light CHRYSLER TOWN AND COUNTRY 2014 5.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2014, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2014 5.GPages: 148, PDF Size: 4.26 MB

Page 88 of 148

Programming A Rolling Code

NOTE:

For programming Garage Door Openers that were manufactured after 1995. These Garage

Door Openers can be identified by the “LEARN” or “TRAIN” button located where the hanging

antenna is attached to the Garage Door Opener. It is NOT the button that is normally used to

open and close the door. The name and color of the button may vary by manufacturer.

1. Place the ignition switch into the ON/RUN position.

2. Place the hand-held transmitter 1 to 3 in (3 to 8 cm) away from the HomeLink® button you wishto program while keeping the HomeLink® indicator light in view.

3. Simultaneously press and hold both the HomeLink® button you want to program and the hand-held transmitter button.

4. Continue to hold both buttons and observe the indicator light. The HomeLink® indicator will flash slowly and then rapidly after HomeLink® has received the frequency signal from the

hand-held transmitter. Release both buttons after the indicator light changes from slow to

rapid.

5. At the garage door opener motor (in the garage), locate the “LEARN” or “TRAINING” button. This can usually be found where the hanging antenna wire is attached to the garage

door opener motor. Firmly press and release the “LEARN” or “TRAINING” button.

NOTE:

You have 30 seconds in which to initiate the next step after the LEARN button has been pressed.

6. Return to the vehicle and press the programmed HomeLink® button twice (holding the button for two seconds each time). If the device is plugged in and activates, programming is

complete.

NOTE:

If the device does not activate, press the button a third time (for two seconds) to complete the

training.

7. To program the remaining two HomeLink® buttons, repeat each step for each remaining button. DO NOT erase the channels.

ELECTRONICS

86

Page 89 of 148

Programming A Non-Rolling Code

NOTE:

For programming Garage Door Openers manufactured before 1995.

1. Turn the ignition switch to the ON/RUN position.

2. Place the hand-held transmitter 1 to 3 inches (3 to 8 cm) away from the HomeLink® button youwish to program while keeping the HomeLink® indicator light in view.

3. Simultaneously press and hold both the HomeLink® button you want to program and the hand-held transmitter button.

4. Continue to hold both buttons and observe the indicator light. The HomeLink® indicator will flash slowly and then rapidly after HomeLink® has received the frequency signal from the

hand-held transmitter. Release both buttons after the indicator light changes from slow to

rapid.

5. Press and hold the programmed HomeLink® button and observe the indicator light. If the indicator light stays on constantly, programming is complete and the garage door (or device)

should activate when the HomeLink® button is pressed.

6. To program the two remaining HomeLink® buttons, repeat each step for each remaining button. DO NOT erase the channels.

Using HomeLink®

• To operate, press and release the programmed HomeLink® button. Activation will now occurfor the programmed device (e.g., garage door opener, gate operator, security system, entry

door lock, home/office lighting, etc.,). The hand-held transmitter of the device may also be

used at any time.

WARNING!

• Your motorized door or gate will open and close while you are programming the universal

transceiver. Do not program the transceiver if people or pets are in the path of the door or

gate.

• Do not run your vehicle in a closed garage or confined area while programming the

transceiver. Exhaust gas from your vehicle contains Carbon Monoxide (CO) which is

odorless and colorless. Carbon Monoxide is poisonous when inhaled and can cause you

and others to be severely injured or killed.

ELECTRONICS

87

Page 90 of 148

POWER INVERTER

• There is a 115 Volt, 150 Watt power inverteroutlet located on the left rear trim panel

immediately behind the second row left

passenger seat. This outlet can power cellu-

lar phones, electronics and other low power

devices requiring power up to 150 Watts.

• Press the switch located in the center of the instrument panel to turn the power to the

outlet on.

• Press the switch again to turn the power off.

•

The status indicator of the AC power inverter

indicates whether the inverter is producing

AC power.

