servo CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 102 of 1938

SERVICE PROCEDURES

MASTER CYLINDER FLUID LEVEL CHECK

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

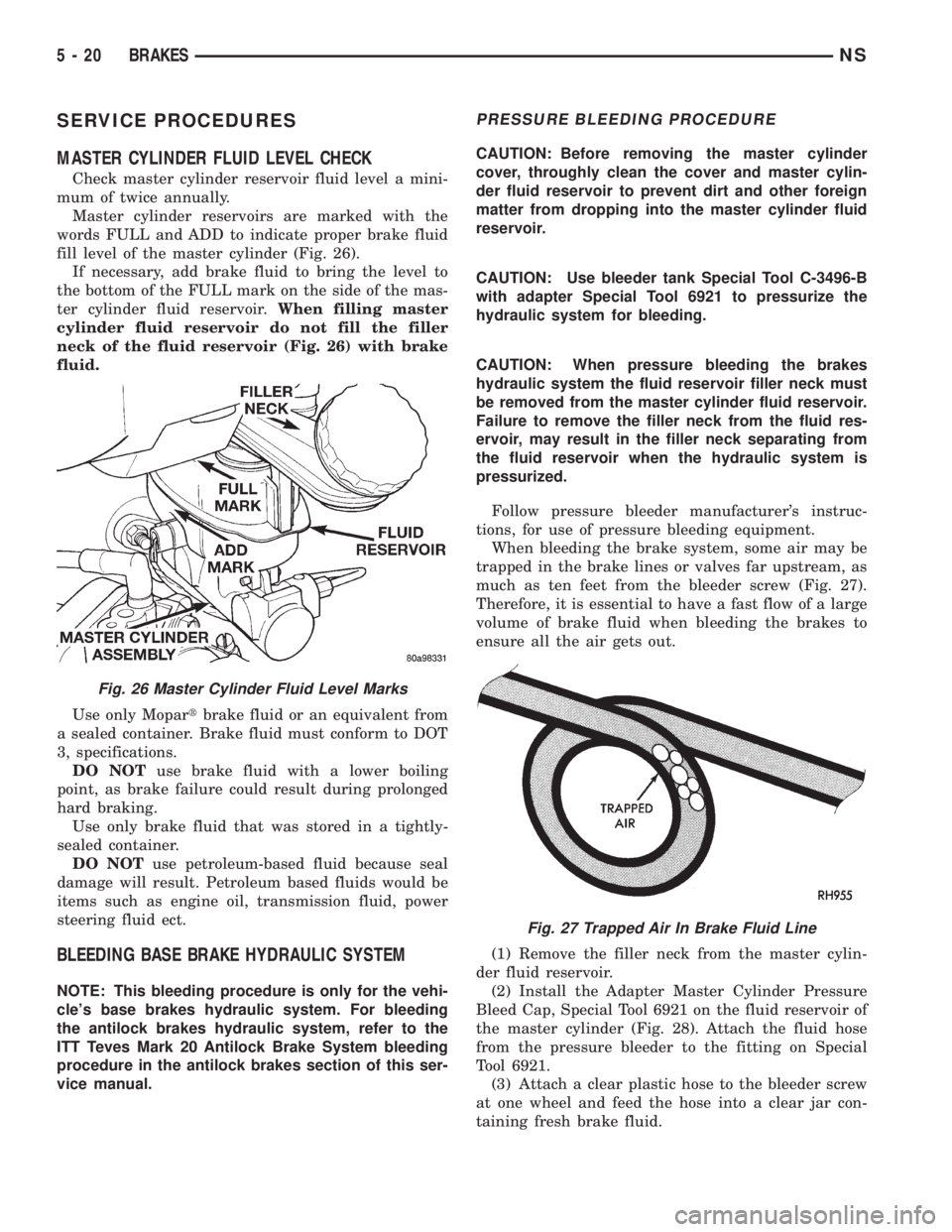

Master cylinder reservoirs are marked with the

words FULL and ADD to indicate proper brake fluid

fill level of the master cylinder (Fig. 26).

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.When filling master

cylinder fluid reservoir do not fill the filler

neck of the fluid reservoir (Fig. 26) with brake

fluid.

