR - REMOVAL .........8N-30

SIGNAL LAMP - INSTALLATION, PARK/TURN ......................... 8L-18

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-18

SIGNAL SYSTEM - DESCRIPTION, TURN . . 8L-17

SIGNAL SYSTEM - OPERATION, TURN ....8L-17

SILL PLATE - INSTALLATION, LIFTGATE . . . 23-95

SILL PLATE - INSTALLATION, SLIDING DOOR ............................. 23-99

SILL PLATE - REMOVAL, LIFTGATE .......23-94

SILL PLATE - REMOVAL, SLIDING DOOR . . 23-98

SILL TRIM PLATE - INSTALLATION, DOOR ............................. 23-89

SILL TRIM PLATE - REMOVAL, DOOR ....23-89

SINGLE ZONE, DESCRIPTION - MANUAL . . . 24-2

SINGLE ZONE, OPERATION - MANUAL .....24-4

SLEEVE - INSTALLATION, HEADREST ....23-107

SLEEVE - REMOVAL, HEADREST .......23-107

SLEEVE - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, HEADREST ....23-131

SLEEVE - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, HEADREST ........23-131

RS INDEX29

Description Group-Page Description Group-Page Description Group-Page

Page 2334 of 2339

TO CYLINDER BORE FITTING -STANDARD PROCEDURE, PISTON ........9-44

TO FILLER NECK SEAL - DIAGNOSIS AND TESTING, RADIATOR CAP ...........7-28

TO GROUND - STANDARD PROCEDURE, TESTING FOR A SHORT .............8W-01-9

TO GROUND ON FUSES POWERING SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . 8W-01-10

TO USE WIRING DIAGRAMS - DESCRIPTION, HOW ................8W -01-1

TONE WHEEL - INSPECTION .............5-94

TONE WHEEL RUNOUT, SPECIFICATIONS . . . 5-91

TOOLS - 2.4L ENGINE, SPECIAL ..........9-21

TOOLS - 3.3/3.8L ENGINE, SPECIAL .......9-98

TOOLS - 41TE AUTOMATIC TRANSAXLE, SPECIAL .......................... 21-213

TOOLS - BASE BRAKE SYSTEM, SPECIAL . . 5-10

TOOLS - BATTERY SYSTEM SPECIAL TOOLS, SPECIAL ...................... 8F-7

TOOLS - BODY, SPECIAL ...............23-13

TOOLS - COOLING SYSTEM, SPECIAL ......7-6

TOOLS - EXHAUST SYSTEM, SPECIAL .....11-4

TOOLS - FRONT SUSPENSION, SPECIAL ....2-3

TOOLS - FUEL, SPECIAL ...........14-27,14-4

TOOLS - OVERHEAD CONSOLE, SPECIAL . . 8M-7

TOOLS - POWER DISTRIBUTION SYSTEMS, SPECIAL ................8W -97-1

TOOLS - POWER STEERING GEAR, SPECIAL ........................... 19-34

TOOLS - POWER STEERING PUMP, SPECIAL ........................... 19-44

TOOLS - POWER STEERING, SPECIAL .....19-9

TOOLS - REAR SUSPENSION, SPECIAL ....2-28

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, SCHEMATICS AND DIAGRAMS - SPECIAL ........................... 21-68

