instrument cluster CHRYSLER CARAVAN 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1734 of 2339

SPEED SENSOR - OUTPUT

DESCRIPTION

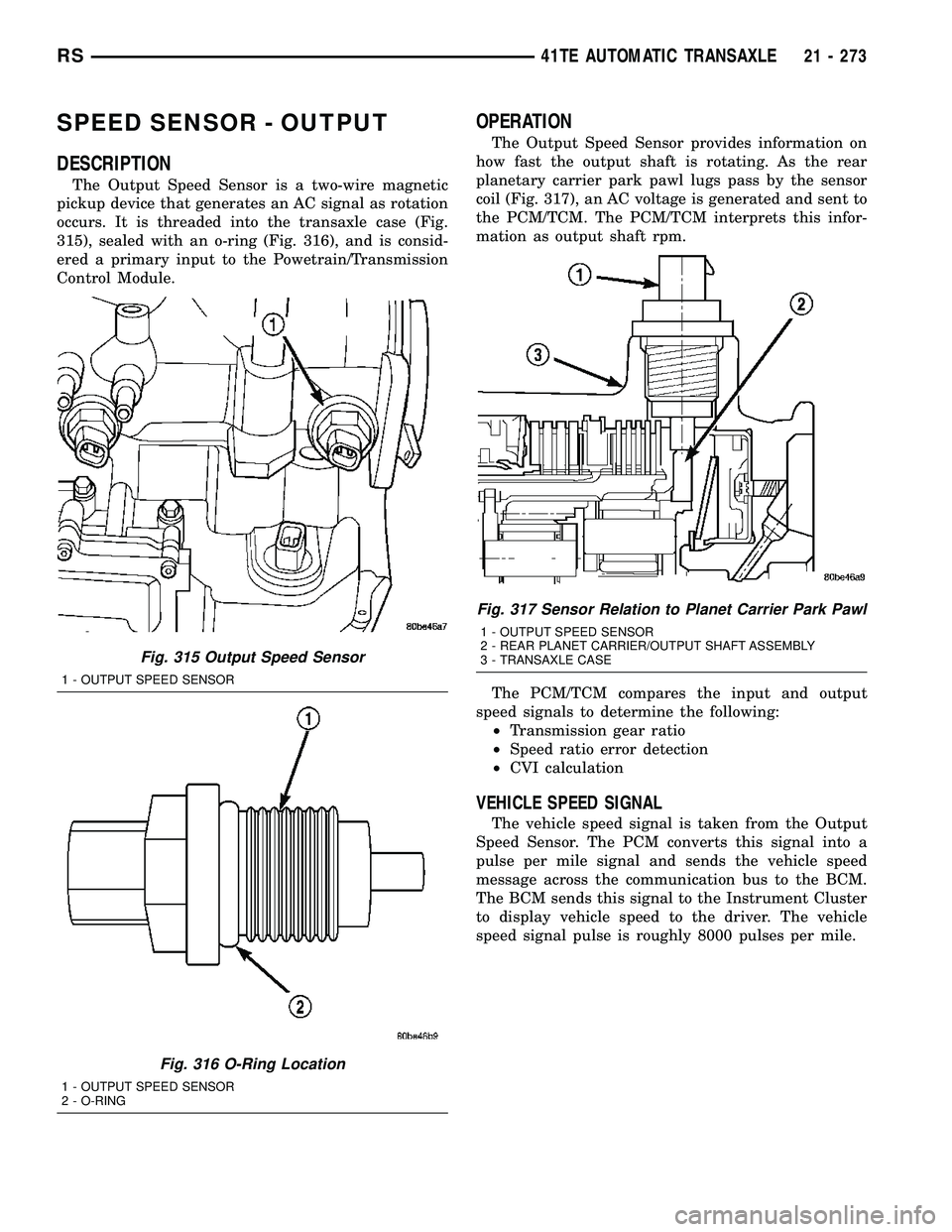

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

315), sealed with an o-ring (Fig. 316), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

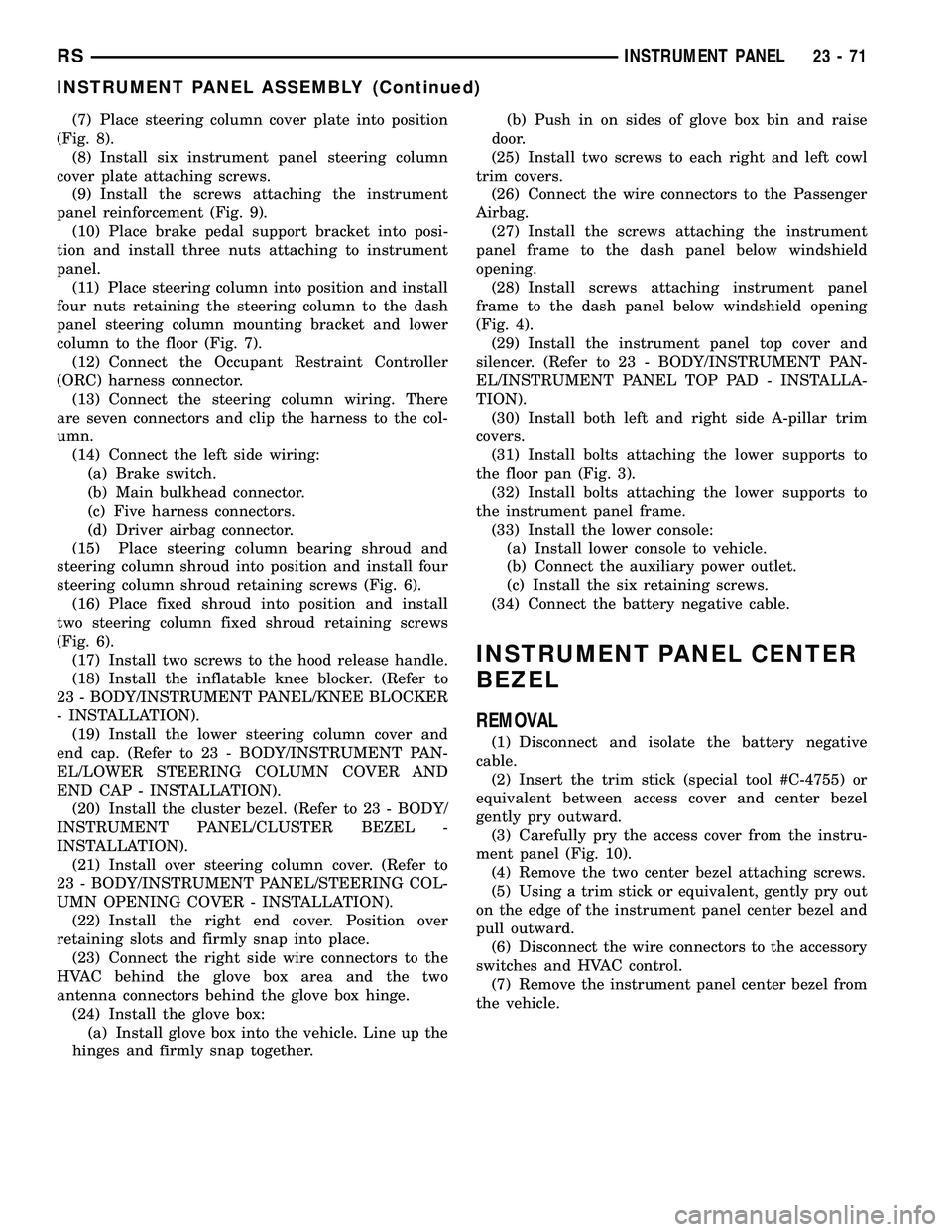

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 317), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

Fig. 315 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 316 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 317 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