Use only Mopartbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications.

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid ect.

BLEEDING BASE BRAKE HYDRAULIC SYSTEM

NOTE: This bleeding procedure is only for the vehi-

cle's base brakes hydraulic system. For bleeding

the antilock brakes hydraulic system, refer to the

ITT Teves Mark 20 Antilock Brake System bleeding

procedure in the antilock brakes section of this ser-

vice manual.

PRESSURE BLEEDING PROCEDURE

CAUTION: Before removing the master cylinder

cover, throughly clean the cover and master cylin-

der fluid reservoir to prevent dirt and other foreign

matter from dropping into the master cylinder fluid

reservoir.

CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool 6921 to pressurize the

hydraulic system for bleeding.

CAUTION: When pressure bleeding the brakes

hydraulic system the fluid reservoir filler neck must

be removed from the master cylinder fluid reservoir.

Failure to remove the filler neck from the fluid res-

ervoir, may result in the filler neck separating from

the fluid reservoir when the hydraulic system is

pressurized.

Follow pressure bleeder manufacturer's instruc-

tions, for use of pressure bleeding equipment.

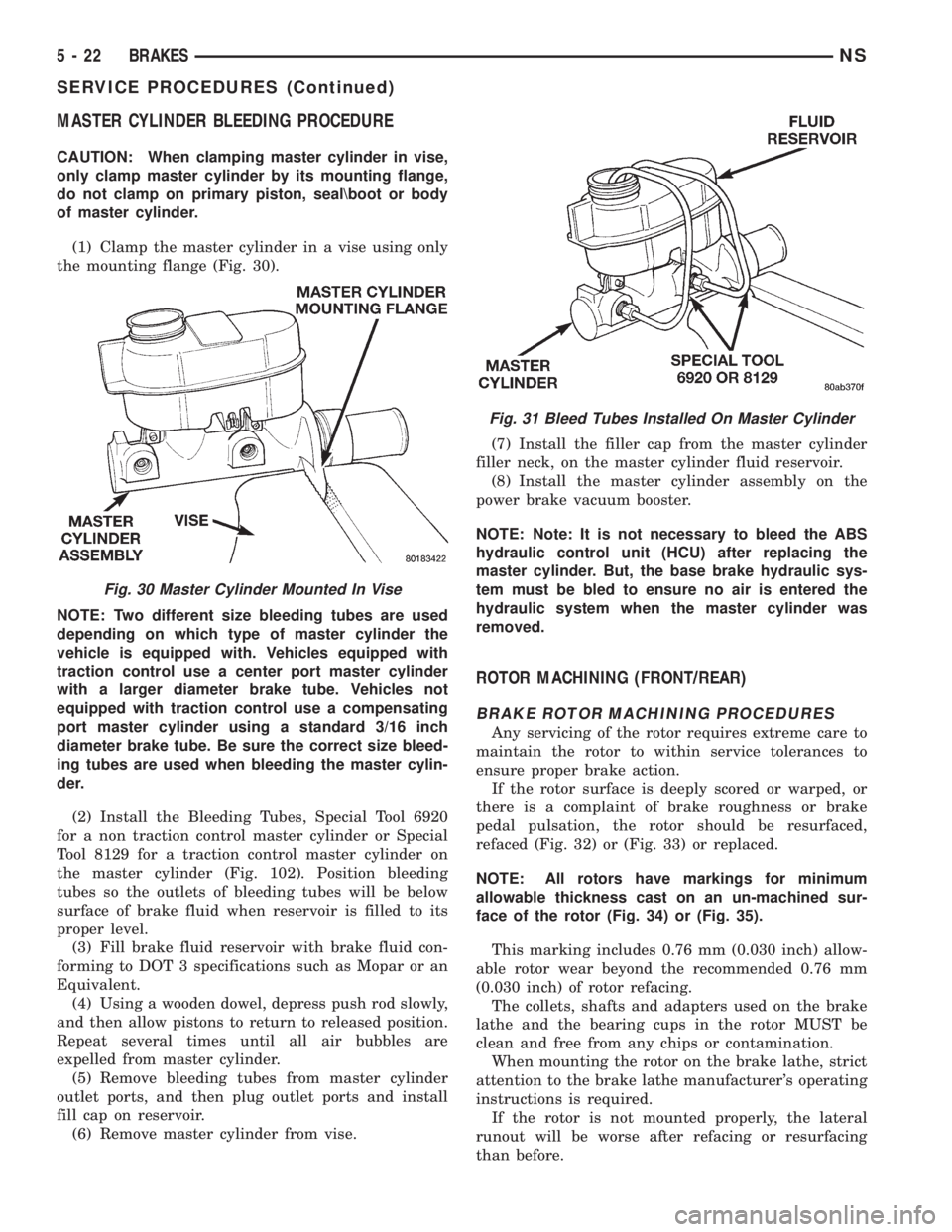

When bleeding the brake system, some air may be

trapped in the brake lines or valves far upstream, as

much as ten feet from the bleeder screw (Fig. 27).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

(1) Remove the filler neck from the master cylin-

der fluid reservoir.

(2) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 28). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(3) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

