check engine CHRYSLER PT CRUISER 2005 1.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: PT CRUISER, Model: CHRYSLER PT CRUISER 2005 1.GPages: 360, PDF Size: 11.21 MB

Page 272 of 360

Cooling System

WARNING!

•When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at any time the ignition

switch is in the ON position.

•You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don’t open

the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap

when the radiator is hot.

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant.

Check the front of the radiator for an accumulation of

bugs, leaves, etc. Clean the radiator by gently spraying

water from a garden hose at the back of the core.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

272 MAINTAINING YOUR VEHICLE

Page 273 of 360

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

coolant from the radiator drain cock. If the cap is sealing

properly, the engine coolant (antifreeze) will begin to

drain from the coolant recovery bottle. DO NOT RE-

MOVE THE COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

Cooling System—Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules,

the system should be drained, flushed and refilled.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals. Discard oil antifreeze

solution.

Selection Of Coolant

Use only the manufacturers recommended coolant, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct coolant type.

MAINTAINING YOUR VEHICLE 273

7

Page 275 of 360

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

coolant, and to insure that coolant will return to the

radiator from the coolant recovery bottle.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

WARNING!

The warning words“DO NOT OPEN HOT”on the

cooling system pressure cap are a safety precaution.

Never add coolant when the engine is overheated.

Do not loosen or remove the cap to cool an over-

heated engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or injury, do

not remove the pressure cap while the system is hot

or under pressure.

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. To prevent ingestion by animals or children

do not store ethylene glycol based engine coolant in open

containers or allow it to remain in puddles on the

ground. If ingested by a child, contact a physician

immediately. Clean up any ground spills immediately.

Coolant Level

The coolant recovery bottle provides a quick visual

method for determining that the coolant level is ad-

equate. With the engine idling, and warm to normal

operating temperature, the level of the coolant in the

bottle should be between the“FULL”and“ADD”marks.

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

coolant freeze point or replacing coolant. Advise your

MAINTAINING YOUR VEHICLE 275

7

Page 276 of 360

service attendant of this. As long as the engine operating

temperature is satisfactory, the coolant recovery bottle

need only be checked once a month.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant recovery

bottle. Do not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few kilome-

ters (a few miles) of operation, you may observe vapor

coming from the front of the engine compartment. This is

normally a result of moisture from rain, snow, or high

humidity accumulation on the radiator and being vapor-

ized when the thermostat opens, allowing hot water to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant recovery bottle.

•Check coolant freeze point in the system.

•If frequent coolant additions are required, the cooling

system should be pressure tested for leaks.

•Maintain coolant concentration at 50% HOAT ethylene

glycol engine coolant (minimum) and distilled water

for proper corrosion protection of your engine which

contains aluminum components.

•Make sure that the radiator and coolant recovery

bottle hoses are not kinked or obstructed.

•Keep the front of the radiator clean. If your vehicle has

air conditioning, keep the front of the condenser clean,

also.

276 MAINTAINING YOUR VEHICLE

Page 279 of 360

NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and at every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

