wheel alignment CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1414 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

6. Loose power steering pump drive

belt.6. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

7. Faulty power steering pump

(Perform Power Steering Flow and

Pressure Test).7. Replace power steering pump.

8. Faulty power steering gear

(Perform Power Steering Flow and

Pressure Test).8. Replace power steering gear.

9. Excessive friction in steering

column or intermediate shaft/coupler.9. Isolate and correct condition.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

11. Worn or binding seat and bearing

in front strut assembly.11. Replace seat and bearing in front strut

assembly.

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mispositioned or

unlubricated steering column coupler

to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding mount bearing in front

strut assembly.7. Replace mount bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

RSSTEERING19-7

STEERING (Continued)

Page 1440 of 2339

(17) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(18) Remove the steering wheel holding tool.

(19) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(20) Inspect system for leaks.

(21) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - RHD GEAR

(1) Install the steering gear up in the front sus-

pension cradle crossmember, leaving room to install

intermediate coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 12). Hold threaded rod station-

ary while turning nut. This will pull the roll pin into

the intermediate coupler.

(4) Install power steering gear on the front suspen-

sion cradle. Install the 2 steering gear mounting

bolts and nuts. Tighten the M-14 size steering gear

to suspension cradle mounting bolt to a torque of 183

N´m (135 ft. lbs.). Tighten the M-12 size steering

gear to suspension cradle mounting bolt to a torque

of 95 N´m (70 ft. lbs.).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Install the heat shield on the steering gear

(Fig. 10).

(6) Attach the power steering fluid pressure and

return hoses to the proper fittings on the steering

gear (Fig. 10). Do not fully tighten the fittings at this

time.

(7) Install the routing clamp with the bolt securing

the power steering fluid hoses to the rear of the cra-

dle crossmember (Fig. 11).

(8) Using a crowfoot wrench on a torque wrench,

tighten the power steering fluid hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

(9) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut ontostud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 4), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(10) If the vehicle is equipped with All-Wheel-

Drive, install the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(11) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(12) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(13) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(14) If power steering cooler equipped, install the

previously disconnected power steering cooler hose on

the cooler. Install the clamp.

(15) If power steering cooler equipped, install the

power steering fluid cooler on the cradle crossmem-

ber reinforcement (Fig. 3). Install the mounting bolts

and tighten to 11 N´m (100 in. lbs.).

(16) Install the front tire and wheel assemblies on

vehicle. Install the wheel mounting lug nuts and

tighten to a torque to 135 N´m (100 ft. lbs.).

(17) Lower the vehicle to a level were the interior

of vehicle is accessible (keeping tires off the ground).

(18) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(19) Remove the steering wheel holding tool.

(20) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(21) Inspect for leaks.

(22) Adjust front wheel toe (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

RSGEAR19-33

GEAR (Continued)

Page 1442 of 2339

(4) Remove outer tie rod end by un-threading it

from the inner tie rod.

INSTALLATION

NOTE: Before installing the outer tie rod, make sure

the jam nut is on inner tie rod (Fig. 14).

(1) Install outer tie rod onto inner tie rod.

(2) Do not tighten jam nut.

(3) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 15). Then using a crow-

foot and 11/32 socket (Fig. 17), torque tie rod end

attaching nut to 75 N´m (55 ft. lbs.).

(4) Tighten tie rod jam nut (Fig. 14) to 75 N´m (55

ft. lbs.) torque.

CAUTION: During this procedure do not allow the

steering gear boot to become twisted.

(5) Adjust the front toe setting on the vehicle

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

Fig. 17 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-35

OUTER TIE ROD (Continued)

Page 1775 of 2339

CLEANING - TIRES

Before delivery of a vehicle, remove the protective

coating on the tires with white sidewalls or raised

white letters. To remove the protective coating, apply

warm water and let it soak for a few minutes. After-

wards, scrub the coating away with a soft bristle

brush. Steam cleaning may also be used to remove

the coating.

CAUTION: DO NOT use gasoline, mineral oil, oil-

based solvent or a wire brush for cleaning.

WHEELS

DESCRIPTION - WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

All models use either steel or aluminum drop-cen-

ter wheels. Every wheel has raised sections between

the rim flanges and rim drop well called safety

humps (Fig. 27). Initial inflation of the tires forces

the bead over these raised sections. In case of air

loss, the safety humps hold the tire in position on the

wheel until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the flange of the rim (Fig. 28).When wheel alignment is necessary on a vehicle

with cast aluminum wheels, special wheel clamps are

required to avoid damage to the wheel's finish.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts.

All aluminum wheels have wheel mounting (lug)

nuts with an enlarged nose. This enlarged nose is

necessary to ensure proper retention of the wheels.

Fig. 26 Tire Repair Area

1 - REPAIRABLE AREA

Fig. 27 Safety Rim

1 - TIRE

2 - WELL

3 - SAFETY HUMPS

4 - FLANGE

Fig. 28 Styled Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - STYLED WHEEL WEIGHT

22 - 18 TIRES/WHEELSRS

TIRES (Continued)

Page 1795 of 2339

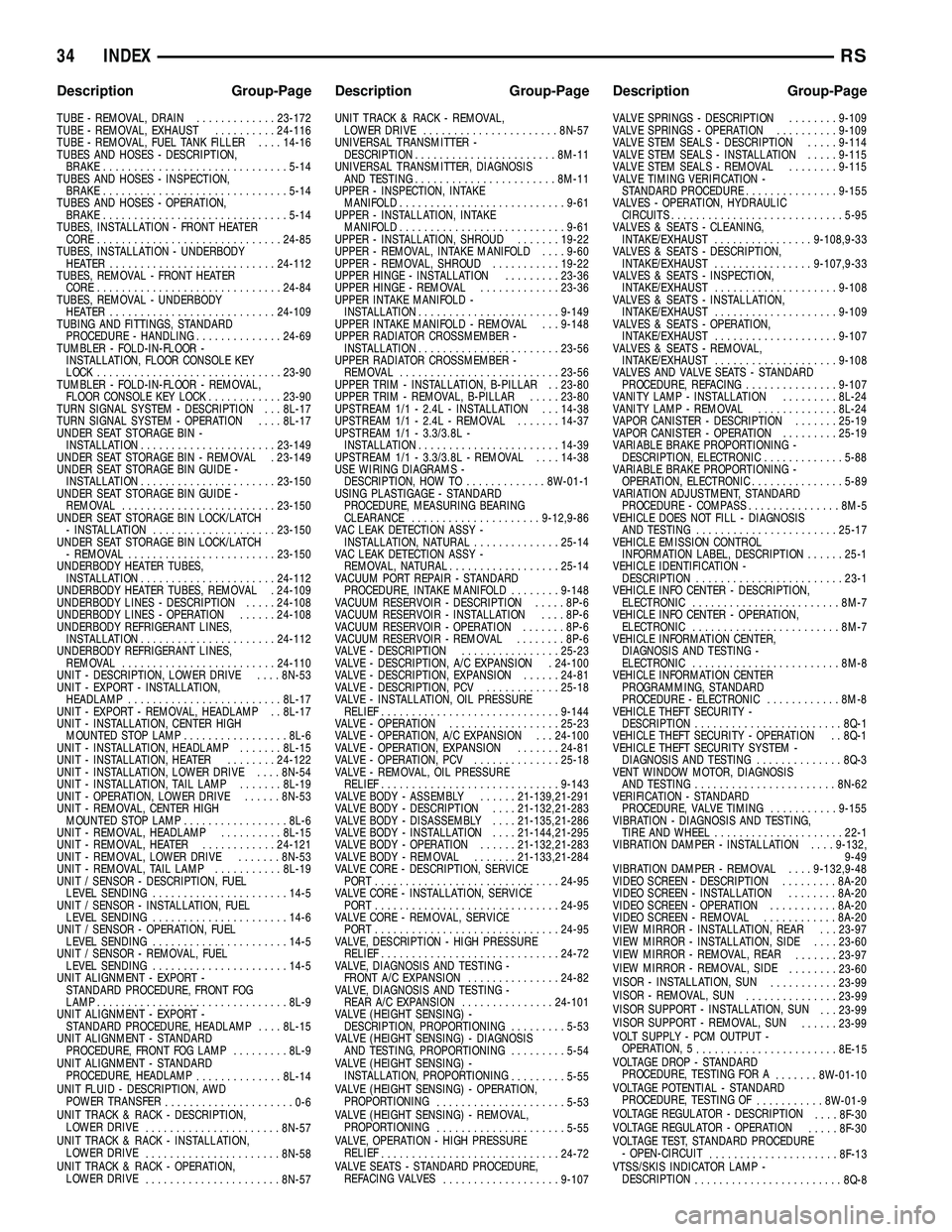

(2) Position door to vehicle. Verify net pierce nub-

bin is engaged if reusing original hinges. Applies to

body half of hinge only.

