relay CHRYSLER CARAVAN 2005 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 392 of 2339

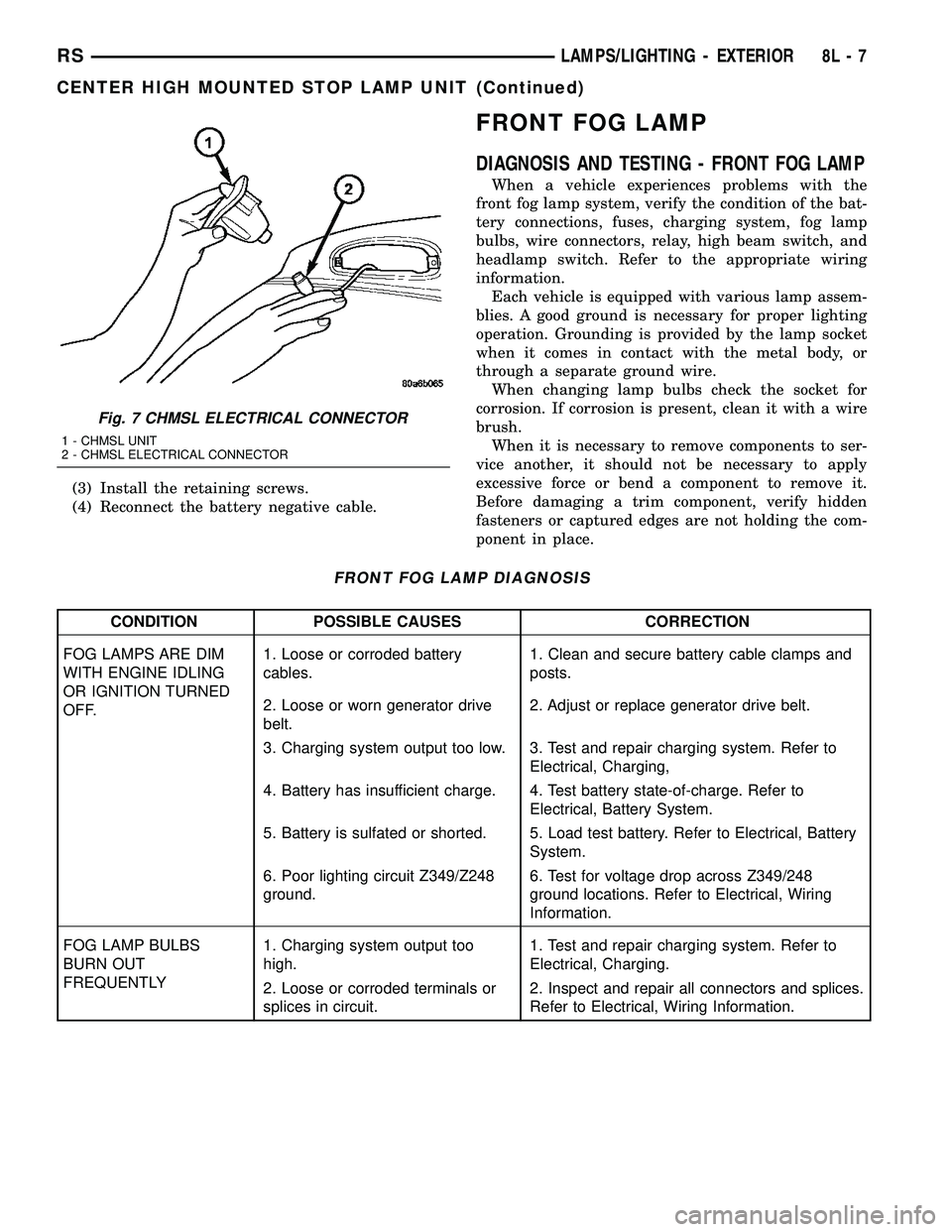

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG LAMP

When a vehicle experiences problems with the

front fog lamp system, verify the condition of the bat-

tery connections, fuses, charging system, fog lamp

