check engine CHRYSLER TOWN AND COUNTRY 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 303 of 2399

ENGINE

TABLE OF CONTENTS

page page

COOLANT

DESCRIPTION.........................15

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING.............15

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT

SERVICE............................16

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................16

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................16

STANDARD PROCEDURE - COOLING

SYSTEM FILLING.....................16

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING....................17

COOLANT RECOVERY PRESS CONTAINER

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................18

INSTALLATION.........................18

ENGINE COOLANT TEMP SENSOR

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

ENGINE COOLANT THERMOSTAT

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

RADIATOR

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................22

RADIATOR DRAINCOCK

REMOVAL.............................22

INSTALLATION.........................22

WATER PUMP

DESCRIPTION.........................23OPERATION...........................23

REMOVAL

REMOVAL - WATER PUMP..............23

REMOVAL - WATER PUMP HOUSING......23

CLEANING............................23

INSTALLATION

INSTALLATION - WATER PUMP..........23

INSTALLATION - WATER PUMP HOUSING . . 24

RADIATOR PRESSURE CAP

DESCRIPTION.........................25

OPERATION...........................25

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM PRESSURE CAP...............25

DIAGNOSIS AND TESTING - PRESSURE

RELIEF TEST........................26

CLEANING............................26

INSPECTION..........................26

RADIATOR FAN

DESCRIPTION.........................26

OPERATION...........................27

DIAGNOSIS AND TESTING - RADIATOR FAN

MOTOR .............................27

REMOVAL.............................28

INSTALLATION.........................28

HOSE CLAMPS

DESCRIPTION - HOSE CLAMPS...........28

OPERATION - HOSE CLAMPS.............28

RADIATOR FAN RELAY

DESCRIPTION.........................29

OPERATION...........................29

COOLANT SYSTEM HOSES

REMOVAL

REMOVAL - UPPER RADIATOR HOSE.....29

REMOVAL - LOWER RADIATOR HOSE.....29

REMOVAL - COOLANT BYPASS HOSE.....30

INSTALLATION

INSTALLATION - UPPER RADIATOR HOSE . . 30

INSTALLATION - LOWER RADIATOR HOSE . 30

INSTALLATION - COOLANT BYPASS HOSE . 30

7a - 14 ENGINERG

ProCarManuals.com

Page 304 of 2399

COOLANT

DESCRIPTION

Coolant flows through the engine water jackets

and cylinder heads absorbing heat produced by the

engine during operation. The coolant carries heat to

the radiator and heater core. Here it is transferred to

ambient air passing through the radiator and heater

core fins.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37 deg. C (-35 deg. F). The anti-

freeze concentrationmust alwaysbe a minimum of

44 percent, year-round in all climates.If percentage

is lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system com-

ponents may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7 deg. C (-90 deg. F). A

higher percentage will freeze at a warmer tempera-

ture. Also, a higher percentage of antifreeze can

cause the engine to overheat because the specific

heat of antifreeze is lower than that of water.

100 Percent Ethylene-GlycolÐShould Not Be Used in

Chrysler Vehicles

Use of 100 percent ethylene-glycol will cause for-

mation of additive deposits in the system, as the cor-

rosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149 deg. C (300 deg. F). This temperature is hot

enough to melt plastic and soften solder. The

increased temperature can result in engine detona-

tion. In addition, 100 percent ethylene-glycol freezes

at -22 deg. C (-8 deg. F ).

Propylene-glycol FormulationsÐShould Not Be Used in

Chrysler Vehicles

Propylene-glycol formulations do not meet

Chrysler coolant specifications.It's overall effec-

tive temperature range is smaller than that of ethyl-

ene-glycol. The freeze point of 50/50 propylene-glycol

and water is -32 deg. C (-26 deg. F). 5 deg. C higher

than ethylene-glycol's freeze point. The boiling point

(protection against summer boil-over) of propylene-

glycol is 125 deg. C (257 deg.F)at96.5 kPa (14 psi),

compared to 128 deg. C (263 deg. F) for ethylene-gly-

col. Use of propylene-glycol can result in boil-over or

freeze-up in Chrysler vehicles, which are designed for

ethylene-glycol. Propylene glycol also has poorer heat

transfer characteristics than ethylene glycol. Thiscan increase cylinder head temperatures under cer-

tain conditions.

Propylene-glycol/Ethylene-glycol MixturesÐShould Not Be

Used in Chrysler Vehicles

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibi-

tors, causing damage to the various cooling system

components. Also, once ethylene-glycol and propy-

lene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and spe-

cific gravity differ between ethylene glycol and propy-

lene glycol.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -59ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer will test the amount of glycol in a

coolant mixture by measuring the amount a beam of

light bends as it passes through the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is not rec-

ommended.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

RGENGINE7a-15

ProCarManuals.com

Page 305 of 2399

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAIN-

TENANCE SCHEDULES - DESCRIPTION).