(3) Steady door on lifting device and install bolts

attaching upper hinge to door end frame. Tighten

bolts to 34 N´m (25 ft. lbs.) torque.

(4) Install bolts attaching lower hinge to door end

frame. Tighten bolts to 34 N´m (25 ft. lbs.) torque.

Align door to achieve equal spacing to surrounding

body panels. Panels should be flush across all gaps.

(5) Install bolts attaching door check strap to

A-pillar. Tighten bolts to 12 N´m (105 in. lbs.) torque.

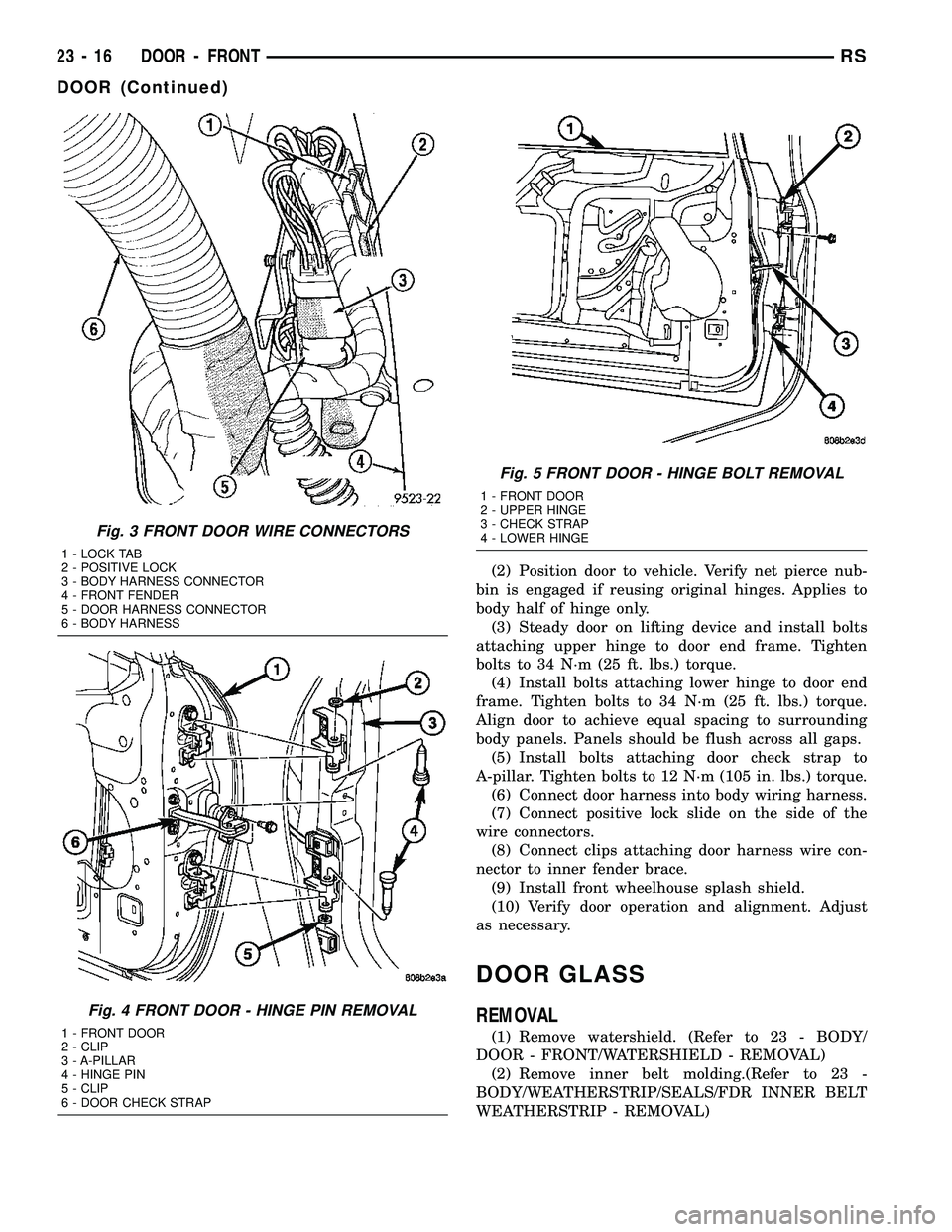

(6) Connect door harness into body wiring harness.

(7) Connect positive lock slide on the side of the

wire connectors.

(8) Connect clips attaching door harness wire con-

nector to inner fender brace.

(9) Install front wheelhouse splash shield.

(10) Verify door operation and alignment. Adjust

as necessary.

DOOR GLASS

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

Fig. 3 FRONT DOOR WIRE CONNECTORS

1 - LOCK TAB

2 - POSITIVE LOCK

3 - BODY HARNESS CONNECTOR

4 - FRONT FENDER

5 - DOOR HARNESS CONNECTOR

6 - BODY HARNESS

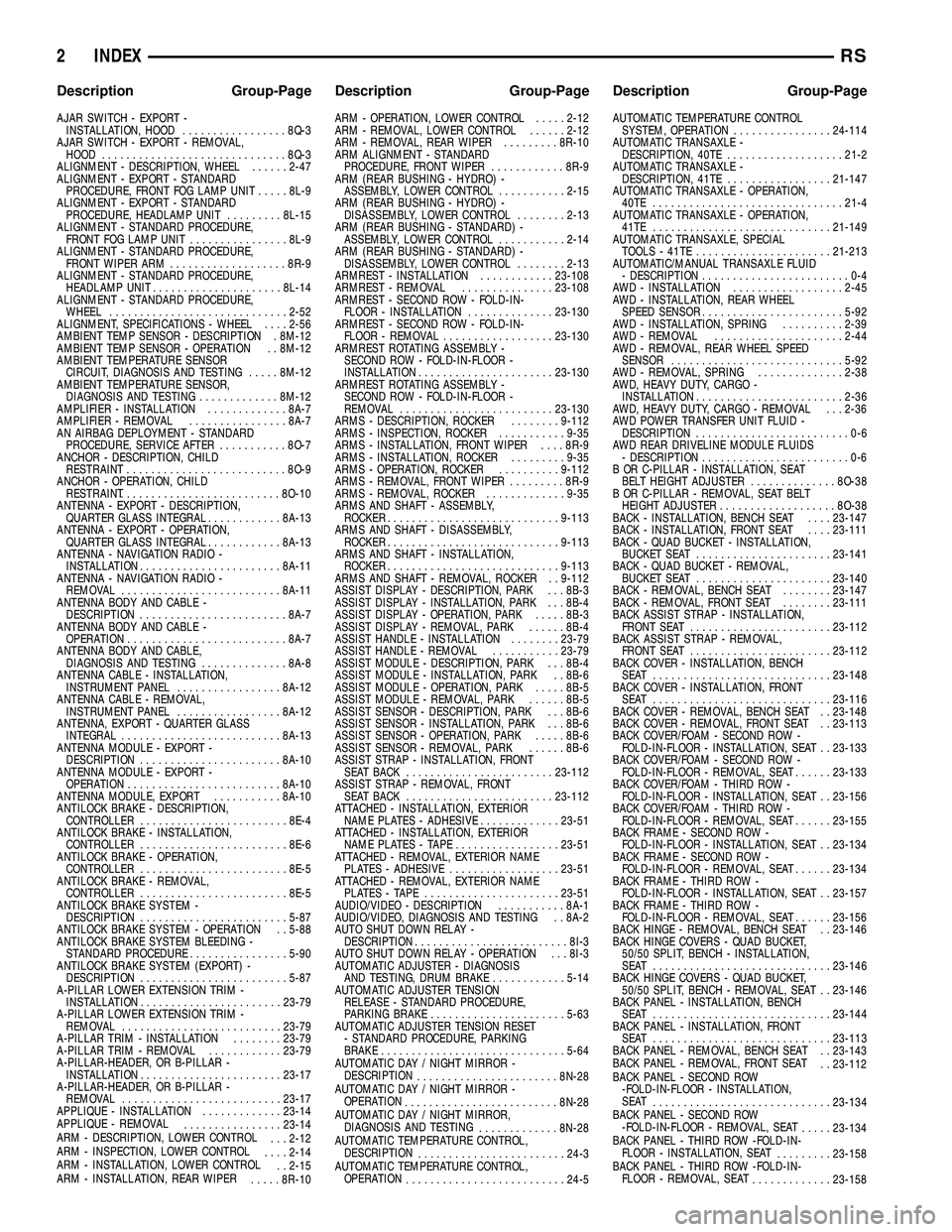

Fig. 4 FRONT DOOR - HINGE PIN REMOVAL

1 - FRONT DOOR

2 - CLIP

3 - A-PILLAR

4 - HINGE PIN

5 - CLIP

6 - DOOR CHECK STRAP

Fig. 5 FRONT DOOR - HINGE BOLT REMOVAL

1 - FRONT DOOR

2 - UPPER HINGE

3 - CHECK STRAP

4 - LOWER HINGE

23 - 16 DOOR - FRONTRS

DOOR (Continued)

Page 1836 of 2339

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 16). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install hood prop rod.