RS41TE AUTOMATIC TRANSAXLE21 - 273

Page 1844 of 2339

INSTRUMENT PANEL

TABLE OF CONTENTS

page page

CLUSTER BEZEL

REMOVAL.............................65

INSTALLATION.........................65

CUP HOLDER

REMOVAL.............................65

INSTALLATION.........................65

GLOVE BOX

REMOVAL.............................66

INSTALLATION.........................66

GLOVE BOX LATCH

REMOVAL.............................66

INSTALLATION.........................66

GLOVE BOX LATCH STRIKER

REMOVAL.............................66

INSTALLATION.........................66

INSTRUMENT PANEL ASSEMBLY

REMOVAL.............................67

INSTALLATION.........................70

INSTRUMENT PANEL CENTER BEZEL

REMOVAL.............................71

INSTALLATION.........................72

INSTRUMENT PANEL RIGHT END CAP

REMOVAL.............................72INSTALLATION.........................72

INSTRUMENT PANEL TOP COVER

REMOVAL.............................72

INSTALLATION.........................72

LOWER CONSOLE

REMOVAL.............................73

INSTALLATION.........................73

LOWER INSTRUMENT PANEL

REMOVAL.............................73

INSTALLATION.........................73

LOWER STEERING COLUMN COVER

REMOVAL.............................74

INSTALLATION.........................74

BLOCKER- INFLATABLE KNEE

REMOVAL.............................75

INSTALLATION.........................75

OVER STEERING COLUMN COVER

REMOVAL.............................76

INSTALLATION.........................76

INSTRUMENT PANEL TOP PAD ASSEMBLY

REMOVAL.............................77

INSTALLATION.........................77

CLUSTER BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(3) Remove the four bezel attaching screws (Fig.

1).

(4) Tilt the steering column in the full down posi-

tion.

(5) Pull rearward on the cluster bezel and remove.

INSTALLATION

(1) Maneuver cluster bezel over steering column

and into position (Fig. 1).

(2) Install the four bezel attaching screws.

(3) Install the Over Steering Column Bezel by

positioning it over the retaining slots and firmly

snapping it into place.

(4) Connect the battery negative cable.

CUP HOLDER

REMOVAL

(1) Remove the screw access cover from the bottom

of the center bezel.

(2) Remove the center bezel attaching screws.

(3) Using a trim stick (special tool # C-4755) or

equivalent, gently pry out on the edge of the instru-

ment panel center bezel. Hang off to the side leaving

the accessory switches connected.

(4) Pull the cup holder assembly rearward to dis-

engage the rear guide studs from instrument panel

(Fig. 2).

(5) Remove the cup holder assembly from lower

instrument panel.

INSTALLATION

(1) Ensure the cup holder assembly is in the closed

position. The cup holder assembly must be installed

as an assembly to ensure proper track position.

(2) Place the cup holder assembly into position in

the lower instrument panel and slide into opening

until the rear guide struts snap into place (Fig. 2).

(3) Install the center bezel.

RSINSTRUMENT PANEL23-65

Page 1845 of 2339

(4) Install the center bezel attaching screws

(5) Install the screw access cover to the bottom of

the center bezel.

GLOVE BOX

REMOVAL

(1) Open glove box.

(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

INSTALLATION

(1) Place glove box in position.

(2) Engage hinge hooks into instrument panel and

pivot glove box upward.

(3) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(4) Close glove box door.

GLOVE BOX LATCH

REMOVAL

(1) Open glove box.

(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

(5) Remove the assembly screws.

(6) Disassemble the glove box.

(7) Separate the latch from the glove box assembly.

INSTALLATION

(1) Install the latch onto the glove box assembly.

(2) Assemble the glove box.

(3) Install the assembly screws.

(4) Engage hinge hooks into instrument panel and

pivot glove box upward.

(5) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(6) Close glove box door.

GLOVE BOX LATCH STRIKER

REMOVAL

(1) Open glove box door.

(2) Remove screws holding lock striker to instru-

ment panel.

(3) Remove glove box latch striker.

INSTALLATION

(1) Install the glove box latch striker.

(2) Install the screws holding latch striker to

instrument panel.

(3) Close glove box door.

Fig. 1 INSTRUMENT PANEL CLUSTER BEZEL

1 - WIRE CONNECTOR

2 - SPEEDOMETER

3 - ATTACHING SCREW(S)

4 - INSTRUMENT PANEL CLUSTER BEZEL

5 - INSTRUMENT PANEL

6 - CENTER STACK FILLER BEZEL

7 - CUP HOLDER AND TRAY

Fig. 2 TRAY CUP HOLDER

1 - WIRE CONNECTOR

2 - CENTER SWITCH AND BEZEL ASSEMBLY

3 - ATTACHING SCREW(S)

4 - TRAY AND CUP HOLDER

23 - 66 INSTRUMENT PANELRS

CUP HOLDER (Continued)

Page 1847 of 2339

(13) Remove the right end cover by pulling out-

board.

(14) Remove the right side A-pillar retaining bolts

(Fig. 5). There are two 13 mm bolts and one 10 mm

bolt.

(15) Loosen the right side cowl side roll down bolt.

(16) Remove over steering column cover. (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(17) Remove the cluster bezel. (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(18) Remove the lower steering column cover and

end cap. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/LOWER STEERING COLUMN COVER -

REMOVAL)

(19) Remove the inflatable knee blocker. (Refer to

23 - BODY/INSTRUMENT PANEL/INFLATABLE

KNEE BLOCKER - REMOVAL)(20) Remove the two screws to the hood release

handle.

(21) Remove the two steering column fixed shroud

retaining screws (Fig. 6).

(22) Remove the four steering column shroud

retaining screws. Separate the steering column bear-

ing shroud and steering column shroud and remove

from vehicle (Fig. 6).

(23) Disconnect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(24) Disconnect the steering column wiring. There

are seven connectors and then unclip the harness

from the column.

(25) Disconnect the Occupant Restraint Controller

(ORC) harness connector.

Fig. 4 INSTRUMENT PANEL REMOVAL

1 - INSTRUMENT PANEL

2 - SIX ATTACHING SCREWS

3 - 13 mm BOLT - TWO ON EACH SIDE4 - ROLL DOWN BRACKET

5 - 10 mm BOLT - STARTING BOLT ONE EACH SIDE

23 - 68 INSTRUMENT PANELRS

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1850 of 2339

(7) Place steering column cover plate into position

(Fig. 8).

(8) Install six instrument panel steering column

cover plate attaching screws.

(9) Install the screws attaching the instrument

panel reinforcement (Fig. 9).

(10) Place brake pedal support bracket into posi-

tion and install three nuts attaching to instrument

panel.

(11) Place steering column into position and install

four nuts retaining the steering column to the dash

panel steering column mounting bracket and lower

column to the floor (Fig. 7).

(12) Connect the Occupant Restraint Controller

(ORC) harness connector.

(13) Connect the steering column wiring. There

are seven connectors and clip the harness to the col-

umn.

(14) Connect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(15) Place steering column bearing shroud and

steering column shroud into position and install four

steering column shroud retaining screws (Fig. 6).

(16) Place fixed shroud into position and install

two steering column fixed shroud retaining screws

(Fig. 6).

(17) Install two screws to the hood release handle.

(18) Install the inflatable knee blocker. (Refer to

23 - BODY/INSTRUMENT PANEL/KNEE BLOCKER

- INSTALLATION).

(19) Install the lower steering column cover and

end cap. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/LOWER STEERING COLUMN COVER AND

END CAP - INSTALLATION).

(20) Install the cluster bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(21) Install over steering column cover. (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - INSTALLATION).

(22) Install the right end cover. Position over

retaining slots and firmly snap into place.

(23) Connect the right side wire connectors to the

HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(24) Install the glove box:

(a) Install glove box into the vehicle. Line up the

hinges and firmly snap together.(b) Push in on sides of glove box bin and raise

door.

