lock CHRYSLER PACIFICA 2020 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2020, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2020Pages: 516, PDF Size: 28.69 MB

Page 312 of 516

310IN CASE OF EMERGENCY

2. Firmly grasp the front side marker lamp

socket and rotate a quarter turn counter-

clockwise to remove it from the lamp

assembly.

Front Side Marker Lamp Bulb Removal

3. Remove bulb from the front side marker lamp socket and replace with a new bulb.

4. Install front side marker lamp socket in lamp assembly and rotate a quarter turn

clockwise to lock into place.

5. Position the inner wheel liner in place and install the three fasteners.Front Fog Lamp — Halogen

1. Remove fasteners from inner wheel liner and carefully peel back liner for access.

2. Reach through the front fascia to the fog lamp housing to access the bulb.

3. Rotate the front fog lamp bulb counter -

clockwise, and remove the bulb from the

front fog lamp housing.

Front Fog Lamp Socket

4. Disconnect the bulb from the electrical connector and then connect the

replacement bulb. 5. Install the front fog lamp bulb into the front

fog lamp housing, and rotate the bulb

clockwise to lock it in place.

6. Position the inner wheel liner in place and install fasteners.

Rear Liftgate Mounted Back-Up Lamps And

Tail Lamps (If Bulb Equipped)

1. Raise the liftgate.

2. Use a fiber stick or flat blade screw driver to pry off the bulb access cover on the lower

liftgate trim.

3. Back-up lamps/tail lamp (if bulb equipped) are now visible. Rotate socket(s) counter -

clockwise.

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb

life. If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

20_RU_OM_EN_US_t.book Page 310

Page 313 of 516

IN CASE OF EMERGENCY311

(Continued)

4. Remove/replace bulb(s).

5. Reinstall the socket(s).

6. Reverse process to reinstall the liftgate trim.

Rear Bodyside Mounted Taillamps

1. Raise the liftgate.

2. Remove two torx head screws on the bodyside lamp using a T30 screwdriver.

3. Remove lamp from vehicle body and locate bulb socket on rear of lamp. Rotate socket

counterclockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s).

6. Reverse process to reinstall the lamp onto vehicle.

Center High Mounted Stop Lamp (CHMSL)

The center high-mounted stop lamp is an LED

assembly. See an authorized dealer for

replacement.

Rear License Lamp

The rear license lamps are LED. See an

authorized dealer for replacement.

FUSES

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans -

mission system) or steering system blows,

contact an authorized dealer.

WARNING! (Continued)

6

20_RU_OM_EN_US_t.book Page 311

Page 314 of 516

312IN CASE OF EMERGENCY

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery

discharge.