(10) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(11) Install bolts attaching hood latch to cross-

member and clip cable. Tighten bolts to 13.5 N´m (10

ft. lbs.) torque.

(12) Install radiator sight shield.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 17).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

17).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 18).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 19).

Fig. 17 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 18 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

RSEXTERIOR23-57

UPPER RADIATOR CROSSMEMBER (Continued)

Page 2303 of 2339

AJAR SWITCH - EXPORT -INSTALLATION, HOOD .................8Q-3

AJAR SWITCH - EXPORT - REMOVAL, HOOD .............................. 8Q-3

ALIGNMENT - DESCRIPTION, WHEEL ......2-47

ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG LAMP UNIT .....8L-9

ALIGNMENT - EXPORT - STANDARD PROCEDURE, HEADLAMP UNIT .........8L-15

ALIGNMENT - STANDARD PROCEDURE, FRONT FOG LAMP UNIT ................8L-9

ALIGNMENT - STANDARD PROCEDURE, FRONT WIPER ARM ................... 8R-9

ALIGNMENT - STANDARD PROCEDURE, HEADLAMP UNIT ..................... 8L-14

ALIGNMENT - STANDARD PROCEDURE, WHEEL ............................. 2-52

ALIGNMENT, SPECIFICATIONS - WHEEL ....2-56

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-12

AMBIENT TEMP SENSOR - OPERATION . . 8M-12

AMBIENT TEMPERATURE SENSOR CIRCUIT, DIAGNOSIS AND TESTING .....8M-12

AMBIENT TEMPERATURE SENSOR, DIAGNOSIS AND TESTING .............8M-12

AMPLIFIER - INSTALLATION .............8A-7

AMPLIFIER - REMOVAL ................8A-7

AN AIRBAG DEPLOYMENT - STANDARD PROCEDURE, SERVICE AFTER ...........8O-7

ANCHOR - DESCRIPTION, CHILD RESTRAINT .......................... 8O-9

ANCHOR - OPERATION, CHILD RESTRAINT .......................... 8O-10

ANTENNA - EXPORT - DESCRIPTION, QUARTER GLASS INTEGRAL ............8A-13

ANTENNA - EXPORT - OPERATION, QUARTER GLASS INTEGRAL ............8A-13

ANTENNA - NAVIGATION RADIO - INSTALLATION ....................... 8A-11

ANTENNA - NAVIGATION RADIO - REMOVAL .......................... 8A-11

ANTENNA BODY AND CABLE - DESCRIPTION ........................ 8A-7

ANTENNA BODY AND CABLE - OPERATION .......................... 8A-7

ANTENNA BODY AND CABLE, DIAGNOSIS AND TESTING ..............8A-8

ANTENNA CABLE - INSTALLATION, INSTRUMENT PANEL .................8A-12

ANTENNA CABLE - REMOVAL, INSTRUMENT PANEL .................8A-12

ANTENNA, EXPORT - QUARTER GLASS INTEGRAL .......................... 8A-13

ANTENNA MODULE - EXPORT - DESCRIPTION ....................... 8A-10

ANTENNA MODULE - EXPORT - OPERATION ......................... 8A-10

ANTENNA MODULE, EXPORT ...........8A-10

ANTILOCK BRAKE - DESCRIPTION, CONTROLLER ........................ 8E-4

ANTILOCK BRAKE - INSTALLATION, CONTROLLER ........................ 8E-6

ANTILOCK BRAKE - OPERATION, CONTROLLER ........................ 8E-5

ANTILOCK BRAKE - REMOVAL, CONTROLLER ........................ 8E-5

ANTILOCK BRAKE SYSTEM - DESCRIPTION ........................ 5-87

ANTILOCK BRAKE SYSTEM - OPERATION . . 5-88

ANTILOCK BRAKE SYSTEM BLEEDING - STANDARD PROCEDURE ................5-90

ANTILOCK BRAKE SYSTEM (EXPORT) - DESCRIPTION ........................ 5-87

A-PILLAR LOWER EXTENSION TRIM - INSTALLATION ....................... 23-79

A-PILLAR LOWER EXTENSION TRIM - REMOVAL .......................... 23-79

A-PILLAR TRIM - INSTALLATION ........23-79

A-PILLAR TRIM - REMOVAL ............23-79

A-PILLAR-HEADER, OR B-PILLAR - INSTALLATION ....................... 23-17

A-PILLAR-HEADER, OR B-PILLAR - REMOVAL .......................... 23-17

APPLIQUE - INSTALLATION .............23-14

APPLIQUE - REMOVAL ................23-14

ARM - DESCRIPTION, LOWER CONTROL . . . 2-12

ARM - INSPECTION, LOWER CONTROL ....2-14

ARM - INSTALLATION, LOWER CONTROL . . 2-15

ARM - INSTALLATION, REAR WIPER .....8R-10 ARM - OPERATION, LOWER CONTROL

.....2-12

ARM - REMOVAL, LOWER CONTROL ......2-12

ARM - REMOVAL, REAR WIPER .........8R-10

ARM ALIGNMENT - STANDARD PROCEDURE, FRONT WIPER ............8R-9

ARM (REAR BUSHING - HYDRO) - ASSEMBLY, LOWER CONTROL ...........2-15

ARM (REAR BUSHING - HYDRO) - DISASSEMBLY, LOWER CONTROL ........2-13

ARM (REAR BUSHING - STANDARD) - ASSEMBLY, LOWER CONTROL ...........2-14

ARM (REAR BUSHING - STANDARD) - DISASSEMBLY, LOWER CONTROL ........2-13

ARMREST - INSTALLATION ............23-108

ARMREST - REMOVAL ...............23-108

ARMREST - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION ..............23-130

