air conditioning CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 30 of 2339

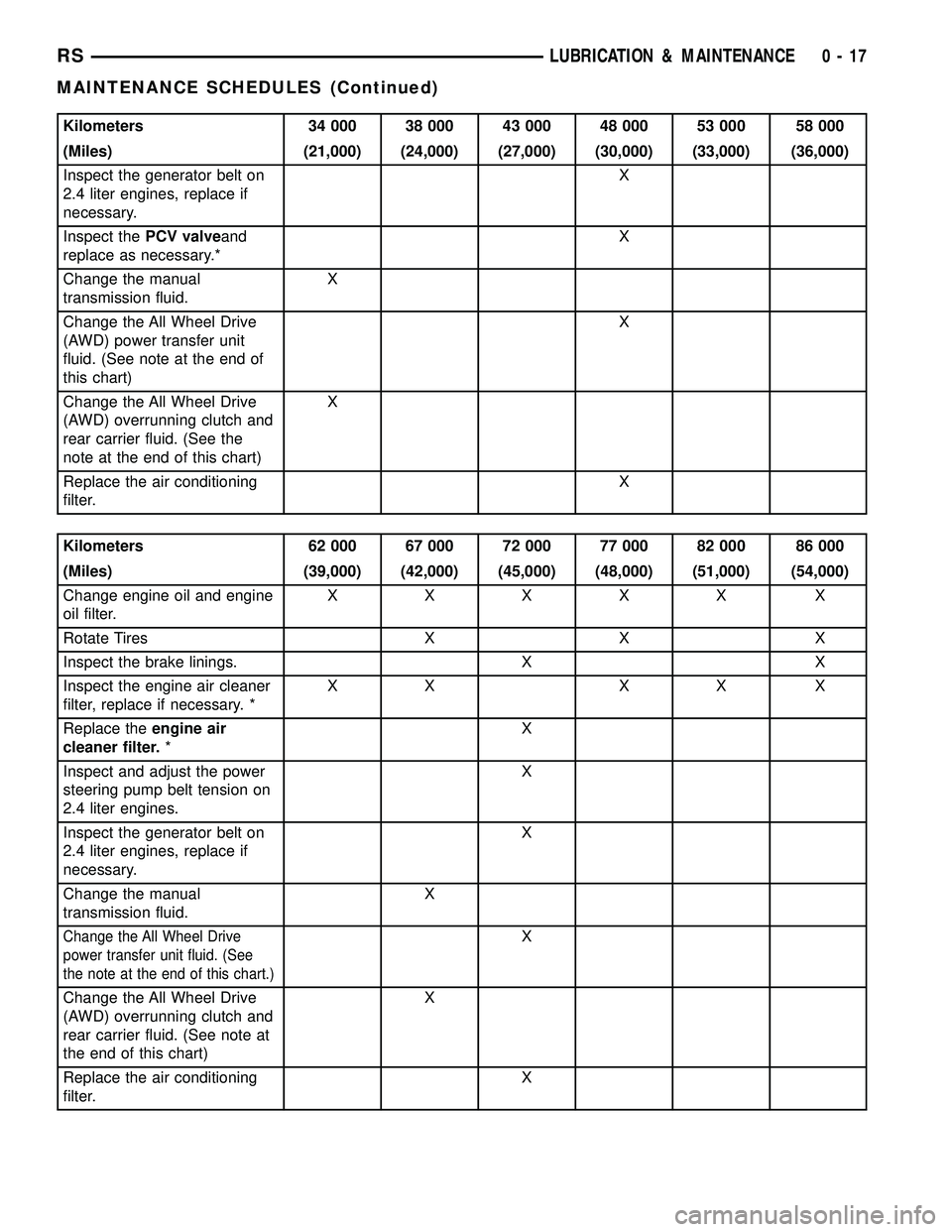

Kilometers 34 000 38 000 43 000 48 000 53 000 58 000

(Miles) (21,000) (24,000) (27,000) (30,000) (33,000) (36,000)

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect thePCV valveand

replace as necessary.*X

Change the manual

transmission fluid.X

Change the All Wheel Drive

(AWD) power transfer unit

fluid. (See note at the end of

this chart)X

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See the

note at the end of this chart)X

Replace the air conditioning

filter.X

Kilometers 62 000 67 000 72 000 77 000 82 000 86 000

(Miles) (39,000) (42,000) (45,000) (48,000) (51,000) (54,000)

Change engine oil and engine

oil filter.XXXXX X

Rotate Tires X X X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *XX XX X

Replace theengine air

cleaner filter.*X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Change the manual

transmission fluid.X

Change the All Wheel Drive

power transfer unit fluid. (See

the note at the end of this chart.)X

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See note at

the end of this chart)X

Replace the air conditioning

filter.X

RSLUBRICATION & MAINTENANCE0-17

MAINTENANCE SCHEDULES (Continued)