bulbs, wire connectors, relay, high beam switch, and

headlamp switch. Refer to the appropriate wiring

information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

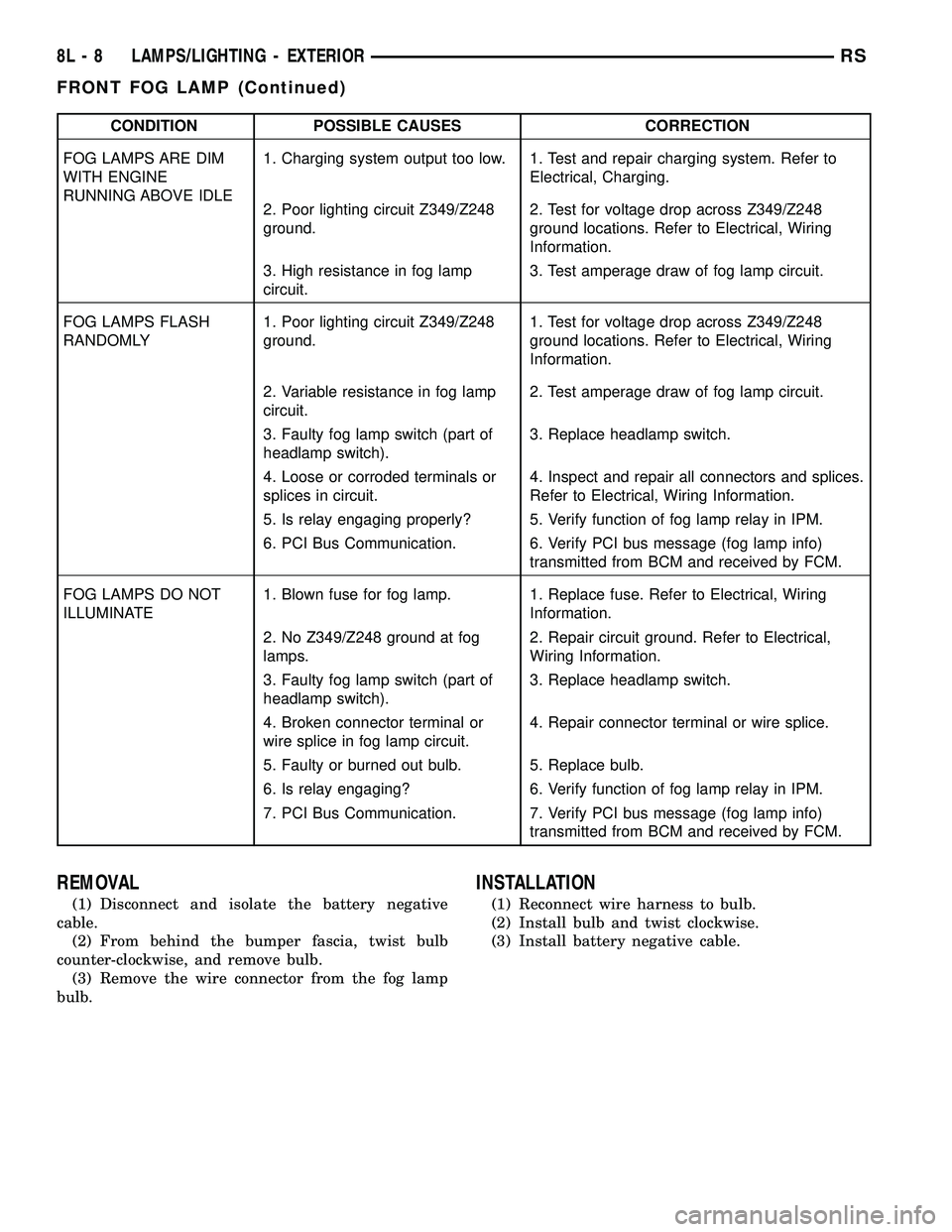

FRONT FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of-charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical, Battery

System.

