air conditioning CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 231 of 2339

INSTALLATION

(1) Route and position the drive belt onto all pul-

leys, except for the crankshaft (Fig. 10).

(2) Rotate belt tensioner counterclockwise until

belt can be installed onto the crankshaft pulley (Fig.

9). Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys (Fig. 11).

(4) Install drive belt shield (Fig. 8) and lower vehi-

cle.

BELT TENSIONER - 3.3/3.8L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield.

(3) Remove the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

(4) Remove the belt tensioner (Fig. 12).

INSTALLATION

(1) Install the belt tensioner and bolt (Fig. 12).

Tighten bolt to 28 N´m (250 in. lbs.).

(2) Install the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION)

(3) Install the drive belt shield.

(4) Lower the vehicle.

Fig. 10 ACCESSORY DRIVE BELT

1 - DRIVE BELT

2 - POWER STEERING PUMP PULLEY

3 - BELT TENIONER PULLEY

4 - IDLER PULLEY

5 - GENERATOR PULLEY

6 - AIR CONDITIONING COMPRESSOR PULLEY

7 - CRANKSHAFT PULLEY

8 - WATER PUMP PULLEY

Fig. 11 3.3/3.8L Belt Routing

1 - GENERATOR PULLEY

2 - A/C COMPRESSOR PULLEY

3 - CRANKSHAFT PULLEY

4 - TENSIONER PULLEY

5 - WATER PUMP PULLEY

6 - P/S PUMP PULLEY

7 - IDLER PULLEY

Fig. 12 BELT TENSIONER - 3.3/3.8L

1 - BELT TENSIONER

2 - BOLT

7 - 12 ACCESSORY DRIVERS

DRIVE BELTS - 3.3/3.8L (Continued)

Page 246 of 2339

INSTALLATION

(1)Be sure the air seal is in position before

radiator is installed.Slide radiator down into posi-

tion. Seat the radiator with the rubber isolators into

the mounting holes provided, with a 10 lbs. force.

(2) Position air conditioning condenser onto the

radiator lower mounts and ingage upper mounting

tabs. (Fig. 15).

(3) Install the radiator upper and lower hoses (Fig.

13) or (Fig. 14).

(4) Connect the coolant reserve/recovery hose.

(5) Connect the vapor purge solenoid to the mount-

ing bracket.

(6) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(7) Install the radiator upper crossmember sup-

port. (Refer to 23 - BODY/EXTERIOR/GRILLE

OPENING REINFORCEMENT - INSTALLATION)

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

(9) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

NOTE: It is not necessary to remove draincock dur-

ing a routine coolant drain.

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Using a screwdriver, open the draincock by

turning it counterclockwise until it stops.

(3) Pull the draincock from the radiator tank.

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

CAUTION: Do not overtighten. The head of the

draincock may break off.

(3) Using a screwdriver, tighten the draincock by

turning clockwise until it stops.

