auxiliary battery CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1383 of 2339

QUICK CONNECT FITTING

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Make sure that the o-ring in installed in

fitting. Never install a quick-connect fitting without

the retainer being either on the fuel tube or already

in the quick-connect fitting. In either case, ensure

the retainer locks securely into the quick-connect

fitting by firmly push-pulling-push on fuel tube and

fitting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean engine oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

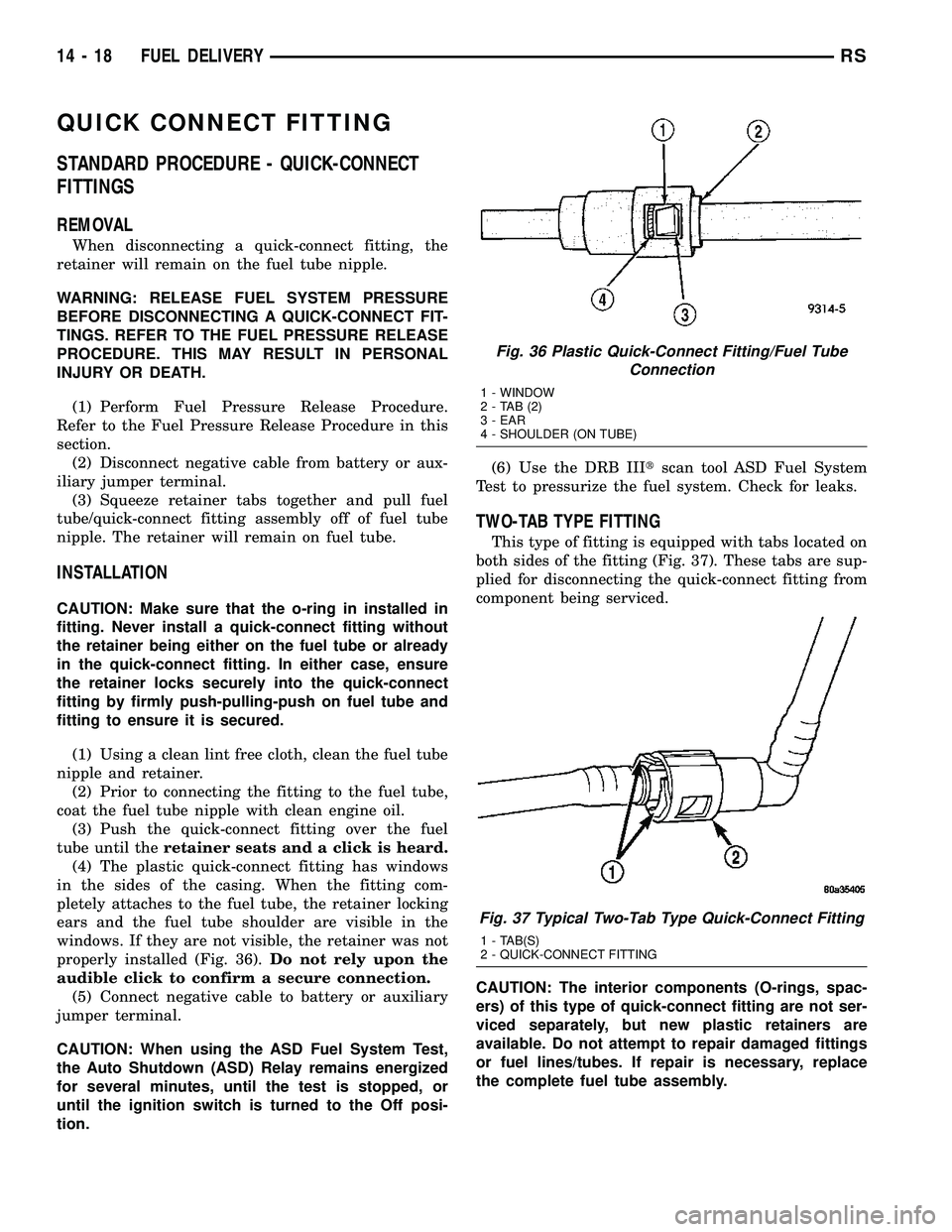

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 36).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for several minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