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

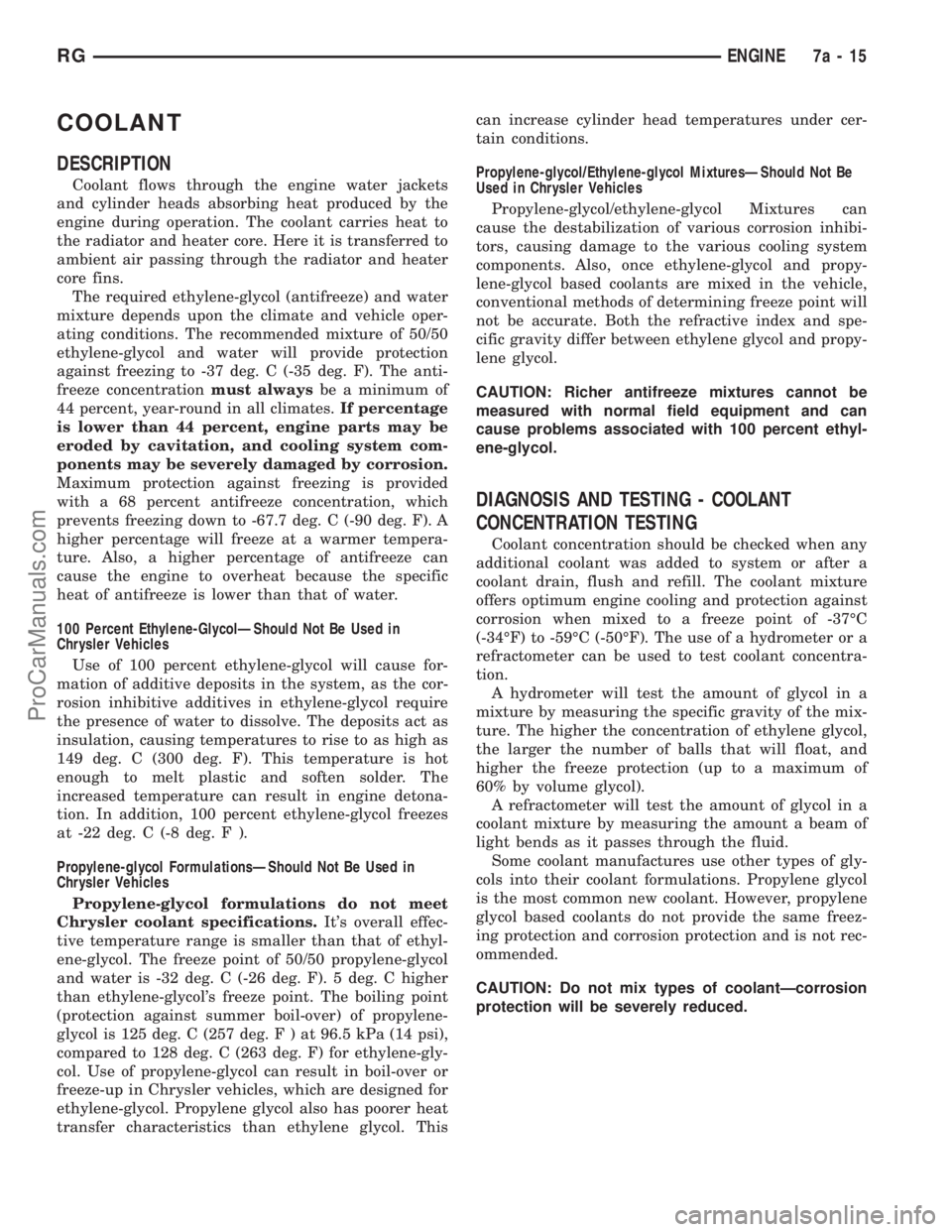

The pressure/vent cap should not be removed

from the coolant recovery pressure container

when the engine is hot.When additional coolant is

needed to maintain this level, it should be added to

the coolant recovery pressure container (Fig. 1). Use

only 50/50 mix of ethylene glycol type antifreeze and

distilled water. For the recommeded antifreeze/cool-

ant type (Refer to LUBRICATION & MAINTE-

NANCE/FLUID TYPES - DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove pressure/vent cap for routine

coolant level inspections.

