battery location CHRYSLER CARAVAN 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 469 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Inoperative fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism.

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or overhead

console switch does not

operate power sliding doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Inoperative latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Inoperative BCM Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Inoperative key fob Verify inoperative key fob by trying other key

fob functions

Replace key fob battery

Reprogram key fob

Replace key fob if necessary

Inoperative sliding door control module Disconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage, replace

assembly

8N - 46 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 470 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative hold open latch striker Replace hold open latch striker, if necessary

High inside/outside opening

effortInoperative latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Binding or sticking of components Establish location of binding and replace

necessary components

Door continues to cinch

closed during power modeInoperative latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Door continues to open

during power mode (runaway

motor)Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative drive assembly Remove lower drive unit and check for no

drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door opens very slowly Inoperative door motor assembly Check wire/cable connections

Replace motor assembly, if necessary

RSPOWER SLIDING DOOR SYSTEM8N-47

POWER SLIDING DOOR SYSTEM (Continued)

Page 480 of 2339

LOWER DRIVE UNIT TRACK &

RACK

DESCRIPTION

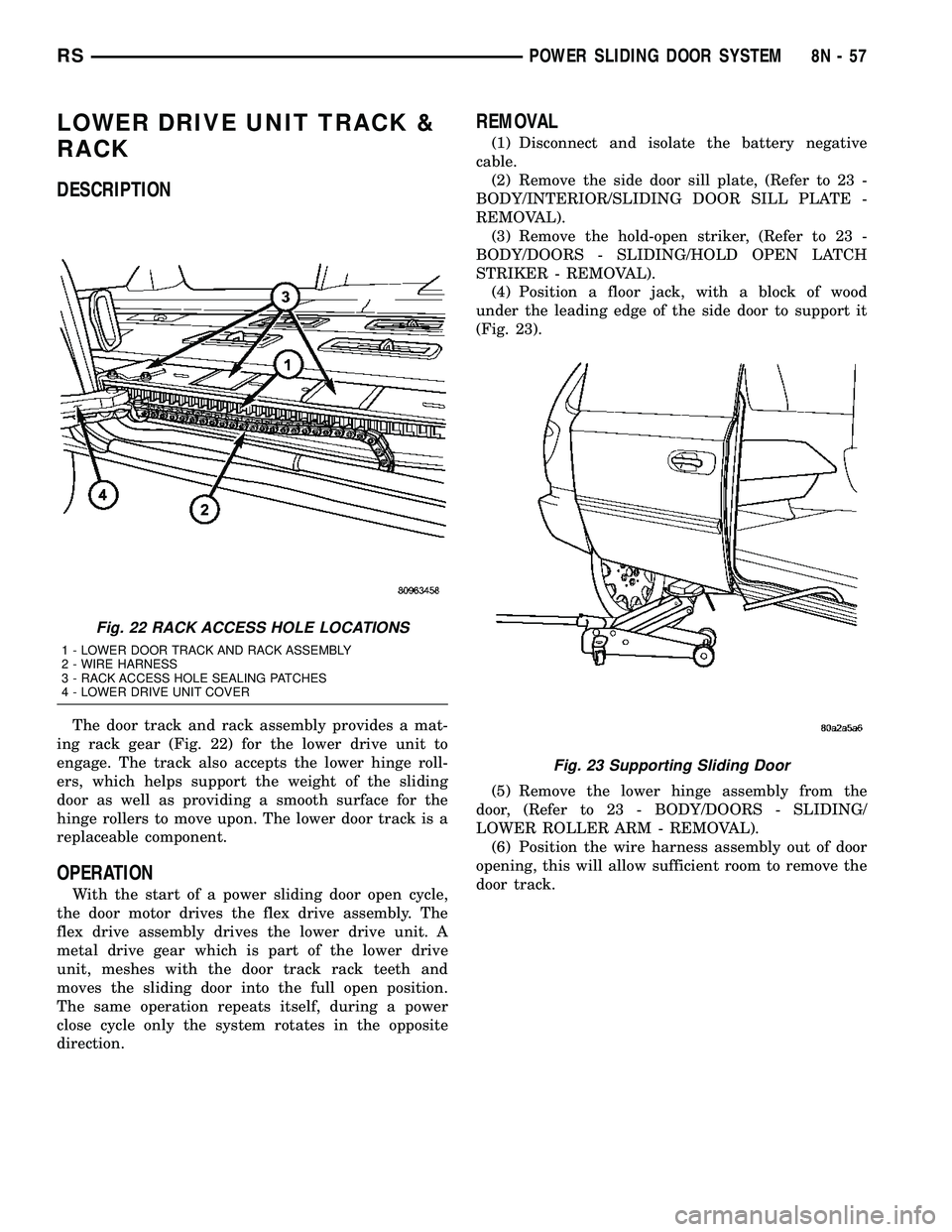

The door track and rack assembly provides a mat-

ing rack gear (Fig. 22) for the lower drive unit to

engage. The track also accepts the lower hinge roll-

ers, which helps support the weight of the sliding

door as well as providing a smooth surface for the

hinge rollers to move upon. The lower door track is a

replaceable component.

OPERATION

With the start of a power sliding door open cycle,

the door motor drives the flex drive assembly. The

flex drive assembly drives the lower drive unit. A

metal drive gear which is part of the lower drive

unit, meshes with the door track rack teeth and

moves the sliding door into the full open position.

The same operation repeats itself, during a power

close cycle only the system rotates in the opposite

direction.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the side door sill plate, (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL).

(3) Remove the hold-open striker, (Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - REMOVAL).

