wheel CHRYSLER SEBRING COUPE 2005 2.G Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: SEBRING COUPE, Model: CHRYSLER SEBRING COUPE 2005 2.GPages: 394, PDF Size: 2.47 MB

Page 275 of 394

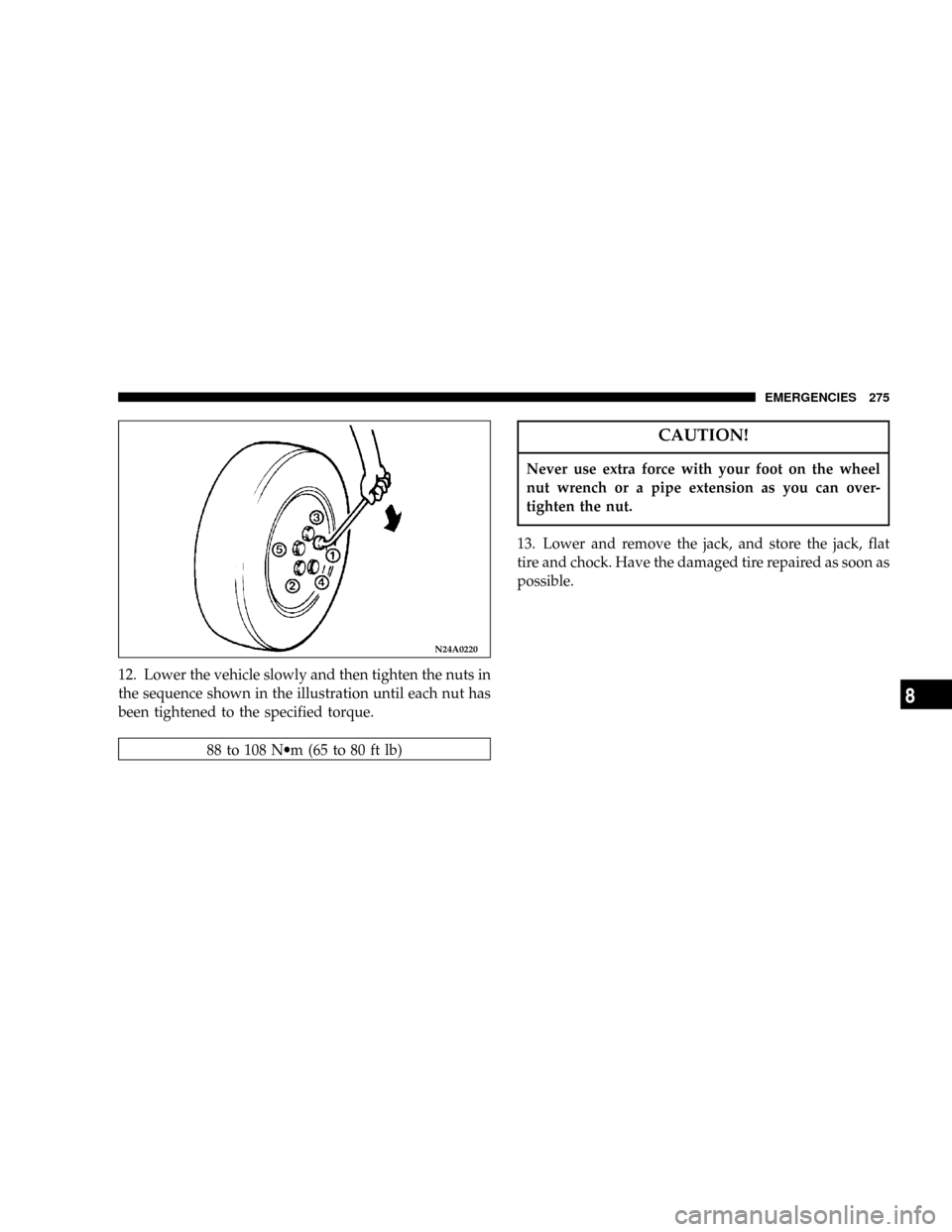

12. Lower the vehicle slowly and then tighten the nuts in

the sequence shown in the illustration until each nut has

been tightened to the specified torque.

