tailgate CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 431 of 2339

STANDARD PROCEDURE

LIFTGATE ADJUSTMENT

In order for the power liftgate system to function

properly the liftgate must move freely and smoothly.

The power liftgate system can accommodate for some

minor changes in the effort required to move the lift-

gate. However, in extreme conditions the liftgate may

need to be mechanically adjusted for proper fit and

finish. (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/LIFTGATE - INSTALLATION) for

detailed instructions.

If a problem exists with the power liftgate and it is

suspected to be extreme effort, check the liftgate prop

rods and hinges for free movement.

NOTE: Routine application of Mopar MP-50Tor

equivalent on the chrome prop rod shafts and lift-

gate latch and hinges will help keep the liftgate in

good working order.

POWER LIFTGATE LEARN CYCLE

Any time a power liftgate component is removed,

replaced or a liftgate adjustment is performed a learn

cycle must be performed. This learn cycle enables the

power liftgate control module to learn or relearn

information (travel limits, resistance to door travel,

etc.) which allows it to perform properly and safely.

Perform the following to complete a power liftgate

learn cycle:

(1) Obtain a DRBIIIt, or equivalent scan tool.

(2) Connect the scan tool to the vehicle and check

for any power liftgate system stored Diagnostic Trou-

ble Codes (DTCs), correct and erase any stored

DTCs.

(3) Using the scan tool, Go into Test Routine Menu

and select the power open command.

(4) Select the power close command.

(5) The liftgate learn cycle is complete.

If a DRBIIItor equivalent scan tool is not avail-

able, the learn cycle can be performed by actuating

the liftgate using any of the normal command

switches. Be certain to cycle the liftgate through a

complete open and close cycle before returning the

vehicle to service.

NOTE: If the power liftgate will not complete a full

cycle a problem exists with the power liftgate sys-

tem. (Refer to 8 - ELECTRICAL/POWER DOORS -

DIAGNOSIS AND TESTING).

CHIME/THERMISTOR

DESCRIPTION

The chime/thermistor assembly is a small capacitor

shaped electrical component mounted to the rear

license plate lamp housing assembly (Fig. 2) , located

just above the license plate. The chime portion of the

assembly controls the audible chime sound heard at

the rear of the vehicle when the power liftgate is in

motion. The thermistor portion of the assembly is a

temperature sensor, used by the power liftgate con-

trol module. The chime/thermistor assembly is a ser-

viceable component.

OPERATION

The chime/thermistor assembly performs two dif-

ferent functions for the power liftgate system. First,

the chime portion provides an audible chime sound

which is controlled by the power liftgate control mod-

ule. The chime/thermistor assembly is hardwired to

the power liftgate control module. Second the ther-

mistor provides a outside temperature reading by

way of a resistance reading supplied to the power

liftgate control module. As temperature increases the

resistance reading increases, as temperature

decreases the resistance reading decreases.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 2 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

8N - 8 POWER LIFTGATE SYSTEMRS

POWER LIFTGATE SYSTEM (Continued)

Page 433 of 2339

INSTALLATION

(1) Position the engage actuator in the vehicle and

connect the engage actuator electrical connector.

(2) Install the two engage actuator retaining

screws.

(3) Manually disengage the actuator.

(4) Install the left rear D-pillar trim on the vehi-

cle, (Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes.

(7) Verify power liftgate system and engage actua-

tor operation. Cycle the power liftgate through one

complete open and close cycle.

