key CHRYSLER CROSSFIRE 2007 1.G Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2007, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2007 1.GPages: 299, PDF Size: 8.26 MB

Page 190 of 299

With the key in the ignition switch turned to the ON/

RUN position, the fuel reserve warning light comes on. It

should go out immediately when the engine is running.

If the warning light does not go out after starting the

engine, or if it comes on while driving, it indicates that

the fuel level is down to the reserve quantity of approxi-

mately 2 gallons (7.5 liters).

Leaving the engine running and the fuel cap open can

cause the CHECK ENGINE light to illuminate.

NOTE:

²

When the fuel nozzle ªclicksº or shuts off, the fuel

tank is full.

²Tighten the gas cap until you hear a single click. This

is an indication that the gas cap is properly tightened.

The CHECK ENGINE light will come on if the gas cap

is not properly secured. Make sure that the gas cap is

tightened each time the vehicle is refueled.

WARNING!

²Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank is filled.

²Never add fuel to the vehicle when the engine is

running.

²A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on

the ground outside the vehicle while filling.

190 STARTING AND OPERATING

Page 194 of 299

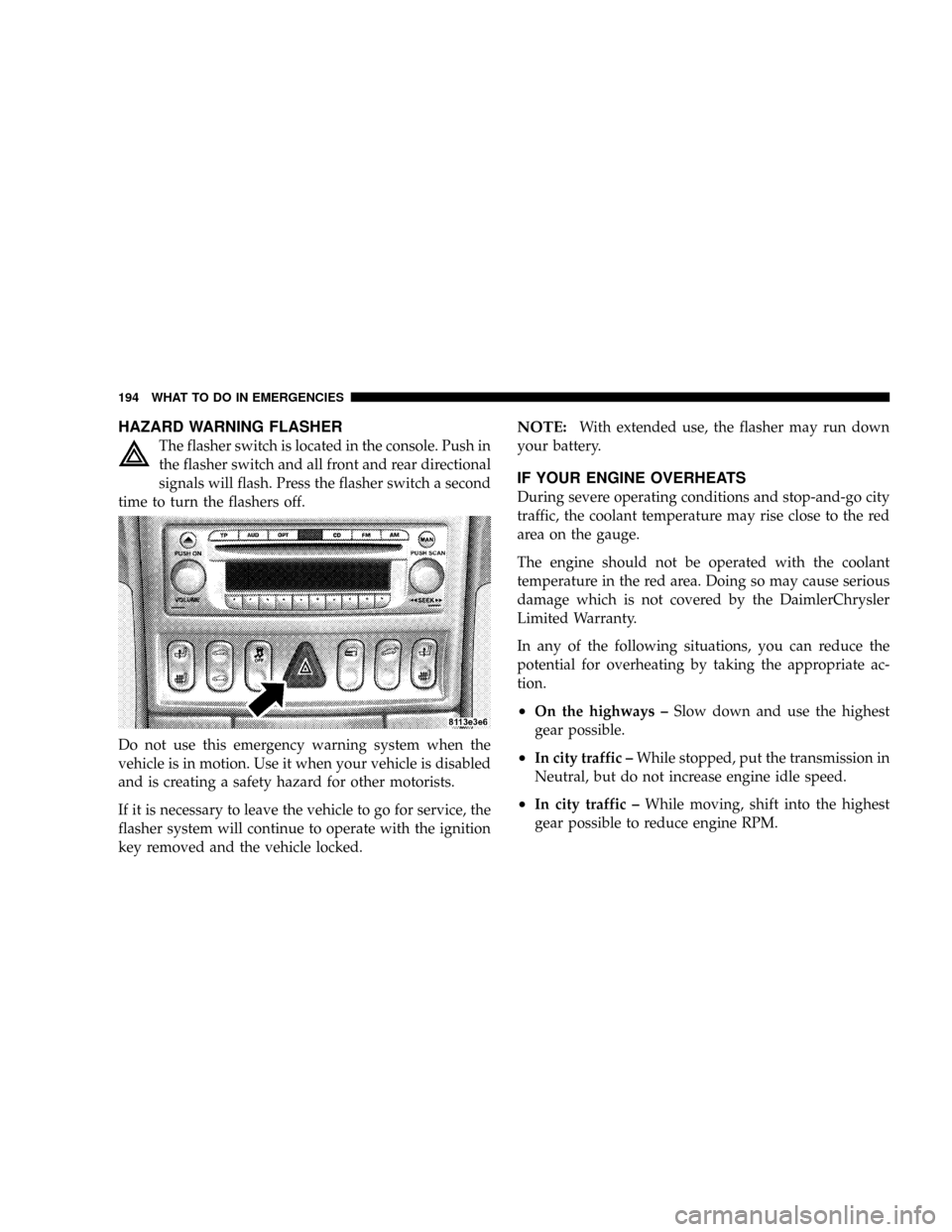

HAZARD WARNING FLASHER

The flasher switch is located in the console. Push in

the flasher switch and all front and rear directional

signals will flash. Press the flasher switch a second

time to turn the flashers off.

Do not use this emergency warning system when the

vehicle is in motion. Use it when your vehicle is disabled

and is creating a safety hazard for other motorists.

If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

NOTE:With extended use, the flasher may run down

your battery.

IF YOUR ENGINE OVERHEATS

During severe operating conditions and stop-and-go city

traffic, the coolant temperature may rise close to the red

area on the gauge.

The engine should not be operated with the coolant

temperature in the red area. Doing so may cause serious

damage which is not covered by the DaimlerChrysler

Limited Warranty.

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate ac-

tion.

²On the highways ±Slow down and use the highest

gear possible.