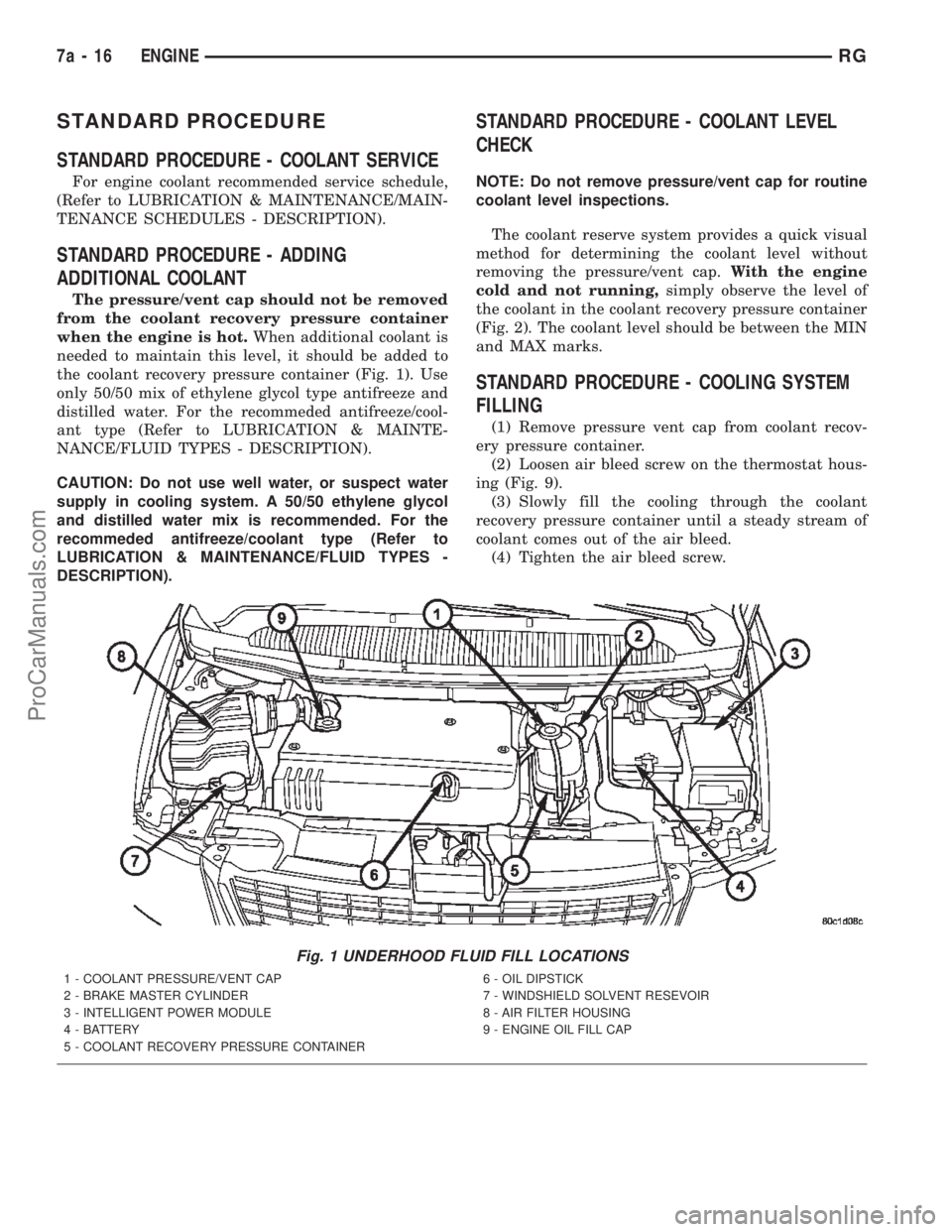

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the pressure/vent cap.With the engine

cold and not running,simply observe the level of

the coolant in the coolant recovery pressure container

(Fig. 2). The coolant level should be between the MIN

and MAX marks.

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

(1) Remove pressure vent cap from coolant recov-

ery pressure container.

(2) Loosen air bleed screw on the thermostat hous-

ing (Fig. 9).

(3) Slowly fill the cooling through the coolant

recovery pressure container until a steady stream of

coolant comes out of the air bleed.

(4) Tighten the air bleed screw.

Fig. 1 UNDERHOOD FLUID FILL LOCATIONS

1 - COOLANT PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - INTELLIGENT POWER MODULE

4 - BATTERY

5 - COOLANT RECOVERY PRESSURE CONTAINER6 - OIL DIPSTICK

7 - WINDSHIELD SOLVENT RESEVOIR

8 - AIR FILTER HOUSING

9 - ENGINE OIL FILL CAP

7a - 16 ENGINERG

ProCarManuals.com

Page 306 of 2399

(5) Continue filling coolant recovery pressure con-

tainer until level reaches the full line.

(6) Without installing the pressure/vent cap, start

and run engine at idle for a couple minutes.

(7) Recheck coolant level and fill as necessary.

(8) Install pressure/vent cap and drive vehicle for

approx. 10 km to reach normal operating tempera-

tures.

(9) Allow vehicle to cool. Check and fill coolant as

needed.

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE/VENT CAP, CYLINDER

BLOCK DRAIN PLUGS, OR THE DRAINCOCK WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.(1)Without removing pressure/vent cap and

with system not under pressure, open the drain-

cock. The draincock is located on the lower right side

of radiator (Fig. 3).

(2) After the coolant recovery pressure container is

empty, then remove coolant pressure/vent cap.

COOLANT RECOVERY PRESS

CONTAINER

DESCRIPTION

The coolant recovery pressure container is

mounted in the engine compartment next to the bat-

tery. The coolant recovery pressure container is made

of plastic (Fig. 4).

OPERATION

The coolant recovery pressure container works

with the pressure/vent cap to use thermal expansion

and contraction of the coolant to keep the coolant

free of trapped air. Provides a convenient and safe

method for checking coolant level and adjusting level

at atmospheric pressure without removing the pres-

sure/vent cap. It also provides some reserve coolant

to cover deaeration, evaporation, or boiling losses.