6. Poor lighting circuit Z349/Z248

ground.6. Test for voltage drop across Z349/248

ground locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS

BURN OUT

FREQUENTLY1. Charging system output too

high.1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

Fig. 7 CHMSL ELECTRICAL CONNECTOR

1 - CHMSL UNIT

2 - CHMSL ELECTRICAL CONNECTOR

RSLAMPS/LIGHTING - EXTERIOR8L-7

CENTER HIGH MOUNTED STOP LAMP UNIT (Continued)

Page 393 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z349/Z248

ground.2. Test for voltage drop across Z349/Z248

ground locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z349/Z248

ground.1. Test for voltage drop across Z349/Z248

ground locations. Refer to Electrical, Wiring

Information.

2. Variable resistance in fog lamp

circuit.2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

5. Is relay engaging properly? 5. Verify function of fog lamp relay in IPM.

6. PCI Bus Communication. 6. Verify PCI bus message (fog lamp info)

transmitted from BCM and received by FCM.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z349/Z248 ground at fog

lamps.2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Broken connector terminal or

wire splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Faulty or burned out bulb. 5. Replace bulb.

6. Is relay engaging? 6. Verify function of fog lamp relay in IPM.

7. PCI Bus Communication. 7. Verify PCI bus message (fog lamp info)

transmitted from BCM and received by FCM.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) From behind the bumper fascia, twist bulb

counter-clockwise, and remove bulb.

(3) Remove the wire connector from the fog lamp

bulb.

INSTALLATION

(1) Reconnect wire harness to bulb.

(2) Install bulb and twist clockwise.

(3) Install battery negative cable.

8L - 8 LAMPS/LIGHTING - EXTERIORRS

FRONT FOG LAMP (Continued)

Page 396 of 2339

HEADLAMP

DIAGNOSIS AND TESTING - HEADLAMP

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, high beam switch, dimmer

switch, and headlamp switch. Refer to the appropri-

ate wiring information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socketwhen it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

