ors CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2178 of 2339

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

The evaporator temperature sensor monitors the

temperature of the conditioned air once it passes

through the A/C evaporator. The evaporator temper-

ature sensor will change its internal resistance in

response to the air temperatures it monitors and is

connected to the A/C-heater control through sensor

ground and signal circuits. As the conditioned air

temperature increases, the resistance of the evapora-

tor temperature sensor decreases and the voltage

monitored by the A/C-heater control decreases. The

external location of the evaporator temperature sen-

sor allows the sensor to be removed or installed with-

out disturbing the refrigerant in the A/C system.

The A/C-heater control uses this monitored voltage

reading as an indication of the evaporator tempera-

ture. The A/C-heater control is programmed to

respond to this input by sending electronic messages

to the powertrain control module (PCM) over the con-

troller area network (CAN) data bus. The PCM then

cycles the A/C compressor clutch as necessary to opti-

mize A/C system performance and to protect the A/C

system from evaporator freezing.

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

The evaporator temperature sensor is diagnosed

using the DRBIIItscan tool. Refer to Body Diagnos-

tic Procedures.

REMOVAL

RG MODELS

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the windshield wiper assembly from

the vehicle (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL).

(4) Remove the temperature sensor retainer from

the expansion valve (Fig. 17).

(5) Pull the evaporator temperature sensor away

from the expansion valve far enough to access the

red release ring on the wiring connector. Push the

red ring toward the connector to release the lock and

disconnect the wire harness connector from the tem-

perature sensor.

(6) Remove the evaporator temperature sensor

from the engine compartment.

RS MODELS

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the instrument panel from the vehicle

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the wire harness connector from the

evaporator temperature sensor located on the top of

the HVAC housing (Fig. 18).

(4) Remove the evaporator temperature sensor

from the HVAC housing.

INSTALLATION

RG MODELS

NOTE: Any grease removed with the evaporator

temperature sensor must be replaced. Failure to do

so could result in poor A/C performance.

(1) Position the evaporator temperature sensor

into the right rear corner of the engine compartment.

(2) Reconnect the wire harness connector to the

evaporator temperature sensor.

(3) Position the evaporator temperature sensor

onto the top of the expansion valve with the sensor

probe inserted into the well in the expansion valve.

(4) Install the temperature sensor retainer.

(5) Install the window wiper module (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(6) Reinstall the air cleaner housing into the right

side of the engine compartment.

(7) Reconnect the battery negative cable.

Fig. 17 Evaporator Temperature Sensor - RG Models

1 - RIGHT FRONT STRUT TOWER

2 - EVAPORATOR TEMPERATURE SENSOR

3 - EXPANSION VALVE

4 - DASH PANEL

5 - RETAINER

RSCONTROLS - FRONT24-27

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 2179 of 2339

(8) Run the HVAC Cool Down test to verify system

is operating properly (Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).

RS MODELS

(1) Install the evaporator temperature sensor into

the top of the HVAC housing.

(2) Connect the wire harness connector to the

evaporator temperature sensor.

(3) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(4) Reconnect the negative battery cable.

INFRARED TEMPERATURE

SENSOR

DESCRIPTION

The infrared temperature sensor consists of two

infrared transducers that are concealed behind a

clear lens located near the bottom of the center panel

outlet near the top of the instrument panel center

bezel (Fig. 19). These sensors are used only on mod-

els equipped with the optional automatic tempera-

ture control (ATC) heating-A/C system. A molded

plastic connector receptacle on the bottom of the

panel outlet unit is concealed behind the center

bezel. A short, dedicated jumper wire harness routedbehind the center bezel connects the sensors directly

to the ATC A/C-heater control module near the bot-

tom of the center bezel. The infrared temperature

sensor is integral to the center bezel panel outlet

unit. The infrared sensors cannot be adjusted or

repaired and, if faulty or damaged, the center bezel

must be replaced.

OPERATION

The dual infrared temperature sensors provide

independent measurement inputs to the Automatic

Temperature Control (ATC) heater-A/C control mod-

ule that indicates the surface temperature of the

driver seat and front seat passenger seat occupants.

By using a surface temperature measurement, rather

than an air temperature measurement, the ATC sys-

tem is able to adjust itself to the comfort level as per-

ceived by the occupant. This allows the system to

detect and compensate for other ambient conditions

affecting comfort levels, such as solar heat gain or

evaporative heat loss. The ATC system logic responds

to the infrared sensor inputs by calculating and

adjusting the air flow temperature and air flow rate

needed to properly obtain and maintain the individ-

ually selected comfort level temperatures of both the

driver and passenger seat occupants. The ATC heat-

er-A/C control module continually monitors the infra-

red sensor circuits, and will store a Diagnostic

Trouble Code (DTC) for any problem it detects. This

DTC information can be retrieved and the infrared

temperature sensor diagnosed using a DRBIIItscan

tool. Refer to Body Diagnostic Procedures.

