CHRYSLER PACIFICA HYBRID 2020 Owners Manual

Manufacturer: CHRYSLER, Model Year: 2020, Model line: PACIFICA HYBRID, Model: CHRYSLER PACIFICA HYBRID 2020Pages: 516, PDF Size: 28.69 MB

Page 361 of 516

SERVICING AND MAINTENANCE359

(Continued)

NOTE:

Resistance will be accompanied by an audible

snap.

4. Still grasping the bottom end of the wiper blade, move the wiper blade upward and

away from the wiper arm to disengage.

Wiper Blade Removed From Wiper Arm

5. Gently lower the tip of the wiper arm onto the glass. Installing The Rear Wiper

1. Lift the rear wiper arm pivot cap away from

the glass to allow the rear wiper blade to be

raised off of the glass.

NOTE:

The rear wiper arm cannot be fully raised off the

glass unless the wiper arm pivot cap is

unsnapped first. Attempting to fully raise the

rear wiper arm without unsnapping the wiper

arm pivot cap may damage the vehicle.

2. Lift the rear wiper arm fully off the glass.

3. Insert the wiper blade pivot pin into the opening on the end of the wiper arm. Grab

the bottom end of the wiper arm with one

hand, and press the wiper blade flush with

the wiper arm until it snaps into place.

4. Lower the wiper blade onto the glass and snap the wiper arm pivot cap back into

place.Exhaust System

The best protection against carbon monoxide

entry into the vehicle body is a properly

maintained engine exhaust system.

If you notice a change in the sound of the

exhaust system; or if the exhaust fumes can be

detected inside the vehicle; or when the

underside or rear of the vehicle is damaged;

have an authorized technician inspect the

complete exhaust system and adjacent body

areas for broken, damaged, deteriorated, or

mispositioned parts. Open seams or loose

connections could permit exhaust fumes to

seep into the passenger compartment. In

addition, have the exhaust system inspected

each time the vehicle is raised for lubrication or

oil change. Replace as required.

1 — Wiper Blade

2 — Wiper Blade Pivot Pin

3 — Wiper Arm Receptacle

4 — Wiper ArmWARNING!

Exhaust gases can injure or kill. They

contain carbon monoxide (CO), which is

colorless and odorless. Breathing it can

make you unconscious and can eventually

poison you. To avoid breathing CO, refer to

“Safety Tips” in “Safety” for further informa -

tion.

7

20_RU_OM_EN_US_t.book Page 359

Page 362 of 516

360SERVICING AND MAINTENANCE

(Continued)

Under normal operating conditions, the catalytic

converter will not require maintenance. However,

it is important to keep the engine properly tuned

to ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:

Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you. In unusual situations involving grossly

malfunctioning engine operation, a scorching

odor may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn

off the engine and allow it to cool. Service,

including a tune-up to manufacturer's

specifications, should be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the trans

-

mission is in gear and the vehicle is in

motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition

components disconnected or removed, such

as when diagnostic testing, or for prolonged

periods during very rough idle or malfunc -

tioning operating conditions.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do

not park or operate your vehicle in areas

where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri -

ously reduce engine performance and

cause serious damage to the engine.

WARNING! (Continued)

Damage to the catalytic converter can

result if your vehicle is not kept in proper

operating condition. In the event of engine

malfunction, particularly involving engine

misfire or other apparent loss of perfor -

mance, have your vehicle serviced

promptly. Continued operation of your

vehicle with a severe malfunction could

cause the converter to overheat, resulting

in possible damage to the converter and

vehicle.

CAUTION! (Continued)

20_RU_OM_EN_US_t.book Page 360

Page 363 of 516

SERVICING AND MAINTENANCE361

Cooling System Engine Coolant Checks

Check the engine coolant (antifreeze)

protection every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty, the system

should be drained, flushed, and refilled with

fresh OAT coolant (conforming to MS.90032) by

an authorized dealer. Check the front of the A/

C condenser for any accumulation of bugs,

leaves, etc. If dirty, clean by gently spraying

water from a garden hose vertically down the

face of the condenser.

Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the coolant

recovery bottle and radiator. Inspect the entire

system for leaks. DO NOT REMOVE THE

COOLANT PRESSURE CAP WHEN THE COOLING

SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized

dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant

(antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

NOTE:

Mixing of engine coolant (antifreeze) other

than specified Organic Additive Technology

(OAT) engine coolant (antifreeze), may result

in engine damage and may decrease corro-

sion protection. Organic Additive Technology

(OAT) engine coolant is different and should

not be mixed with Hybrid Organic Additive

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never open a cooling system pressure

cap when the radiator or coolant bottle is

hot.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts automati -

cally and may start at any time, whether the

engine is running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.7

20_RU_OM_EN_US_t.book Page 361

Page 364 of 516

362SERVICING AND MAINTENANCE

Technology (HOAT) engine coolant (anti -

freeze) or any “globally compatible” coolant

(antifreeze). If a non-OAT engine coolant

(antifreeze) is introduced into the cooling

system in an emergency, the cooling system

will need to be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032), by an authorized dealer as soon

as possible.

Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust prod -

ucts, as they may not be compatible with the

radiator engine coolant and may plug the

radiator.

This vehicle has not been designed for use

with propylene glycol-based engine coolant

(antifreeze). Use of propylene glycol-based

engine coolant (antifreeze) is not recom -

mended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system please contact an authorized

dealer.

Adding Coolant

Your vehicle has been built with an improved

engine coolant (OAT coolant conforming to

MS.90032) that allows extended maintenance

intervals. This engine coolant (antifreeze) can

be used up to ten years or 150,000 miles

(240,000 km) before replacement. To prevent

reducing this extended maintenance period, it

is important that you use the same engine

coolant (OAT coolant conforming to MS.90032)

throughout the life of your vehicle.

Please review these recommendations for

using Organic Additive Technology (OAT) engine

coolant (antifreeze) that meets the

requirements of FCA Material Standard

MS.90032. When adding engine coolant

(antifreeze):

We recommend using Mopar Antifreeze/

Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT (Organic Additive

Technology) that meets the requirements of

FCA Material Standard MS.90032.

Mix a minimum solution of 50% OAT engine

coolant that meets the requirements of FCA

Material Standard MS.90032 and distilled

water. Use higher concentrations (not to exceed 70%) if temperatures below −34°F

(−37°C) are anticipated. Please contact an

authorized dealer for assistance.

Use only high purity water such as distilled or

deionized water when mixing the water/engine

coolant (antifreeze) solution. The use of lower

quality water will reduce the amount of corro

-

sion protection in the engine cooling system.

NOTE:

It is the owner's responsibility to maintain the

proper level of protection against freezing

according to the temperatures occurring in

the area where the vehicle is operated.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system, please contact a local autho -

rized dealer.

Mixing engine coolant (antifreeze) types is not

recommended and can result in cooling system

damage. If HOAT and OAT coolant are mixed in

an emergency, have a authorized dealer drain,

flush, and refill with OAT coolant (conforming to

MS.90032) as soon as possible.

20_RU_OM_EN_US_t.book Page 362

Page 365 of 516

SERVICING AND MAINTENANCE363

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss

of engine coolant (antifreeze), and to ensure

that engine coolant (antifreeze) will return to

the radiator from the coolant expansion bottle/

recovery tank if so equipped.

The cap should be inspected and cleaned if

there is any accumulation of foreign material on

the sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is

a regulated substance requiring proper disposal.

Check with your local authorities to determine the

disposal rules for your community. To prevent

ingestion by animals or children, do not store

ethylene glycol-based coolant in open containers

or allow it to remain in puddles on the ground. If

ingested by a child or pet, seek emergency

assistance immediately. Clean up any ground

spills immediately.

Coolant Level

The coolant expansion bottle provides a quick

visual method for determining that the coolant

level is adequate. With the engine off and cold,

the level of the coolant (antifreeze) in the bottle

should be between the “MAX” and “MIN” lines

marked on the bottle.

As long as the engine operating temperature is

satisfactory, the coolant bottle need only be

checked once a month.

When additional coolant (antifreeze) is needed

to maintain the proper level, it should be added

to the coolant bottle. Do not overfill.

See an authorized dealer for service.

Points To Remember

NOTE:

When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor

coming from the front of the engine compart -

ment. This is normally a result of moisture from

rain, snow, or high humidity accumulating on

the radiator and being vaporized when the ther -

mostat opens, allowing hot engine coolant (anti -

freeze) to enter the radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks,

the vehicle may be safely driven. The vapor will

soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant (antifreeze) needs to be added, the

contents of the coolant expansion bottle

must also be protected against freezing.

If frequent engine coolant (antifreeze) addi-

tions are required, the cooling system should

be pressure tested for leaks.

WARNING!

Do not open hot engine cooling system.