ARMREST - SECOND ROW - FOLD-IN- FLOOR - REMOVAL .................. 23-130

ARMREST ROTATING ASSEMBLY - SECOND ROW - FOLD-IN-FLOOR -

INSTALLATION ...................... 23-130

ARMREST ROTATING ASSEMBLY - SECOND ROW - FOLD-IN-FLOOR -

REMOVAL ......................... 23-130

ARMS - DESCRIPTION, ROCKER ........9-112

ARMS - INSPECTION, ROCKER ...........9-35

ARMS - INSTALLATION, FRONT WIPER ....8R-9

ARMS - INSTALLATION, ROCKER .........9-35

ARMS - OPERATION, ROCKER ..........9-112

ARMS - REMOVAL, FRONT WIPER .........8R-9

ARMS - REMOVAL, ROCKER .............9-35

ARMS AND SHAFT - ASSEMBLY, ROCKER ............................ 9-113

ARMS AND SHAFT - DISASSEMBLY, ROCKER ............................ 9-113

ARMS AND SHAFT - INSTALLATION, ROCKER ............................ 9-113

ARMS AND SHAFT - REMOVAL, ROCKER . . 9-112

ASSIST DISPLAY - DESCRIPTION, PARK . . . 8B-3

ASSIST DISPLAY - INSTALLATION, PARK . . . 8B-4

ASSIST DISPLAY - OPERATION, PARK .....8B-3

ASSIST DISPLAY - REMOVAL, PARK ......8B-4

ASSIST HANDLE - INSTALLATION ........23-79

ASSIST HANDLE - REMOVAL ...........23-79

ASSIST MODULE - DESCRIPTION, PARK . . . 8B-4

ASSIST MODULE - INSTALLATION, PARK . . 8B-6

ASSIST MODULE - OPERATION, PARK .....8B-5

ASSIST MODULE - REMOVAL, PARK ......8B-5

ASSIST SENSOR - DESCRIPTION, PARK . . . 8B-6

ASSIST SENSOR - INSTALLATION, PARK . . . 8B-6

ASSIST SENSOR - OPERATION, PARK .....8B-6

ASSIST SENSOR - REMOVAL, PARK ......8B-6

ASSIST STRAP - INSTALLATION, FRONT SEAT BACK ........................ 23-112

ASSIST STRAP - REMOVAL, FRONT SEAT BACK ........................ 23-112

ATTACHED - INSTALLATION, EXTERIOR NAME PLATES - ADHESIVE .............23-51

ATTACHED - INSTALLATION, EXTERIOR NAME PLATES - TAPE .................23-51

ATTACHED - REMOVAL, EXTERIOR NAME PLATES - ADHESIVE .................. 23-51

ATTACHED - REMOVAL, EXTERIOR NAME PLATES - TAPE ...................... 23-51

AUDIO/VIDEO - DESCRIPTION ...........8A-1

AUDIO/VIDEO, DIAGNOSIS AND TESTING . . 8A-2

AUTO SHUT DOWN RELAY - DESCRIPTION ......................... 8I-3

AUTO SHUT DOWN RELAY - OPERATION . . . 8I-3

AUTOMATIC ADJUSTER - DIAGNOSIS AND TESTING, DRUM BRAKE ............5-14

AUTOMATIC ADJUSTER TENSION RELEASE - STANDARD PROCEDURE,

PARKING BRAKE ...................... 5-63

AUTOMATIC ADJUSTER TENSION RESET - STANDARD PROCEDURE, PARKING

BRAKE .............................. 5-64

AUTOMATIC DAY / NIGHT MIRROR - DESCRIPTION ....................... 8N-28

AUTOMATIC DAY / NIGHT MIRROR - OPERATION ......................... 8N-28

AUTOMATIC DAY / NIGHT MIRROR, DIAGNOSIS AND TESTING .............8N-28

AUTOMATIC TEMPERATURE CONTROL, DESCRIPTION ........................ 24-3

AUTOMATIC TEMPERATURE CONTROL, OPERATION .......................... 24-5AUTOMATIC TEMPERATURE CONTROL

SYSTEM, OPERATION ................24-114

AUTOMATIC TRANSAXLE - DESCRIPTION, 40TE ................... 21-2

AUTOMATIC TRANSAXLE - DESCRIPTION, 41TE .................21-147

AUTOMATIC TRANSAXLE - OPERATION, 40TE ............................... 21-4

AUTOMATIC TRANSAXLE - OPERATION, 41TE ............................. 21-149

AUTOMATIC TRANSAXLE, SPECIAL TOOLS - 41TE ...................... 21-213

AUTOMATIC/MANUAL TRANSAXLE FLUID - DESCRIPTION ........................0-4

AWD - INSTALLATION ..................2-45

AWD - INSTALLATION, REAR WHEEL SPEED SENSOR ....................... 5-92

AWD - INSTALLATION, SPRING ..........2-39

AWD - REMOVAL ..................... 2-44

AWD - REMOVAL, REAR WHEEL SPEED SENSOR ............................ 5-92

AWD - REMOVAL, SPRING ..............2-38

AWD, HEAVY DUTY, CARGO - INSTALLATION ........................ 2-36

AWD, HEAVY DUTY, CARGO - REMOVAL . . . 2-36

AWD POWER TRANSFER UNIT FLUID - DESCRIPTION .........................0-6

AWD REAR DRIVELINE MODULE FLUIDS - DESCRIPTION ........................0-6

B OR C-PILLAR - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ..............8O-38

B OR C-PILLAR - REMOVAL, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

BACK - INSTALLATION, BENCH SEAT ....23-147

BACK - INSTALLATION, FRONT SEAT ....23-111

BACK - QUAD BUCKET - INSTALLATION, BUCKET SEAT ...................... 23-141

BACK - QUAD BUCKET - REMOVAL, BUCKET SEAT ...................... 23-140

BACK - REMOVAL, BENCH SEAT ........23-147

BACK - REMOVAL, FRONT SEAT ........23-111

BACK ASSIST STRAP - INSTALLATION, FRONT SEAT ....................... 23-112

BACK ASSIST STRAP - REMOVAL, FRONT SEAT ....................... 23-112

BACK COVER - INSTALLATION, BENCH SEAT ............................. 23-148

BACK COVER - INSTALLATION, FRONT SEAT ............................. 23-116

BACK COVER - REMOVAL, BENCH SEAT . . 23-148

BACK COVER - REMOVAL, FRONT SEAT . . 23-113

BACK COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-133

BACK COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-133

BACK COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-156

BACK COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-155

BACK FRAME - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-134

BACK FRAME - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-134

BACK FRAME - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-157

BACK FRAME - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-156

BACK HINGE - REMOVAL, BENCH SEAT . . 23-146

BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION,

SEAT ............................. 23-146

BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT . . 23-146

BACK PANEL - INSTALLATION, BENCH SEAT ............................. 23-144

BACK PANEL - INSTALLATION, FRONT SEAT ............................. 23-113

BACK PANEL - REMOVAL, BENCH SEAT . . 23-143

BACK PANEL - REMOVAL, FRONT SEAT . . 23-112

BACK PANEL - SECOND ROW -FOLD-IN-FLOOR - INSTALLATION,

SEAT ............................. 23-134

BACK PANEL - SECOND ROW -FOLD-IN-FLOOR - REMOVAL, SEAT .....23-134

BACK PANEL - THIRD ROW -FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-158

BACK PANEL - THIRD ROW -FOLD-IN- FLOOR - REMOVAL, SEAT .............23-158

2 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2315 of 2339

FOLD-IN-FLOOR - REMOVAL, SEATCUSHION COVER/FOAM - THIRD ROW . . . 23-159

FOLD-IN-FLOOR - REMOVAL, SEAT CUSHION COVER/FOAM -SECOND

ROW ............................. 23-136

FOLD-IN-FLOOR - REMOVAL, SEAT CUSHION SIDE SHIELD - SECOND

ROW ............................. 23-138

FOLD-IN-FLOOR - REMOVAL, SEAT GAS STRUT - SECOND ROW ...............23-138

FOLD-IN-FLOOR - REMOVAL, SEAT PROP ROD - SECOND ROW ................23-139

FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR TUB CARPET INSERT .......23-98

FOLD-IN-FLOOR - REMOVAL, SIDE SHIELD CUP HOLDER ................23-160

FOLD-IN-FLOOR - REMOVAL, WITH NVLD .............................. 25-20

FOLD-IN-FLOOR - SPECIFICATIONS, WELD LOCATIONS ................... 23-350

FOLD-IN-FLOOR ONLY - SPECIFICATIONS, BODY SEALING

LOCATIONS ........................ 23-209

FOLD-IN-FLOOR ONLY - SPECIFICATIONS, STRUCTURAL

ADHESIVE LOCATIONS ...............23-228

FOLD-IN-FLOOR SEATING - INSTALLATION .................... 5-68,5-75

FOLD-IN-FLOOR SEATING - INSTALLATION, FWD ................... 2-45

FOLD-IN-FLOOR SEATING - REMOVAL . 5-66,5-72

FOLD-IN-FLOOR SEATING - REMOVAL, FWD................................ 2-45

FOLD-IN-FLOOR SEATS ONLY - SPECIFICATIONS, FRAME DIMENSIONS .....13-11

FOLDING MECHANISM -SECOND ROW -FOLD-IN-FLOOR - INSTALLATION,

SEAT RECLINER/FORWARD ............23-137

FOLDING MECHANISM -SECOND ROW -FOLD-IN-FLOOR - REMOVAL, SEAT

RECLINER/FORWARD ................23-137

FORM-IN-PLACE GASKETS AND SEALERS, STANDARD PROCEDURE . . . 9-11,9-86

FORWARD MECHANISM -THIRD ROW -FOLD-IN-FLOOR - INSTALLATION,

SEAT RECLINER/FOLD ................23-160

FORWARD MECHANISM -THIRD ROW -FOLD-IN-FLOOR - REMOVAL, SEAT

RECLINER/FOLD .................... 23-160

FRAME - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT BACK ....23-134

FRAME - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT BACK ........23-134

FRAME - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACK ..........23-157

FRAME - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACK ..............23-156

