light CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1859 of 2339

(1) Slide lower seat belt cover rearward to expose

anchor fastener.

(2) Remove bolt/nut attaching lower seat belt

anchor to floor.

(3) Remove upper B-pillar trim cover.

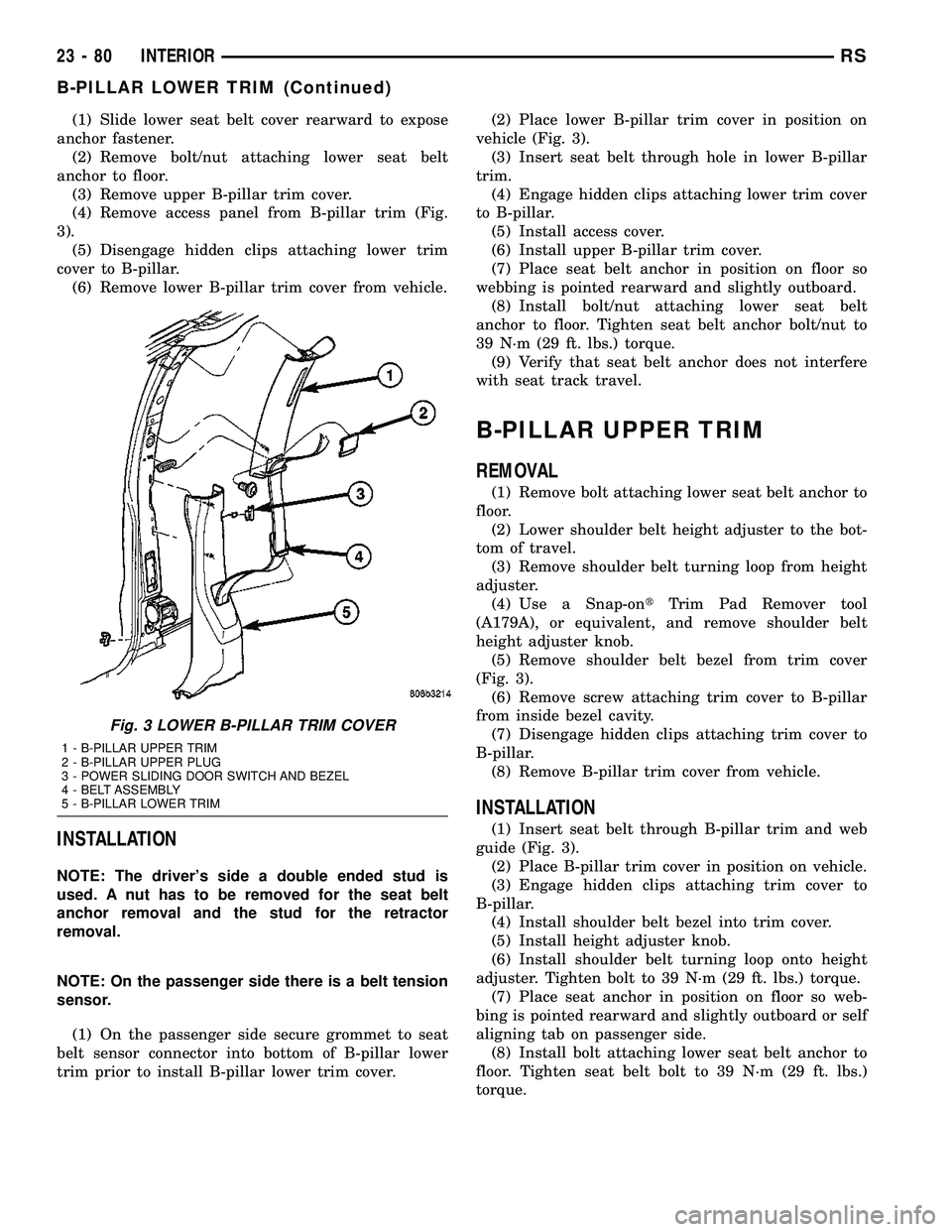

(4) Remove access panel from B-pillar trim (Fig.

3).

(5) Disengage hidden clips attaching lower trim

cover to B-pillar.

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

NOTE: The driver's side a double ended stud is

used. A nut has to be removed for the seat belt

anchor removal and the stud for the retractor

removal.

NOTE: On the passenger side there is a belt tension

sensor.

(1) On the passenger side secure grommet to seat

belt sensor connector into bottom of B-pillar lower

trim prior to install B-pillar lower trim cover.(2) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(3) Insert seat belt through hole in lower B-pillar

trim.

(4) Engage hidden clips attaching lower trim cover

to B-pillar.

(5) Install access cover.

(6) Install upper B-pillar trim cover.