NOTE:

The power inverter is designed with built-in overload protection. If the power rating of 150 Watts

is exceeded, the power inverter will automatically shut down. Once the electrical device has been

removed from the outlet, the inverter should automatically reset. If the power rating exceeds

approximately 170 Watts, the power inverter may have to be reset manually. To reset the inverter

manually, unplug the device and plug it in again. To avoid overloading the circuit, check the power

ratings on electrical devices prior to using the inverter.

WARNING!

To Avoid Serious Injury or Death DO NOT:

• use a three-prong adaptor

• insert any objects into the receptacles

• touch with wet hands

Close the lid when not in use. If this outlet is mishandled, it may cause an electric shock and

failure.

POWER OUTLETS

• Two 12 Volt (13 Amp) power outlets are

located on the lower instrument panel,

below the open storage bin. The driver-side

power outlet is controlled by the ignition

switch and the passenger-side power outlet

is connected directly to the battery. The

driver-side power outlet will also operate a

conventional cigar lighter unit (if equipped

with an optional Smoker's Package).

ELECTRONICS

88

Page 94 of 148

ROADSIDE ASSISTANCE

Dial toll-free 1-800-521-2779 for U.S. Residents or 1-800-363-4869 for Canadian Residents.

• Provide your name, vehicle identification number, license plate number, and your location,including the telephone number from which you are calling.

• Briefly describe the nature of the problem and answer a few simple questions.

• You will be given the name of the service provider and an estimated time of arrival. If you feel you are in an “unsafe situation”, please let us know. With your consent, we will contact local

police or safety authorities.

INSTRUMENT CLUSTER WARNING LIGHTS

- Electronic Stability Control (ESC) Indicator Light

If this indicator light flashes during acceleration, apply as little throttle as possible. While driving,

ease up on the accelerator. Adapt your speed and driving to the prevailing road conditions.

To improve the vehicle's traction when starting off in deep snow, sand or gravel, it may be

desirable to switch the ESC system off.

- Tire Pressure Monitoring System (TPMS) Light

Each tire, including the spare (if provided), should be checked monthly when cold and inflated to

the inflation pressure recommended by the vehicle manufacturer on the vehicle placard or tire

inflation pressure label. (If your vehicle has tires of a different size than the size indicated on the

vehicle placard or tire inflation pressure label, you should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle has been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire pressure telltale when one or more of your tires is

significantly under-inflated. Accordingly, when the low tire pressure telltale illuminates, you

should stop and check your tires as soon as possible, and inflate them to the proper pressure.

Driving on a significantly under-inflated tire causes the tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle’s

handling and stopping ability.

IF THE LIGHT STARTS FLASHING INDICATING A LOW TIRE PRESSURE, ADJUST

THE AIR PRESSURE IN THE LOW TIRE TO THE AIR PRESSURE SHOWN ON THE

VEHICLE PLACARD OR TIRE INFLATION PRESSURE LABEL LOCATED ON THE

DRIVER'S DOOR.

NOTE:

AFTER INFLATION, THE VEHICLE MAY NEED TO BE DRIVEN FOR 20 MINUTES

BEFORE THE FLASHING LIGHT WILL TURN OFF.

Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure, even if under-inflation has not reached the level to

trigger illumination of the TPMS low tire pressure telltale.

WHAT TO DO IN EMERGENCIES

92

Page 95 of 148

Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the

system is not operating properly. The TPMS malfunction indicator is combined with the low tire

pressure telltale.

When the system detects a malfunction, the telltale will flash for approximately one minute and

then remain continuously illuminated. This sequence will continue upon subsequent vehicle

start-ups as long as the malfunction exists. When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may

occur for a variety of reasons, including the installation of replacement or alternate tires or wheels

on the vehicle that prevent the TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or wheels on your vehicle to ensure that the

replacement or alternate tires and wheels allow the TPMS to continue to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature change.

