engine CHRYSLER CROSSFIRE 2008 1.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2008 1.GPages: 358, PDF Size: 4.7 MB

Page 313 of 358

VEHICLE STORAGE

We recommend that you follow these guidelines before

storing your vehicle for extended periods.

²Fill the gas tank. This will prevent water condensation

inside the tank. If you plan on storing your vehicle

more than two months, add an anti-oxidant fuel

stabilizer to the gas tank.

²Change the oil to remove any corrosive combustion-

related acids in the crankcase.

²Wash and wax the vehicle to protect the finish.

²Cover the vehicle whenever possible to prevent acci-

dental damage to the finish.

²Store the vehicle in a dry, well-ventilated location.

²If the vehicle will be subjected to freezing tempera-

tures, remove the battery and store it in a dry, well-

ventilated place. If the vehicle is not going to be driven

in the next three weeks, follow the battery recharge

procedure in the Service Manual, then disconnect the

battery at the negative terminal.

CAUTION!

Use care when disconnecting the remote positive

cable. It is connected to the battery and can short out

to any metal on the vehicle. Always tape or wrap the

exposed cable end to prevent electrical shorts.

Disconnecting the battery causes the engine control sys-

tem to lose memory of some ªlearnedº functions. The

engine may run rough when first started after a battery

disconnect until the control module ªrelearnsº these

functions.

