heater CHRYSLER CARAVAN 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1093 of 2339

REAR A/C-HEATER UNIT (3 ZONE MTC) - LT. GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 C53 20LB REAR MODE DOOR DRIVER

2 C154 20LB/OR REAR COMMON DOOR DRIVER

3 C51 12LB/BR FUSED REAR BLOWER MOTOR RELAY OUTPUT

4 C152 16LB/LG REAR BLOWER MOTOR MED

5 C151 18LB/DG REAR BLOWER MOTOR LOW

6 C153 12DB/BR REAR BLOWER MOTOR HIGH

7 C54 20LB/YL REAR BLEND DOOR DRIVER

8 C154 20LB/OR REAR COMMON DOOR DRIVER

9- -

10 - -

REAR AUTO TEMP CONTROL SWITCH (3 ZONE ATC) - BLACK 13 WAY

CAV CIRCUIT FUNCTION

1 F504 20GY/PK FUSED IGNITION SWITCH OUTPUT (RUN)

2 Z27 18BK/DG GROUND

3 D22 22WT/TN KDB CLOCK

4 D17 22WT/DG KDB DATA

5 E10 20OR/DG PANEL LAMPS DRIVER

6- -

7- -

8- -

9- -

10 - -

11 - -

12 - -

13 - -

REAR BLOWER FRONT CONTROL SWITCH (3 ZONE MTC) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z440 12BK/DG GROUND

3- -

4 C153 12DB/BR REAR BLOWER MOTOR HIGH

5- -

6 C152 16LB/LG REAR BLOWER MOTOR MED

7 C151 18LB/DG REAR BLOWER MOTOR LOW

8 C50 12DB/OR REAR BLOWER FRONT CONTROL FEED

8W - 80 - 124 8W-80 CONNECTOR PIN-OUTSRS

Page 1114 of 2339

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.Connector, ground, and splice indexes are provided.

Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

appropriate index for the proper figure number. For

items that are not shown in this section N/S is placed

in the Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

A/C Compressor Clutch LTGY Top of A/C Compressor 10, 11, 15, 17, 18

A/C Pressure Sensor GY At Throttle Body 9, 10, 15, 16, 17

A/C-Heater Control C1 (MTC) BK/RD Rear of Control 20, 23, 25

A/C-Heater Control C2 (MTC) BK/BL Rear of Control 20, 23, 25

Accelerator Pedal Position

Sensor (Diesel)At Accelerator Pedal 42

Adjustable Pedals Module

(Except Export)Near Brake Lamp Switch N/S

Adjustable Pedals Motor On Pedal Support N/S

Adjustable Pedals Relay (Except

Export)Left Side Engine Compartment 6

Adjustable Pedals Sensor On Adjustable Pedals Motor N/S

Adjustable Pedals Switch (Except

Export)Left Side Kick Panel 41

Ambient Temperature Sensor

(Except Base)BK On Radiator Closure Panel 1

Amplifier C1 NAT Right Quarter Panel 48

Amplifier C2 NAT Right Quarter Panel 48

ATC Remote Sensor Above ATC Control N/S

Auto Temp Control C1 NAT Rear of Control 20

Auto Temp Control C2 BK Rear of Control 20

Auto Temp Control C3 (MTX) Rear of Control N/S

Back-Up Lamp Switch BK On Transmission 16

Battery Temperature Sensor BK At Battery N/S

Blower Motor Resistor C1 (MTC) BK Right Side of HVAC N/S

Blower Motor Resistor C2 (MTC) BK Right Side of HVAC N/S

Body Control Module C1 BK Under Left Instrument Panel 41, 42

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-1

Page 1115 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Body Control Module C2 BK/GN Under Left Instrument Panel 41, 42