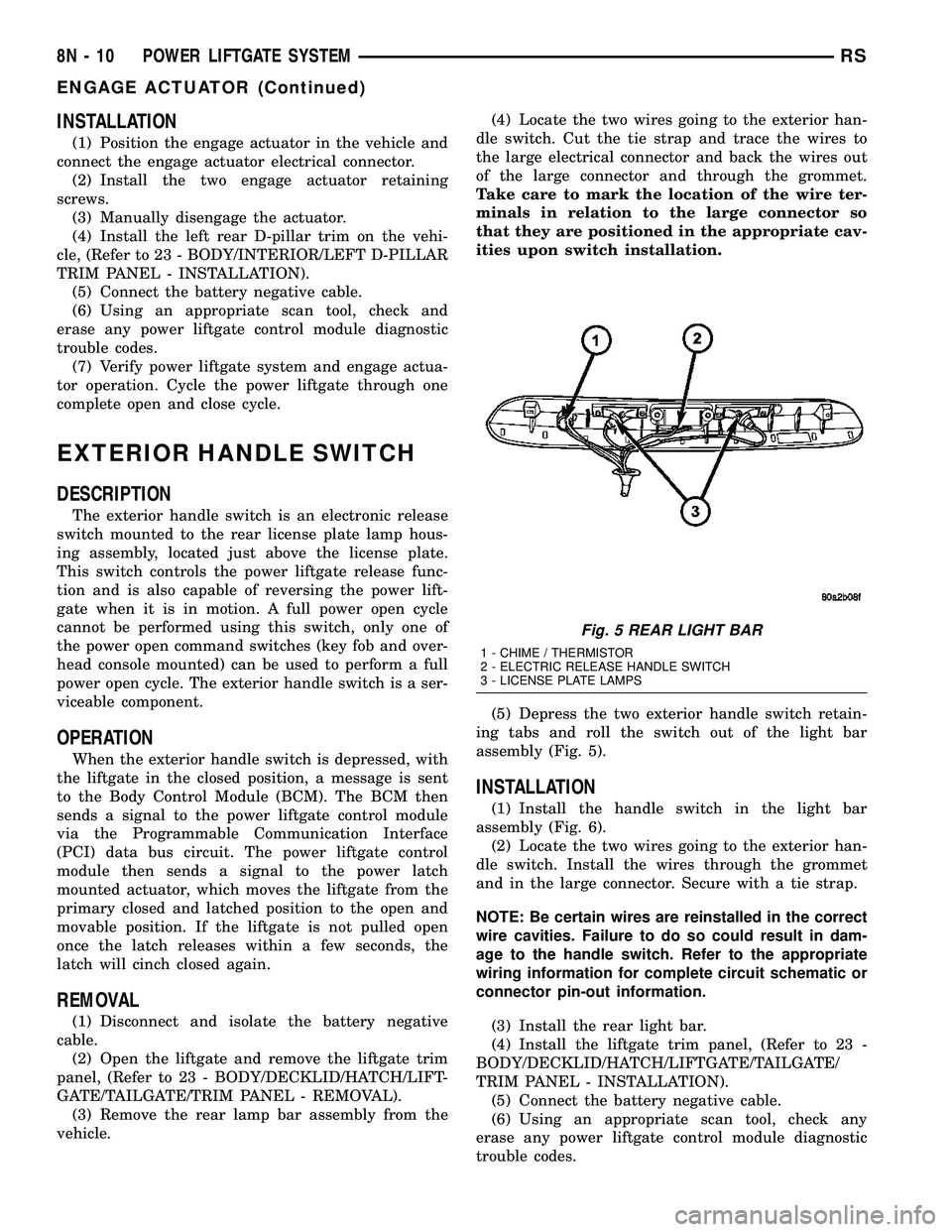

EXTERIOR HANDLE SWITCH

DESCRIPTION

The exterior handle switch is an electronic release

switch mounted to the rear license plate lamp hous-

ing assembly, located just above the license plate.

This switch controls the power liftgate release func-

tion and is also capable of reversing the power lift-

gate when it is in motion. A full power open cycle

cannot be performed using this switch, only one of

the power open command switches (key fob and over-

head console mounted) can be used to perform a full

power open cycle. The exterior handle switch is a ser-

viceable component.