(7) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(8) Install bolt/nut attaching lower seat belt

anchor to floor. Tighten seat belt anchor bolt/nut to

39 N´m (29 ft. lbs.) torque.

(9) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.

(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.

(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard or self

aligning tab on passenger side.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

23 - 80 INTERIORRS

B-PILLAR LOWER TRIM (Continued)

Page 1879 of 2339

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - COLOR CODE CHARTS . . 100

BASE COAT/CLEARCOAT FINISH

DESCRIPTION........................101

PAINT CODE

DESCRIPTION........................101PAINTED TOUCH-UP

DESCRIPTION........................101

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION........................101

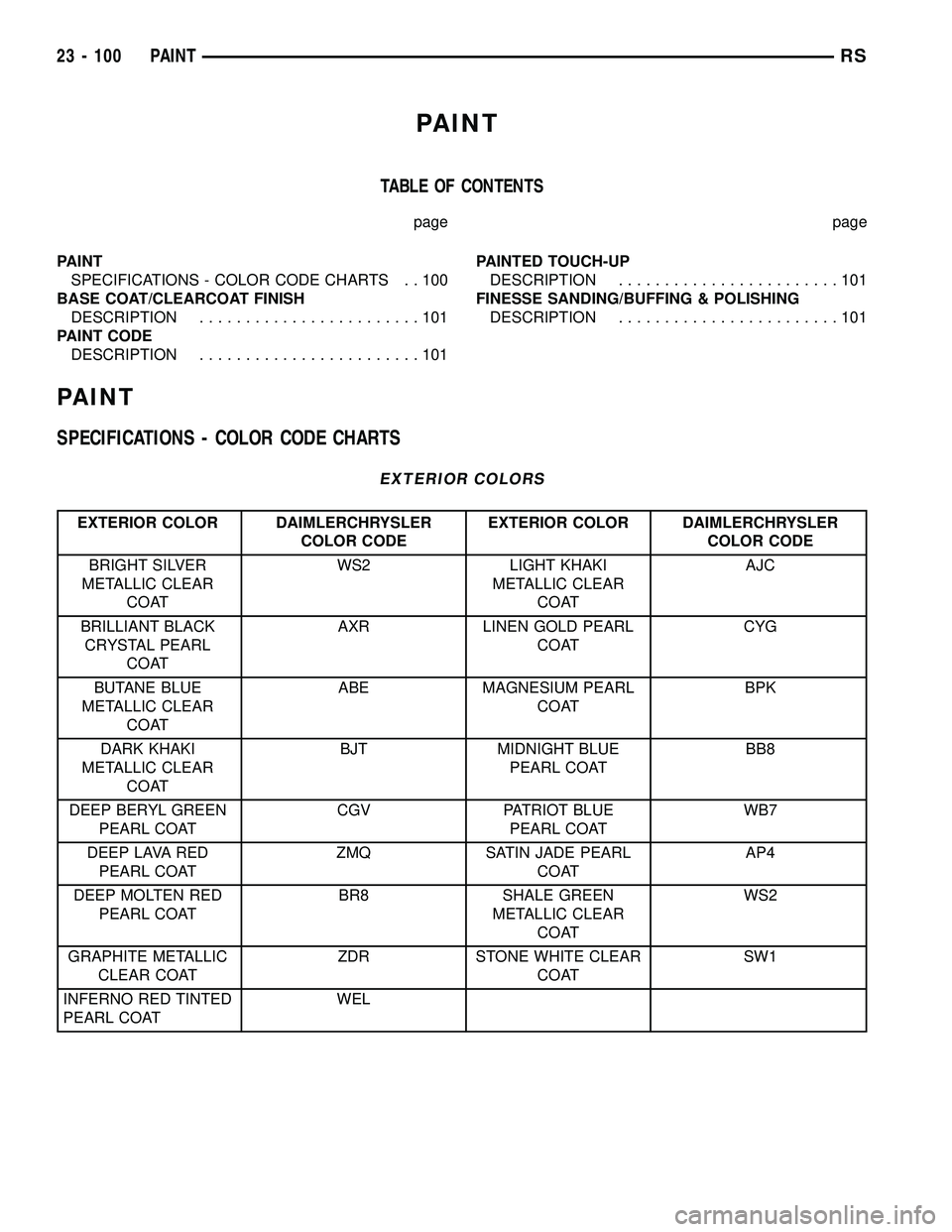

PAINT

SPECIFICATIONS - COLOR CODE CHARTS

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEEXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