(25) Install two screws to each right and left cowl

trim covers.

(26) Connect the wire connectors to the Passenger

Airbag.

(27) Install the screws attaching the instrument

panel frame to the dash panel below windshield

opening.

(28) Install screws attaching instrument panel

frame to the dash panel below windshield opening

(Fig. 4).

(29) Install the instrument panel top cover and

silencer. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/INSTRUMENT PANEL TOP PAD - INSTALLA-

TION).

(30) Install both left and right side A-pillar trim

covers.

(31) Install bolts attaching the lower supports to

the floor pan (Fig. 3).

(32) Install bolts attaching the lower supports to

the instrument panel frame.

(33) Install the lower console:

(a) Install lower console to vehicle.

(b) Connect the auxiliary power outlet.

(c) Install the six retaining screws.

(34) Connect the battery negative cable.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the trim stick (special tool #C-4755) or

equivalent between access cover and center bezel

gently pry outward.

(3) Carefully pry the access cover from the instru-

ment panel (Fig. 10).

(4) Remove the two center bezel attaching screws.

(5) Using a trim stick or equivalent, gently pry out

on the edge of the instrument panel center bezel and

pull outward.

(6) Disconnect the wire connectors to the accessory

switches and HVAC control.

(7) Remove the instrument panel center bezel from

the vehicle.

RSINSTRUMENT PANEL23-71

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1856 of 2339

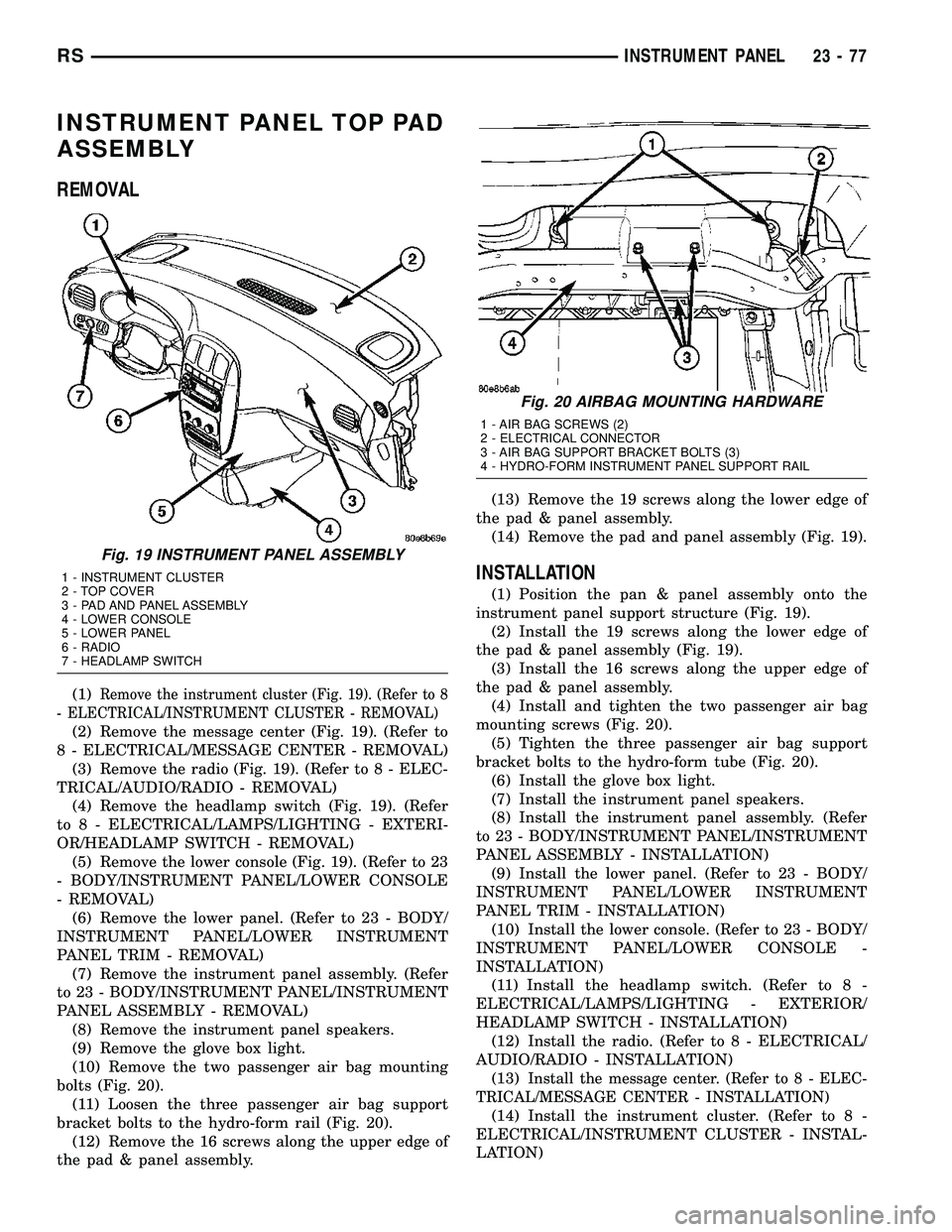

INSTRUMENT PANEL TOP PAD

ASSEMBLY

REMOVAL

(1)Remove the instrument cluster (Fig. 19). (Refer to 8

- ELECTRICAL/INSTRUMENT CLUSTER - REMOVAL)

(2) Remove the message center (Fig. 19). (Refer to

8 - ELECTRICAL/MESSAGE CENTER - REMOVAL)

(3) Remove the radio (Fig. 19). (Refer to 8 - ELEC-

TRICAL/AUDIO/RADIO - REMOVAL)

(4) Remove the headlamp switch (Fig. 19). (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/HEADLAMP SWITCH - REMOVAL)

(5) Remove the lower console (Fig. 19). (Refer to 23

- BODY/INSTRUMENT PANEL/LOWER CONSOLE

- REMOVAL)

(6) Remove the lower panel. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER INSTRUMENT

PANEL TRIM - REMOVAL)

(7) Remove the instrument panel assembly. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(8) Remove the instrument panel speakers.

(9) Remove the glove box light.

(10) Remove the two passenger air bag mounting

bolts (Fig. 20).

(11) Loosen the three passenger air bag support

bracket bolts to the hydro-form rail (Fig. 20).

(12) Remove the 16 screws along the upper edge of

the pad & panel assembly.(13) Remove the 19 screws along the lower edge of

the pad & panel assembly.

(14) Remove the pad and panel assembly (Fig. 19).

INSTALLATION

(1) Position the pan & panel assembly onto the

instrument panel support structure (Fig. 19).

(2) Install the 19 screws along the lower edge of

the pad & panel assembly (Fig. 19).

(3) Install the 16 screws along the upper edge of

the pad & panel assembly.

(4) Install and tighten the two passenger air bag

mounting screws (Fig. 20).

(5) Tighten the three passenger air bag support

bracket bolts to the hydro-form tube (Fig. 20).

(6) Install the glove box light.

(7) Install the instrument panel speakers.