88 to 108 N·m (65 to 80 ft lb)

CAUTION!

Never use extra force with your foot on the wheel

nut wrench or a pipe extension as you can over-

tighten the nut.

13. Lower and remove the jack, and store the jack, flat

tire and chock. Have the damaged tire repaired as soon as

possible.

N24A0220

EMERGENCIES 275

8

Page 276 of 394

14. Check tire inflation pressure. Tire inflation pressure

specifications are shown on a placard located on the

driver 's side ``B''-Pillar.

CAUTION!

²The emergency tire is to be used only temporarily

when the standard tire is damaged. Repair the

damaged tire as soon as possible. Replace the

emergency tire with the standard tire.

²After changing the tire and driving the vehicle

approximately 621 miles (1000 km), retighten the

wheel nuts to make sure that they are not loose.

²If the steering wheel vibrates after changing the

tire, have the tire checked for balance at an autho-

rized dealer.

²Avoid mixing one type of tire with another type or

using tires of a size other than the specified size.

Premature mechanical wear and reduced handling

may result.N24A1420

276 EMERGENCIES

Page 282 of 394

WARNING!

²Charging the battery installed in the vehicle

might cause the battery to catch fire and explode.

Or, damage to the vehicle could result. If it has to

be charged in that condition for unavoidable

reasons, disconnect the vehicle side negative lead.

²Keep sparks, cigarettes and flames away from the

battery because the battery may produce an explosion.

²Use adequate ventilation when charging or using

the battery in an enclosed space.

²Remove all the caps before charging the battery.

²Electrolyte (battery acid) is corrosive diluted sulfuric

acid. If electrolyte comes in contact with your hands,

eyes, clothes, or the painted surface of your vehicle,

thoroughly flush with water. If electrolyte gets in

your eyes, flush them thoroughly with water imme-

diately, and get prompt medical attention.

WARNING!

²Always wear protective clothing and goggles

when working near the battery.

²Keep the battery out of the reach of children.

If your vehicle has anti-lock brakes

If the vehicle is driven without sufficient battery charge,

after the engine has been started by using booster cables,

the engine may misfire. This can cause the anti-lock

braking system warning light to blink on and off. This is

a result of insufficient battery voltage; it is not a malfunc-

tion of the brake system. If this happens, fully charge the

battery before driving.

