power steering fluid CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 241 of 2339

(1) Drain cooling system below engine coolant tem-

perature sensor level. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(2) Remove power steering reservoir and relocate

(Fig. 4). Do not disconnect hoses.

(3) Remove ignition coil and bracket (Fig. 5).

(4) Disconnect coolant sensor electrical connector

(Fig. 6).

(5) Remove coolant sensor (Fig. 6).

Fig. 4 Power Steering Fluid Reservoir

1 - POWER STEERING RESERVOIR

2 - BOLT - RESERVOIR TO MANIFOLD

3 - NUT - RESERVOIR TO COIL BRACKET

Fig. 5 Fuel Rail, Ignition Coil and Bracket

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

7 - 22 ENGINERS

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L (Continued)

Page 1125 of 2339

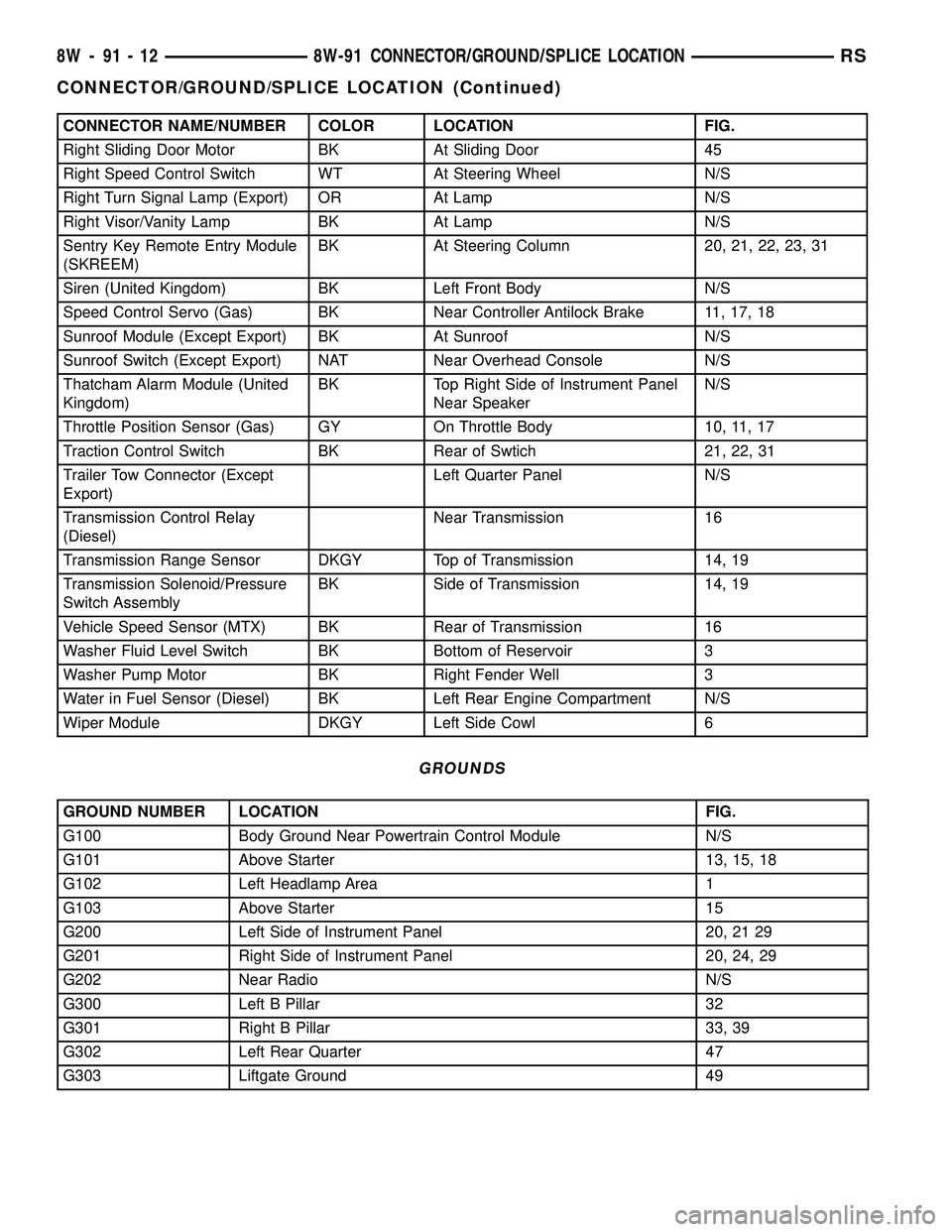

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Sliding Door Motor BK At Sliding Door 45

Right Speed Control Switch WT At Steering Wheel N/S

Right Turn Signal Lamp (Export) OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Remote Entry Module