(8) Install the instrument panel assembly. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

(9) Install the lower panel. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER INSTRUMENT

PANEL TRIM - INSTALLATION)

(10) Install the lower console. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER CONSOLE -

INSTALLATION)

(11) Install the headlamp switch. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP SWITCH - INSTALLATION)

(12) Install the radio. (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - INSTALLATION)

(13)

Install the message center. (Refer to 8 - ELEC-

TRICAL/MESSAGE CENTER - INSTALLATION)

(14) Install the instrument cluster. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - INSTAL-

LATION)

Fig. 19 INSTRUMENT PANEL ASSEMBLY

1 - INSTRUMENT CLUSTER

2 - TOP COVER

3 - PAD AND PANEL ASSEMBLY

4 - LOWER CONSOLE

5 - LOWER PANEL

6 - RADIO

7 - HEADLAMP SWITCH

Fig. 20 AIRBAG MOUNTING HARDWARE

1 - AIR BAG SCREWS (2)

2 - ELECTRICAL CONNECTOR

3 - AIR BAG SUPPORT BRACKET BOLTS (3)

4 - HYDRO-FORM INSTRUMENT PANEL SUPPORT RAIL

RSINSTRUMENT PANEL23-77

Page 2305 of 2339

BENCH SEAT RISER - 50/50 SPLIT -INSTALLATION ...................... 23-145

BENCH SEAT RISER - 50/50 SPLIT - REMOVAL ......................... 23-145

BENCH SEAT RISER - SECOND ROW - INSTALLATION ...................... 23-145

BENCH SEAT RISER - SECOND ROW - REMOVAL ......................... 23-145

BENCH SEAT RISER - THIRD ROW - INSTALLATION ...................... 23-145

BENCH SEAT RISER - THIRD ROW - REMOVAL ......................... 23-145

BENCH SEAT TRACK - INSTALLATION . . . 23-148

BENCH SEAT TRACK - REMOVAL .......23-148

BEZEL - INSTALLATION, CLUSTER .......23-65

BEZEL - INSTALLATION, INSTRUMENT PANEL CENTER ...................... 23-72

BEZEL - INSTALLATION, SLIDING DOOR STOP BUMPER ...................... 23-25

BEZEL - REMOVAL, CLUSTER ...........23-65

BEZEL - REMOVAL, INSTRUMENT PANEL CENTER ............................ 23-71

BEZEL - REMOVAL, SLIDING DOOR STOP BUMPER ...................... 23-25

BEZEL OUTLETS, INSTALLATION - FRONT CENTER ...................... 24-45

BEZEL OUTLETS, REMOVAL - FRONT CENTER ............................ 24-44

BIN - INSTALLATION, UNDER SEAT STORAGE .......................... 23-149

BIN - REMOVAL, UNDER SEAT STORAGE . 23-149

BIN GUIDE - INSTALLATION, UNDER SEAT STORAGE ..................... 23-150

BIN GUIDE - REMOVAL, UNDER SEAT STORAGE .......................... 23-150

BIN LOCK/LATCH - INSTALLATION, UNDER SEAT STORAGE ...............23-150

BIN LOCK/LATCH - REMOVAL, UNDER SEAT STORAGE ..................... 23-150

BLADDER & PRESSURE SENSOR - DESCRIPTION, SEAT WEIGHT ...........8O-43

BLADDER & PRESSURE SENSOR - OPERATION, SEAT WEIGHT ............8O-44

BLADES - CLEANING, WIPER ...........8R-13

BLADES - INSTALLATION, WIPER ........8R-13

BLADES - REMOVAL, WIPER ...........8R-13

BLEEDING - STANDARD PROCEDURE, ANTILOCK BRAKE SYSTEM ..............5-90

BLEEDING - STANDARD PROCEDURE, BASE BRAKE ..........................5-8

BLEEDING - STANDARD PROCEDURE, MASTER CYLINDER ................... 5-36

BLEND DOOR ACTUATOR - DESCRIPTION .................. 24-22,24-34

BLEND DOOR ACTUATOR - INSTALLATION .................. 24-22,24-35

BLEND DOOR ACTUATOR - OPERATION . . 24-22, 24-35

BLEND DOOR ACTUATOR - REMOVAL ....24-22,

24-35

BLOCK - CLEANING, ENGINE .......9-115,9-37

BLOCK - DESCRIPTION, BLOWER MOTOR RESISTOR ..............24-24,24-37

BLOCK - DESCRIPTION, ENGINE .....9-115,9-36

BLOCK - DESCRIPTION, NON-ABS JUNCTION ........................... 5-33

BLOCK - INSPECTION, ENGINE ......9-115,9-37

BLOCK - INSTALLATION, NON-ABS JUNCTION ........................... 5-34

BLOCK - OPERATION, BLOWER MOTOR RESISTOR ..................... 24-24,24-37

BLOCK - OPERATION, NON-ABS JUNCTION ........................... 5-33

BLOCK - REMOVAL, NON-ABS JUNCTION . . 5-34

BLOCK, DIAGNOSIS AND TESTING - FRONT BLOWER MOTOR RESISTOR ......24-25

BLOCK, DIAGNOSIS AND TESTING - REAR BLOWER MOTOR RESISTOR ......24-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-20

