airbag CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 151 of 2339

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.

(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

50). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.).

(5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

46).

(6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopart

Brake Fluid or equivalent.

(11) Road test vehicle to ensure proper operation of

brakes.

PEDALS - ADJUSTABLE

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Move driver's seat to full rearward position.

(2) Disconnect negative battery cable from battery

post and isolate.

(3) Remove throttle cable from throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(4) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 53).

(5) Disconnect parking brake release link at

release handle.

(6) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.

(7) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 53).

(8) Remove hood release from lower left reinforce-

ment.

(9) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 54).(10) Remove brake lamp switch.Discard original

switch; it must not be reused.(Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL)

(11) Remove upper and lower steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - REMOVAL)

Fig. 53 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 54 Instrument Panel Lower Left Reinforcement

1 - INSTRUMENT PANEL LOWER REINFORCEMENT

2 - STEERING WHEEL

3 - LOWER LEFT REINFORCEMENT

5 - 40 BRAKES - BASERS

MASTER CYLINDER (Continued)

Page 154 of 2339

INSTALLATION

(1) Install adjustable pedals assembly under

instrument panel.

(2) Attach throttle cable to accelerator pedal using

cable retainer.

(3) Install two upper mounting bolts attaching

pedals assembly to steering column support bracket

on dash panel.Do not fully tighten at this time.

(4) Install four nuts attaching pedals assembly and

power brake booster to dash panel (Fig. 61).

(5) Tighten four booster mounting nuts and two

upper mounting bolts to 28 N´m (21 ft. lbs.) torque.

(6) Route pedal adjuster cable up and over right

side of pedals assembly and steering column bracket,

then down through hole in steering column bracket

as shown (Fig. 60). Attach end of cable to gear box.

(7) Place adjuster cable through loop on right side

of steering column bracket as shown (Fig. 60).

(8) Install booster input rod onto brake pedal pin

and install a NEW retaining clip.

(9) Connect wiring connector connecting vehicle

wiring harness to pedal wiring harness (Fig. 58).

(10) Connect routing clips retaining vehicle wiring

harness to pedal wiring harness (Fig. 58).

(11) Install brake lamp switch bracket on pedals

assembly. Tighten mounting nuts to 6 N´m (50 in.

lbs.) torque.

(12) Install dash seal silencer shell over steering

column intermediate shaft and fasten in place (Fig.

57).

(13) Install steering column onto lower mounting

studs with nuts started, then install column onto

upper mounting studs and install two upper mount-

ing nuts. Tighten upper, then lower mounting nuts to

12 N´m (105 in. lbs.) torque.

(14) Install column shaft coupling onto intermedi-

ate shaft and install pinch bolt. Make sure rounded

side of intermediate shaft is matched to the curva-

ture of the coupling. Tighten pinch bolt to 28 N´m

(250 in. lbs.) torque.

(15) Remove retainer holding steering wheel in

place on steering column.

(16) Attach shift cable to bracket on column.

(17) Connect shift cable end to shift lever mecha-

nism pin (Fig. 55).

(18) If equipped, connect PRNDL cable to end of

shift lever mechanism pin and column bracket (Fig.

55).(19) Connect column wiring harness connectors (as

equipped) to SKIM, BTSI solenoid, ignition switch,

multi-function switch, and clockspring.

(20) Install lower and upper steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(21) Install and adjust NEW brake lamp switch.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - INSTALLA-

TION)

(22) Install instrument panel lower left reinforce-

ment (Fig. 54).

(23) Attach hood release to lower left reinforce-

ment.

(24) Install knee blocker reinforcement plate (Fig.

53).

(25) Connect parking brake release link to release

handle.

(26) Install data link diagnostic connector to

mounting hole in reinforcement plate.

(27) Install lower steering column cover/knee

blocker (Fig. 53).

(28) Install throttle cable onto throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - INSTALLATION)

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery following special Diagnosis And Testing pro-

cedure. (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING)

(30) Test operation of adjustable pedals and all

functions that are steering column operated. If appli-

cable, reset radio and clock.

(31) Road test the vehicle to ensure proper opera-

tion of steering and brake systems.

RSBRAKES - BASE5-43

PEDALS - ADJUSTABLE (Continued)

Page 261 of 2339

mation. For diagnosis of these electronic modules or

of the data bus network, the use of a DRB IIItscan

tool and the proper Diagnostic Procedures informa-

tion is recommended.

DIAGNOSIS AND TESTING

AUDIO/VIDEO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRBIIIt, refer to the appropriate Diagnostic Service

information.