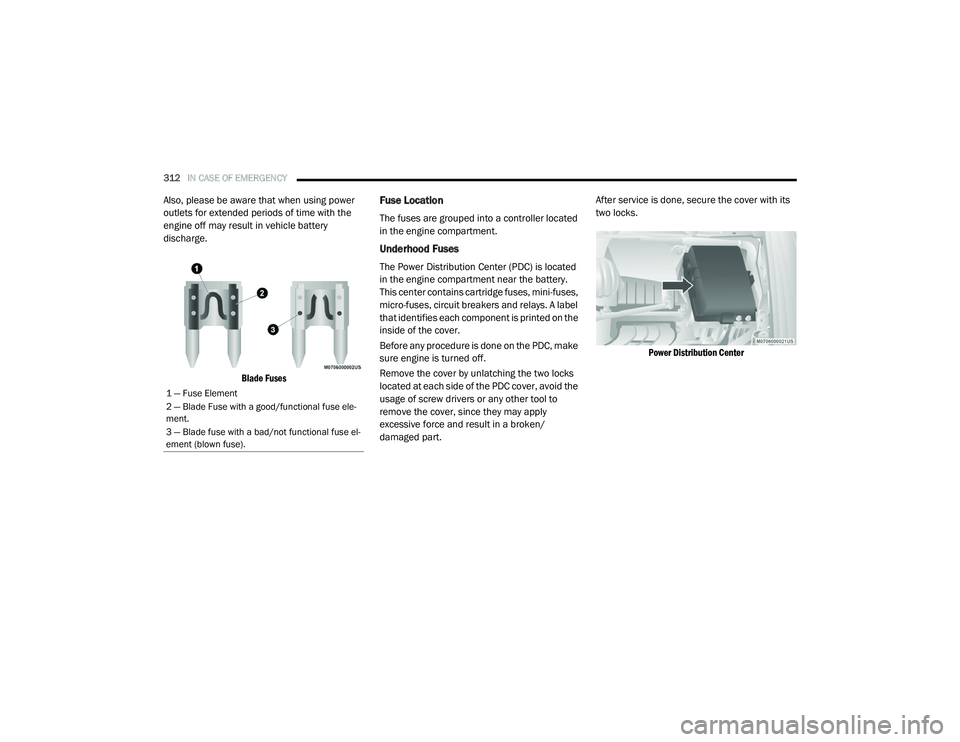

Blade Fuses

Fuse Location

The fuses are grouped into a controller located

in the engine compartment.

Underhood Fuses

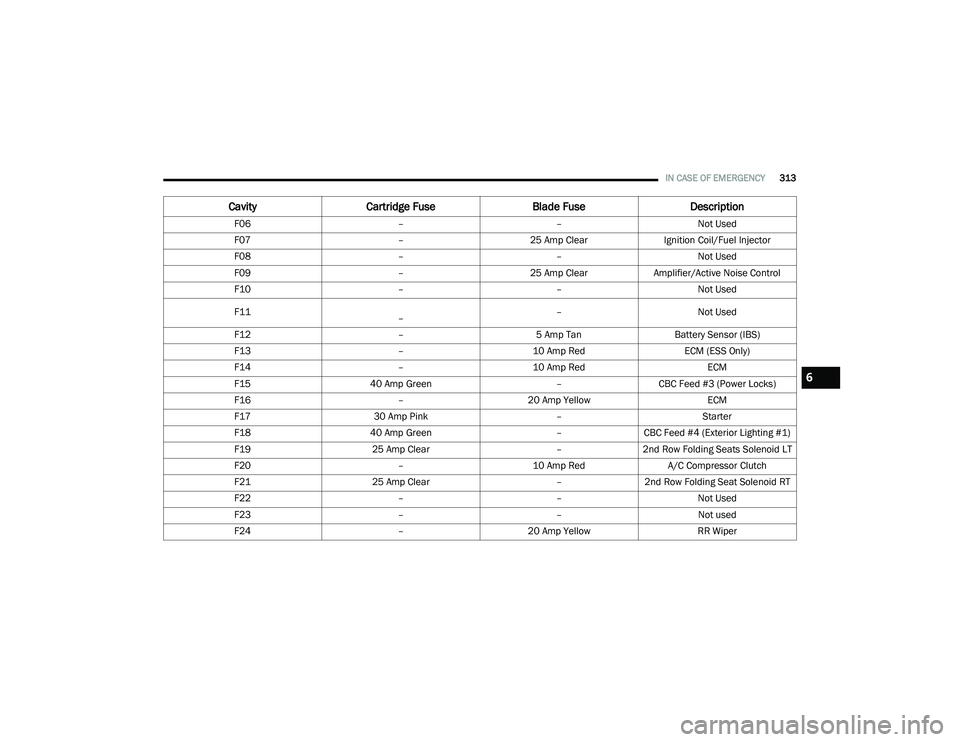

The Power Distribution Center (PDC) is located

in the engine compartment near the battery.

This center contains cartridge fuses, mini-fuses,

micro-fuses, circuit breakers and relays. A label

that identifies each component is printed on the

inside of the cover.

Before any procedure is done on the PDC, make

sure engine is turned off.

Remove the cover by unlatching the two locks

located at each side of the PDC cover, avoid the

usage of screw drivers or any other tool to

remove the cover, since they may apply

excessive force and result in a broken/

damaged part. After service is done, secure the cover with its

two locks.

Power Distribution Center

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse ele -

ment.

3 — Blade fuse with a bad/not functional fuse el -

ement (blown fuse).