Page 31 of 2339

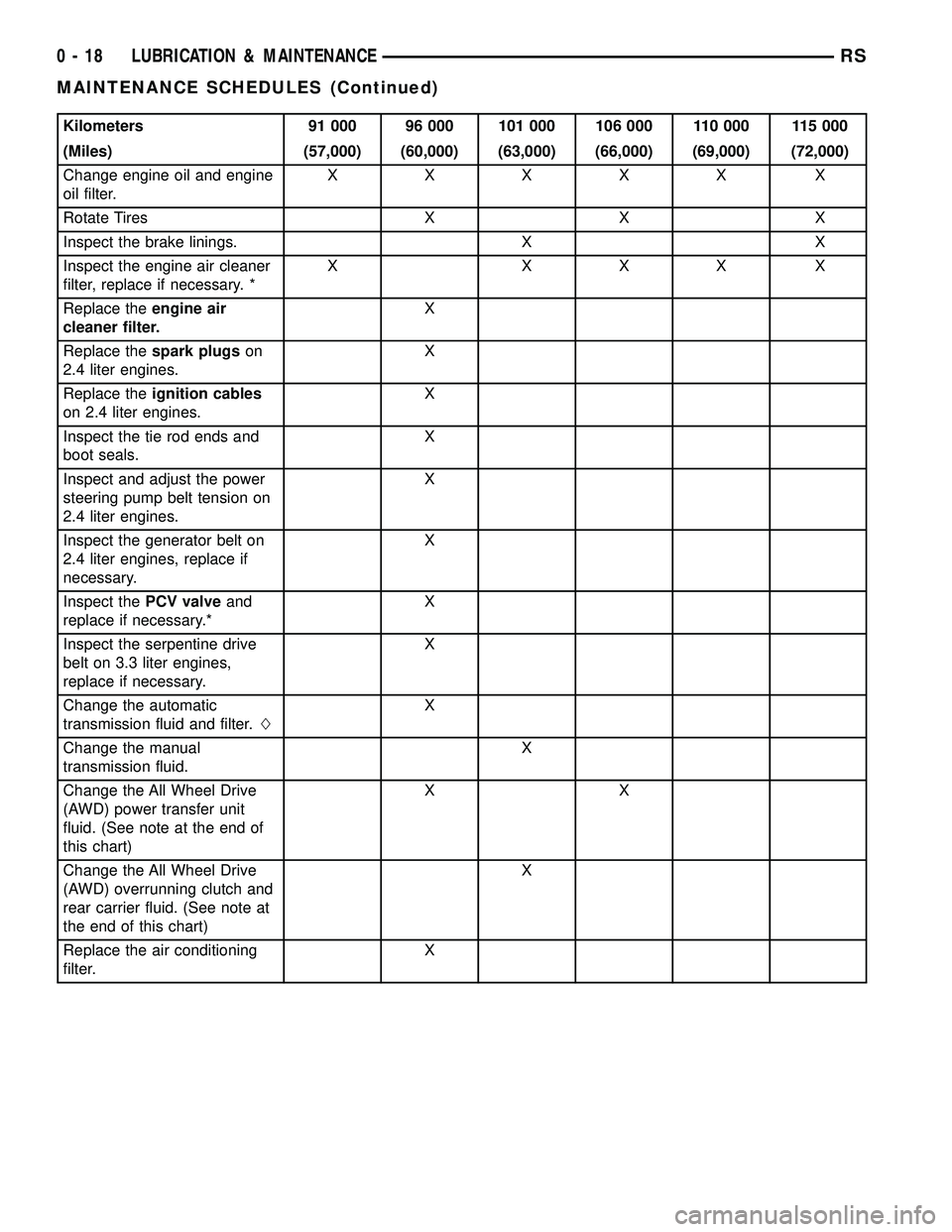

Kilometers 91 000 96 000 101 000 106 000 110 000 115 000

(Miles) (57,000) (60,000) (63,000) (66,000) (69,000) (72,000)

Change engine oil and engine

oil filter.XXXXX X

Rotate Tires X X X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *X XXX X

Replace theengine air

cleaner filter.X

Replace thespark plugson

2.4 liter engines.X

Replace theignition cables

on 2.4 liter engines.X

Inspect the tie rod ends and

boot seals.X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect thePCV valveand