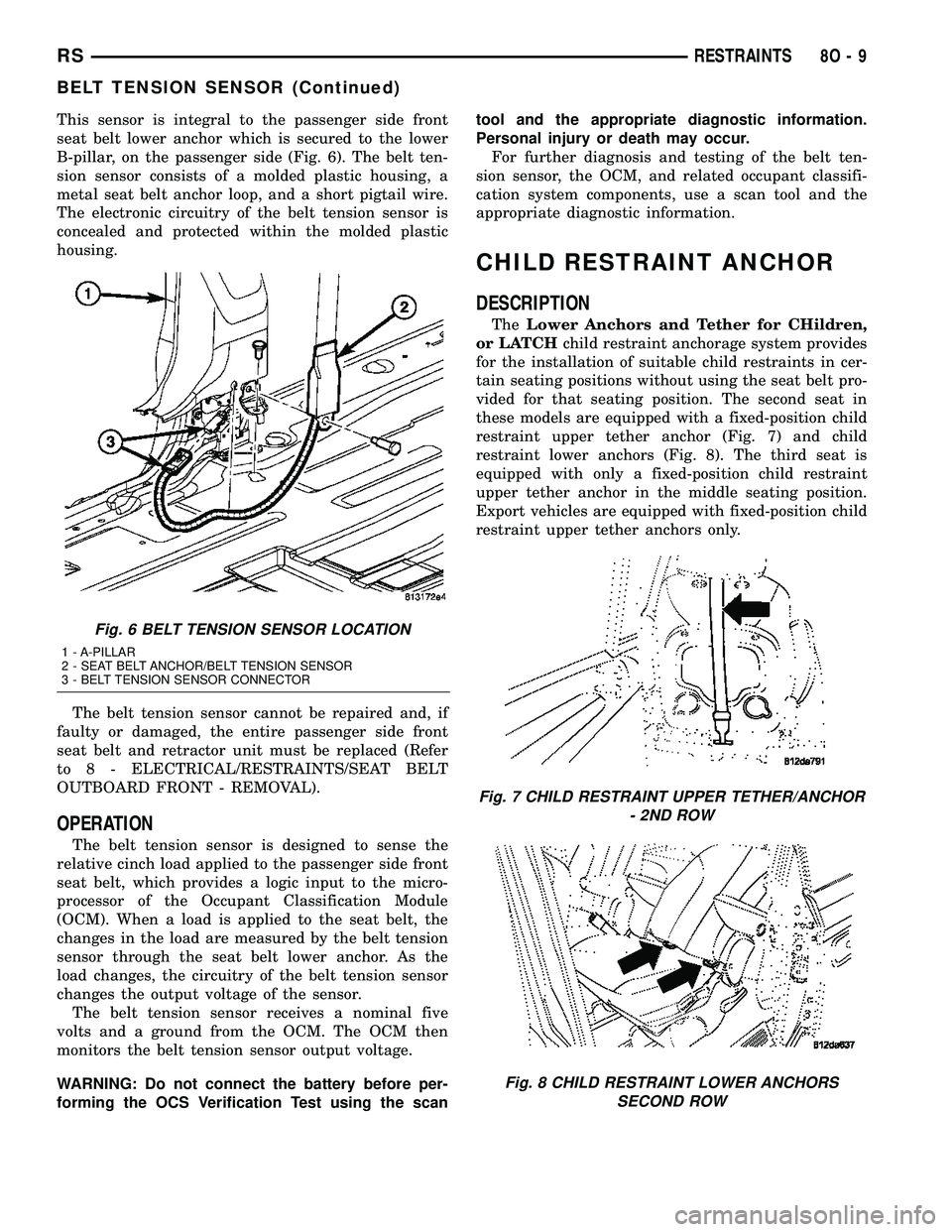

(4) Position a floor jack, with a block of wood

under the leading edge of the side door to support it

(Fig. 23).

(5) Remove the lower hinge assembly from the

door, (Refer to 23 - BODY/DOORS - SLIDING/

LOWER ROLLER ARM - REMOVAL).

(6) Position the wire harness assembly out of door

opening, this will allow sufficient room to remove the

door track.

Fig. 22 RACK ACCESS HOLE LOCATIONS

1 - LOWER DOOR TRACK AND RACK ASSEMBLY

2 - WIRE HARNESS

3 - RACK ACCESS HOLE SEALING PATCHES

4 - LOWER DRIVE UNIT COVER

Fig. 23 Supporting Sliding Door

RSPOWER SLIDING DOOR SYSTEM8N-57

Page 496 of 2339

This sensor is integral to the passenger side front

seat belt lower anchor which is secured to the lower

B-pillar, on the passenger side (Fig. 6). The belt ten-

sion sensor consists of a molded plastic housing, a

metal seat belt anchor loop, and a short pigtail wire.

The electronic circuitry of the belt tension sensor is

concealed and protected within the molded plastic

housing.

The belt tension sensor cannot be repaired and, if

faulty or damaged, the entire passenger side front

seat belt and retractor unit must be replaced (Refer

to 8 - ELECTRICAL/RESTRAINTS/SEAT BELT

OUTBOARD FRONT - REMOVAL).

OPERATION

The belt tension sensor is designed to sense the

relative cinch load applied to the passenger side front

seat belt, which provides a logic input to the micro-

processor of the Occupant Classification Module

(OCM). When a load is applied to the seat belt, the

changes in the load are measured by the belt tension

sensor through the seat belt lower anchor. As the

load changes, the circuitry of the belt tension sensor

changes the output voltage of the sensor.

The belt tension sensor receives a nominal five

volts and a ground from the OCM. The OCM then

monitors the belt tension sensor output voltage.

WARNING: Do not connect the battery before per-

forming the OCS Verification Test using the scantool and the appropriate diagnostic information.

Personal injury or death may occur.

For further diagnosis and testing of the belt ten-

sion sensor, the OCM, and related occupant classifi-

cation system components, use a scan tool and the

appropriate diagnostic information.

CHILD RESTRAINT ANCHOR

DESCRIPTION

TheLower Anchors and Tether for CHildren,

or LATCHchild restraint anchorage system provides

for the installation of suitable child restraints in cer-

tain seating positions without using the seat belt pro-

vided for that seating position. The second seat in

these models are equipped with a fixed-position child

restraint upper tether anchor (Fig. 7) and child

restraint lower anchors (Fig. 8). The third seat is

equipped with only a fixed-position child restraint

upper tether anchor in the middle seating position.

Export vehicles are equipped with fixed-position child

restraint upper tether anchors only.