Body Control Module C3 BK/WT Under Left Instrument Panel 41, 42

Body Control Module C4 BK/GY Under Left Instrument Panel 20, 21, 30

Body Control Module C5 BK Under Left Instrument Panel 20, 21, 30

Boost Pressure Sensor (Diesel) BK Top Left of Engine 15

Brake Fuid Level Switch BK On Master Cylinder 6

Brake Lamp Switch BK At Top Of Brake Pedal 41, 42

Brake Transmission Shift

Interlock Solenoid (EATX)BK Near Steering Column 20, 21, 22, 31

C100 BK Left Fender Shield 5, 11

C101 LTGY Left Fender Shield 5

C102 (Gas) BK At Fuel Rail 11, 17

C103 (Diesel) BK Left Side Engine Compartment N/S

C104 (Except Export LTGY Near Controller Antilock Brake 18

C106 (Export) BK/YL Near Left Headlamp Leveling Motor N/S

C107 (Export) BK/YL Near Right Headlamp Leveling

MotorN/S

C111 (EATX) LTGY Left Front Engine 11

C112 (Gas) BK Near T/O for C101 N/S

C200 GY Left Side Instrument Panel 20, 21, 30, 41, 42

C202 GY Right Side Instrument Panel A/C

Heater Unit20, 24, 29

C204 (Premium NAT Rear of Radio 50

C206 BK Near Radio 20

C207 Near Radio N/S

C300 (LHD) BK Left Front Door Lower 36, 43

C300 (RHD) BK Right Front Door Lower N/S

C301 LTGY Left Front Door Upper 36, 43

C302 LTGY Right Front Door Upper 8, 39, 44

C303 BK Right Front Door Lower 8, 39, 44

C304 (LHD) YL Left Wire Track Seat to Body 32

C305 GY Left Wire Track Seat to Body 32 33

C306 (RHD) YL Right Wire Track Seat to Body 33

C307 YL Right Wire Track Seat to Body N/S

C308 (Except Side Airbags) GN Left Rear Sliding Door 40

C309 (Except Side Airbags) GN/GY Right Rear Sliding Door 32, 33, 39

C310 (Front Console) BK At Front Console 34

C311 (3 Zone HVAC) GY Rear A/C Switch 40

C312 GY Right B Pillar 33, 39, 50

C313 (Rear Console/Export) BK At Rear Console 34

C314 BK Left Side Liftgate 49

C315 (Power Liftgate) BK Right Side Liftgate 49

C316 (Power Sliding Door) BK Wire Track to Sliding Door N/S

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1116 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C317 (Power Sliding Door) BK Right Sliding Door 32, 45

C318 (Trailer Tow) BK Left Quarter N/S

C319 (Trailer Tow)

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 (Memory) BK On Seat Harness to Body 32

C324 (Manual Sliding Door) BK Left Sliding Door N/S

C325 (Manual Sliding Door) BK Right Sliding Door 32

C328 (Sunroof) Left Quarter Panel 47

C329 (Diesel) BK Near Fuel Tank N/S

C330 (Diesel) LTGY Near Throttle Body 15, 16

C331 (Diesel) BK Left Rear Engine Compartment N/S

C332 (3 Zone ATC) BK/LTGN Near T/O for Right Rear Lamp

Assembly48

C333 (Except Export DKGY Left Side Instrument Panel 21

C334 BK Right Quarter Panel 48

C335 LTGY Near Fuel Tank 34

Cabin Heater Assist C1 (Diesel) BK Top of Engine N/S

Cabin Heater Assist C2 (Diesel) BK Top of Engine N/S

Camshaft Position Sensor (Gas) BK Rear of Cylinder Head

Right Side of Engine11 , 1 7

Camshaft Position Sensor

(Diesel)BK Rear of Cylinder Head 15, 16

CD Changer Behind CD Changer N/S

Center High Mounted Stop Lamp BK At Lamp 49

Clockspring - C1 WT Steering Column 20, 21, 22, 23, 31

Clockspring - C2 YL Steering Column 20, 21, 22, 23, 31

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 Steering Column N/S

Clutch Pedal Interlock Switch

(MTX)BK At Switch/Driver Side 42

Clutch Pedal Upstop Switch

(Diesel)RD At Switch/Driver Side 42

Controller Anti-Lock Brake BK Right Side of Engine Compartment 11, 16, 17, 18

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 15

Crankshaft Position Sensor

(Diesel)BK Rear of Engine 16

Crankshaft Position Sensor (Gas) BK Rear of Engine 13, 17

Data Link Connector BK Lower Instrument Panel Near

Steering Column41, 42

Dosing Pump (Diesel) BK Top of Engine N/S

Driver Airbag Squib1 BN/YL Steering Column N/S

Driver Airbag Squib2 BK/YL Steering Column N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1118 of 2339