²In city traffic ±While stopped, put the transmission in

Neutral, but do not increase engine idle speed.

²In city traffic ±While moving, shift into the highest

gear possible to reduce engine RPM.

194 WHAT TO DO IN EMERGENCIES

Page 197 of 299

Sealing tire with TIREFIT

1. Set the parking brake and turn on the hazard warning

flashers.

2. Move the transmission selector lever to the PARK

position (manual transmission to FIRST or REVERSE

gear) and turn off the engine.

3. Remove the TIREFIT kit and electric air pump from

the area below the cargo compartment carpet.

4. Open flap (2) on the electric air pump.

5. Pull the power plug (4) and air hose (5) along with the

pressure gauge out of the air pump housing.

6. Screw the air hose (5) onto the hose connection on the

TIREFIT sealant bottle (1).

7. Holding the sealant bottle by the top, insert it down-

wards into the recess (3) on the air pump.

8. Unscrew the valve cap from the valve on the deflated

tire.

9. Screw the filler hose from the sealant bottle on the tire

valve.10. Insert the power plug (4) into the power point on the

instrument panel.

11. Turn the ignition key to the ON/RUN position.

12. Press the switch on the air pump to 1. The air pump

should start to inflate the tire.

13. After five minutes, the tire should be inflated to at

least 26 psi (180 kPa) on the pressure gauge.

14. If the tire doesn't inflate to this level, press the air

pump switch to 0, disconnect the TIREFIT system from

the tire, and drive the vehicle back and forth approxi-

mately 30 feet (9 m) to distribute the sealant more evenly

within the tire.

15. Attach the air pump hose directly to the tire, press the

switch to 1, and inflate the tire again.NOTE:If a tire

pressure of 26 psi (180 kPa) is not reached after five

minutes, the tire is too badly damaged. Do not attempt to

drive the vehicle further, and call for assistance.

WHAT TO DO IN EMERGENCIES 197

6

Page 206 of 299

FREEING A STUCK VEHICLE

In order to free a stuck vehicle you must turn off the

Electronic Stability Program (ESP) before attempting to

ªrockº the vehicle.

If your vehicle becomes stuck in mud, sand or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between Reverse

and Drive. Usually the least accelerator pedal pressure to

maintain the rocking motion without spinning the

wheels is most effective.