replace if necessary.*X

Inspect the serpentine drive

belt on 3.3 liter engines,

replace if necessary.X

Change the automatic

transmission fluid and filter.LX

Change the manual

transmission fluid.X

Change the All Wheel Drive

(AWD) power transfer unit

fluid. (See note at the end of

this chart)XX

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See note at

the end of this chart)X

Replace the air conditioning

filter.X

0 - 18 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 32 of 2339

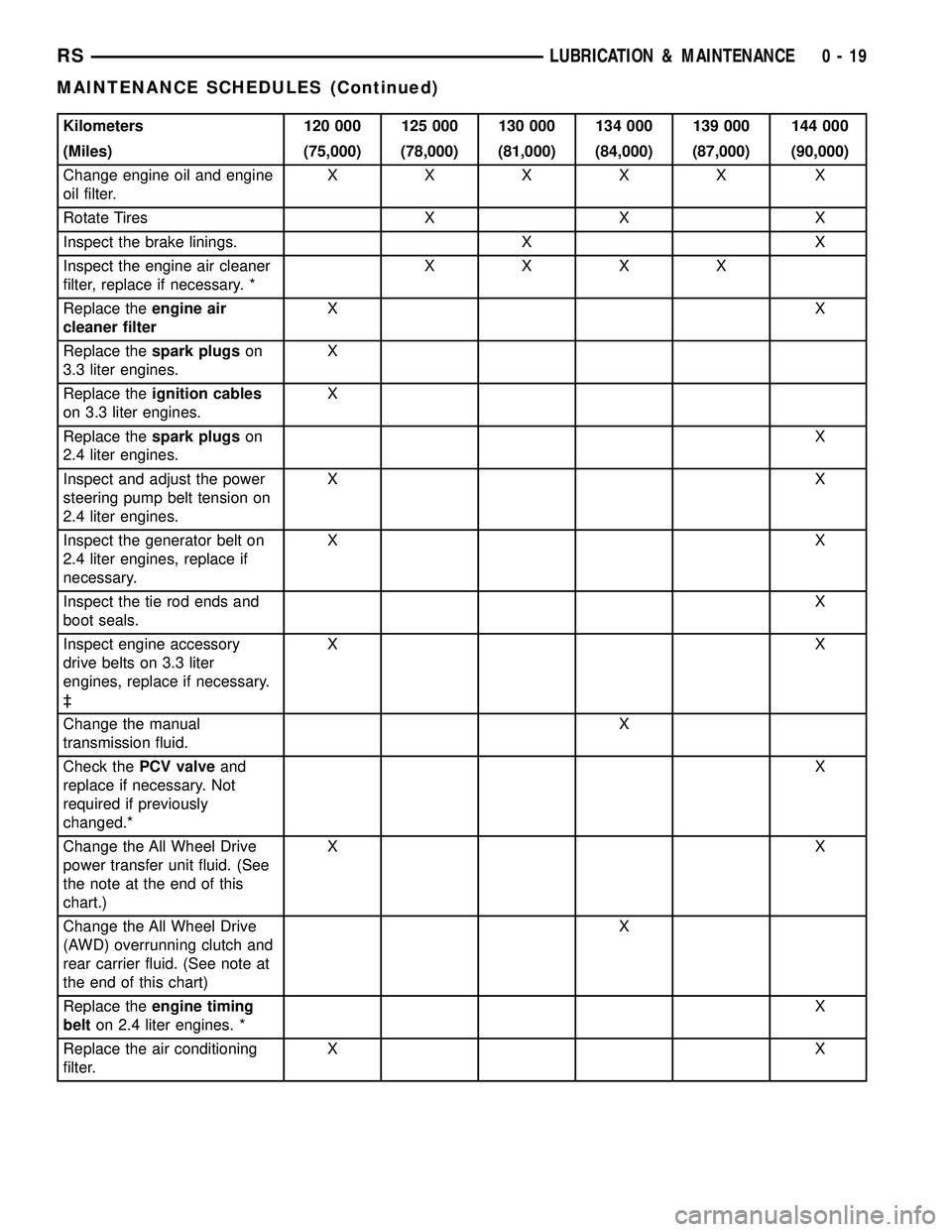

Kilometers 120 000 125 000 130 000 134 000 139 000 144 000

(Miles) (75,000) (78,000) (81,000) (84,000) (87,000) (90,000)

Change engine oil and engine

oil filter.XXXXX X

Rotate Tires X X X

Inspect the brake linings. X X

Inspect the engine air cleaner

filter, replace if necessary. *XXXX

Replace theengine air

cleaner filterXX

Replace thespark plugson

3.3 liter engines.X

Replace theignition cables

on 3.3 liter engines.X

Replace thespark plugson

2.4 liter engines.X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.XX

Inspect the generator belt on

2.4 liter engines, replace if

necessary.XX

Inspect the tie rod ends and

boot seals.X

Inspect engine accessory

drive belts on 3.3 liter

engines, replace if necessary.

³XX

Change the manual

transmission fluid.X

Check thePCV valveand

replace if necessary. Not

required if previously

changed.*X

Change the All Wheel Drive

power transfer unit fluid. (See

the note at the end of this

chart.)XX

Change the All Wheel Drive

(AWD) overrunning clutch and

rear carrier fluid. (See note at

the end of this chart)X

Replace theengine timing

belton 2.4 liter engines. *X

Replace the air conditioning

filter.XX

RSLUBRICATION & MAINTENANCE0-19

MAINTENANCE SCHEDULES (Continued)