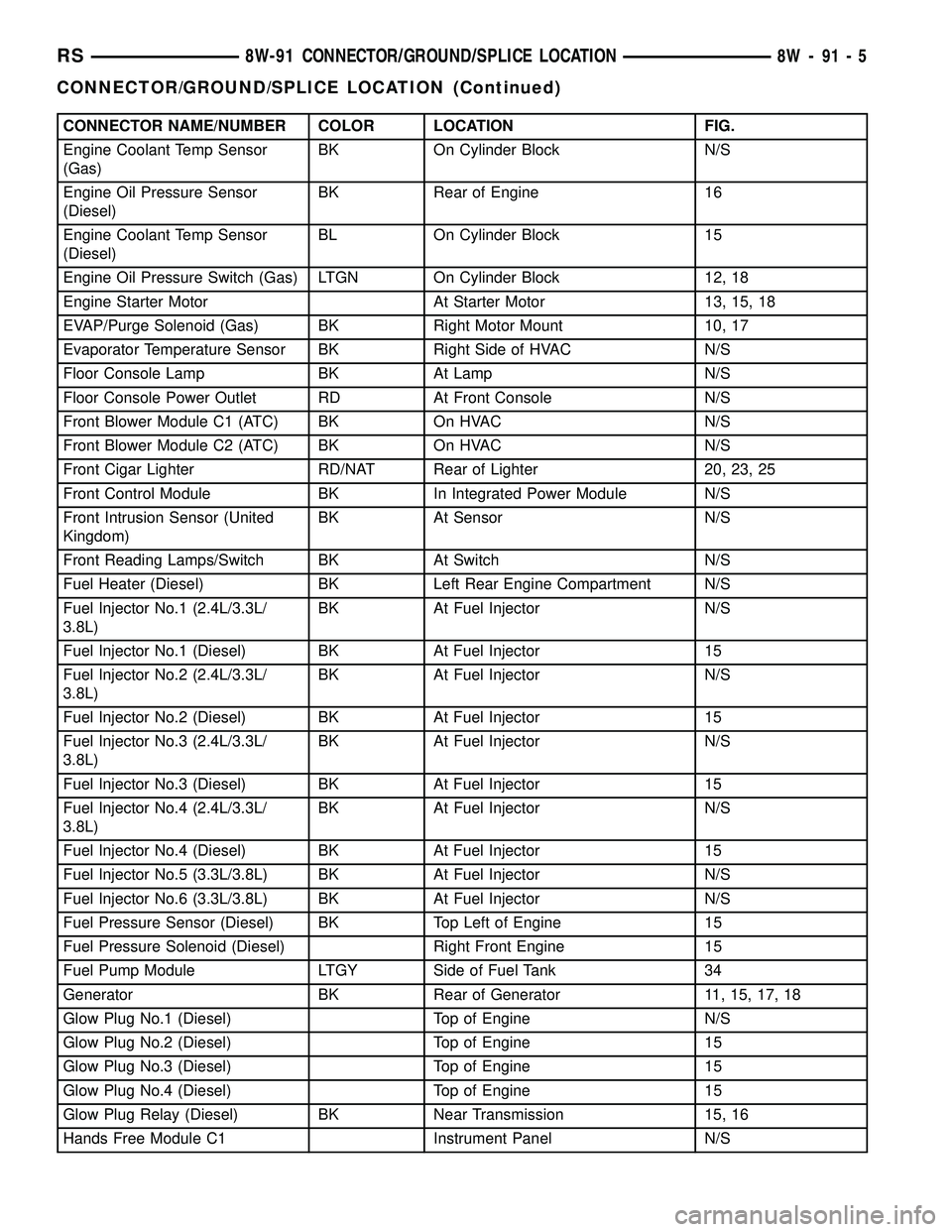

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Engine Coolant Temp Sensor

(Gas)BK On Cylinder Block N/S

Engine Oil Pressure Sensor

(Diesel)BK Rear of Engine 16

Engine Coolant Temp Sensor

(Diesel)BL On Cylinder Block 15

Engine Oil Pressure Switch (Gas) LTGN On Cylinder Block 12, 18

Engine Starter Motor At Starter Motor 13, 15, 18

EVAP/Purge Solenoid (Gas) BK Right Motor Mount 10, 17

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Floor Console Lamp BK At Lamp N/S