BRIGHT SILVER

METALLIC CLEAR

COATWS2 LIGHT KHAKI

METALLIC CLEAR

COATAJC

BRILLIANT BLACK

CRYSTAL PEARL

COATAXR LINEN GOLD PEARL

COATCYG

BUTANE BLUE

METALLIC CLEAR

COATABE MAGNESIUM PEARL

COATBPK

DARK KHAKI

METALLIC CLEAR

COATBJT MIDNIGHT BLUE

PEARL COATBB8

DEEP BERYL GREEN

PEARL COATCGV PATRIOT BLUE

PEARL COATWB7

DEEP LAVA RED

PEARL COATZMQ SATIN JADE PEARL

COATAP4

DEEP MOLTEN RED

PEARL COATBR8 SHALE GREEN

METALLIC CLEAR

COATWS2

GRAPHITE METALLIC

CLEAR COATZDR STONE WHITE CLEAR

COATSW1

INFERNO RED TINTED

PEARL COATWEL

23 - 100 PAINTRS

Page 1880 of 2339

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEINTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

DARK KHAKI/LIGHT

GRAYSTONEJ1 MEDIUM SLATE

GRAYD5

KHAKI J3

BASE COAT/CLEARCOAT

FINISH

DESCRIPTION

On most vehicles a two-part paint application

(basecoat/clearcoat) is used. Color paint that is

applied to primer is called basecoat. The clearcoat

protects the basecoat from ultraviolet light and pro-

vides a durable high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning solvents on

painted surfaces. Damage to finish or color can result.

PAINT CODE

DESCRIPTION

Exterior vehicle body colors are identified on the

Body Code plate. (Refer to VEHICLE DATA/VEHI-

CLE INFORMATION/BODY CODE PLATE -

DESCRIPTION). The paint code is also identified on

the Vehicle Safety Certification Label which is

located on the drivers door shut face. The first digit

of the paint code listed on the vehicle indicates the

sequence of application, i.e.: P = primary coat, Q =

secondary coat. The codes listed in the Color Code

Chart are used for manufacturing purposes.

PAINTED TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch Up Paints and Clear Top

Coat. (Refer to VEHICLE DATA/VEHICLE INFOR-

MATION/BODY CODE PLATE - DESCRIPTION).

WARNING: USE AN OSHA APPROVED RESPIRATOR

AND SAFETY GLASSES WHEN SPRAYING PAINT

OR SOLVENTS IN A CONFINED AREA. PERSONAL

INJURY CAN RESULT.

TOUCH UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the scratch or chip without run-

ning. Do not stroke brush applicator on body surface.

Allow the filler/primer to dry hard.

(4) Cover the filler/primer with color touch up

paint. Do not overlap touch up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch up

paint to dry hard.

(5) On vehicles without clearcoat, the touch up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clearcoat, apply clear top coat

to touch up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISHING

DESCRIPTION

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

CAUTION: Do not remove clearcoat finish, if

equipped. Basecoat paint must retain clearcoat for

durability.

RSPAINT23 - 101

PAINT (Continued)

Page 2156 of 2339

MANUAL DUAL ZONE

²The two slide controls enable continuously vari-

able proportioning of the conditioned air.

²The mode control knob enables continuously

variable proportioning of air flow between modes and

has detents adjacent to each icon.

²The blower control provides four separate speeds

and an Off position.

²When the heater-A/C system is off, the HVAC

computer closes the recirculation door to prevent out-

side air from entering the passenger compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes except defrost and

mix by pressing the Recirculate button on the A/C-

heater control.

²To reduce humidity for rapid defogging, the A/C

compressor runs automatically in modes from ªmixº

to full defrost when outside temperatures are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off button.

MANUAL THREE ZONE

FRONT CONTROL PANEL

²Primary control of the rear heater-A/C system is

on the instrument panel. This control allows the

driver to set the rear compartment fan speed, to turn

the rear heater-A/C system off, or to give control to

the intermediate seat occupants by switching to the

Rear position. When the rear heater-A/C system is

controlled from the instrument panel, rear air tem-

perature is based on the driver-side temperature con-

trol position, and the mode (floor or overhead air) is

based on the front control's mode position.

²The mode control knob enables continuously

variable proportioning of air flow between modes but

has detents adjacent to each icon.

²The blower control provides four separate speeds

and an Off position. When the heater-A/C system is

off, the HVAC computer closes the recirculation door

to prevent outside air from entering the passenger

compartment.

²Interior air may be recirculated to speed up

heating or cooling in all modes except defrost and

mix by pressing the Recirculate button on the control

panel.

²To reduce humidity for rapid defogging the A/C

compressor runs automatically in modes from ªmix'

to full defrost when outside temperatures are above

freezing.

²Air conditioning is available in any mode by

pressing the snowflake, A/C on/off, button.