20_RU_OM_EN_US_t.book Page 312

Page 315 of 516

IN CASE OF EMERGENCY313

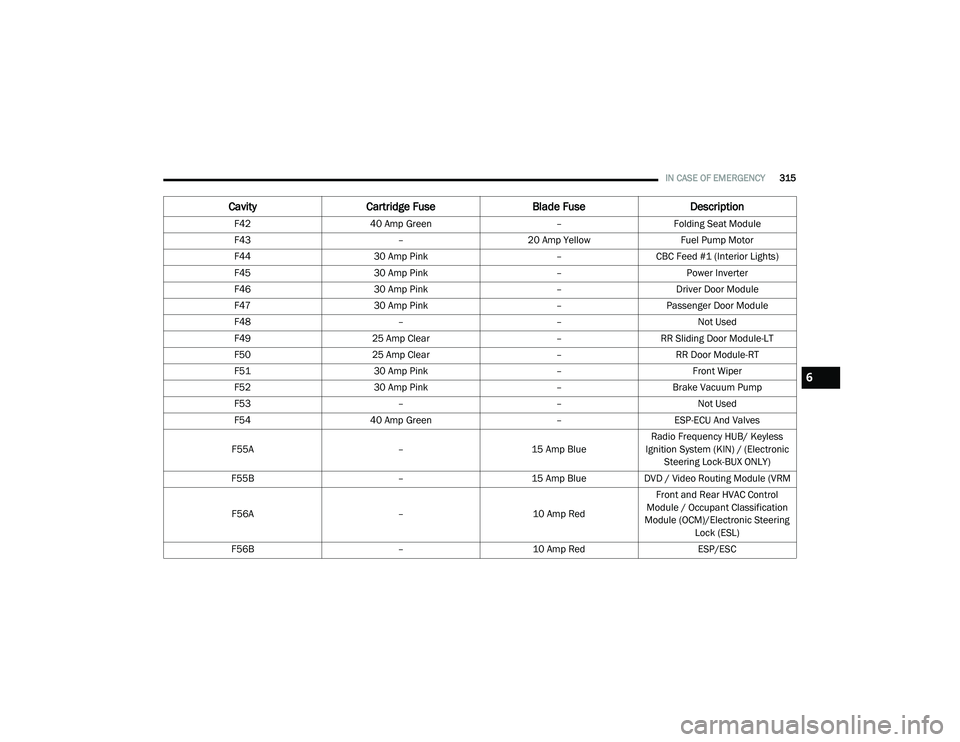

Cavity Cartridge Fuse Blade FuseDescription

F06 ––Not Used

F07 –25 Amp Clear Ignition Coil/Fuel Injector

F08 ––Not Used

F09 –25 Amp ClearAmplifier/Active Noise Control

F10 ––Not Used

F11

– –

Not Used

F12 –5 Amp TanBattery Sensor (IBS)

F13 –10 Amp Red ECM (ESS Only)

F14 –10 Amp Red ECM

F15 40 Amp Green –CBC Feed #3 (Power Locks)

F16 –20 Amp Yellow ECM

F17 30 Amp Pink –Starter

F18 40 Amp Green –CBC Feed #4 (Exterior Lighting #1)

F19 25 Amp Clear –2nd Row Folding Seats Solenoid LT

F20 –10 Amp Red A/C Compressor Clutch

F21 25 Amp Clear –2nd Row Folding Seat Solenoid RT

F22 ––Not Used

F23 ––Not used

F24 –20 Amp Yellow RR Wiper

6

20_RU_OM_EN_US_t.book Page 313

Page 317 of 516

IN CASE OF EMERGENCY315

F42 40 Amp Green –Folding Seat Module

F43 –20 Amp Yellow Fuel Pump Motor

F44 30 Amp Pink –CBC Feed #1 (Interior Lights)

F45 30 Amp Pink –Power Inverter

F46 30 Amp Pink –Driver Door Module

F47 30 Amp Pink –Passenger Door Module

F48 ––Not Used

F49 25 Amp Clear –RR Sliding Door Module-LT

F50 25 Amp Clear –RR Door Module-RT

F51 30 Amp Pink –Front Wiper

F52 30 Amp Pink –Brake Vacuum Pump

F53 ––Not Used

F54 40 Amp Green –ESP-ECU And Valves

F55A –15 Amp BlueRadio Frequency HUB/ Keyless

Ignition System (KIN) / (Electronic Steering Lock-BUX ONLY)

F55B –15 Amp BlueDVD / Video Routing Module (VRM

F56A –10 Amp RedFront and Rear HVAC Control

Module / Occupant Classification

Module (OCM)/Electronic Steering Lock (ESL)