Fig. 26 Master Cylinder Fluid Level Marks

Fig. 27 Trapped Air In Brake Fluid Line

5 - 20 BRAKESNS

Page 104 of 1938

MASTER CYLINDER BLEEDING PROCEDURE

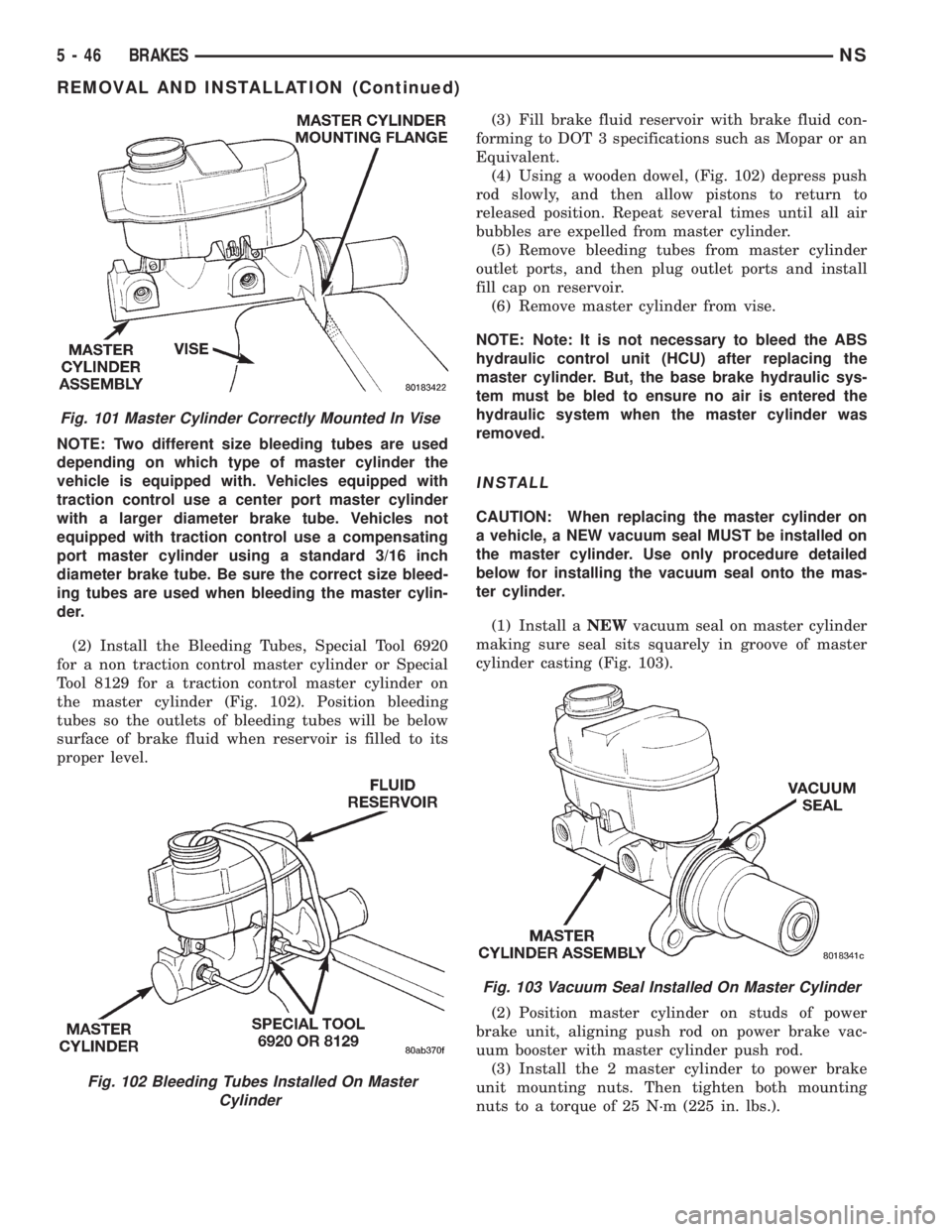

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange,

do not clamp on primary piston, seal\boot or body

of master cylinder.

(1) Clamp the master cylinder in a vise using only

the mounting flange (Fig. 30).