(SKREEM)BK At Steering Column 20, 21, 22, 23, 31

Siren (United Kingdom) BK Left Front Body N/S

Speed Control Servo (Gas) BK Near Controller Antilock Brake 11, 17, 18

Sunroof Module (Except Export) BK At Sunroof N/S

Sunroof Switch (Except Export) NAT Near Overhead Console N/S

Thatcham Alarm Module (United

Kingdom)BK Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor (Gas) GY On Throttle Body 10, 11, 17

Traction Control Switch BK Rear of Swtich 21, 22, 31

Trailer Tow Connector (Except

Export)Left Quarter Panel N/S

Transmission Control Relay

(Diesel)Near Transmission 16

Transmission Range Sensor DKGY Top of Transmission 14, 19

Transmission Solenoid/Pressure

Switch AssemblyBK Side of Transmission 14, 19

Vehicle Speed Sensor (MTX) BK Rear of Transmission 16

Washer Fluid Level Switch BK Bottom of Reservoir 3

Washer Pump Motor BK Right Fender Well 3

Water in Fuel Sensor (Diesel) BK Left Rear Engine Compartment N/S

Wiper Module DKGY Left Side Cowl 6

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 13, 15, 18

G102 Left Headlamp Area 1

G103 Above Starter 15

G200 Left Side of Instrument Panel 20, 21 29

G201 Right Side of Instrument Panel 20, 24, 29

G202 Near Radio N/S

G300 Left B Pillar 32

G301 Right B Pillar 33, 39

G302 Left Rear Quarter 47

G303 Liftgate Ground 49

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1326 of 2339

INSPECTION

Check manifold for:

²Damage and cracks.

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - UPPER INTAKE MANIFOLD

(1) If the following components were removed from

manifold, install and tighten to specifications:

CAUTION: The special screws used for the compos-

ite manifold attached components must be installed

slowly using hand tools only. This requirement is to

prevent the melting of material that causes stripped

threads. If threads become stripped, an oversize

repair screw is available. For more information and

procedure (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - STANDARD PROCEDURE - MAN-

IFOLD STRIPPED THREAD REPAIR).

²MAP sensor - 1.7 N´m (15 in. lbs.)

²Throttle cable bracket - 5.6 N´m (50 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

(3) Inspect manifold gasket condition. Gaskets can

be re-used, if not damaged. To replace, remove gasket

from upper manifold (Fig. 118). Position new gasket

in seal channel and press lightly in-place. Repeat

procedure for each gasket position.

(4) Position upper manifold on lower manifold (Fig.

118). Apply MopartLock & Seal Adhesive (Medium

Strength Threadlocker) to each upper intake mani-

fold bolt. Install and tighten bolts to 12 N´m (105 in.

lbs.) following torque sequence in (Fig. 119).

Fig. 115 PCV & HOSE

1 - HOSE - PCV

2 - P C V VA LV E

Fig. 116 POWER STEERING FLUID RESERVOIR

1 - POWER STEERING RESERVOIR

2 - BOLT - RESERVOIR TO MANIFOLD

3 - NUT - RESERVOIR TO COIL BRACKET

Fig. 117 BRAKE BOOSTER & LDP VACUUM HOSES

1 - LDP & SPEED CONTROL VACUUM HOSE

2 - BRAKE BOOSTER VACUUM HOSE

3 - MAP SENSOR

RSENGINE 3.3/3.8L9 - 149

INTAKE MANIFOLD - UPPER (Continued)

