wheel CHRYSLER TOWN AND COUNTRY 2004 4.G Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2004 4.GPages: 401

Page 268 of 401

Improper alignment will not cause vehicle vibration.

Vibration may be a result of tire and wheel out-of-

balance. Proper balancing will reduce vibration and

avoid tire cupping and spotty wear.

ALL WHEEL DRIVE (AWD) Ð IF EQUIPPED

CAUTION!

All Wheel Drive (AWD) vehicles must have the same

size and type tires on all wheel positions. Unequal

tire sizes must not be used. Unequal tire size may

cause failure of the power transfer unit and/or the

viscous coupling.

TIRE PRESSURE MONITOR SYSTEM Ð IF

EQUIPPED

The Tire Pressure Monitor System (TPM) system uses

wireless technology with wheel rim mounted electronic

sensors to monitor tire pressure levels (EXCLUDING

THE SPARE TIRE). Sensors, mounted to each wheel as

part of the valve stem, transmit tire pressure readings to

a receiver located in the overhead console.

NOTE:The tire pressure monitoring system on your

vehicle will warn you when one of your tires is signifi-

cantly underinflated and when some combinations of

your tires are significantly underinflated. However, there

are other combinations of significantly underinflated

tires for which your tire pressure monitoring system may

not warn you. These other combinations are relatively

common, accounting for approximately half the instances

in which vehicles have significantly underinflated tires.

For example, your system may not warn you when both

tires on the same side or on the same axle of your vehicle

268 STARTING AND OPERATING

Page 270 of 401

TIRE PRESSURE NOW AVAILABLE

The TPM system is functioning normally and the external

interference is no longer affecting the system.

SPARE TIRE IN USE? YES/NO

The TPM system requires more information to determine

the correct mode of operation, one or more of the vehicle

active tires has been replaced by the spare, a wheel rim

not equipped with a TPM sensor or the TPM system

requires service.

If the spare tire or non TPM sensor equipped wheel rim

is in active use (mounted on the vehicle), answer YES and

the TPM system will resume normal operation.

If the spare tire or non TPM sensor equipped wheel rim

isNOTin active use (mounted on the vehicle), answer

NO and the TPM system will resume normal operation.

ALL 5 TIRES WITH CAR? YES/NO

The TPM system requires more information to determine

the correct mode of operation, one or more of the vehicle

active tires has been replaced by the spare, a wheel rim

not equipped with a TPM sensor or the TPM system

requires service.

If the spare tire or non TPM sensor equipped wheel rim

is in active use (mounted on the vehicle), answer YES and

the TPM system will resume normal operation.

If the spare tire or non TPM sensor equipped wheel rim

isNOTin active use (mounted on the vehicle), answer

NO and the TPM system will resume normal operation.

270 STARTING AND OPERATING

Page 271 of 401

CAUTION!

The TPM system has been optimized for the original

equipment tires and wheels. TPM system pressures

have been established for the tire size equipped on

your vehicle. Undesirable operation or sensor dam-

age may result when using replacement equipment

that is not of the same size, type, and/or style.

After-market wheels can cause sensor damage. Do

not use tire sealant or balance beads if your vehicle

is equipped with TPM system as damage to the

sensors may result.

NOTE:

²The TPM system can inform the driver of a low tire

pressure condition of 28 psi [1.9 bars] (193 kPa) or less,

or high a tire pressure condition of 48 psi [3.3 bars]

(330 kPa) or more.

²The TPM system is not intended to replace normal tire

care and maintenance, nor to provide warning of a tire

failure or condition.

²The TPM system should not be used as a tire pressure

gauge while adjusting your tire pressure.

²The TPM system must be retrained after a tire rotation

or wheel rim mounted sensor replacement. See your

authorized dealer for service.

CAUTION!

After inspecting or adjusting the tire pressure al-

ways reinstall the valve stem cap. This will prevent

moisture and dirt entry into the valve stem, which

could damage the wheel rim sensor.

STARTING AND OPERATING 271

5

Page 272 of 401

General Information

This device complies with part 15 of the FCC rules and

RSS 210 of Industry Canada. Operation is subject to the

following conditions:

²This device may not cause harmful interference.

²This device must accept any interference received,

including interference that may cause undesired op-

eration.

The tire pressure sensors are covered under one of the

following licenses:

United States.....................KR5S120123

Canada........................2671-S120123

TIRE CHAINS

Use only compact chains, or other traction aids that meet

SAE type ªClass Sº specifications. Chains must be the

proper size for the vehicle, as recommended by the chain

manufacturer.

NOTE:Do not use tire chains on a compact spare tire.