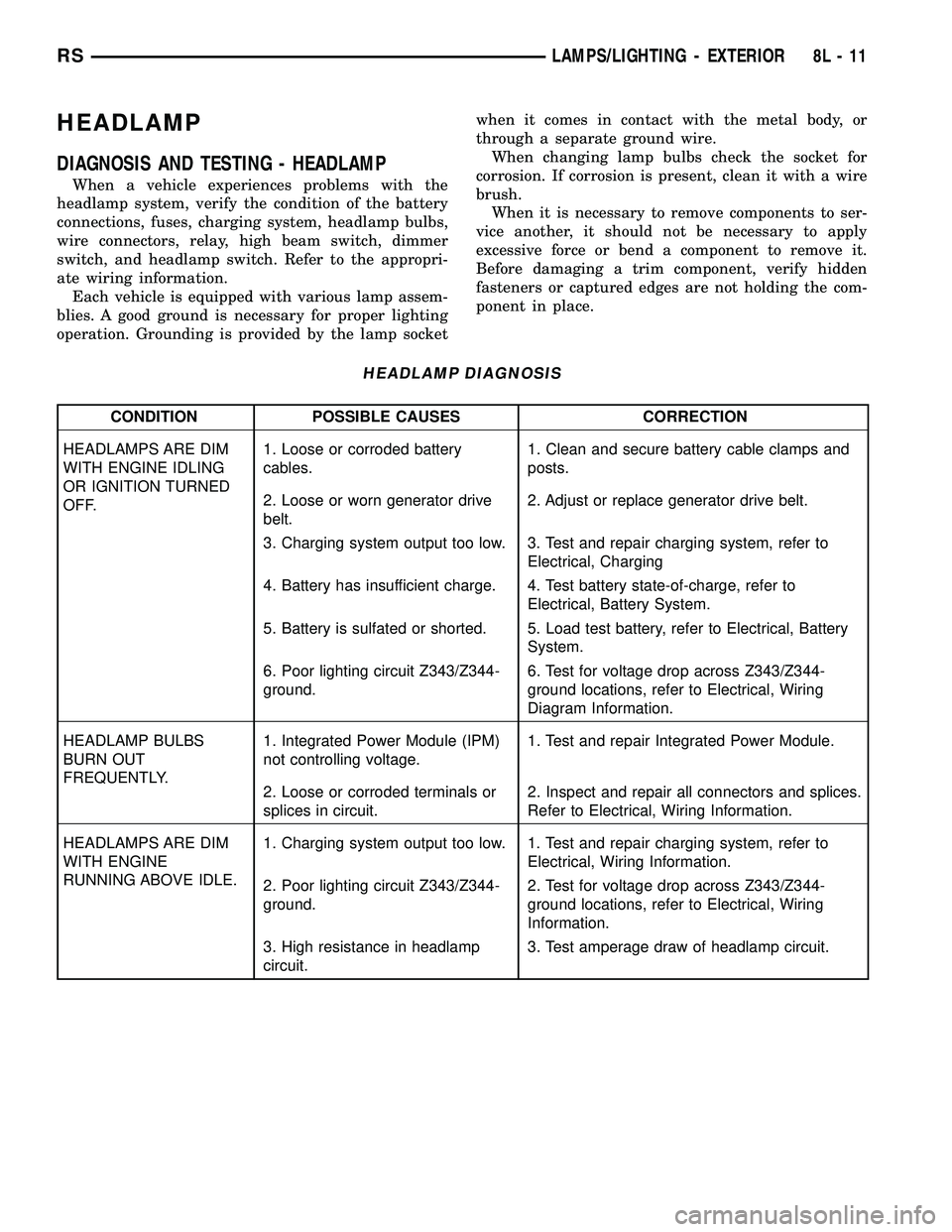

HEADLAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Electrical, Charging

4. Battery has insufficient charge. 4. Test battery state-of-charge, refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Electrical, Battery

System.

6. Poor lighting circuit Z343/Z344-

ground.6. Test for voltage drop across Z343/Z344-

ground locations, refer to Electrical, Wiring

Diagram Information.

HEADLAMP BULBS

BURN OUT

FREQUENTLY.1. Integrated Power Module (IPM)

not controlling voltage.1. Test and repair Integrated Power Module.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

HEADLAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE.1. Charging system output too low. 1. Test and repair charging system, refer to

Electrical, Wiring Information.

2. Poor lighting circuit Z343/Z344-

ground.2. Test for voltage drop across Z343/Z344-

ground locations, refer to Electrical, Wiring

Information.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

RSLAMPS/LIGHTING - EXTERIOR8L-11

Page 452 of 2339

OFF and back ON with the forward-facing light sen-

sor still covered. This defeats the day-detect logic. If

OK, go to Step 8. If not OK, replace the faulty mirror

unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+), and

the fifth is outside mirror (-).Do not apply 12 volts to

the fourth and fifth pins.With 12 volts on pins 1 and

2, the mirror can be tested by blocking the rear sensor

and shining a light into the forward sensor. For an out-

side mirror, there is a 2±pin connector. Applying 1.2

volts will cause the mirror to dim. If the mirror does not

dim, the entire glass assembly can be replaced just as it

is when the glass is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

POWER FOLDAWAY MIRROR

SWITCH - EXPORT

DESCRIPTION

These vehicles may be equipped with Power Fold-

away Mirrors. This feature allows both the driver

and passenger side view mirrors to fold inward

(retract) on demand. The vehicle has an additional

switch located on the steering column that controls

the folding function of the mirror assembly (Fig. 2).

The fold-away side view mirror is attached to the

vehicle's door in the same manner as mirrors without

the fold-away option. The fold-away mirrors unique

option is the internal motor which allows the mirrors to

fold inward on demand. The fold-away mirror motor is

not serviceable separately and if a motor is found to be

faulty the entire side view mirror must be replaced.

OPERATION

When the mirror retract switch is depressed, both

of the side view mirrors will fold inward, Thus mak-

ing the overall width of the vehicle the smallest pos-

sible. This can be helpful were parking space is a

absolute minimum.