Page 1362 of 2339

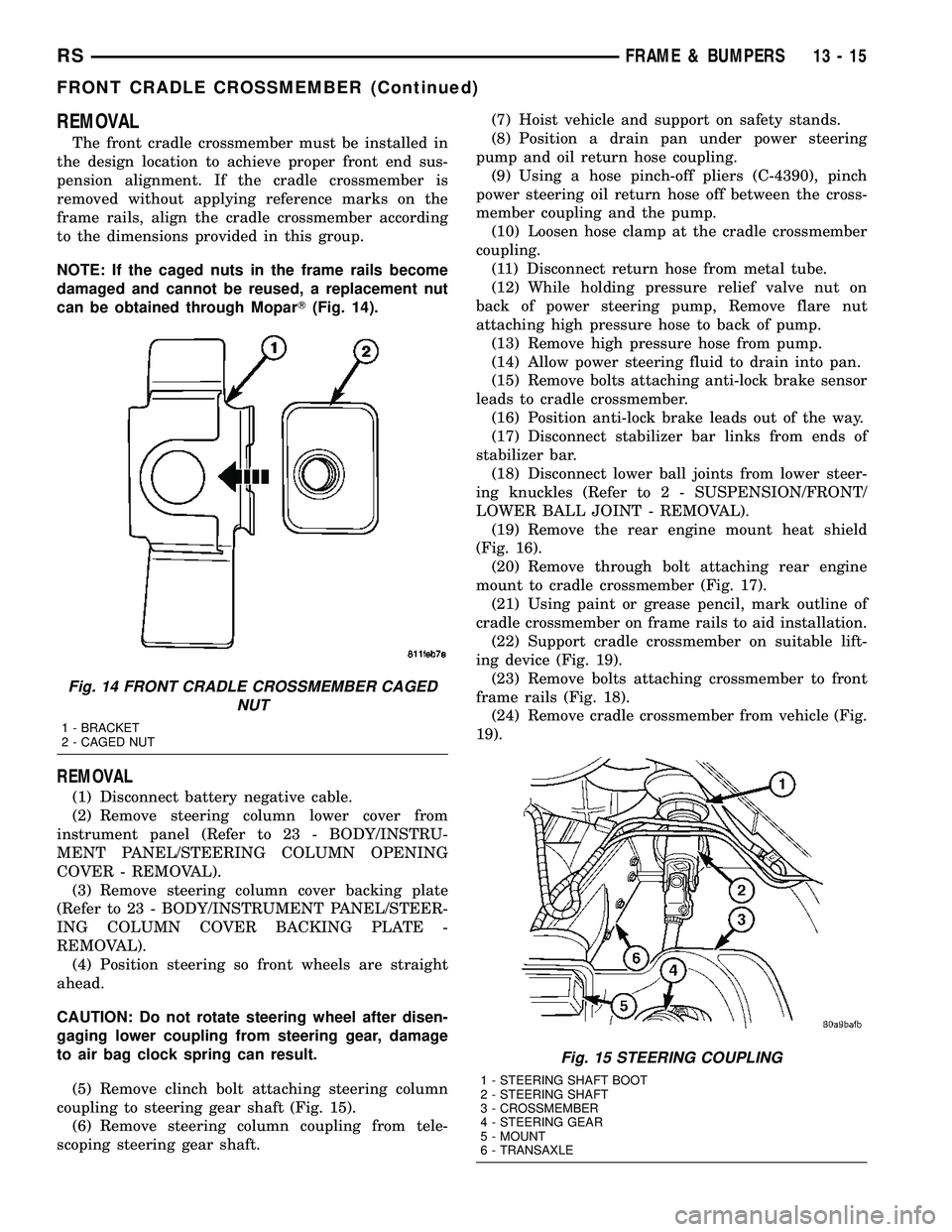

REMOVAL

The front cradle crossmember must be installed in

the design location to achieve proper front end sus-

pension alignment. If the cradle crossmember is

removed without applying reference marks on the

frame rails, align the cradle crossmember according

to the dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through MoparT(Fig. 14).

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - REMOVAL).

(3) Remove steering column cover backing plate

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN COVER BACKING PLATE -

REMOVAL).

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to air bag clock spring can result.

(5) Remove clinch bolt attaching steering column

coupling to steering gear shaft (Fig. 15).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.(7) Hoist vehicle and support on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the cradle crossmember

coupling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut

attaching high pressure hose to back of pump.

(13) Remove high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts attaching anti-lock brake sensor

leads to cradle crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar.

(18) Disconnect lower ball joints from lower steer-

ing knuckles (Refer to 2 - SUSPENSION/FRONT/

LOWER BALL JOINT - REMOVAL).

(19) Remove the rear engine mount heat shield

(Fig. 16).

(20) Remove through bolt attaching rear engine

mount to cradle crossmember (Fig. 17).

(21) Using paint or grease pencil, mark outline of

cradle crossmember on frame rails to aid installation.

(22) Support cradle crossmember on suitable lift-

ing device (Fig. 19).

(23) Remove bolts attaching crossmember to front

frame rails (Fig. 18).

(24) Remove cradle crossmember from vehicle (Fig.

19).

Fig. 14 FRONT CRADLE CROSSMEMBER CAGED

NUT

1 - BRACKET

2 - CAGED NUT

Fig. 15 STEERING COUPLING

1 - STEERING SHAFT BOOT

2 - STEERING SHAFT

3 - CROSSMEMBER

4 - STEERING GEAR

5 - MOUNT

6 - TRANSAXLE

RSFRAME & BUMPERS13-15

FRONT CRADLE CROSSMEMBER (Continued)

Page 1408 of 2339

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION - POWER STEERING SYSTEM . . 1

OPERATION - POWER STEERING SYSTEM . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM FLOW AND

PRESSURE TEST......................1

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS............3SPECIFICATIONS

POWER STEERING FASTENER TORQUE . . . 9

SPECIAL TOOLS

POWER STEERING....................9

COLUMN..............................10

GEAR.................................26

PUMP.................................36

STEERING

DESCRIPTION - POWER STEERING SYSTEM

This vehicle comes with power steering as stan-

dard equipment. The power steering system consists

of these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID

²POWER STEERING FLUID COOLER (If

Equipped)

²POWER STEERING FLUID RESERVOIR

²POWER STEERING FLUID SUPPLY HOSE

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on all other components can

be found in POWER STEERING PUMP.

OPERATION - POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth within the

steering gear. The lateral travel pushes and pulls the

tie rods to change the direction of the vehicle's front

wheels.