Refer to the appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

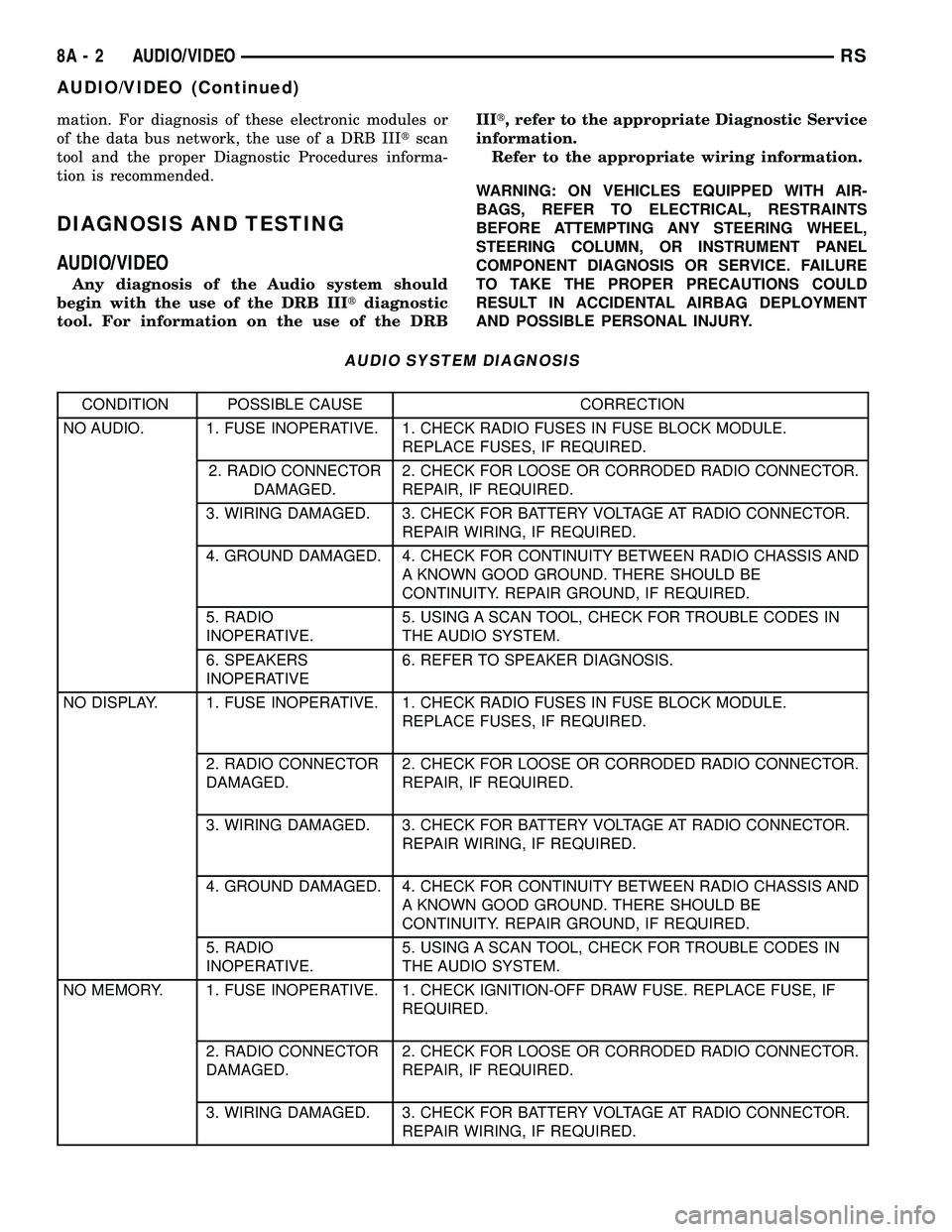

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE INOPERATIVE. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND DAMAGED. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO

INOPERATIVE.5. USING A SCAN TOOL, CHECK FOR TROUBLE CODES IN

THE AUDIO SYSTEM.

6. SPEAKERS

INOPERATIVE6. REFER TO SPEAKER DIAGNOSIS.

NO DISPLAY. 1. FUSE INOPERATIVE. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND DAMAGED. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO

INOPERATIVE.5. USING A SCAN TOOL, CHECK FOR TROUBLE CODES IN

THE AUDIO SYSTEM.

NO MEMORY. 1. FUSE INOPERATIVE. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

8A - 2 AUDIO/VIDEORS

AUDIO/VIDEO (Continued)