Fig. 18 Evaporator Temperature Sensor - RS Models

1 - EVAPORATOR TEMPERATURE SENSOR

2 - WIRE HARNESS CONNECTOR

3 - HVAC HOUSING

Fig. 19 Infrared Temperature Sensor ± RS shown,

RG typical

1 - INSTRUMENT PANEL CENTER BEZEL

2 - CENTER IP AIR OUTLETS

3 - INFRARED TEMPERATURE SENSOR

24 - 28 CONTROLS - FRONTRS

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 2180 of 2339

MODE DOOR ACTUATOR

DESCRIPTION

The mode door actuator is a reversible, 12-volt

Direct Current (DC), servo motor. The single mode

door actuator is located on the driver's side end of

the HVAC housing, close to the top of the distribution

housing. The mode door actuator is mechanically con-

nected to the mode door.

The mode door actuator is interchangeable with

the actuators for the blend air door(s) and the recir-

culation air door. Each actuator is contained within

an identical black molded plastic housing with an

integral wire connector receptacle. Two integral

mounting tabs allow the actuator to be secured with

two screws to the distribution housing. Each actuator

also has an identical output shaft with splines that

connects it to the linkage that drives the mode door.

The mode door actuator does not require mechanical

indexing to the mode door linkage, as it is electroni-

cally calibrated by the heater-A/C control module.

OPERATION

The mode door actuator is connected to the A/C-

heater control through the vehicle electrical system

by a dedicated two-wire lead and connector from the

HVAC wire harness. The mode door actuator can

move the mode door in two directions. When the A/C-

heater control pulls the voltage on one side of the

motor connection high and the other connection low,

the mode door will move in one direction. When the

A/C-heater control reverses the polarity of the volt-

age to the motor, the mode door moves in the oppo-

site direction. When the A/C-heater control makes

the voltage to both connections high or both connec-

tions low, the mode door stops and will not move.

These same motor connections also provide a feed-

back signal to the A/C-heater control. This feedback

signal allows the A/C-heater control to monitor the

operation and relative position of the mode door

actuator and the mode door. The A/C-heater control

learns the mode door stop positions during the cali-

bration procedure and will store a diagnostic trouble

code (DTC) for any problems it detects in the mode

door actuator circuits.

The mode door actuator can be diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures for more information. The mode door actuator

cannot be adjusted or repaired and, if damaged or

faulty, it must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

(3) Disconnect the wire harness connector from the

mode door actuator (Fig. 20).

(4) Remove the two screws that secure the mode

door actuator to the HVAC distribution housing.

(5) Remove the mode door actuator from the distri-

bution housing.

Fig. 20 Mode Door Actuator - LHD Shown, RHD

Typical

1 - WIRE HARNESS CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)

RSCONTROLS - FRONT24-29

Page 2182 of 2339

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor power module (Fig. 21).

(4) Remove the two screws that secure the blower

motor power module to the HVAC housing.

(5) Remove the blower motor power module from

the HVAC housing.

INSTALLATION

(1) Position the blower motor power module into

the HVAC housing.

(2) Install the two screws that secure the blower

motor power module to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the blower

motor power module.

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the negative battery cable.

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt direct current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the HVAC housing, on the air inlet

housing. The recirculation door actuator is mechani-

cally connected to the recirculation-air door. The

recirculation door actuator is interchangeable with

the actuators for the blend-air door(s) and the mode

door. Each actuator is contained within an identical

black molded plastic housing with an integral wire

connector receptacle. Two integral mounting tabs

allow the actuator to be secured with two screws to

the air inlet housing. Each actuator also has an iden-

tical output shaft with splines that connects it to the

linkage that drives the recirculation-air door. The

recirculation door actuator does not require mechan-

ical indexing to the recirculation-air door, as it is

electronically calibrated by the A/C-heater control.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire lead and con-

nector of the HVAC wire harness. The recirculation

door actuator can move the recirculation-air door in

two directions. When the A/C-heater control pulls the

voltage on one side of the motor connection high and

the other connection low, the recirculation-air door

will move in one direction.

When the A/C-heater control makes the voltage to

both connections high or both connections low, the

recirculation-air door stops and will not move. The

A/C-heater control uses a feedback signal positioning

system to monitor the operation and relative position

of the recirculation door actuator and the recircula-

tion-air door. The A/C-heater control learns the recir-

culation-air door stop positions during the calibration

procedure and will store a diagnostic trouble code

(DTC) for any problems it detects in the recirculation

door actuator circuits.