BLOCK HEATER - INSTALLATION, ENGINE ............................. 7-21

BLOCK HEATER - OPERATION, ENGINE ....7-20

BLOCK HEATER - REMOVAL, ENGINE ......7-21

BLOCK HEATER TESTING - DIAGNOSIS AND TESTING, ENGINE .................7-21

BLOCKER AIRBAG - DESCRIPTION, KNEE . 8O-22

BLOCKER AIRBAG - INSTALLATION, KNEE .............................. 8O-23BLOCKER AIRBAG - OPERATION, KNEE . . . 8O-22

BLOCKER AIRBAG - REMOVAL, KNEE

....8O-23

BLOCKER- INFLATABLE KNEE - INSTALLATION ....................... 23-75

BLOCKER- INFLATABLE KNEE - REMOVAL .......................... 23-75

BLOCKER LATCH - INSTALLATION, FUEL FILL DOOR ......................... 23-53

BLOCKER LATCH - REMOVAL, FUEL FILL DOOR ............................. 23-53

BLOCKER LATCH STRIKER - INSTALLATION, FUEL FILL DOOR ........23-53

BLOCKER LATCH STRIKER - REMOVAL, FUEL FILL DOOR ..................... 23-53

BLOCKER LOCKOUT LINK - INSTALLATION, FUEL FILL DOOR ........23-54

BLOCKER LOCKOUT LINK - REMOVAL, FUEL FILL DOOR ..................... 23-54

BLOWER MOTOR - DESCRIPTION . . 24-45,24-57

BLOWER MOTOR - DESCRIPTION, POWER MODULE .................... 24-30

BLOWER MOTOR - DESCRIPTION, POWER MODULE - REAR ..............24-40

BLOWER MOTOR - INSTALLATION, POWER MODULE .................... 24-31

BLOWER MOTOR - INSTALLATION, POWER MODULE - REAR ..............24-41

BLOWER MOTOR - OPERATION ....24-45,24-57

BLOWER MOTOR - OPERATION, POWER MODULE ........................... 24-30

BLOWER MOTOR - OPERATION, POWER MODULE - REAR ..................... 24-40

BLOWER MOTOR - REMOVAL, POWER MODULE ........................... 24-30

BLOWER MOTOR - REMOVAL, POWER MODULE - REAR ..................... 24-41

BLOWER MOTOR, DIAGNOSIS AND TESTING - FRONT .................... 24-46

BLOWER MOTOR, DIAGNOSIS AND TESTING - REAR ..................... 24-58

BLOWER MOTOR RELAY - DESCRIPTION . 24-23, 24-36

BLOWER MOTOR RELAY - INSTALLATION .................. 24-24,24-37

BLOWER MOTOR RELAY - OPERATION . . . 24-23, 24-36

BLOWER MOTOR RELAY - REMOVAL ....24-24,

24-37

BLOWER MOTOR RESISTOR BLOCK - DESCRIPTION .................. 24-24,24-37

BLOWER MOTOR RESISTOR BLOCK - OPERATION .................... 24-24,24-37

BLOWER MOTOR RESISTOR BLOCK, DIAGNOSIS AND TESTING - FRONT ......24-25

BLOWER MOTOR RESISTOR BLOCK, DIAGNOSIS AND TESTING - REAR .......24-38

BODY - ASSEMBLY, VALVE ......21-139,21-291

BODY - DESCRIPTION, THROTTLE .......14-39

BODY - DESCRIPTION, VALVE ....21-132,21-283

BODY - DISASSEMBLY, VALVE . . . 21-135,21-286

BODY - INSTALLATION, THROTTLE .......14-40

BODY - INSTALLATION, VALVE . . . 21-144,21-295

BODY - OPERATION, THROTTLE .........14-39

BODY - OPERATION, VALVE .....21-132,21-283

BODY - REMOVAL, THROTTLE ..........14-40

BODY - REMOVAL, VALVE .......21-133,21-284

BODY AND CABLE - DESCRIPTION, ANTENNA ........................... 8A-7

BODY AND CABLE - OPERATION, ANTENNA ........................... 8A-7

BODY AND CABLE, DIAGNOSIS AND TESTING - ANTENNA ................... 8A-8

BODY CONTROL MODULE - DESCRIPTION ........................ 8E-2

BODY CONTROL MODULE - INSTALLATION ........................ 8E-4

BODY CONTROL MODULE - OPERATION . . . 8E-3

BODY CONTROL MODULE - REMOVAL .....8E-4

BODY LUBRICATION, SPECIFICATIONS ....23-12

BODY OPENING DIMENSIONS - SPECIFICATIONS .................... 23-180

BODY PANEL REPAIR - STANDARD PROCEDURE, PLASTIC .................23-3

BODY SEALING LOCATIONS - FOLD-IN- FLOOR ONLY - SPECIFICATIONS ........23-209

BODY SEALING LOCATIONS - SPECIFICATIONS .................... 23-183

BODY SIDE - INSTALLATION ............23-44BODY SIDE - REMOVAL

...............23-44

BODY SIDE MOLDINGS - INSTALLATION . . 23-46

BODY SIDE MOLDINGS - REMOVAL ......23-45

BODY, SPECIAL TOOLS ................23-13

BOLSTER - INSTALLATION, QUARTER TRIM .............................. 23-95

BOLSTER - REMOVAL, QUARTER TRIM . . . 23-95

BOOSTER - DESCRIPTION, POWER BRAKE .............................. 5-45

BOOSTER - DIAGNOSIS AND TESTING, POWER BRAKE ....................... 5-46

BOOSTER - OPERATION, POWER BRAKE . . . 5-46

BOOT - INNER - INSTALLATION, CV ........3-7

BOOT - INNER - REMOVAL, CV ...........3-6

BOOT - OUTER - INSTALLATION, CV ......3-11

BOOT - OUTER - REMOVAL, CV ..........3-10

BORE FITTING - STANDARD PROCEDURE, PISTON TO CYLINDER ......9-44

BORE HONING - STANDARD PROCEDURE, CYLINDER ...........9-115,9-36

BOTTOM OF SEAT CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR

- INSTALLATION .................... 23-152

BOTTOM OF SEAT CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR

- REMOVAL ........................ 23-152

BOX - INSTALLATION, GLOVE ...........23-66

BOX - REMOVAL, GLOVE ..............23-66

BOX LAMP SWITCH - INSTALLATION, GLOVE ............................. 8L-22

BOX LAMP SWITCH - REMOVAL, GLOVE . . 8L-22

BOX LATCH - INSTALLATION, GLOVE .....23-66

BOX LATCH - REMOVAL, GLOVE .........23-66

BOX LATCH STRIKER - INSTALLATION, GLOVE ............................. 23-66

BOX LATCH STRIKER - REMOVAL, GLOVE ............................. 23-66

B-PILLAR - INSTALLATION, A-PILLAR- HEADER, OR ........................ 23-17

B-PILLAR - REMOVAL, A-PILLAR- HEADER, OR ........................ 23-17

B-PILLAR LOWER TRIM - INSTALLATION . . 23-80

B-PILLAR LOWER TRIM - REMOVAL .....23-79

B-PILLAR SWITCH - DESCRIPTION ......8N-52

B-PILLAR SWITCH - INSTALLATION ......8N-52

B-PILLAR SWITCH - OPERATION ........8N-52

B-PILLAR SWITCH - REMOVAL .........8N-52

B-PILLAR UPPER TRIM - INSTALLATION . . 23-80

B-PILLAR UPPER TRIM - REMOVAL ......23-80

BRACKET - DESCRIPTION, TRANSVERSE . . 8N-19

BRACKET - INSTALLATION, TRANSVERSE . 8N-19

BRACKET - OPERATION, TRANSVERSE . . . 8N-19

BRACKET - REMOVAL, TRANSVERSE .....8N-19

BRACKET, 2.4L ENGINE - A/C COMPRESSOR MOUNTING ........24-74,24-75

BRAKE - DESCRIPTION, CONTROLLER ANTILOCK ........................... 8E-4

BRAKE - INSTALLATION, CONTROLLER ANTILOCK ........................... 8E-6

BRAKE - INSTALLATION, LEVER - PARKING ............................ 5-76

BRAKE - INSTALLATION, SHOES - PARKING ............................ 5-84

BRAKE - INSTALLATION, SUPPORT PLATE - DRUM ....................... 5-61

BRAKE - OPERATION, CONTROLLER ANTILOCK ........................... 8E-5

BRAKE - REMOVAL, CONTROLLER ANTILOCK ........................... 8E-5

BRAKE - REMOVAL, LEVER - PARKING ....5-75

BRAKE - REMOVAL, SHOES - PARKING ....5-78

BRAKE - REMOVAL, SUPPORT PLATE - DRUM .............................. 5-61

BRAKE AUTOMATIC ADJUSTER - DIAGNOSIS AND TESTING, DRUM ........5-14

BRAKE AUTOMATIC ADJUSTER TENSION RELEASE - STANDARD PROCEDURE,

PARKING ............................ 5-63

BRAKE AUTOMATIC ADJUSTER TENSION RESET - STANDARD PROCEDURE,

PARKING ............................ 5-64

BRAKE BLEEDING - STANDARD PROCEDURE, BASE .....................5-8

BRAKE BOOSTER - DESCRIPTION, POWER ............................. 5-45

BRAKE BOOSTER - DIAGNOSIS AND TESTING, POWER ..................... 5-46

BRAKE BOOSTER - OPERATION, POWER . . . 5-46

4 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2308 of 2339

CHIRP PREFERENCE - STANDARDPROCEDURE, HORN .................. 8N-24

CIRCUIT, DIAGNOSIS AND TESTING - AMBIENT TEMPERATURE SENSOR ......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT RESISTANCE TEST - DIAGNOSIS AND TESTING, FEED ........8F-35