Page 267 of 2339

DIAGNOSIS AND TESTING

ANTENNA BODY AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

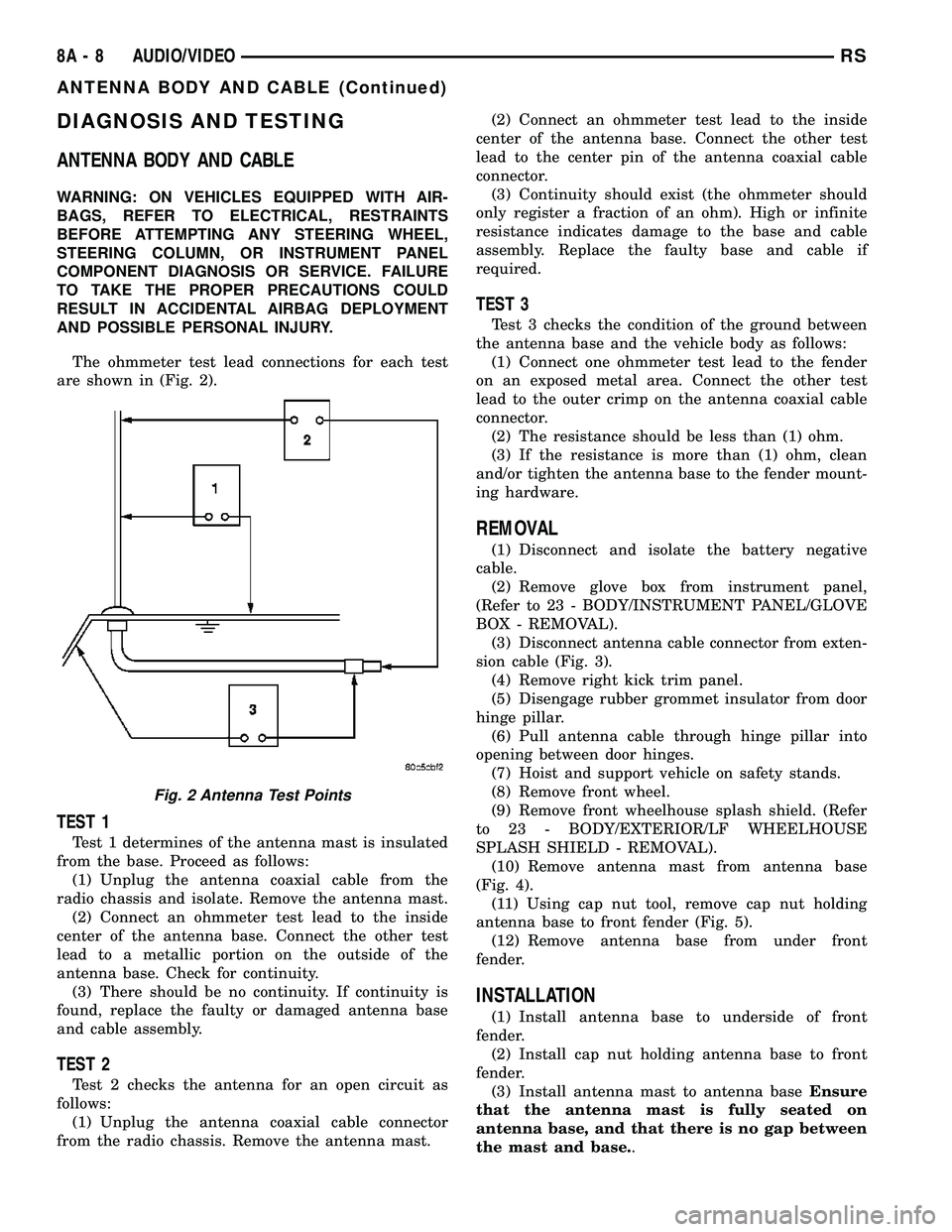

The ohmmeter test lead connections for each test

are shown in (Fig. 2).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

TEST 2

Test 2 checks the antenna for an open circuit as

follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis. Remove the antenna mast.(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to the center pin of the antenna coaxial cable

connector.

(3) Continuity should exist (the ohmmeter should

only register a fraction of an ohm). High or infinite

resistance indicates damage to the base and cable

assembly. Replace the faulty base and cable if

required.

TEST 3

Test 3 checks the condition of the ground between

the antenna base and the vehicle body as follows:

(1) Connect one ohmmeter test lead to the fender

on an exposed metal area. Connect the other test

lead to the outer crimp on the antenna coaxial cable

connector.

(2) The resistance should be less than (1) ohm.

(3) If the resistance is more than (1) ohm, clean

and/or tighten the antenna base to the fender mount-

ing hardware.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box from instrument panel,

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - REMOVAL).

(3) Disconnect antenna cable connector from exten-

sion cable (Fig. 3).

(4) Remove right kick trim panel.

(5) Disengage rubber grommet insulator from door

hinge pillar.

(6) Pull antenna cable through hinge pillar into

opening between door hinges.

(7) Hoist and support vehicle on safety stands.

(8) Remove front wheel.

(9) Remove front wheelhouse splash shield. (Refer

to 23 - BODY/EXTERIOR/LF WHEELHOUSE

SPLASH SHIELD - REMOVAL).

(10) Remove antenna mast from antenna base

(Fig. 4).

(11) Using cap nut tool, remove cap nut holding

antenna base to front fender (Fig. 5).

(12) Remove antenna base from under front

fender.

INSTALLATION

(1) Install antenna base to underside of front

fender.

(2) Install cap nut holding antenna base to front

fender.

(3) Install antenna mast to antenna baseEnsure

that the antenna mast is fully seated on

antenna base, and that there is no gap between

the mast and base..

Fig. 2 Antenna Test Points

8A - 8 AUDIO/VIDEORS

ANTENNA BODY AND CABLE (Continued)

Page 271 of 2339

(3) Install screws holding CD changer.

(4) Reconnect the battery negative cable.