The recirculation door actuator is diagnosed using

a scan tool (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING and to 24 -

HVAC Electrical Diagnostics for more information).

The recirculation door actuator cannot be adjusted

or repaired and, if faulty or damaged, it must be

replaced.

Fig. 21 Blower Motor Power Module - Typical

1 - POWER MODULE

2 - LOWER GLOVE BOX OPENING REINFORCEMENT

3 - HVAC HOUSING

RSCONTROLS - FRONT24-31

POWER MODULE - BLOWER MOTOR (Continued)

Page 2185 of 2339

INSTALLATION

(1) Position the rear A/C-heater control onto the

bezel or video screen housing, depending on applica-

tion.

(2) Install the three screws that secure the rear

A/C-heater control to the bezel or video screen hous-

ing. Tighten the screws to 2 N´m (17 in. lbs.).(3) If the rear A/C-heater control is to be mounted

into the headliner, position the rear A/C-heater con-

trol near the headliner and connect the wire harness

connector to the rear of the control.

(4) Insert the locator tabs on the back of the rear

control bezel over the forward edge of the headliner

opening.

(5) Slide the rear A/C-heater control bezel forward

far enough to align the snap clips on the bezel with

the receptacles on the headliner and by using hand

pressure, press the top edge of the bezel upward

until the two snap clips fully seat into their recepta-

cles.

(6) If the rear A/C-heater control is mounted to the

video screen housing, install the video screen to the

headliner (Refer to 8 - ELECTRICAL/AUDIO/VIDEO

SCREEN - INSTALLATION).

(7) Reconnect the negative battery cable.

(8) Using the DRB-IIItscan tool, reset the Rear

Temperature Selector calibration values.

(9) Verify that the Actuator Calibration of the

Front Control has passed. If an Actuator Calibration

has not passed correct any errors before proceeding

further.

(10) Rotate the Rear Temperature Selector counter

clockwise to the Cold Position, allow the Selector to

remain in the Cold Position for 5 seconds.

(11) Rotate the Rear Temperature Selector Clock-

wise to the Hot Position, allow the Selector to remain

in the Cold Position for 5 seconds.

(12) Calibration is now complete.

BLEND DOOR ACTUATOR

DESCRIPTION

The rear blend door actuator is a reversible,

12-volt Direct Current (DC), servo motor. The single

blend door actuator is located on the outboard side of

the rear HVAC housing, below the mode door actua-

tor. The blend door actuator is mechanically con-

nected to the blend air door.

The rear blend door actuator is interchangeable

with the actuator for the mode door. Each actuator is

contained within an identical black molded plastic

housing with an integral wire connector receptacle.

Two integral mounting tabs allow the actuator to be

secured with two screws to the rear HVAC housing.

Each actuator also has an identical output shaft with

splines that connects it to the pivot or linkage of the

proper door. The rear blend door actuator does not

require mechanical indexing to the blend air door

pivot, as it is electronically calibrated by the front

heater-A/C control module.

Fig. 1 A/C-Heater Control - Rear

1 - TRIM STICK

2 - BEZEL

3 - REAR A/C-HEATER CONTROL

4 - HEADLINER

Fig. 2 Heater-A/C Control Bezel

1 - BEZEL/VIDEO SCREEN HOUSING (AS EQUIPPED)

2 - SNAP CLIP (2)

3 - REAR A/C-HEATER CONTROL

4 - SCREW (3)

5 - BEZEL LOCATOR TAB (2)

24 - 34 CONTROLS - REARRS

A/C-HEATER CONTROL (Continued)

Page 2188 of 2339

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(ATC heater-A/C control) through a fuse in the IPM

on the fused rear blower motor relay output circuit

only when the blower motor relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear blower