When the driver's door is opened, only the driver's

door mirror will unfold. If the passenger door is

opened, both mirrors will unfold.

The power fold away mirror system consists of the fol-

lowing components: mirror switch, side view mirror,relay, wires and fuse. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair procedures,

details of wire harness routing and retention, connector

pin-out information and location views for the various

wire harness connectors, splices and grounds.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the upper and lower steering column

shroud (Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(3) Disconnect electrical harness connector.

(4) Remove switch from steering column shroud

(Fig. 3).

Fig. 2 POWER FOLDAWAY MIRROR SWITCH

1 - POWER FOLDAWAY MIRROR SWITCH

2 - STEERING COLUMN

Fig. 3 POWER FOLDING MIRROR SWITCH

1 - STEERING COLUMN SHROUD

2 - POWER FOLDAWAY SWITCH

RSPOWER MIRRORS8N-29

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 456 of 2339

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

MEMORY SYSTEM

The Memory Seat Mirror Module (MSMM) receives

battery current through fuse #22 in the Integrated

Power Module (IPM) and the power seat system cir-

cuit breaker, located under the driver side front seat

near the rear edge of the seat cushion pan. The mem-

ory system does not operate with the Ignition-Off

Draw (IOD) fuse removed. The MSMM will drive a

maximum of 2 motors at a time in a given direction.

If conflicting directions are requested, the priority for

response will be approximately as follows:

²Seat Track Rearward or Forward

²Seat Front Down or Up

²Seat Rear Down or Up

²Recliner Rearward or Forward

The inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

For diagnosis of the MSMM, the Programmable

Communication Interface (PCI) data bus, or the other

electronic modules on the PCI data bus that provide

inputs and outputs for the memory system, the use of

a DRBIIItor equivalent scan tool and the proper

Diagnostic Procedures information is recommended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION) for additional information on the

EVIC.

DIAGNOSIS AND TESTING

POWER SEAT SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing ofthe driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked,

(Refer to 8 - ELECTRICAL/POWER SEATS - DIAG-

NOSIS AND TESTING).

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) If either power seat is completely inoperable,

check the power seat circuit breaker, located under

the trailing edge of the driver side power seat. If the

power seat circuit breaker is OK, continue to the

next step.

(2) Check for proper battery and ground connec-

tions at the power seat switch and/or memory seat

module. Repair any wiring as necessary.

(3) Check the power seat system wire harness con-

nections and pins to ensure proper circuit continuity

and ground paths.

MEMORY SYSTEM

In order to obtain conclusive testing of the memory

system, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBIIItor

equivalent scan tool and the proper Diagnostic Proce-

dures information. The DRBIIItscan tool can pro-

vide confirmation that the PCI data bus is functional,

that all of the electronic modules are sending and

receiving the proper messages on the PCI data bus,

and that the memory system is receiving the proper

hard wired inputs and relaying the proper hard

wired outputs to perform its driver side power seat

functions.

(1) If the driver power seat exhibits an interrupted

or jerky motion, ensure the wire harness is connected

correctly. To verify the concern, obtain a DRB IIItor

equivalent scan tool and energize each axis one at a

time. If any axis stops in approximately 2 seconds

(without hitting the end of travel), the feedback for

RSPOWER SEAT SYSTEM8N-33

POWER SEAT SYSTEM (Continued)

Page 486 of 2339

WINDOW SWITCH

DIAGNOSIS AND TESTING

WINDOW SWITCH

(1) Remove the desired switch to be tested from

the door trim panel. Driver's side (master) or passen-

ger side. (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/POWER WINDOW SWITCH - REMOVAL).

(2) Using an ohmmeter, Test driver door switch for

continuity as described in (Fig. 2).