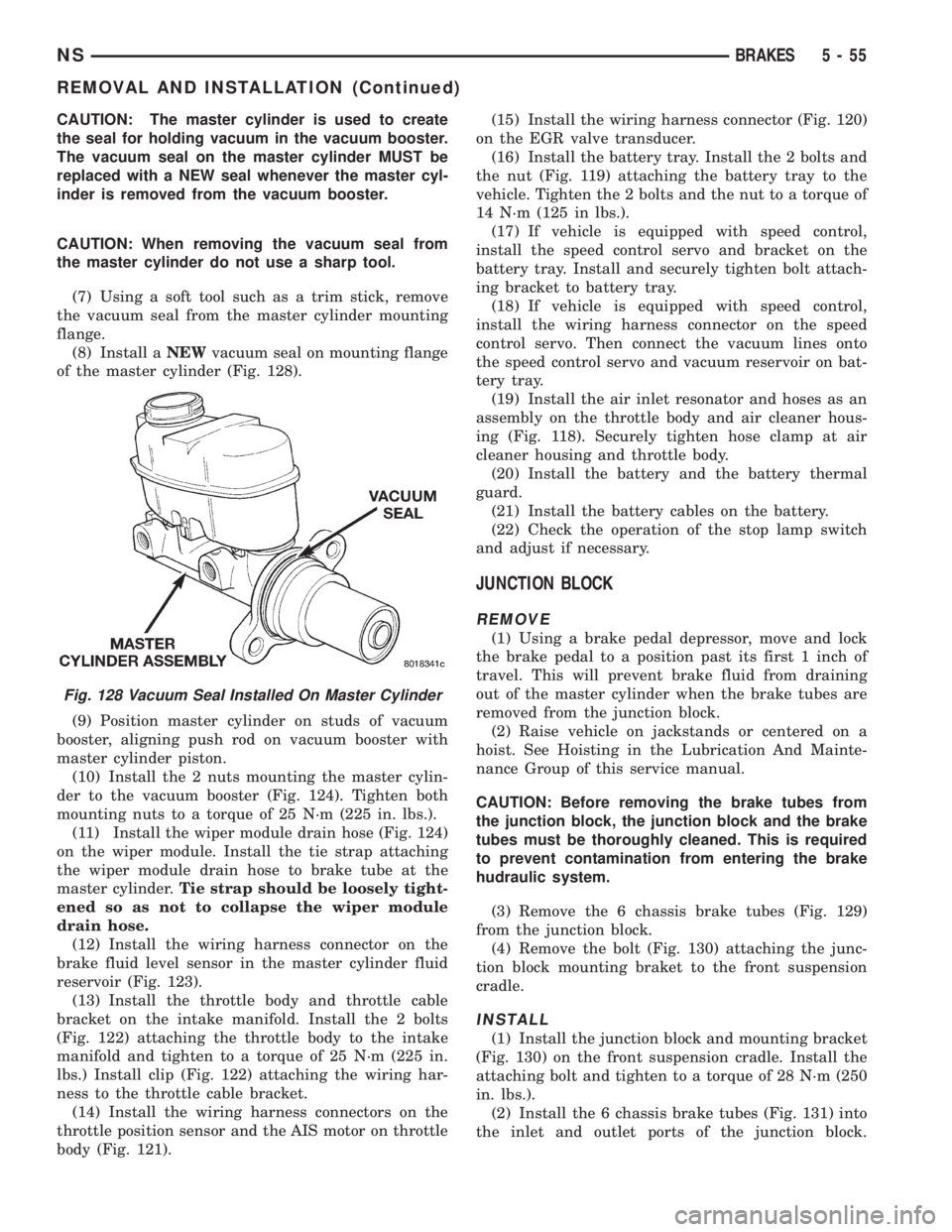

NOTE: Two different size bleeding tubes are used

depending on which type of master cylinder the

vehicle is equipped with. Vehicles equipped with

traction control use a center port master cylinder

with a larger diameter brake tube. Vehicles not

equipped with traction control use a compensating

port master cylinder using a standard 3/16 inch

diameter brake tube. Be sure the correct size bleed-

ing tubes are used when bleeding the master cylin-

der.

(2) Install the Bleeding Tubes, Special Tool 6920

for a non traction control master cylinder or Special

Tool 8129 for a traction control master cylinder on

the master cylinder (Fig. 102). Position bleeding

tubes so the outlets of bleeding tubes will be below

surface of brake fluid when reservoir is filled to its

proper level.

(3) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(4) Using a wooden dowel, depress push rod slowly,

and then allow pistons to return to released position.

Repeat several times until all air bubbles are

expelled from master cylinder.

(5) Remove bleeding tubes from master cylinder

outlet ports, and then plug outlet ports and install

fill cap on reservoir.

(6) Remove master cylinder from vise.(7) Install the filler cap from the master cylinder

filler neck, on the master cylinder fluid reservoir.

(8) Install the master cylinder assembly on the

power brake vacuum booster.

NOTE: Note: It is not necessary to bleed the ABS

hydraulic control unit (HCU) after replacing the

master cylinder. But, the base brake hydraulic sys-

tem must be bled to ensure no air is entered the

hydraulic system when the master cylinder was

removed.

ROTOR MACHINING (FRONT/REAR)

BRAKE ROTOR MACHINING PROCEDURES

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.

If the rotor surface is deeply scored or warped, or

there is a complaint of brake roughness or brake

pedal pulsation, the rotor should be resurfaced,