motor relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

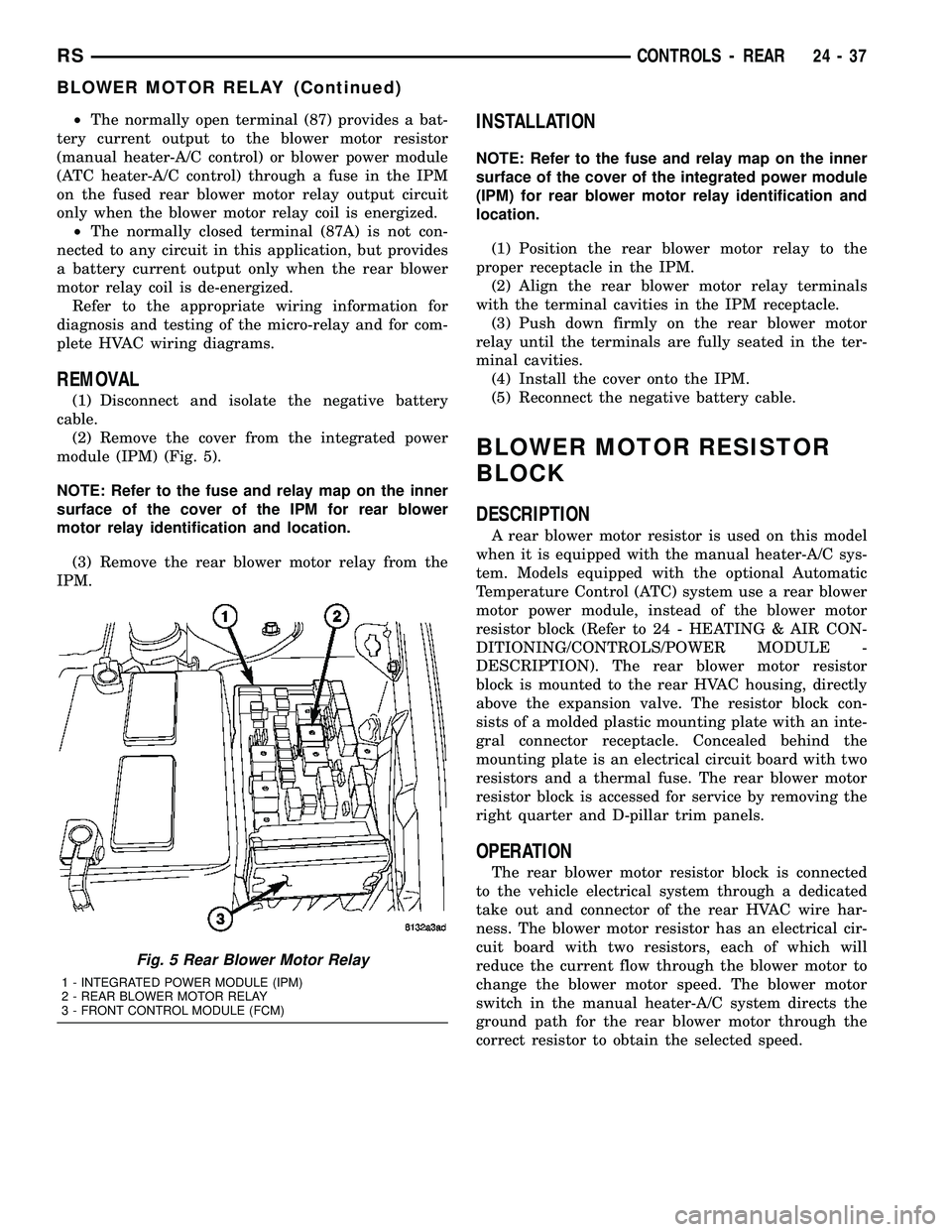

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 5).

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the IPM for rear blower

motor relay identification and location.

(3) Remove the rear blower motor relay from the

IPM.

INSTALLATION

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the integrated power module

(IPM) for rear blower motor relay identification and

location.

(1) Position the rear blower motor relay to the

proper receptacle in the IPM.

(2) Align the rear blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(3) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities.

(4) Install the cover onto the IPM.

(5) Reconnect the negative battery cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A rear blower motor resistor is used on this model

when it is equipped with the manual heater-A/C sys-

tem. Models equipped with the optional Automatic

Temperature Control (ATC) system use a rear blower

motor power module, instead of the blower motor

resistor block (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/POWER MODULE -

DESCRIPTION). The rear blower motor resistor

block is mounted to the rear HVAC housing, directly

above the expansion valve. The resistor block con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate is an electrical circuit board with two

resistors and a thermal fuse. The rear blower motor

resistor block is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor resistor block is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. The blower motor resistor has an electrical cir-

cuit board with two resistors, each of which will

reduce the current flow through the blower motor to

change the blower motor speed. The blower motor

switch in the manual heater-A/C system directs the

ground path for the rear blower motor through the

correct resistor to obtain the selected speed.

Fig. 5 Rear Blower Motor Relay

1 - INTEGRATED POWER MODULE (IPM)

2 - REAR BLOWER MOTOR RELAY

3 - FRONT CONTROL MODULE (FCM)

RSCONTROLS - REAR24-37

BLOWER MOTOR RELAY (Continued)

Page 2189 of 2339

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through both resistors. Each higher speed selected

with the blower motor switch applies the blower

motor ground path through fewer of the resistors,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistors are bypassed and the blower

motor receives a direct path to ground through the

blower motor switch.