Fig. 2 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

Fig. 3 DRAINCOCK LOCATION

1 - RADIATOR

2 - DRAINCOCK

3 - LOWER RADIATOR SUPPORT

4 - ELECTRIC COOLING FAN

RGENGINE7a-17

COOLANT (Continued)

ProCarManuals.com

Page 314 of 2399

RADIATOR PRESSURE CAP

DESCRIPTION

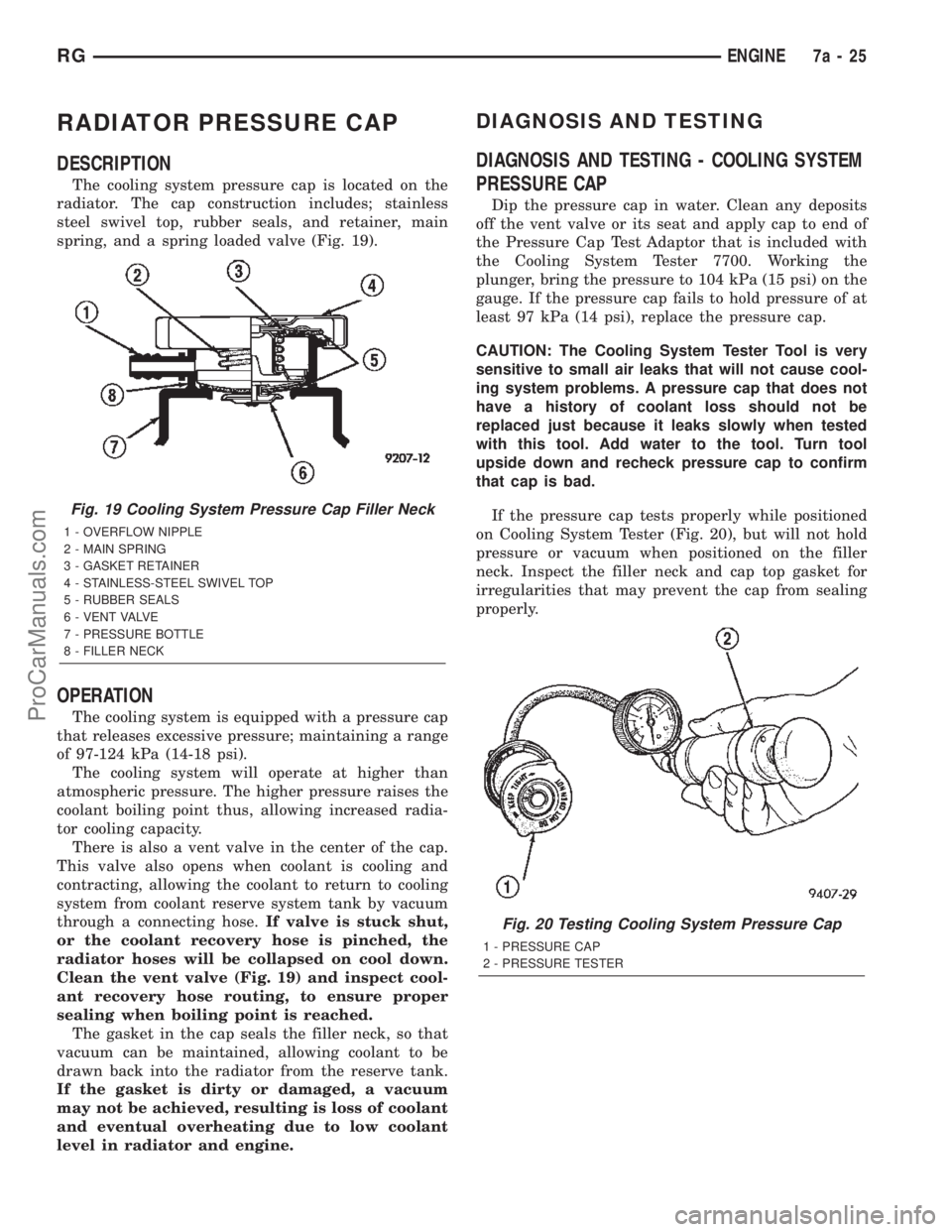

The cooling system pressure cap is located on the

radiator. The cap construction includes; stainless

steel swivel top, rubber seals, and retainer, main

spring, and a spring loaded valve (Fig. 19).

OPERATION

The cooling system is equipped with a pressure cap

that releases excessive pressure; maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is also a vent valve in the center of the cap.

This valve also opens when coolant is cooling and

contracting, allowing the coolant to return to cooling

system from coolant reserve system tank by vacuum

through a connecting hose.If valve is stuck shut,

or the coolant recovery hose is pinched, the

radiator hoses will be collapsed on cool down.

Clean the vent valve (Fig. 19) and inspect cool-

ant recovery hose routing, to ensure proper

sealing when boiling point is reached.

The gasket in the cap seals the filler neck, so that

vacuum can be maintained, allowing coolant to be

drawn back into the radiator from the reserve tank.