refaced (Fig. 32) or (Fig. 33) or replaced.

NOTE: All rotors have markings for minimum

allowable thickness cast on an un-machined sur-

face of the rotor (Fig. 34) or (Fig. 35).

This marking includes 0.76 mm (0.030 inch) allow-

able rotor wear beyond the recommended 0.76 mm

(0.030 inch) of rotor refacing.

The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination.

When mounting the rotor on the brake lathe, strict

attention to the brake lathe manufacturer's operating

instructions is required.

If the rotor is not mounted properly, the lateral

runout will be worse after refacing or resurfacing

than before.

Fig. 30 Master Cylinder Mounted In Vise

Fig. 31 Bleed Tubes Installed On Master Cylinder

5 - 22 BRAKESNS

SERVICE PROCEDURES (Continued)

Page 126 of 1938

caliper adapter and hub/bearing are squarely seated

against the axle. Then tighten the hub/bearing

mounting bolts to a torque of 129 N´m (95 ft. lbs.).

(3) Install driveshaft in hub/bearing and on output

shaft of rear drive line module. Driveshaft is

installed by first sliding the outer joint of the drive-

shaft into the hub/bearing and then compressing the

inner joint on the driveshaft and installing it on the

output shaft the drive line module.

(4) Install rotor on hub/bearing.

(5) Carefully lower disc brake caliper and brake

shoes over rotor and onto caliper adapter by revers-

ing the removal procedure (Fig. 92).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(6) Install the disc brake caliper guide pin bolts

(Fig. 91). Tighten the guide pin bolts to a torque of

22 N´m (192 in. lbs.).

(7) Clean all foreign material off the threads of the

outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 88) on the stub shaft of the outer C/V

joint.

(8) Lower vehicle.

(9) Set the park brake.This is required to keep

the driveshaft from rotating when tightening

and torquing the hub nut and driveshaft inner

joint to driveline module mounting nuts.

(10) Raise vehicle.