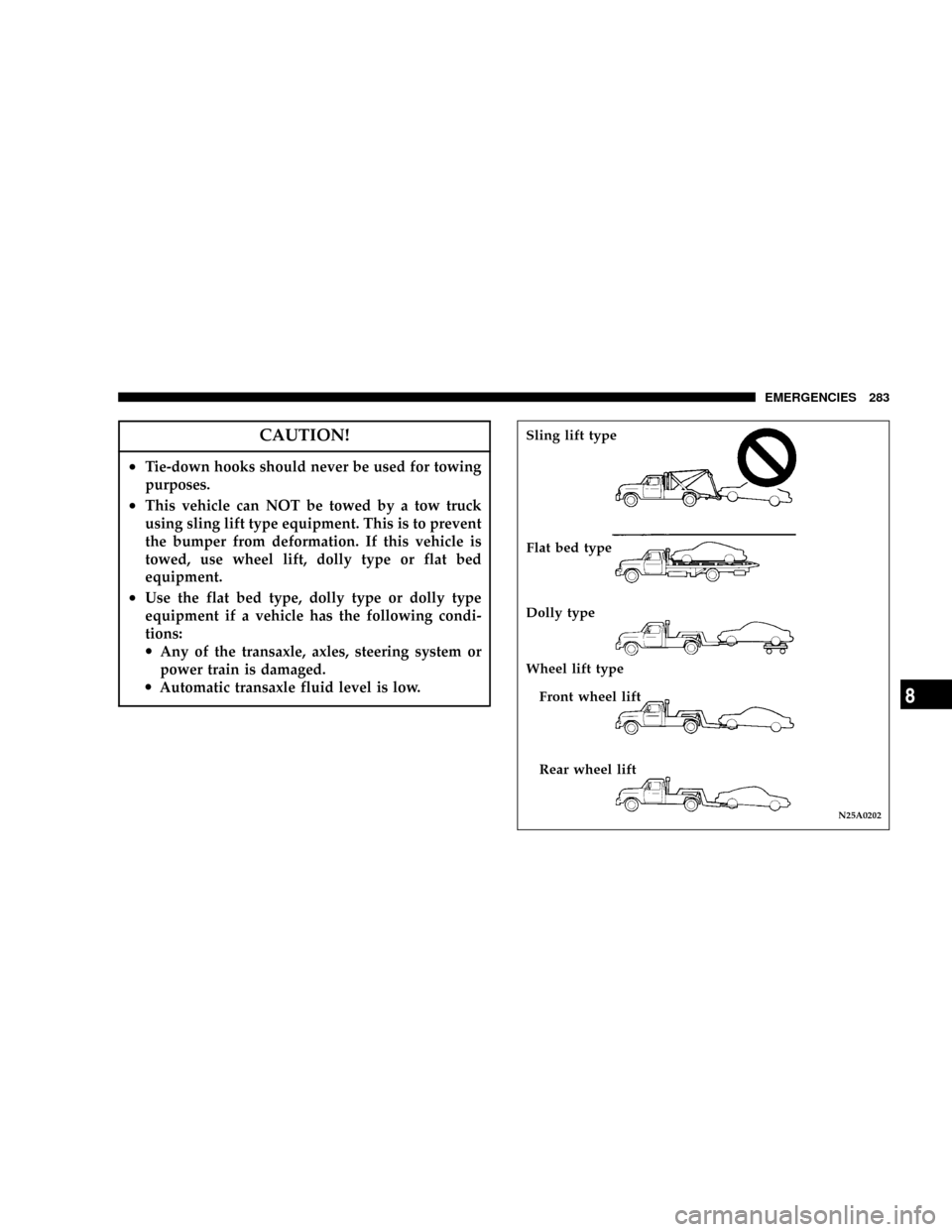

TOWING

When towing your vehicle, all state and local regulations for

towing must be followed. Incorrect towing equipment could

damage your vehicle. When towing is required, contact a

professional towing service and make sure that flat bed type,

dolly type or wheel lift type towing equipment is used. Do

not attempt to be towed by another vehicle with a rope using

the tie-down hooks.

282 EMERGENCIES

Page 283 of 394

CAUTION!

²Tie-down hooks should never be used for towing

purposes.

²This vehicle can NOT be towed by a tow truck

using sling lift type equipment. This is to prevent

the bumper from deformation. If this vehicle is

towed, use wheel lift, dolly type or flat bed

equipment.

²Use the flat bed type, dolly type or dolly type

equipment if a vehicle has the following condi-

tions:

·Any of the transaxle, axles, steering system or

power train is damaged.

·Automatic transaxle fluid level is low.

N25A0202

Sling lift type

Flat bed type

Dolly type

Wheel lift type

Front wheel lift

Rear wheel lift

EMERGENCIES 283

8

Page 284 of 394

CAUTION!

²Towing should only be done by a professional

tow service particularly if it will involve towing

on winding roads, hills or heavy traffic. If you

have any doubts, use a professional tow service.

TowingÐfront wheel lift

Place the gearshift lever (manual transaxle) to Neutral or

the selector lever (automatic transaxle) in the ªNº (NEU-

TRAL) position. Release the parking brake.