CIRCUIT TEST - DIAGNOSIS AND TESTING, CONTROL .................. 8F-33

CIRCUIT TEST - DIAGNOSIS AND TESTING, FEED ...................... 8F-36

CIRCUITS AND VALVES - OPERATION, HYDRAULIC .......................... 5-95

CIRCUITS, DESCRIPTION - NON- MONITORED ......................... 25-5

CLAMP - STANDARD PROCEDURE, HOSES .............................. 14-7

CLAMPS - DESCRIPTION, FUEL LINES/HOSES ........................ 14-7

CLAMPS - DESCRIPTION, HOSE ...........7-1

CLAMPS - OPERATION, HOSE .............7-2

CLASSIFICATION MODULE - DESCRIPTION, OCCUPANT .............8O-25

CLASSIFICATION MODULE - INSTALLATION, OCCUPANT ............8O-26

CLASSIFICATION MODULE - OPERATION, OCCUPANT ......................... 8O-25

CLASSIFICATION MODULE - REMOVAL, OCCUPANT ......................... 8O-26

CLEARANCE - STANDARD PROCEDURE, MEASURING CONNECTING ROD

BEARING ............................ 9-123

CLEARANCE USING PLASTIGAGE - STANDARD PROCEDURE, MEASURING

BEARING ........................ 9-12,9-86

CLOCKSPRING - DESCRIPTION .........8O-10

CLOCKSPRING - INSTALLATION .........8O-12

CLOCKSPRING - OPERATION ...........8O-11

CLOCKSPRING - REMOVAL ............8O-12

CLOCKSPRING CENTERING - STANDARD PROCEDURE ........................ 8O-11

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT .....8J-1

CLUSTER BEZEL - INSTALLATION ........23-65

CLUSTER BEZEL - REMOVAL ...........23-65

CLUSTER DIAGNOSIS - DIAGNOSIS AND TESTING ............................ 8J-3

CLUSTER ILLUMINATION LAMPS - INSTALLATION ....................... 8L-21

CLUSTER ILLUMINATION LAMPS - REMOVAL .......................... 8L-21

CLUSTER LENS - INSTALLATION ........8J-11

CLUSTER LENS - REMOVAL ............8J-11

CLUTCH AIR PRESSURE TESTS - DIAGNOSIS AND TESTING ........21-153,21-8

CLUTCH ASSEMBLY - ASSEMBLY, INPUT ....................... 21-246,21-95

CLUTCH ASSEMBLY - DISASSEMBLY, INPUT ....................... 21-237,21-86

CLUTCH BREAK-IN, STANDARD PROCEDURE - A/C ................... 24-15

CLUTCH COIL, DIAGNOSIS AND TESTING - A/C COMPRESSOR .................. 24-14

CLUTCH INSPECTION, STANDARD PROCEDURE ........................ 24-15

CLUTCH RELAY - DESCRIPTION, A/C COMPRESSOR ....................... 24-18

CLUTCH RELAY - INSTALLATION, A/C COMPRESSOR ....................... 24-19

CLUTCH RELAY - OPERATION, A/C COMPRESSOR ....................... 24-18

CLUTCH RELAY - REMOVAL, A/C COMPRESSOR ....................... 24-19

CLUTCH/COIL - DESCRIPTION, A/C COMPRESSOR ....................... 24-13

CLUTCH/COIL - OPERATION, A/C COMPRESSOR ....................... 24-13

CLUTCHES - DESCRIPTION, DRIVING . . . 21-219,

21-74

CLUTCHES - DESCRIPTION, HOLDING . . . 21-236,

21-86

CLUTCHES - OPERATION, DRIVING .....21-219,

21-74

CLUTCHES - OPERATION, HOLDING ....21-236,

21-86

COAT/CLEARCOAT FINISH - DESCRIPTION, BASE .................23-101CODE - DESCRIPTION, PAINT

..........23-101

CODE CHARTS - SPECIFICATIONS, COLOR ............................ 23-100

CODES - STANDARD PROCEDURE, OBTAINING DIAGNOSTIC TROUBLE ......8E-15

CODES, STANDARD PROCEDURE - ERASING TRANSMITTER ..............8M-12

CODES, STANDARD PROCEDURE - SETTING TRANSMITTER ..............8M-12

COIL - DESCRIPTION, IGNITION ..........8I-6

COIL - OPERATION, IGNITION ............8I-6

COIL, DIAGNOSIS AND TESTING - A/C COMPRESSOR CLUTCH ...............24-14

COLLAR - INSTALLATION, STRUCTURAL . . . 9-49

COLLAR - REMOVAL, STRUCTURAL .......9-49

COLOR CODE CHARTS - SPECIFICATIONS .................... 23-100

COLUMN - DESCRIPTION, STEERING .....19-10

COLUMN - DIAGNOSIS AND TESTING, STEERING .......................... 19-11

COLUMN COVER - INSTALLATION, LOWER STEERING ................... 23-74

COLUMN COVER - INSTALLATION, OVER STEERING .......................... 23-76

COLUMN COVER - REMOVAL, LOWER STEERING .......................... 23-74

COLUMN COVER - REMOVAL, OVER STEERING .......................... 23-76

COLUMN FASTENER TORQUE, SPECIFICATIONS ..................... 19-17

COMBUSTION PRESSURE LEAKAGE TEST - DIAGNOSIS AND TESTING,

CYLINDER ........................ 9-85,9-9

COMMUNICATION RECEIVE - PCM INPUT - OPERATION, DATA BUS ..............8E-14

COMMUNICATIONS INTERFACE (PCI) BUS, OPERATION - PROGRAMMABLE ....14-25

COMPASS CALIBRATION, STANDARD PROCEDURE ......................... 8M-4

COMPASS DEMAGNETIZING, STANDARD PROCEDURE ......................... 8M-5

COMPASS MINI-TRIP COMPUTER, DIAGNOSIS AND TESTING .............8M-10

COMPASS VARIATION ADJUSTMENT, STANDARD PROCEDURE ...............8M-5

COMPASS/MINI-TRIP COMPUTER - DESCRIPTION ....................... 8M-10

COMPASS/MINI-TRIP COMPUTER - OPERATION ........................ 8M-10

COMPRESSION PRESSURE TEST - DIAGNOSIS AND TESTING, CYLINDER . . 9-85,9-9

COMPRESSOR CLUTCH COIL, DIAGNOSIS AND TESTING - A/ C.........24-14

COMPRESSOR CLUTCH RELAY - DESCRIPTION, A/C ................... 24-18

COMPRESSOR CLUTCH RELAY - INSTALLATION, A/C ................... 24-19

COMPRESSOR CLUTCH RELAY - OPERATION, A/C ..................... 24-18

COMPRESSOR CLUTCH RELAY - REMOVAL, A/C ...................... 24-19

COMPRESSOR CLUTCH/COIL - DESCRIPTION, A/C ................... 24-13

COMPRESSOR CLUTCH/COIL - OPERATION, A/C ..................... 24-13

COMPRESSOR, DESCRIPTION - A/C ......24-72

COMPRESSOR, INSTALLATION - A/C .....24-74

COMPRESSOR MOUNTING BRACKET, 2.4L ENGINE - A/C ..............24-74,24-75

COMPRESSOR NOISE DIAGNOSIS, DIAGNOSIS AND TESTING - A/C .........24-72

COMPRESSOR, OPERATION - A/C ........24-72

COMPRESSOR, REMOVAL - A/C .........24-73

COMPUTER - DESCRIPTION, COMPASS/ MINI-TRIP ......................... 8M-10

COMPUTER - OPERATION, COMPASS/ MINI-TRIP ......................... 8M-10

COMPUTER, DIAGNOSIS AND TESTING - COMPASS MINI-TRIP .................8M-10

CONCENTRATION TESTING - DIAGNOSIS AND TESTING, COOLANT ...............7-19

CONDENSER - DESCRIPTION, A/C .......24-75

CONDENSER - OPERATION, A/C .........24-75

CONDITION CHECK, STANDARD PROCEDURE - FLUID LEVEL ......21-230,21-82

CONDITIONER, DESCRIPTION - HEATER AND AIR ............................ 24-1CONDITIONER, OPERATION - HEATER

AND AIR ............................ 24-4

CONNECT FITTING DISASSEMBLY/ ASSEMBLY - STANDARD PROCEDURE,

TRANSMISSION COOLER LINE QUICK .....7-38

CONNECTING ROD - DESCRIPTION, PISTON ........................ 9-119,9-44

CONNECTING ROD - INSTALLATION, PISTON ............................. 9-45

CONNECTING ROD - REMOVAL, PISTON . . . 9-44

CONNECTING ROD BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING .............9-123