(4) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

RADIATOR PRESSURE CAP

DESCRIPTION

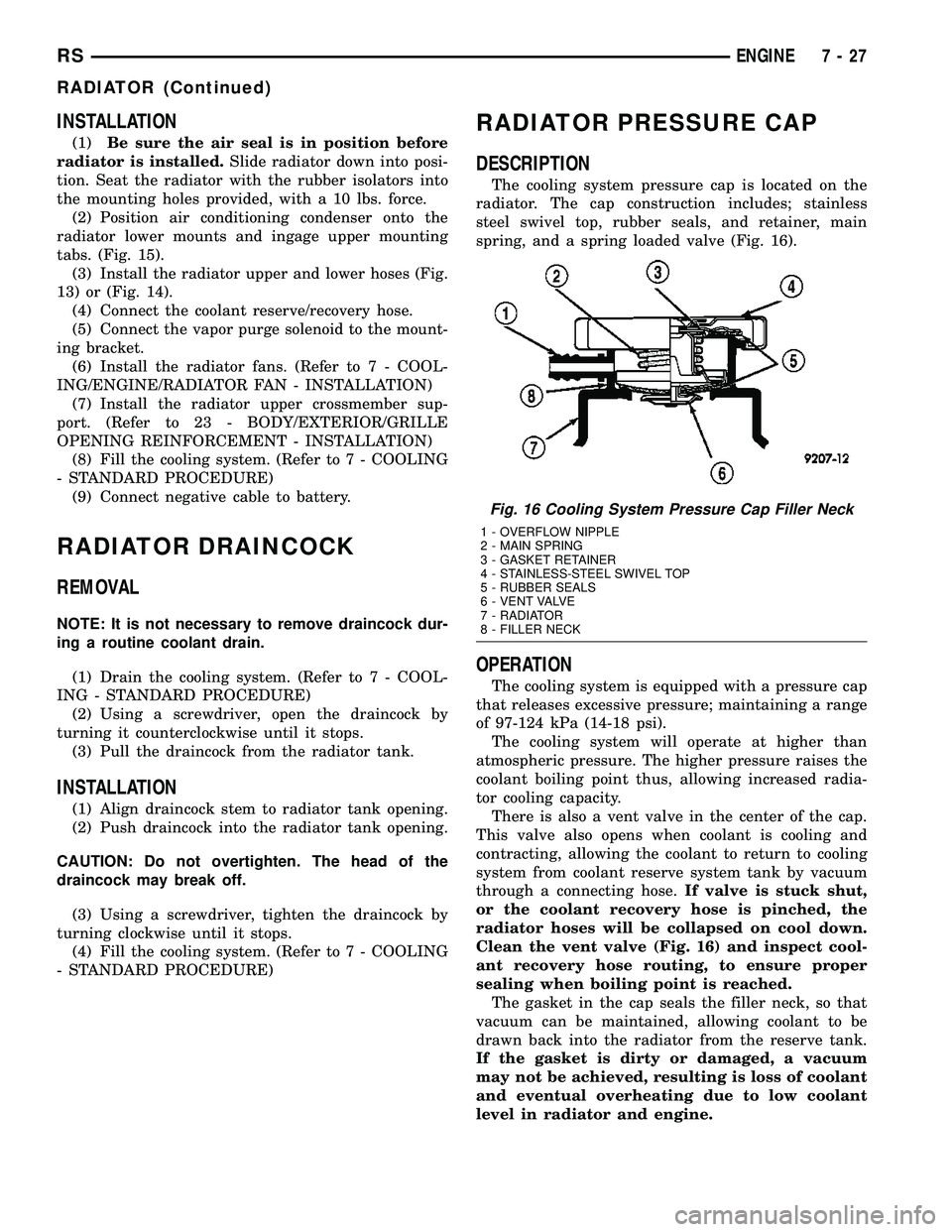

The cooling system pressure cap is located on the

radiator. The cap construction includes; stainless

steel swivel top, rubber seals, and retainer, main

spring, and a spring loaded valve (Fig. 16).

OPERATION

The cooling system is equipped with a pressure cap

that releases excessive pressure; maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is also a vent valve in the center of the cap.

This valve also opens when coolant is cooling and

contracting, allowing the coolant to return to cooling

system from coolant reserve system tank by vacuum

through a connecting hose.If valve is stuck shut,

or the coolant recovery hose is pinched, the

radiator hoses will be collapsed on cool down.

Clean the vent valve (Fig. 16) and inspect cool-

ant recovery hose routing, to ensure proper

sealing when boiling point is reached.

The gasket in the cap seals the filler neck, so that

vacuum can be maintained, allowing coolant to be

drawn back into the radiator from the reserve tank.

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

Fig. 16 Cooling System Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

RSENGINE7-27

RADIATOR (Continued)

Page 258 of 2339

TRANSMISSION OIL COOLER

DESCRIPTION

The automatic transmission cooler is located in the

front of the radiator and behind the front fascia and

is conbined with the A/C condensor. The transmission

cooler is a heat exchanger that allows heat in the

transmission flud to be transferred to the air passing

over the cooler fins.

The Transmission oil cooler/A/C condenser assem-

blly is equipped with quick connect fitting for the

transmission oil cooler lines, a tapping block, for the

receiver/drier, and mounting provisions for the power

steering cooler.