(11) Tighten the driveshaft inner joint to drive line

module output shaft mounting bolts (Fig. 89) to a

torque of 61 N´m (45 ft. lbs.).

(12) Tighten the outer C/V joint hub nut (Fig. 88)

to a torque of 244 N´m (180 ft. lbs.).

(13) Install the spring washer (Fig. 87) on the stub

shaft of the outer C/V joint.

(14) Install the nut retainer and cotter pin (Fig.

86) on the stub shaft of the outer C/V joint.

(15) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 90). Tighten the wheel speed sen-

sor attaching bolt to a torque of 12 N´m (105 in. lbs).

(16) Install wheel and tire.

(17) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(18) Remove jackstands or lower hoist.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

(19) Road test vehicle to ensure proper operation

of the brake system.MASTER CYLINDER

CAUTION: Different types of master cylinders are

used on this vehicle. Vehicles equipped with trac-

tion control use a center port master cylinder. Vehi-

cles not equipped with traction control use a

compensating port master cylinder. Be sure to ver-

ify if the vehicle is equipped with traction control

and that the correct replacement master cylinder is

used. Also, vehicles that are equipped with four

wheel disc brakes have a master with a different

size piston bore than the other master cylinders. If

a new master cylinder is being installed, be sure

the correct master cylinder is used for the type of

brake system the vehicle is equipped with.

REMOVE

CAUTION: Vacuum in the power brake booster

must be pumped down (removed) before removing

master cylinder from power brake booster. This is

necessary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

CAUTION: Before removing the master cylinder

filler tube from the brake fluid reservoir, the filler

tube, brake fluid reservoir and master cylinder must

be thoroughly cleaned. This must be done to pre-

vent dirt particles from falling into the brake fluid

reservoir and entering the brakes hydraulic system.

(2) Thoroughly clean all surfaces of the filler neck,

brake fluid reservoir, and master cylinder. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent.

(3) Remove master cylinder filler tube from brake

fluid reservoir by pushing down and rotating (Fig.

97). Then remove the cap from the removed filler

tube and install it on the master cylinder reservoir.

(4) Remove vehicle wiring harness connector, from

the brake fluid level sensor, in master cylinder brake

fluid reservoir (Fig. 98).

(5) Disconnect the primary and secondary brake

tubes from the master cylinder housing (Fig. 99).

Install sealing plugs in the open brake tube outlets

on master cylinder assembly.

5 - 44 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 128 of 1938

NOTE: Two different size bleeding tubes are used

depending on which type of master cylinder the

vehicle is equipped with. Vehicles equipped with

traction control use a center port master cylinder

with a larger diameter brake tube. Vehicles not

equipped with traction control use a compensating

port master cylinder using a standard 3/16 inch

diameter brake tube. Be sure the correct size bleed-

ing tubes are used when bleeding the master cylin-

der.

(2) Install the Bleeding Tubes, Special Tool 6920

for a non traction control master cylinder or Special

Tool 8129 for a traction control master cylinder on

the master cylinder (Fig. 102). Position bleeding

tubes so the outlets of bleeding tubes will be below

surface of brake fluid when reservoir is filled to its

proper level.(3) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(4) Using a wooden dowel, (Fig. 102) depress push

rod slowly, and then allow pistons to return to

released position. Repeat several times until all air

bubbles are expelled from master cylinder.

(5) Remove bleeding tubes from master cylinder

outlet ports, and then plug outlet ports and install

fill cap on reservoir.

(6) Remove master cylinder from vise.

NOTE: Note: It is not necessary to bleed the ABS

hydraulic control unit (HCU) after replacing the

master cylinder. But, the base brake hydraulic sys-

tem must be bled to ensure no air is entered the

hydraulic system when the master cylinder was

removed.

INSTALL

CAUTION: When replacing the master cylinder on

a vehicle, a NEW vacuum seal MUST be installed on

the master cylinder. Use only procedure detailed

below for installing the vacuum seal onto the mas-

ter cylinder.

(1) Install aNEWvacuum seal on master cylinder

making sure seal sits squarely in groove of master

cylinder casting (Fig. 103).