Keep this in mind when checking tire pressure inside a garage, especially in the Winter. Example:

If garage temperature is 68°F (20°C) and the outside temperature is 32°F (0°C), then the cold

tire inflation pressure should be increased by 3 psi (21 kPa), which equals 1 psi (7 kPa) for every

12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS pressures

and warning have been established for the tire size equipped on your vehicle. Undesirable

system operation or sensor damage may result when using replacement equipment that is not

of the same size, type, and/or style. Aftermarket wheels can cause sensor damage. Do not use

tire sealant from a can, or balance beads if your vehicle is equipped with a TPMS, as damage

to the sensors may result.

- Engine Temperature Warning Light

• This light warns of an overheated engine condition.

• If the light turns on or flashes continuously while driving, safely pull over and stop the vehicle.If the A/C system is on, turn it off. Also, shift the transmission into NEUTRAL and idle the

vehicle. If the temperature reading does not return to normal, turn the engine off immediately

and call for service.

• We recommend that you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by steam or

boiling coolant.

WHAT TO DO IN EMERGENCIES

93

Page 96 of 148

BRAKE- Brake Warning Light

The Brake Warning light illuminates when there is either a system malfunction or the parking

brake is applied. If the light is on and the parking brake is not applied, it indicates a possible brake

hydraulic malfunction, brake booster problem or an Anti-Lock Brake System problem.

Please have your vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may have

failed. It will take longer to stop the vehicle. You could have a collision. Have the vehicle

checked immediately.

- Malfunction Indicator Light (MIL)

Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may illuminate the

MIL after engine start. The vehicle should be serviced if the light stays on through several typical

driving cycles. In most situations, the vehicle will drive normally and not require towing.

If the MIL flashes when the engine is running, serious conditions may exist that could lead to

immediate loss of power or severe catalytic converter damage. We recommend you do not

operate the vehicle. Have the vehicle serviced immediately.

- Electronic Stability Control (ESC) OFF Indicator

• If the ESC OFF indicator light comes on when the Electronic Stability Control (ESC) is off.

- Charging System Light

This light shows the status of the electrical charging system. If the charging system light remains

on, it means that the vehicle is experiencing a problem with the charging system.

We recommend you do not continue driving if the charging system light is on. Have the vehicle

serviced immediately.

- Oil Pressure Warning Light

This light indicates low engine oil pressure. If the light turns on while driving, stop the vehicle and

shut off the engine as soon as possible. A chime will sound when this light turns on.

We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle

serviced immediately.

- Anti-Lock Brake (ABS) Light

This light monitors the Anti-Lock Brake System (ABS).

If the light is not on during starting, stays on, or turns on while driving, we recommend you contact

the nearest authorized dealer and have the vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

94

Page 97 of 148

- Electronic Throttle Control (ETC) Indicator Light

This light informs you of a problem with the system.

If a problem is detected, the light will come on while the engine is running. Cycle the ignition

when the vehicle has completely stopped and the shift lever is placed in the PARK position; the

light should turn off.

If the light remains lit with the engine running, your vehicle will usually be drivable; however, see

an authorized dealer immediately. If the light is flashing when the engine is running, immediate

service is required and you may experience reduced performance, an elevated/rough idle or

engine stall and your vehicle may require towing.

- Air Bag Warning Light

If the light is not on during starting, stays on, or turns on while driving, have the vehicle serviced

by an authorized dealer immediately.

Fuel Cap/Loose Gas Cap Message

If a “gas cap” message (shown as gASCAP) appears, tighten the gas cap until a “clicking” sound

is heard.

If the message continues to appear for more than three days after tightening the gas cap, see your

authorized service center.

“CHANGE OIL” MESSAGE

• If a “Change Oil” message appears and a single chime sounds, it is time for your next requiredoil change.

Resetting The Light After Servicing

Vehicles Equipped With Keyless Enter-N-Go™

• Without pressing the brake pedal, push the ENGINE START/STOP button and cycle theignition to the ON/RUN position (do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Without pressing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

Vehicles Not Equipped With Keyless Enter-N-Go™

• Turn the ignition switch to the ON/RUN position (do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did

not reset. If necessary, repeat this procedure.