MAINTAINING YOUR VEHICLE 311

7

Page 315 of 358

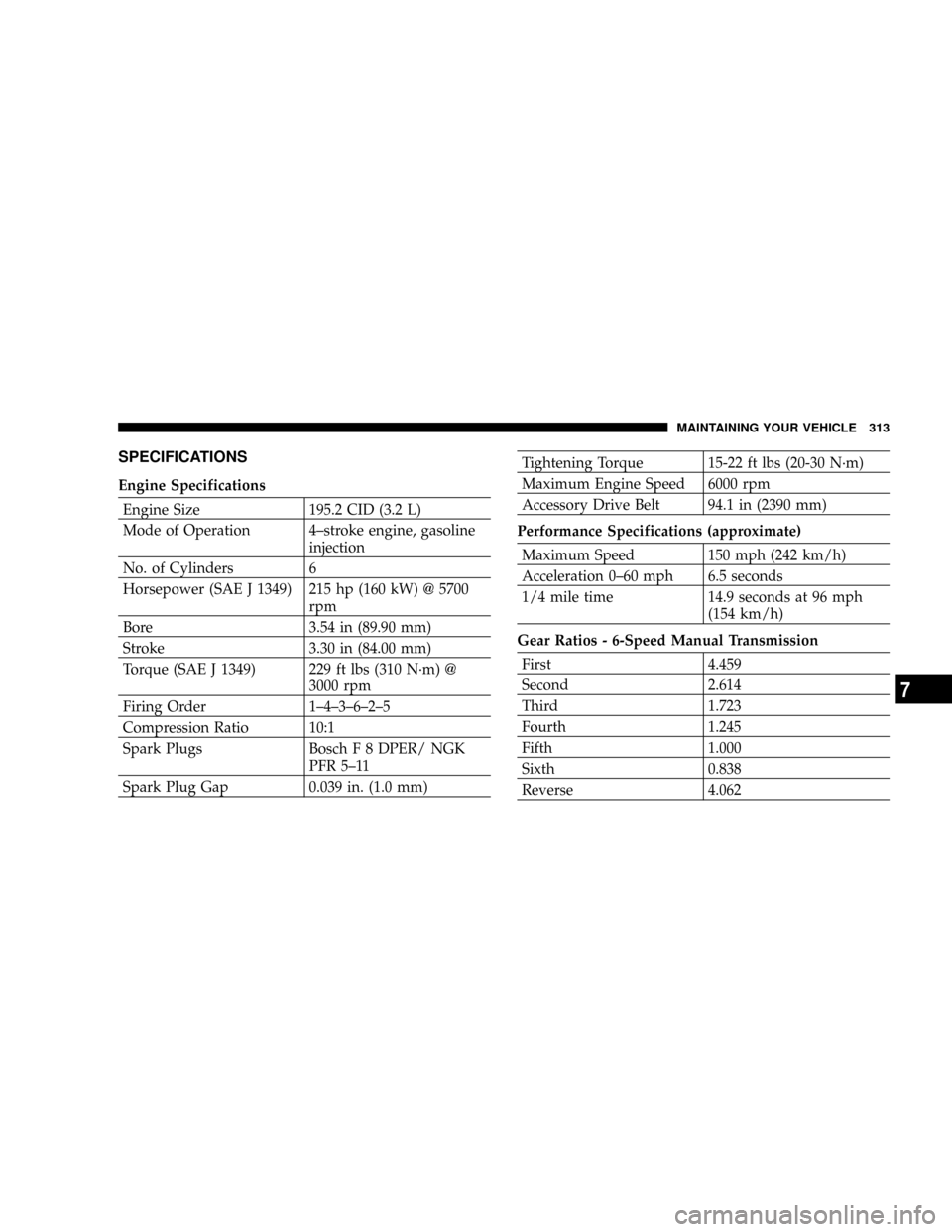

SPECIFICATIONS

Engine Specifications

Engine Size 195.2 CID (3.2 L)

Mode of Operation 4±stroke engine, gasoline

injection

No. of Cylinders 6

Horsepower (SAE J 1349) 215 hp (160 kW) @ 5700

rpm

Bore 3.54 in (89.90 mm)

Stroke 3.30 in (84.00 mm)

Torque (SAE J 1349) 229 ft lbs (310 N´m) @

3000 rpm

Firing Order 1±4±3±6±2±5

Compression Ratio 10:1

Spark Plugs Bosch F 8 DPER/ NGK

PFR 5±11

Spark Plug Gap 0.039 in. (1.0 mm)

Tightening Torque 15-22 ft lbs (20-30 N´m)

Maximum Engine Speed 6000 rpm

Accessory Drive Belt 94.1 in (2390 mm)

Performance Specifications (approximate)

Maximum Speed 150 mph (242 km/h)

Acceleration 0±60 mph 6.5 seconds

1/4 mile time 14.9 seconds at 96 mph

(154 km/h)

