injec CHRYSLER TOWN AND COUNTRY 2015 5.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2015, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2015 5.GPages: 726, PDF Size: 20.14 MB

Page 560 of 726

For best results, a refueling pattern that avoids alternat-

ing between E-85 and unleaded gasoline is recom-

mended.

When you do switch fuel types it is recommended that:

•You do not add less than 5 gallons (19 Liters) when

refueling.

•You drive the vehicle immediately after refueling for at

least 5 miles (8 km).

Observing these precautions will avoid possible hard

starting and/or significant deterioration in driveability

during warm up.

NOTE:

•Use seasonally adjusted E-85 fuel (ASTM D5798). With

non-seasonally adjusted E-85 fuel, you may experience

hard starting and rough idle following start up even if

the above recommendations are followed, especially

when the ambient temperature is below 32°F (0°C).

•Some additives used in regular gasoline are not fully

compatible with E-85 and may form deposits in your

engine. To eliminate driveability issues that may be

caused by these deposits, a supplemental gasoline

additive, such as MOPAR® Injector Cleanup or

Techron may be used.

Selection Of Engine Oil For Flexible Fuel Vehicles

(E-85) And Gasoline Vehicles

FFV vehicles operated on E-85 require specially formu-

lated engine oils. These special requirements are included

in MOPAR® engine oils, and in equivalent oils meeting

Chrysler Specification MS-6395. The manufacturer only

recommends engine oils that are API Certified and meet

the requirements of Material Standard MS-6395. MS-6395

contains additional requirements, developed during ex-

tensive fleet testing, to provide additional protection to

Chrysler Group LLC engines. Use MOPAR® or an

equivalent oil meeting the specification MS-6395.

558 STARTING AND OPERATING

Page 586 of 726

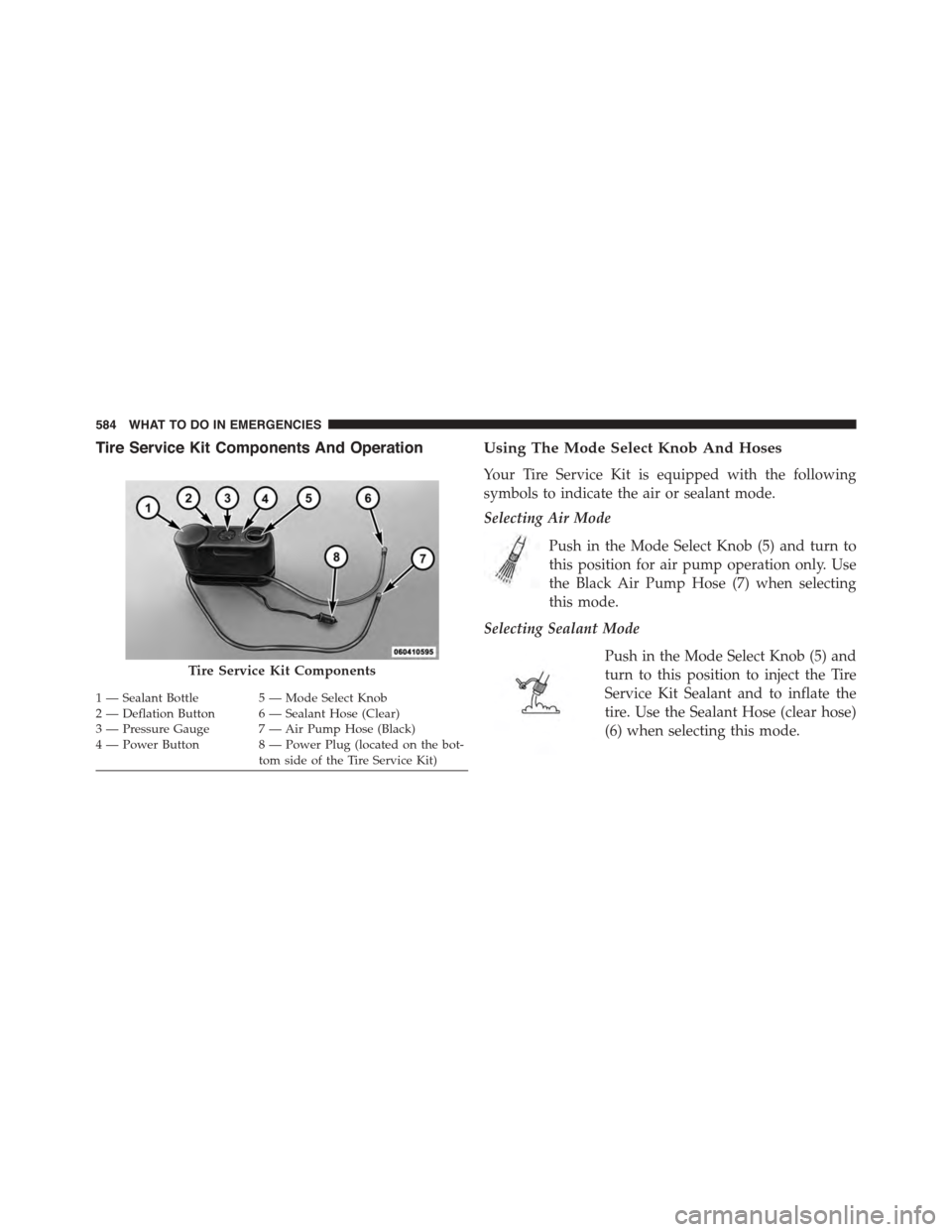

Tire Service Kit Components And OperationUsing The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode

Push in the Mode Select Knob (5) and turn to

this position for air pump operation only. Use

the Black Air Pump Hose (7) when selecting

this mode.