FRAME DIMENSIONS - FOLD-IN-FLOOR SEATS ONLY - SPECIFICATIONS .........13-11

FRAME DIMENSIONS - SPECIFICATIONS . . . 13-6

FREE MODULE - INSTALLATION, HANDS . . . 8T-3

FREE MODULE - REMOVAL, HANDS .......8T-3

FRONT - DESCRIPTION, HALF SHAFT .......3-1

FRONT - DESCRIPTION, PLUMBING ......24-65

FRONT - INSTALLATION, BUSHING - LEAF SPRING ........................ 2-30

FRONT - INSTALLATION, CRANKSHAFT OIL SEAL ....................... 9-130,9-42

FRONT - INSTALLATION, HALF SHAFT ......3-4

FRONT - INSTALLATION, SEAT BELT & RETRACTOR - OUTBOARD .............8O-39

FRONT - INSTALLATION, SPRING MOUNTS ............................ 2-43

FRONT - INSTALLATION, WHEEL MOUNTING STUDS ................... 22-21

FRONT - OPERATION, PLUMBING ........24-65

FRONT - REMOVAL, BUSHING - LEAF SPRING ............................. 2-29

FRONT - REMOVAL, CRANKSHAFT OIL SEAL .......................... 9-130,9-41

FRONT - REMOVAL, HALF SHAFT ..........3-2

FRONT - REMOVAL, SEAT BELT & RETRACTOR - OUTBOARD .............8O-38

FRONT - REMOVAL, SPRING MOUNTS .....2-42

FRONT - REMOVAL, WHEEL MOUNTING STUDS ............................. 22-21

FRONT - SPECIFICATIONS, HALF SHAFT ....3-6FRONT A/C EXPANSION VALVE,

DIAGNOSIS AND TESTING .............24-82

FRONT BLOWER MOTOR, DIAGNOSIS AND TESTING ....................... 24-46

FRONT BLOWER MOTOR RESISTOR BLOCK, DIAGNOSIS AND TESTING .......24-25

FRONT BRAKE ROTOR - INSTALLATION ....5-59

FRONT BRAKE ROTOR - REMOVAL .......5-59

FRONT BUMPER REINFORCEMENT - INSTALLATION ........................ 13-3

FRONT BUMPER REINFORCEMENT - REMOVAL ........................... 13-3

FRONT CABLE - INSTALLATION, PARKING BRAKE LEVER ................5-77

FRONT CABLE - REMOVAL, PARKING BRAKE LEVER ........................ 5-77

FRONT CENTER BEZEL OUTLETS, INSTALLATION ....................... 24-45

FRONT CENTER BEZEL OUTLETS, REMOVAL .......................... 24-44

FRONT CONTROL MODULE - DESCRIPTION ........................ 8E-7

FRONT CONTROL MODULE - OPERATION . . 8E-7

FRONT CONTROL MODULE, DIAGNOSIS AND TESTING ........................ 8E-7

FRONT CRADLE CROSSMEMBER - DESCRIPTION ....................... 13-14

FRONT CRADLE CROSSMEMBER THREAD REPAIR - DESCRIPTION ........13-14

FRONT CROSSMEMBER MOUNT BUSHINGS - INSTALLATION ............13-17

FRONT CROSSMEMBER MOUNT BUSHINGS - REMOVAL .................13-17

FRONT DEMISTER OUTLETS, INSTALLATION ....................... 24-45

FRONT DEMISTER OUTLETS, REMOVAL . . . 24-44

FRONT DISC BRAKE CALIPER ADAPTER - INSTALLATION ...................... 5-31

FRONT DISC BRAKE CALIPER ADAPTER - REMOVAL .......................... 5-31

FRONT DISC BRAKE CALIPER (CONTINENTAL TEVES BRAKES) -

INSTALLATION ........................ 5-27

FRONT DISC BRAKE CALIPER (CONTINENTAL TEVES BRAKES) -

REMOVAL ........................... 5-24

FRONT DISC BRAKE CALIPER (TRW BRAKES) - INSTALLATION ...............5-27

FRONT DISC BRAKE CALIPER (TRW BRAKES) - REMOVAL .................. 5-24

FRONT DISC BRAKE SHOES (CONTINENTAL TEVES BRAKES) -

INSTALLATION ........................ 5-16

FRONT DISC BRAKE SHOES (CONTINENTAL TEVES BRAKES) -

REMOVAL ........................... 5-15

FRONT DISC BRAKE SHOES (TRW BRAKES) - INSTALLATION ...............5-17

FRONT DISC BRAKE SHOES (TRW BRAKES) - REMOVAL .................. 5-15

FRONT DOOR GLASS RUN WEATHERSTRIP - INSTALLATION .......23-166

FRONT DOOR GLASS RUN WEATHERSTRIP - REMOVAL ...........23-166

FRONT DOOR INNER BELT MOLDING - INSTALLATION ...................... 23-168

FRONT DOOR INNER BELT MOLDING - REMOVAL ......................... 23-168

FRONT DOOR OUTER BELT MOLDING - INSTALLATION ...................... 23-167

FRONT DOOR OUTER BELT MOLDING - REMOVAL ......................... 23-167

FRONT DOOR WEATHERSTRIP - INSTALLATION ...................... 23-168

FRONT DOOR WEATHERSTRIP - REMOVAL ......................... 23-168

FRONT FASCIA - INSTALLATION ..........13-1

FRONT FASCIA - REMOVAL ..............13-1

FRONT FENDER - INSTALLATION ........23-52

FRONT FENDER - REMOVAL ............23-51

FRONT FOG LAMP - DIAGNOSIS AND TESTING ............................ 8L-7

FRONT FOG LAMP - INSTALLATION .......8L-8

FRONT FOG LAMP - REMOVAL ...........8L-8

FRONT FOG LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE .......8L-9

FRONT FOG LAMP UNIT ALIGNMENT - STANDARD PROCEDURE ................8L-9FRONT HEATER CORE, INSTALLATION

....24-86

FRONT HEATER CORE, REMOVAL ........24-85

FRONT HEATER CORE TUBES, INSTALLATION ....................... 24-85

FRONT HEATER CORE TUBES, REMOVAL . . 24-84

FRONT INBOARD - INSTALLATION, SEAT BELT BUCKLE ....................... 8O-35

FRONT INBOARD - REMOVAL, SEAT BELT BUCKLE ....................... 8O-35

FRONT MOUNT - INSTALLATION ....9-134,9-50

FRONT MOUNT - REMOVAL ........9-134,9-50

FRONT SEAT - INSTALLATION ..........23-110

FRONT SEAT - REMOVAL .............23-108

FRONT SEAT BACK - INSTALLATION .....23-111

FRONT SEAT BACK - REMOVAL ........23-111

FRONT SEAT BACK ASSIST STRAP - INSTALLATION ...................... 23-112

FRONT SEAT BACK ASSIST STRAP - REMOVAL ......................... 23-112

FRONT SEAT BACK COVER - INSTALLATION ...................... 23-116

FRONT SEAT BACK COVER - REMOVAL . . 23-113

FRONT SEAT BACK PANEL - INSTALLATION ...................... 23-113

FRONT SEAT BACK PANEL - REMOVAL . . 23-112

FRONT SEAT CUSHION - INSTALLATION . . 23-118

FRONT SEAT CUSHION - OCS - INSTALLATION ...................... 23-120

FRONT SEAT CUSHION - OCS - REMOVAL ........................... 23-119

FRONT SEAT CUSHION - REMOVAL .....23-117

FRONT SEAT CUSHION SIDE COVER - INSTALLATION ...................... 23-121

FRONT SEAT CUSHION SIDE COVER - OCS - INSTALLATION ................23-122

FRONT SEAT CUSHION SIDE COVER - OCS - REMOVAL .................... 23-121

FRONT SEAT CUSHION SIDE COVER - REMOVAL ......................... 23-120

FRONT SEAT RISER - MANUAL - OCS - INSTALLATION ...................... 23-123

FRONT SEAT RISER - MANUAL - OCS - REMOVAL ......................... 23-123

FRONT SEAT TRACK - REAR COVER - INSTALLATION ...................... 23-128

FRONT SEAT TRACK - REAR COVER - REMOVAL ......................... 23-128

FRONT SEAT TRACK ADJUSTER/MANUAL - OCS - INSTALLATION ...............23-128

FRONT SEAT TRACK ADJUSTER/MANUAL - OCS - REMOVAL ................... 23-126

FRONT SEAT TRACK ADJUSTER/POWER - OCS - INSTALLATION ...............23-125

FRONT SEAT TRACK ADJUSTER/POWER - OCS - REMOVAL ................... 23-124

FRONT SEAT TRACK MANUAL ADJUSTER - INSTALLATION ...........23-126

FRONT SEAT TRACK MANUAL ADJUSTER - REMOVAL ...............23-125

FRONT SEAT TRACK POWER ADJUSTER - INSTALLATION .................... 23-124

FRONT SEAT TRACK POWER ADJUSTER - REMOVAL ........................ 23-124

FRONT SEAT TRACK REAR COVER - OCS - INSTALLATION .................... 23-129

FRONT SEAT TRACK REAR COVER - OCS - REMOVAL ........................ 23-129

FRONT SUSPENSION - DESCRIPTION ......2-2

FRONT SUSPENSION - OPERATION ........2-2

FRONT SUSPENSION FASTENER TORQUE, SPECIFICATIONS ...............2-3

FRONT SUSPENSION, SPECIAL TOOLS .....2-3

FRONT WHEEL SPEED SENSOR - INSTALLATION ........................ 5-92

FRONT WHEEL SPEED SENSOR - REMOVAL ........................... 5-91

FRONT WHEELHOUSE SPLASH SHIELD - INSTALLATION ....................... 23-57

FRONT WHEELHOUSE SPLASH SHIELD - REMOVAL .......................... 23-57

FRONT WIPER ARM ALIGNMENT - STANDARD PROCEDURE ...............8R-9

FRONT WIPER ARMS - INSTALLATION ....8R-9

FRONT WIPER ARMS - REMOVAL ........8R-9

FRONT WIPER MOTOR - INSTALLATION . . 8R-10

FRONT WIPER MOTOR - REMOVAL .......8R-9

FRONT WIPER SYSTEM - DIAGNOSIS AND TESTING ........................ 8R-2

14 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2335 of 2339

TUBE - REMOVAL, DRAIN.............23-172

TUBE - REMOVAL, EXHAUST ..........24-116

TUBE - REMOVAL, FUEL TANK FILLER ....14-16

TUBES AND HOSES - DESCRIPTION, BRAKE .............................. 5-14

TUBES AND HOSES - INSPECTION, BRAKE .............................. 5-14

TUBES AND HOSES - OPERATION, BRAKE .............................. 5-14

TUBES, INSTALLATION - FRONT HEATER CORE .............................. 24-85

TUBES, INSTALLATION - UNDERBODY HEATER ........................... 24-112

TUBES, REMOVAL - FRONT HEATER CORE .............................. 24-84

TUBES, REMOVAL - UNDERBODY HEATER ........................... 24-109

TUBING AND FITTINGS, STANDARD PROCEDURE - HANDLING ..............24-69

TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE KEY

LOCK .............................. 23-90

TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE KEY LOCK ............23-90