TowingÐrear wheel lift

Turn the ignition key to the ªACCº position and secure

the steering wheel in a straight-ahead position with a

rope or similar device. Never place the ignition key in the

ªLOCKº position. This will result in damage to the

steering lock mechanism.

If you have to tow an automatic transaxle model with the rear

wheels raised (with the front wheels on the ground):

Observe the following restricted towing speeds and distances.

·Speed: 30 mph (50 km/h)

·Distance: 18 miles (30 km)

CAUTION!

Never tow an automatic transaxle model with the

rear wheels raised (with the front wheels on the

ground) when the automatic transaxle fluid level is

low. This may cause serious and expensive damage

to the transaxle.

FUSES

N09A1230

Passenger compartment

284 EMERGENCIES

Page 306 of 394

NDisconnection and connection.............323

mAutomatic transaxle.....................325

NTo check the fluid level..................326

NProcedure for checking the fluid level.......326

mManual transaxle.......................327

mDisc brake pads, rear drum brake linings

and rear wheel cylinders.................327

mBrake hoses...........................327

mBall joint, steering linkage seal and drive

shaft boots...........................327

mSupplemental Restraint System (SRS)........327

mHood lock release mechanism and safety

catch

................................328

mExhaust system........................328

mWindshield wiper blades.................329

NWindshield washers....................329

mParking brake.........................330

mDrive belt (for generator, water pump, power

steering pump)

........................331

mTiming belt...........................332

mTi re s................................332

NTire inflation pressures..................336

NRadial ply tires.......................337

N

Tire pressure for sustained high-speed driving...338

NReplacing tire and wheels................338

NTire maintenance......................338

NCargo loads..........................343

NTread wear indicators...................343

NTire rotation.........................344

NTire chains...........................345

NSnow tires...........................345

mRegular Maintenance Schedule.............346

mSevere Maintenance Schedule..............354

306 MAINTENANCE

Page 327 of 394

Special additives

DaimlerChrysler does not recommend the addition of

any fluid additives to the transaxle.

MANUAL TRANSAXLE

Add oil to maintain the proper level. Refill or change oil

according to the scheduled maintenance table.

Lubricant Gear Oil Classification GL-4

Viscosity range SAE75W-90 or 75W-85W

DISC BRAKE PADS, REAR DRUM BRAKE

LININGS AND REAR WHEEL CYLINDERS

Proper brakes are essential to safe operation of your

vehicle. Check brake pads and rear brake linings for

wear, and check rear wheel cylinders for leakage.

For proper braking performance, replace brake pads with

original equipment type pads.

BRAKE HOSES

Brake hoses and tubing should be checked for:

1. Severe surface cracking, scuffing or worn spots. If the

casing of the hose is exposed by cracks or abrasions in therubber hose cover, the hose should be replaced. Deterio-

ration of the hose could cause brake failure.

2. Faulty installation may cause twisting, or wheel, tire

or chassis interference.

BALL JOINT, STEERING LINKAGE SEAL AND

DRIVE SHAFT BOOTS

Check the following parts for damage and grease leak-

age:

1. Ball joint boots of the front suspension and steering

linkage

2. Bellows on both ends of the drive shaft

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The entire SRS system must be inspected by an autho-

rized dealer 10 years after the vehicle manufacture date

shown on the certification label. [See ªSRS servicingº on

page 100.]

MAINTENANCE 327

9

Page 336 of 394

wet pavement as measured under controlled conditions

on specified government tests surfaces of asphalt and

concrete. A tire marked C may have poor traction perfor-

mance.

Temperature

The temperature grades are A (the highest), B, and C,

representing the tire's resistance to the generation of heat

and its ability to dissipate heat when tested under

controlled conditions on a specified indoor laboratory

test wheel. Sustained high temperature can cause the

material of the tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire failure. The

grade C corresponds to a level of performance which all

passenger car tires must meet under the Federal Motor

Vehicle Safety Standard No. 109. Grades B and A repre-

sent higher levels of performance on the laboratory test

wheel than the minimum required by law.