Fig. 6 BELT TENSION SENSOR LOCATION

1 - A-PILLAR

2 - SEAT BELT ANCHOR/BELT TENSION SENSOR

3 - BELT TENSION SENSOR CONNECTOR

Fig. 7 CHILD RESTRAINT UPPER TETHER/ANCHOR

- 2ND ROW

Fig. 8 CHILD RESTRAINT LOWER ANCHORS

SECOND ROW

RSRESTRAINTS8O-9

BELT TENSION SENSOR (Continued)

Page 501 of 2339

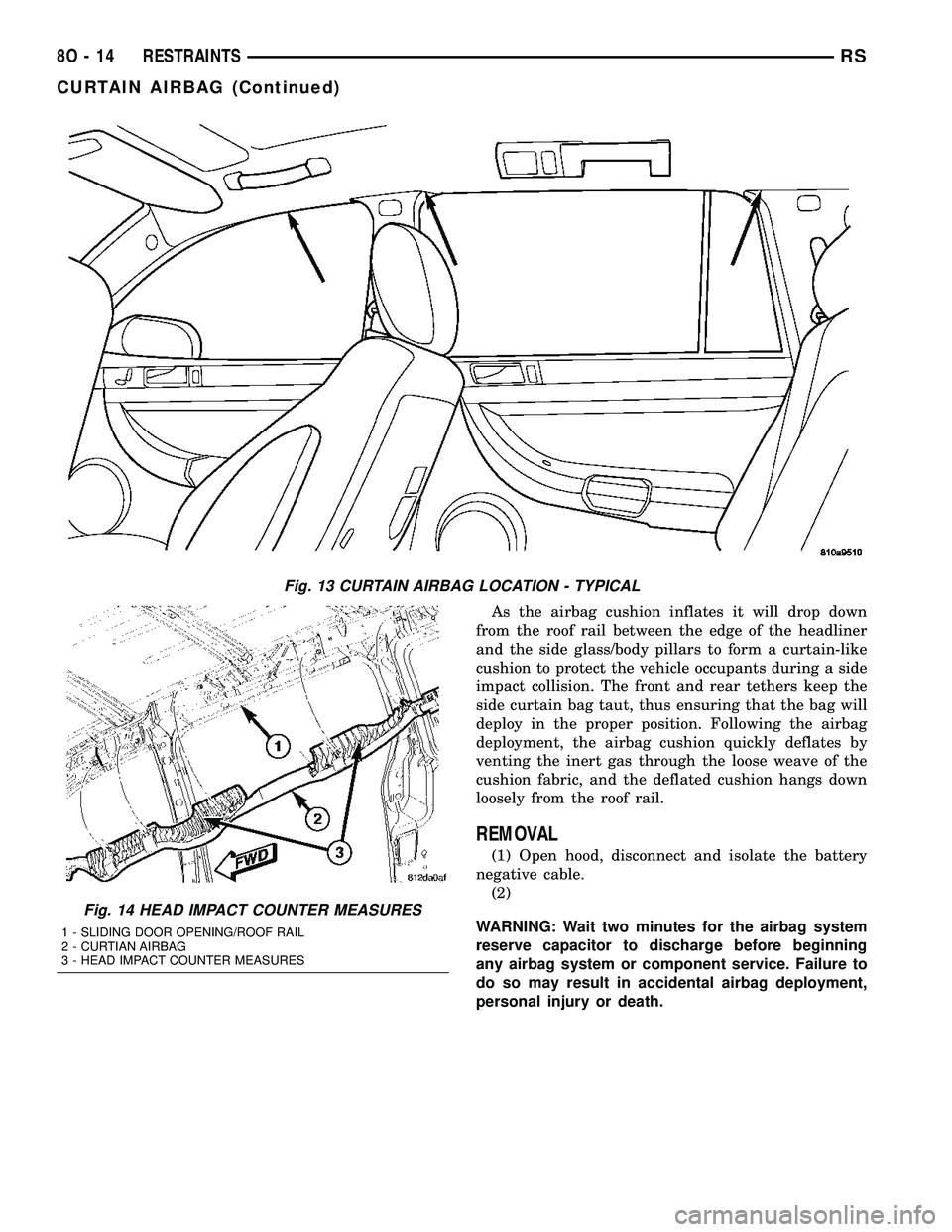

As the airbag cushion inflates it will drop down

from the roof rail between the edge of the headliner

and the side glass/body pillars to form a curtain-like

cushion to protect the vehicle occupants during a side

impact collision. The front and rear tethers keep the

side curtain bag taut, thus ensuring that the bag will

deploy in the proper position. Following the airbag

deployment, the airbag cushion quickly deflates by

venting the inert gas through the loose weave of the

cushion fabric, and the deflated cushion hangs down

loosely from the roof rail.

REMOVAL

(1) Open hood, disconnect and isolate the battery

negative cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

Fig. 13 CURTAIN AIRBAG LOCATION - TYPICAL

Fig. 14 HEAD IMPACT COUNTER MEASURES

1 - SLIDING DOOR OPENING/ROOF RAIL

2 - CURTIAN AIRBAG

3 - HEAD IMPACT COUNTER MEASURES

8O - 14 RESTRAINTSRS

CURTAIN AIRBAG (Continued)