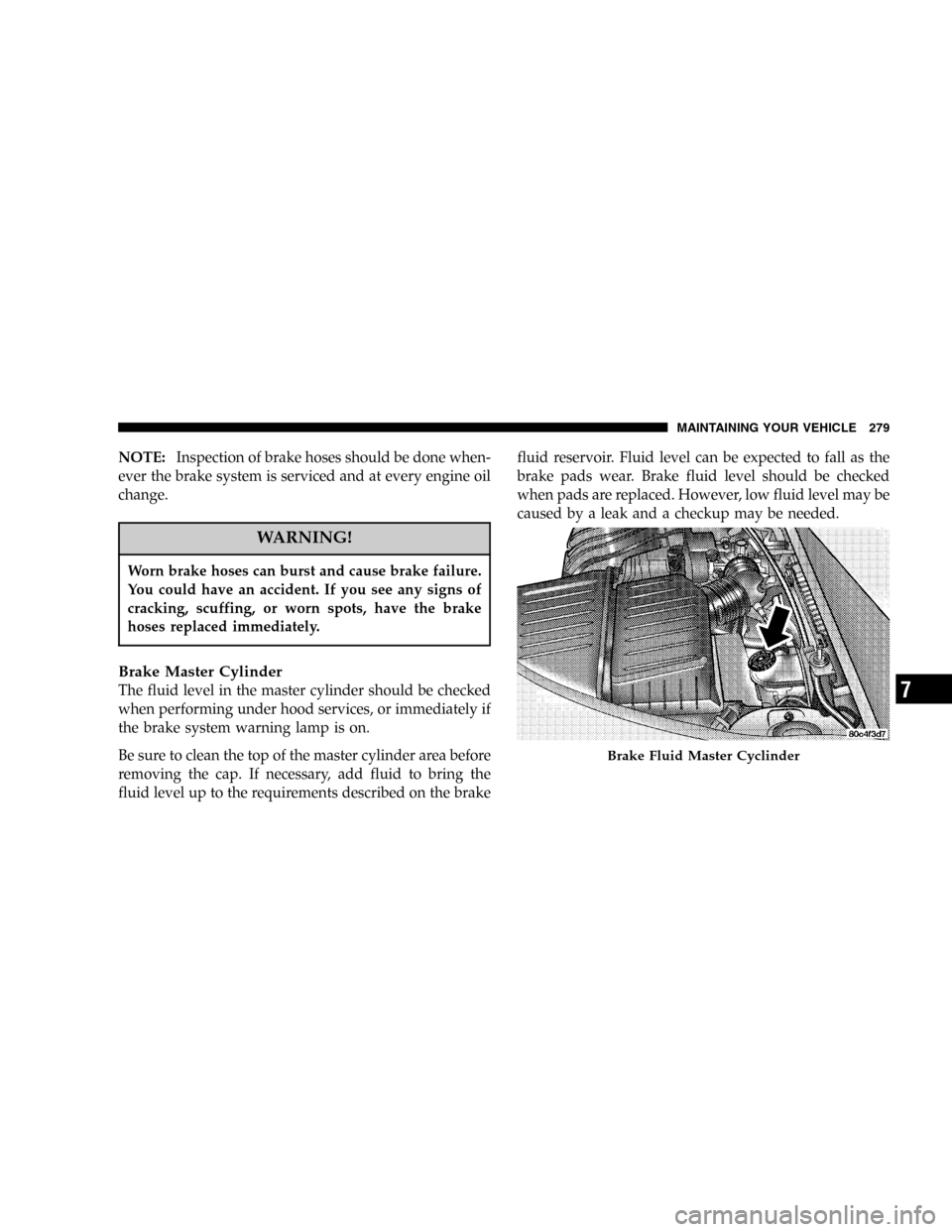

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brakefluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Brake Fluid Master Cyclinder

MAINTAINING YOUR VEHICLE 279

7

Page 281 of 360

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked whenever the vehicle is serviced. Operation with

an improper fluid level will greatly reduce the life of the

transaxle and of the fluid.

Procedure For Checking Fluid Level

To properly check the automatic transaxle fluid level, the

following procedure must be used:

1. The vehicle must be on level ground.

2. The engine should be running at curb idle speed for a

minimum of 60 seconds.

3. Fully apply parking brake.

4. Place the gear selector momentarily in each gear

position ending with the lever in P (PARK).

MAINTAINING YOUR VEHICLE 281

7

Page 283 of 360

CAUTION!

Do not overfill. Dirt and water in the transaxle can

cause serious damage. To prevent dirt and water

from entering the transaxle after checking or replen-

ishing fluid, make certain that the dipstick cap is

seated properly.

Fluid And Filter Changes

Automatic transmission fluid and filter should be

changed as follows:

Maintenance schedule“A”—Turbo Charged Engines–

No change necessary.

Maintenance schedule“B”–Every 60,000 miles (96 000

km) change fluid and filter under the following condi-

tions:

•Police, taxi, limousine, commercial type operation, or

trailer towing where the vehicle is drivenregularlyfor

more than 45 minutes of continuous operation.