The transmission oil cooler/AC condenser is ser-

viced as an assembly. For removal on vehicles

equipped with 2.4L/3.3L/3.8L engines, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

CONDENSER - REMOVAL), vehicles equipped with2.5L/2.8L engines (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/A/C CONDENSER -

REMOVAL). For installation on vehicles equipped

with 2.4L/3.3L/3.8L engines (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION), and vehicles equipped

with 2.5L/2.8L engines (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION).

INSPECTION

Inspect all hoses, tubes, clamps and connections for

leaks, cracks, or damage. Replace as necessary. Use

only approved transmission oil cooler hoses that are

molded to fit the space available.

Inspect external coolers for leaks, loose mounts, or

damage. Replace as necessary.

TRANSMISSION OIL COOLER

LINES

REMOVAL

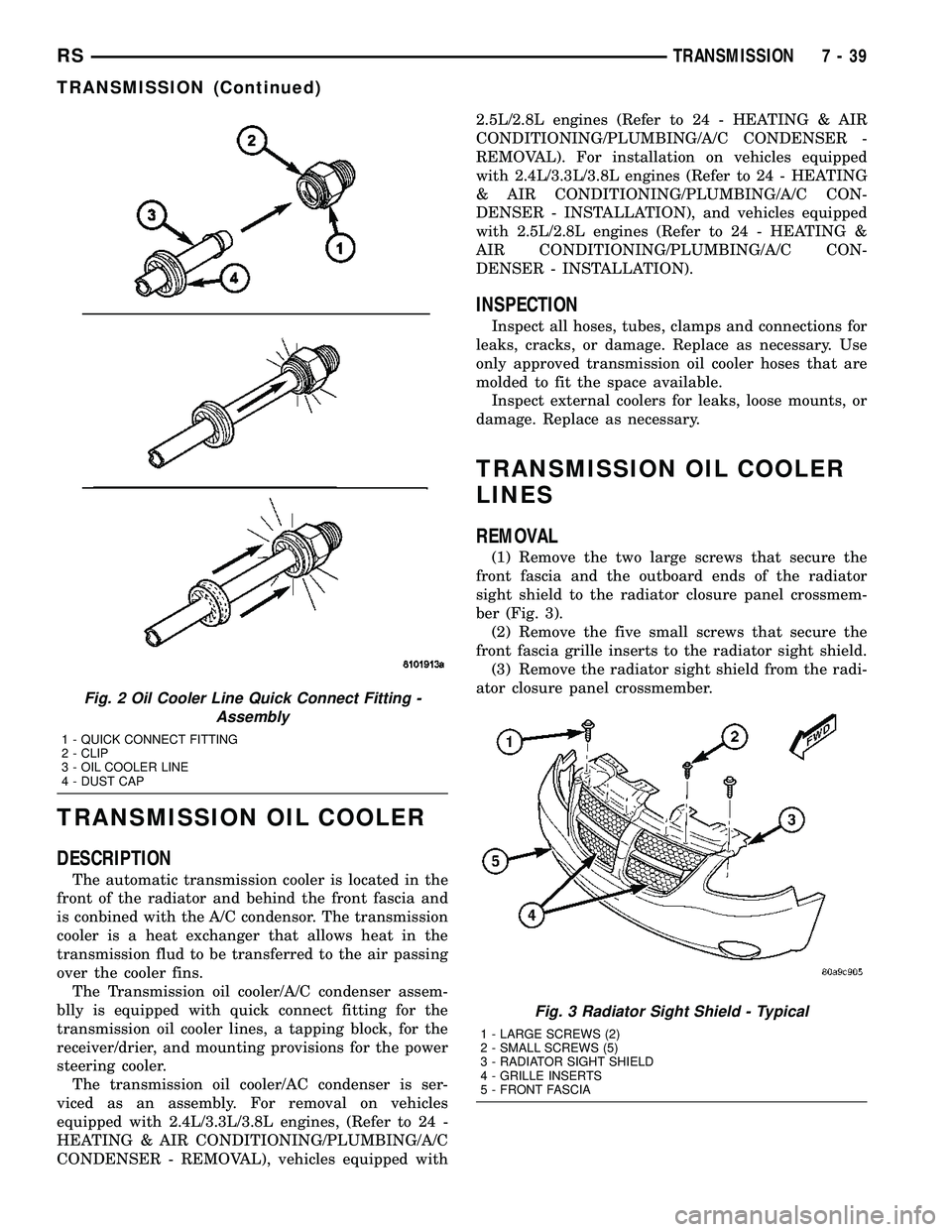

(1) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 3).