REAR CONTROL PANEL

With the rear control active, temperature selection

dictates the air distribution mode (floor or overhead

air) of the rear unit: a cool temperature setting

directs flow to the overhead outlets and a warm tem-

perature setting to the floor.

AUTOMATIC TEMPERATURE CONTROL

Comfort temperature or perceived temperature is

affected by air flow, sun levels on exposed skin, etc.

The air temperature may be higher or lower than the

comfort temperature. The automatic temperature

control (ATC) system uses two infrared sensors in the

instrument panel center stack to measure the tem-

perature of the front occupants in order determine

their comfort level relative to their selected comfort

temperature. The integral HVAC computer adjusts

temperature and air flow rates to maintain the cus-

tomer-perceived comfort temperatures. The air tem-

perature in the passenger compartment may be

slightly higher or lower than the comfort tempera-

ture at any time. For instance, on sunny summer

days the air flow will probably be cooler than the

comfort temperature; on cold or cloudy days and at

night it will probably be slightly warmer.

The Three-Zone ATC system uses the infrared sen-

sors located in the instrument panel center stack

along with an offset calibration strategy to meet the

comfort requirements of the rear seat occupants.

FRONT CONTROL PANEL

²AUTO HI/LO± This system features two sets of

automatic control logic that allow either a rapid cool-

down rate or a somewhat slower cool-down rate with

less fan noise. HI-AUTO controls the system to reach

its assigned temperature quickly with a higher fan

speed. LO-AUTO controls the system to reach its

assigned temperature somewhat slower with less fan

noise. Both modes will automatically engage auto

recirculation.

²DEFROST± The defrost function must be man-

ually selected to direct air flow to the windshield to

remove fog or ice. The ATC system cannot automati-

cally sense the presence of fog or ice on the wind-

shield.

²RECIRC± The RECIRC button will close the

air inlet door. If the system is in auto recirc (indica-

tor being displayed automatically), pressing the man-

ual recirc button will disable the auto recirc function

until one of the auto keys are pressed or the ignition

is cycled. If Auto HI/LO is pressed while manual

recirc is active, manual recirc will be deactivated.

²REAR WINDOW DEFOGGER± Pushing the

button sends a PCI bus message to the intelligent

power module which controls the rear window defog-

ger and side view mirror (if equipped) circuitry. The

RSHEATING & AIR CONDITIONING24-5

HEATING & AIR CONDITIONING (Continued)

Page 2160 of 2339

Condition Possible Causes Correction

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil Level in this group.

Recover the refrigerant from the refrigerant

system and inspect the refrigerant oil content.

Restore the refrigerant oil to the proper level, if

required.

2. Blend door actuator

improperly installed or faulty.2. See Blend Door Actuator in this group. Inspect

the actuator for proper operation and replace, if

required.

3. Blend door inoperative or

sealing improperly.3. See HVAC Housing in this group. Inspect the

blend door for proper operation and sealing.

Repair if required.

4. Blend door not in full cold

position.Use a DRBIII Scan Tool to check for DTCs and

blend door position. Refer to Body Diagnostic

Procedures.

The low side pressure is

normal or slightly low, and the

high side pressure is too low.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Refrigerant flow through

the A/C evaporator is

restricted.2. See A/C Evaporator in this group. Replace the

restricted A/C evaporator, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. A/C condenser air flow

restricted.1. Check the A/C condenser for damaged fins,

foreign objects obstructing air flow through the

condenser fins, and missing or improperly

installed air seals. Clean, repair, or replace

components as required.

2. Refrigerant flow through

the receiver/drier is

restricted.2. See Receiver/Drier in this group. Replace the

restricted receiver/drier, if required.

3. Inoperative radiator

cooling fan.3. Test the radiator cooling fan and replace, if

required. Refer to Group 7.

4. Refrigerant system

overcharged.4. See Refrigerant System Charge in this group.

Recover the refrigerant from the refrigerant

system. Charge the refrigerant system to the

proper level, if required.

5. Air in the refrigerant

system.5. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

6. Engine overheating. 6. Test the engine cooling system and repair, if

required. Refer to Group 7.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Inspect the accessory drive belt condition and

tension. Tighten or replace the accessory drive

belt, if required. Refer to Group 7.

2. Faulty A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

RSHEATING & AIR CONDITIONING24-9

HEATING & AIR CONDITIONING (Continued)

Page 2161 of 2339

Condition Possible Causes Correction

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid Line, Suction Line and Discharge

Line in this group. Inspect the refrigerant lines for

kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if

required.

2. Restricted refrigerant flow

through the A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Restricted refrigerant flow

through the A/C condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

HEATER PERFORMANCE TEST

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE PERFORMING

THIS PROCEDURE (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING).