WHAT TO DO IN EMERGENCIES

95

Page 109 of 148

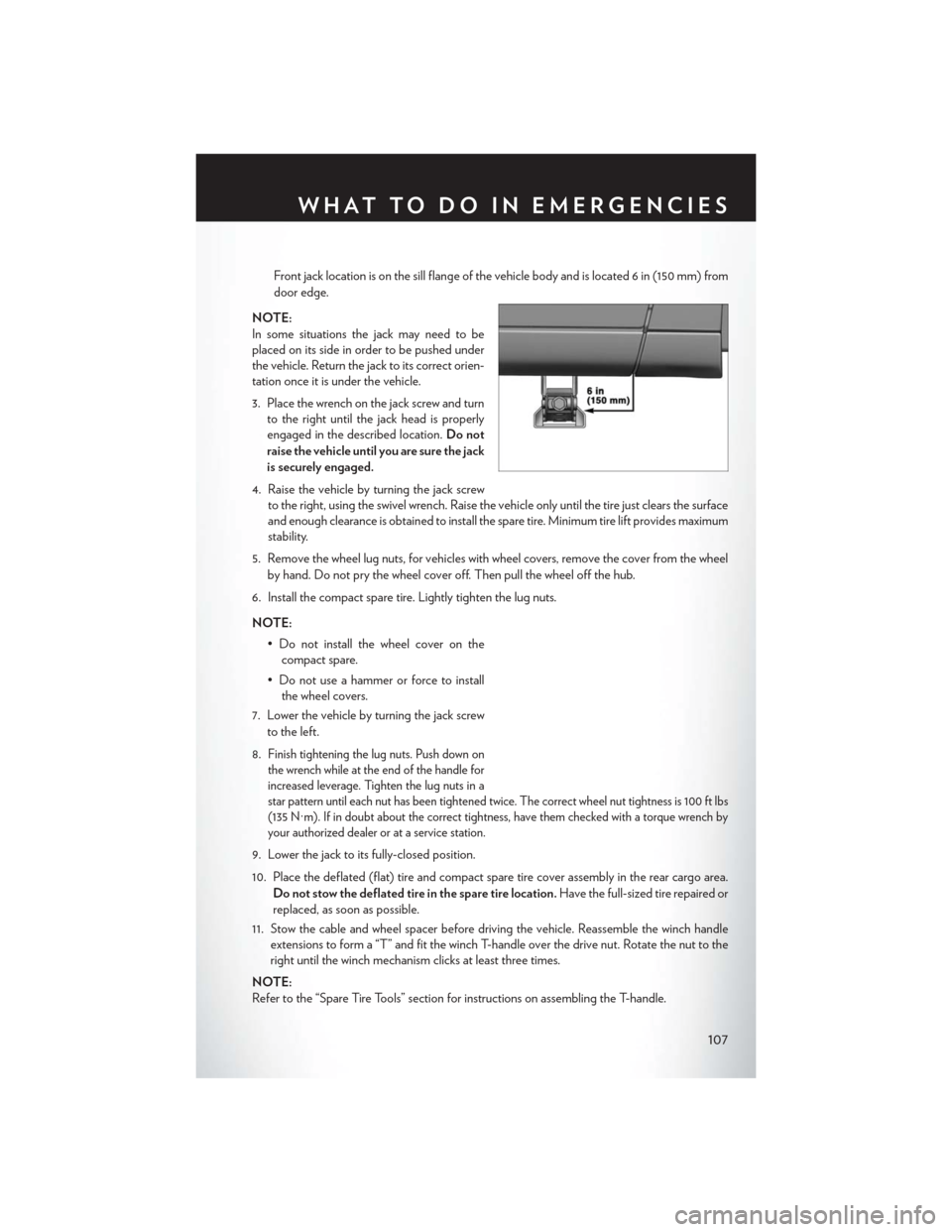

Front jack location is on the sill flange of the vehicle body and is located 6 in (150 mm) from

door edge.