TURN SIGNAL SYSTEM - DESCRIPTION . . . 8L-17

TURN SIGNAL SYSTEM - OPERATION ....8L-17

UNDER SEAT STORAGE BIN - INSTALLATION ...................... 23-149

UNDER SEAT STORAGE BIN - REMOVAL . 23-149

UNDER SEAT STORAGE BIN GUIDE - INSTALLATION ...................... 23-150

UNDER SEAT STORAGE BIN GUIDE - REMOVAL ......................... 23-150

UNDER SEAT STORAGE BIN LOCK/LATCH - INSTALLATION .................... 23-150

UNDER SEAT STORAGE BIN LOCK/LATCH - REMOVAL ........................ 23-150

UNDERBODY HEATER TUBES, INSTALLATION ...................... 24-112

UNDERBODY HEATER TUBES, REMOVAL . 24-109

UNDERBODY LINES - DESCRIPTION .....24-108

UNDERBODY LINES - OPERATION ......24-108

UNDERBODY REFRIGERANT LINES, INSTALLATION ...................... 24-112

UNDERBODY REFRIGERANT LINES, REMOVAL ......................... 24-110

UNIT - DESCRIPTION, LOWER DRIVE ....8N-53

UNIT - EXPORT - INSTALLATION, HEADLAMP ......................... 8L-17

UNIT - EXPORT - REMOVAL, HEADLAMP . . 8L-17

UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP LAMP .................8L-6