(2) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(3) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

Fig. 2 Oil Cooler Line Quick Connect Fitting -

Assembly

1 - QUICK CONNECT FITTING

2 - CLIP

3 - OIL COOLER LINE

4 - DUST CAP

Fig. 3 Radiator Sight Shield - Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSTRANSMISSION7-39

TRANSMISSION (Continued)

Page 296 of 2339

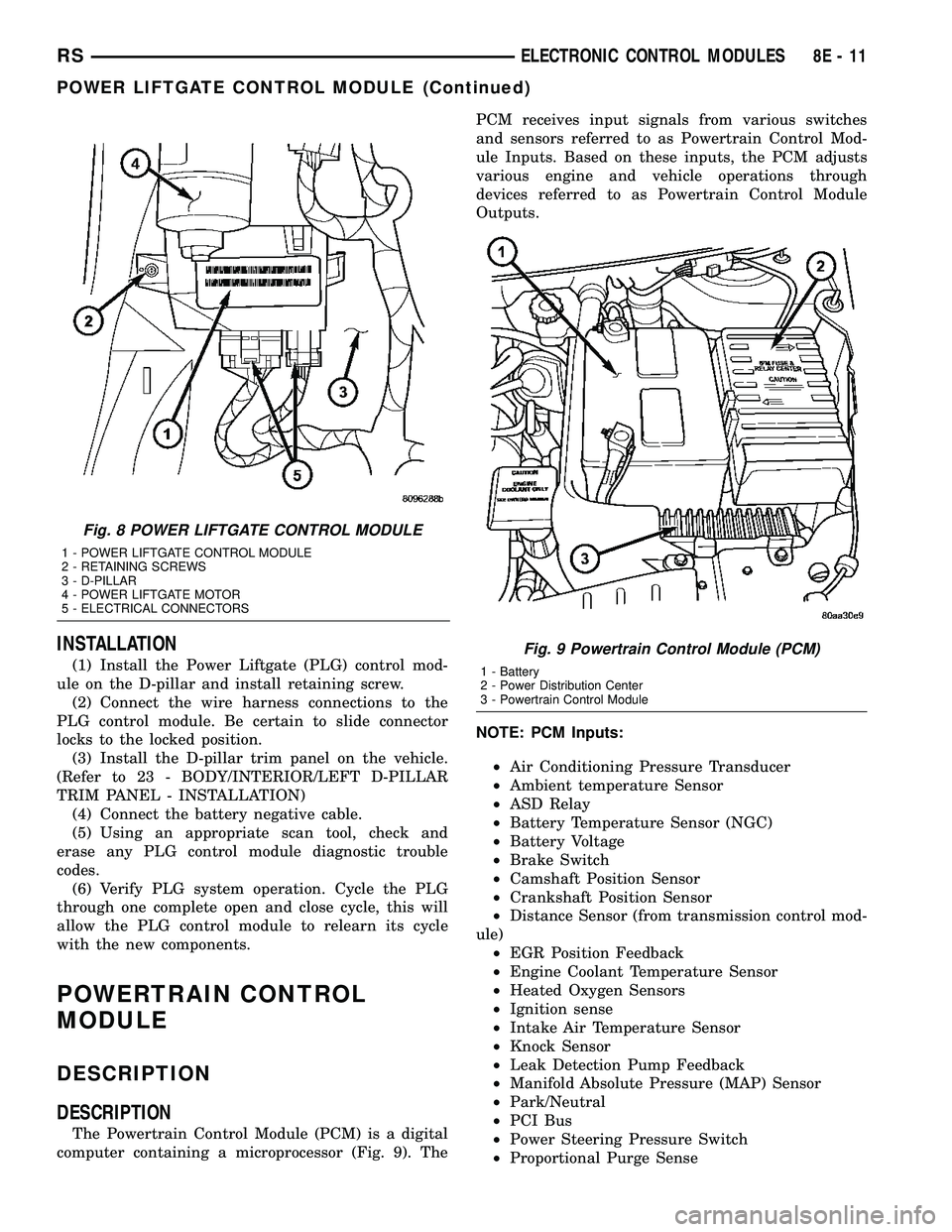

INSTALLATION

(1) Install the Power Liftgate (PLG) control mod-

ule on the D-pillar and install retaining screw.