Check the coolant level, drive belt tension, radiator

air flow and fan operation. Start engine and allow to

warm up to normal operating temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing the radiator cap. Place a rag overthe cap and turn it to the first safety stop. Allow

pressure to escape through the overflow tube. When

the system pressure stabilizes, remove the cap com-

pletely.

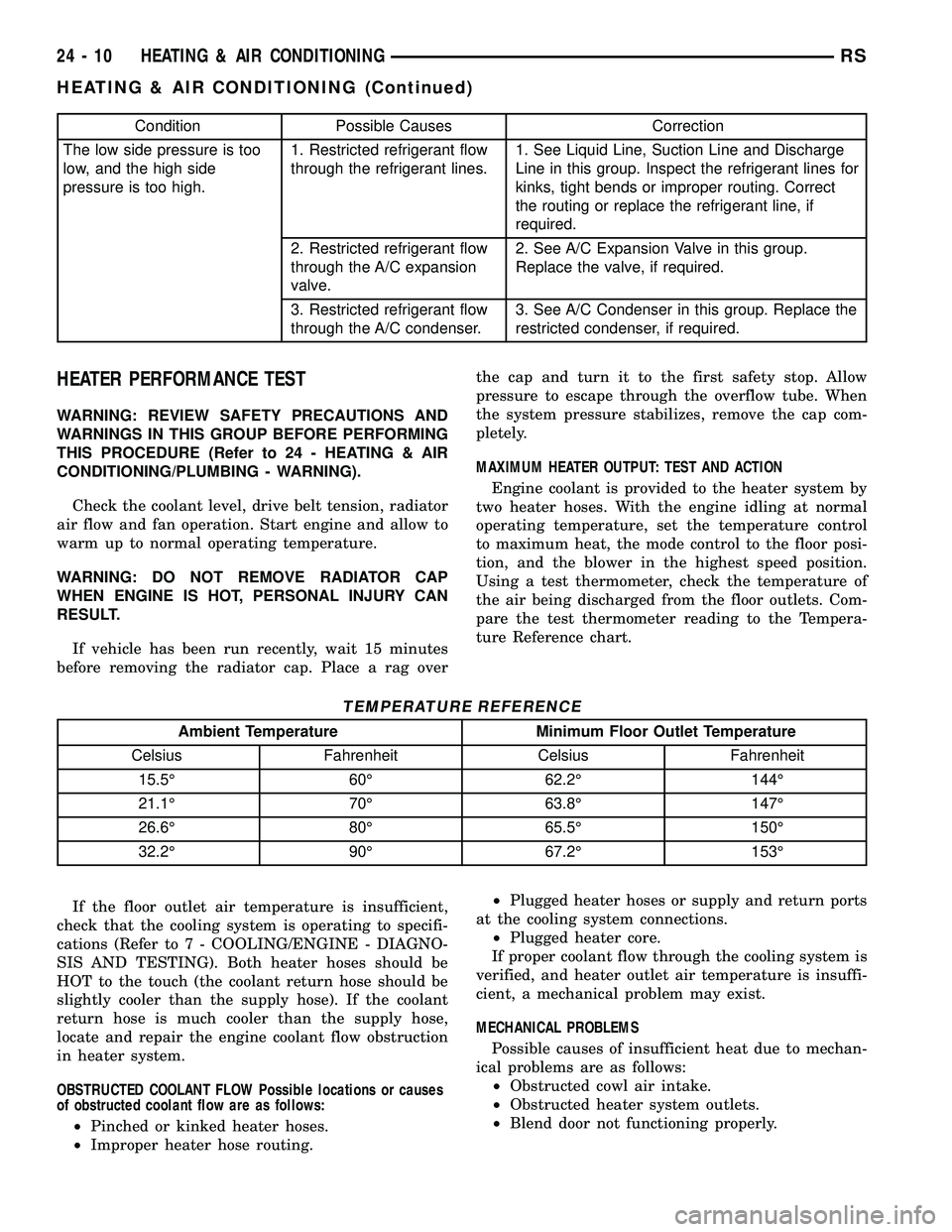

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two heater hoses. With the engine idling at normal

operating temperature, set the temperature control

to maximum heat, the mode control to the floor posi-

tion, and the blower in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged from the floor outlets. Com-

pare the test thermometer reading to the Tempera-

ture Reference chart.

TEMPERATURE REFERENCE

Ambient Temperature Minimum Floor Outlet Temperature

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

If the floor outlet air temperature is insufficient,

check that the cooling system is operating to specifi-

cations (Refer to 7 - COOLING/ENGINE - DIAGNO-

SIS AND TESTING). Both heater hoses should be

HOT to the touch (the coolant return hose should be

slightly cooler than the supply hose). If the coolant

return hose is much cooler than the supply hose,

locate and repair the engine coolant flow obstruction

in heater system.