Page 503 of 2339

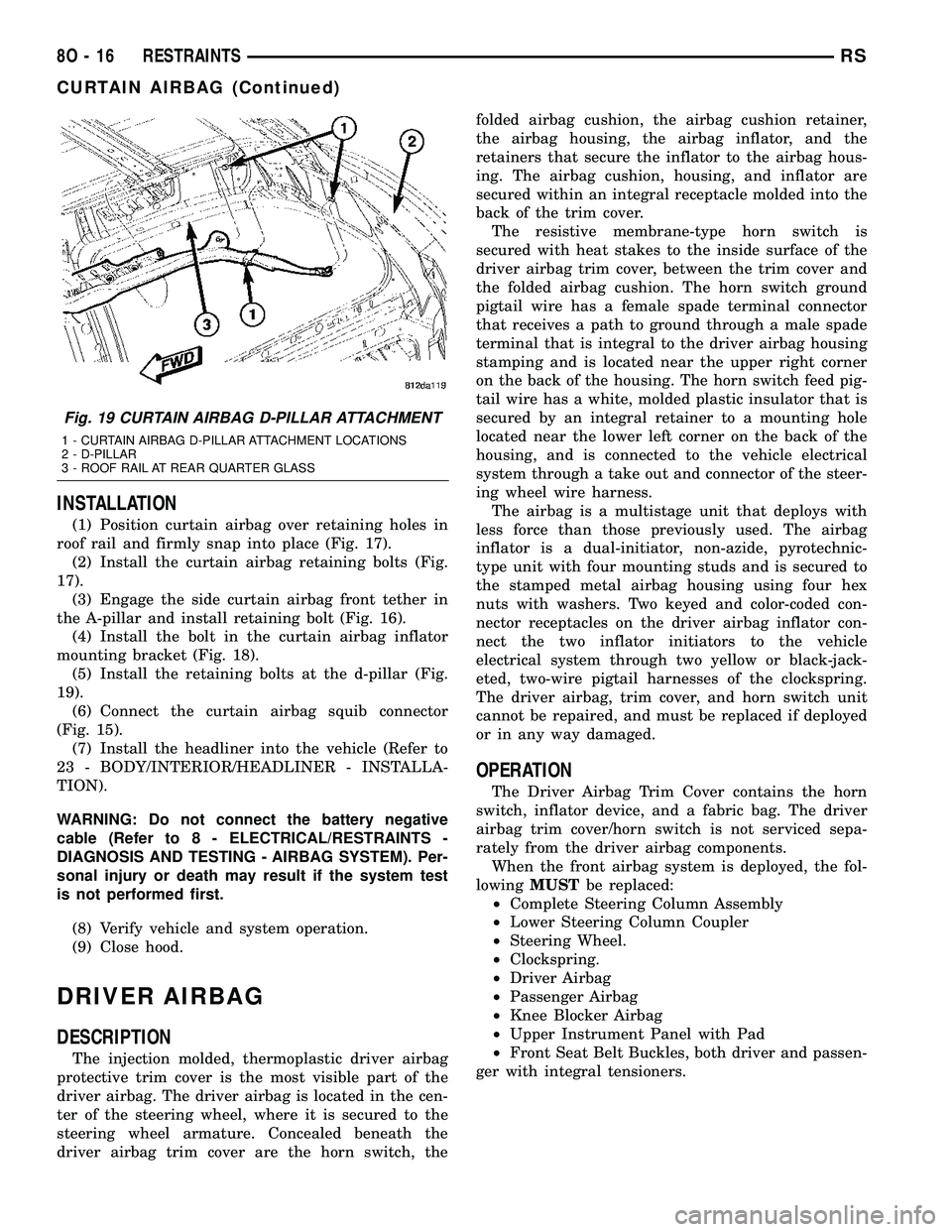

INSTALLATION

(1) Position curtain airbag over retaining holes in

roof rail and firmly snap into place (Fig. 17).

(2) Install the curtain airbag retaining bolts (Fig.

17).

(3) Engage the side curtain airbag front tether in

the A-pillar and install retaining bolt (Fig. 16).

(4) Install the bolt in the curtain airbag inflator

mounting bracket (Fig. 18).

(5) Install the retaining bolts at the d-pillar (Fig.

19).

(6) Connect the curtain airbag squib connector

(Fig. 15).

(7) Install the headliner into the vehicle (Refer to

23 - BODY/INTERIOR/HEADLINER - INSTALLA-

TION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(8) Verify vehicle and system operation.

(9) Close hood.

DRIVER AIRBAG

DESCRIPTION

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag. The driver airbag is located in the cen-

ter of the steering wheel, where it is secured to the

steering wheel armature. Concealed beneath the

driver airbag trim cover are the horn switch, thefolded airbag cushion, the airbag cushion retainer,

the airbag housing, the airbag inflator, and the

retainers that secure the inflator to the airbag hous-

ing. The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover.

The resistive membrane-type horn switch is

secured with heat stakes to the inside surface of the

driver airbag trim cover, between the trim cover and

the folded airbag cushion. The horn switch ground

pigtail wire has a female spade terminal connector

that receives a path to ground through a male spade

terminal that is integral to the driver airbag housing

stamping and is located near the upper right corner

on the back of the housing. The horn switch feed pig-

tail wire has a white, molded plastic insulator that is

secured by an integral retainer to a mounting hole

located near the lower left corner on the back of the

housing, and is connected to the vehicle electrical

system through a take out and connector of the steer-

ing wheel wire harness.

The airbag is a multistage unit that deploys with

less force than those previously used. The airbag

inflator is a dual-initiator, non-azide, pyrotechnic-

type unit with four mounting studs and is secured to

the stamped metal airbag housing using four hex

nuts with washers. Two keyed and color-coded con-

nector receptacles on the driver airbag inflator con-

nect the two inflator initiators to the vehicle

electrical system through two yellow or black-jack-

eted, two-wire pigtail harnesses of the clockspring.

The driver airbag, trim cover, and horn switch unit

cannot be repaired, and must be replaced if deployed

or in any way damaged.

OPERATION

The Driver Airbag Trim Cover contains the horn

switch, inflator device, and a fabric bag. The driver

airbag trim cover/horn switch is not serviced sepa-

rately from the driver airbag components.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly

²Lower Steering Column Coupler

²Steering Wheel.

²Clockspring.

²Driver Airbag

²Passenger Airbag

²Knee Blocker Airbag

²Upper Instrument Panel with Pad

²Front Seat Belt Buckles, both driver and passen-

ger with integral tensioners.