Gear Ratios - 6-Speed Manual Transmission

First 4.459

Second 2.614

Third 1.723

Fourth 1.245

Fifth 1.000

Sixth 0.838

Reverse 4.062

MAINTAINING YOUR VEHICLE 313

7

Page 317 of 358

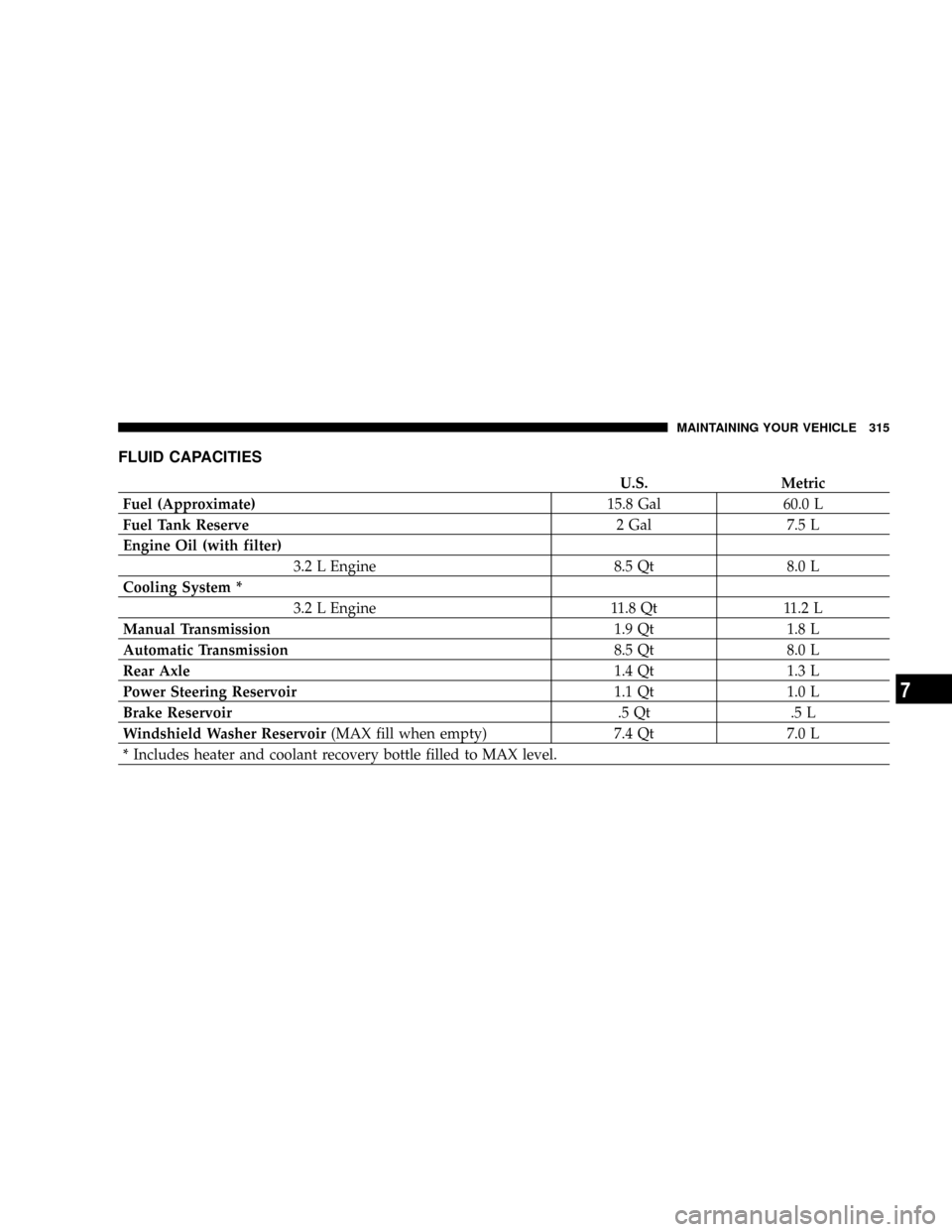

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate)15.8 Gal 60.0 L

Fuel Tank Reserve2 Gal 7.5 L

Engine Oil (with filter)

3.2 L Engine 8.5 Qt 8.0 L

Cooling System *

3.2 L Engine 11.8 Qt 11.2 L

Manual Transmission1.9 Qt 1.8 L

Automatic Transmission8.5 Qt 8.0 L

Rear Axle1.4 Qt 1.3 L

Power Steering Reservoir1.1 Qt 1.0 L

Brake Reservoir.5 Qt .5 L

Windshield Washer Reservoir(MAX fill when empty) 7.4 Qt 7.0 L

* Includes heater and coolant recovery bottle filled to MAX level.