UNIT - INSTALLATION, HEADLAMP .......8L-15

UNIT - INSTALLATION, HEATER ........24-122

UNIT - INSTALLATION, LOWER DRIVE ....8N-54

UNIT - INSTALLATION, TAIL LAMP .......8L-19

UNIT - OPERATION, LOWER DRIVE ......8N-53

UNIT - REMOVAL, CENTER HIGH MOUNTED STOP LAMP .................8L-6

UNIT - REMOVAL, HEADLAMP ..........8L-15

UNIT - REMOVAL, HEATER ............24-121

UNIT - REMOVAL, LOWER DRIVE .......8N-53

UNIT - REMOVAL, TAIL LAMP ...........8L-19

UNIT / SENSOR - DESCRIPTION, FUEL LEVEL SENDING ...................... 14-5

UNIT / SENSOR - INSTALLATION, FUEL LEVEL SENDING ...................... 14-6

UNIT / SENSOR - OPERATION, FUEL LEVEL SENDING ...................... 14-5

UNIT / SENSOR - REMOVAL, FUEL LEVEL SENDING ...................... 14-5

UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG

LAMP ............................... 8L-9

UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, HEADLAMP ....8L-15

UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG LAMP .........8L-9

UNIT ALIGNMENT - STANDARD PROCEDURE, HEADLAMP ..............8L-14

UNIT FLUID - DESCRIPTION, AWD POWER TRANSFER .....................0-6

UNIT TRACK & RACK - DESCRIPTION, LOWER DRIVE ...................... 8N-57

UNIT TRACK & RACK - INSTALLATION, LOWER DRIVE ...................... 8N-58

UNIT TRACK & RACK - OPERATION, LOWER DRIVE ...................... 8N-57UNIT TRACK & RACK - REMOVAL,

LOWER DRIVE ...................... 8N-57

UNIVERSAL TRANSMITTER - DESCRIPTION ....................... 8M-11

UNIVERSAL TRANSMITTER, DIAGNOSIS AND TESTING ....................... 8M-11

UPPER - INSPECTION, INTAKE MANIFOLD ........................... 9-61

UPPER - INSTALLATION, INTAKE MANIFOLD ........................... 9-61

UPPER - INSTALLATION, SHROUD .......19-22

UPPER - REMOVAL, INTAKE MANIFOLD ....9-60

UPPER - REMOVAL, SHROUD ...........19-22

UPPER HINGE - INSTALLATION .........23-36

UPPER HINGE - REMOVAL .............23-36

UPPER INTAKE MANIFOLD - INSTALLATION ....................... 9-149

UPPER INTAKE MANIFOLD - REMOVAL . . . 9-148

UPPER RADIATOR CROSSMEMBER - INSTALLATION ....................... 23-56

UPPER RADIATOR CROSSMEMBER - REMOVAL .......................... 23-56

UPPER TRIM - INSTALLATION, B-PILLAR . . 23-80

UPPER TRIM - REMOVAL, B-PILLAR .....23-80

UPSTREAM 1/1 - 2.4L - INSTALLATION . . . 14-38

UPSTREAM 1/1 - 2.4L - REMOVAL .......14-37

UPSTREAM 1/1 - 3.3/3.8L - INSTALLATION ....................... 14-39

UPSTREAM 1/1 - 3.3/3.8L - REMOVAL ....14-38

USE WIRING DIAGRAMS - DESCRIPTION, HOW TO .............8W-01-1

USING PLASTIGAGE - STANDARD PROCEDURE, MEASURING BEARING

CLEARANCE ..................... 9-12,9-86

VAC LEAK DETECTION ASSY - INSTALLATION, NATURAL ..............25-14

VAC LEAK DETECTION ASSY - REMOVAL, NATURAL .................. 25-14

VACUUM PORT REPAIR - STANDARD PROCEDURE, INTAKE MANIFOLD ........9-148

VACUUM RESERVOIR - DESCRIPTION .....8P-6

VACUUM RESERVOIR - INSTALLATION ....8P-6

VACUUM RESERVOIR - OPERATION .......8P-6

VACUUM RESERVOIR - REMOVAL ........8P-6

VALVE - DESCRIPTION ................25-23

VALVE - DESCRIPTION, A/C EXPANSION . 24-100

VALVE - DESCRIPTION, EXPANSION ......24-81

VALVE - DESCRIPTION, PCV ............25-18

VALVE - INSTALLATION, OIL PRESSURE RELIEF ............................. 9-144

VALVE - OPERATION ..................25-23

VALVE - OPERATION, A/C EXPANSION . . . 24-100

VALVE - OPERATION, EXPANSION .......24-81

VALVE - OPERATION, PCV ..............25-18

VALVE - REMOVAL, OIL PRESSURE RELIEF ............................. 9-143

VALVE BODY - ASSEMBLY ......21-139,21-291

VALVE BODY - DESCRIPTION ....21-132,21-283

VALVE BODY - DISASSEMBLY ....21-135,21-286

VALVE BODY - INSTALLATION ....21-144,21-295

VALVE BODY - OPERATION ......21-132,21-283

VALVE BODY - REMOVAL .......21-133,21-284

VALVE CORE - DESCRIPTION, SERVICE PORT.............................. 24-95

VALVE CORE - INSTALLATION, SERVICE PORT.............................. 24-95

VALVE CORE - REMOVAL, SERVICE PORT.............................. 24-95

VALVE, DESCRIPTION - HIGH PRESSURE RELIEF ............................. 24-72

VALVE, DIAGNOSIS AND TESTING - FRONT A/C EXPANSION ...............24-82

VALVE, DIAGNOSIS AND TESTING - REAR A/C EXPANSION ...............24-101

VALVE (HEIGHT SENSING) - DESCRIPTION, PROPORTIONING .........5-53

VALVE (HEIGHT SENSING) - DIAGNOSIS AND TESTING, PROPORTIONING .........5-54

VALVE (HEIGHT SENSING) - INSTALLATION, PROPORTIONING .........5-55

VALVE (HEIGHT SENSING) - OPERATION, PROPORTIONING ..................... 5-53

VALVE (HEIGHT SENSING) - REMOVAL, PROPORTIONING ..................... 5-55

VALVE, OPERATION - HIGH PRESSURE RELIEF ............................. 24-72

VALVE SEATS - STANDARD PROCEDURE, REFACING VALVES ................... 9-107VALVE SPRINGS - DESCRIPTION

........9-109

VALVE SPRINGS - OPERATION ..........9-109

VALVE STEM SEALS - DESCRIPTION .....9-114

VALVE STEM SEALS - INSTALLATION .....9-115

VALVE STEM SEALS - REMOVAL ........9-115

VALVE TIMING VERIFICATION - STANDARD PROCEDURE ...............9-155

VALVES - OPERATION, HYDRAULIC CIRCUITS ............................ 5-95

VALVES & SEATS - CLEANING, INTAKE/EXHAUST ................ 9-108,9-33

VALVES & SEATS - DESCRIPTION, INTAKE/EXHAUST ................ 9-107,9-33

VALVES & SEATS - INSPECTION, INTAKE/EXHAUST .................... 9-108

VALVES & SEATS - INSTALLATION, INTAKE/EXHAUST .................... 9-109

VALVES & SEATS - OPERATION, INTAKE/EXHAUST .................... 9-107

VALVES & SEATS - REMOVAL, INTAKE/EXHAUST .................... 9-108

VALVES AND VALVE SEATS - STANDARD PROCEDURE, REFACING ...............9-107

VANITY LAMP - INSTALLATION .........8L-24

VANITY LAMP - REMOVAL .............8L-24

VAPOR CANISTER - DESCRIPTION .......25-19

VAPOR CANISTER - OPERATION .........25-19

VARIABLE BRAKE PROPORTIONING - DESCRIPTION, ELECTRONIC .............5-88

VARIABLE BRAKE PROPORTIONING - OPERATION, ELECTRONIC ................5-89

VARIATION ADJUSTMENT, STANDARD PROCEDURE - COMPASS ...............8M-5

VEHICLE DOES NOT FILL - DIAGNOSIS AND TESTING ....................... 25-17

VEHICLE EMISSION CONTROL INFORMATION LABEL, DESCRIPTION ......25-1

VEHICLE IDENTIFICATION - DESCRIPTION ........................ 23-1

VEHICLE INFO CENTER - DESCRIPTION, ELECTRONIC ........................ 8M-7

VEHICLE INFO CENTER - OPERATION, ELECTRONIC ........................ 8M-7

VEHICLE INFORMATION CENTER, DIAGNOSIS AND TESTING -

ELECTRONIC ........................ 8M-8

VEHICLE INFORMATION CENTER PROGRAMMING, STANDARD

PROCEDURE - ELECTRONIC ............8M-8

VEHICLE THEFT SECURITY - DESCRIPTION ........................ 8Q-1

VEHICLE THEFT SECURITY - OPERATION . . 8Q-1

VEHICLE THEFT SECURITY SYSTEM - DIAGNOSIS AND TESTING ..............8Q-3

VENT WINDOW MOTOR, DIAGNOSIS AND TESTING ....................... 8N-62

VERIFICATION - STANDARD PROCEDURE, VALVE TIMING ...........9-155

VIBRATION - DIAGNOSIS AND TESTING, TIRE AND WHEEL ..................... 22-1

VIBRATION DAMPER - INSTALLATION ....9-132,

9-49

VIBRATION DAMPER - REMOVAL ....9-132,9-48

VIDEO SCREEN - DESCRIPTION .........8A-20

VIDEO SCREEN - INSTALLATION ........8A-20

VIDEO SCREEN - OPERATION ...........8A-20

VIDEO SCREEN - REMOVAL ............8A-20

VIEW MIRROR - INSTALLATION, REAR . . . 23-97

VIEW MIRROR - INSTALLATION, SIDE ....23-60

VIEW MIRROR - REMOVAL, REAR .......23-97

VIEW MIRROR - REMOVAL, SIDE ........23-60

VISOR - INSTALLATION, SUN ...........23-99

VISOR - REMOVAL, SUN ...............23-99

VISOR SUPPORT - INSTALLATION, SUN . . . 23-99

VISOR SUPPORT - REMOVAL, SUN ......23-99

VOLT SUPPLY - PCM OUTPUT - OPERATION, 5 ....................... 8E-15

VOLTAGE DROP - STANDARD PROCEDURE, TESTING FOR A .......8W-01-10

VOLTAGE POTENTIAL - STANDARD PROCEDURE, TESTING OF ...........8W-01-9

VOLTAGE REGULATOR - DESCRIPTION ....8F-30

VOLTAGE REGULATOR - OPERATION .....8F-30

VOLTAGE TEST, STANDARD PROCEDURE - OPEN-CIRCUIT ..................... 8F-13

VTSS/SKIS INDICATOR LAMP - DESCRIPTION ........................ 8Q-8

34 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2336 of 2339

VTSS/SKIS INDICATOR LAMP -OPERATION .......................... 8Q-8

WARNING - A/C SYSTEM ..............24-66

WARNING - ENGINE COOLING SYSTEM . . . 24-65

WARNING - INSTALLATION ............23-162

WARNING - INSTALLATION .............19-16

WARNING - REMOVAL ...............23-161

WARNING - REMOVAL ................19-11

WARNING - SAFETY PRECAUTIONS AND WARNINGS .......................... 23-1

WARNING - WARNINGS ................8O-5

WARNING - WARNINGS AND CAUTIONS . . 19-10, 19-26

WARNING - WINDSHIELD SAFETY PRECAUTIONS ...................... 23-161

WARNING, CHIME/BUZZER ..............8B-2

WARNING, DESCRIPTION ................5-4