OPERATION

When the exterior handle switch is depressed, with

the liftgate in the closed position, a message is sent

to the Body Control Module (BCM). The BCM then

sends a signal to the power liftgate control module

via the Programmable Communication Interface

(PCI) data bus circuit. The power liftgate control

module then sends a signal to the power latch

mounted actuator, which moves the liftgate from the

primary closed and latched position to the open and

movable position. If the liftgate is not pulled open

once the latch releases within a few seconds, the

latch will cinch closed again.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the liftgate and remove the liftgate trim

panel, (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Remove the rear lamp bar assembly from the

vehicle.(4) Locate the two wires going to the exterior han-

dle switch. Cut the tie strap and trace the wires to

the large electrical connector and back the wires out

of the large connector and through the grommet.

Take care to mark the location of the wire ter-

minals in relation to the large connector so

that they are positioned in the appropriate cav-

ities upon switch installation.

(5) Depress the two exterior handle switch retain-

ing tabs and roll the switch out of the light bar

assembly (Fig. 5).

INSTALLATION

(1) Install the handle switch in the light bar

assembly (Fig. 6).

(2) Locate the two wires going to the exterior han-

dle switch. Install the wires through the grommet

and in the large connector. Secure with a tie strap.

NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the handle switch. Refer to the appropriate

wiring information for complete circuit schematic or

connector pin-out information.

(3) Install the rear light bar.

(4) Install the liftgate trim panel, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check any

erase any power liftgate control module diagnostic

trouble codes.

Fig. 5 REAR LIGHT BAR

1 - CHIME / THERMISTOR

2 - ELECTRIC RELEASE HANDLE SWITCH

3 - LICENSE PLATE LAMPS

8N - 10 POWER LIFTGATE SYSTEMRS

ENGAGE ACTUATOR (Continued)

Page 435 of 2339

LATCH

DESCRIPTION

The power cinch/release latch performs the same

features as a manual liftgate latch as well as the

power cinch and / or release capability. A second type

of power latch can also be found on some vehicles,

this latch is designed to perform a power release

only. The power cinch and release capability is

accomplished by an actuator mounted to the leading

edge of the latch assembly. The latch is located in the

lower center of the power liftgate assembly (Fig. 8)

and contains integral pawl and ratchet switches. The

ratchet switch also acts as a liftgate ajar switch. The

power latch assembly can be serviced as a complete

assembly, latch without actuator or just the actuator.

OPERATION

On the power cinch/release latch, the latch

mounted actuator provides the torque required to

close the power liftgate from the secondary to the pri-mary closed and latched position. On the power

cinch/release latch and the power release only latch,

the actuator releases the liftgate from the primary

closed and latched position to the fully unlatched and

movable position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the liftgate and remove the liftgate trim

panel, (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Disconnect the power latch electrical connector

(Fig. 9).

(4) Remove the power latch retaining bolts.

(5) Disconnect the liftgate lock cylinder link rod

(Fig. 9) from the key cylinder or latch assembly. To

disconnect from latch, rotate the plastic retaining clip

90 É to unsnap clip from linkrod. Then pull link rod

straight out of latch arm.

(6) Remove the power latch from the vehicle.

Fig. 8 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 9 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

8N - 12 POWER LIFTGATE SYSTEMRS

Page 436 of 2339

INSTALLATION

(1) Position the power latch in the vehicle.

(2) Connect the liftgate lock cylinder link rod (Fig.

10) on the cinch latch assembly. Rotate the plastic

retaining clip 90 É to lock retaining clip onto the link

rod.

(3) Connect the link rod on the lock cylinder.

(4) Install three new power latch retaining bolts.

Torque to 10 N´m (90 in. lbs.).

(5) Connect the power latch electrical connector

and secure push pin retainers.

(6) Connect the battery negative cable.

(7) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the power latch.

(8) Verify power liftgate system and power cinch /

release latch operation. Cycle the power liftgate

through one complete open and close cycle, this will

allow the power liftgate control module to relearn its

cycle with the new components.

(9) Verify power liftgate manual operation. Using

liftgate key rotate the lock cylinder to verify door

operation. Pull door open using exterior liftgate han-

dle / switch.

(10) Install the liftgate trim panel, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

LATCH ACTUATOR

DESCRIPTION

The power cinch and/or power release latch (Fig.