MAINTAINING YOUR VEHICLE 315

7

Page 318 of 358

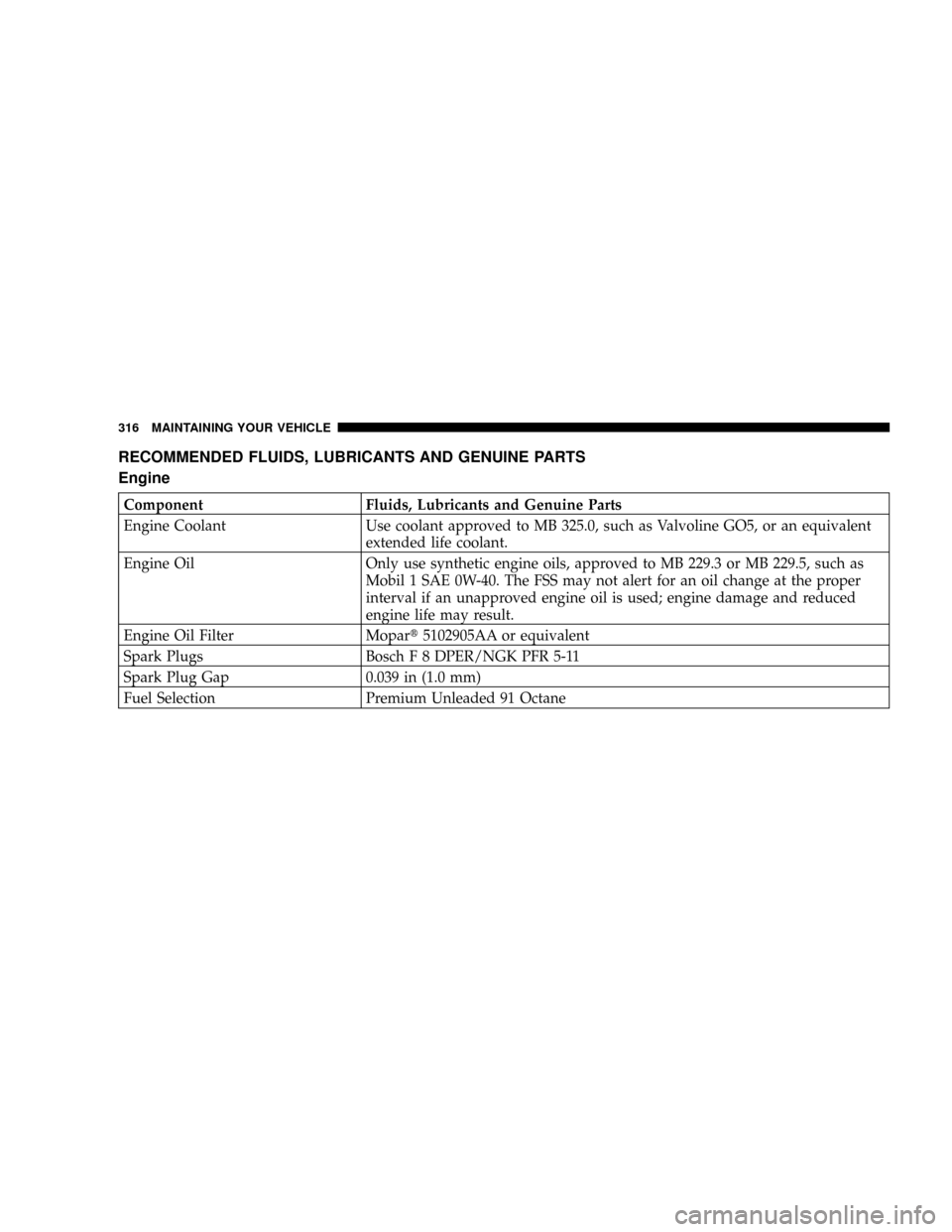

RECOMMENDED FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluids, Lubricants and Genuine Parts

Engine Coolant Use coolant approved to MB 325.0, such as Valvoline GO5, or an equivalent

extended life coolant.

Engine Oil Only use synthetic engine oils, approved to MB 229.3 or MB 229.5, such as

Mobil 1 SAE 0W-40. The FSS may not alert for an oil change at the proper

interval if an unapproved engine oil is used; engine damage and reduced

engine life may result.

Engine Oil Filter Mopart5102905AA or equivalent

Spark Plugs Bosch F 8 DPER/NGK PFR 5-11

Spark Plug Gap 0.039 in (1.0 mm)