POWER WINDOW MASTER SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 13 and 1

13 and 2

13 and 3

13 and 4

13 and 5

13 and 6

13 and 7

13 and 8

UP DRIVER 11 and 8

*DOWN DRIVER 11 and 6

*X DOWN DRIVER 11and 6

UP PASSENGER 9 and 4

DOWN PASSENGER 9 and 2

LEFT VENT OPEN 11 and 7

LEFT VENT CLOSE 9 and 3

RIGHT VENT OPEN 9 and 1

RIGHT VENT CLOSE 11 and 5

* MUST TEST WITH B+ ON PIN 9 AND

GROUND ON PIN 13 FOR CONTINUITY

BETWEEN PINS 11 AND 6

(3) If the result are not OK, replace the driver side

window lift switch.

(4) Test passenger door switch for continuity as

described in (Fig. 3).

PASSENGER WINDOW SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 3 AND 8

OFF 2 AND 5

UP 1 AND 8

DOWN 1 AND 5

(5) If the results are not OK, replace the switch.

The power window master switch has a Auto-Down

feature. The switch is equipped with two detent posi-

tions when actuating the power window OPEN. The

first detent position allows the window to roll down

and stop when the switch is released. The second

detent position actuates an integral express roll

down relay that rolls the window down after the

switch is released. When the express down circuit

senses stall current (window has reached end of

down travel), the switch will turn current off to the

motor. The AUTO feature can be cancelled by actuat-

ing the switch UP or DOWN while window is in

motion. If the electronic circuit in the switch fails to

detect a stall current, the auto down circuit will time

out within 9 to 13 seconds.

Fig. 2 Power Window Master Switch Connector

Fig. 3 Passenger Door Power Window Switch

RSPOWER WINDOWS8N-63

Page 547 of 2339

OPERATION

FRONT WIPER/WASHER SYSTEM

The windshield washer circuit is protected by a 15

amp Cartridge Fuse located in the IPM. The wiper

motor has permanent magnetic fields. The speeds are

determined by current flow to the appropriate set of

brushes inside the motor. The current flow is con-

trolled by the multi-function switch. The high speed/

low speed relays are located in the IPM. The speed

sensitive intermittent wiper is controlled by the Body

Control Module (BCM). The intermittent mode, with

the vehicle traveling greater than 10.4 mph, has a

range of 0.5 to 18 seconds. With the vehicle traveling

less than 10.4 mph, the time delay doubles to a

range of 1 to 36 seconds. The wiper arms will park at

the base of the windshield just above the cowl cover

after the wiper switch is turned OFF.

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

The front and rear washer systems share the same

washer pump motor.

REAR WIPER/WASHER SYSTEM

When rear wiper operation is required, the BCM

will provide ignition ON voltage to the rear wiper

motor (Export and ATC equipped vehicles only).

When the wiper switch is turned OFF, the BCM pro-

vides circuit ground to operate the motor until the

wipe cycle is complete and the wiper arm returns to

the base of the rear window.

Switch only offers an intermittent rear wiper

mode. The wiper motor will cycle every 7 seconds.

The intermittent delay time is also adjusted based

upon vehicle speed. With the vehicle traveling

greater than 50 mph, the cycle changes to every 5

seconds.

When rear washer is requested by depressing and

holding down the switch, the BCM then provides a

ground for the washer motor. Until the switch is

released, the motor will be in a continuous wipe

mode, then return to an intermittent wipe mode.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Park (switch OFF)The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. DTC's can

be retrieved using a DRB IIItscan tool. Refer to the

proper Body Diagnostic Procedures manual for DTC

descriptions and retrieval information.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

table.