CONNECTING ROD, FITTING .............9-46

CONNECTING RODS - STANDARD PROCEDURE, FITTING .................9-119

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-6

CONNECTOR - INSTALLATION .......8W-01-11

CONNECTOR - OPERATION, DATA LINK ....8E-6

CONNECTOR - REMOVAL ...........8W-01-11

CONNECTOR, GROUND AND SPLICE INFORMATION - DESCRIPTION ........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION - DESCRIPTION ....................8W -91-1

CONSOLE - DESCRIPTION, OVERHEAD ....8M-2

CONSOLE - FOLD-IN-FLOOR - INSTALLATION, FLOOR ................23-89

CONSOLE - FOLD-IN-FLOOR - REMOVAL, FLOOR ............................. 23-89

CONSOLE - INSTALLATION, LOWER ......23-73

CONSOLE - REMOVAL, LOWER ..........23-73

CONSOLE BASE TRAY - INSTALLATION, FLOOR ............................. 23-89

CONSOLE BASE TRAY - REMOVAL, FLOOR ............................. 23-89

CONSOLE, DIAGNOSIS AND TESTING - OVERHEAD .......................... 8M-3

CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION,

FLOOR ............................. 23-90

CONSOLE KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR .....23-90

CONSOLE LAMP - INSTALLATION, CENTER ............................ 8L-21

CONSOLE LAMP - REMOVAL, CENTER ....8L-21

CONSOLE LAMP SWITCH - INSTALLATION, CENTER ...............8L-21

CONSOLE LAMP SWITCH - REMOVAL, CENTER ............................ 8L-21

CONSOLE LID LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR ................23-90

CONSOLE LID LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR .................... 23-90

CONSOLE, SPECIAL TOOLS - OVERHEAD . . 8M-7

CONTAINER - DESCRIPTION, COOLANT RECOVERY .......................... 7-20

CONTAINER - INSTALLATION, COOLANT RECOVERY .......................... 7-20

CONTAINER - OPERATION, COOLANT RECOVERY .......................... 7-20

CONTAINER - REMOVAL, COOLANT RECOVERY .......................... 7-20

CONTAMINATION - DIAGNOSIS AND TESTING, BRAKE FLUID ................5-33

CONTINUITY - STANDARD PROCEDURE, TESTING .........................8W -01-9

CONTROL (4 SPEED EATX ONLY) - OPERATION, INTERACTIVE SPEED ........8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-12

CONTROL ARM - INSPECTION, LOWER ....2-14

CONTROL ARM - INSTALLATION, LOWER . . 2-15

CONTROL ARM - OPERATION, LOWER .....2-12

CONTROL ARM - REMOVAL, LOWER ......2-12

CONTROL ARM (REAR BUSHING - HYDRO) - ASSEMBLY, LOWER ...........2-15

CONTROL ARM (REAR BUSHING - HYDRO) - DISASSEMBLY, LOWER ........2-13

CONTROL ARM (REAR BUSHING - STANDARD) - ASSEMBLY, LOWER ........2-14

CONTROL ARM (REAR BUSHING - STANDARD) - DISASSEMBLY, LOWER .....2-13

CONTROL CABLE - INSTALLATION, THROTTLE .......................... 14-40

CONTROL CABLE - REMOVAL, THROTTLE .......................... 14-40

CONTROL CALIBRATION, STANDARD PROCEDURE - A/C-HEATER .............24-19

RS INDEX7

Description Group-Page Description Group-Page Description Group-Page

Page 2318 of 2339

HYDRAULIC CIRCUITS AND VALVES -OPERATION .......................... 5-95

HYDRAULIC LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND

TESTING ............................ 9-34

HYDRAULIC LASH ADJUSTERS - INSTALLATION ........................ 9-35

HYDRAULIC LASH ADJUSTERS - REMOVAL ........................... 9-35

HYDRAULIC LIFTERS - DIAGNOSIS AND TESTING ........................... 9-116

HYDRAULIC LIFTERS (CAM IN BLOCK) - DESCRIPTION ....................... 9-116

HYDRAULIC LIFTERS (CAM IN BLOCK) - INSTALLATION ....................... 9-117

HYDRAULIC LIFTERS (CAM IN BLOCK) - REMOVAL .......................... 9-117

HYDRAULIC PRESSURE TESTS - DIAGNOSIS AND TESTING ........21-150,21-6

HYDRAULIC SCHEMATICS, SCHEMATICS AND DIAGRAMS - 4XTE TRANSAXLE ....21-199,

21-54

HYDROSTATIC LOCKED ENGINE, STANDARD PROCEDURE ............9-10,9-87

ICU - ASSEMBLY ..................... 5-106

ICU - DISASSEMBLY ..................5-105

ICU (INTEGRATED CONTROL UNIT) - DESCRIPTION ....................... 5-102

ICU (INTEGRATED CONTROL UNIT) - OPERATION ......................... 5-102

IDENTIFICATION - DESCRIPTION, VEHICLE ............................ 23-1

IDENTIFICATION AND INFORMATION - DESCRIPTION, SECTION ..............8W-01-6

IDLE AIR CONTROL MOTOR - DESCRIPTION ....................... 14-33

IDLE AIR CONTROL MOTOR - INSTALLATION ....................... 14-33

IDLE AIR CONTROL MOTOR - OPERATION ......................... 14-33

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-33

IGNITION COIL - DESCRIPTION ...........8I-6

IGNITION COIL - OPERATION .............8I-6

IGNITION SENSE - PCM INPUT - OPERATION ......................... 8E-14

IGNITION SWITCH - INSTALLATION ......19-19

IGNITION SWITCH - REMOVAL ..........19-17

IGNITION SYSTEM - DESCRIPTION ........8I-1

IGNITION SYSTEM - OPERATION ..........8I-1

IGNITION-OFF DRAW TEST, STANDARD PROCEDURE ........................ 8F-13

ILLUMINATION LAMPS - INSTALLATION, CLUSTER ........................... 8L-21

ILLUMINATION LAMPS - REMOVAL, CLUSTER ........................... 8L-21

IMPACT SENSOR - DESCRIPTION .......8O-18

IMPACT SENSOR - INSTALLATION .......8O-21

IMPACT SENSOR - REMOVAL ...........8O-19

INBOARD - 50/50 BENCH - INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW ....................... 8O-38

INBOARD - 50/50 BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW .....8O-37

INBOARD - INSTALLATION, SEAT BELT BUCKLE - FRONT .................... 8O-35

INBOARD - QUAD BUCKET - INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW ......................... 8O-36