Fuel Selection Premium Unleaded 91 Octane

316 MAINTAINING YOUR VEHICLE

Page 319 of 358

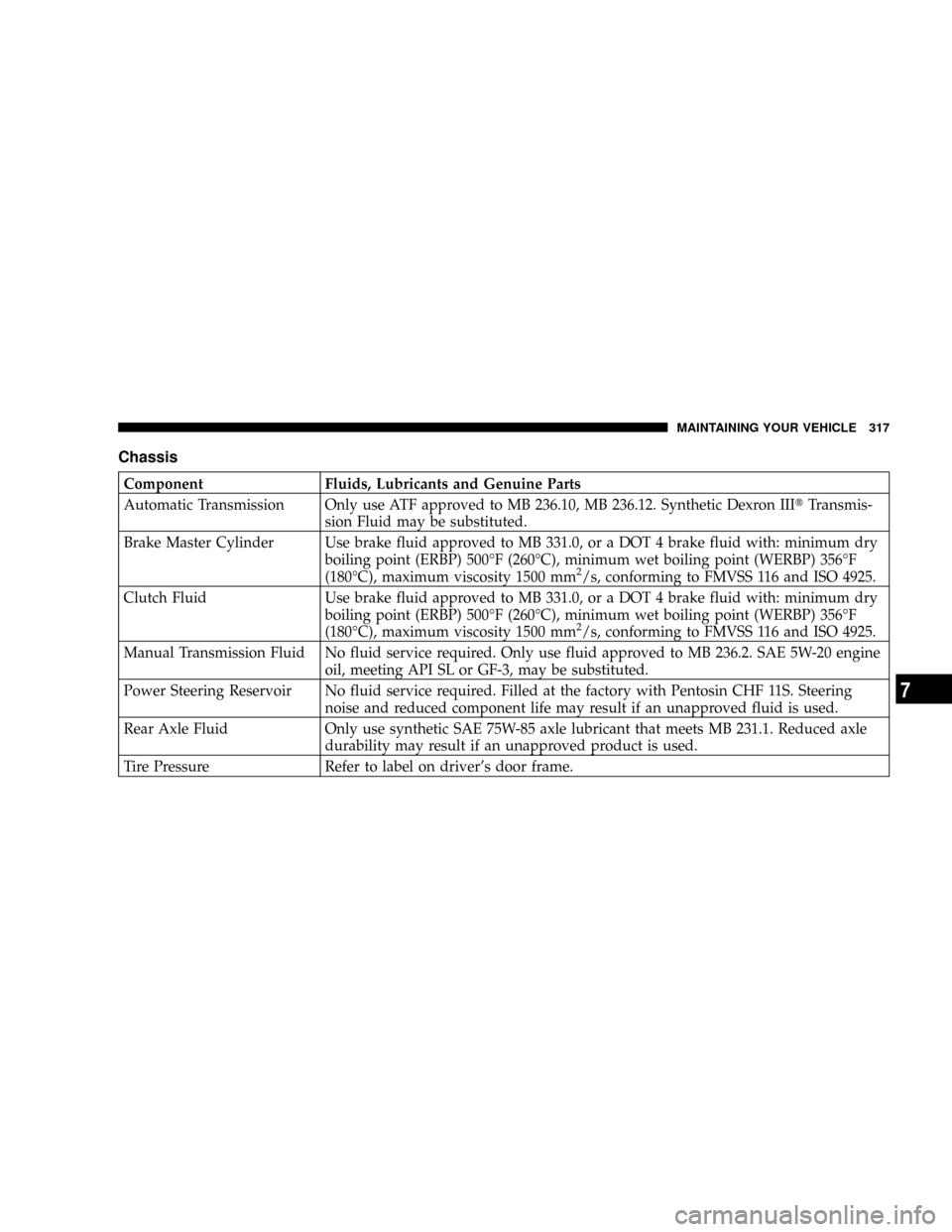

Chassis

Component Fluids, Lubricants and Genuine Parts

Automatic Transmission Only use ATF approved to MB 236.10, MB 236.12. Synthetic Dexron IIItTransmis-

sion Fluid may be substituted.

Brake Master Cylinder Use brake fluid approved to MB 331.0, or a DOT 4 brake fluid with: minimum dry

boiling point (ERBP) 500ÉF (260ÉC), minimum wet boiling point (WERBP) 356ÉF

(180ÉC), maximum viscosity 1500 mm

2/s, conforming to FMVSS 116 and ISO 4925.

Clutch Fluid Use brake fluid approved to MB 331.0, or a DOT 4 brake fluid with: minimum dry

boiling point (ERBP) 500ÉF (260ÉC), minimum wet boiling point (WERBP) 356ÉF

(180ÉC), maximum viscosity 1500 mm

2/s, conforming to FMVSS 116 and ISO 4925.

Manual Transmission Fluid No fluid service required. Only use fluid approved to MB 236.2. SAE 5W-20 engine

oil, meeting API SL or GF-3, may be substituted.

Power Steering Reservoir No fluid service required. Filled at the factory with Pentosin CHF 11S. Steering

noise and reduced component life may result if an unapproved fluid is used.

Rear Axle Fluid Only use synthetic SAE 75W-85 axle lubricant that meets MB 231.1. Reduced axle

durability may result if an unapproved product is used.

Tire Pressure Refer to label on driver's door frame.