Page 33 of 2339

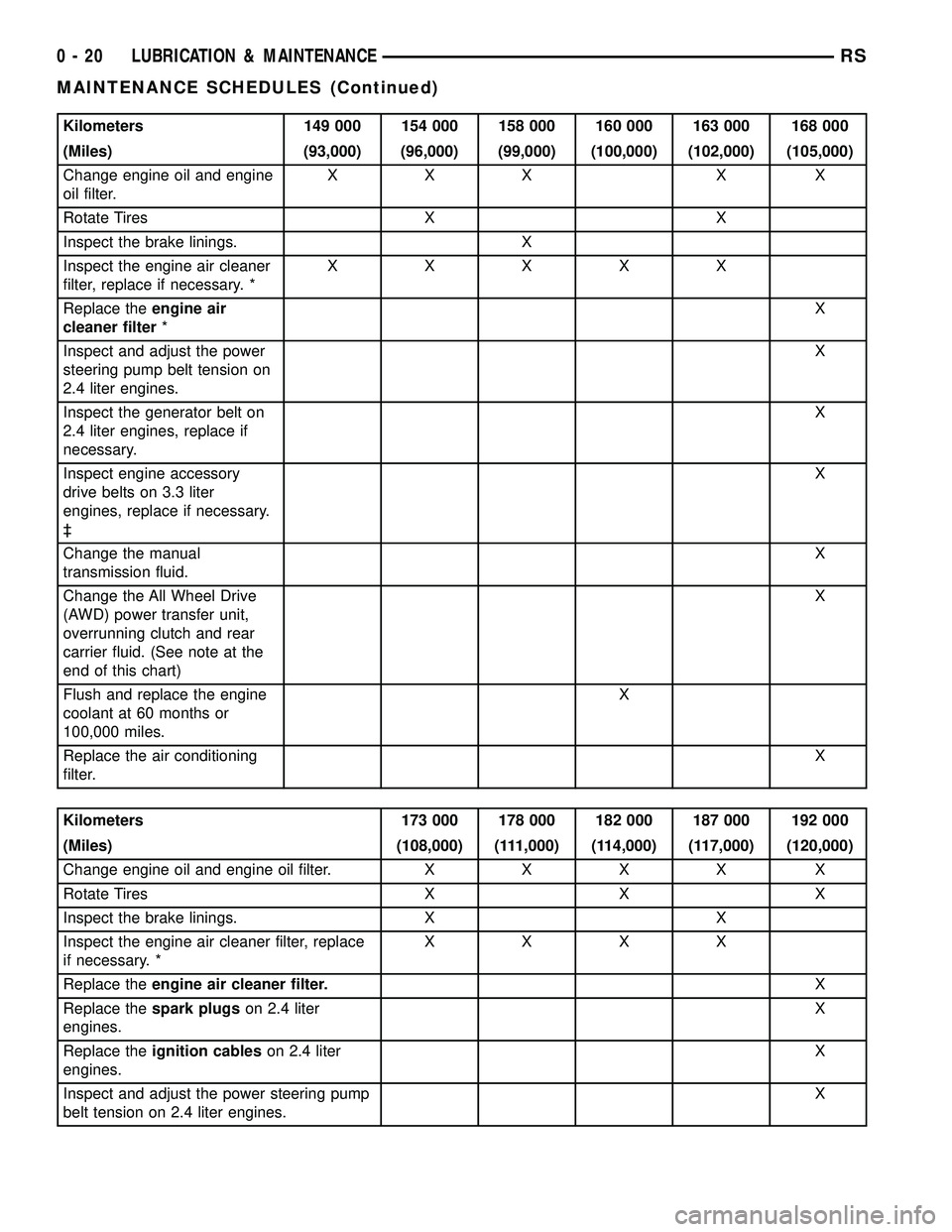

Kilometers 149 000 154 000 158 000 160 000 163 000 168 000

(Miles) (93,000) (96,000) (99,000) (100,000) (102,000) (105,000)

Change engine oil and engine

oil filter.XXX X X

Rotate Tires X X

Inspect the brake linings. X

Inspect the engine air cleaner

filter, replace if necessary. *XXXXX

Replace theengine air

cleaner filter*X

Inspect and adjust the power

steering pump belt tension on

2.4 liter engines.X

Inspect the generator belt on

2.4 liter engines, replace if

necessary.X

Inspect engine accessory

drive belts on 3.3 liter

engines, replace if necessary.