11) is made possible by a latch actuator attached to

the leading edge of the power latch assembly. This 12

volt latch actuator contains a small drive gear that

meshes with the latch assemblies internal gears to

perform the power cinch close / power release opera-

tions. (Refer to 8 - ELECTRICAL/POWER DOORS/

LATCH - DESCRIPTION) for additional information.

The power cinch/release actuator is serviceable com-

ponent.

OPERATION

During a power close cycle, the power cinch actua-

tor provides the torque required to close the power

liftgate from the secondary to the primary closed and

latched position. During a power open cycle, the

power release actuator releases the liftgate from the

primary closed and latched position to the fully

unlatched and movable position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 10 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 11 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

RSPOWER LIFTGATE SYSTEM8N-13

LATCH (Continued)

Page 437 of 2339

(2) Open the liftgate and remove the lower liftgate

trim panel. (Refer to 23 - BODY/DECKLID/HATCH/

LIFTGATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Disconnect the power latch electrical connector

(Fig. 12).

(4) Remove the three latch retaining bolts.

(5) Grab the latch assembly and unhook the key

cylinder link rod from the key cylinder (Fig. 12).

(6) Place the latch assembly on a bench and locate

the three wires leading from the actuator portion of

the latch assembly.

(7) Disengage the main connector retaining push

pins from the latch actuator housing.

(8) Back the three wires out of the main latch elec-

trical connector.

(9) Flip the latch assembly over and remove the

latch actuator retaining screw(s).

(10) Remove the latch actuator from the latch

assembly.

INSTALLATION

(1) Install the latch actuator onto the latch assem-

bly.

(2) Install the three latch actuator retaining

screws.

(3) Install the three wires in the main latch elec-

trical connector.NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the latch actuator. Refer to the appropriate

wiring information for complete circuit schematic or

connector pin-out information.

(4) Secure the main connector retaining push pins

on the latch actuator housing.

(5) Grab the latch assembly and hook the key cyl-

inder link rod on the key cylinder (Fig. 13).

(6) Position the latch and install three new latch

retaining bolts. Torque to 10 N´m (90 in. lbs.).

(7) Connect the power latch electrical connector

(Fig. 13).

(8) Install the lower liftgate trim panel, (Refer to

23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/TRIM PANEL - INSTALLATION).

(9) Connect the battery negative cable.

(10) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the power latch.

(11) Verify power liftgate system and power cinch /

release latch operation. Cycle the power liftgate

through one complete open and close cycle, this will

allow the power liftgate control module to relearn its

cycle with the new components.

(12) Verify power liftgate manual operation. Using

liftgate key rotate the lock cylinder to verify door

operation. Pull door open using exterior liftgate han-

dle / switch.

Fig. 12 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 13 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

8N - 14 POWER LIFTGATE SYSTEMRS

LATCH ACTUATOR (Continued)