TOOLS, SPECIAL TOOLS - BATTERY SYSTEM SPECIAL ..................... 8F-7

TOOLS, SPECIFICATIONS - SPECIAL ......8F-24

TOP COVER - INSTALLATION, INSTRUMENT PANEL .................. 23-72

TOP COVER - REMOVAL, INSTRUMENT PANEL ............................. 23-72

TOP PAD ASSEMBLY - INSTALLATION, INSTRUMENT PANEL .................. 23-77

TOP PAD ASSEMBLY - REMOVAL, INSTRUMENT PANEL .................. 23-77

TORQUES, SPECIFICATIONS ............8F-36

TOUCH-UP - DESCRIPTION, PAINTED ....23-101

TOWING - STANDARD PROCEDURE .......0-26

TPM - CAUTION, SENSOR ..............22-11

TPM - DESCRIPTION, SENSOR ..........22-10

TPM - INSTALLATION, SENSOR .........22-11

TPM - OPERATION, SENSOR ............22-10

TPM - REMOVAL, SENSOR .............22-11

TRACK - DESCRIPTION, POWER SEAT ....8N-37

TRACK - INSTALLATION, BENCH SEAT . . . 23-148

TRACK - OPERATION, POWER SEAT .....8N-38

TRACK & RACK - DESCRIPTION, LOWER DRIVE UNIT ........................ 8N-57

TRACK & RACK - INSTALLATION, LOWER DRIVE UNIT .................. 8N-58

TRACK & RACK - OPERATION, LOWER DRIVE UNIT ........................ 8N-57

TRACK & RACK - REMOVAL, LOWER DRIVE UNIT ........................ 8N-57

TRACK - REAR COVER - INSTALLATION, FRONT SEAT ....................... 23-128

TRACK - REAR COVER - REMOVAL, FRONT SEAT ....................... 23-128

TRACK - REMOVAL, BENCH SEAT .......23-148

TRACK ADJUSTER/MANUAL - OCS - INSTALLATION, FRONT SEAT ..........23-128

TRACK ADJUSTER/MANUAL - OCS - REMOVAL, FRONT SEAT ..............23-126

TRACK ADJUSTER/POWER - OCS - INSTALLATION, FRONT SEAT ..........23-125

TRACK ADJUSTER/POWER - OCS - REMOVAL, FRONT SEAT ..............23-124

TRACK BAR - DESCRIPTION .............2-45

TRACK BAR - INSTALLATION ............2-46

TRACK BAR - OPERATION ...............2-46

TRACK BAR - REMOVAL ................2-46

TRACK, DIAGNOSIS AND TESTING - POWER SEAT ....................... 8N-38

TRACK MANUAL ADJUSTER - INSTALLATION, FRONT SEAT ..........23-126TRACK MANUAL ADJUSTER - REMOVAL,

FRONT SEAT ....................... 23-125

TRACK POWER ADJUSTER - INSTALLATION, FRONT SEAT ..........23-124

TRACK POWER ADJUSTER - REMOVAL, FRONT SEAT ....................... 23-124

TRACK REAR COVER - OCS - INSTALLATION, FRONT SEAT ..........23-129

TRACK REAR COVER - OCS - REMOVAL, FRONT SEAT ....................... 23-129

TRACTION CONTROL SWITCH - DIAGNOSIS AND TESTING ..............5-94

TRACTION CONTROL SWITCH - INSTALLATION ........................ 5-95

TRACTION CONTROL SWITCH - REMOVAL ........................... 5-95

TRACTION CONTROL SYSTEM - DESCRIPTION ........................ 5-88

TRACTION CONTROL SYSTEM - OPERATION .......................... 5-89

TRANSAXLE - DESCRIPTION, 40TE AUTOMATIC .......................... 21-2

TRANSAXLE - DESCRIPTION, 41TE AUTOMATIC ........................ 21-147

TRANSAXLE - OPERATION, 40TE AUTOMATIC .......................... 21-4

TRANSAXLE - OPERATION, 41TE AUTOMATIC ........................ 21-149

TRANSAXLE - SPECIFICATIONS, 41TE . . . 21-211, 21-66

TRANSAXLE FLUID - DESCRIPTION, AUTOMATIC/MANUAL ...................0-4

TRANSAXLE GENERAL DIAGNOSIS - DIAGNOSIS AND TESTING, 4XTE .....21-149,21-5

TRANSAXLE HYDRAULIC SCHEMATICS, SCHEMATICS AND DIAGRAMS - 4XTE . . . 21-199, 21-54

TRANSAXLE, SPECIAL TOOLS - 41TE AUTOMATIC ........................ 21-213

TRANSDUCER - DESCRIPTION, A/C PRESSURE ......................... 24-20

TRANSDUCER - OPERATION, A/C PRESSURE ......................... 24-20

TRANSDUCER, DIAGNOSIS AND TESTING - A/C PRESSURE .............24-21

TRANSFER UNIT FLUID - DESCRIPTION, AWD POWER ..........................0-6

TRANSMISSION CONTROL RELAY - DESCRIPTION ................ 21-130,21-281

TRANSMISSION CONTROL RELAY - OPERATION .................. 21-130,21-281

TRANSMISSION COOLER LINE QUICK CONNECT FITTING DISASSEMBLY/

ASSEMBLY - STANDARD PROCEDURE .....7-38

TRANSMISSION OIL COOLER - DESCRIPTION ........................ 7-39