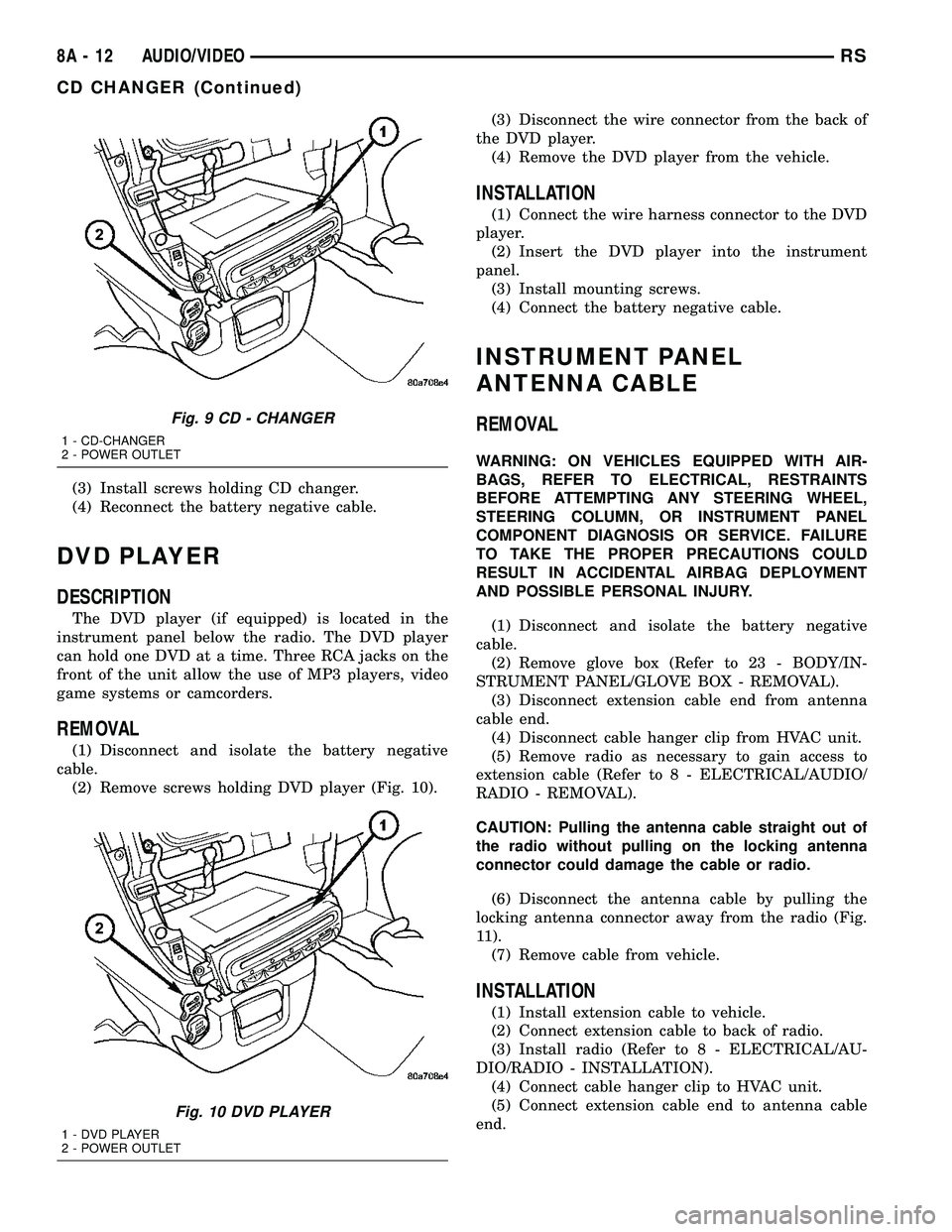

DVD PLAYER

DESCRIPTION

The DVD player (if equipped) is located in the

instrument panel below the radio. The DVD player

can hold one DVD at a time. Three RCA jacks on the

front of the unit allow the use of MP3 players, video

game systems or camcorders.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding DVD player (Fig. 10).(3) Disconnect the wire connector from the back of

the DVD player.

(4) Remove the DVD player from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the DVD

player.

(2) Insert the DVD player into the instrument

panel.

(3) Install mounting screws.

(4) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

(3) Disconnect extension cable end from antenna

cable end.

(4) Disconnect cable hanger clip from HVAC unit.

(5) Remove radio as necessary to gain access to

extension cable (Refer to 8 - ELECTRICAL/AUDIO/

RADIO - REMOVAL).

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(6) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

11).

(7) Remove cable from vehicle.

INSTALLATION

(1) Install extension cable to vehicle.

(2) Connect extension cable to back of radio.

(3) Install radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

(4) Connect cable hanger clip to HVAC unit.

(5) Connect extension cable end to antenna cable

end.

Fig. 9 CD - CHANGER

1 - CD-CHANGER

2 - POWER OUTLET

Fig. 10 DVD PLAYER

1 - DVD PLAYER

2 - POWER OUTLET

8A - 12 AUDIO/VIDEORS

CD CHANGER (Continued)

Page 273 of 2339

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For complete circuit diagrams, refer to the appro-

priate wiring information.