NOTE:ESP should be turned on again after freeing the

vehicle from a stuck condition.

CAUTION!

Racing the engine or spinning the wheels too fast

may lead to transmission/axle overheating and fail-

ure. It can also damage the tires. Do not spin the

wheels above 35 mph (55 km/h).

TOWING A DISABLED VEHICLE

We recommend that the vehicle be transported using flat

bed equipment. This method is preferable to other types

of towing.

CAUTION!

Important! If towing the vehicle, please note the

following: With the automatic central locking acti-

vated and the key in the ignition switch turned to the

ON/RUN position, the vehicle doors lock if the left

front wheel and the right rear wheel are turning at

vehicle speeds of approximately 9 mph (15 km/h) or

more. To prevent the vehicle door locks from locking,

deactivate the automatic central locking.

206 WHAT TO DO IN EMERGENCIES

Page 207 of 299

CAUTION!

If the vehicle is towed with the front wheels raised,

the engine must be shut off (key in the ignition

switch turned to the OFF/LOCK or ACC positions).

Otherwise, the ESP will immediately be engaged and

will apply the rear wheel brakes. Switch off the

tow-away alarm as well as the automatic central

locking system.

Towing restrictions for vehicles with automatic transmis-

sion: The vehicle may be towed with all wheels on the

ground and the transmission selector lever in the Neutral

position for distances up to 30 miles (48 km) and at a

speed not to exceed 30 mph (48 km/h). The key must be

turned to the ON/RUN position in the ignition. To be

certain to avoid a possibility of damage to the transmis-

sion, however, we recommend the drive shaft be discon-

nected at the rear axle drive flange for any towing

beyond a short tow to a nearby garage.Always comply with applicable state or local towing

ordinances.CAUTION!

²Do not attempt to tow this vehicle from the front

with sling-type towing equipment. Damage to the

front fascia will result.

²Always use wheel lift equipment when towing

from the front. The only other approved method of

towing is with a flatbed truck.

²Do not tow the vehicle from the rear. Damage to

the rear sheet metal and fascia will occur.

²Do not push or tow this vehicle with another

vehicle as damage to the bumper fascia and trans-

mission may result.