TRANSMISSION OIL COOLER - INSPECTION ......................... 7-39

TRANSMISSION OIL COOLER LINES - INSTALLATION ........................ 7-40

TRANSMISSION OIL COOLER LINES - REMOVAL ........................... 7-39

TRANSMISSION RANGE SENSOR - DESCRIPTION ................ 21-130,21-281

TRANSMISSION RANGE SENSOR - INSTALLATION ................ 21-131,21-282

TRANSMISSION RANGE SENSOR - OPERATION .................. 21-131,21-282

TRANSMISSION RANGE SENSOR - REMOVAL ................... 21-131,21-282

TRANSMITTER - DESCRIPTION, UNIVERSAL ........................ 8M-11

TRANSMITTER CODES, STANDARD PROCEDURE - ERASING ..............8M-12

TRANSMITTER CODES, STANDARD PROCEDURE - SETTING ...............8M-12

TRANSMITTER, DIAGNOSIS AND TESTING - KEYLESS ENTRY ............8N-24

TRANSMITTER, DIAGNOSIS AND TESTING - UNIVERSAL ...............8M-11

TRANSMITTER PROGRAMMING - STANDARD PROCEDURE, REMOTE

KEYLESS ENTRY ..................... 8N-24

TRANSMITTER RANGE - SPECIFICATIONS ..................... 8N-24

TRANSPONDER KEY - DESCRIPTION ......8Q-6

TRANSPONDER KEY - OPERATION ........8Q-6TRANSPONDER PROGRAMMING -

STANDARD PROCEDURE ...............8Q-6

TRANSVERSE BRACKET - DESCRIPTION . . 8N-19

TRANSVERSE BRACKET - INSTALLATION . . 8N-19

TRANSVERSE BRACKET - OPERATION ....8N-19

TRANSVERSE BRACKET - REMOVAL .....8N-19

TRAY - DESCRIPTION, BATTERY .........8F-19

TRAY - INSTALLATION, BATTERY ........8F-20

TRAY - INSTALLATION, FLOOR CONSOLE BASE .............................. 23-89

TRAY - REMOVAL, BATTERY ............8F-19

TRAY - REMOVAL, FLOOR CONSOLE BASE .............................. 23-89

TREAD WEAR INDICATORS - DIAGNOSIS AND TESTING ....................... 22-16

TRIM - INSTALLATION, A-PILLAR ........23-79

TRIM - INSTALLATION, A-PILLAR LOWER EXTENSION .................. 23-79

TRIM - INSTALLATION, B-PILLAR LOWER ............................ 23-80

TRIM - INSTALLATION, B-PILLAR UPPER . . 23-80

TRIM - INSTALLATION, COWL ..........23-88

TRIM - INSTALLATION, C-PILLAR ........23-88

TRIM - INSTALLATION, REAR HEADER ....23-96

TRIM - REMOVAL, A-PILLAR ...........23-79

TRIM - REMOVAL, A-PILLAR LOWER EXTENSION ......................... 23-79

TRIM - REMOVAL, B-PILLAR LOWER .....23-79

TRIM - REMOVAL, B-PILLAR UPPER .......23-80

TRIM - REMOVAL, COWL ..............23-88

TRIM - REMOVAL, C-PILLAR ...........23-88

TRIM - REMOVAL, REAR HEADER .......23-96

TRIM BOLSTER - INSTALLATION, QUARTER .......................... 23-95

TRIM BOLSTER - REMOVAL, QUARTER . . . 23-95

TRIM CARE, CLEANING - WHEEL AND WHEEL ............................ 22-19

TRIM PANEL - INSTALLATION .....23-20,23-34,

23-43

TRIM PANEL - INSTALLATION, LEFT D-PILLAR ........................... 23-94

TRIM PANEL - INSTALLATION, LEFT QUARTER .......................... 23-94

TRIM PANEL - INSTALLATION, RIGHT D-PILLAR ........................... 23-98

TRIM PANEL - INSTALLATION, RIGHT QUARTER .......................... 23-97

TRIM PANEL - REMOVAL ....23-20,23-34,23-43

TRIM PANEL - REMOVAL, LEFT D-PILLAR ........................... 23-94

TRIM PANEL - REMOVAL, LEFT QUARTER .......................... 23-94

TRIM PANEL - REMOVAL, RIGHT D-PILLAR ........................... 23-97

TRIM PANEL - REMOVAL, RIGHT QUARTER .......................... 23-97

TRIM PLATE - INSTALLATION, DOOR SILL ............................... 23-89

TRIM PLATE - REMOVAL, DOOR SILL ....23-89

TRIM RING AND COVER - FOLD-IN- FLOOR - INSTALLATION, CARPET ........23-84

TRIM RING AND COVER - FOLD-IN- FLOOR - REMOVAL, CARPET ...........23-84

TRIP DEFINITION, DESCRIPTION .........25-1

TROUBLE CODES - STANDARD PROCEDURE, OBTAINING DIAGNOSTIC . . . 8E-15

TUB CARPET INSERT - FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR ....23-98

TUB CARPET INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR ........23-98

TUB CARPETS INSERT - FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR ..........23-96