Page 441 of 2339

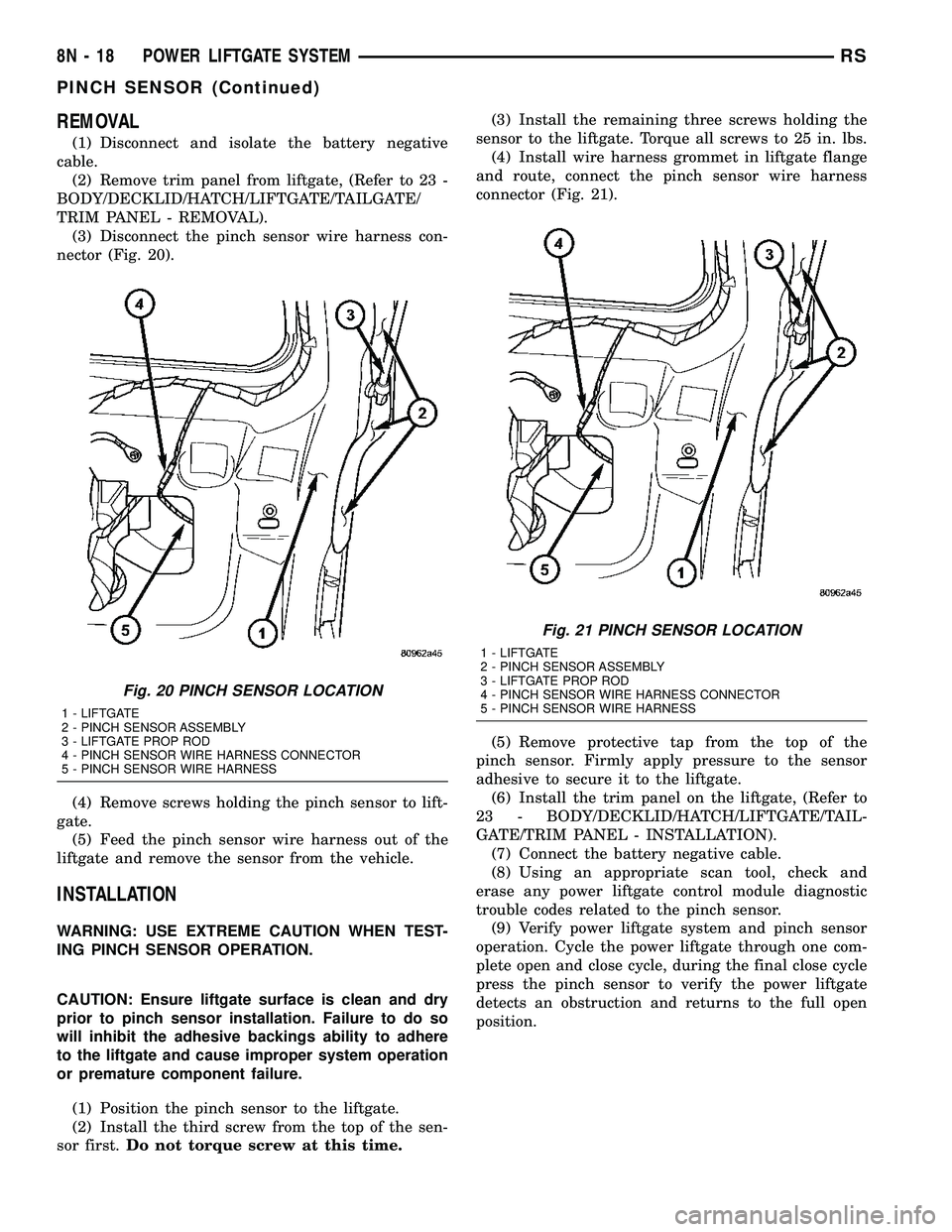

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove trim panel from liftgate, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect the pinch sensor wire harness con-

nector (Fig. 20).

(4) Remove screws holding the pinch sensor to lift-

gate.

(5) Feed the pinch sensor wire harness out of the

liftgate and remove the sensor from the vehicle.

INSTALLATION

WARNING: USE EXTREME CAUTION WHEN TEST-

ING PINCH SENSOR OPERATION.

CAUTION: Ensure liftgate surface is clean and dry

prior to pinch sensor installation. Failure to do so

will inhibit the adhesive backings ability to adhere

to the liftgate and cause improper system operation

or premature component failure.

(1) Position the pinch sensor to the liftgate.

(2) Install the third screw from the top of the sen-

sor first.Do not torque screw at this time.(3) Install the remaining three screws holding the

sensor to the liftgate. Torque all screws to 25 in. lbs.

(4) Install wire harness grommet in liftgate flange

and route, connect the pinch sensor wire harness

connector (Fig. 21).

(5) Remove protective tap from the top of the

pinch sensor. Firmly apply pressure to the sensor

adhesive to secure it to the liftgate.

(6) Install the trim panel on the liftgate, (Refer to

23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/TRIM PANEL - INSTALLATION).

(7) Connect the battery negative cable.

(8) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the pinch sensor.