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP

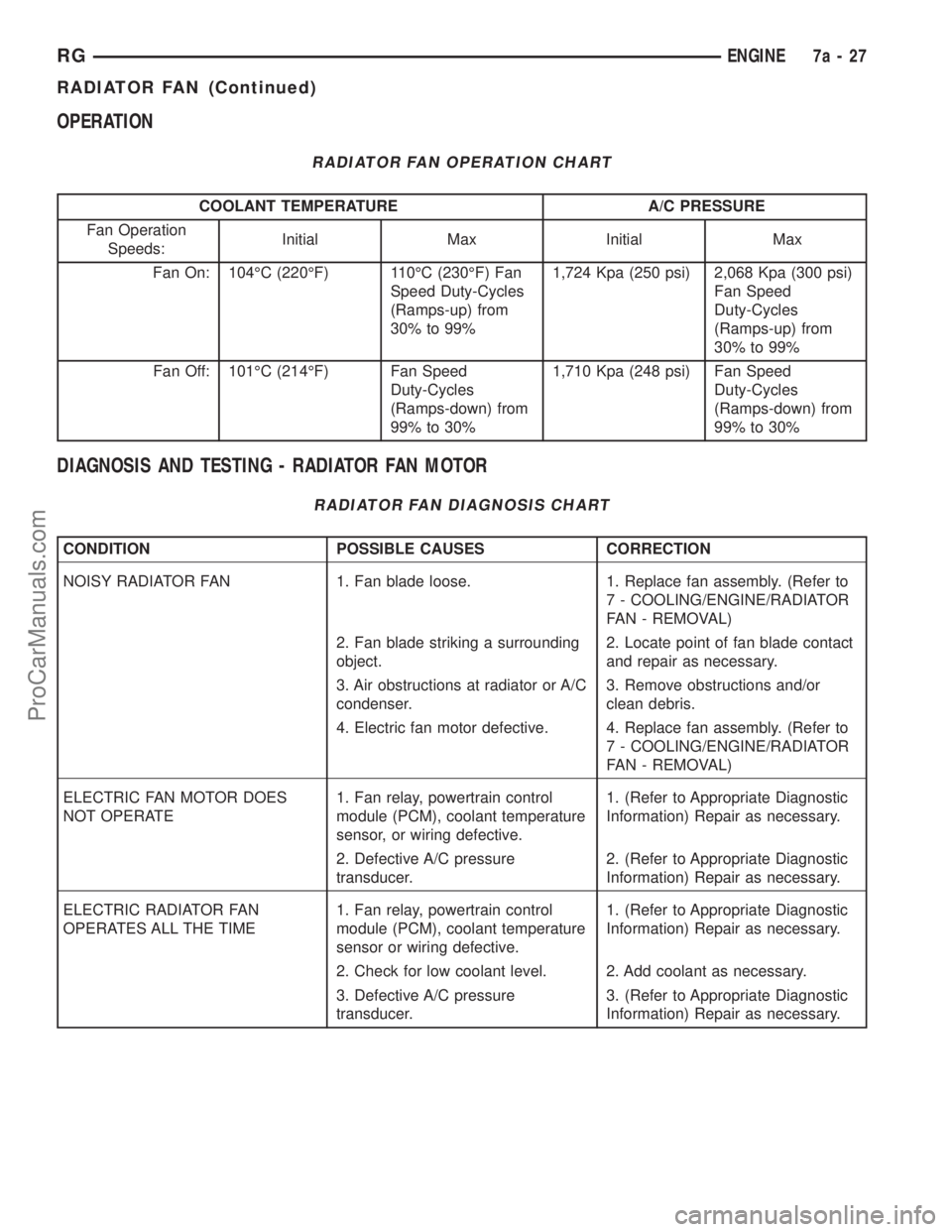

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700. Working the

plunger, bring the pressure to 104 kPa (15 psi) on the

gauge. If the pressure cap fails to hold pressure of at

least 97 kPa (14 psi), replace the pressure cap.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 20), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

Fig. 19 Cooling System Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8 - FILLER NECK

Fig. 20 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

RGENGINE7a-25

ProCarManuals.com

Page 315 of 2399

DIAGNOSIS AND TESTING - PRESSURE

RELIEF TEST

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 21). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

INSPECTION

Hold the cap in your hand,top side up(Fig. 21).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.

Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 22). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

Fig. 21 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8 - FILLER NECK

7a - 26 ENGINERG

RADIATOR PRESSURE CAP (Continued)