(2) Position master cylinder on studs of power

brake unit, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(3) Install the 2 master cylinder to power brake

unit mounting nuts. Then tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

Fig. 101 Master Cylinder Correctly Mounted In Vise

Fig. 102 Bleeding Tubes Installed On Master

Cylinder

Fig. 103 Vacuum Seal Installed On Master Cylinder

5 - 46 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 129 of 1938

CAUTION: When installing the primary and second-

ary brake tubes on master cylinder, be sure brake

tubes do not contact any other components within

the vehicle and that there is slack in the flexible

sections of the tubes. This is required due to the

movement between the ABS hydraulic control mod-

ule (HCU) and the master cylinder, when the vehicle

is in motion.

(4) Connect the primary and secondary brake

tubes to master cylinder primary and secondary

ports (Fig. 99). Brake tubes must be held securely

when tightened to control orientation of flex section.

Then fully tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

(5) Install the vehicle wiring harness connector, on

the brake fluid level sensor in the master cylinder

brake fluid reservoir (Fig. 98).

(6) Install filler tube into the master cylinder fluid

reservoir (Fig. 97).

VACUUM BOOSTER 2.4 LITER ENGINE

REMOVE

CAUTION: Reserve vacuum in the vacuum booster

must be pumped down (removed) before removing

master cylinder from vacuum booster. This is nec-

essary to prevent the vacuum booster from sucking

in any contamination as the master cylinder is

removed. This can be done simply by pumping the

brake pedal, with the vehicle's engine not running,

until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4-5 strokes).

(2) Remove both battery cables from battery.

(3) Remove the battery thermal guard and the bat-

tery from the battery tray.

(4) Remove the air inlet resonator and hoses as an

assembly from the throttle body and air cleaner

housing (Fig. 104)

(5) If vehicle is equipped with speed control,

unplug wiring harness connector from the speed con-

trol servo. Then disconnect vacuum lines from the

speed control servo and vacuum reservoir on battery

tray.

(6) Remove bolt attaching the speed control servo

bracket to the battery tray. Slide the bracket forward

to unhook it from the battery tray and remove.

(7) Remove the 2 bolts and the nut (Fig. 105)

attaching the battery tray to the body.

(8) Remove wiring harness connector from brake

fluid level sensor in master cylinder fluid reservoir

(Fig. 106).

(9) Clean the area where the master cylinder

assembly attaches to the power brake booster. Useonly a solvent such as Mopar Brake Parts Cleaner or

an equivalent.

(10) Remove clip attaching drain hose for wiper

module to brake tube at master cylinder. Remove

Fig. 104 Air Inlet Resonator

Fig. 105 Battery Tray Mounting Locations

Fig. 106 Fluid Level Sensor Electrical Connection

NSBRAKES 5 - 47

REMOVAL AND INSTALLATION (Continued)

Page 131 of 1938

(7) Install aNEWvacuum seal on mounting flange

of master cylinder (Fig. 110).

(8) Position master cylinder on studs of vacuum

booster aligning push rod on vacuum booster with

master cylinder piston.

(9) Install the 2 nuts (Fig. 107) mounting the mas-

ter cylinder to the vacuum booster. Tighten the

mounting nuts to a torque of 25 N´m (225 in. lbs.).

(10) Install the wiper module drain hose (Fig. 107)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to the brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

(11) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 106).

(12) Install the battery tray in the vehicle. Install

the 2 bolts and the nut (Fig. 105) attaching the bat-

tery tray. Tighten the 2 bolts and the nut to a torque

of 14 N´m (125 in lbs.).(13) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(14) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(15) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 104). Securely tighten the hose clamp at the

air cleaner housing and throttle body.

(16) Install the battery and the battery thermal

guard.

(17) Install the battery cables on the battery.

(18) Check the operation of the stop lamp switch

and adjust if necessary.

VACUUM BOOSTER 3.0 LITER ENGINE

REMOVE

CAUTION: Stored vacuum in the vacuum booster

must be pumped down (removed) before removing

master cylinder from power brake booster. This is

necessary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove both battery cables from battery.

(3) Remove the battery thermal guard and the bat-

tery from the battery tray.

(4) Remove the air inlet resonator and hoses as an

assembly from the throttle body and air cleaner

housing (Fig. 111)

(5) If vehicle is equipped with speed control,

unplug wiring harness connector from the speed con-

trol servo. Then disconnect vacuum lines from the

speed control servo and vacuum reservoir on battery

tray.