Fig. 19 CURTAIN AIRBAG D-PILLAR ATTACHMENT

1 - CURTAIN AIRBAG D-PILLAR ATTACHMENT LOCATIONS

2 - D-PILLAR

3 - ROOF RAIL AT REAR QUARTER GLASS

8O - 16 RESTRAINTSRS

CURTAIN AIRBAG (Continued)

Page 506 of 2339

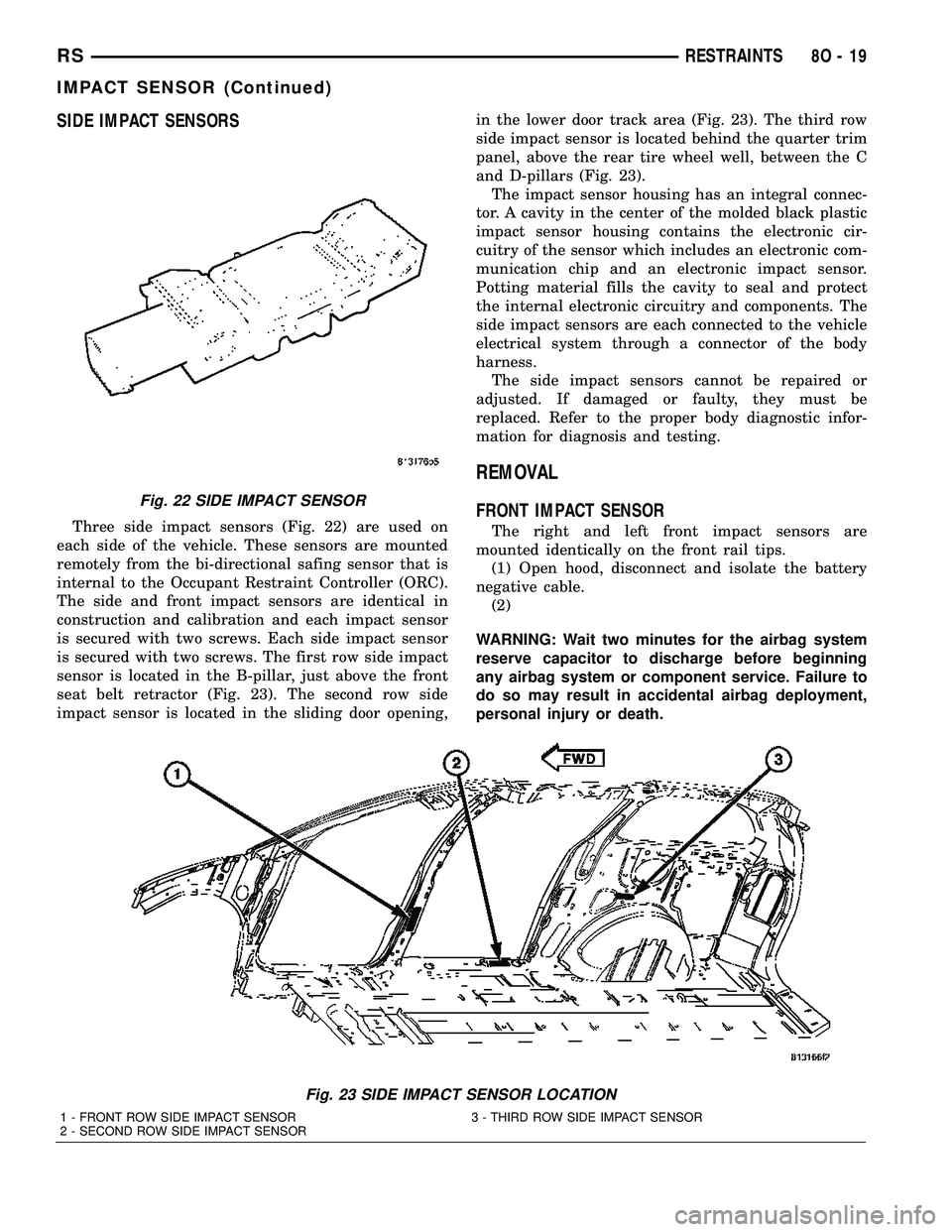

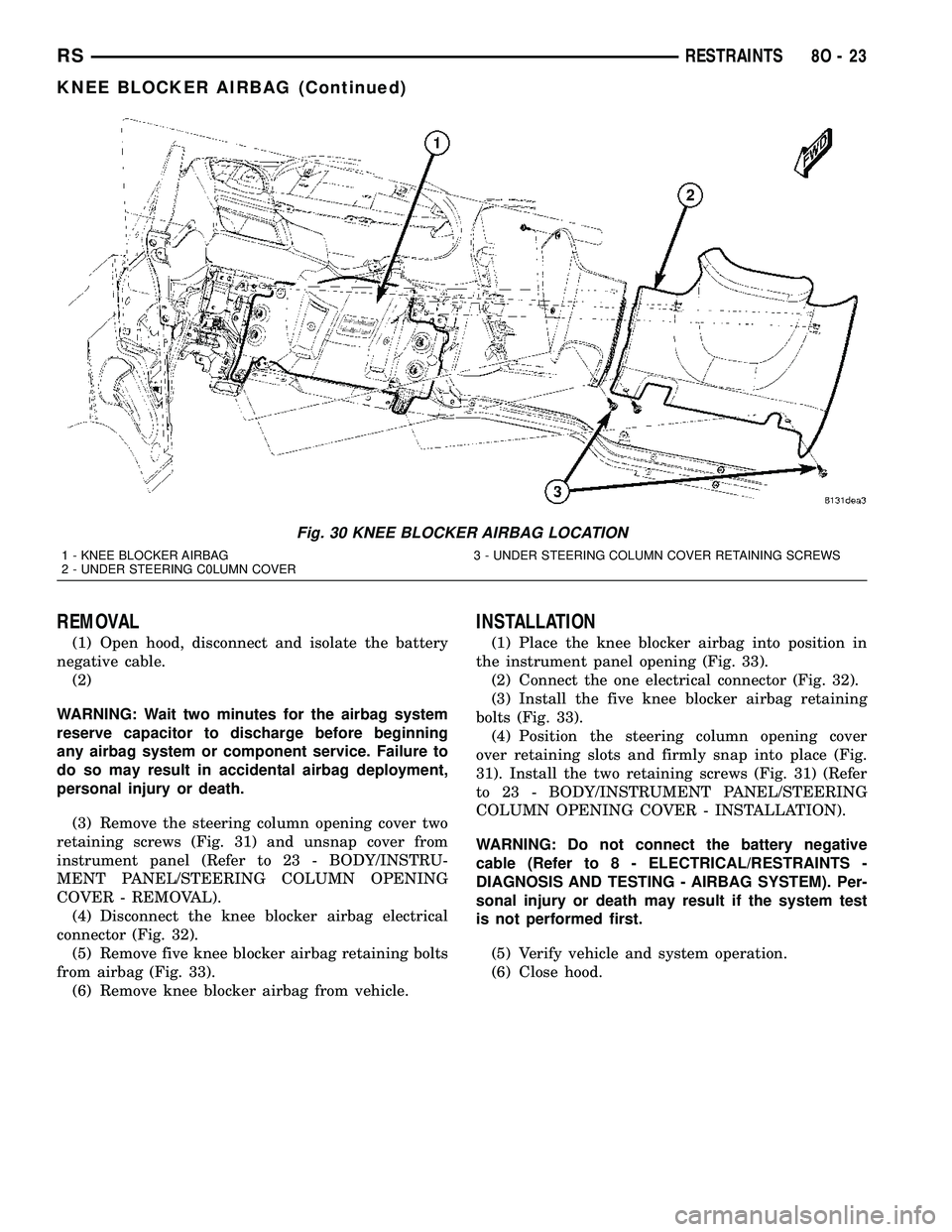

SIDE IMPACT SENSORS

Three side impact sensors (Fig. 22) are used on

each side of the vehicle. These sensors are mounted

remotely from the bi-directional safing sensor that is

internal to the Occupant Restraint Controller (ORC).

The side and front impact sensors are identical in

construction and calibration and each impact sensor

is secured with two screws. Each side impact sensor

is secured with two screws. The first row side impact

sensor is located in the B-pillar, just above the front

seat belt retractor (Fig. 23). The second row side

impact sensor is located in the sliding door opening,in the lower door track area (Fig. 23). The third row

side impact sensor is located behind the quarter trim

panel, above the rear tire wheel well, between the C

and D-pillars (Fig. 23).

The impact sensor housing has an integral connec-

tor. A cavity in the center of the molded black plastic

impact sensor housing contains the electronic cir-

cuitry of the sensor which includes an electronic com-