(9) Verify power liftgate system and pinch sensor

operation. Cycle the power liftgate through one com-

plete open and close cycle, during the final close cycle

press the pinch sensor to verify the power liftgate

detects an obstruction and returns to the full open

position.

Fig. 20 PINCH SENSOR LOCATION

1 - LIFTGATE

2 - PINCH SENSOR ASSEMBLY

3 - LIFTGATE PROP ROD

4 - PINCH SENSOR WIRE HARNESS CONNECTOR

5 - PINCH SENSOR WIRE HARNESS

Fig. 21 PINCH SENSOR LOCATION

1 - LIFTGATE

2 - PINCH SENSOR ASSEMBLY

3 - LIFTGATE PROP ROD

4 - PINCH SENSOR WIRE HARNESS CONNECTOR

5 - PINCH SENSOR WIRE HARNESS

8N - 18 POWER LIFTGATE SYSTEMRS

PINCH SENSOR (Continued)

Page 555 of 2339

(5) Remove wiper linkage from motor crank. DO

NOT remove crank from motor.

(6) Remove bolts holding wiper motor and remove

motor.

INSTALLATION

(1) Place wiper module on a suitable work surface.

(2) Install wiper linkage into wiper unit.

(3) Connect wire connectors to wiper motor.

(4) Place the wiper module into engine compart-

ment and connect wiper module wire connector to

engine wire harness (Fig. 7).

(5) Install the four backwall bolts and four brace

nuts to wiper module.

(6) Operate wiper motor and verify that the wiper

motor parks when wiper switch is turned OFF.

REAR WIPER ARM

REMOVAL

(1) Remove arm nut cap.

(2) Remove wiper arm nut.

(3) Pull wiper from pivot by rocking back and

forth.

INSTALLATION

(1) Verify that wipers are in parked position.

(2) Position arm on pivot.

(3) Install wiper arm nut and torque to 20 N´m

(175 in. lbs.).

REAR WIPER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear wiper arm. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/REAR WIPER ARM -

REMOVAL) in this section.

(3) Open liftgate.

(4) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(5) Disconnect wire connector from rear wiper

motor.

(6) Remove screws holding rear wiper motor to lift-

gate.

(7) Remove wiper motor from liftgate.

INSTALLATION

(1) Position the wiper motor in the liftgate.

(2) Install the retaining screws.

(3) Connect the wire harness connector.(4) Install the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

(5) Connect wire connector to rear wiper motor.

(6) Install the screws holding rear wiper motor to

liftgate.

(7) Install the wiper motor to the liftgate.

(8) Close the liftgate.

(9) Install the wiper arm. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/REAR WIPER ARM -

INSTALLATION) in this section.

(10) Connect the battery negative cable.

REAR WIPER/WASHER

SWITCH

DESCRIPTION

On Automatic Temperature Control (ATC) vehicles

only, the rear window wiper/washer switches are

located on the center bezel with the hazard and

heated seat switches (Fig. 3). They are not service-

able separately from the hazard and heated seat

switches. If defective, the entire switch assembly

must be replaced.

On Manual Temperature Control (MTC) vehicles

only, the rear window wiper/washer switch is located

on the HVAC control head (Fig. 4) attached to the

center bezel. They are not serviceable separately

from the control head. If found faulty, the entire

MTC head must be replaced.

Fig. 3 INSTRUMENT PANEL CENTER BEZEL

1 - TRIM BEZEL

2 - IN CAR TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8R - 10 WIPERS/WASHERSRS

FRONT WIPER MOTOR (Continued)