MAINTAINING YOUR VEHICLE 317

7

Page 321 of 358

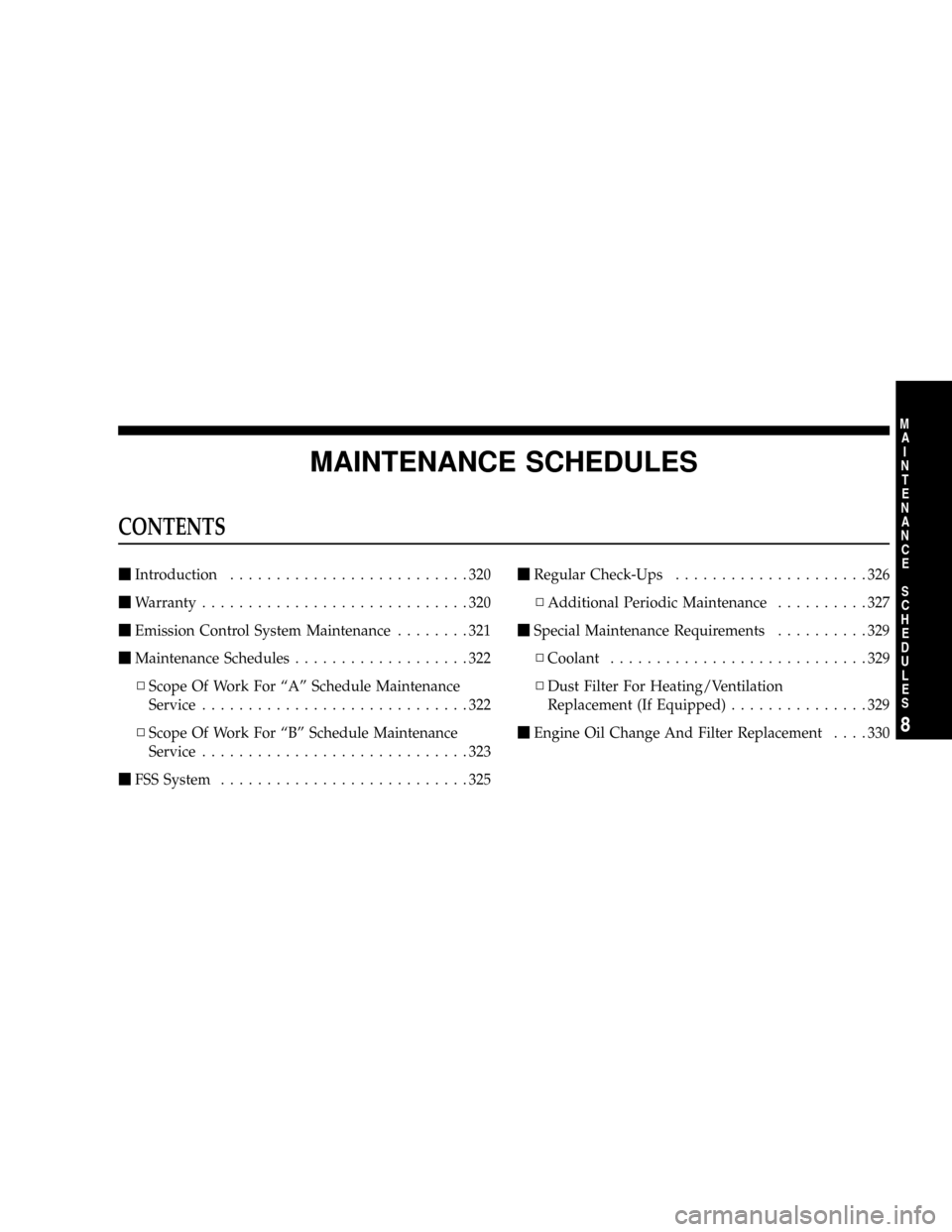

MAINTENANCE SCHEDULES

CONTENTS

mIntroduction..........................320

mWarranty.............................320

mEmission Control System Maintenance........321

mMaintenance Schedules...................322

NScope Of Work For ªAº Schedule Maintenance

Service.............................322

NScope Of Work For ªBº Schedule Maintenance

Service.............................323

mFSS System...........................325mRegular Check-Ups.....................326

NAdditional Periodic Maintenance..........327

mSpecial Maintenance Requirements..........329

NCoolant............................329

NDust Filter For Heating/Ventilation

Replacement (If Equipped)...............329

mEngine Oil Change And Filter Replacement....330

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 323 of 358

The use of Special lubricant additives is not recom-

mended. The use of such additives may affect your

warranty rights. With regard to legal stipulations con-

cerning emissions control, please note that engines have

to be serviced and adjusted in accordance with special

instructions and using special measuring equipment.