F56B –10 Amp Red ESP/ESC

CavityCartridge Fuse Blade FuseDescription

6

20_RU_OM_EN_US_t.book Page 315

Page 321 of 516

IN CASE OF EMERGENCY319

* 30 Amp mini fuse is substituted for 25 Amp Circuit Breaker.F98

–15 Amp Blue Left HID Headlamp

F99 30 Amp Pink –Trailer Tow Module - If Equipped

F100A –10 Amp Red AHLM

F100B –10 Amp RedRear Camera/LBSS/RBSS/CVPM/

Humidity Sensor/In Vehicle Temperature Sensor

Circuit Breakers

CB1 25 AmpPower Seats (Driver)

CB2 25 Amp *Power Seats (Pass)

CB3 25 AmpFRT PWR Window W/O Door Nodes

+ RR PWR Window Lockout

Cavity Cartridge Fuse Blade FuseDescription

6

20_RU_OM_EN_US_t.book Page 319

Page 323 of 516

IN CASE OF EMERGENCY321

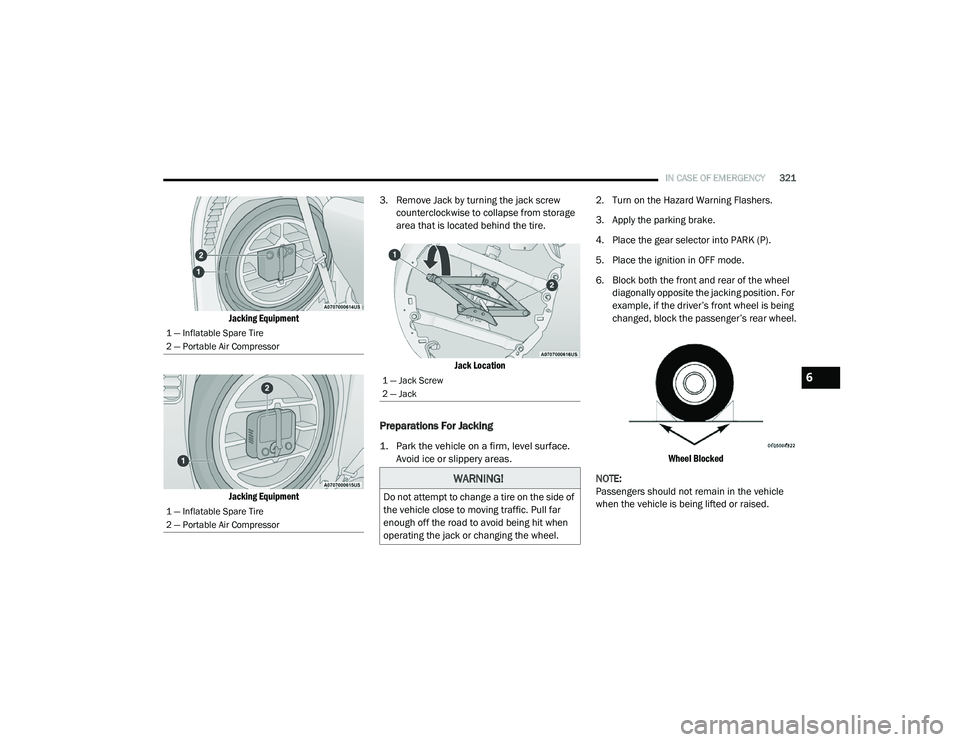

Jacking Equipment

Jacking Equipment

3. Remove Jack by turning the jack screw

counterclockwise to collapse from storage

area that is located behind the tire.

Jack Location

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK (P).

5. Place the ignition in OFF mode.

6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.

1 — Inflatable Spare Tire

2 — Portable Air Compressor

1 — Inflatable Spare Tire

2 — Portable Air Compressor

1 — Jack Screw

2 — Jack

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

6

20_RU_OM_EN_US_t.book Page 321

Page 324 of 516

322IN CASE OF EMERGENCY

(Continued)

Jacking Instructions

Jack Warning Label

NOTE:

Refer to “Tires” in “Servicing And Maintenance”

for information about the inflatable spare tire,

its use, and operation.

Extending The Wrench

1. Loosen (but do not remove) the wheel lug nuts by turning them to the left, one turn

while the wheel is still on the ground.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the

wheel to be raised.

Do not let any passenger sit in the vehicle

when it is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING! (Continued)

20_RU_OM_EN_US_t.book Page 322

Page 326 of 516

324IN CASE OF EMERGENCY

3. Place the wrench on the jack screw and turn

clockwise until the jack head is properly

engaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the swivel wrench. Raise

the vehicle only until the tire just clears the

surface and enough clearance is obtained

to install the compact spare tire. Minimum

tire lift provides maximum stability.