³X

Change the manual

transmission fluid.X

Change the All Wheel Drive

(AWD) power transfer unit,

overrunning clutch and rear

carrier fluid. (See note at the

end of this chart)X

Flush and replace the engine

coolant at 60 months or

100,000 miles.X

Replace the air conditioning

filter.X

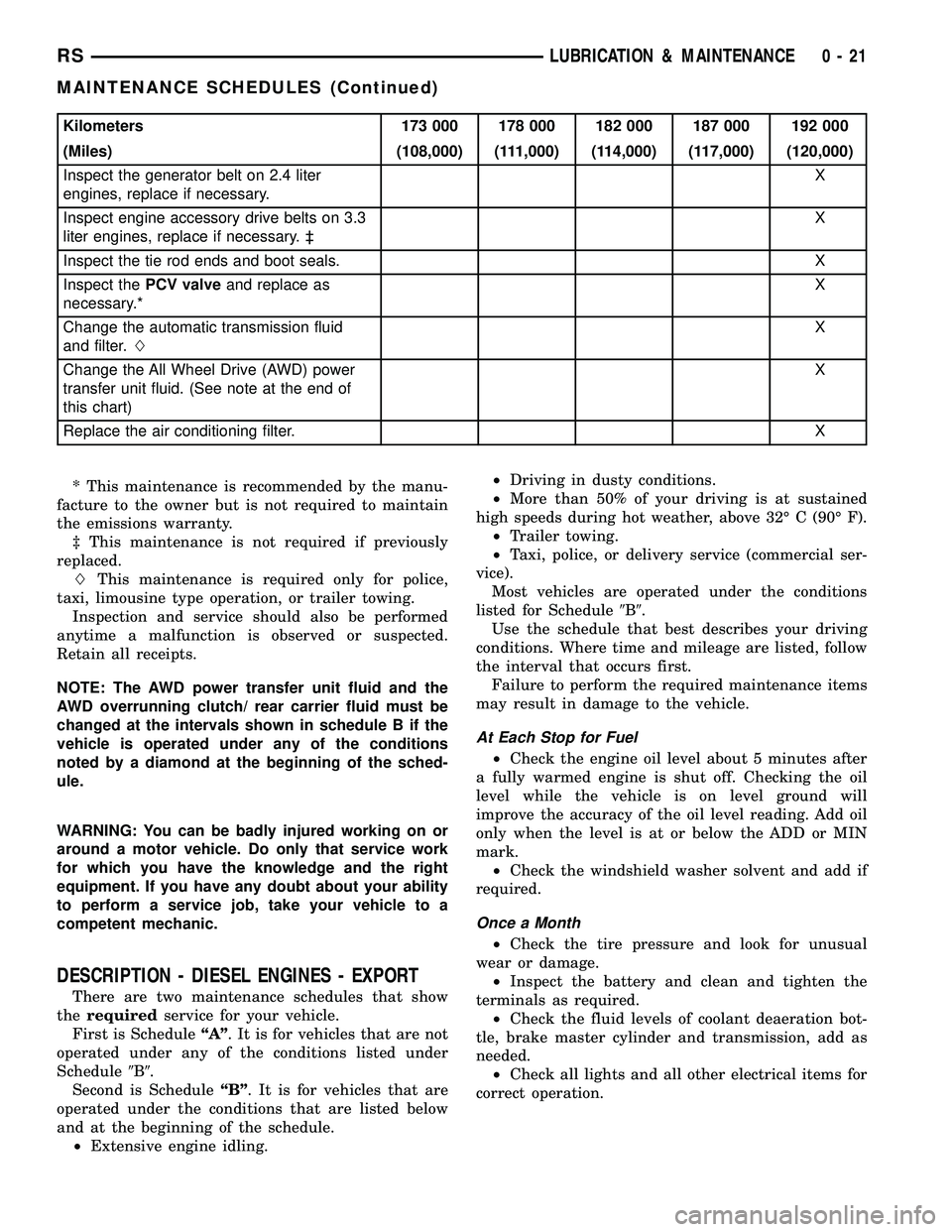

Kilometers 173 000 178 000 182 000 187 000 192 000

(Miles) (108,000) (111,000) (114,000) (117,000) (120,000)

Change engine oil and engine oil filter.XXXX X

Rotate Tires X X X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

0 - 20 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 34 of 2339

Kilometers 173 000 178 000 182 000 187 000 192 000

(Miles) (108,000) (111,000) (114,000) (117,000) (120,000)

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter engines, replace if necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the automatic transmission fluid

and filter.LX

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter.X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

LThis maintenance is required only for police,

taxi, limousine type operation, or trailer towing.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must be

changed at the intervals shown in schedule B if the

vehicle is operated under any of the conditions

noted by a diamond at the beginning of the sched-

ule.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

DESCRIPTION - DIESEL ENGINES - EXPORT

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under

Schedule9B9.

Second is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Extensive engine idling.²Driving in dusty conditions.

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

Most vehicles are operated under the conditions

listed for Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant deaeration bot-

tle, brake master cylinder and transmission, add as

needed.

²Check all lights and all other electrical items for

correct operation.

RSLUBRICATION & MAINTENANCE0-21

MAINTENANCE SCHEDULES (Continued)

Page 155 of 2339

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Remove

the link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 62). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

63).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 63).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nut to a torque of 29 N´m (250 in. lbs.).

(4) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

the brake pedal torque shaft pin where it contacts

the brake pedal link.

CAUTION: When installing the power brake booster

input rod on the brake pedal torque shaft pin, do

not reuse the old retaining clip.

(6) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 62).

CAUTION: When installing the brake pedal link on

the brake pedal torque shaft pin, do not reuse the

old retaining clip.

Fig. 62 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

Fig. 63 BOOSTER, TORQUE SHAFT AND PEDAL

MOUNTING

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

5 - 44 BRAKES - BASERS

Page 156 of 2339

(7) Connect the brake pedal link to the torque

shaft. Install a NEW retaining clip at the torque

shaft end of the brake pedal-to-torque shaft link.

(8) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

(9) Install the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(10) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(11) Road test vehicle to ensure proper operation of

the brakes.

POWER BRAKE BOOSTER

DESCRIPTION

The power brake booster mounts on the engine

compartment side of the dash panel. It is connected

to the brake pedal by the input (push) rod (Fig. 64).

The master cylinder is bolted to the front of the

booster. A vacuum line connects the power brake

booster to the intake manifold.

All Left-Hand-Drive (LHD) vehicles use a 270 mm

single diaphragm vacuum power brake booster. All

Right-Hand-Drive (RHD) vehicles use a 225/200 mm

tandem diaphragm vacuum power brake booster.

Vehicles equipped with Disc/Disc brakes use a dif-

ferent power brake booster than vehicles equipped

with Disc/Drum brakes. Differences between the two

are internal. Service is the same for all boosters.

The power brake booster can be identified by the

tag attached to the body of the booster (Fig. 65). This

tag contains the production part number, the date it

was built, and who the manufacturer of the power

brake booster is.

NOTE: The power brake booster assembly is not a

repairable component and must be replaced as a

complete assembly if found to be faulty in any way.

The check valve located on the power brake

booster face is not repairable, but it can be

replaced separately from the power brake booster.The different engine combinations used in this

vehicle require different vacuum hose routings to the

power brake booster. All vacuum hoses must be

routed from the engine to the power brake booster

without kinks or excessively tight bends.