Modifications to or interference with the emissions con-

trol systems are not permissible.

All DaimlerChrysler Corporation authorized dealers are

familiar with the relevant and applicable regulations.

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typemust be done at the times or mileages specified to

assure the continued proper functioning of the emission

control system. These, and all other maintenance services

included in this manual, should be done to provide bestvehicle performance and reliability. More frequent main-

tenance may be needed for your Crossfire in severe

operating conditions such as dusty areas and very short

trip driving.

Inspection and service also should be done any time a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the emis-

sion control devices and systems on your vehicle may be

performed by any automotive repair establishment or

individual using any automotive part which has been

certified pursuant to U.S. EPA or, in the State of Califor-

nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES 321

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 325 of 358

²Check tires for damage and general condition

²Check tire inflation pressures and correct if necessary

Fluid Levels

Check fluid levels for the following systems and correct if

necessary. Should there be a loss of fluid that cannot be

explained by regular use, trace and eliminate the cause.

²Engine cooling system (check corrosion inhibitor/

antifreeze)

²Hydraulic brake system

²Power steering system

²Windshield washer system

SCOPE OF WORK FOR ªBº SCHEDULE

MAINTENANCE SERVICE

Oil Change

²Change oil and replace filter

Maintenance

²Rotate tires

²Replace dust filter (if equipped)

²Lubricate hood hinges, latch, and secondary latch

²Reset FSS Display

Function Check

²Horn, hazard warning flashers, turn signals, and indi-

cator lamps

²Headlamps and exterior lighting

²Windshield wipers and washer system

MAINTENANCE SCHEDULES 323

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 326 of 358

²Check seat belts for damage and proper function

²Test hydraulic brakes and check parking brake func-

tion

Inspection

²Check front and rear brake pads for lining thickness

²Check condition of front and rear brake discs

²Check tires for damage and general condition

²Check tire inflation pressures and correct if necessary

²Check major underbody components for leakage or

damage (if there are signs of leakage, determine cause

and repair)

²Check condition of front axle ball joints and rubber

boots

²Check condition of steering components and rubber

boots

²Check underhood components for leakage or damage

(if there are signs of leakage determine cause and

repair)

²Check condition of accessory drive belt

²Check headlamp aiming, adjust if necessary

²Check windshield wiper blades, replace if necessary

Fluid Levels

Check fluid levels for the following systems and correct if

necessary. Should there be a loss of fluid that cannot be

explained by regular use, trace and eliminate the cause.

²Engine cooling system (check corrosion inhibitor/

antifreeze)

²Hydraulic brake system

²Power steering system

²Windshield washer system

324 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 327 of 358

FSS SYSTEM

The Flexible Service System (FSS) permits a flexible

service schedule that is directly related to the operating

conditions of the vehicle. See the Understanding Your

Instrument Panel section for details on how to use the

FSS.

The oil change interval for your vehicle is initially set at

7,000 mi (Canada: 11 000 km). Very light duty driving

cycles (most trips more than 10 mi [16 km]) at moderate

speeds in moderate temperature conditions) can extend

the service interval beyond 7,000 mi (Canada: 11 000 km).

IfANYof the following apply to your driving, the oil

change interval can be reduced significantly:

þDay or night temperatures are below 32ÉF (0ÉC).

þStop and go driving.

þExtensive engine idling.

þDriving in dusty conditions.

þShort trips of less than 10 mi (16 km).

þMore than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC).

There are two symbols which will appear in the main

odometer display field prior to the next suggested ser-

vice.

This symbol represents Service A.

This second symbol represents Service B. Ser-

vice B rotates with Service A and includes

additional service tasks.

The next service is normally calculated and

displayed next to the Service A or Service B

symbol as distance remaining before the next

service is required.

MAINTENANCE SCHEDULES 325

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S