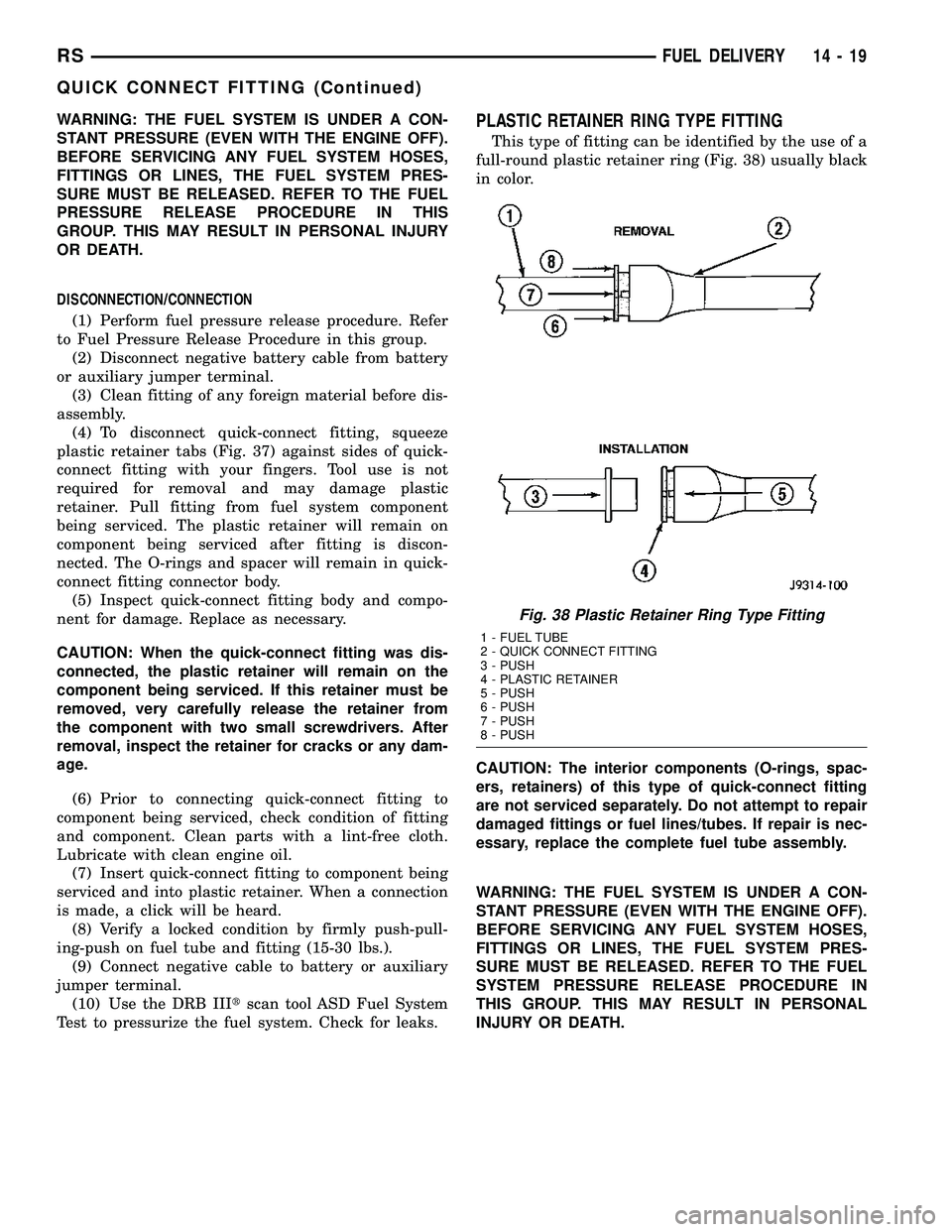

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 37). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

Fig. 36 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

Fig. 37 Typical Two-Tab Type Quick-Connect Fitting

1 - TAB(S)

2 - QUICK-CONNECT FITTING

14 - 18 FUEL DELIVERYRS

Page 1384 of 2339

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP. THIS MAY RESULT IN PERSONAL INJURY

OR DEATH.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 37) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION: When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the

component being serviced. If this retainer must be

removed, very carefully release the retainer from

the component with two small screwdrivers. After

removal, inspect the retainer for cracks or any dam-

age.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly push-pull-

ing-push on fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Use the DRB IIItscan tool ASD Fuel System