Floor Console Power Outlet RD At Front Console N/S

Front Blower Module C1 (ATC) BK On HVAC N/S

Front Blower Module C2 (ATC) BK On HVAC N/S

Front Cigar Lighter RD/NAT Rear of Lighter 20, 23, 25

Front Control Module BK In Integrated Power Module N/S

Front Intrusion Sensor (United

Kingdom)BK At Sensor N/S

Front Reading Lamps/Switch BK At Switch N/S

Fuel Heater (Diesel) BK Left Rear Engine Compartment N/S

Fuel Injector No.1 (2.4L/3.3L/

3.8L)BK At Fuel Injector N/S

Fuel Injector No.1 (Diesel) BK At Fuel Injector 15

Fuel Injector No.2 (2.4L/3.3L/

3.8L)BK At Fuel Injector N/S

Fuel Injector No.2 (Diesel) BK At Fuel Injector 15

Fuel Injector No.3 (2.4L/3.3L/

3.8L)BK At Fuel Injector N/S

Fuel Injector No.3 (Diesel) BK At Fuel Injector 15

Fuel Injector No.4 (2.4L/3.3L/

3.8L)BK At Fuel Injector N/S

Fuel Injector No.4 (Diesel) BK At Fuel Injector 15

Fuel Injector No.5 (3.3L/3.8L) BK At Fuel Injector N/S

Fuel Injector No.6 (3.3L/3.8L) BK At Fuel Injector N/S

Fuel Pressure Sensor (Diesel) BK Top Left of Engine 15

Fuel Pressure Solenoid (Diesel) Right Front Engine 15

Fuel Pump Module LTGY Side of Fuel Tank 34

Generator BK Rear of Generator 11, 15, 17, 18

Glow Plug No.1 (Diesel) Top of Engine N/S

Glow Plug No.2 (Diesel) Top of Engine 15

Glow Plug No.3 (Diesel) Top of Engine 15

Glow Plug No.4 (Diesel) Top of Engine 15

Glow Plug Relay (Diesel) BK Near Transmission 15, 16

Hands Free Module C1 Instrument Panel N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1123 of 2339