OBSTRUCTED COOLANT FLOW Possible locations or causes

of obstructed coolant flow are as follows:

²Pinched or kinked heater hoses.

²Improper heater hose routing.²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is insuffi-

cient, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible causes of insufficient heat due to mechan-

ical problems are as follows:

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend door not functioning properly.

24 - 10 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2166 of 2339

(b) If the compressor clutch coil current reading

is four amperes or more, the coil is shorted and

must be replaced.

STANDARD PROCEDURE

CLUTCH INSPECTION

NOTE: The compressor clutch can be serviced in

the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley, or coil

replacement.

Examine the friction surfaces of the clutch pulley

and the clutch plate for wear. The pulley and plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft

and nose area of the A/C compressor for refrigerant

oil. If refrigerant oil is found, the compressor shaft

seal is leaking and the A/C compressor must be

replaced.

Check the clutch pulley bearing for roughness or

excessive leakage of grease. Replace the pulley and

bearing assembly, if required.

A/C CLUTCH BREAK-IN

After a new A/C compressor clutch has been

installed, cycle the compressor clutch approximately

twenty times (five seconds on, then five seconds off).

During this procedure, set the A/C-heater controls to

the A/C Recirculation Mode, the blower motor in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces of the compressor

clutch, which provides optimum compressor clutch

torque capability.

REMOVAL

NOTE: The compressor clutch can be serviced in

the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley, or coil

replacement.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil pig-

tail wire connector on the top of the A/C compressor.

(5) On models with the 3.3L and 3.8L engines, dis-

engage the retainer on the engine wire harness com-pressor clutch coil take out from the bracket on the

top of the A/C compressor.

(6) On models with the 2.4L, 2.5L and 2.8L

engines, remove all of the compressor mounting bolts

except the upper left (rear of the A/C compressor),

which should only be loosened. Allow the front (pul-

ley end) of the A/C compressor to tilt downward far

enough to access the clutch for removal, then tighten

the loosened upper left compressor mounting bolt.

(7) On models with the 3.3L and 3.8L engines,

remove the two bolts and two nuts that secure the

A/C compressor to the engine. Disengage the mount-

ing ear at the front of the A/C compressor from the

stud on the engine, allow the front (pulley end) of the

A/C compressor to tilt downward far enough to access

the clutch for removal, then reinstall and tighten the

upper left compressor mounting bolt.

(8) Remove the compressor shaft bolt (Fig. 2). A

band-type oil filter wrench or a strap wrench may be

used to secure the clutch during bolt removal.

(9) Tap the clutch plate lightly with a plastic mal-

let to release it from the splines on the compressor

shaft. Remove the clutch plate and shim(s) from the

compressor shaft (Fig. 3).

NOTE: Use care not to lose any of the shim(s).

Fig. 2 A/C Compressor Shaft Bolt

1 - BOLT

2 - COMPRESSOR CLUTCH PLATE

RSCONTROLS - FRONT24-15

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2170 of 2339

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 8).

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the IPM for A/C compressor

clutch relay identification and location.

(3) Remove the A/C compressor clutch relay from

the IPM.

INSTALLATION

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the integrated power module

(IPM) for A/C compressor clutch relay identification

and location.

(1) Position the A/C compressor clutch relay into

the proper receptacle in the IPM.

(2) Align the A/C compressor clutch relay termi-

nals with the terminal cavities in the IPM receptacle.

(3) Push down firmly on the A/C compressor clutch

relay until the terminals are fully seated in the ter-

minal cavities.

(4) Install the cover onto the IPM.

(5) Reconnect the negative battery cable.

A/C HEATER CONTROL

DESCRIPTION

The A/C-heater control is located at the center of

the instrument panel and uses electrical controls.

These controls provide the vehicle operator with a

number of setting options to help control the climate

and comfort within the vehicle. Refer to the owner's

manual in the vehicle glove box for more information

on the suggested operation and use of these controls.

The A/C-heater control cannot be repaired. If faulty

or damaged, the entire unit must be replaced. The

control knobs are available for service replacement.

STANDARD PROCEDURE

A/C-HEATER CONTROL CALIBRATION

The A/C-heater control module must be recali-

brated each time an actuator motor or the control

module is replaced. If the vehicle is so equipped, the

calibration procedure also includes rear HVAC posi-

tions for each actuator motor.

(1) Turn the ignition switch to the On position.

(2) If equipped with the manual temperature con-

trol (MTC) system, press and hold the Rear Wipe/

Wash and Recirculation buttoms for at least five

seconds. If equipped with the automatic temperature

control (ATC) systen, simultaneously press and hold

the Power and Recirculation buttons on the A/C-

heater control for at least five seconds. The MTC

A/C-heater control Rear Wipe/Wash Light Emitting

Diode (LED) and Recirculation LED, or the ATC A/C-

heater control Delay and Recirculation graphics will

begin to flash when the calibration procedure has

begun.