Never add engine coolant (antifreeze) when

the engine is overheated. Do not loosen or

remove the cap to cool an overheated

engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or

injury, do not remove the pressure cap

while the system is hot or under pressure.

Do not use a pressure cap other than the

one specified for your vehicle. Personal

injury or engine damage may result.

7

20_RU_OM_EN_US_t.book Page 363

Page 366 of 516

364SERVICING AND MAINTENANCE

(Continued)

Maintain engine coolant (antifreeze) concen-

tration at a minimum of 50% OAT coolant

(conforming to MS.90032) and distilled

water for proper corrosion protection of your

engine which contains aluminum compo -

nents.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood services

or immediately if the “Brake Warning Light” is

illuminated.

Be sure to clean the top of the master cylinder

area before removing the cap. If necessary, add

fluid to bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further infor-

mation. Using the wrong type of brake fluid

can severely damage your brake system

and/or impair its performance. The proper

type of brake fluid for your vehicle is also

identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or fluid

that has been in a tightly closed container.

Keep the master cylinder reservoir cap

secured at all times. Brake fluid in a open

container absorbs moisture from the air

resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or

prolonged braking, resulting in sudden brake

failure. This could result in a collision.

20_RU_OM_EN_US_t.book Page 364

Page 367 of 516

SERVICING AND MAINTENANCE365

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid. NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe

transmission damage.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING!

(Continued)

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An

authorized dealer has the proper tools to

adjust the fluid level accurately.