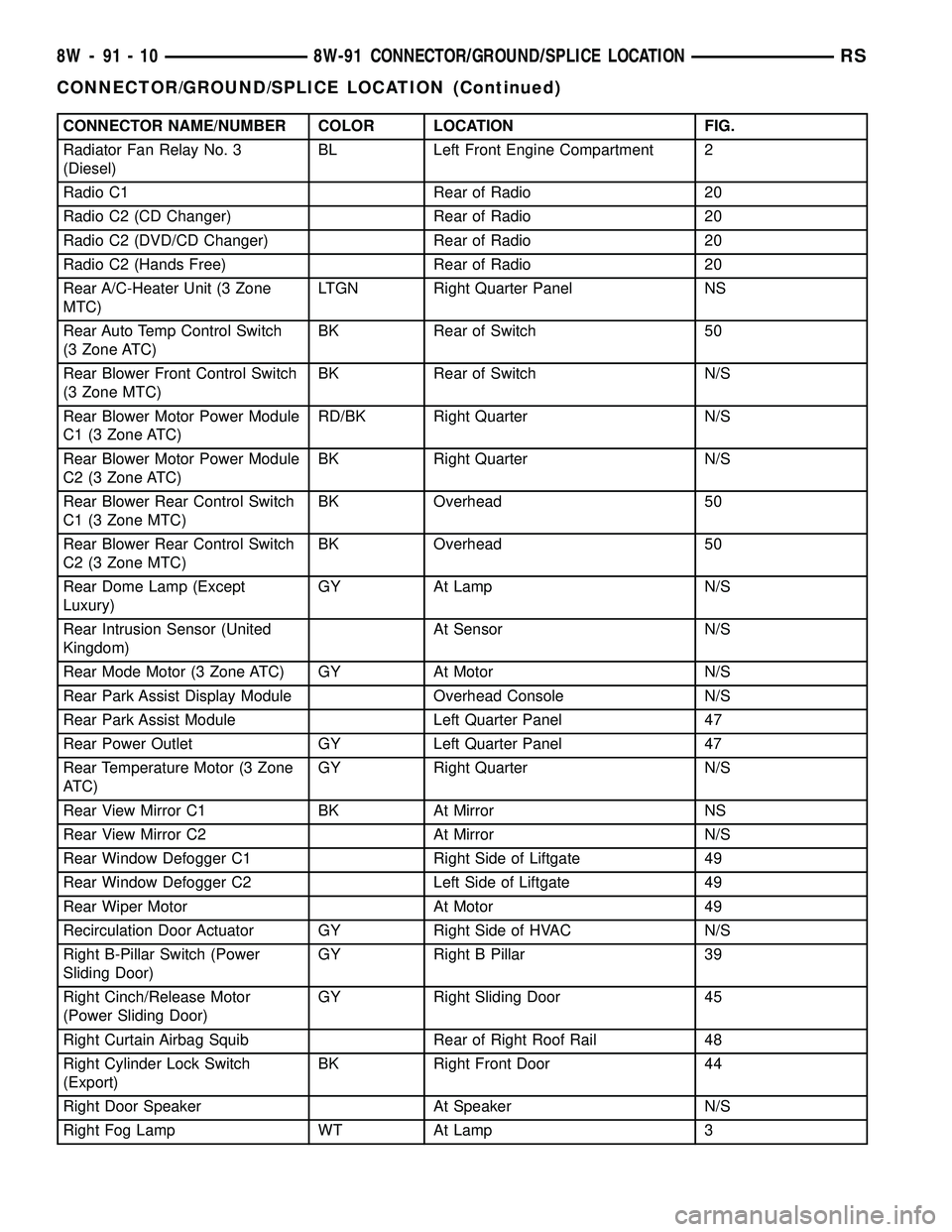

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Radiator Fan Relay No. 3

(Diesel)BL Left Front Engine Compartment 2

Radio C1 Rear of Radio 20

Radio C2 (CD Changer) Rear of Radio 20

Radio C2 (DVD/CD Changer) Rear of Radio 20

Radio C2 (Hands Free) Rear of Radio 20

Rear A/C-Heater Unit (3 Zone

MTC)LTGN Right Quarter Panel NS

Rear Auto Temp Control Switch

(3 Zone ATC)BK Rear of Switch 50

Rear Blower Front Control Switch

(3 Zone MTC)BK Rear of Switch N/S

Rear Blower Motor Power Module

C1 (3 Zone ATC)RD/BK Right Quarter N/S

Rear Blower Motor Power Module

C2 (3 Zone ATC)BK Right Quarter N/S

Rear Blower Rear Control Switch

C1 (3 Zone MTC)BK Overhead 50

Rear Blower Rear Control Switch

C2 (3 Zone MTC)BK Overhead 50

Rear Dome Lamp (Except

Luxury)GY At Lamp N/S

Rear Intrusion Sensor (United

Kingdom)At Sensor N/S

Rear Mode Motor (3 Zone ATC) GY At Motor N/S