WHAT TO DO IN EMERGENCIES 207

6

Page 210 of 299

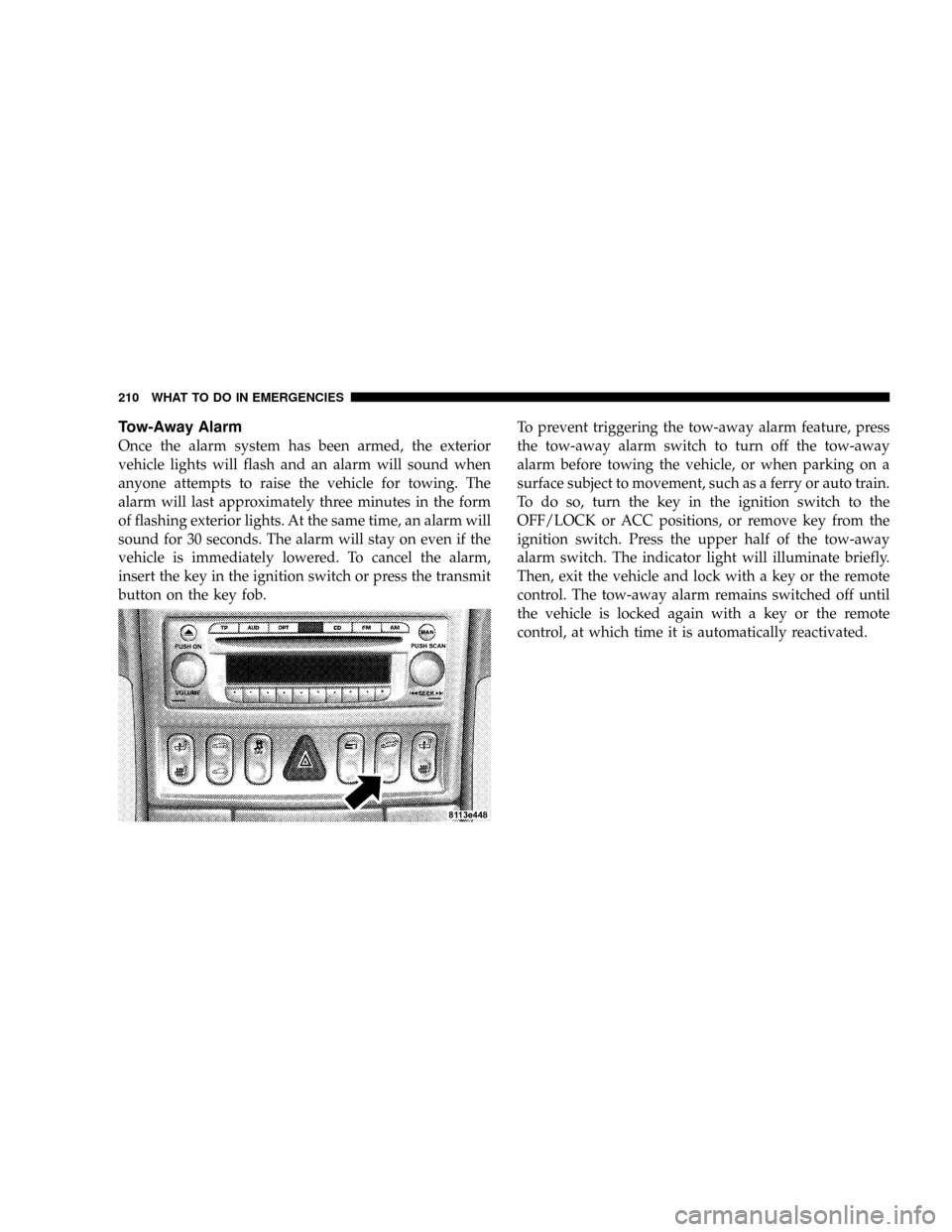

Tow-Away Alarm

Once the alarm system has been armed, the exterior

vehicle lights will flash and an alarm will sound when

anyone attempts to raise the vehicle for towing. The

alarm will last approximately three minutes in the form

of flashing exterior lights. At the same time, an alarm will

sound for 30 seconds. The alarm will stay on even if the

vehicle is immediately lowered. To cancel the alarm,

insert the key in the ignition switch or press the transmit

button on the key fob.To prevent triggering the tow-away alarm feature, press

the tow-away alarm switch to turn off the tow-away

alarm before towing the vehicle, or when parking on a

surface subject to movement, such as a ferry or auto train.

To do so, turn the key in the ignition switch to the

OFF/LOCK or ACC positions, or remove key from the

ignition switch. Press the upper half of the tow-away

alarm switch. The indicator light will illuminate briefly.

Then, exit the vehicle and lock with a key or the remote

control. The tow-away alarm remains switched off until

the vehicle is locked again with a key or the remote

control, at which time it is automatically reactivated.

210 WHAT TO DO IN EMERGENCIES

Page 212 of 299

Relieving Hydraulic Pressure

NOTE:

The hydraulic pressure must be relieved before

the top can manually be raised or lowered.

1. Turn the ignition to the ªONº position.

2. Push down on the convertible top switch and hold in

that position.

3. Turn the ignition ªOFFº and continue to push down

on the switch for 5 seconds.

4. After 5 seconds the hydraulic system pressure will be

relieved.

WARNING!

It is important that a second person assist you to close

the convertible top manually to prevent injuries.

1. Lower the windows and open the doors.

2. Turn the ignition key off.

CAUTION!

Ensure that the decklid is closed while raising the

convertible top manually to prevent the possibility of

contact between the decklid and the tonneau cover.

WARNING!