DIAGNOSIS AND TESTING

RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

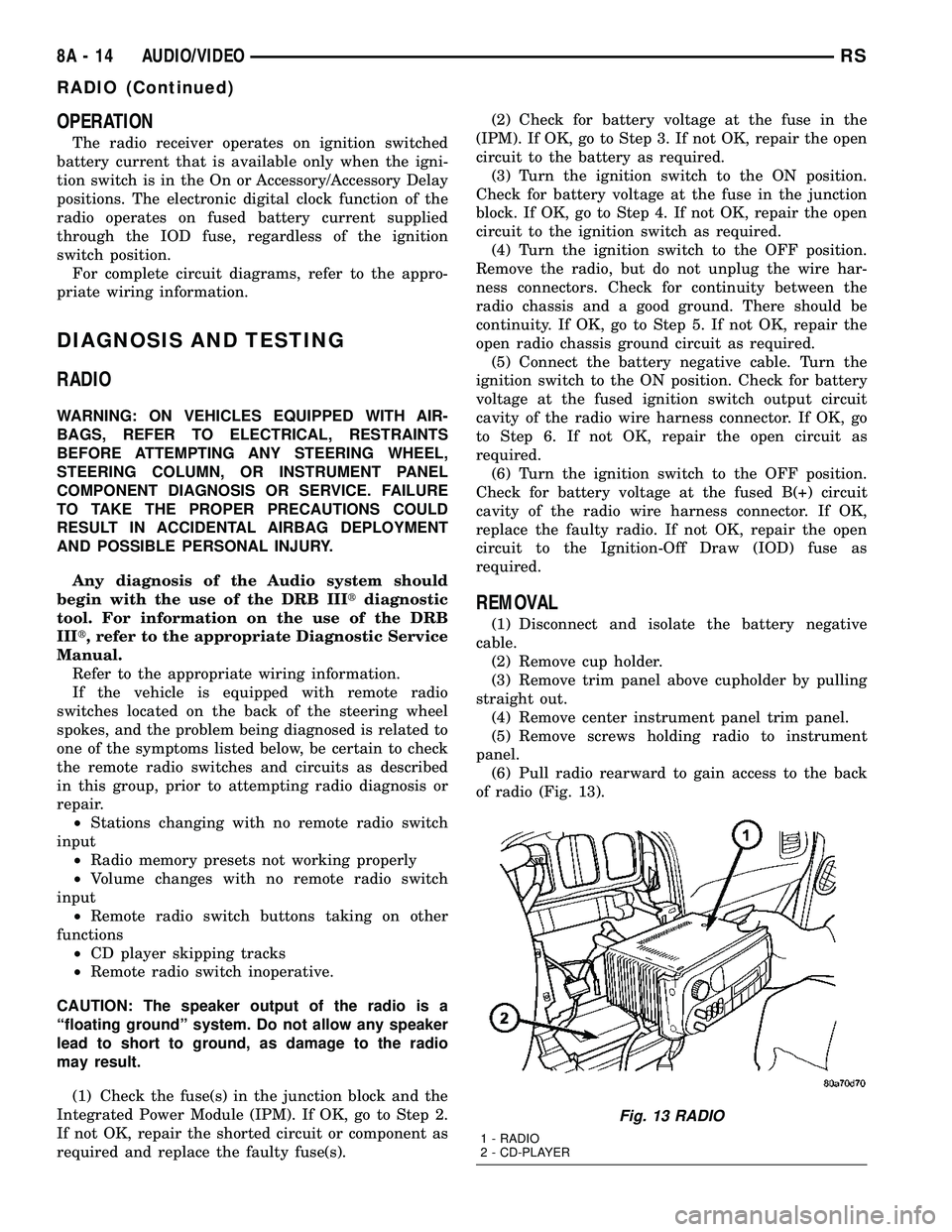

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 13).

Fig. 13 RADIO

1 - RADIO

2 - CD-PLAYER

8A - 14 AUDIO/VIDEORS

RADIO (Continued)