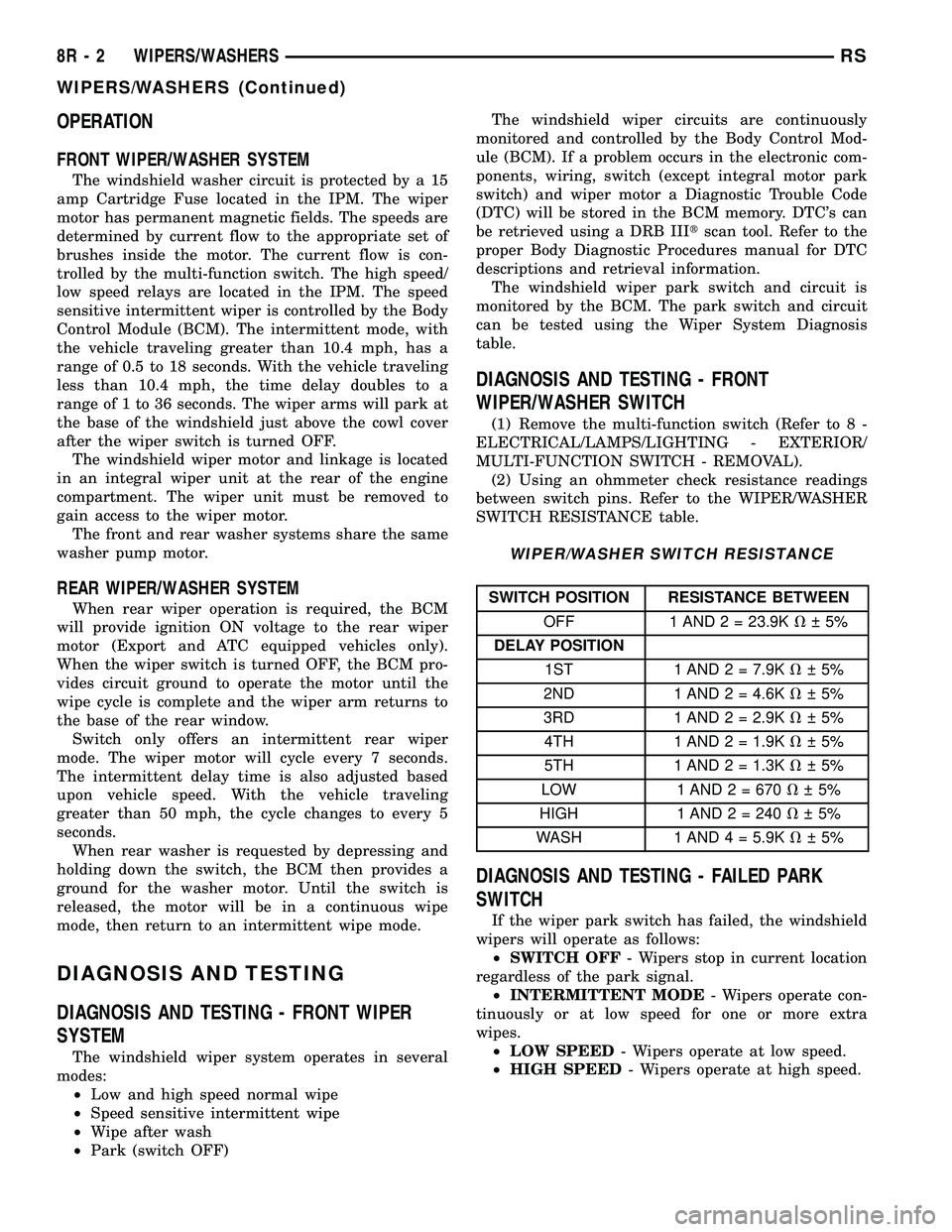

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH

(1) Remove the multi-function switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - REMOVAL).

(2) Using an ohmmeter check resistance readings

between switch pins. Refer to the WIPER/WASHER

SWITCH RESISTANCE table.

WIPER/WASHER SWITCH RESISTANCE

SWITCH POSITION RESISTANCE BETWEEN

OFF 1 AND 2 = 23.9KV 5%

DELAY POSITION

1ST 1 AND 2 = 7.9KV 5%

2ND 1 AND 2 = 4.6KV 5%

3RD 1 AND 2 = 2.9KV 5%

4TH 1 AND 2 = 1.9KV 5%

5TH 1 AND 2 = 1.3KV 5%

LOW 1 AND 2 = 670V 5%

HIGH 1 AND2=240V 5%

WASH 1 AND 4 = 5.9KV 5%

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH

If the wiper park switch has failed, the windshield

wipers will operate as follows:

²SWITCH OFF- Wipers stop in current location

regardless of the park signal.