The rear blower motor resistor block cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the rear HVAC wire harness con-

nector from the rear blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the blower

motor resistor and the resistor output terminal. In

each case there should be continuity. If OK, repair

the wire harness circuits between the blower motor

switch and the blower motor resistor, blower motor or

blower motor relay as required. If not OK, replace

the faulty blower motor resistor block.

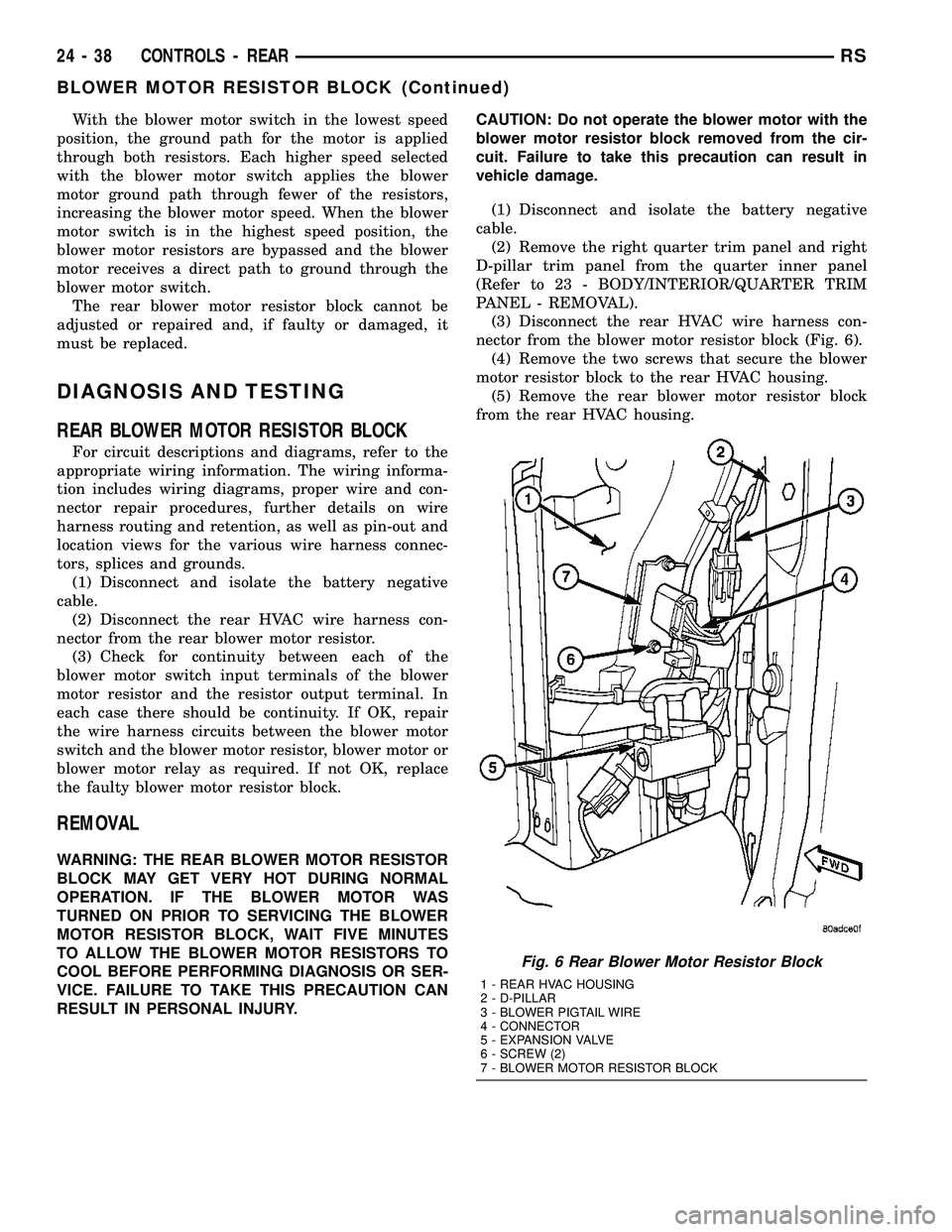

REMOVAL

WARNING: THE REAR BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.CAUTION: Do not operate the blower motor with the

blower motor resistor block removed from the cir-

cuit. Failure to take this precaution can result in

vehicle damage.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Disconnect the rear HVAC wire harness con-

nector from the blower motor resistor block (Fig. 6).