WARNING, DESCRIPTION ..............19-37

WARNING, LAMPS/LIGHTING - EXTERIOR ........................... 8L-3

WARNING, OPERATION ...............24-114

WARNINGS AND CAUTIONS, WARNING . . 19-10, 19-26

WARNINGS, GENERAL ..............8W-01-7

WARNINGS, WARNING .................8O-5

WARNINGS, WARNING - SAFETY PRECAUTIONS ........................ 23-1

WASHER FLUID LEVEL SWITCH - INSTALLATION ...................... 8R-11

WASHER FLUID LEVEL SWITCH - REMOVAL .......................... 8R-11

WASHER HOSES - INSTALLATION .......8R-12

WASHER HOSES - REMOVAL ...........8R-11

WASHER PUMP MOTOR - INSTALLATION . 8R-12

WASHER PUMP MOTOR - REMOVAL .....8R-12

WASHER RESERVOIR - INSTALLATION . . . 8R-13

WASHER RESERVOIR - REMOVAL .......8R-12

WASHER SYSTEM - DIAGNOSIS AND TESTING ............................ 8R-5

WATER CHANNEL - INSTALLATION ......23-174

WATER CHANNEL - REMOVAL .........23-174

WATER LEAKS, DIAGNOSIS AND TESTING ............................ 23-1

WATER PUMP - 2.4L - CLEANING ........7-32

WATER PUMP - 2.4L - DESCRIPTION ......7-32

WATER PUMP - 2.4L - INSPECTION .......7-32

WATER PUMP - 2.4L - INSTALLATION .....7-32

WATER PUMP - 2.4L - REMOVAL .........7-32

WATER PUMP - 3.3/3.8L - CLEANING .....7-35

WATER PUMP - 3.3/3.8L - DESCRIPTION . . . 7-34

WATER PUMP - 3.3/3.8L - INSPECTION ....7-35

WATER PUMP - 3.3/3.8L - INSTALLATION ........................ 7-35

WATER PUMP - 3.3/3.8L - REMOVAL ......7-34

WATER PUMP INLET TUBE - 2.4L - DESCRIPTION ........................ 7-36

WATER PUMP INLET TUBE - 2.4L - INSTALLATION ........................ 7-36

WATER PUMP INLET TUBE - 2.4L - REMOVAL ........................... 7-36

WATER PUMP INLET TUBE - 3.3/3.8L - INSTALLATION ........................ 7-37

WATER PUMP INLET TUBE - 3.3/3.8L - REMOVAL ........................... 7-37

WATERSHIELD - INSTALLATION .........23-21

WATERSHIELD - REMOVAL .............23-21

WEAR - STANDARD PROCEDURE, MEASURING TIMING CHAIN ............9-155

WEAR INDICATORS - DIAGNOSIS AND TESTING, TREAD ..................... 22-16

WEAR PATTERNS - DIAGNOSIS AND TESTING, TIRE ...................... 22-16

WEATHERSTRIP - INSTALLATION, FRONT DOOR ............................ 23-168

WEATHERSTRIP - INSTALLATION, FRONT DOOR GLASS RUN .................. 23-166

WEATHERSTRIP - INSTALLATION, SLIDING DOOR ..................... 23-168

WEATHERSTRIP - REMOVAL, FRONT DOOR ............................ 23-168

WEATHERSTRIP - REMOVAL, FRONT DOOR GLASS RUN .................. 23-166WEATHERSTRIP - REMOVAL, SLIDING

DOOR ............................ 23-168

WEIGHT BLADDER & PRESSURE SENSOR - DESCRIPTION, SEAT .........8O-43

WEIGHT BLADDER & PRESSURE SENSOR - OPERATION, SEAT ...........8O-44

WELD LOCATIONS - FOLD-IN-FLOOR - SPECIFICATIONS .................... 23-350

WELD LOCATIONS - SPECIFICATIONS . . . 23-234

WHEEL - DESCRIPTION ...............22-18

WHEEL - INSPECTION, TONE ............5-94

WHEEL - INSTALLATION, STEERING ......19-24

WHEEL - REMOVAL, STEERING .........19-23

WHEEL ALIGNMENT - DESCRIPTION ......2-47

WHEEL ALIGNMENT - STANDARD PROCEDURE ......................... 2-52

WHEEL ALIGNMENT, SPECIFICATIONS .....2-56

WHEEL AND WHEEL TRIM CARE, CLEANING .......................... 22-19

WHEEL ASSEMBLY (ALUMINUM WHEEL) - INSTALLATION, TIRE .................22-8

WHEEL ASSEMBLY (ALUMINUM WHEEL) - REMOVAL, TIRE ..................... 22-8

WHEEL ASSEMBLY (STEEL WHEEL) - INSTALLATION, TIRE ................... 22-8

WHEEL ASSEMBLY (STEEL WHEEL) - REMOVAL, TIRE ...................... 22-8

WHEEL BALANCE - STANDARD PROCEDURE, TIRE .................... 22-5

WHEEL COVER - DESCRIPTION .........22-19

WHEEL COVER - INSTALLATION ..........22-20

WHEEL COVER - REMOVAL ............22-19

WHEEL CYLINDERS - INSPECTION ........5-62

WHEEL CYLINDERS - INSTALLATION ......5-62

WHEEL CYLINDERS - REMOVAL ..........5-62

WHEEL INSPECTION - DIAGNOSIS AND TESTING ........................... 22-19

WHEEL MATCH MOUNTING - STANDARD PROCEDURE, TIRE .................... 22-7

WHEEL MOUNTING STUDS - FRONT - INSTALLATION ....................... 22-21

WHEEL MOUNTING STUDS - FRONT - REMOVAL .......................... 22-21

WHEEL MOUNTING STUDS - REAR - INSTALLATION ....................... 22-22

WHEEL MOUNTING STUDS - REAR - REMOVAL .......................... 22-22

WHEEL ROTATION - STANDARD PROCEDURE, TIRE .................... 22-7

WHEEL RUNOUT, SPECIFICATIONS - TONE ............................... 5-91

WHEEL, SPECIFICATIONS ..............22-19

WHEEL SPEED SENSOR - AWD - INSTALLATION, REAR .................. 5-92

WHEEL SPEED SENSOR - AWD - REMOVAL, REAR ...................... 5-92

WHEEL SPEED SENSOR - FWD - INSTALLATION, REAR .................. 5-93

WHEEL SPEED SENSOR - FWD - REMOVAL, REAR ...................... 5-93

WHEEL SPEED SENSOR - INSTALLATION, FRONT .................5-92

WHEEL SPEED SENSOR - REMOVAL, FRONT .............................. 5-91

WHEEL SPEED SENSOR AIR GAP, SPECIFICATIONS ...................... 5-91

WHEEL TRIM CARE, CLEANING - WHEEL . . 22-19

WHEEL VIBRATION - DIAGNOSIS AND TESTING, TIRE ....................... 22-1

WHEELHOUSE SPLASH SHIELD - INSTALLATION, FRONT ................23-57

WHEELHOUSE SPLASH SHIELD - REMOVAL, FRONT .................... 23-57

WIND DEFLECTOR - INSTALLATION .....23-174

WIND DEFLECTOR - REMOVAL .........23-174

WIND NOISE, DIAGNOSIS AND TESTING . . . 23-2

WINDOW - INSTALLATION, QUARTER . . . 23-164

WINDOW - REMOVAL, QUARTER .......23-164

WINDOW CRANK - INSTALLATION .......23-21

WINDOW CRANK - REMOVAL ...........23-21

WINDOW DEFOGGER RELAY - DESCRIPTION, REAR .................. 8G-3WINDOW DEFOGGER RELAY -

INSTALLATION, REAR .................. 8G-4

WINDOW DEFOGGER RELAY - OPERATION, REAR .................... 8G-3

WINDOW DEFOGGER RELAY - REMOVAL, REAR ..................... 8G-4

WINDOW DEFOGGER SWITCH - DESCRIPTION, REAR .................. 8G-4

WINDOW DEFOGGER SWITCH - OPERATION, REAR .................... 8G-4

WINDOW MOTOR - REMOVAL ..........8N-62

WINDOW MOTOR, DIAGNOSIS AND TESTING - VENT ..................... 8N-62

WINDOW REGULATOR - MANUAL - INSTALLATION ....................... 23-23

WINDOW REGULATOR - MANUAL - REMOVAL .......................... 23-22

WINDOW REGULATOR - POWER - INSTALLATION ....................... 23-22

WINDOW REGULATOR - POWER - REMOVAL .......................... 23-22

WINDOW SWITCH, DIAGNOSIS AND TESTING ........................... 8N-63

WINDOWS - DESCRIPTION, POWER .....8N-61

WINDOWS - OPERATION, POWER .......8N-61

WINDOWS, DIAGNOSIS AND TESTING - POWER ............................ 8N-61

WINDSHIELD - DESCRIPTION ..........23-161

WINDSHIELD SAFETY PRECAUTIONS, WARNING ......................... 23-161

WIPER ARM - INSTALLATION, REAR .....8R-10

WIPER ARM - REMOVAL, REAR ..........8R-10

WIPER ARM ALIGNMENT - STANDARD PROCEDURE, FRONT .................. 8R-9

WIPER ARMS - INSTALLATION, FRONT ....8R-9

WIPER ARMS - REMOVAL, FRONT ........8R-9

WIPER BLADES - CLEANING ...........8R-13

WIPER BLADES - INSTALLATION ........8R-13

WIPER BLADES - REMOVAL ............8R-13

WIPER LINKAGE - INSTALLATION .......8R-14

WIPER LINKAGE - REMOVAL ...........8R-13

WIPER MODULE - INSTALLATION .......8R-14

WIPER MODULE - REMOVAL ...........8R-14

WIPER MOTOR - INSTALLATION, FRONT . . 8R-10

WIPER MOTOR - INSTALLATION, REAR . . . 8R-10

WIPER MOTOR - REMOVAL, FRONT ......8R-9

WIPER MOTOR - REMOVAL, REAR ......8R-10

WIPER SYSTEM - DIAGNOSIS AND TESTING, FRONT ..................... 8R-2

WIPER SYSTEM - DIAGNOSIS AND TESTING, REAR ...................... 8R-4

WIPERS/WASHERS - DESCRIPTION .......8R-1

WIPERS/WASHERS - OPERATION ........8R-2

WIPER/WASHER SWITCH - DESCRIPTION, REAR .................8R-10

WIPER/WASHER SWITCH - DIAGNOSIS AND TESTING, FRONT .................8R-2

WIPER/WASHER SWITCH - OPERATION, REAR .............................. 8R-11

WIRE SPLICING - STANDARD PROCEDURE .....................8W -01-15

WIRING - INSTALLATION, HEATER ......24-122

WIRING - REMOVAL, HEATER ..........24-122

WIRING DIAGRAMS - DESCRIPTION, HOW TO USE .....................8W -01-1

WIRING HARNESS - DESCRIPTION ......8N-59

WIRING HARNESS - DIAGNOSIS AND TESTING .........................8W -01-7

WIRING HARNESS - INSTALLATION ......8N-59

WIRING HARNESS - OPERATION ........8N-59

WIRING HARNESS - REMOVAL .........8N-59

WIRING/TERMINAL, SPECIAL TOOLS . . 8W-01-10

WORN THREADS - STANDARD PROCEDURE, REPAIR OF DAMAGED

OR............................. 9-10,9-88

ZONE, DESCRIPTION - MANUAL DUAL .....24-2

ZONE, DESCRIPTION - MANUAL SINGLE . . . 24-2

ZONE, DESCRIPTION - MANUAL THREE ....24-2

ZONE, OPERATION - MANUAL DUAL ......24-5

ZONE, OPERATION - MANUAL SINGLE .....24-4

ZONE, OPERATION - MANUAL THREE .....24-5

RS INDEX35

Description Group-Page Description Group-Page Description Group-Page