ProCarManuals.com

Page 316 of 2399

OPERATION

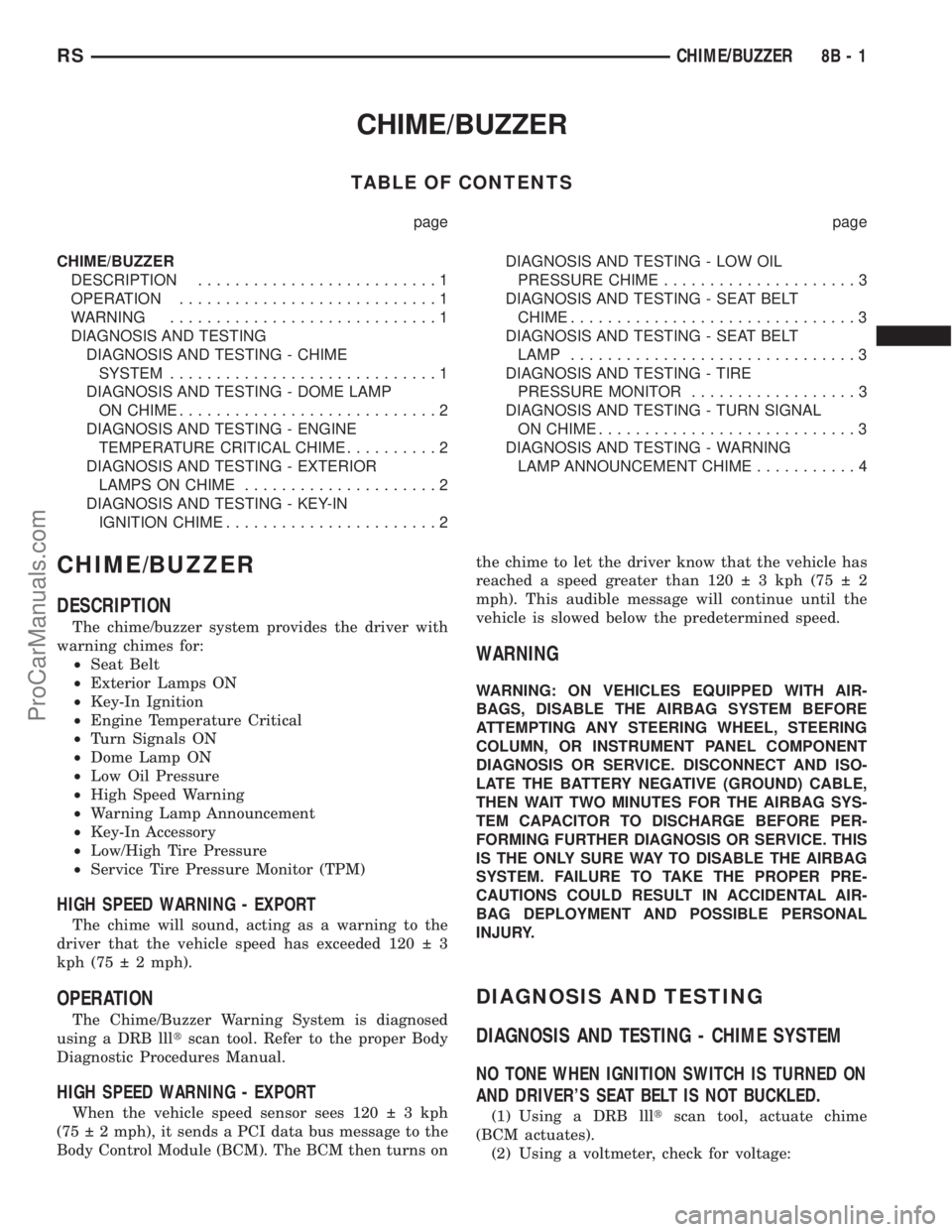

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE

Fan Operation

Speeds:Initial Max Initial Max

Fan On: 104ÉC (220ÉF) 110ÉC (230ÉF) Fan

Speed Duty-Cycles

(Ramps-up) from

30% to 99%1,724 Kpa (250 psi) 2,068 Kpa (300 psi)