Power assist steering is provided by a belt driven

rotary type pump. It directs fluid through power

steering fluid hoses to the power steering gear where

it is used to assist the driver's turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM FLOW AND PRESSURE TEST

ALL ENGINES

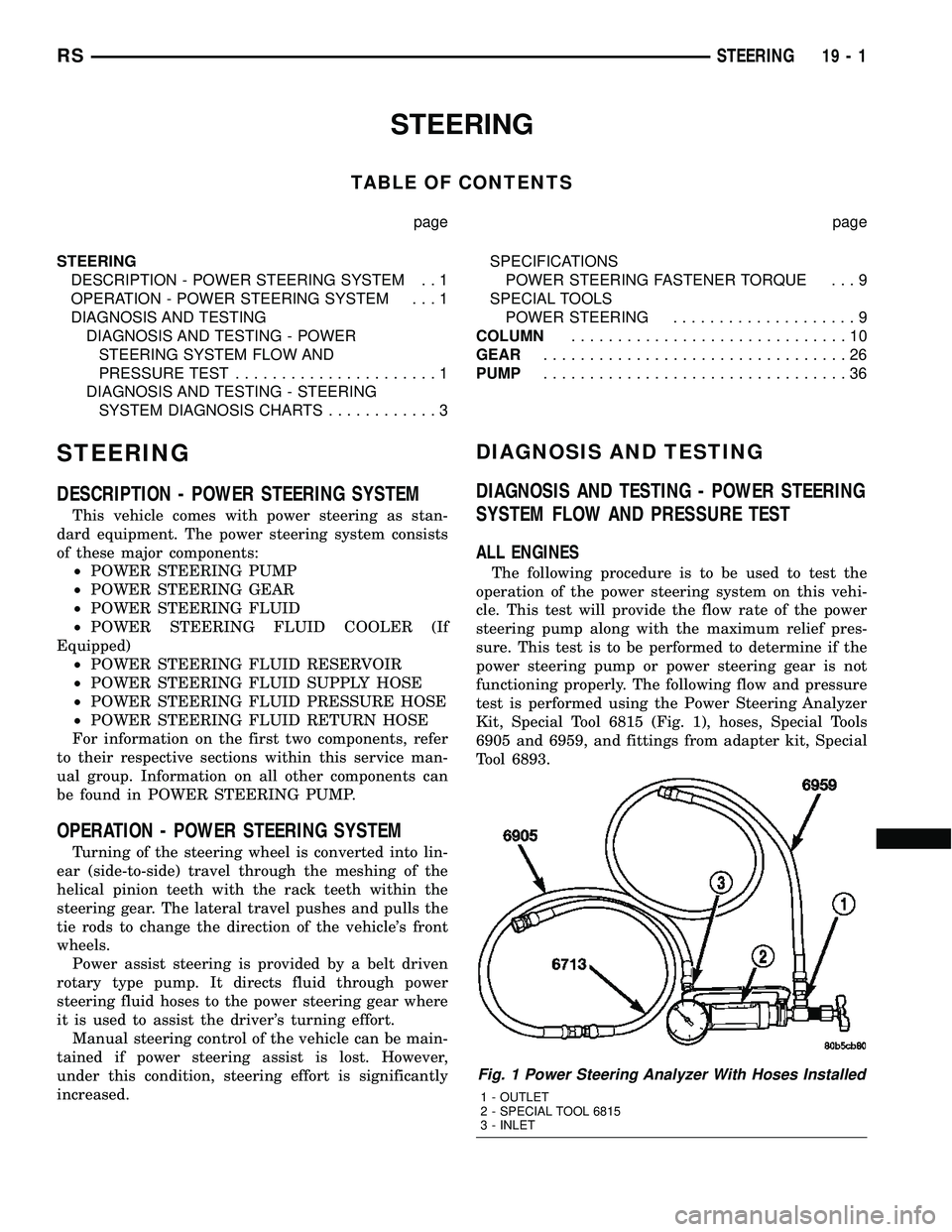

The following procedure is to be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed to determine if the

power steering pump or power steering gear is not

functioning properly. The following flow and pressure

test is performed using the Power Steering Analyzer

Kit, Special Tool 6815 (Fig. 1), hoses, Special Tools

6905 and 6959, and fittings from adapter kit, Special

Tool 6893.