Rear Park Assist Display Module Overhead Console N/S

Rear Park Assist Module Left Quarter Panel 47

Rear Power Outlet GY Left Quarter Panel 47

Rear Temperature Motor (3 Zone

ATC)GY Right Quarter N/S

Rear View Mirror C1 BK At Mirror NS

Rear View Mirror C2 At Mirror N/S

Rear Window Defogger C1 Right Side of Liftgate 49

Rear Window Defogger C2 Left Side of Liftgate 49

Rear Wiper Motor At Motor 49

Recirculation Door Actuator GY Right Side of HVAC N/S

Right B-Pillar Switch (Power

Sliding Door)GY Right B Pillar 39

Right Cinch/Release Motor

(Power Sliding Door)GY Right Sliding Door 45

Right Curtain Airbag Squib Rear of Right Roof Rail 48

Right Cylinder Lock Switch

(Export)BK Right Front Door 44

Right Door Speaker At Speaker N/S

Right Fog Lamp WT At Lamp 3

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1127 of 2339

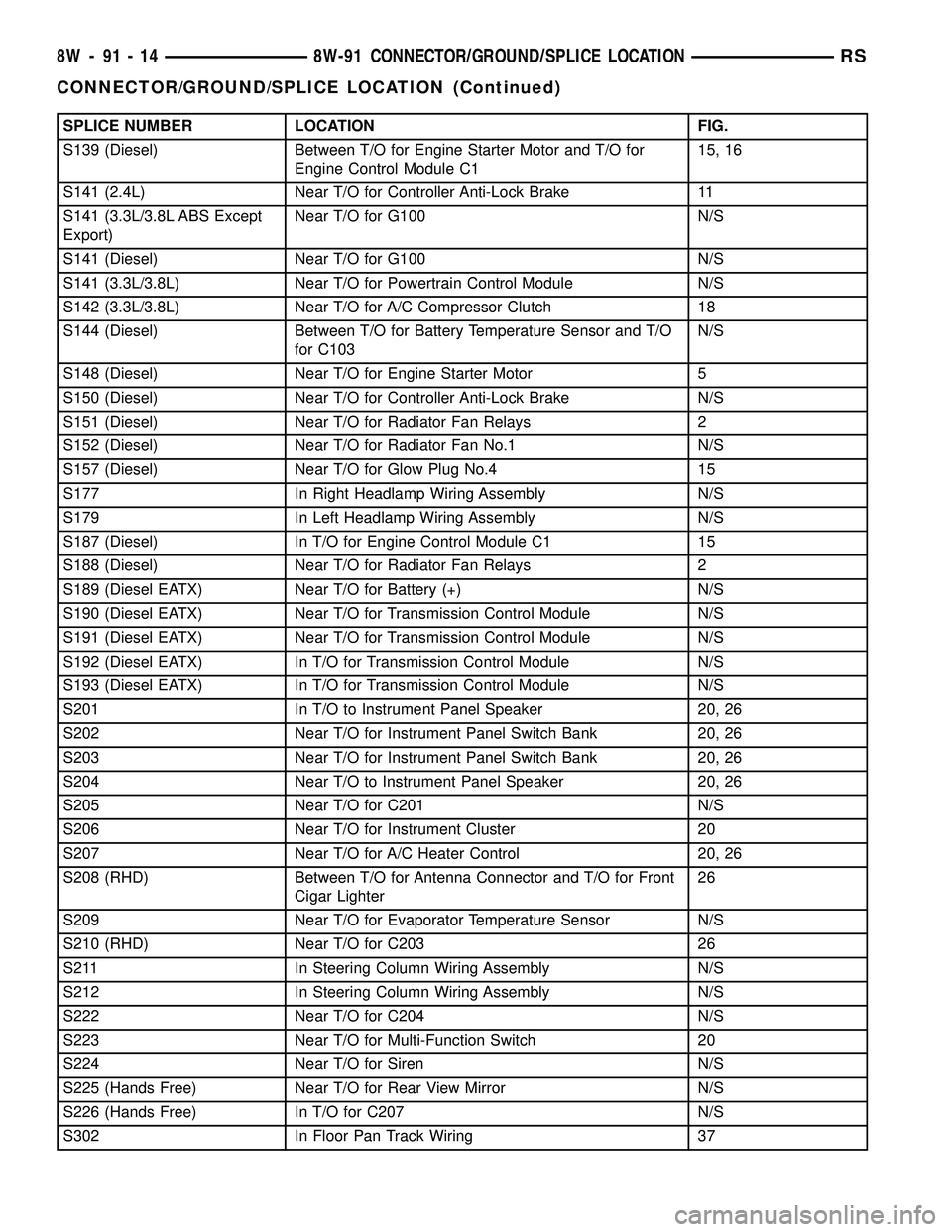

SPLICE NUMBER LOCATION FIG.