(2) Connect the wire harness connections to the

PLG control module. Be certain to slide connector

locks to the locked position.

(3) Install the D-pillar trim panel on the vehicle.

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - INSTALLATION)

(4) Connect the battery negative cable.

(5) Using an appropriate scan tool, check and

erase any PLG control module diagnostic trouble

codes.

(6) Verify PLG system operation. Cycle the PLG

through one complete open and close cycle, this will

allow the PLG control module to relearn its cycle

with the new components.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

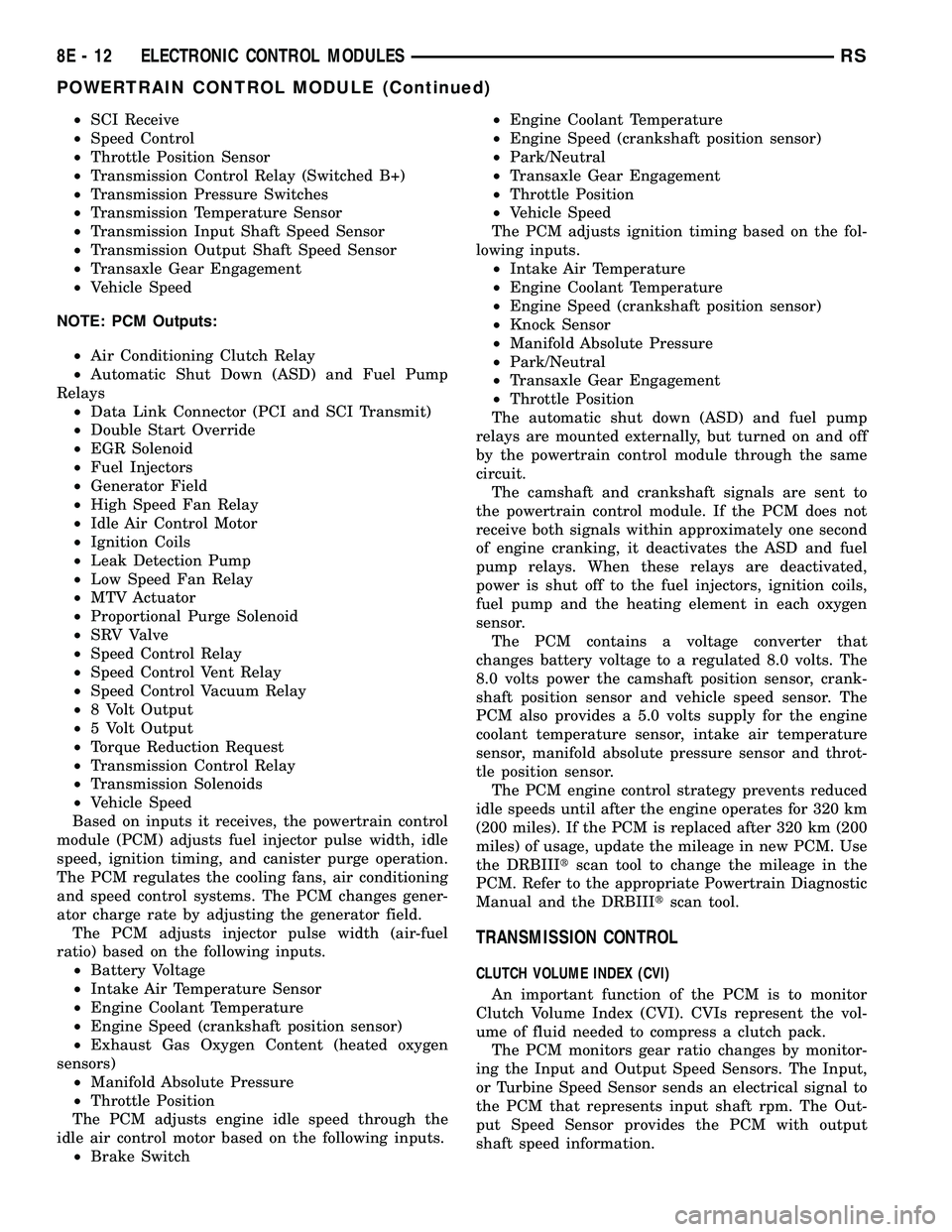

DESCRIPTION

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 9). ThePCM receives input signals from various switches