Fig. 1 Power Steering Analyzer With Hoses Installed

1 - OUTLET

2 - SPECIAL TOOL 6815

3 - INLET

RSSTEERING19-1

Page 1409 of 2339

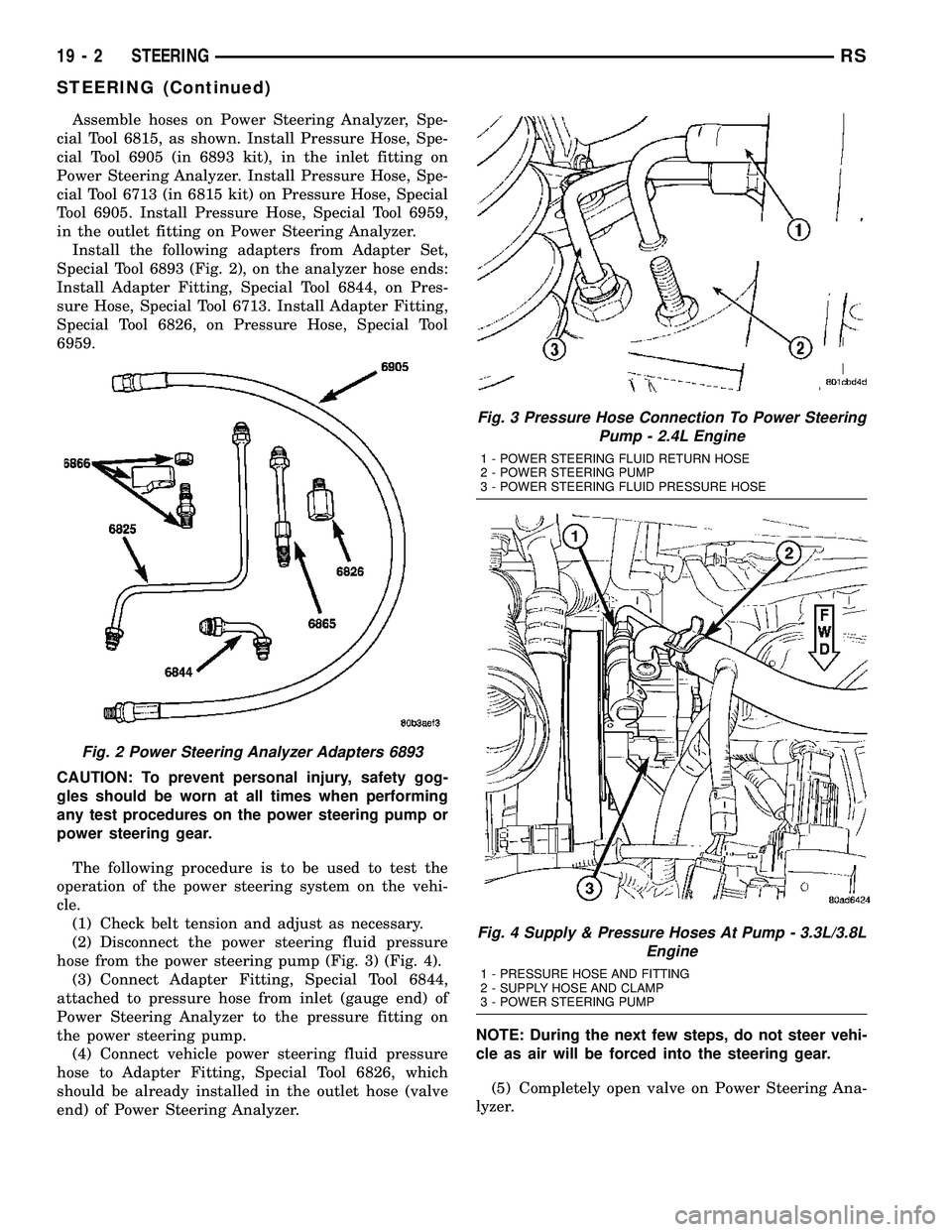

Assemble hoses on Power Steering Analyzer, Spe-

cial Tool 6815, as shown. Install Pressure Hose, Spe-

cial Tool 6905 (in 6893 kit), in the inlet fitting on

Power Steering Analyzer. Install Pressure Hose, Spe-

cial Tool 6713 (in 6815 kit) on Pressure Hose, Special

Tool 6905. Install Pressure Hose, Special Tool 6959,

in the outlet fitting on Power Steering Analyzer.

Install the following adapters from Adapter Set,

Special Tool 6893 (Fig. 2), on the analyzer hose ends:

Install Adapter Fitting, Special Tool 6844, on Pres-

sure Hose, Special Tool 6713. Install Adapter Fitting,

Special Tool 6826, on Pressure Hose, Special Tool

6959.

CAUTION: To prevent personal injury, safety gog-

gles should be worn at all times when performing

any test procedures on the power steering pump or

power steering gear.

The following procedure is to be used to test the

operation of the power steering system on the vehi-

cle.

(1) Check belt tension and adjust as necessary.

(2) Disconnect the power steering fluid pressure

hose from the power steering pump (Fig. 3) (Fig. 4).

(3) Connect Adapter Fitting, Special Tool 6844,

attached to pressure hose from inlet (gauge end) of

Power Steering Analyzer to the pressure fitting on

the power steering pump.

(4) Connect vehicle power steering fluid pressure

hose to Adapter Fitting, Special Tool 6826, which

should be already installed in the outlet hose (valve

end) of Power Steering Analyzer.NOTE: During the next few steps, do not steer vehi-

cle as air will be forced into the steering gear.