S139 (Diesel) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C115, 16

S141 (2.4L) Near T/O for Controller Anti-Lock Brake 11

S141 (3.3L/3.8L ABS Except

Export)Near T/O for G100 N/S

S141 (Diesel) Near T/O for G100 N/S

S141 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S142 (3.3L/3.8L) Near T/O for A/C Compressor Clutch 18

S144 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C103N/S

S148 (Diesel) Near T/O for Engine Starter Motor 5

S150 (Diesel) Near T/O for Controller Anti-Lock Brake N/S

S151 (Diesel) Near T/O for Radiator Fan Relays 2

S152 (Diesel) Near T/O for Radiator Fan No.1 N/S

S157 (Diesel) Near T/O for Glow Plug No.4 15

S177 In Right Headlamp Wiring Assembly N/S

S179 In Left Headlamp Wiring Assembly N/S

S187 (Diesel) In T/O for Engine Control Module C1 15

S188 (Diesel) Near T/O for Radiator Fan Relays 2

S189 (Diesel EATX) Near T/O for Battery (+) N/S

S190 (Diesel EATX) Near T/O for Transmission Control Module N/S

S191 (Diesel EATX) Near T/O for Transmission Control Module N/S

S192 (Diesel EATX) In T/O for Transmission Control Module N/S

S193 (Diesel EATX) In T/O for Transmission Control Module N/S

S201 In T/O to Instrument Panel Speaker 20, 26

S202 Near T/O for Instrument Panel Switch Bank 20, 26

S203 Near T/O for Instrument Panel Switch Bank 20, 26

S204 Near T/O to Instrument Panel Speaker 20, 26

S205 Near T/O for C201 N/S

S206 Near T/O for Instrument Cluster 20

S207 Near T/O for A/C Heater Control 20, 26

S208 (RHD) Between T/O for Antenna Connector and T/O for Front

Cigar Lighter26

S209 Near T/O for Evaporator Temperature Sensor N/S

S210 (RHD) Near T/O for C203 26

S211 In Steering Column Wiring Assembly N/S

S212 In Steering Column Wiring Assembly N/S

S222 Near T/O for C204 N/S

S223 Near T/O for Multi-Function Switch 20

S224 Near T/O for Siren N/S

S225 (Hands Free) Near T/O for Rear View Mirror N/S

S226 (Hands Free) In T/O for C207 N/S

S302 In Floor Pan Track Wiring 37

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1190 of 2339

(9) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug cooler

lines and fittings to prevent debris from entering

transaxle or cooler circuit. A service splice kit will be

installed upon reassembly.

(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

RSENGINE 2.4L9-13

ENGINE 2.4L (Continued)

Page 1191 of 2339

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(24) Remove rear engine mount bracket. (Refer to

9 - ENGINE/ENGINE MOUNTING/REAR MOUNT -

REMOVAL)

(25) Mark flex plate to torque converter and

remove torque converter bolts.

(26) Pinch-off power steering supply hose at pump.

Remove hose from pump.

(27) Remove and set aside the power steering

pump and bracket. Do not disconnect pressure line.

(28) Lower vehicle.

(29) Remove A/C lines at compressor and cap open-

ings.

(30) Remove engine ground straps (strap at engine

right mount and at starter).

(31) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 to be installed under vehicle

(Fig. 8).

(32) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

oil pan rails (Fig. 8). Lower vehicle and position cra-

dle mounts until the engine is resting on mounts.Tighten mounts to cradle frame. This will keep

mounts from moving when removing or installing

engine and transmission.

(33) Install safety straps around the engine to cra-

dle. Tighten straps and lock.

(34) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(35) Remove engine and transmission mount bolts.

(36) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the

dolly to allow for removal around the body.

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.