NOTE:Refer to Section 8 of this manual for mainte-

nance schedules.

If the transaxle is disassembled for any reason, the fluid

and filter should be changed.

Special Additives

The manufacturer recommends against the addition of

any fluid additives to the transaxle. The only exception to

this policy is the use of special dyes to aid in detecting

fluid leaks. The use of transmission sealers should be

avoided as they may adversely affect seals.

MAINTAINING YOUR VEHICLE 283

7

Page 308 of 360

At Each Stop for Fuel

•Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

•Check the windshield washer solvent and add if

required.

Once a Month

•Check tire pressure and look for unusual wear or

damage.

•Inspect the battery and clean and tighten the terminals

as required.

•Check the fluid levels of coolant reservoir, brake

master cylinder and transaxle and add as needed.

•Check all lights and all other electrical items for correct

operation.

•Check rubber seals on each side of the radiator for

proper fit.

At Each Oil Change

•Change the engine oil filter.

•Inspect the exhaust system.

•Inspect the brake hoses.

•Inspect the CV joints and front suspension compo-

nents.

•Check the automatic transaxle fluid level.

•Check the manual transaxle fluid level and fill plug

condition.

•Check the coolant level, hoses, and clamps.

308 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 340 of 360

ABS (Anti-Lock Brake) System.............. 198

Adding Engine Coolant (Antifreeze).......... 274

Adding Fuel........................... 225

Adding Washer Fluid..................... 100

Additives, Fuel......................... 223

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 264

Air Conditioner Maintenance............... 267

Air Conditioning Controls................. 169

Air Conditioning, Operating Tips............ 174

Air Conditioning Refrigerant.............267,268

Air Conditioning System................169,267

Air Pressure, Tires....................... 211

Airbag................................ 40

Airbag Deployment....................... 46

Airbag Light.....................44,48,58,132

Airbag Maintenance....................... 48

Airbag, Side............................ 46

Alarm, Panic............................ 22

Alarm System........................25,127Alignment and Balance................... 218

Alterations/Modifications, Vehicle............. 7

Antifreeze (Engine Coolant)...........273,302,303

Capacities........................... 302

Anti-Lock Brake System (ABS).............. 198

Anti-Lock Warning Light.................. 129

Anti-Theft Security Alarm.................. 25

Appearance Care........................ 284

Auto Down Power Windows................ 29

Automatic Door Locks..................... 20

Automatic Transaxle..............12,182,185,280

Fluid and Filter Changes................. 283

Fluid Level Check...................... 281

Interlock System.....................18,186

Reset Mode.......................... 187

Selection Of Lubricant................... 280

Shifting............................. 187

Special Additives...................... 283

Autostick...........................134,190

340 INDEX

Page 342 of 360

Cellular Phone.......................... 168

Center High Mounted Stop Light............ 301

Central Door Locks....................... 20

Chains, Tire............................ 219

Changing A Flat Tire..................... 235

Chart, Tire Sizing........................ 203

Check Engine Light (Malfunction Indicator Light) . 255

Child Restraint.......................... 49

Child Restraint Tether Anchors............... 53

Child Seat.............................. 54

Clean Air Gasoline....................... 222

Climate Control......................... 169

Clock................................ 134

Coin Holder........................... 115

Compact Disc Maintenance................. 168

Compact Disc Player..................136,142

Compact Spare Tire...................... 214

Compass.............................. 75

Compass Calibration...................... 78Compass Variance........................ 77

Console............................... 115

Contract, Service........................ 332

Convertible............................. 62

Convertible Boot.......................68,72

Convertible Top.......................... 62

Convertible Top Maintenance............... 290

Convertible Top Manual Override..........73,247

Cool Down, Turbo....................... 184

Coolant............................302,303

Coolant Pressure Cap..................... 275

Cooling System......................... 272

Adding Coolant (Antifreeze).............. 274

Coolant Level......................272,275

Disposal of Used Coolant................ 275

Drain, Flush, and Refill.................. 273

Inspection........................... 275

Points to Remember.................... 276

Pressure Cap......................... 275

342 INDEX