TUB CARPETS INSERT - FOLD-IN-FLOOR - REMOVAL, REAR FLOOR .............23-95

TUBE - 2.4L - DESCRIPTION, WATER PUMP INLET ......................... 7-36

TUBE - 2.4L - INSTALLATION, WATER PUMP INLET ......................... 7-36

TUBE - 2.4L - REMOVAL, WATER PUMP INLET ............................... 7-36

TUBE - 3.3/3.8L - INSTALLATION, WATER PUMP INLET ......................... 7-37

TUBE - 3.3/3.8L - REMOVAL, WATER PUMP INLET ......................... 7-37

TUBE - INSTALLATION, DRAIN .........23-172

TUBE - INSTALLATION, EXHAUST .......24-116

TUBE - INSTALLATION, FUEL TANK FILLER ............................. 14-17

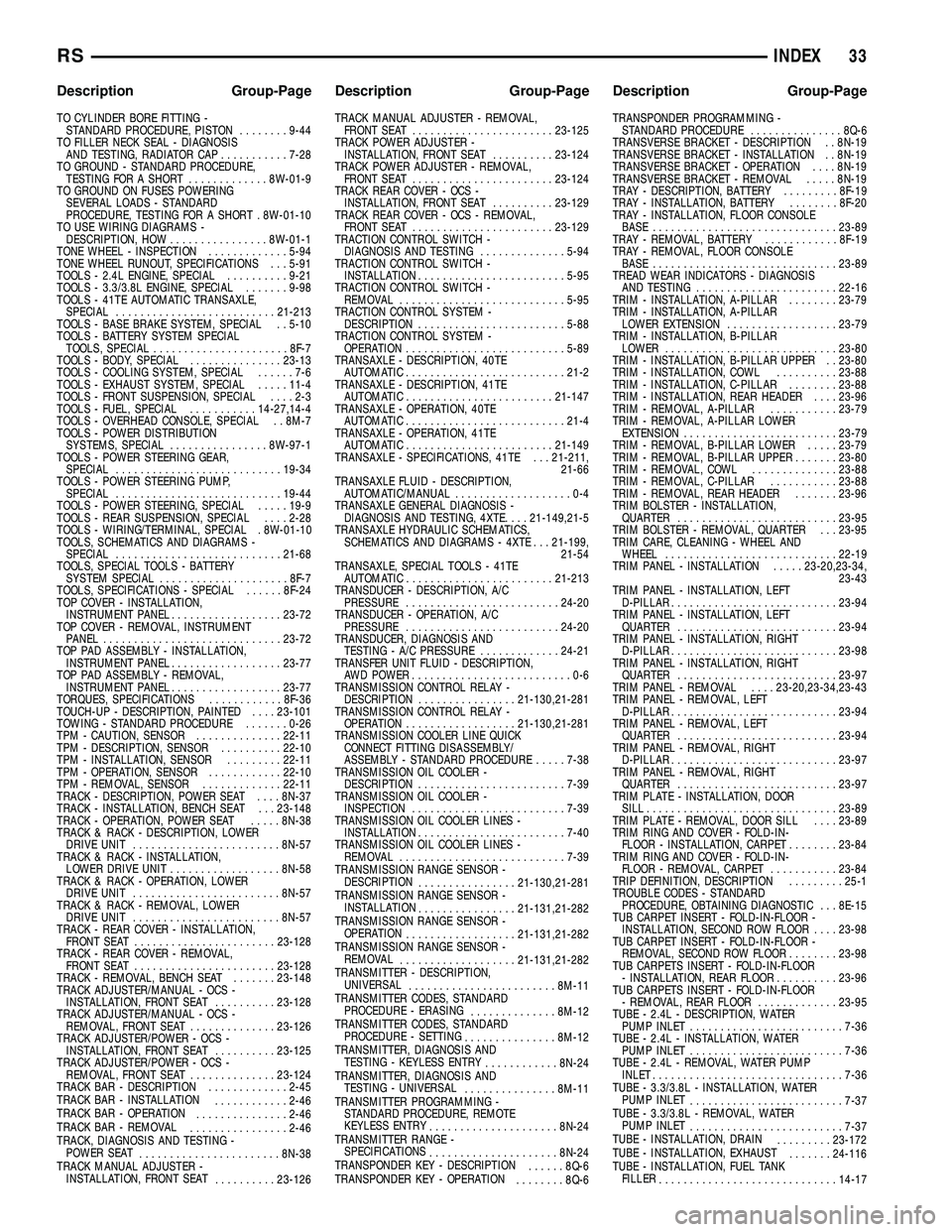

RS INDEX33

Description Group-Page Description Group-Page Description Group-Page