Fan Speed

Duty-Cycles

(Ramps-up) from

30% to 99%

Fan Off: 101ÉC (214ÉF) Fan Speed

Duty-Cycles

(Ramps-down) from

99% to 30%1,710 Kpa (248 psi) Fan Speed

Duty-Cycles

(Ramps-down) from

99% to 30%

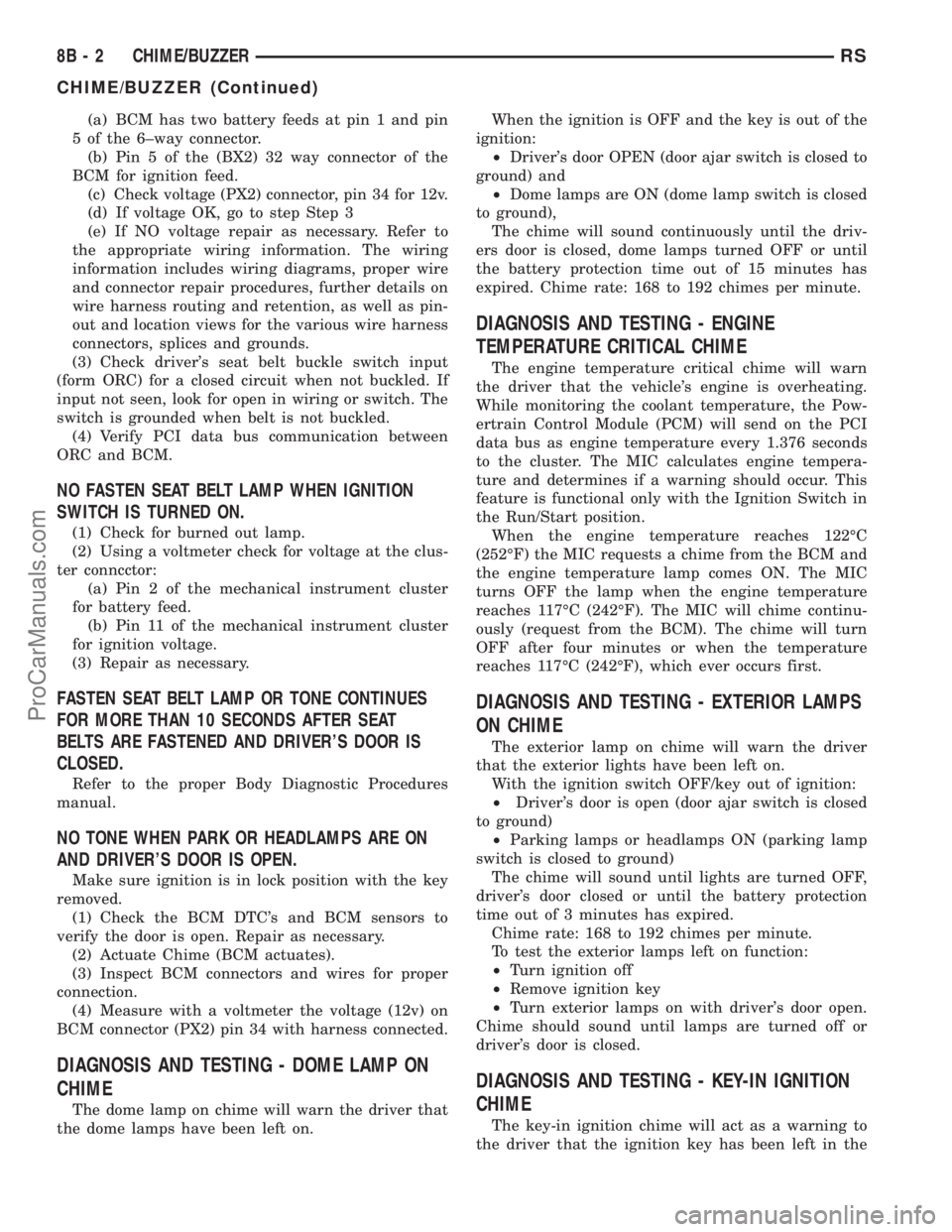

DIAGNOSIS AND TESTING - RADIATOR FAN MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

RGENGINE7a-27

RADIATOR FAN (Continued)

ProCarManuals.com

Page 334 of 2399

CHIME/BUZZER

TABLE OF CONTENTS

page page

CHIME/BUZZER

DESCRIPTION..........................1

OPERATION............................1

WARNING.............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHIME

SYSTEM.............................1

DIAGNOSIS AND TESTING - DOME LAMP

ON CHIME............................2

DIAGNOSIS AND TESTING - ENGINE

TEMPERATURE CRITICAL CHIME..........2

DIAGNOSIS AND TESTING - EXTERIOR

LAMPS ON CHIME.....................2

DIAGNOSIS AND TESTING - KEY-IN

IGNITION CHIME.......................2DIAGNOSIS AND TESTING - LOW OIL

PRESSURE CHIME.....................3

DIAGNOSIS AND TESTING - SEAT BELT

CHIME...............................3

DIAGNOSIS AND TESTING - SEAT BELT

LAMP...............................3

DIAGNOSIS AND TESTING - TIRE

PRESSURE MONITOR..................3

DIAGNOSIS AND TESTING - TURN SIGNAL

ON CHIME............................3

DIAGNOSIS AND TESTING - WARNING

LAMP ANNOUNCEMENT CHIME...........4

CHIME/BUZZER

DESCRIPTION

The chime/buzzer system provides the driver with

warning chimes for:

²Seat Belt

²Exterior Lamps ON

²Key-In Ignition

²Engine Temperature Critical

²Turn Signals ON

²Dome Lamp ON

²Low Oil Pressure

²High Speed Warning

²Warning Lamp Announcement

²Key-In Accessory

²Low/High Tire Pressure

²Service Tire Pressure Monitor (TPM)

HIGH SPEED WARNING - EXPORT

The chime will sound, acting as a warning to the

driver that the vehicle speed has exceeded 120 3

kph (75 2 mph).

OPERATION

The Chime/Buzzer Warning System is diagnosed

using a DRB llltscan tool. Refer to the proper Body

Diagnostic Procedures Manual.

HIGH SPEED WARNING - EXPORT

When the vehicle speed sensor sees 120 3kph

(75 2 mph), it sends a PCI data bus message to the

Body Control Module (BCM). The BCM then turns onthe chime to let the driver know that the vehicle has

reached a speed greater than 120 3kph(75 2

mph). This audible message will continue until the

vehicle is slowed below the predetermined speed.

WARNING

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHIME SYSTEM

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVER'S SEAT BELT IS NOT BUCKLED.

(1) Using a DRB llltscan tool, actuate chime

(BCM actuates).

(2) Using a voltmeter, check for voltage:

RSCHIME/BUZZER8B-1

ProCarManuals.com

Page 335 of 2399

(a) BCM has two battery feeds at pin 1 and pin

5 of the 6±way connector.

(b) Pin 5 of the (BX2) 32 way connector of the

BCM for ignition feed.

(c) Check voltage (PX2) connector, pin 34 for 12v.

(d) If voltage OK, go to step Step 3

(e) If NO voltage repair as necessary. Refer to

the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

(3) Check driver's seat belt buckle switch input

(form ORC) for a closed circuit when not buckled. If

input not seen, look for open in wiring or switch. The

switch is grounded when belt is not buckled.

(4) Verify PCI data bus communication between

ORC and BCM.

NO FASTEN SEAT BELT LAMP WHEN IGNITION

SWITCH IS TURNED ON.

(1) Check for burned out lamp.

(2) Using a voltmeter check for voltage at the clus-

ter conncctor:

(a) Pin 2 of the mechanical instrument cluster

for battery feed.

(b) Pin 11 of the mechanical instrument cluster

for ignition voltage.

(3) Repair as necessary.

FASTEN SEAT BELT LAMP OR TONE CONTINUES

FOR MORE THAN 10 SECONDS AFTER SEAT

BELTS ARE FASTENED AND DRIVER'S DOOR IS

CLOSED.

Refer to the proper Body Diagnostic Procedures

manual.

NO TONE WHEN PARK OR HEADLAMPS ARE ON

AND DRIVER'S DOOR IS OPEN.

Make sure ignition is in lock position with the key

removed.

(1) Check the BCM DTC's and BCM sensors to

verify the door is open. Repair as necessary.