and sensors referred to as Powertrain Control Mod-

ule Inputs. Based on these inputs, the PCM adjusts

various engine and vehicle operations through

devices referred to as Powertrain Control Module

Outputs.

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²Ambient temperature Sensor

²ASD Relay

²Battery Temperature Sensor (NGC)

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

Fig. 8 POWER LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - ELECTRICAL CONNECTORS

Fig. 9 Powertrain Control Module (PCM)

1 - Battery

2 - Power Distribution Center

3 - Powertrain Control Module

RSELECTRONIC CONTROL MODULES8E-11

POWER LIFTGATE CONTROL MODULE (Continued)

Page 297 of 2339

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Transmission Control Relay (Switched B+)

²Transmission Pressure Switches

²Transmission Temperature Sensor

²Transmission Input Shaft Speed Sensor

²Transmission Output Shaft Speed Sensor

²Transaxle Gear Engagement

²Vehicle Speed

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid

²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

²Torque Reduction Request

²Transmission Control Relay

²Transmission Solenoids

²Vehicle Speed

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRBIIItscan tool to change the mileage in the

PCM. Refer to the appropriate Powertrain Diagnostic

Manual and the DRBIIItscan tool.

TRANSMISSION CONTROL

CLUTCH VOLUME INDEX (CVI)

An important function of the PCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The PCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the PCM that represents input shaft rpm. The Out-

put Speed Sensor provides the PCM with output

shaft speed information.