Do not place your hands near the convertible top

frame, upper windshield area, or the convertible top

storage compartment while the convertible top is

being raised and locked. Serious personal injury may

occur.

3. Unlock the storage compartment by placing the tool

on the bolt between the backrest and the tonneau cover.

Turn the wrench in the direction of the arrow to its stop

and remove the tool.

212 WHAT TO DO IN EMERGENCIES

Page 223 of 299

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of your vehicle's emissions control system.

Failure to pass could prevent vehicle registration.

For states which have an I/M (Inspection and

Maintenance) requirement, this check verifies

the following: the CHECK ENGINE Light is functioning

and is not on when the engine is running, and that the

OBD (Onboard Diagnostic) system is ready for testing.

Normally, the OBD system will be ready. The OBD

system maynotbe ready if your vehicle was recently

serviced, if you recently had a dead battery, or a battery

replacement. If the OBD system should be determined

not ready for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition key actuated test

which you can use prior to going to the test station. To

check if your vehicle's OBD system is ready, you must do

the following:

1. Insert your ignition key into the ignition switch.2. Turn the ignition to the ON/RUN position, but do not

crank or start the engine.

3. If you crank or start the engine, you will have to start

this test over.

4. As soon as you turn your key to the ON/RUN

position, you will see your CHECK ENGINE light come

on as part of a normal bulb check.

5. Approximately 15 seconds later, one of two things will

happen:

a. The CHECK ENGINE light will flash for about 10

seconds and then return to being fully illuminated

until you turn off the ignition key or start the

engine. This means that your vehicle's OBD system

isnot readyand you shouldnotproceed to the I/M

station.

b. The CHECK ENGINE light will not flash at all

and will remain fully illuminated until you turn off

the ignition key or start the engine. This means that

your vehicle's OBD system isreadyand you can

proceed to the I/M station.

MAINTAINING YOUR VEHICLE 223

7

Page 235 of 299

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, and rear liftgate / decklid hinges,

should be lubricated periodically to assure quiet, easy

operation and to protect against rust and wear.

Hood Latch

When performing other under hood services, the hood

latch release mechanism and safety catch should be

inspected, cleaned, and lubricated.

It is important to maintain proper lubrication to insure

that the hood mechanisms work properly and safely.

Multi-Purpose Lubricant, NLGI Grade 2, should be ap-

plied sparingly to all pivot and sliding contact areas.

Driver's Door Lock Cylinder

The driver's door lock cylinder should be lubricated

twice a year, preferably in the fall and spring. Apply a

small amount of a high quality lubricant, such as Mopart

Lock Cylinder Lubricant directly into the lock cylinder

(avoid excess lubricant).

Insert the key into the lock cylinder and rotate from the

unlocked to the locked position without adding morelubricant. Repeat this procedure three or four times. Wipe

all the lubricant off the key with a clean cloth, to avoid

soiling clothing.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild non-abrasive cleaner, or use the washer solvent.

This will remove accumulations of salt or road film and

help reduce streaking, chatter, and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield. Avoid using the wiper blades to

remove frost or ice from the windshield. Make sure that

they are not frozen to the glass before turning them on to

avoid damaging the blade. Keep the blade rubber out of

contact with petroleum products such as engine oil,

gasoline, etc.

MAINTAINING YOUR VEHICLE 235

7

Page 238 of 299

Cooling System

WARNING!

²When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at any time the ignition

key is in the ON position.

²You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don't open the

hood until the radiator has had time to cool. Never

try to open a cooling system pressure cap when the

radiator is hot.

Coolant Checks

Check coolant protection every 12 months (before the

onset of freezing weather, where applicable). If the cool-

ant is dirty or rusty in appearance, the system should be

drained, flushed and refilled with fresh coolant.Check the front of the radiator and condenser for an

accumulation of bugs, leaves, etc. Clean the radiator and

condenser by gently spraying water from a garden hose

at the back of the radiator core.

Check the recovery bottle tank tubing for condition and

tightness of connection at the bottle and radiator. Inspect

the entire system for leaks.