NOTE:

In some situations the jack may need to be

placed on its side in order to be pushed under

the vehicle. Return the jack to its correct orien-

tation once it is under the vehicle.

3. Place the wrench on the jack screw and turn to the right until the jack head is properly

engaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jack screw to the right, using the swivel wrench. Raise the vehicle only until the tire just clears the surface

and enough clearance is obtained to install the spare tire. Minimum tire lift provides maximum

stability.

5. Remove the wheel lug nuts, for vehicles with wheel covers, remove the cover from the wheel by hand. Do not pry the wheel cover off. Then pull the wheel off the hub.

6. Install the compact spare tire. Lightly tighten the lug nuts.

NOTE: • Do not install the wheel cover on thecompact spare.

• Do not use a hammer or force to install the wheel covers.

7. Lower the vehicle by turning the jack screw to the left.

8.

Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tightened twice. The correct wheel nut tightness is 100 ft lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a torque wrench by

your authorized dealer or at a service station.

9. Lower the jack to its fully-closed position.

10. Place the deflated (flat) tire and compact spare tire cover assembly in the rear cargo area.

Do not stow the deflated tire in the spare tire location. Have the full-sized tire repaired or

replaced, as soon as possible.

11. Stow the cable and wheel spacer before driving the vehicle. Reassemble the winch handle extensions to form a “T” and fit the winch T-handle over the drive nut. Rotate the nut to the

right until the winch mechanism clicks at least three times.

NOTE:

Refer to the “Spare Tire Tools” section for instructions on assembling the T-handle.

WHAT TO DO IN EMERGENCIES

107

Page 110 of 148

12. Stow the jack, jack handle and winch handle tools back in the stowage compartment.

13. Check the compact spare tire pressure as soon as possible. Correct the tire pressure, asrequired.

Securing The Spare Tire

1. Assemble the winch handle extensions to form a T-handle and fit the winch T-handle over thedrive nut. Rotate the nut to the left until the winch mechanism stops turning freely. This will

allow enough slack in the cable to allow you to pull the wheel spacer out from under the vehicle.

2. Assemble the winch handle extensions to form the spare tire hook, and pull the wheel spacer from under the vehicle.

3. Turn the compact spare tire so that the valve stem is down, and place the tire into the spare tire/cover assembly. Slide the wheel spacer through the center of the wheel and spare

tire/cover assembly, so that the two retainer tabs snap out and engage the spare tire cover on

the opposite side.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is drawn into place against the underside of the vehicle.

5. Continue to rotate the nut to the right until you hear the winch mechanism click three times. It cannot be overtightened. Check under the vehicle to ensure the compact spare tire/cover

assembly is positioned correctly against the underside of the vehicle.