²INTERMITTENT MODE- Wipers operate con-

tinuously or at low speed for one or more extra

wipes.

²LOW SPEED- Wipers operate at low speed.

²HIGH SPEED- Wipers operate at high speed.

8R - 2 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 560 of 2339

NAVIGATION/TELECOMMUNICATION

TABLE OF CONTENTS

page page

NAVIGATION/TELECOMMUNICATION

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

TELECOMMUNICATION.................1HANDS FREE MODULE

REMOVAL.............................3

INSTALLATION..........................3

NAVIGATION/

TELECOMMUNICATION

DESCRIPTION

TELECOMMUNICATIONS

A hands-free cellular system is an available option

on this vehicle. It uses BluetoothŸ technology to pro-

vide wireless communication between the operator's

compatible cellular telephone and the vehicle's

on-board receiver.

The system uses voice recognition technology to

control operation. The incoming voice is broadcast

through the vehicle's radio speakers, automatically

overriding any other audio signals on the speakers

when the hands-free system is in use. A microphone

in the rearview mirror picks up vehicle occupant's

voices. If a call is in progress when the ignition is

switched off, the hands-free system will continue to

operate for up to 45 seconds as part of the Accessory

Relay Delay function. Thereafter, the call can con-

tinue on the hand-held telephone.

The center console front storage compartment

includes a cellular telephone holder, but the system

will communicate with a telephone that is anywhere

within the vehicle. However, covering the hand held

phone or the hands-free phone module with a metal

object may block the signal. The system will recog-

nize up to seven telephones, each of which is given a

spoken identification by the user during the setup

process. The system includes Spanish voice recogni-

tion in addition to English.

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command.

OPERATION

TELECOMMUNICATION

Two buttons on the rearview mirror, identified with

ISO icons, control the system: A9phone9button turns

the system on and off; a9voice recognition9(or voice

command) button prompts the hands-free system to

listen for a voice command. The system includes the

following features:

²Phonebook - Stores telephone numbers for later

recall by name or other verbal identification, called a

voice tag, and memory location.

²Four memory locations - Home, Work, Mobile

and Pager. A maximum of 32 unique names or voice

tags may be stored at the same time, with a different

number in each of the four memory locations.

²Voice tag dialing - Dials the number associated

with a voice tag and memory location.

²Digit dialing - Dials the telephone number by

recognizing the names of the digits as they are spo-

ken.

²Receiving calls - A voice prompt notifies the user

of an incoming call. Pressing the ªphoneº button

answers the call.

²Privacy Mode - Switches the call to the hand-

held telephone and the hands-free system and back

again using the ªvoice recognitionº (or ªvoice com-

mandº) button and a voice command, if desired.

DIAGNOSIS AND TESTING

TELECOMMUNICATION

Any diagnosis of the Telecommunication sys-

tem should begin with the use of the DRB IIIt

diagnostic tool. For information on the use of

the DRB IIIt, refer to the appropriate Diagnos-

tic Service Information.

For complete circuit diagrams, refer to the appro-

priate wiring information.

RSNAVIGATION/TELECOMMUNICATION8T-1

Page 571 of 2339

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H MULTIPLE

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N MULTIPLE

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W WIPERS

X AUDIO SYSTEMS

Y TEMPORARY

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)

Page 573 of 2339

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²

Terminals in the wiring assembly are fully seated

into the connector/component and locked into position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem area.

(6) Verify the proper operation. For this step,

check for proper operation of all items on the

repaired circuit. Refer to the wiring diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ELECTROSTATIC

DISCHARGE (ESD) SENSITIVE DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 6) is used to indicate this. When han-

dling any component with this symbol, comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part form it's protective

packing until it is time to install the part.

(5) Before removing the part from it's pakage,

ground the pakage to a known good ground on the

vehicle.

Fig. 5 PROBING TOOL

1 - SPECIAL TOOL 6801

2 - PROBING END

Fig. 6 ELECTROSTATIC DISCHARGE SYMBOL

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)