munication chip and an electronic impact sensor.

Potting material fills the cavity to seal and protect

the internal electronic circuitry and components. The

side impact sensors are each connected to the vehicle

electrical system through a connector of the body

harness.

The side impact sensors cannot be repaired or

adjusted. If damaged or faulty, they must be

replaced. Refer to the proper body diagnostic infor-

mation for diagnosis and testing.

REMOVAL

FRONT IMPACT SENSOR

The right and left front impact sensors are

mounted identically on the front rail tips.

(1) Open hood, disconnect and isolate the battery

negative cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

Fig. 23 SIDE IMPACT SENSOR LOCATION

1 - FRONT ROW SIDE IMPACT SENSOR 3 - THIRD ROW SIDE IMPACT SENSOR

2 - SECOND ROW SIDE IMPACT SENSOR

Fig. 22 SIDE IMPACT SENSOR

RSRESTRAINTS8O-19

IMPACT SENSOR (Continued)

Page 510 of 2339

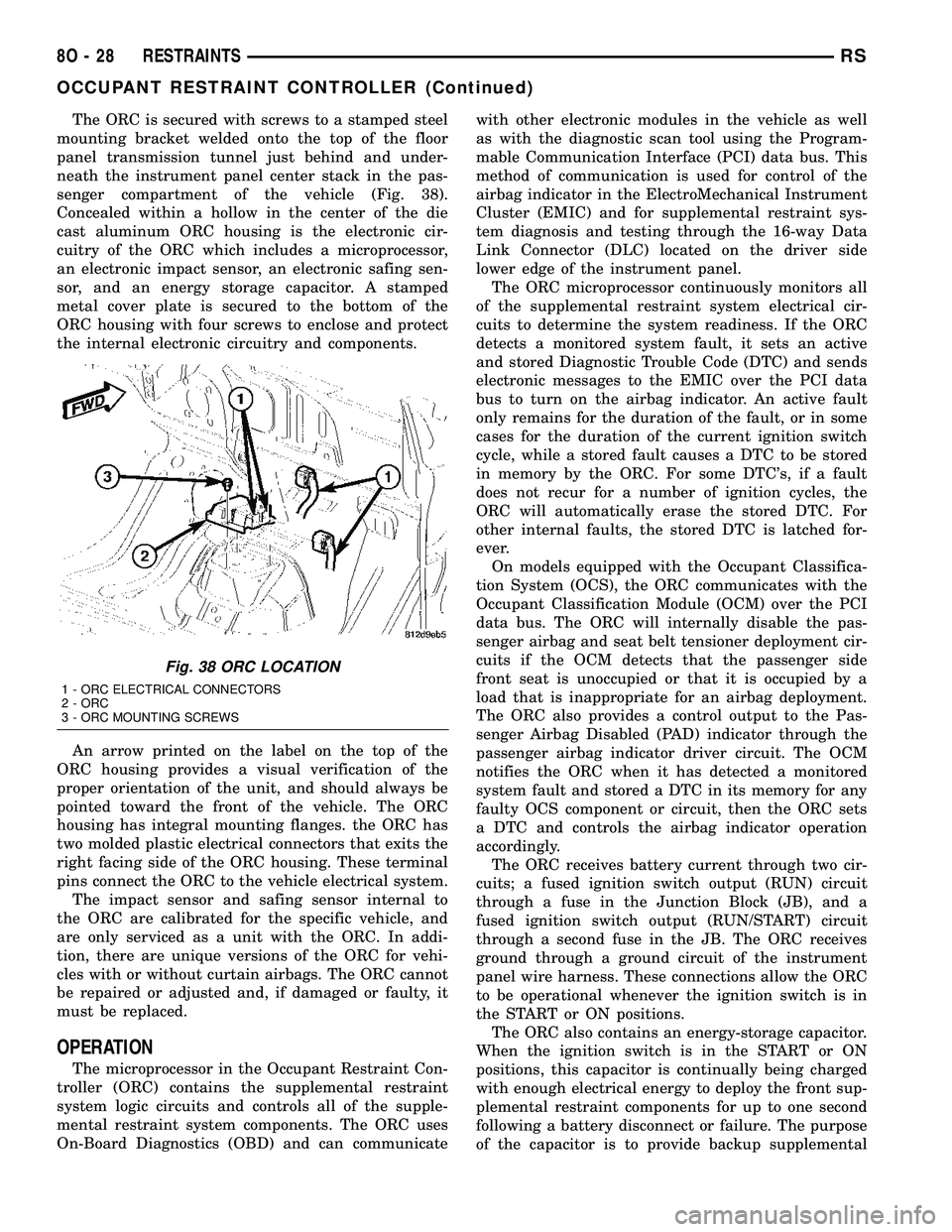

REMOVAL

(1) Open hood, disconnect and isolate the battery

negative cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Remove the steering column opening cover two

retaining screws (Fig. 31) and unsnap cover from

instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - REMOVAL).