Page 275 of 2339

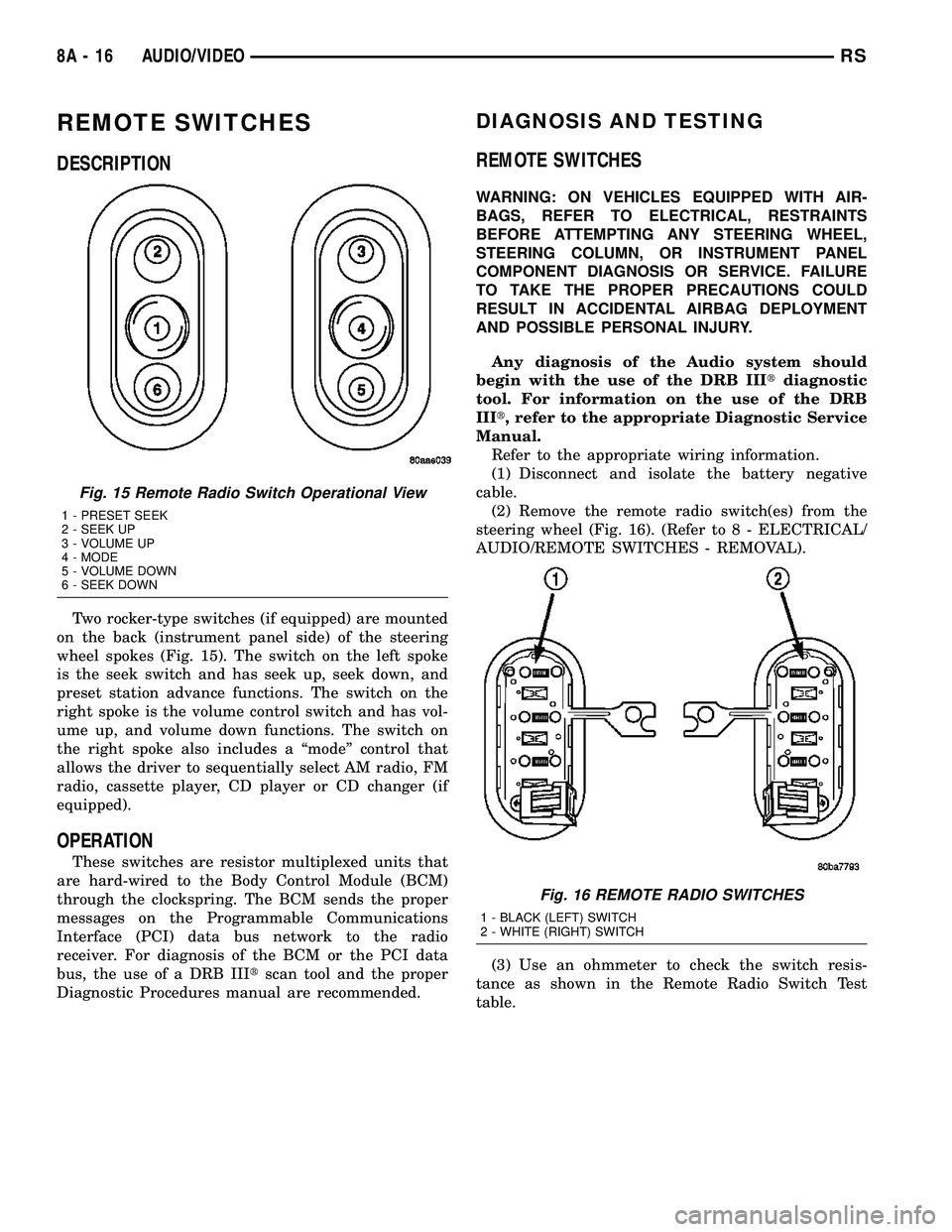

REMOTE SWITCHES

DESCRIPTION

Two rocker-type switches (if equipped) are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 15). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended.