(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

9 - 14 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1203 of 2339

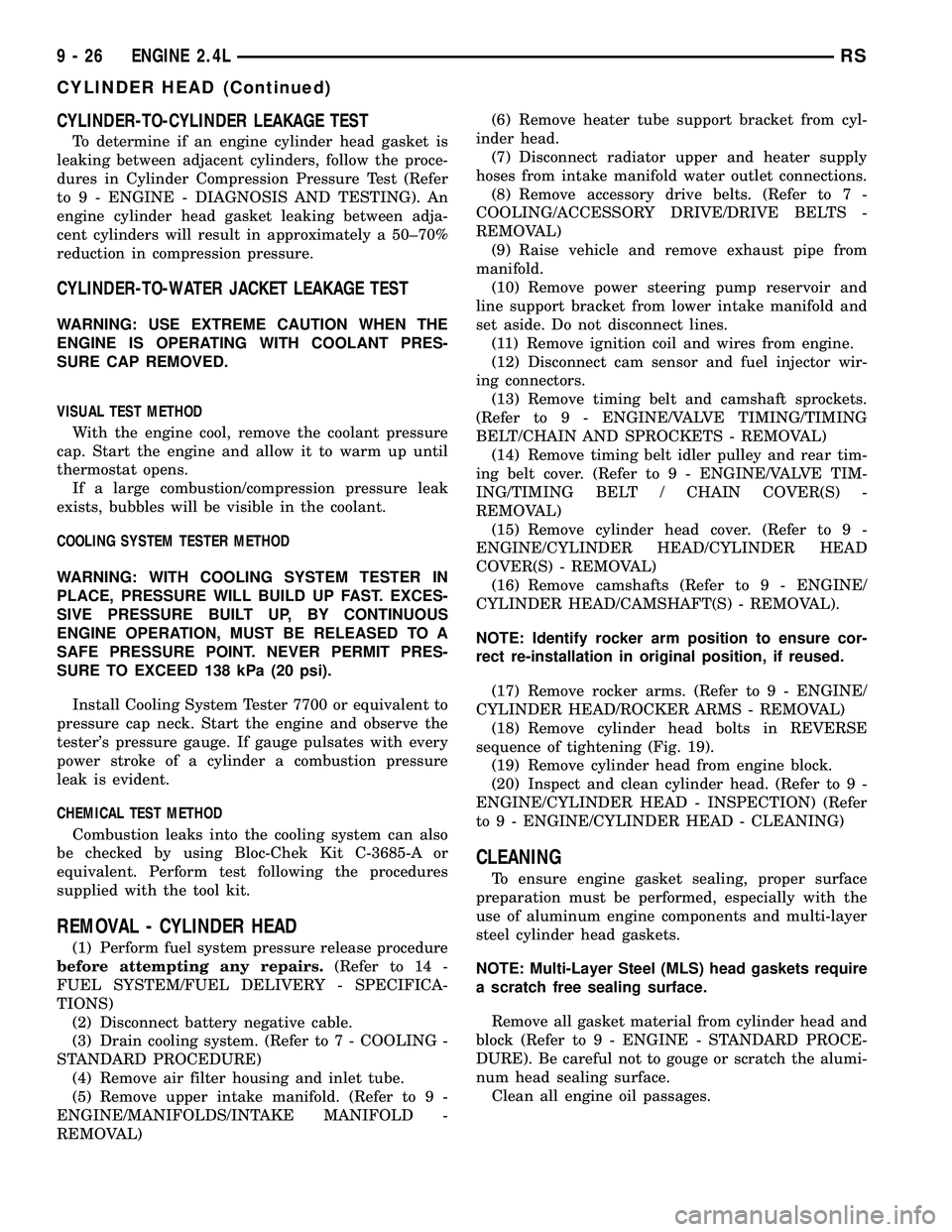

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Perform fuel system pressure release procedure

before attempting any repairs.(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - SPECIFICA-

TIONS)

(2) Disconnect battery negative cable.

(3) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(4) Remove air filter housing and inlet tube.

(5) Remove upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from intake manifold water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump reservoir and

line support bracket from lower intake manifold and

set aside. Do not disconnect lines.

(11) Remove ignition coil and wires from engine.

(12) Disconnect cam sensor and fuel injector wir-

ing connectors.

(13) Remove timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL)

(14) Remove timing belt idler pulley and rear tim-

ing belt cover. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT / CHAIN COVER(S) -

REMOVAL)

(15) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(16) Remove camshafts (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: Identify rocker arm position to ensure cor-

rect re-installation in original position, if reused.

(17) Remove rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL)

(18) Remove cylinder head bolts in REVERSE

sequence of tightening (Fig. 19).

(19) Remove cylinder head from engine block.

(20) Inspect and clean cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSPECTION) (Refer

to 9 - ENGINE/CYLINDER HEAD - CLEANING)

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

9 - 26 ENGINE 2.4LRS

CYLINDER HEAD (Continued)