Fig. 64 Power Brake Booster (Typical)

1 - VACUUM CHECK VALVE

2 - POWER BRAKE BOOSTER ASSEMBLY

3 - INPUT ROD

4 - POWER BOOSTER ASSEMBLY TO DASH PANEL MOUNTING

STUDS (4)

5 - MASTER CYLINDER MOUNTING STUDS (2)

6 - OUTPUT ROD

Fig. 65 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RSBRAKES - BASE5-45

PEDAL TORQUE SHAFT - RHD (Continued)

Page 224 of 2339

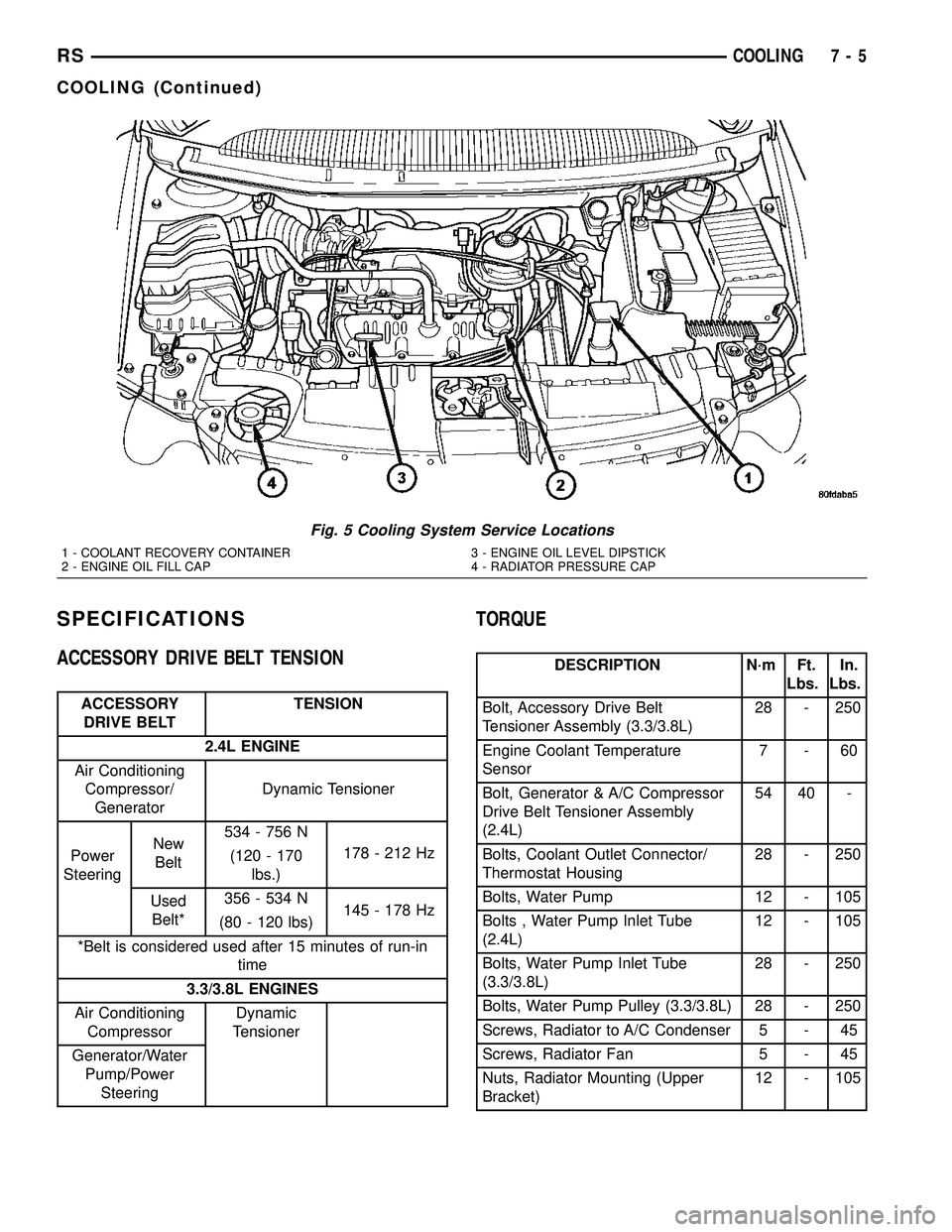

SPECIFICATIONS

ACCESSORY DRIVE BELT TENSION

ACCESSORY

DRIVE BELTTENSION

2.4L ENGINE

Air Conditioning

Compressor/

GeneratorDynamic Tensioner

Power

SteeringNew

Belt534 - 756 N

178 - 212 Hz

(120 - 170

lbs.)

Used

Belt*356 - 534 N

145 - 178 Hz

(80 - 120 lbs)

*Belt is considered used after 15 minutes of run-in

time

3.3/3.8L ENGINES

Air Conditioning

CompressorDynamic

Tensioner

Generator/Water

Pump/Power

Steering

TORQUE

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Bolt, Accessory Drive Belt

Tensioner Assembly (3.3/3.8L)28 - 250

Engine Coolant Temperature

Sensor7-60

Bolt, Generator & A/C Compressor

Drive Belt Tensioner Assembly

(2.4L)54 40 -

Bolts, Coolant Outlet Connector/

Thermostat Housing28 - 250

Bolts, Water Pump 12 - 105

Bolts , Water Pump Inlet Tube

(2.4L)12 - 105

Bolts, Water Pump Inlet Tube

(3.3/3.8L)28 - 250

Bolts, Water Pump Pulley (3.3/3.8L) 28 - 250

Screws, Radiator to A/C Condenser 5 - 45

Screws, Radiator Fan 5 - 45

Nuts, Radiator Mounting (Upper

Bracket)12 - 105

Fig. 5 Cooling System Service Locations

1 - COOLANT RECOVERY CONTAINER 3 - ENGINE OIL LEVEL DIPSTICK

2 - ENGINE OIL FILL CAP 4 - RADIATOR PRESSURE CAP

RSCOOLING7-5

COOLING (Continued)

Page 227 of 2339

CONDITION POSSIBLE CAUSES CORRECTIONS

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. (a) Replace belt (auto-tensioned

belts.)