INBOARD - QUAD BUCKET - REMOVAL, SEAT BELT BUCKLE - FIRST ROW .......8O-35

INBOARD - REMOVAL, SEAT BELT BUCKLE - FRONT .................... 8O-35

INDICATOR - DESCRIPTION, PASSENGER AIRBAG DISABLED ................... 8O-33

INDICATOR - INSTALLATION, PASSENGER AIRBAG DISABLED .........8O-34

INDICATOR - OPERATION, PASSENGER AIRBAG DISABLED ................... 8O-33

INDICATOR - REMOVAL, PASSENGER AIRBAG DISABLED ................... 8O-34

INDICATOR LAMP - DESCRIPTION, VTSS/SKIS .......................... 8Q-8

INDICATOR LAMP - OPERATION, VTSS/SKIS .......................... 8Q-8

INDICATORS - DIAGNOSIS AND TESTING, TREAD WEAR ...............22-16

INFLATABLE KNEE - INSTALLATION, BLOCKER ........................... 23-75INFLATABLE KNEE - REMOVAL,

BLOCKER ........................... 23-75

INFLATION PRESSURES - STANDARD PROCEDURE, TIRE ................... 22-16

INFO CENTER - DESCRIPTION, ELECTRONIC VEHICLE .................8M-7

INFO CENTER - OPERATION, ELECTRONIC VEHICLE .................8M-7

INFRARED TEMPERATURE SENSOR - DESCRIPTION ....................... 24-28

INFRARED TEMPERATURE SENSOR - OPERATION ......................... 24-28

INITIAL OPERATION - STANDARD PROCEDURE, POWER STEERING

PUMP ............................. 19-37

INJECTION SYSTEM - OPERATION .......14-22

INJECTOR - DESCRIPTION, FUEL ........14-30

INJECTOR - OPERATION, FUEL ..........14-31

INLET AIR TEMPERATURE SENSOR - DESCRIPTION ....................... 14-34

INLET FILTER - INSTALLATION ..........14-17

INLET FILTER - REMOVAL ..............14-17

INLET HOSE - INSTALLATION, HEATER ....24-87

INLET HOSE - REMOVAL, HEATER .......24-86

INLET TUBE - 2.4L - DESCRIPTION, WATER PUMP ........................ 7-36

INLET TUBE - 2.4L - INSTALLATION, WATER PUMP ........................ 7-36

INLET TUBE - 2.4L - REMOVAL, WATER PUMP .............................. 7-36

INLET TUBE - 3.3/3.8L - INSTALLATION, WATER PUMP ......................... 7-37

INLET TUBE - 3.3/3.8L - REMOVAL, WATER PUMP ........................ 7-37

INNER - INSTALLATION, CV BOOT .........3-7

INNER - REMOVAL, CV BOOT .............3-6

INNER BELT MOLDING - INSTALLATION, FRONT DOOR ...................... 23-168

INNER BELT MOLDING - REMOVAL, FRONT DOOR ...................... 23-168

INPUT - DESCRIPTION, SPEED SENSOR . 21-120, 21-271

INPUT - INSTALLATION, SPEED SENSOR ..................... 21-121,21-272

INPUT - OPERATION, DATA BUS COMMUNICATION RECEIVE - PCM .......8E-14

INPUT - OPERATION, IGNITION SENSE - PCM............................... 8E-14

INPUT - OPERATION, SENSOR RETURN - PCM............................... 8E-14

INPUT - OPERATION, SPEED SENSOR . . . 21-120, 21-271

INPUT - REMOVAL, SPEED SENSOR ....21-121,

21-272

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-246, 21-95

INPUT CLUTCH ASSEMBLY - DISASSEMBLY ................. 21-237,21-86

INSERT - FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR TUB

CARPETS ........................... 23-96

INSERT - FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR

TUB CARPET ........................ 23-98

INSERT - FOLD-IN-FLOOR - REMOVAL, REAR FLOOR TUB CARPETS ............23-95

INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR TUB CARPET ......23-98

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-1

INSTRUMENT CLUSTER - OPERATION .....8J-1

INSTRUMENT PANEL - INSTALLATION, LOWER ............................ 23-73

INSTRUMENT PANEL - REMOVAL, LOWER ............................ 23-73

INSTRUMENT PANEL ANTENNA CABLE - INSTALLATION ....................... 8A-12

INSTRUMENT PANEL ANTENNA CABLE - REMOVAL .......................... 8A-12

INSTRUMENT PANEL ASSEMBLY - INSTALLATION ....................... 23-70

INSTRUMENT PANEL ASSEMBLY - REMOVAL .......................... 23-67

INSTRUMENT PANEL CENTER BEZEL - INSTALLATION ....................... 23-72

INSTRUMENT PANEL CENTER BEZEL - REMOVAL .......................... 23-71

INSTRUMENT PANEL DEMISTER DUCTS - INSTALLATION ..................... 24-54INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL ......................... 24-54

INSTRUMENT PANEL DUCTS - INSTALLATION ....................... 24-55

INSTRUMENT PANEL DUCTS - REMOVAL . 24-55

INSTRUMENT PANEL OUTLETS, INSTALLATION ....................... 24-45

INSTRUMENT PANEL OUTLETS, REMOVAL .......................... 24-45

INSTRUMENT PANEL RIGHT END CAP - INSTALLATION ....................... 23-72

INSTRUMENT PANEL RIGHT END CAP - REMOVAL .......................... 23-72

INSTRUMENT PANEL TOP COVER - INSTALLATION ....................... 23-72

INSTRUMENT PANEL TOP COVER - REMOVAL .......................... 23-72

INSTRUMENT PANEL TOP PAD ASSEMBLY - INSTALLATION ............23-77

INSTRUMENT PANEL TOP PAD ASSEMBLY - REMOVAL ................23-77

INTAKE MANIFOLD - DESCRIPTION . . 9-147,9-60

INTAKE MANIFOLD - INSTALLATION, LOWER ............................ 9-151

INTAKE MANIFOLD - INSTALLATION, UPPER ............................. 9-149

INTAKE MANIFOLD - LOWER - CLEANING .......................... 9-151

INTAKE MANIFOLD - LOWER - INSPECTION .................... 9-151,9-62

INTAKE MANIFOLD - LOWER - INSTALLATION ........................ 9-62

INTAKE MANIFOLD - LOWER - REMOVAL ....9-62

INTAKE MANIFOLD - REMOVAL, LOWER . . 9-150

INTAKE MANIFOLD - REMOVAL, UPPER . . . 9-148

INTAKE MANIFOLD - UPPER - INSPECTION ......................... 9-61

INTAKE MANIFOLD - UPPER - INSTALLATION ........................ 9-61

INTAKE MANIFOLD - UPPER - REMOVAL . . . 9-60

INTAKE MANIFOLD LEAKS - DIAGNOSIS AND TESTING ................... 9-147,9-60

INTAKE MANIFOLD VACUUM PORT REPAIR - STANDARD PROCEDURE .......9-148

INTAKE PIPE - INSTALLATION, AIR ......24-115

INTAKE PIPE - REMOVAL, AIR .........24-115

INTAKE/EXHAUST VALVES & SEATS - CLEANING ...................... 9-108,9-33

INTAKE/EXHAUST VALVES & SEATS - DESCRIPTION ................... 9-107,9-33

INTAKE/EXHAUST VALVES & SEATS - INSPECTION ........................ 9-108

INTAKE/EXHAUST VALVES & SEATS - INSTALLATION ....................... 9-109

INTAKE/EXHAUST VALVES & SEATS - OPERATION ......................... 9-107

INTAKE/EXHAUST VALVES & SEATS - REMOVAL .......................... 9-108

INTEGRAL ANTENNA - EXPORT - DESCRIPTION, QUARTER GLASS ........8A-13

INTEGRAL ANTENNA - EXPORT - OPERATION, QUARTER GLASS ..........8A-13

INTEGRAL ANTENNA, EXPORT - QUARTER GLASS .................... 8A-13

INTEGRATED POWER MODULE - DESCRIPTION .....................8W -97-1

INTEGRATED POWER MODULE - INSTALLATION ....................8W -97-2

INTEGRATED POWER MODULE - OPERATION .......................8W -97-2

INTEGRATED POWER MODULE - REMOVAL ........................8W -97-2

INTERACTIVE SPEED CONTROL (4 SPEED EATX ONLY) - OPERATION ........8P-2

INTERFACE (PCI) BUS, OPERATION - PROGRAMMABLE COMMUNICATIONS ....14-25

INTERIOR LAMPS, SPECIFICATIONS ......8L-20

INTERLOCK SOLENOID - DESCRIPTION, SHIFT ....................... 21-113,21-264

INTERLOCK SOLENOID - DIAGNOSIS AND TESTING, BRAKE/TRANSMISSION

SHIFT ....................... 21-115,21-266

INTERLOCK SOLENOID - INSTALLATION, SHIFT ....................... 21-116,21-267

INTERLOCK SOLENOID - OPERATION, SHIFT ....................... 21-114,21-265

INTERLOCK SOLENOID - REMOVAL, SHIFT ....................... 21-115,21-266

RS INDEX17

Description Group-Page Description Group-Page Description Group-Page