(5) Completely open valve on Power Steering Ana-

lyzer.

Fig. 2 Power Steering Analyzer Adapters 6893

Fig. 3 Pressure Hose Connection To Power Steering

Pump - 2.4L Engine

1 - POWER STEERING FLUID RETURN HOSE

2 - POWER STEERING PUMP

3 - POWER STEERING FLUID PRESSURE HOSE

Fig. 4 Supply & Pressure Hoses At Pump - 3.3L/3.8L

Engine

1 - PRESSURE HOSE AND FITTING

2 - SUPPLY HOSE AND CLAMP

3 - POWER STEERING PUMP

19 - 2 STEERINGRS

STEERING (Continued)

Page 1410 of 2339

(6) Start engine and let idle just long enough to

circulate power steering fluid through the analyzer

and hoses. Shut off engine.

(7) Check power steering fluid level and add fluid

as necessary. Start engine again and let idle until the

air is out of the fluid.

(8) Gauge should read below 300 psi (2068 kPa). If

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the range

of 100-275 psi (689-1896 kPa) depending on fluid

temperature. The flow meter should read above 1.5

GPM.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than four seconds as the pump could be

damaged.

NOTE: Power steering pump maximum pressure for

2.4L engines is 1,200 ± 1,350 psi (8,274 ± 9,308

kPa). Power steering pump maximum pressure for

all other engines is 1,400 ± 1,500 psi (9,653 ± 10,342

kPa).

(9) Close analyzer valve fully three times and

record highest pressure indicated each time. All three

readings must be within specifications. If any of the

three power steering pump pressures are above orbelow specifications, replace pump. (Refer to 19 -

STEERING/PUMP - REMOVAL)

CAUTION: Do not force the steering to operate

against the stops for more than 4 seconds at a time

because pump damage can result.

(10) Once the pump has been verified as working

correctly, completely open the valve on the Power

Steering Analyzer. Turn the steering wheel to the

extreme left until the stop in the steering gear is

met. Hold it there for 2±4 seconds, then release it.

Now turn the steering wheel to the right until the

right stop is met. Hold it there for 2±4 seconds, then

release it. Record the stabilized pressure at each

position. Compare the recorded readings to the spec-

ifications. If the output pressures are not within 100

psi (689 kPa) of one another against either stop or

are below specifications, the steering gear is leaking

internally and must be replaced. (Refer to 19 -

STEERING/GEAR - REMOVAL)

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover POWER STEERING NOISE, STEERING

WHEEL FEEL, and POWER STEERING FLUID.