(b) Adjust power steering belt

tension (4 cyl. engine)

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley4. Replace pulley

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

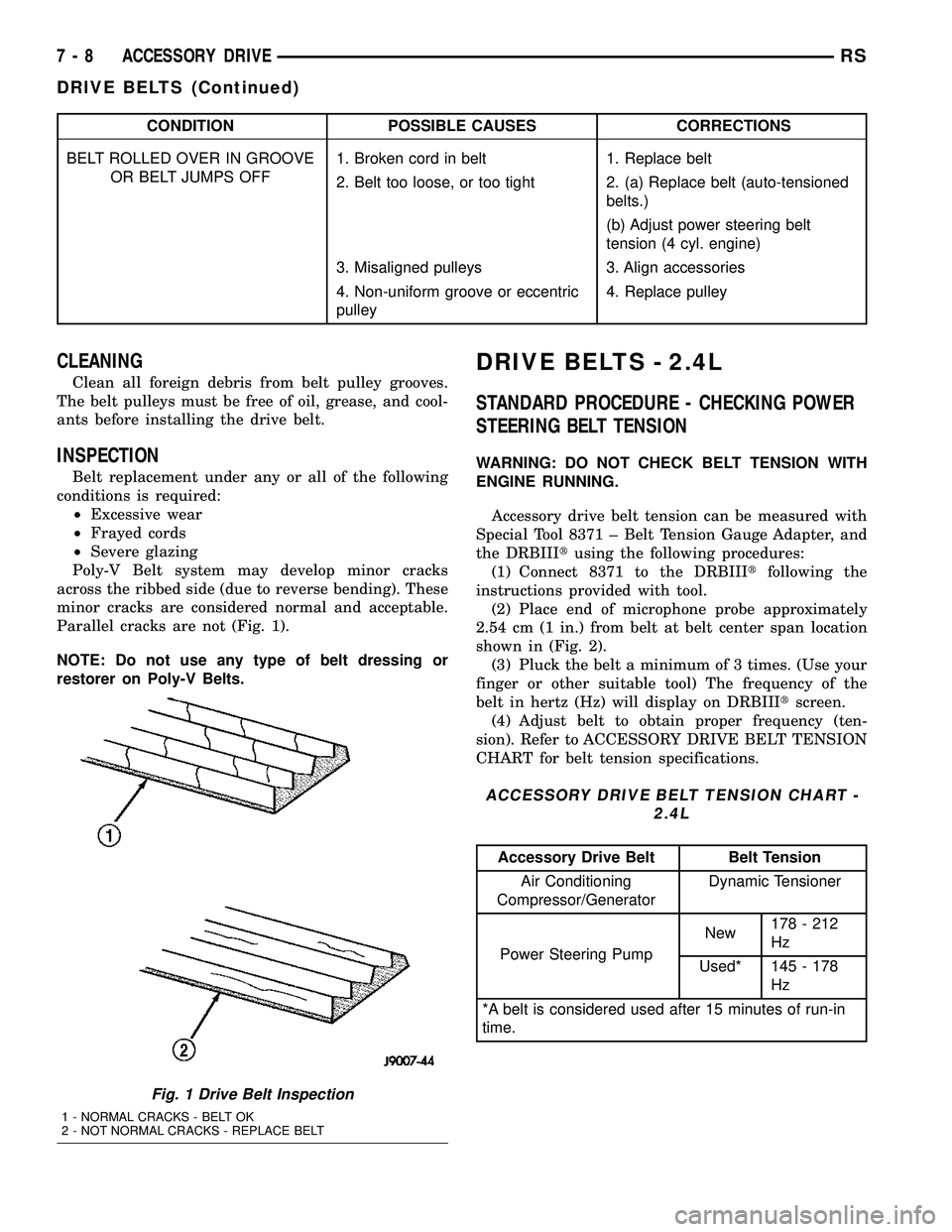

INSPECTION

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 1).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

DRIVE BELTS - 2.4L

STANDARD PROCEDURE - CHECKING POWER

STEERING BELT TENSION

WARNING: DO NOT CHECK BELT TENSION WITH

ENGINE RUNNING.

Accessory drive belt tension can be measured with

Special Tool 8371 ± Belt Tension Gauge Adapter, and

the DRBIIItusing the following procedures:

(1) Connect 8371 to the DRBIIItfollowing the

instructions provided with tool.

(2) Place end of microphone probe approximately

2.54 cm (1 in.) from belt at belt center span location

shown in (Fig. 2).

(3) Pluck the belt a minimum of 3 times. (Use your

finger or other suitable tool) The frequency of the

belt in hertz (Hz) will display on DRBIIItscreen.

(4) Adjust belt to obtain proper frequency (ten-

sion). Refer to ACCESSORY DRIVE BELT TENSION

CHART for belt tension specifications.

ACCESSORY DRIVE BELT TENSION CHART -

2.4L

Accessory Drive Belt Belt Tension

Air Conditioning

Compressor/GeneratorDynamic Tensioner

Power Steering PumpNew178 - 212

Hz

Used* 145 - 178

Hz

*A belt is considered used after 15 minutes of run-in

time.