(3) The calibration procedure should take less than

two minutes to complete for the manual A/C-heater

control, and less than twenty seconds for the ATC

A/C-heater control. When the LEDs or graphics stop

flashing, the calibration procedure is complete.

(4) If the LEDs or graphics continue to flash

beyond the two minute (manual) or twenty second

(ATC) calibration time, it indicates that the A/C-

heater control has detected a failure and a Diagnostic

Trouble Code (DTC) has been set. Refer to Body

Diagnostic Procedures to perform further diagnosis.

The LEDs or graphics will continue to flash even

after the ignition switch is cycled Off and On, until a

successful calibration is completed or until the vehi-

cle has been driven about 13 kilometers (8 miles).

Fig. 8 A/C Compressor Clutch Relay

1 - INTEGRATED POWER MODULE (IPM)

2 - A/C COMPRESSOR CLUTCH RELAY

3 - FRONT CONTROL MODULE

RSCONTROLS - FRONT24-19

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2173 of 2339

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a single

blend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver's side end of the

HVAC housing, close to the middle of the distribution

housing. In the dual zone system, the same blend

door actuator used for the single zone system

becomes the passenger blend door actuator, and is

mechanically connected to only the passenger side

blend air door. In the dual zone system, a second sep-

arate blend door actuator is also located on the

driver side end of the HVAC housing, close to the

middle of the distribution housing, and is mechani-

cally connected to only the driver's side blend air

door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the distri-

bution housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module.

OPERATION

The blend door actuators are connected to the A/C-

heater control through the vehicle electrical system

by a dedicated two-wire lead and connector of the

HVAC wire harness. The blend door actuator(s) can

move the blend-air door(s) in two directions. When

the A/C-heater control pulls the voltage on one side

of the motor connection high and the other connec-

tion low, the blend-air door will move in one direc-

tion. When the A/C-heater control reverses the

polarity of the voltage to the motor, the blend-air

door moves in the opposite direction.

When the A/C-heater control makes the voltage to

both connections high or both connections low, the

blend-air door stops and will not move. The A/C-

heater control uses a feedback signal positioning sys-

tem to monitor the operation and relative position of

the blend door actuator(s) and the blend-air door(s).

The A/C-heater control learns the blend-air door stoppositions during the calibration procedure and will

store a diagnostic trouble code (DTC) for any prob-

lems it detects in the blend door actuator circuits.

The blend door actuators are diagnosed using a

scan tool (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING and to 24 -

HVAC Electrical Diagnostics for more information).

The blend door actuators cannot be adjusted or

repaired and, if faulty or damaged, they must be

replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The single zone heating and air conditioning

system is equipped with a single blend door actua-

tor. The dual zone system has two blend door

actuators, one for the driver side blend air door and

one for the passenger side blend air door. The

same service procedures can be used for each of

these actuators.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

(3) Disconnect the wire harness connector from the

blend door actuator(s) (Fig. 11).

(4) Remove the two screws that secure the blend

door actuator to the distribution housing.

(5) Remove the blend door actuator.

INSTALLATION

(1) Position the blend door actuator onto the distri-

bution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the blend air door linkage.

(2) Install the two screws that secure the blend

door actuator to the housing. Tighten the screws to 2

N´m (17 in. lbs.).

24 - 22 CONTROLS - FRONTRS

Page 2181 of 2339

INSTALLATION

(1) Position the mode door actuator onto the HVAC

distribution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install the two screws that secure the mode

door actuator to the distribution housing. Tighten the

screws to 2 N´m (17 in. lbs.).

(3) Connect the wire harness connector to the

mode door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the negative battery cable.

(6) Perform the A/C-heater control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