DIAGNOSIS AND TESTING

REMOTE SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

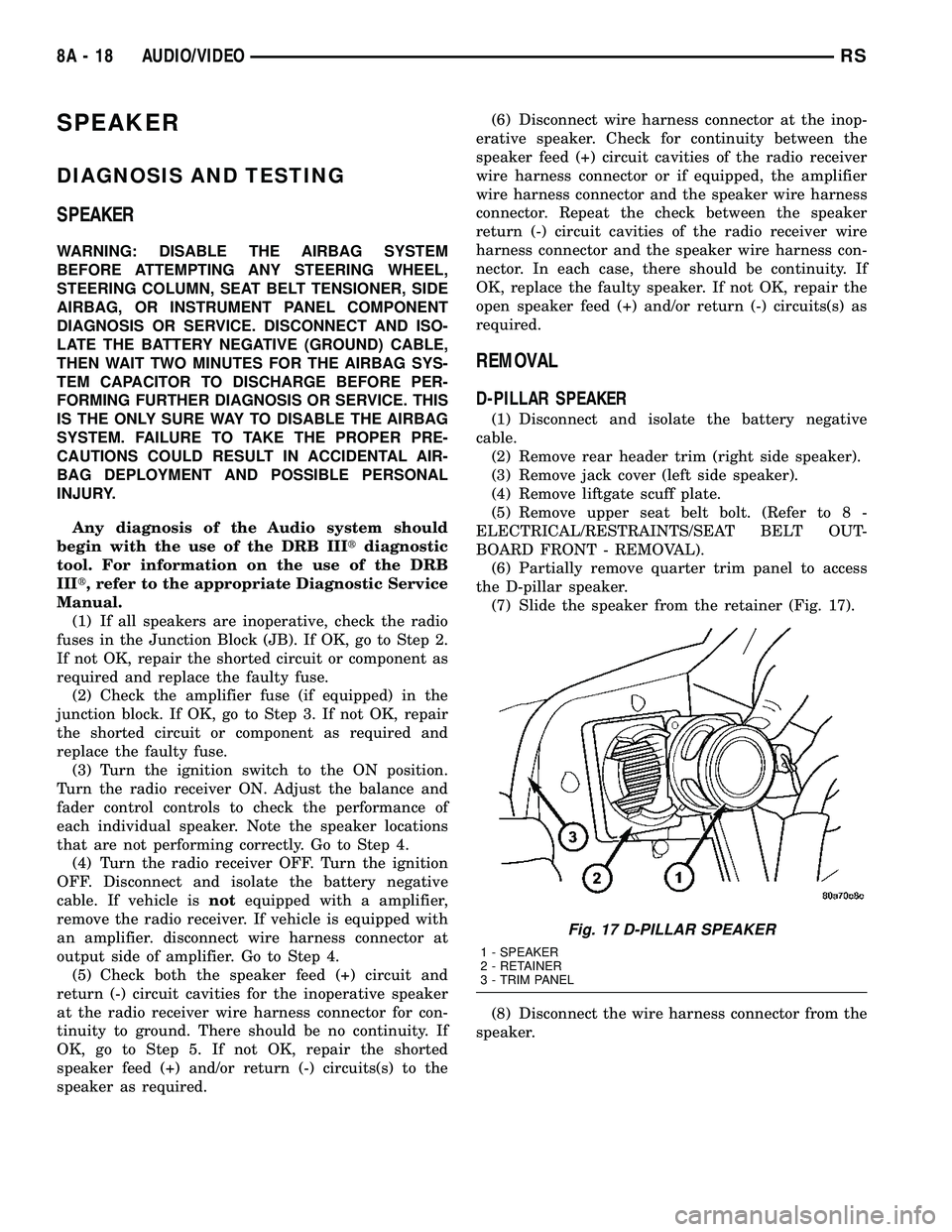

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the remote radio switch(es) from the

steering wheel (Fig. 16). (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table.

Fig. 15 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 16 REMOTE RADIO SWITCHES

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

8A - 16 AUDIO/VIDEORS

Page 276 of 2339

REMOTE RADIO SWITCH TEST

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

(4) If the switch resistance checks OK, go to Step

5. If not OK, replace the faulty switch.

(5) Check for continuity between the ground cir-

cuit cavity of the switch wire harness connector and

a good ground. There should be continuity. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Unplug the 24-way white wire harness connec-

tor from the Body Control Module (BCM). Check for

continuity between the radio control circuit cavity of

the remote radio switch wire harness connector and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the short circuit as

required.

(7) Check for continuity between the radio control

circuit cavities of the remote radio switch wire har-

ness connector and the BCM wire harness connector.

There should be continuity. If OK, refer to the proper

Diagnostic Procedures manual to test the BCM and

the PCI data bus. If not OK, repair the open circuit

as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

REMOVAL).

(3) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch (es).

(5) Remove three screws securing steering wheel

rear cover.

(6) Remove the remote radio switch from the steer-

ing wheel by depressing tabs on each side of each

switch.

NOTE: The right remote radio switch back is white

in color. The left switch back is black in color. The

right/left remote radio switch orientation is with the

steering wheel installed, and driver in drivers seat.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Install three screws securing steering wheel

rear cover.

(3) Connect the wire harness to the remote radio

switch.

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Install the driver side airbag (Refer to 8 -

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG -

INSTALLATION).

(6) Connect the battery negative cable.

RSAUDIO/VIDEO8A-17

REMOTE SWITCHES (Continued)

Page 277 of 2339

SPEAKER

DIAGNOSIS AND TESTING

SPEAKER

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

(1) If all speakers are inoperative, check the radio

fuses in the Junction Block (JB). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

junction block. If OK, go to Step 3. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 4.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