(2) Actuate Chime (BCM actuates).

(3) Inspect BCM connectors and wires for proper

connection.

(4) Measure with a voltmeter the voltage (12v) on

BCM connector (PX2) pin 34 with harness connected.

DIAGNOSIS AND TESTING - DOME LAMP ON

CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.When the ignition is OFF and the key is out of the

ignition:

²Driver's door OPEN (door ajar switch is closed to

ground) and

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until the driv-

ers door is closed, dome lamps turned OFF or until

the battery protection time out of 15 minutes has

expired. Chime rate: 168 to 192 chimes per minute.

DIAGNOSIS AND TESTING - ENGINE

TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the PCI

data bus as engine temperature every 1.376 seconds

to the cluster. The MIC calculates engine tempera-

ture and determines if a warning should occur. This

feature is functional only with the Ignition Switch in

the Run/Start position.

When the engine temperature reaches 122ÉC

(252ÉF) the MIC requests a chime from the BCM and

the engine temperature lamp comes ON. The MIC

turns OFF the lamp when the engine temperature

reaches 117ÉC (242ÉF). The MIC will chime continu-

ously (request from the BCM). The chime will turn

OFF after four minutes or when the temperature

reaches 117ÉC (242ÉF), which ever occurs first.

DIAGNOSIS AND TESTING - EXTERIOR LAMPS

ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF/key out of ignition:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

DIAGNOSIS AND TESTING - KEY-IN IGNITION

CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

8B - 2 CHIME/BUZZERRS

CHIME/BUZZER (Continued)

ProCarManuals.com

Page 336 of 2399

ignition switch. This chime will operate for all igni-

tion positions except ON and START.

With the ignition switch in the OFF position

O N LY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (ignition is in the

LOCK position)

The chime will sound until one of the above condi-

tions is removed or until battery protection time out

(15 min.) has expired. Chime rate: 168 to 192 chimes

per minute.

To test the key-in ignition function, insert key into

the ignition and open drivers door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or drivers door is closed.

For diagnosis and testing of the Key-In chime for

other ignition positions, use the same testing proce-

dure as above but with the key in the accessory or

unlock position.

DIAGNOSIS AND TESTING - LOW OIL

PRESSURE CHIME

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The PCM will monitor the oil

pressure switch and signal a low oil pressure condi-

tion. A continuous four minute warning chime will

sound and the oil pressure lamp will come ON when

the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

DIAGNOSIS AND TESTING - SEAT BELT CHIME

The seat belt chime will sound for 4 to 8 seconds,

when the ignition is turned on and the driver's seat

belt is not buckled (seat belt switch is closed to

ground). This is a reminder to the driver to buckle

the seat belt. The seat belt lamp is controlled by the

ORC. The cluster will also bulb check the seat belt

warning lamp for 6 seconds. Buckling the driver's

seat belt before the time out has expired will cause

the chime to stop immediately. Chime rate: 38 to 62

chimes per minute but the lamp will remain on until

6 seconds have expired.

To test the seat belt warning system, the ignition

switch must be in the OFF position for 1 minute

before starting the test. Turn the ignition switch to

the on position with the driver's seat belt not buck-led. The seat belt warning lamp should light and the

chime should sound 4 to 8 seconds.

DIAGNOSIS AND TESTING - SEAT BELT LAMP

The seat belt lamp in the instrument cluster sig-

nals the vehicle passengers to fasten their seat belts.

The seat belt lamp is illuminated directly by the

instrument cluster for 6 seconds after the instrument

cluster receives the message from the ORC. The seat

belt lamp is therefore illuminated for 6 seconds

whenever the ignition switch is moved to run/start

position.

(1) While ignition is off, the seat belt lamp will not

be illuminated.

(2) The ignition power feed status will be updated

every 250 milliseconds or on change.

(3) This lamp will be checked by the instrument

cluster for 6 seconds with every run/start cycle of the

ignition switch.

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITOR

The Tire Pressure Warning chime, as well as the

information being displayed in the EVIC, will act as

a warning to the driver that a tire has either Low or

High pressure, or if there is a need to service the

Tire Pressure Monitor System. With the ignition

switch in the ON position and the ªLow Pressure/

High Pressureº or ªService the TPM Systemº dis-

played on the EVIC display, a single chime will

sound.

DIAGNOSIS AND TESTING - TURN SIGNAL ON

CHIME

The turn signal on chime will warn the driver that

the turn signals have been left on. When the body

control module receives a turn signal input for 1.0

mile, vehicle speed is greater than 24 km/h (15 mph),

the chime will sound continuously until the turn sig-

nal is turned OFF. If vehicle speed drops below 24

km/h (15 mph) prior to the warning being activated,

the accumulated distance traveled will be reset. The

turn signal chime is not activated when the emer-

gency flashers are turned on. Chime rate: 50 12

chimes per minute.

For the turn signal warning system to operate:

²Must have input from either the right or left

turn signal lamps. Creates a voltage change between

0 and battery voltage.

²The vehicle speed sensor sends a message to the

Powertrain Control Module that vehicle has exceeded

24 km/h (15 mph) for 1.0 mile).

²When the above two conditions are met, the

chime will sound. The chime will stop when no fur-

ther voltage change is detected.

RSCHIME/BUZZER8B-3

CHIME/BUZZER (Continued)

ProCarManuals.com