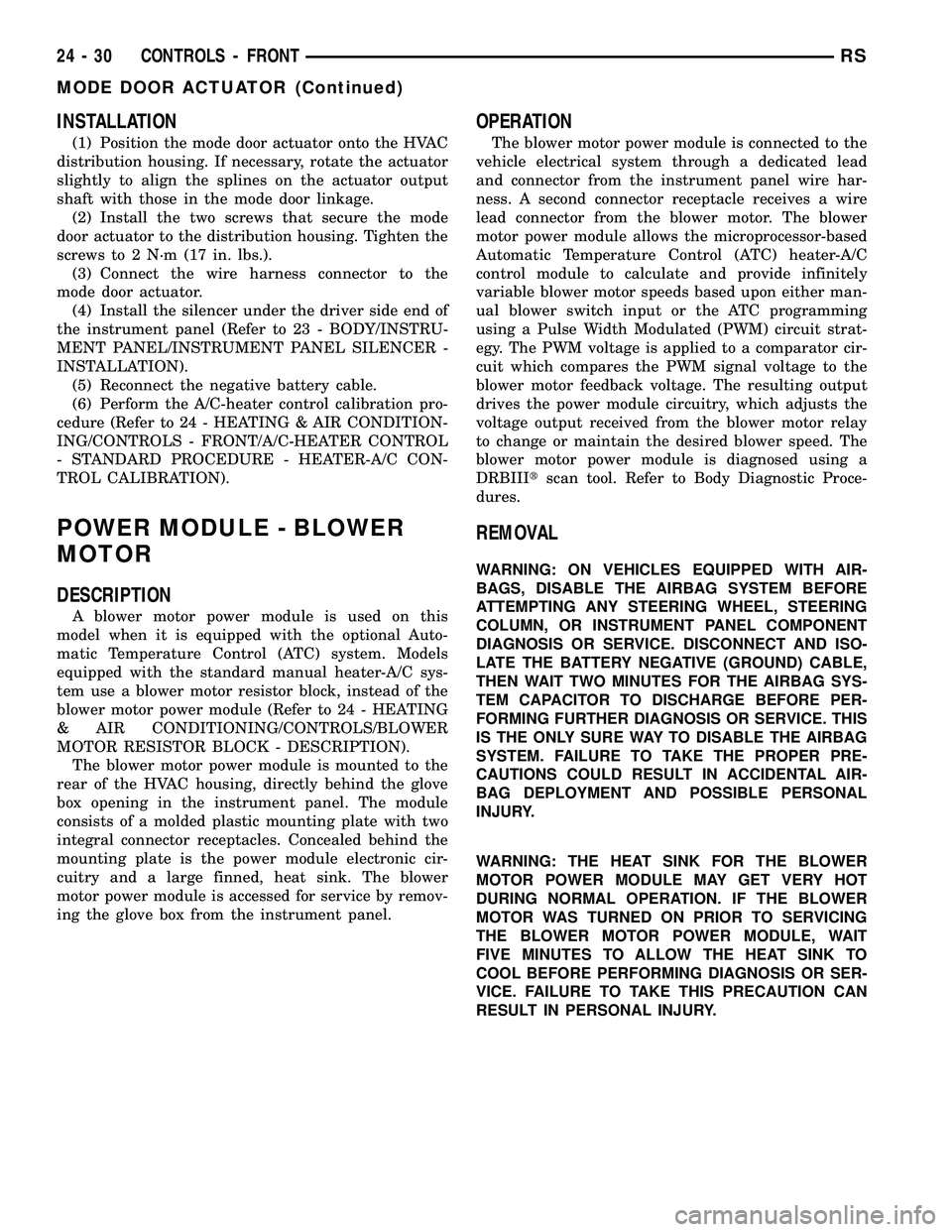

POWER MODULE - BLOWER

MOTOR

DESCRIPTION

A blower motor power module is used on this

model when it is equipped with the optional Auto-

matic Temperature Control (ATC) system. Models

equipped with the standard manual heater-A/C sys-

tem use a blower motor resistor block, instead of the

blower motor power module (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - DESCRIPTION).

The blower motor power module is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The module

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate is the power module electronic cir-

cuitry and a large finned, heat sink. The blower

motor power module is accessed for service by remov-

ing the glove box from the instrument panel.

OPERATION

The blower motor power module is connected to the

vehicle electrical system through a dedicated lead

and connector from the instrument panel wire har-

ness. A second connector receptacle receives a wire

lead connector from the blower motor. The blower

motor power module allows the microprocessor-based

Automatic Temperature Control (ATC) heater-A/C

control module to calculate and provide infinitely

variable blower motor speeds based upon either man-

ual blower switch input or the ATC programming

using a Pulse Width Modulated (PWM) circuit strat-

egy. The PWM voltage is applied to a comparator cir-

cuit which compares the PWM signal voltage to the

blower motor feedback voltage. The resulting output

drives the power module circuitry, which adjusts the

voltage output received from the blower motor relay

to change or maintain the desired blower speed. The

blower motor power module is diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE HEAT SINK FOR THE BLOWER

MOTOR POWER MODULE MAY GET VERY HOT

DURING NORMAL OPERATION. IF THE BLOWER

MOTOR WAS TURNED ON PRIOR TO SERVICING

THE BLOWER MOTOR POWER MODULE, WAIT

FIVE MINUTES TO ALLOW THE HEAT SINK TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 30 CONTROLS - FRONTRS

MODE DOOR ACTUATOR (Continued)