Tire inflation pressures

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:1. Safety

Under-inflation increases tire flexing and can result in tire

failure. Over-inflation results in a tire losing its ability to

cushion shock. Objects on the road and potholes could

cause tire damage that may result in tire failure.

2. Economy

Improper inflation pressures can cause uneven wear

patterns to develop across the tire tread. These abnormal

wear patterns will reduce tread life, resulting in a need

for earlier tire replacement.

Under-inflation also increases tire rolling resistance and

results in higher fuel consumption.

3. Ride comfort and vehicle stability

Proper tire inflation pressures contribute to the excellent

ride quality built into your vehicle. Over-inflation pro-

duces an uncomfortable and jarring ride.

Under-inflation can produce a feeling of sluggish re-

sponse.

Unequal inflation pressures can produce erratic and

unpredictable vehicle response to steering maneuvers.

The proper tire pressure for your vehicle is listed on a

placard attached near the door sill striker on the driver's

336 MAINTENANCE

Page 338 of 394

factory-installed tires on this vehicle are of belted con-

struction and are selected to complement the ride and

handling characteristics of your vehicle.

Radial ply tires have the same load carrying capacity as

bias or bias-belted tires of the same letter size, and use the

same recommended inflation pressures.

Mixing of radial ply tires with bias or bias-belted tires is

not recommended. Combining radial ply and bias or

bias-belted tires on one vehicle will negatively affect

vehicle handling. It is recommended that radial ply tires

should always be used as a set of four.

As longer wearing tires can be more susceptible to

irregular tread wear, it is very important to follow the tire

rotation interval shown in the section ªTire rotationº to

achieve full tread life potential in these tires.

Cuts and punctures in radial ply tires are repairable only

in the tread area, because of sidewall flexing. Consult

your tire dealer for radial ply tire repairs.Tire pressure for sustained high-speed driving

For sustained high-speed driving, increase inflation pres-

sure 4 psi (28 kPa) above the recommended pressure but

do not exceed the maximum cold inflation pressure

molded into the tire sidewall.

Replacing tire and wheels

CAUTION!

²Avoid using different size tires from the one listed

and the combined use of different types of tires,

as this can affect driving safety.

Refer to the ``TIRES AND WHEELS'' on page 373.

²Even if a wheel has the same rim size and offset as

the specified type of wheel, its shape may prevent

it from being fitted correctly. Consult an autho-

rized dealer before using wheels that you have.

Tire maintenance

The following maintenance steps are recommended:

1. Check pressure regularly.

338 MAINTENANCE

Page 339 of 394

2. Maintain wheel balance and front suspension align-

ment.

3. Rotate tires regularly in accordance with the recom-

mendation in the section ªTire rotationº on page 344.

Loading information

WARNING!

Overloading of your tire is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never

overload them.

It is important to familiarize yourself with the following

terms before loading your vehicle:

²Vehicle maximum load on the tire : load on an

individual tire that is determined by distributing to

each axle its share of the maximum loaded vehicle

weight and dividing by two.

²Vehicle normal load on the tire : load on an indi-

vidual tire that is determined by distributing to each

axle its share of the curb weight, accessory weight,

and normal occupant weight and dividing by two.

²Maximum loaded vehicle weight : the sum of -

(a) Curb weight;

(b) Accessory weight

(c) Vehicle capacity weight; and

(d) Production option weight.

²Curb weight : the weight of a motor vehicle with

standard equipment including the maximum capac-

ity of fuel, oil, and coolant, and, if so equipped, air

conditioning and additional weight optional engine.

²Accessory weight : the combined weight (in excess

of those standard items which may be replaced) of

automatic transmission, power steering, power

brakes, power windows, power seats, radio, and

heater, to the extent that these items are available as

factory-installed equipment (whether installed or

not).

MAINTENANCE 339

9