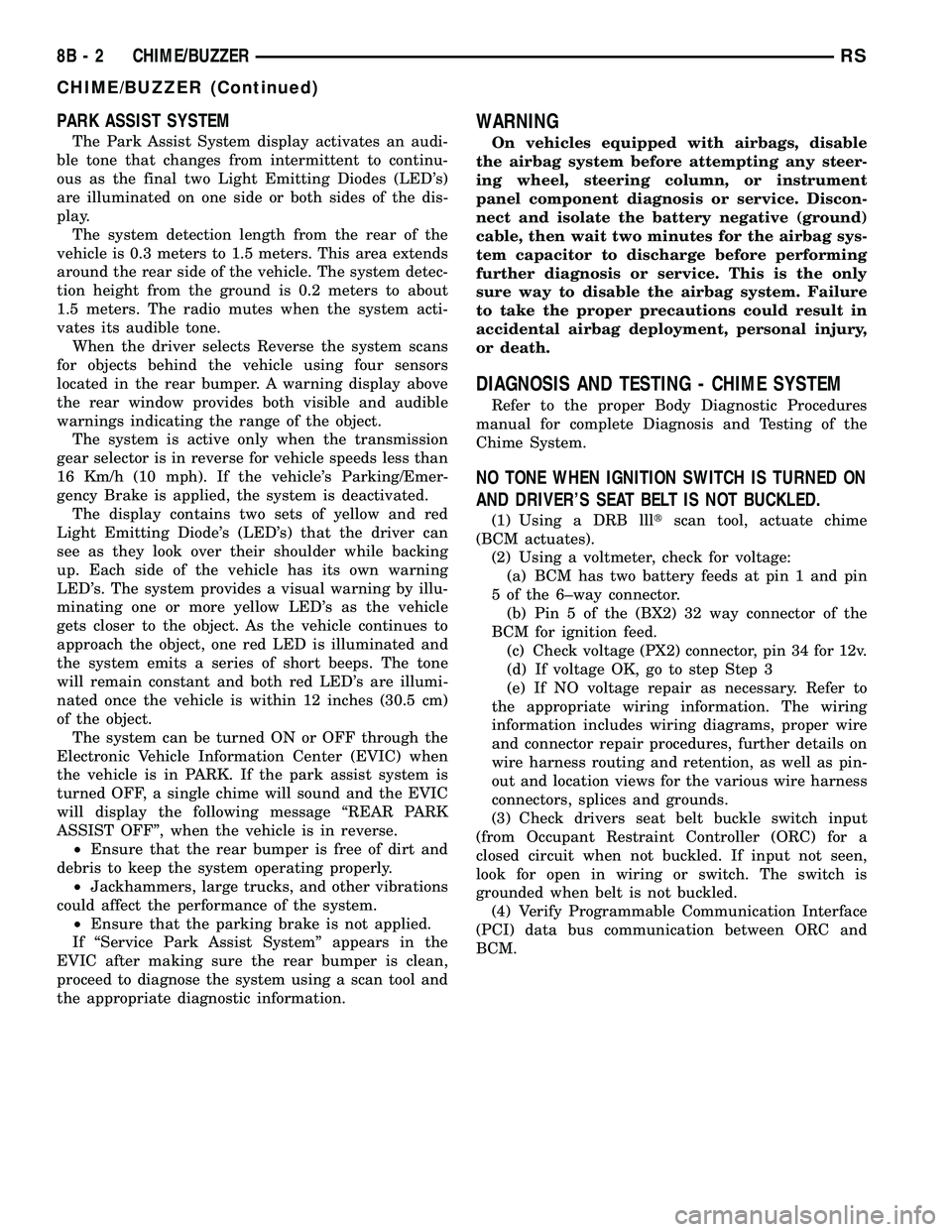

REMOVAL

D-PILLAR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 17).

(8) Disconnect the wire harness connector from the

speaker.

Fig. 17 D-PILLAR SPEAKER

1 - SPEAKER

2 - RETAINER

3 - TRIM PANEL

8A - 18 AUDIO/VIDEORS

Page 281 of 2339

PARK ASSIST SYSTEM

The Park Assist System display activates an audi-

ble tone that changes from intermittent to continu-

ous as the final two Light Emitting Diodes (LED's)

are illuminated on one side or both sides of the dis-

play.

The system detection length from the rear of the

vehicle is 0.3 meters to 1.5 meters. This area extends

around the rear side of the vehicle. The system detec-

tion height from the ground is 0.2 meters to about

1.5 meters. The radio mutes when the system acti-

vates its audible tone.

When the driver selects Reverse the system scans

for objects behind the vehicle using four sensors

located in the rear bumper. A warning display above

the rear window provides both visible and audible

warnings indicating the range of the object.

The system is active only when the transmission

gear selector is in reverse for vehicle speeds less than

16 Km/h (10 mph). If the vehicle's Parking/Emer-

gency Brake is applied, the system is deactivated.

The display contains two sets of yellow and red

Light Emitting Diode's (LED's) that the driver can

see as they look over their shoulder while backing

up. Each side of the vehicle has its own warning

LED's. The system provides a visual warning by illu-

minating one or more yellow LED's as the vehicle

gets closer to the object. As the vehicle continues to

approach the object, one red LED is illuminated and

the system emits a series of short beeps. The tone

will remain constant and both red LED's are illumi-

nated once the vehicle is within 12 inches (30.5 cm)

of the object.

The system can be turned ON or OFF through the

Electronic Vehicle Information Center (EVIC) when

the vehicle is in PARK. If the park assist system is

turned OFF, a single chime will sound and the EVIC

will display the following message ªREAR PARK

ASSIST OFFº, when the vehicle is in reverse.

²Ensure that the rear bumper is free of dirt and

debris to keep the system operating properly.

²Jackhammers, large trucks, and other vibrations

could affect the performance of the system.

²Ensure that the parking brake is not applied.

If ªService Park Assist Systemº appears in the

EVIC after making sure the rear bumper is clean,

proceed to diagnose the system using a scan tool and

the appropriate diagnostic information.

WARNING

On vehicles equipped with airbags, disable

the airbag system before attempting any steer-

ing wheel, steering column, or instrument

panel component diagnosis or service. Discon-

nect and isolate the battery negative (ground)

cable, then wait two minutes for the airbag sys-

tem capacitor to discharge before performing

further diagnosis or service. This is the only

sure way to disable the airbag system. Failure

to take the proper precautions could result in

accidental airbag deployment, personal injury,

or death.

DIAGNOSIS AND TESTING - CHIME SYSTEM

Refer to the proper Body Diagnostic Procedures

manual for complete Diagnosis and Testing of the

Chime System.

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVER'S SEAT BELT IS NOT BUCKLED.

(1) Using a DRB llltscan tool, actuate chime

(BCM actuates).

(2) Using a voltmeter, check for voltage:

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

(3) Check drivers seat belt buckle switch input

(from Occupant Restraint Controller (ORC) for a

closed circuit when not buckled. If input not seen,

look for open in wiring or switch. The switch is

grounded when belt is not buckled.

(4) Verify Programmable Communication Interface

(PCI) data bus communication between ORC and

BCM.

8B - 2 CHIME/BUZZERRS

CHIME/BUZZER (Continued)