(4) Disconnect the knee blocker airbag electrical

connector (Fig. 32).

(5) Remove five knee blocker airbag retaining bolts

from airbag (Fig. 33).

(6) Remove knee blocker airbag from vehicle.

INSTALLATION

(1) Place the knee blocker airbag into position in

the instrument panel opening (Fig. 33).

(2) Connect the one electrical connector (Fig. 32).

(3) Install the five knee blocker airbag retaining

bolts (Fig. 33).

(4) Position the steering column opening cover

over retaining slots and firmly snap into place (Fig.

31). Install the two retaining screws (Fig. 31) (Refer

to 23 - BODY/INSTRUMENT PANEL/STEERING

COLUMN OPENING COVER - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

Fig. 30 KNEE BLOCKER AIRBAG LOCATION

1 - KNEE BLOCKER AIRBAG 3 - UNDER STEERING COLUMN COVER RETAINING SCREWS

2 - UNDER STEERING C0LUMN COVER

RSRESTRAINTS8O-23

KNEE BLOCKER AIRBAG (Continued)

Page 515 of 2339

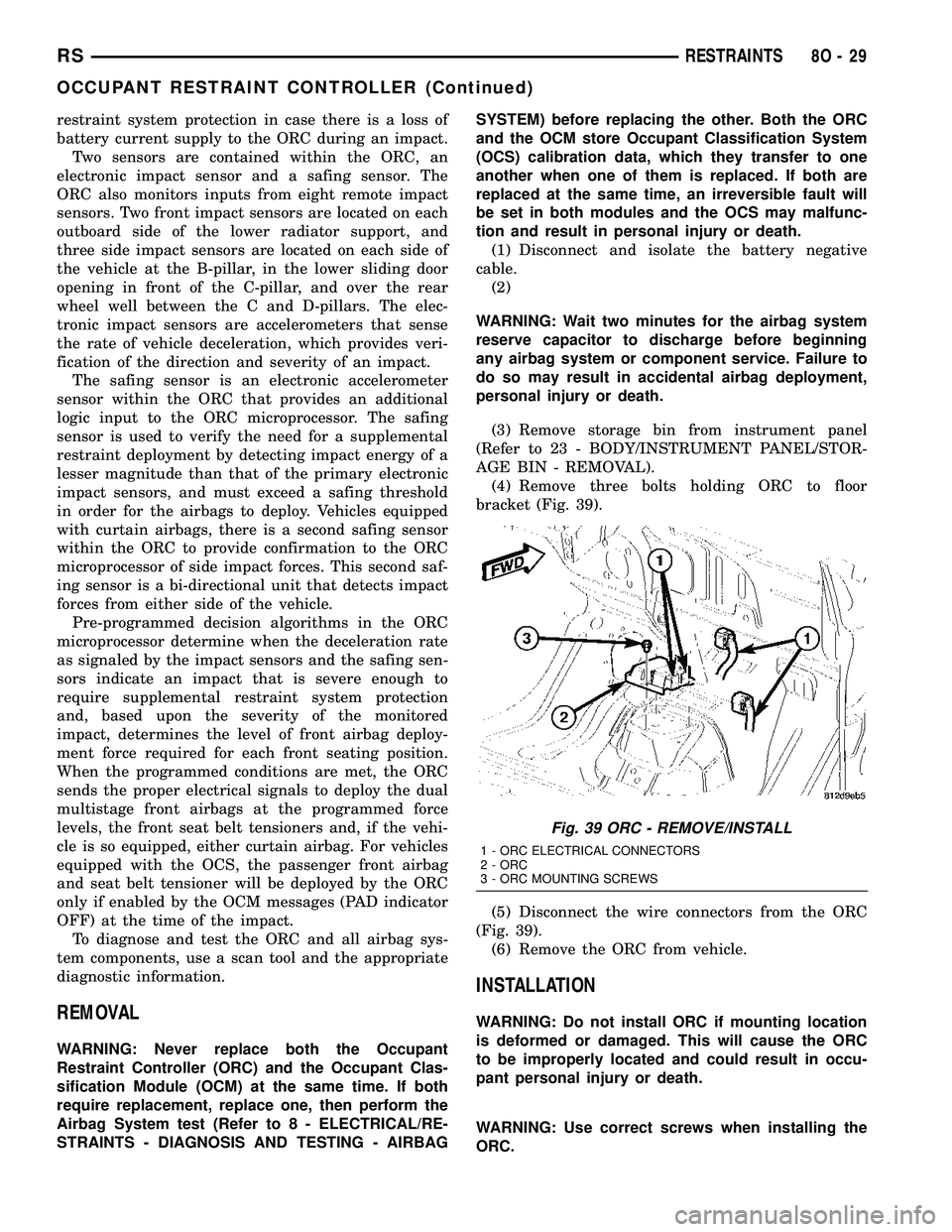

The ORC is secured with screws to a stamped steel

mounting bracket welded onto the top of the floor

panel transmission tunnel just behind and under-

neath the instrument panel center stack in the pas-

senger compartment of the vehicle (Fig. 38).

Concealed within a hollow in the center of the die

cast aluminum ORC housing is the electronic cir-

cuitry of the ORC which includes a microprocessor,

an electronic impact sensor, an electronic safing sen-

sor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ORC housing with four screws to enclose and protect

the internal electronic circuitry and components.