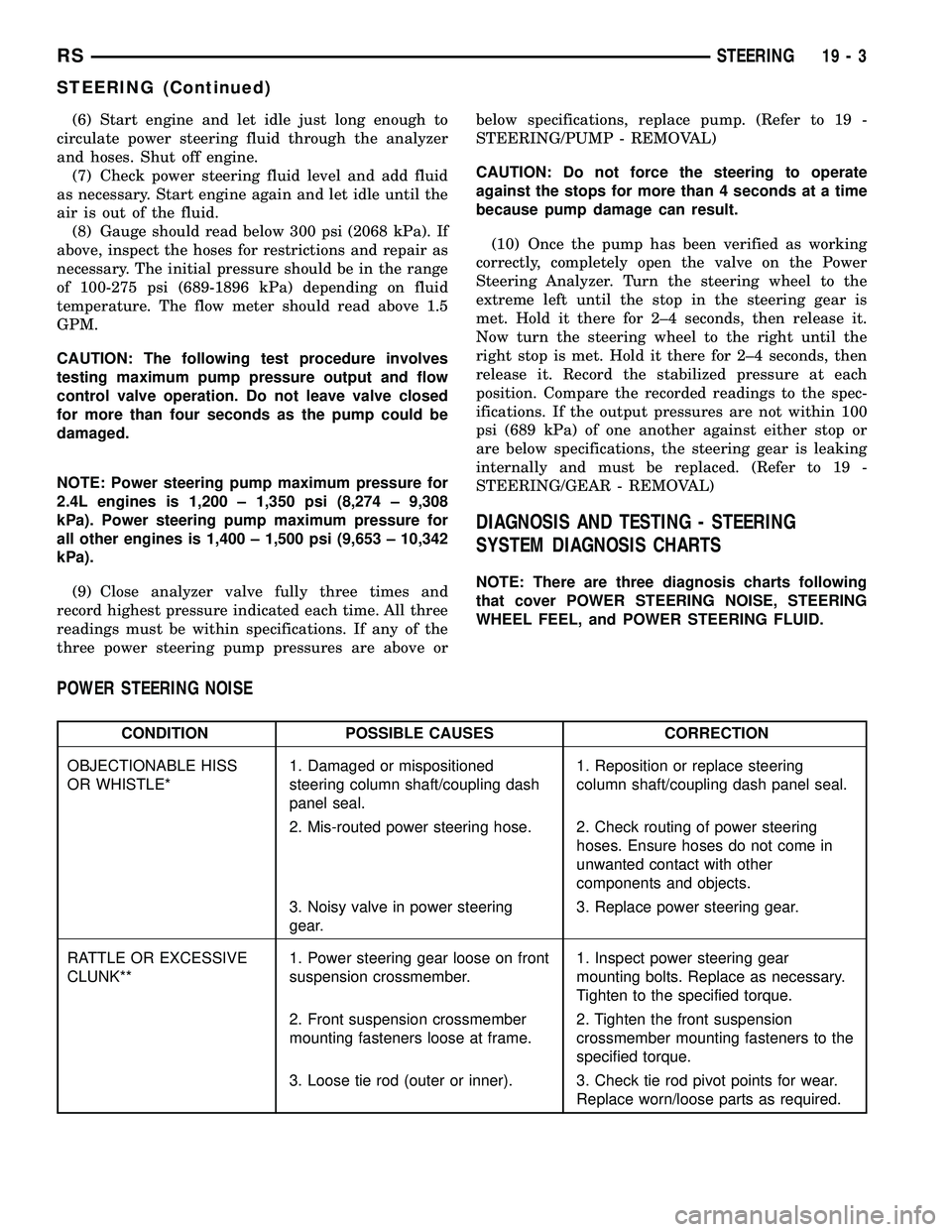

POWER STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONABLE HISS

OR WHISTLE*1. Damaged or mispositioned

steering column shaft/coupling dash

panel seal.1. Reposition or replace steering

column shaft/coupling dash panel seal.

2. Mis-routed power steering hose. 2. Check routing of power steering

hoses. Ensure hoses do not come in

unwanted contact with other

components and objects.

3. Noisy valve in power steering

gear.3. Replace power steering gear.

RATTLE OR EXCESSIVE

CLUNK**1. Power steering gear loose on front

suspension crossmember.1. Inspect power steering gear

mounting bolts. Replace as necessary.

Tighten to the specified torque.

2. Front suspension crossmember

mounting fasteners loose at frame.2. Tighten the front suspension

crossmember mounting fasteners to the

specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for wear.

Replace worn/loose parts as required.

RSSTEERING19-3

STEERING (Continued)

Page 1411 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower or knuckle.6. Tighten strut assembly fasteners to

the specified torque.

7. Power steering fluid hose touching

the body of the vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

attachments to specified torque. Do not

bend tubing.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Stabilizer bar link ball joints worn. 9. Replace stabilizer bar link.

10. Lug nuts loose. 10. Tighten lug nuts to specifications.

11. Excessive Wheel bearing

free-play.11. Verify correct halfshaft hub nut

torque. Replace hub and bearing if

torque is okay.

12. Internal power steering gear

noise.12. Replace power steering gear.

POPPING NOISE 1. Worn outer tie rod. 1. Check ball joint for free-play;

Replace outer tie rod.

2. Loose inner tie rod. 2. Replace power steering gear.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

2. Malfuctioning belt auto-tensioner 2. Replace belt auto-tensioner.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)***1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extremely low ambient

temperature.3. Some noise can be expected, but will

go away as vehicle warms. Replace

pump if noise is excessive.

4. Extreme wear of power steering

pump internal components.4. Replace power steering pump and

flush system as necessary.

19 - 4 STEERINGRS

STEERING (Continued)

Page 1412 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Loose clamp on fluid supply hose. 4. Tighten or replace hose clamp.

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Seal lubrication inadequate. 4. Lube seal (if external).

5. Steering gear internally noisy. 5. Replace steering gear (if no other

cause can be found).

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

* NOTE: There is some noise in all power steering

systems. One of the most common is a hissing

sound evident when turning the steering wheel

when at a standstill or when parking and the steer-

ing wheel is at the end of its travel. Hiss is a very

high frequency noise similar to that experienced

while slowly closing a water tap. The noise is

present in every valve and results when high veloc-

ity fluid passes valve orifice edges. There is no

relationship between this noise and the perfor-

mance of the steering system.** NOTE: A light clunk may be felt or heard during

steering wheel reversal while vehicle is stationary.

This results from internal steering gear rack move-

ment at the bushings and in no way affects the per-

formance of the steering system. This movement

may be felt in the steering components during

steering wheel reversal.

*** NOTE: Power steering pump growl/moan/groan

results from the development of high pressure fluid

flow. Normally this noise level should not be high

enough to be objectionable.