Road Tire Installation

Vehicles Equipped With Wheel Covers

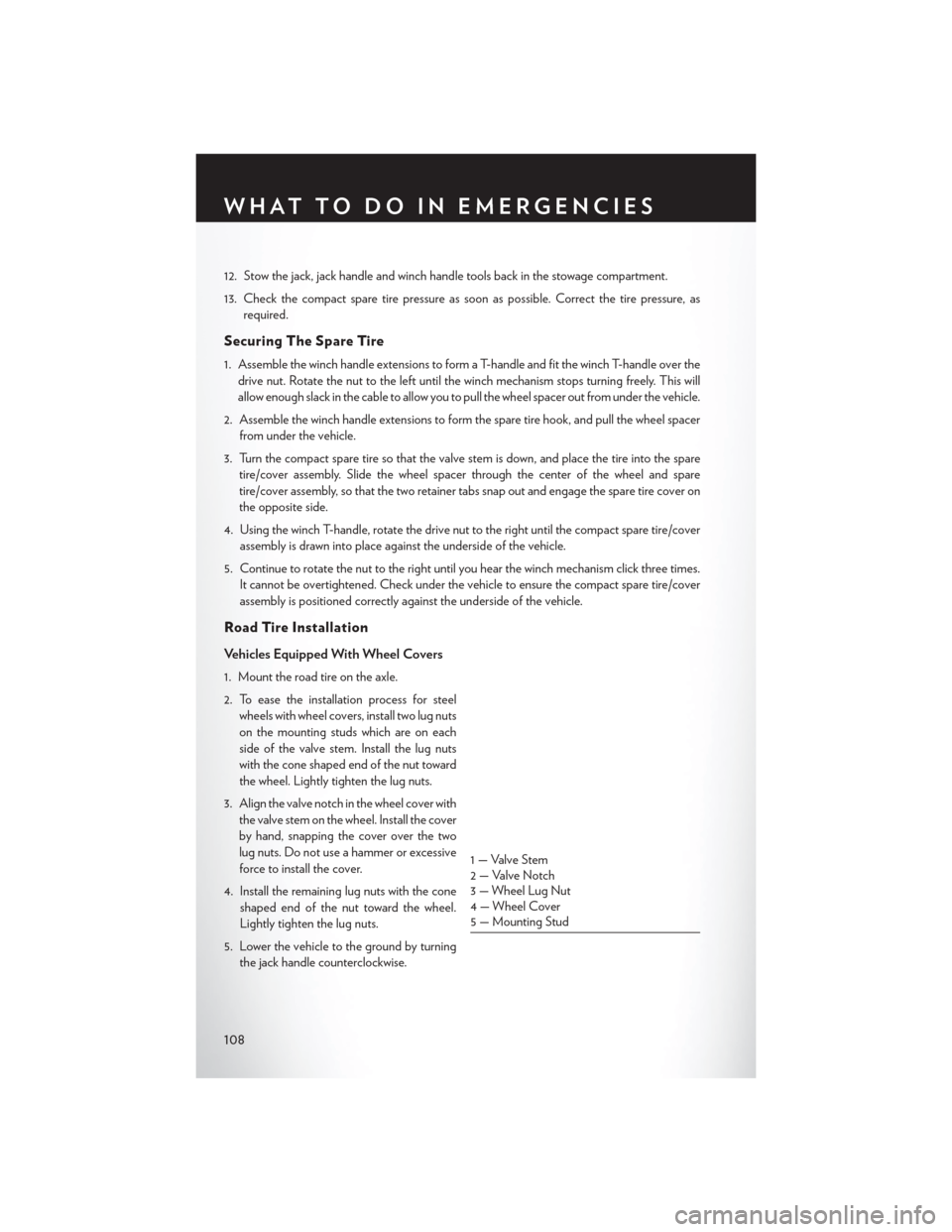

1. Mount the road tire on the axle.

2. To ease the installation process for steelwheels with wheel covers, install two lug nuts

on the mounting studs which are on each

side of the valve stem. Install the lug nuts

with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover

by hand, snapping the cover over the two

lug nuts. Do not use a hammer or excessive

force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

108

Page 111 of 148

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle forincreased leverage. Tighten the lug nuts in a star pattern until each nut has been tightened

twice. The correct tightness of each lug nut is 100 ft/lbs (135 N·m). If in doubt about the

correct tightness, have them checked with a torque wrench by your authorized dealer or

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut has been tightened

twice. The correct tightness of each lug nut is 100 ft/lbs (135 N·m). If in doubt about the

correct tightness, have them checked with a torque wrench by your authorized dealer or

service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

CAUTION!

• The winch mechanism is designed for use with the winch T-handle only. Use of air wrench or other power tools is not recommended and can damage the winch.

• Do not attempt to raise the vehicle by jacking on locations other than those indicated in

the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

• The compact spare tire/cover assembly must be used when the compact spare tire is

stored. Failure to use this cover could drastically reduce the life of the compact spare tire.

• The winch mechanism is designed specifically to stow a compact spare tire only. Do not attempt to use the winch to stow the full size flat tire, or any other full-size tire. Vehicle

damage may result.

WHAT TO DO IN EMERGENCIES

109