An arrow printed on the label on the top of the

ORC housing provides a visual verification of the

proper orientation of the unit, and should always be

pointed toward the front of the vehicle. The ORC

housing has integral mounting flanges. the ORC has

two molded plastic electrical connectors that exits the

right facing side of the ORC housing. These terminal

pins connect the ORC to the vehicle electrical system.

The impact sensor and safing sensor internal to

the ORC are calibrated for the specific vehicle, and

are only serviced as a unit with the ORC. In addi-

tion, there are unique versions of the ORC for vehi-

cles with or without curtain airbags. The ORC cannot

be repaired or adjusted and, if damaged or faulty, it

must be replaced.

OPERATION

The microprocessor in the Occupant Restraint Con-

troller (ORC) contains the supplemental restraint

system logic circuits and controls all of the supple-

mental restraint system components. The ORC uses

On-Board Diagnostics (OBD) and can communicatewith other electronic modules in the vehicle as well

as with the diagnostic scan tool using the Program-

mable Communication Interface (PCI) data bus. This

method of communication is used for control of the

airbag indicator in the ElectroMechanical Instrument

Cluster (EMIC) and for supplemental restraint sys-

tem diagnosis and testing through the 16-way Data

Link Connector (DLC) located on the driver side

lower edge of the instrument panel.

The ORC microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ORC

detects a monitored system fault, it sets an active

and stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the EMIC over the PCI data

bus to turn on the airbag indicator. An active fault

only remains for the duration of the fault, or in some

cases for the duration of the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the ORC. For some DTC's, if a fault

does not recur for a number of ignition cycles, the

ORC will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

On models equipped with the Occupant Classifica-

tion System (OCS), the ORC communicates with the

Occupant Classification Module (OCM) over the PCI

data bus. The ORC will internally disable the pas-

senger airbag and seat belt tensioner deployment cir-

cuits if the OCM detects that the passenger side

front seat is unoccupied or that it is occupied by a

load that is inappropriate for an airbag deployment.

The ORC also provides a control output to the Pas-

senger Airbag Disabled (PAD) indicator through the

passenger airbag indicator driver circuit. The OCM

notifies the ORC when it has detected a monitored

system fault and stored a DTC in its memory for any

faulty OCS component or circuit, then the ORC sets

a DTC and controls the airbag indicator operation

accordingly.

The ORC receives battery current through two cir-

cuits; a fused ignition switch output (RUN) circuit

through a fuse in the Junction Block (JB), and a

fused ignition switch output (RUN/START) circuit

through a second fuse in the JB. The ORC receives

ground through a ground circuit of the instrument

panel wire harness. These connections allow the ORC

to be operational whenever the ignition switch is in

the START or ON positions.

The ORC also contains an energy-storage capacitor.

When the ignition switch is in the START or ON

positions, this capacitor is continually being charged

with enough electrical energy to deploy the front sup-

plemental restraint components for up to one second

following a battery disconnect or failure. The purpose

of the capacitor is to provide backup supplemental

Fig. 38 ORC LOCATION

1 - ORC ELECTRICAL CONNECTORS

2 - ORC

3 - ORC MOUNTING SCREWS

8O - 28 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 516 of 2339

restraint system protection in case there is a loss of

battery current supply to the ORC during an impact.

Two sensors are contained within the ORC, an

electronic impact sensor and a safing sensor. The

ORC also monitors inputs from eight remote impact

sensors. Two front impact sensors are located on each

outboard side of the lower radiator support, and

three side impact sensors are located on each side of

the vehicle at the B-pillar, in the lower sliding door

opening in front of the C-pillar, and over the rear

wheel well between the C and D-pillars. The elec-

tronic impact sensors are accelerometers that sense

the rate of vehicle deceleration, which provides veri-

fication of the direction and severity of an impact.

The safing sensor is an electronic accelerometer

sensor within the ORC that provides an additional

logic input to the ORC microprocessor. The safing

sensor is used to verify the need for a supplemental

restraint deployment by detecting impact energy of a

lesser magnitude than that of the primary electronic

impact sensors, and must exceed a safing threshold

in order for the airbags to deploy. Vehicles equipped

with curtain airbags, there is a second safing sensor

within the ORC to provide confirmation to the ORC

microprocessor of side impact forces. This second saf-

ing sensor is a bi-directional unit that detects impact

forces from either side of the vehicle.

Pre-programmed decision algorithms in the ORC

microprocessor determine when the deceleration rate

as signaled by the impact sensors and the safing sen-

sors indicate an impact that is severe enough to

require supplemental restraint system protection

and, based upon the severity of the monitored

impact, determines the level of front airbag deploy-

ment force required for each front seating position.

When the programmed conditions are met, the ORC

sends the proper electrical signals to deploy the dual

multistage front airbags at the programmed force

levels, the front seat belt tensioners and, if the vehi-

cle is so equipped, either curtain airbag. For vehicles

equipped with the OCS, the passenger front airbag

and seat belt tensioner will be deployed by the ORC

only if enabled by the OCM messages (PAD indicator

OFF) at the time of the impact.

To diagnose and test the ORC and all airbag sys-

tem components, use a scan tool and the appropriate

diagnostic information.

REMOVAL

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAGSYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Disconnect and isolate the battery negative

cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Remove storage bin from instrument panel

(Refer to 23 - BODY/INSTRUMENT PANEL/STOR-

AGE BIN - REMOVAL).

(4) Remove three bolts holding ORC to floor

bracket (Fig. 39).

(5) Disconnect the wire connectors from the ORC

(Fig. 39).

(6) Remove the ORC from vehicle.

INSTALLATION

WARNING: Do not install ORC if mounting location

is deformed or damaged. This will cause the ORC

to be improperly located and could result in occu-

pant personal injury or death.

WARNING: Use correct screws when installing the

ORC.

Fig. 39 ORC - REMOVE/INSTALL

1 - ORC ELECTRICAL CONNECTORS

2 - ORC

3 - ORC MOUNTING SCREWS

RSRESTRAINTS8O-29

OCCUPANT RESTRAINT CONTROLLER (Continued)