(4) Remove the two screws that secure the blower

motor resistor block to the rear HVAC housing.

(5) Remove the rear blower motor resistor block

from the rear HVAC housing.

Fig. 6 Rear Blower Motor Resistor Block

1 - REAR HVAC HOUSING

2 - D-PILLAR

3 - BLOWER PIGTAIL WIRE

4 - CONNECTOR

5 - EXPANSION VALVE

6 - SCREW (2)

7 - BLOWER MOTOR RESISTOR BLOCK

24 - 38 CONTROLS - REARRS

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2194 of 2339

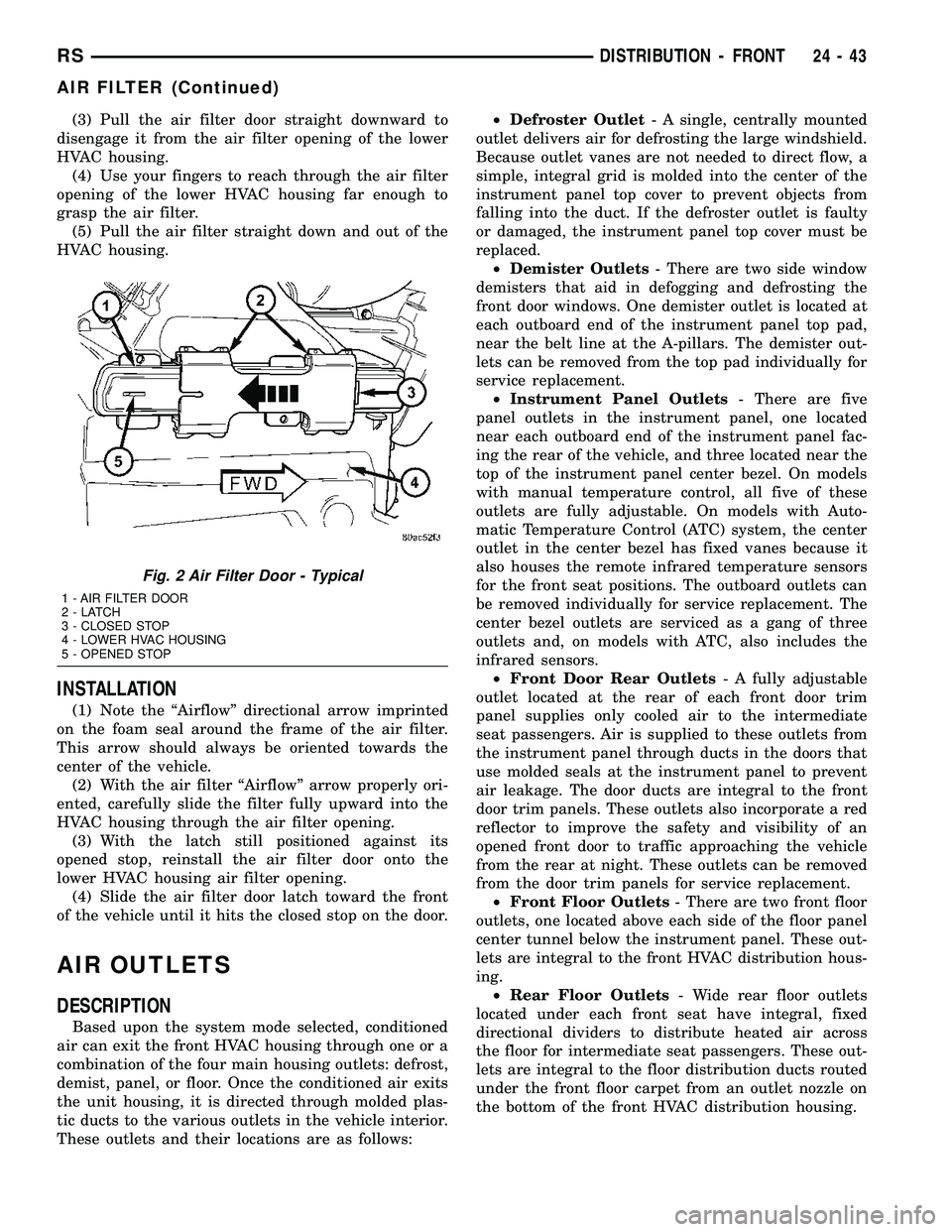

(3) Pull the air filter door straight downward to

disengage it from the air filter opening of the lower

HVAC housing.

(4) Use your fingers to reach through the air filter

opening of the lower HVAC housing far enough to

grasp the air filter.