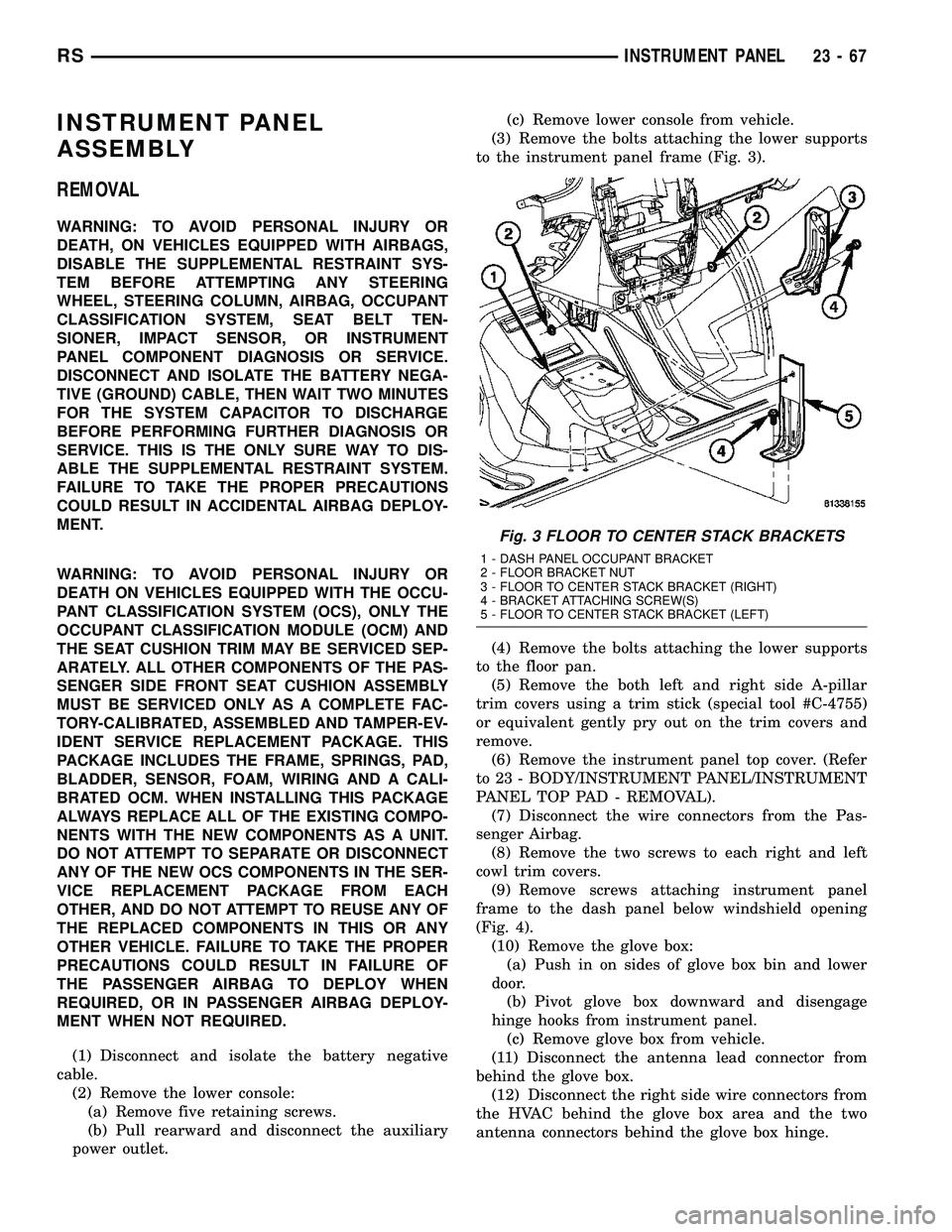

Test to pressurize the fuel system. Check for leaks.PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 38) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

Fig. 38 Plastic Retainer Ring Type Fitting

1 - FUEL TUBE

2 - QUICK CONNECT FITTING

3 - PUSH

4 - PLASTIC RETAINER

5 - PUSH

6 - PUSH

7 - PUSH

8 - PUSH

RSFUEL DELIVERY14-19

QUICK CONNECT FITTING (Continued)

Page 1385 of 2339

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-

nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 38). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly push-pull-

ing-push on fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

14 - 20 FUEL DELIVERYRS

QUICK CONNECT FITTING (Continued)

Page 1846 of 2339

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Disconnect and isolate the battery negative

cable.