5. Remove the wheel lug nuts, for vehicles with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub.

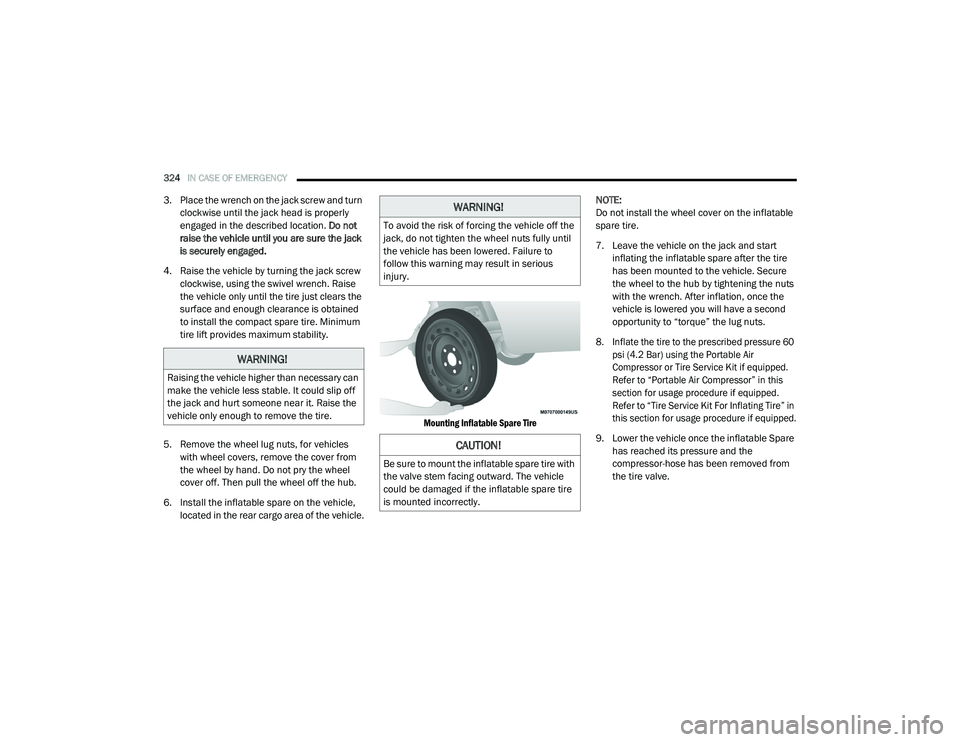

6. Install the inflatable spare on the vehicle, located in the rear cargo area of the vehicle.

Mounting Inflatable Spare Tire

NOTE:

Do not install the wheel cover on the inflatable

spare tire.

7. Leave the vehicle on the jack and start

inflating the inflatable spare after the tire

has been mounted to the vehicle. Secure

the wheel to the hub by tightening the nuts

with the wrench. After inflation, once the

vehicle is lowered you will have a second

opportunity to “torque” the lug nuts.

8. Inflate the tire to the prescribed pressure 60 psi (4.2 Bar) using the Portable Air

Compressor or Tire Service Kit if equipped.

Refer to “Portable Air Compressor” in this

section for usage procedure if equipped.

Refer to “Tire Service Kit For Inflating Tire” in

this section for usage procedure if equipped.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the

compressor-hose has been removed from

the tire valve.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the inflatable spare tire with

the valve stem facing outward. The vehicle

could be damaged if the inflatable spare tire

is mounted incorrectly.

20_RU_OM_EN_US_t.book Page 324

Page 327 of 516

IN CASE OF EMERGENCY325

10. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in “Technical

Specifications” for proper wheel lug nut

torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do

not stow the deflated tire in the inflatable

spare tire location. Have the full-sized tire

repaired or replaced, as soon as possible. 13. Stow the jack back in the stowage

compartment and place the access panel

back. The stud of the storage area must be

threaded through the lower part of the jack.

Then turn the Jack Screw clockwise to

secure it in place.

NOTE:

Stow the foam tray and components in the

cargo area.

Storing The Jack

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug

nuts on the mounting studs which are on

each side of the valve stem. Install the lug

nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug

nuts.

Tire And Wheel Cover Or Center Cap

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

1 — Jack Screw

2 — Jack

3 — Stud

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

6

20_RU_OM_EN_US_t.book Page 325