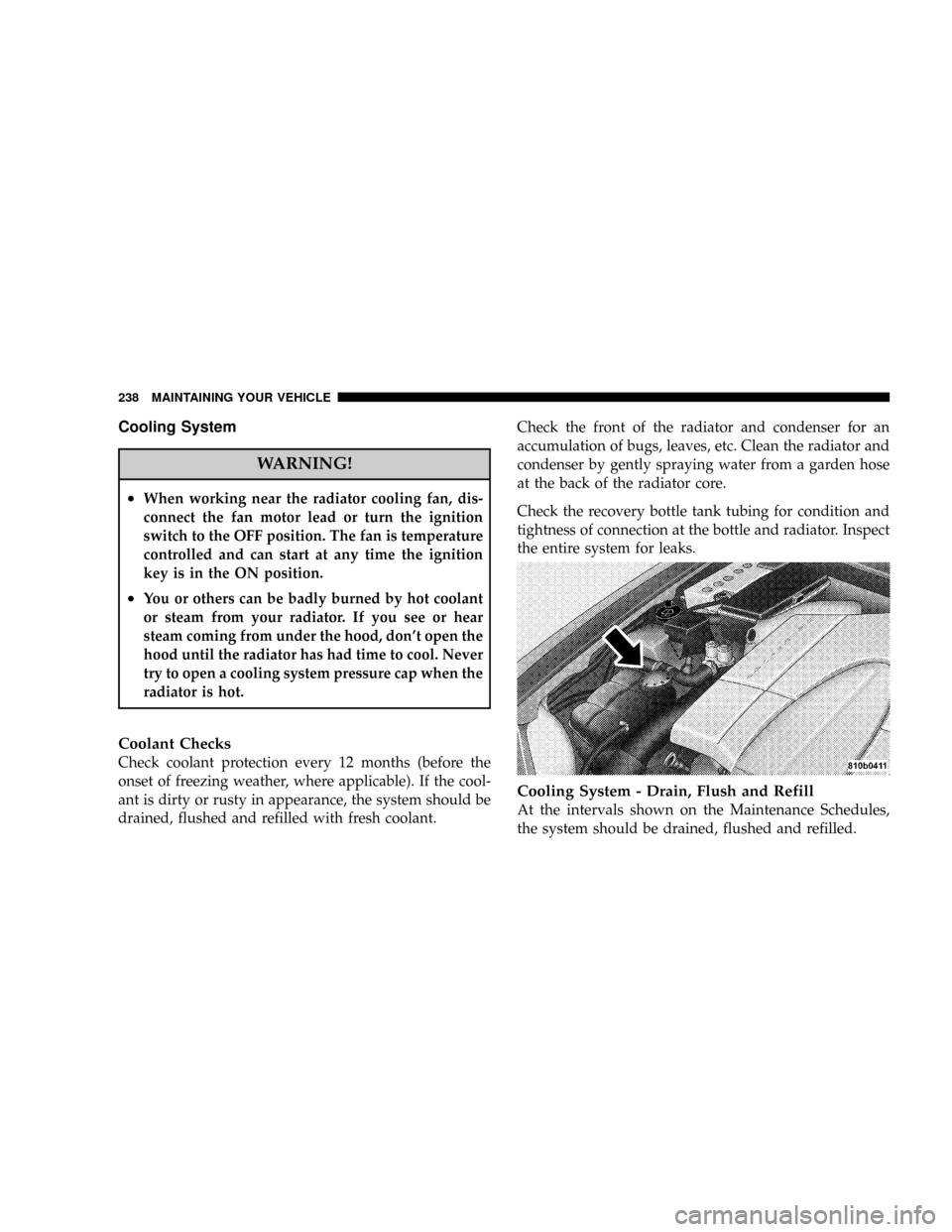

Cooling System - Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules,

the system should be drained, flushed and refilled.

238 MAINTAINING YOUR VEHICLE