(5) Pull the air filter straight down and out of the

HVAC housing.

INSTALLATION

(1) Note the ªAirflowº directional arrow imprinted

on the foam seal around the frame of the air filter.

This arrow should always be oriented towards the

center of the vehicle.

(2) With the air filter ªAirflowº arrow properly ori-

ented, carefully slide the filter fully upward into the

HVAC housing through the air filter opening.

(3) With the latch still positioned against its

opened stop, reinstall the air filter door onto the

lower HVAC housing air filter opening.

(4) Slide the air filter door latch toward the front

of the vehicle until it hits the closed stop on the door.

AIR OUTLETS

DESCRIPTION

Based upon the system mode selected, conditioned

air can exit the front HVAC housing through one or a

combination of the four main housing outlets: defrost,

demist, panel, or floor. Once the conditioned air exits

the unit housing, it is directed through molded plas-

tic ducts to the various outlets in the vehicle interior.

These outlets and their locations are as follows:²Defroster Outlet- A single, centrally mounted

outlet delivers air for defrosting the large windshield.

Because outlet vanes are not needed to direct flow, a

simple, integral grid is molded into the center of the

instrument panel top cover to prevent objects from

falling into the duct. If the defroster outlet is faulty

or damaged, the instrument panel top cover must be

replaced.

²Demister Outlets- There are two side window

demisters that aid in defogging and defrosting the

front door windows. One demister outlet is located at

each outboard end of the instrument panel top pad,

near the belt line at the A-pillars. The demister out-

lets can be removed from the top pad individually for

service replacement.

²Instrument Panel Outlets- There are five

panel outlets in the instrument panel, one located

near each outboard end of the instrument panel fac-

ing the rear of the vehicle, and three located near the

top of the instrument panel center bezel. On models

with manual temperature control, all five of these

outlets are fully adjustable. On models with Auto-

matic Temperature Control (ATC) system, the center

outlet in the center bezel has fixed vanes because it

also houses the remote infrared temperature sensors

for the front seat positions. The outboard outlets can

be removed individually for service replacement. The

center bezel outlets are serviced as a gang of three

outlets and, on models with ATC, also includes the

infrared sensors.

²Front Door Rear Outlets- A fully adjustable

outlet located at the rear of each front door trim

panel supplies only cooled air to the intermediate

seat passengers. Air is supplied to these outlets from

the instrument panel through ducts in the doors that

use molded seals at the instrument panel to prevent

air leakage. The door ducts are integral to the front

door trim panels. These outlets also incorporate a red

reflector to improve the safety and visibility of an

opened front door to traffic approaching the vehicle

from the rear at night. These outlets can be removed

from the door trim panels for service replacement.

²Front Floor Outlets- There are two front floor

outlets, one located above each side of the floor panel

center tunnel below the instrument panel. These out-

lets are integral to the front HVAC distribution hous-

ing.

²Rear Floor Outlets- Wide rear floor outlets

located under each front seat have integral, fixed

directional dividers to distribute heated air across

the floor for intermediate seat passengers. These out-

lets are integral to the floor distribution ducts routed

under the front floor carpet from an outlet nozzle on

the bottom of the front HVAC distribution housing.

Fig. 2 Air Filter Door - Typical

1 - AIR FILTER DOOR

2-LATCH

3 - CLOSED STOP

4 - LOWER HVAC HOUSING

5 - OPENED STOP

RSDISTRIBUTION - FRONT24-43

AIR FILTER (Continued)