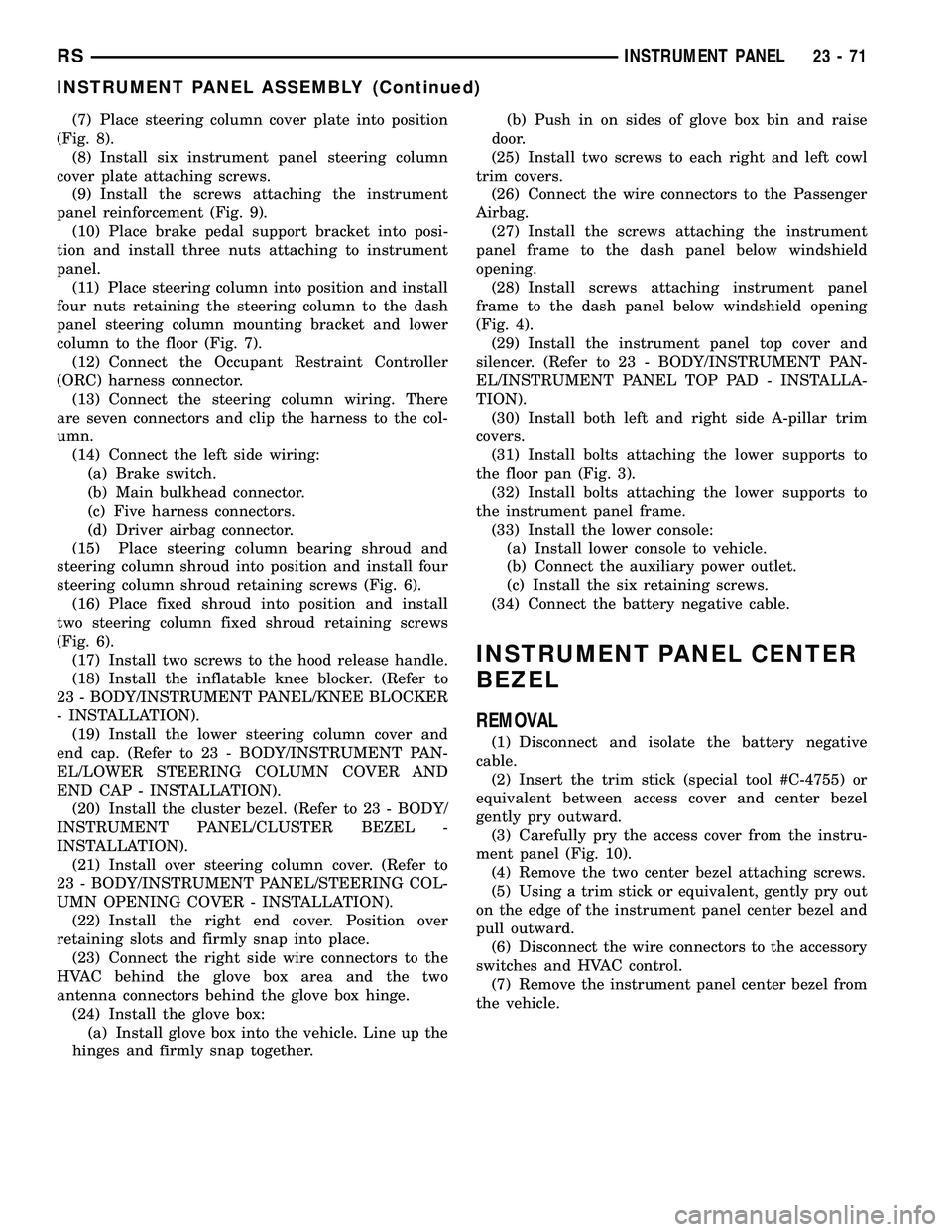

(2) Remove the lower console:

(a) Remove five retaining screws.

(b) Pull rearward and disconnect the auxiliary

power outlet.(c) Remove lower console from vehicle.

(3) Remove the bolts attaching the lower supports

to the instrument panel frame (Fig. 3).