CAUTION!

To avoid damage to your vehicle or tires, observe the following

precautions:

²Because of restricted chain clearance between tires and

other suspension components, it is important that only

chains in good condition are used. Broken chains can cause

serious damage. Stop the vehicle immediately if noise

occurs that could indicate chain breakage. Remove the

damaged parts of the chain before further use.

²Install chains on the front wheels as tightly as possible and

then retighten after driving about1¤2mile (0.8 km).²Do not exceed 45 mph (70 km/h).

²Drive cautiously and avoid severe turns and large

bumps, especially with a loaded vehicle.

²Do not use on rear wheels of All Wheel Drive (AWD)

vehicles.

²Do not drive for prolonged period on dry pavement.

²Observe the tire chain manufacturer's instructions on the

method of installation, operating speed, and conditions for

use. Always use the lower suggested operating speed of the

chain manufacturer if different than the speed recom-

mended by the manufacture.

272 STARTING AND OPERATING

Page 282 of 401

²Vehicle Identification Number (VIN)

²Type of Vehicle

²Month Day and Hour of Manufacture (MDH)

The bar code allows a computer scanner to read the

Vehicle Identification Number (VIN).

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your vehicle.

This includes driver, passengers, and cargo. The total

load must be limited so that you do not exceed the

GVWR.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR.

WARNING!

Because the front wheels drive and steer the vehicle, it is

important that you do not exceed the maximum front or

rear GAWR. A dangerous driving condition can result if

either rating is exceeded. You could lose control of the

vehicle and have an accident.

Overloading

The load carrying components (axle, springs, tires,

wheels, etc.) of your vehicle will provide satisfactory

service as long as you do not exceed the GVWR and

front and rear GAWR.

The best way to figure out the total weight of your

vehicle is to weigh it when it is fully loaded and ready

for operation. Weigh it on a commercial scale to insure

that it is not over the GVWR.

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

282 STARTING AND OPERATING

Page 289 of 401

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher..................290

mIf Your Engine Overheats.................291

mJacking And Tire Changing................292

NJack Location........................293

NSpare Tire Stowage....................293

NPreparations For Jacking................294

NJacking Instructions....................295

mJump-Starting Procedures If Battery Is Low....298

mDriving On Slippery Surfaces..............299

NAcceleration.........................299NTraction............................300

mFreeing A Stuck Vehicle..................300

mTowing A Disabled Vehicle................301

NWith Ignition Key.....................301

NWithout The Ignition Key...............302

NTowing This Vehicle Behind Another Vehicle

(Flat Towing With All Four Wheels On The

Ground)............................302

NTowing This Vehicle Behind Another Vehicle

With A Tow Dolley....................303

6

Page 294 of 401

Spare Tire Removal

Fit the jack-handle over the drive nut. Rotate the nut to

the left until the spare is on the ground with enough slack

cable to allow you to pull the tire out from under the

vehicle.

CAUTION!

The winch mechanism is designed for use with the

jack handle only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

When the spare is clear, tilt the retainer at the end of the

cable and pull it through the center of the wheel.

Preparations For Jacking

Park the vehicle on a firm level surface, avoid ice or

slippery areas,set the parking brakeand place the gear

selector in PARK. Turn OFF the ignition.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