Page 2195 of 2339

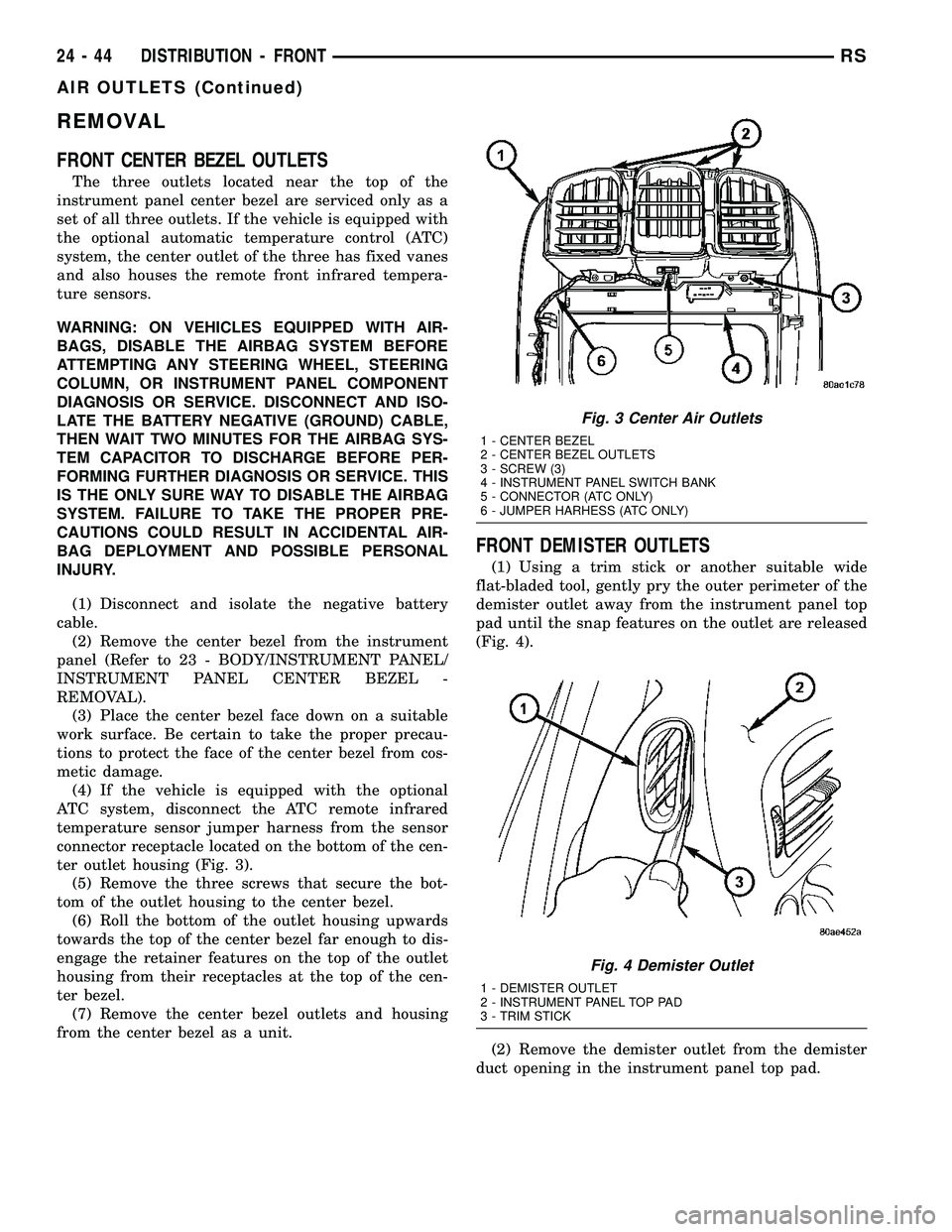

REMOVAL

FRONT CENTER BEZEL OUTLETS

The three outlets located near the top of the

instrument panel center bezel are serviced only as a

set of all three outlets. If the vehicle is equipped with

the optional automatic temperature control (ATC)

system, the center outlet of the three has fixed vanes

and also houses the remote front infrared tempera-

ture sensors.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) Place the center bezel face down on a suitable

work surface. Be certain to take the proper precau-

tions to protect the face of the center bezel from cos-

metic damage.

(4) If the vehicle is equipped with the optional

ATC system, disconnect the ATC remote infrared

temperature sensor jumper harness from the sensor

connector receptacle located on the bottom of the cen-

ter outlet housing (Fig. 3).

(5) Remove the three screws that secure the bot-

tom of the outlet housing to the center bezel.

(6) Roll the bottom of the outlet housing upwards

towards the top of the center bezel far enough to dis-

engage the retainer features on the top of the outlet

housing from their receptacles at the top of the cen-

ter bezel.

(7) Remove the center bezel outlets and housing

from the center bezel as a unit.

FRONT DEMISTER OUTLETS

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the outer perimeter of the

demister outlet away from the instrument panel top

pad until the snap features on the outlet are released

(Fig. 4).

(2) Remove the demister outlet from the demister

duct opening in the instrument panel top pad.

Fig. 3 Center Air Outlets

1 - CENTER BEZEL

2 - CENTER BEZEL OUTLETS

3 - SCREW (3)

4 - INSTRUMENT PANEL SWITCH BANK

5 - CONNECTOR (ATC ONLY)

6 - JUMPER HARHESS (ATC ONLY)

Fig. 4 Demister Outlet

1 - DEMISTER OUTLET

2 - INSTRUMENT PANEL TOP PAD

3 - TRIM STICK

24 - 44 DISTRIBUTION - FRONTRS

AIR OUTLETS (Continued)

Page 2197 of 2339

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) or

the front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)