Fig. 1 Drive Belt Inspection

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

7 - 8 ACCESSORY DRIVERS

DRIVE BELTS (Continued)

Page 228 of 2339

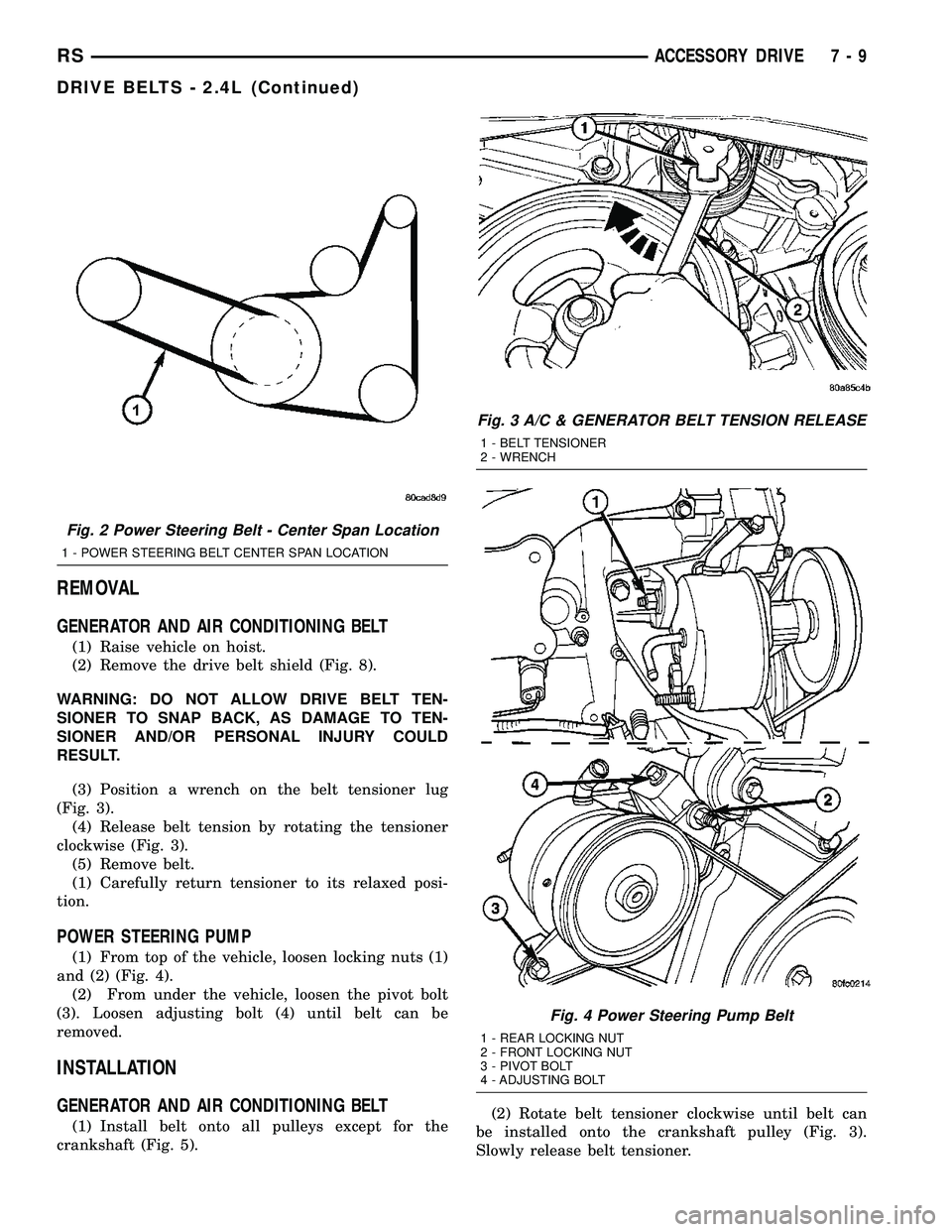

REMOVAL

GENERATOR AND AIR CONDITIONING BELT

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield (Fig. 8).

WARNING: DO NOT ALLOW DRIVE BELT TEN-

SIONER TO SNAP BACK, AS DAMAGE TO TEN-

SIONER AND/OR PERSONAL INJURY COULD

RESULT.

(3) Position a wrench on the belt tensioner lug

(Fig. 3).

(4) Release belt tension by rotating the tensioner

clockwise (Fig. 3).

(5) Remove belt.

(1) Carefully return tensioner to its relaxed posi-

tion.

POWER STEERING PUMP

(1) From top of the vehicle, loosen locking nuts (1)

and (2) (Fig. 4).

(2) From under the vehicle, loosen the pivot bolt

(3). Loosen adjusting bolt (4) until belt can be

removed.

INSTALLATION

GENERATOR AND AIR CONDITIONING BELT

(1) Install belt onto all pulleys except for the

crankshaft (Fig. 5).(2) Rotate belt tensioner clockwise until belt can

be installed onto the crankshaft pulley (Fig. 3).

Slowly release belt tensioner.

Fig. 2 Power Steering Belt - Center Span Location

1 - POWER STEERING BELT CENTER SPAN LOCATION

Fig. 3 A/C & GENERATOR BELT TENSION RELEASE

1 - BELT TENSIONER

2 - WRENCH

Fig. 4 Power Steering Pump Belt

1 - REAR LOCKING NUT

2 - FRONT LOCKING NUT

3 - PIVOT BOLT

4 - ADJUSTING BOLT

RSACCESSORY DRIVE7-9

DRIVE BELTS - 2.4L (Continued)