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 564 of 2339

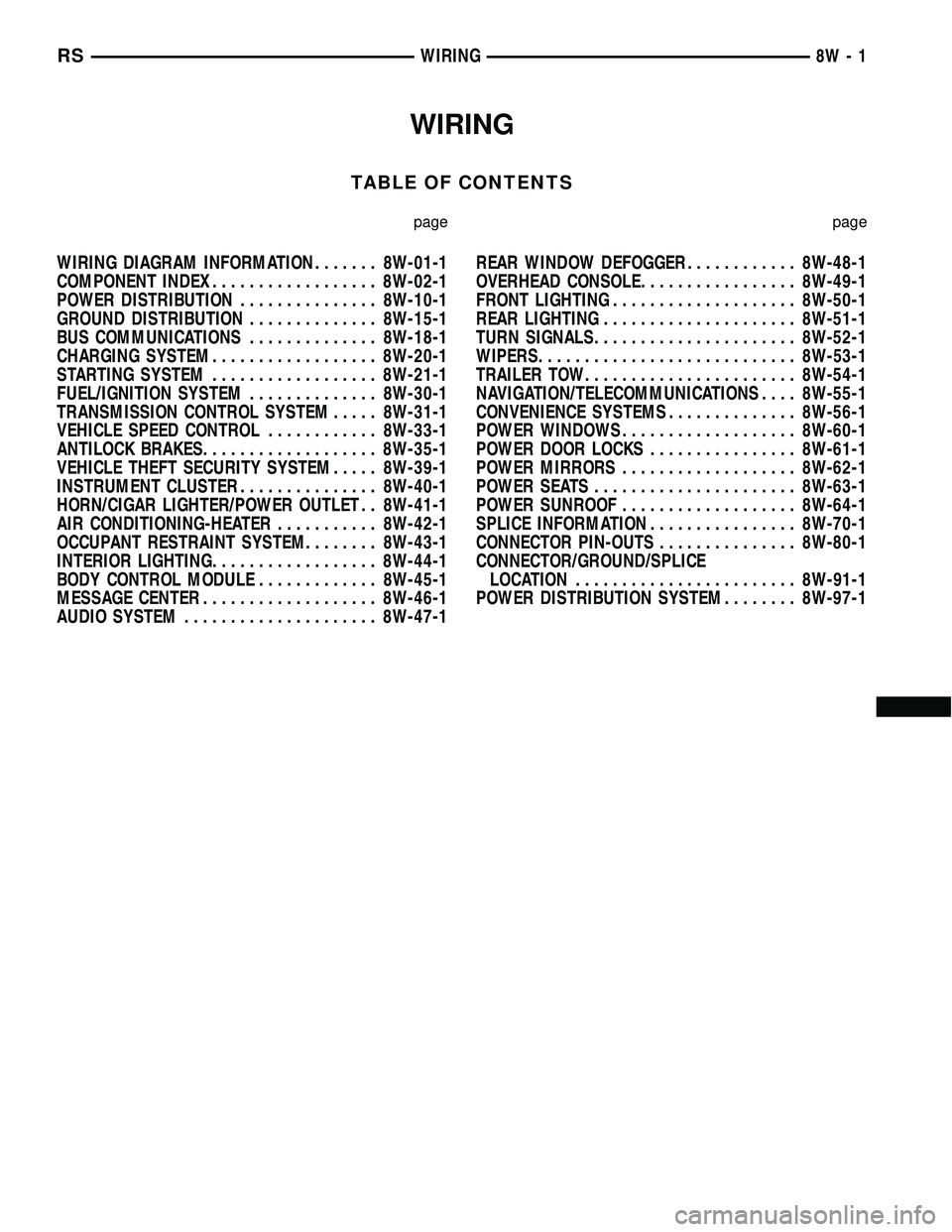

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

OCCUPANT RESTRAINT SYSTEM........ 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1

MESSAGE CENTER................... 8W-46-1

AUDIO SYSTEM..................... 8W-47-1REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATIONS.... 8W-55-1

CONVENIENCE SYSTEMS.............. 8W-56-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