Page 1780 of 2339

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

WATER LEAKS........................1

WIND NOISE..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . . 9

SPECIFICATIONS

TORQUE............................10

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......40

EXTERIOR.............................45

HOOD.................................62

INSTRUMENT PANEL.....................65

INTERIOR..............................78

PAINT................................100

SEATS...............................102

STATIONARY GLASS....................161

WEATHERSTRIP/SEALS..................166

SUNROOF.............................169

BODY STRUCTURE.....................177

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

RSBODY23-1

Page 1819 of 2339

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

EXTERIOR HANDLE

REMOVAL.............................40

INSTALLATION.........................40

HINGE

REMOVAL.............................40

INSTALLATION.........................40

LATCH

REMOVAL.............................41

INSTALLATION.........................41

LATCH STRIKER

REMOVAL.............................41

INSTALLATION.........................42

LIFTGATE

REMOVAL.............................42

INSTALLATION.........................42

LOCK CYLINDER

REMOVAL.............................42INSTALLATION.........................42

SUPPORT CYLINDER

REMOVAL.............................42

INSTALLATION.........................43

TRIM PANEL

REMOVAL.............................43

INSTALLATION.........................43

SLAM BUMPER

REMOVAL

REMOVAL - BODY SIDE................44

REMOVAL - LIFTGATE SIDE.............44

INSTALLATION

INSTALLATION - BODY SIDE............44

INSTALLATION - LIFTGATE SIDE.........44

EXTERIOR HANDLE

REMOVAL

(1) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the exterior handle electrical con-

nectors.

(3) Remove the two outer screws and the two inner

screws.

(4) Remove the exterior handle/license plate light

assembly.

INSTALLATION

(1) Route the exterior handle electrical connector

through the door and position handle.

(2) Install the two out screws and tighten to 3 N´m

(22 in. lbs.).

(3) Install the two inner bolts and tighten to 5

N´m (40 in. lbs.).

(4) Connect the electrical connector.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

HINGE

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Apply several layers of duct tape on the outside

of to roof across the gap to the lift gate to hold the

liftgate in position.

(4) Remove bolts attaching liftgate hinge to roof

header.

(5) Disconnect VTSS switch from the body har-

ness.

(6) Remove bolts attaching hinge to liftgate (Fig.

1).

(7) Remove hinge from vehicle.

INSTALLATION

(1) If necessary, paint replacement hinge before

installation.

(2) Place hinge in position on vehicle.

(3) Align hinge to marks on liftgate.

(4) Install bolts attaching hinge to liftgate (Fig. 1).

Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(5) Align hinge to marks on roof header.

23 - 40 DECKLID/HATCH/LIFTGATE/TAILGATERS

Page 1820 of 2339

(6) Install bolts attaching liftgate hinge to roof

header. Tighten outer two bolts to 33 N´m (24 ft. lbs.)

torque. The sheet medal screw at center 12 N´m (105

in. lbs.)

(7) Remove duct tape from roof and liftgate.

(8) Verify liftgate alignment. Refer to Liftgate

Remove and Installation for proper gap measure-

ments.

LATCH

REMOVAL

(1) Remove liftgate trim panel.

(2) Disengage outside key cylinder link from clip

on latch.

(3) Disconnect wire connector from liftgate latch

(Fig. 2).

(4) Remove screws attaching latch to liftgate.

(5) Remove latch from vehicle.

INSTALLATION

(1) Engage key cylinder link and place latch in

position on vehicle.

(2) Install screws attaching latch to liftgate.

Tighten to 11 N´m (95 in. lbs.) torque.

(3) Connect wire connector to liftgate latch.

(4) Verify liftgate fit and operation. Adjust as nec-

essary.

(5) Install liftgate trim panel.

LATCH STRIKER

REMOVAL

(1) Open liftgate.

(2) Mark outline of striker on sill to aid installa-

tion.

(3) Remove screws attaching striker to sill (Fig. 3).

(4) Remove striker from vehicle.

Fig. 1 LIFTGATE HINGE

1 - LIFTGATE

2 - HINGE

3 - REAR ROOF HEADER

Fig. 2 LIFTGATE LATCH

1 - ELECTRICAL CONNECTOR

2 - LIFTGATE LATCH

3 - SCREW

4 - LIFTGATE

5 - LIFTGATE LOCK CYLINDER

Fig. 3 LIFTGATE LATCH STRIKER

1 - LIFTGATE SILL

2 - LIFTGATE STRIKER

RSDECKLID/HATCH/LIFTGATE/TAILGATE23-41

HINGE (Continued)