(4) Remove the bolts attaching the lower supports

to the floor pan.

(5) Remove the both left and right side A-pillar

trim covers using a trim stick (special tool #C-4755)

or equivalent gently pry out on the trim covers and

remove.

(6) Remove the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - REMOVAL).

(7) Disconnect the wire connectors from the Pas-

senger Airbag.

(8) Remove the two screws to each right and left

cowl trim covers.

(9) Remove screws attaching instrument panel

frame to the dash panel below windshield opening

(Fig. 4).

(10) Remove the glove box:

(a) Push in on sides of glove box bin and lower

door.

(b) Pivot glove box downward and disengage

hinge hooks from instrument panel.

(c) Remove glove box from vehicle.

(11) Disconnect the antenna lead connector from

behind the glove box.

(12) Disconnect the right side wire connectors from

the HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

Fig. 3 FLOOR TO CENTER STACK BRACKETS

1 - DASH PANEL OCCUPANT BRACKET

2 - FLOOR BRACKET NUT

3 - FLOOR TO CENTER STACK BRACKET (RIGHT)

4 - BRACKET ATTACHING SCREW(S)

5 - FLOOR TO CENTER STACK BRACKET (LEFT)

RSINSTRUMENT PANEL23-67

Page 1850 of 2339

(7) Place steering column cover plate into position

(Fig. 8).

(8) Install six instrument panel steering column

cover plate attaching screws.

(9) Install the screws attaching the instrument

panel reinforcement (Fig. 9).

(10) Place brake pedal support bracket into posi-

tion and install three nuts attaching to instrument

panel.

(11) Place steering column into position and install

four nuts retaining the steering column to the dash

panel steering column mounting bracket and lower

column to the floor (Fig. 7).

(12) Connect the Occupant Restraint Controller

(ORC) harness connector.

(13) Connect the steering column wiring. There

are seven connectors and clip the harness to the col-

umn.

(14) Connect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(15) Place steering column bearing shroud and

steering column shroud into position and install four

steering column shroud retaining screws (Fig. 6).

(16) Place fixed shroud into position and install

two steering column fixed shroud retaining screws

(Fig. 6).

(17) Install two screws to the hood release handle.

(18) Install the inflatable knee blocker. (Refer to

23 - BODY/INSTRUMENT PANEL/KNEE BLOCKER

- INSTALLATION).

(19) Install the lower steering column cover and

end cap. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/LOWER STEERING COLUMN COVER AND

END CAP - INSTALLATION).

(20) Install the cluster bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(21) Install over steering column cover. (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - INSTALLATION).

(22) Install the right end cover. Position over

retaining slots and firmly snap into place.

(23) Connect the right side wire connectors to the

HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(24) Install the glove box:

(a) Install glove box into the vehicle. Line up the

hinges and firmly snap together.(b) Push in on sides of glove box bin and raise

door.

(25) Install two screws to each right and left cowl

trim covers.

(26) Connect the wire connectors to the Passenger

Airbag.

(27) Install the screws attaching the instrument

panel frame to the dash panel below windshield

opening.

(28) Install screws attaching instrument panel

frame to the dash panel below windshield opening

(Fig. 4).

(29) Install the instrument panel top cover and

silencer. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/INSTRUMENT PANEL TOP PAD - INSTALLA-

TION).

(30) Install both left and right side A-pillar trim

covers.

(31) Install bolts attaching the lower supports to

the floor pan (Fig. 3).

(32) Install bolts attaching the lower supports to

the instrument panel frame.

(33) Install the lower console:

(a) Install lower console to vehicle.

(b) Connect the auxiliary power outlet.

(c) Install the six retaining screws.

(34) Connect the battery negative cable.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the trim stick (special tool #C-4755) or

equivalent between access cover and center bezel

gently pry outward.

(3) Carefully pry the access cover from the instru-

ment panel (Fig. 10).

(4) Remove the two center bezel attaching screws.

(5) Using a trim stick or equivalent, gently pry out

on the edge of the instrument panel center bezel and

pull outward.

(6) Disconnect the wire connectors to the accessory

switches and HVAC control.

(7) Remove the instrument panel center bezel from

the vehicle.

RSINSTRUMENT PANEL23-71

INSTRUMENT PANEL ASSEMBLY (Continued)