RSSTEERING19-5

STEERING (Continued)

Page 1413 of 2339

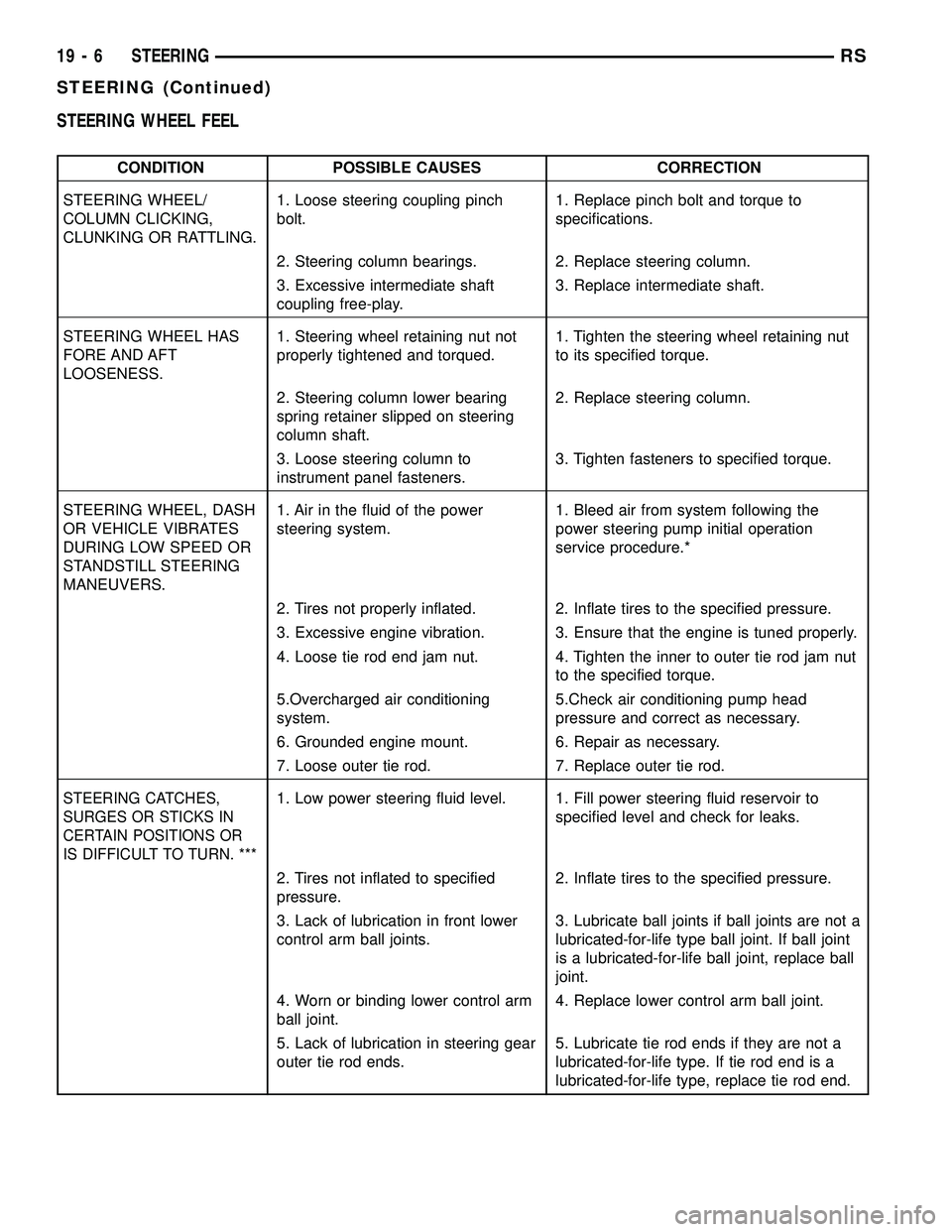

STEERING WHEEL FEEL

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL/

COLUMN CLICKING,

CLUNKING OR RATTLING.1. Loose steering coupling pinch

bolt.1. Replace pinch bolt and torque to

specifications.

2. Steering column bearings. 2. Replace steering column.

3. Excessive intermediate shaft

coupling free-play.3. Replace intermediate shaft.

STEERING WHEEL HAS

FORE AND AFT

LOOSENESS.1. Steering wheel retaining nut not

properly tightened and torqued.1. Tighten the steering wheel retaining nut

to its specified torque.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

3. Loose steering column to

instrument panel fasteners.3. Tighten fasteners to specified torque.

STEERING WHEEL, DASH

OR VEHICLE VIBRATES

DURING LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is tuned properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure and correct as necessary.

6. Grounded engine mount. 6. Repair as necessary.

7. Loose outer tie rod. 7. Replace outer tie rod.

STEERING CATCHES,

SURGES OR STICKS IN

CERTAIN POSITIONS OR

IS DIFFICULT TO TURN. ***1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front lower

control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated-for-life type ball joint. If ball joint

is a lubricated-for-life ball joint, replace ball

joint.

4. Worn or binding lower control arm

ball joint.4. Replace lower control arm ball joint.

5. Lack of lubrication in steering gear

outer tie rod ends.5. Lubricate tie rod ends if they are not a

lubricated-for-life type. If tie rod end is a

lubricated-for-life type, replace tie rod end.

19 - 6 STEERINGRS

STEERING (Continued)