294 WHAT TO DO IN EMERGENCIES

Page 295 of 401

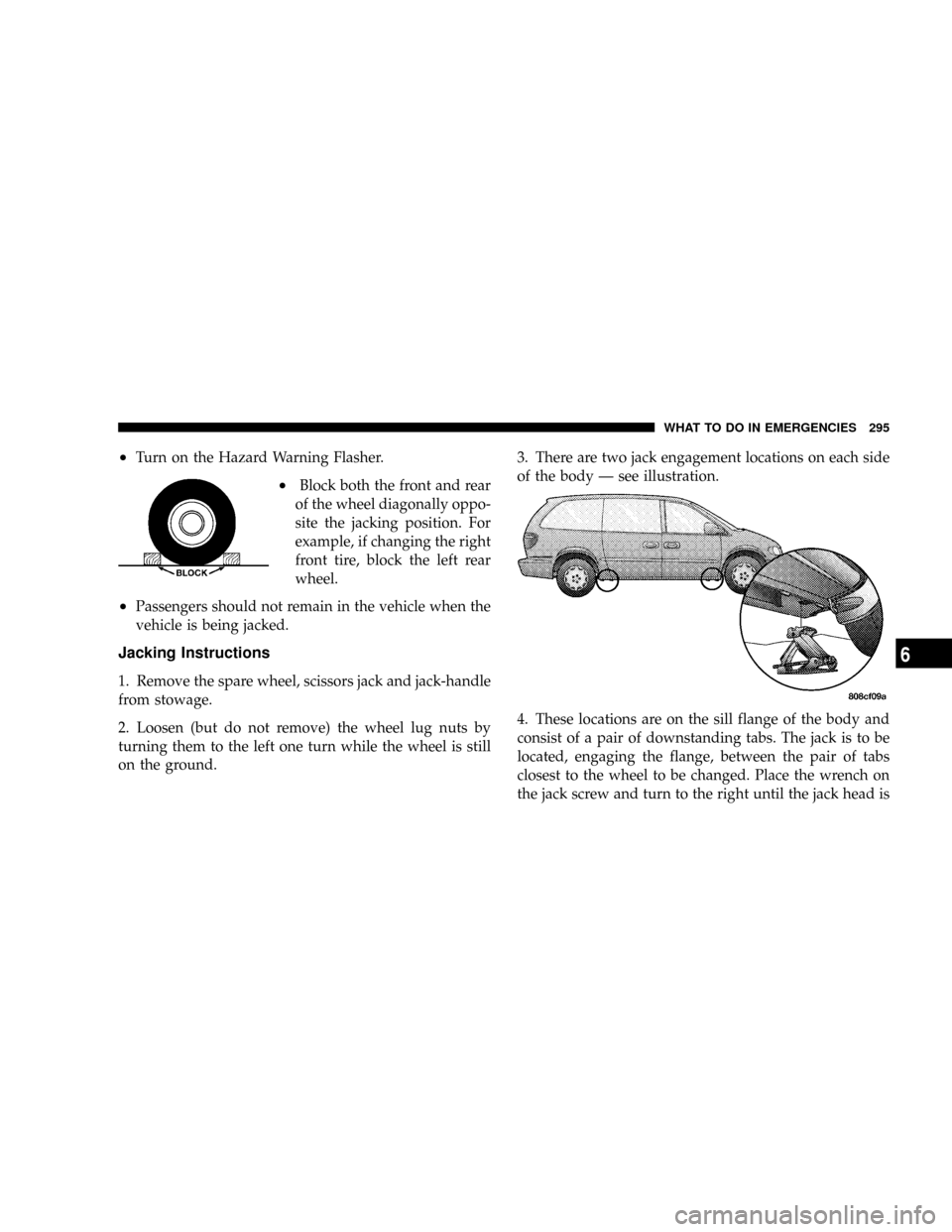

²Turn on the Hazard Warning Flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if changing the right

front tire, block the left rear

wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Jacking Instructions

1. Remove the spare wheel, scissors jack and jack-handle

from stowage.

2. Loosen (but do not remove) the wheel lug nuts by

turning them to the left one turn while the wheel is still

on the ground.3. There are two jack engagement locations on each side

of the body Ð see illustration.

4. These locations are on the sill flange of the body and

consist of a pair of downstanding tabs. The jack is to be

located, engaging the flange, between the pair of tabs

closest to the wheel to be changed. Place the wrench on

the jack screw and turn to the right until the jack head is

WHAT TO DO IN EMERGENCIES 295

6

Page 296 of 401

properly engaged in the described location.Do not raise

the vehicle until you are sure the jack is securely

engaged.

5. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

7. Install the spare wheel, for vehicles with wheel covers,

align the notch in the wheel cover with the valve stem on

the wheel. Install the cover on the wheel by hand only

and install the wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the nuts. To

avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

8. Lower the vehicle by turning the jack screw to the left.

9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

296 WHAT TO DO IN EMERGENCIES

Page 297 of 401

nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your dealer or at a service station.

10. Lower the jack to its fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

11. Secure the flat or spare tire as follows:

²If your vehicle is equipped with cast aluminum

wheels, the center cap of the wheel must be re-

moved prior to flat tire stowage. Store the center cap

inside the glove box or other storage compartment.

²Turn the wheel so that the valve-stem is down. Slide

the wheel retainer through the center of the wheel

and position it properly across the wheel opening.

²For convenience in checking the spare tire inflation,

stow with the valve-stem toward the rear of the

vehicle.

²Using the jack-handle, rotate the drive nut to the

right until the wheel is drawn into place against the

underside of the vehicle.

²Continue to rotate the nut until you hear the mecha-

nism click three times. It cannot be overtightened.

Push against the tire several times to be sure it is

securely in place.

12. Stow jack and handle.

13. Check the tire pressure as soon as possible. Correct

pressure as required.

WHAT TO DO IN EMERGENCIES 297

6