Page 778 of 2339

8W-42 AIR CONDITIONING-HEATER

Component Page

A/C Compressor Clutch............ 8W-42-16, 19

A/C Compressor Clutch Relay....... 8W-42-16, 19

A/C Pressure Sensor.............. 8W-42-16, 19

A/C-Heater Control....... 8W-42-2, 3, 4, 5, 6, 7, 9

ATC Remote Sensor................. 8W-42-13

Auto Temp Control.... 8W-42-10, 11, 12, 13, 14, 15

Battery........................... 8W-42-17

Blower Motor Resistor.............. 8W-42-2, 3

Body Control Module.......... 8W-42-6, 9, 11, 15

Driver Blend Door Actuator......... 8W-42-7, 12

ECM/PCM Relay................... 8W-42-17

Engine Control Module............ 8W-42-16, 17

Evaporator Temperature Sensor...... 8W-42-7, 12

Front Blower Module................ 8W-42-13

Front Blower Motor............. 8W-42-2, 3, 13

Front Blower Motor Relay........ 8W-42-2, 3, 13

Front Control Module....... 8W-42-2, 3, 8, 13, 14

Fuse 10....................... 8W-42-2, 3, 13

Fuse 12......................... 8W-42-8, 14

Fuse 14........................... 8W-42-10

Fuse 16........................... 8W-42-17

Fuse 18........................ 8W-42-16, 19

Fuse 27........................ 8W-42-18, 20

Fuselink.......................... 8W-42-17

G101............................. 8W-42-19

G102.......................... 8W-42-18, 20

G103............................. 8W-42-16Component Page

G200........... 8W-42-2, 3, 4, 5, 6, 8, 10, 11, 13

G300........................... 8W-42-9, 15

G302............................. 8W-42-14

Integrated Power Module.... 8W-42-2, 3, 8, 10, 13,

14, 16, 17, 18, 19, 20

Mode Door Actuator............... 8W-42-7, 12

Passenger Blend Door Actuator...... 8W-42-7, 12

Powertrain Control Module......... 8W-42-19, 20

Radiator Fan No. 1............ 8W-42-17, 18, 20

Radiator Fan No. 2............... 8W-42-18, 20

Radiator Fan Relay................. 8W-42-20

Radiator Fan Relay No. 1.......... 8W-42-17, 18

Radiator Fan Relay No. 2............. 8W-42-18

Radiator Fan Relay No. 3............. 8W-42-18

Rear A/C-Heater Unit............... 8W-42-8, 9

Rear Auto Temp Control Switch........ 8W-42-15

Rear Blower Front Control Switch....... 8W-42-8

Rear Blower Motor.................. 8W-42-14

Rear Blower Motor Power Module...... 8W-42-14

Rear Blower Motor Relay........... 8W-42-8, 14

Rear Blower Rear Control Switch...... 8W-42-8, 9

Rear Mode Motor................... 8W-42-14

Rear Temperature Motor............. 8W-42-14

Rear Wiper/Washer Indicator........... 8W-42-4

Rear Wiper/Washer Switch............. 8W-42-4

Recirculation Door Actuator......... 8W-42-7, 12

RS8W-42 AIR CONDITIONING-HEATER8W-42-1

Page 1190 of 2339

(9) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug cooler

lines and fittings to prevent debris from entering

transaxle or cooler circuit. A service splice kit will be

installed upon reassembly.

(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

RSENGINE 2.4L9-13

ENGINE 2.4L (Continued)

Page 1210 of 2339

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel. They

have chrome plated stems to prevent scuffing. Viton

rubber valve stem seals are integral with the spring

seats. The valves have three-bead lock keepers to

retain springs and to promote valve rotation.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - REMOVAL).

(3) Rotate crankshaft until piston is at TDC on

compression.

(4) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(5) Using Special Tool MD-998772-A with adapter

6779 (Fig. 33), compress valve springs and remove

valve locks.

(6) Remove valve spring(s).

(7) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 35).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed from cylinder

block, compress valve springs using a universal valve

spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves, locks and

retainers to insure installation in original location.

(4) Inspect the valves. (Refer to 9 - ENGINE/CYL-

INDER HEAD/VALVE SPRINGS - INSPECTION)

INSPECTION

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct tension. Discard the

springs that do not meet specifications. The following

specifications apply to both intake and exhaust

valves springs:

²Valve Closed Nominal TensionÐ76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

INSTALLATION

INSTALLATION - CYLINDER HEAD ON

(1) Install valve seal/valve spring seat assembly

(Fig. 34). Push the assembly down to seat it onto the

valve guide.

(2) Install valve spring and retainer, use Special

Tool MD-998772-A with adapter 6779 to compress

valve springs only enough to install locks (Fig. 33).

Correct alignment of tool is necessary to avoid nick-

ing valve stems.

(3) Remove air hose and install spark plugs.

(4) Install camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(5) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER - INSTALLATION).

INSTALLATION - CYLINDER HEAD OFF

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 35). The valve stem

seals should be pushed firmly and squarely over

valve guide.

Fig. 33 Valve Spring - Removal/Installation

1 - VALVE SPRING COMPRESSOR MD 998772A

2 - AIR HOSE

RSENGINE 2.4L9-33

Page 1232 of 2339

(3) Screw oil filter (Fig. 88) on until the gasket

contacts base. Tighten to 12 N´m (105 in. lbs.).

OIL PAN

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle on hoist and drain engine oil.

(3) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(4) Remove air conditioning compressor bracket to

oil pan bolt.

NOTE: The oil pan is sealed with rtv and may need

to be pryed apart.

(5) Remove bolts attaching oil pan.

(6) Insert pry bar at specified locations (Fig. 89)

(Fig. 90) (Fig. 91) and gently pry oil pan away from

the engine.

(7) Clean oil pan and block surfaces.Clean cured

RTV from oil pan and bed plate with a plastic or

brass scraper.

(8) Clean all sealing surfaces with MOPARtBrake

Parts Cleaner.

(9) Inspect surfaces for damage, replace as needed.

INSTALLATION

NOTE: You must assemble oil pan to bed plate

before RTV ªskins overº. If RTV skins before

assembly, parts must be cleaned and a new bead of

RTV applied.

Fig. 88 Oil Filter

Fig. 89 Left Front Pry Point

1 - BED PLATE

2 - OIL PAN

3 - PRY POINT

Fig. 90 Right Front Pry Point

1 - OIL FILTER ADAPTER

2 - PRY POINT

3 - OIL PAN

RSENGINE 2.4L9-55

OIL FILTER (Continued)