Selecting Sealant Mode

Push in the Mode Select Knob (5) and

turn to this position to inject the Tire

Service Kit Sealant and to inflate the

tire. Use the Sealant Hose (clear hose)

(6) when selecting this mode.

Tire Service Kit Components

1—SealantBottle 5—ModeSelectKnob2 — Deflation Button 6 — Sealant Hose (Clear)3—PressureGauge 7—AirPumpHose(Black)4—PowerButton 8—PowerPlug(locatedonthebot-tom side of the Tire Service Kit)

584 WHAT TO DO IN EMERGENCIES

Page 588 of 726

from the vehicle or tire and wheel components. Once

the sealant dries, it can easily be peeled off and

properly discarded.

•For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the Tire

Service Kit.

•You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts,

or similar inflatable items. However, use only the Air

Pump Hose (7) and make sure the Mode Select Knob

(5) is in the Air Mode when inflating such items to

avoid injecting sealant into them. The Tire Service Kit

Sealant is only intended to seal punctures less than¼”

(6 mm) diameter in the tread of your vehicle.

•Do not lift or carry the Tire Service Kit by the hoses.

WARNING!

•Do not attempt to seal a tire on the side of the

vehicle closest to traffic. Pull far enough off the

road to avoid the danger of being hit when using

the Tire Service Kit.

•Do not use Tire Service Kit or drive the vehicle

under the following circumstances:

– If the puncture in the tire tread is approximately

1/4” (6 mm) or larger.

– If the tire has any sidewall damage.

– If the tire has any damage from driving with

extremely low tire pressure.

– If the tire has any damage from driving on a flat

tire.

– If the wheel has any damage.

– If you are unsure of the condition of the tire or

the wheel.

(Continued)

586 WHAT TO DO IN EMERGENCIES

Page 590 of 726

on the ground. This will provide the best positioning

of the kit when injecting the sealant into the deflated

tire and running the air pump. Move the vehicle as

necessary to place the valve stem in this position

before proceeding.

3. Place the transmission in PARK (auto transmission) or

in Gear (manual transmission) and turn Off the igni-

tion.

4. Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (5) and turn to the

Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap

from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the

deflated tire.

4. Remove the cap from the valve stem and then screw

the fitting at the end of the Sealant Hose (6) onto the

valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the

vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

•Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the

parking brake engaged and the shift lever in NEUTRAL.

•After pressing the Power Button (4), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (6) and into the tire.

588 WHAT TO DO IN EMERGENCIES

Page 591 of 726

NOTE:Sealant may leak out through the puncture in the

tire.

If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (6):

1. Press the Power Button (4) to turn Off the Tire Service

Kit. Disconnect the Sealant Hose (6) from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose (6) to the valve stem.

Check that the Mode Select Knob (5) is in the Sealant

Mode position and not Air Mode. Press the Power

Button (4) to turn On the Tire Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt

power outlet in your vehicle or another vehicle, if

available. Make sure the engine is running before

turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous

use. Call for assistance.

NOTE:If the Mode Select Knob (5) is on Air Mode and

the pump is operating, air will dispense from the Air

Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the

Sealant Hose (6):

1. Continue to operate the pump until sealant is no

longer flowing through hose (typically takes 30 - 70

seconds). As the sealant flows through the Sealant

Hose (6), the Pressure Gauge (3) can read as high as

70 psi (4.8 Bar). The Pressure Gauge (3) will decrease

quickly from approximately 70 psi (4.8 Bar) to the

actual tire pressure when the Sealant Bottle (1) is

empty.

2. The pump will start to inject air into the tire immedi-

ately after the Sealant Bottle (1) is empty. Continue to

operate the pump and inflate the tire to the pressure

indicated on the tire pressure label on the driver-side

6

WHAT TO DO IN EMERGENCIES 589

Page 593 of 726

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 55 mph (90 km/h).

WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using Tire Service Kit. Do not exceed 55 mph

(90 km/h) until the tire is repaired or replaced. Failure

to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you.

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop

to Use Tire Service Kit” before continuing.

1. Push in the Mode Select Knob (5) and turn to the Air

Mode position.

2. Uncoil the power plug and insert the plug into the

vehicle’s 12 Volt power outlet.

3. Uncoil the Air Pump Hose (7) (black in color) and

screw the fitting at the end of hose (7) onto the valve

stem.

4. Check the pressure in the tire by reading the Pressure

Gauge (3).

6

WHAT TO DO IN EMERGENCIES 591

Page 619 of 726

4. Connect the opposite end of the negative(-)jumper

cable to a good engine ground (exposed metal part of

the discharged vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the negative (-)

post of the discharged battery. The resulting electri-

cal spark could cause the battery to explode and

could result in personal injury. Only use the specific

ground point, do not use any other exposed metal

parts.

5. Start the engine in the vehicle that has the booster

battery, let the engine idle a few minutes, and then

start the engine in the vehicle with the discharged

battery.

6. Once the engine is started, remove the jumper cables

in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative(-)end of the jumper cable

from the engine ground of the vehicle with the dis-

charged battery.

2. Disconnect the opposite end of the negative(-)jumper

cable from the negative(-)post of the booster battery.

3. Disconnect the positive(+)end of the jumper cable

from the positive(+)post of the booster battery.

4. Disconnect the opposite end of the positive(+)jumper

cable from the positive(+)post of the vehicle with the

discharged battery.

If frequent jump-starting is required to start your vehicle

you should have the battery and charging system in-

spected at your authorized dealer.

6

WHAT TO DO IN EMERGENCIES 617