7

20_RU_OM_EN_US_t.book Page 365

Page 368 of 516

366SERVICING AND MAINTENANCE

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

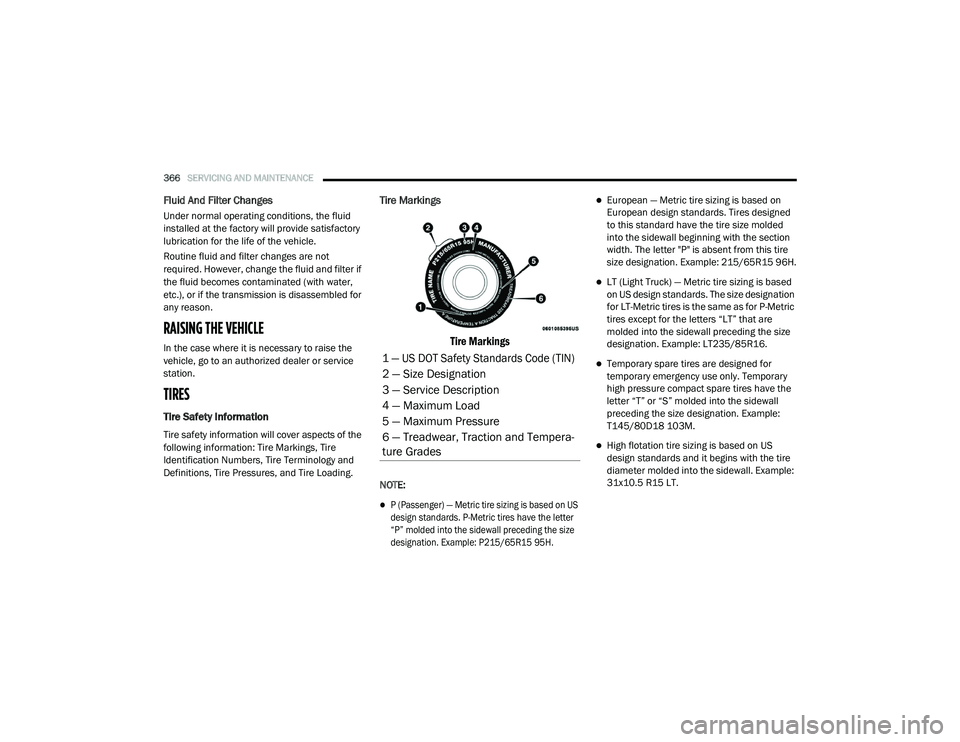

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

20_RU_OM_EN_US_t.book Page 366

Page 369 of 516

SERVICING AND MAINTENANCE367

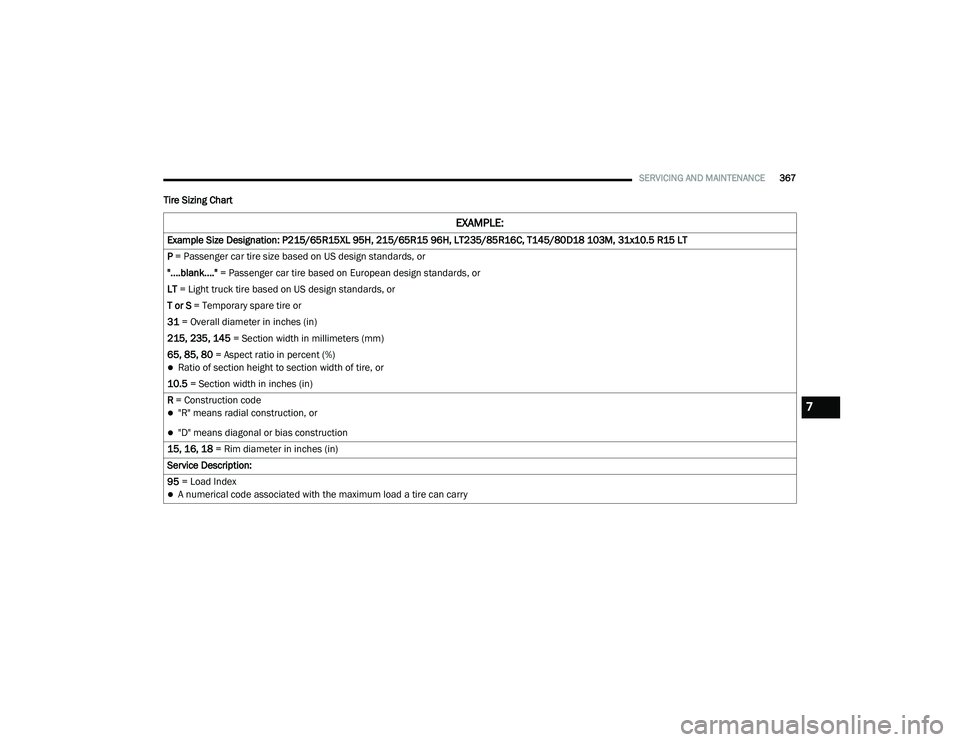

Tire Sizing Chart

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

7

20_RU_OM_EN_US_t.book Page 367

Page 370 of 516

368SERVICING AND MAINTENANCE

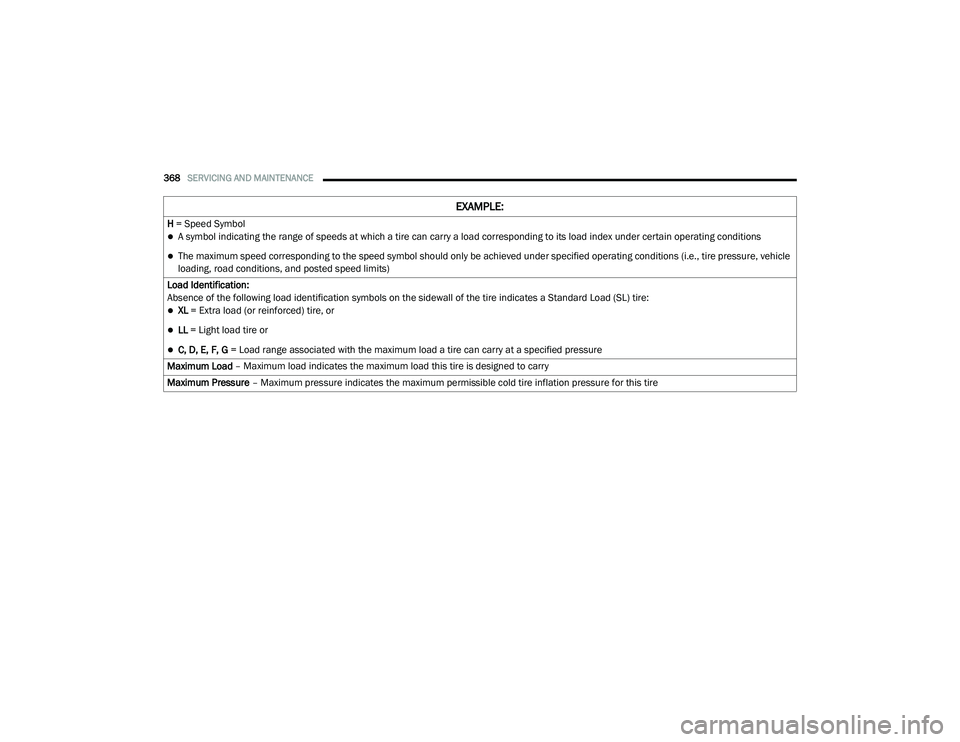

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

20_RU_OM_EN_US_t.book Page 368