(6) Remove bolt attaching the speed control servo

bracket to the battery tray. Slide the bracket forward

to unhook it from the battery tray and remove.

(7) Remove the 2 bolts and the nut (Fig. 112)

attaching the battery tray to the body of the vehicle.

(8) Remove wiring harness connector from brake

fluid level sensor in master cylinder fluid reservoir

(Fig. 113).

(9) Clean the area where the master cylinder

assembly attaches to the power brake booster. Use

only a solvent such as Mopar Brake Parts Cleaner or

an equivalent.

Fig. 109 Retaining Clip Installed On Brake Pedal Pin

Fig. 110 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 49

REMOVAL AND INSTALLATION (Continued)

Page 134 of 1938

(11) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 113).

(12) Install the battery tray in the vehicle. Install

the 2 bolts and the nut (Fig. 112) attaching the bat-

tery tray to the vehicle. Tighten the 2 bolts and the

nut to a torque of 14 N´m (125 in lbs.).

(13) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(14) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(15) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 111). Securely tighten the hose clamp at the

air cleaner housing and throttle body.

(16) Install the battery and the battery thermal

guard.

(17) Install the battery cables on the battery.

(18) Check the operation of the stop lamp switch

and adjust if necessary.

VACUUM BOOSTER 3.3/3.8 LITER ENGINE

REMOVE

CAUTION: Reserve vacuum in the vacuum booster

must be pumped down (removed) before removing

master cylinder from vacuum booster. This is nec-

essary to prevent the vacuum booster from sucking

in any contamination as the master cylinder is

removed. This can be done simply by pumping the

brake pedal, with the vehicle's engine not running,

until a firm feeling brake pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove both battery cables from battery.

(3) Remove the battery thermal guard and the bat-

tery from the battery tray.

(4) Remove the air inlet resonator and hoses as an

assembly from the throttle body and air cleaner

housing (Fig. 118)

(5) If vehicle is equipped with speed control,

unplug wiring harness connector from the speed con-

trol servo. Then disconnect vacuum lines from the

speed control servo and vacuum reservoir on battery

tray.

(6) Remove bolt attaching the speed control servo

bracket to the battery tray. Slide the bracket forward

to unhook it from the battery tray and remove.

(7) Remove the 2 bolts and the nut (Fig. 119)

attaching the battery tray to the body of the vehicle.(8) Remove the wiring harness connector (Fig. 120)

from the EGR valve transducer.

(9) Remove wiring harness connectors from throt-

tle position sensor and AIS motor on throttle body

(Fig. 121).

(10) Remove the 2 bolts (Fig. 122) attaching the

throttle body to the intake manifold and the clip (Fig.

122) attaching the wiring harness to the throttle

cable bracket. Then remove the throttle body and

throttle cable bracket as an assembly from the intake

manifold.

(11) Remove wiring harness connector from brake

fluid level sensor in master cylinder fluid reservoir

(Fig. 123).

(12) Clean the area where the master cylinder

assembly attaches to the power brake booster. Use

Fig. 118 Air Inlet Resonator

Fig. 119 Battery Tray Mounting Locations

5 - 52 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 137 of 1938

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the vacuum booster.

The vacuum seal on the master cylinder MUST be

replaced with a NEW seal whenever the master cyl-

inder is removed from the vacuum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install aNEWvacuum seal on mounting flange

of the master cylinder (Fig. 128).

(9) Position master cylinder on studs of vacuum

booster, aligning push rod on vacuum booster with

master cylinder piston.

(10) Install the 2 nuts mounting the master cylin-

der to the vacuum booster (Fig. 124). Tighten both

mounting nuts to a torque of 25 N´m (225 in. lbs.).

(11) Install the wiper module drain hose (Fig. 124)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

(12) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 123).

(13) Install the throttle body and throttle cable

bracket on the intake manifold. Install the 2 bolts

(Fig. 122) attaching the throttle body to the intake

manifold and tighten to a torque of 25 N´m (225 in.

lbs.) Install clip (Fig. 122) attaching the wiring har-

ness to the throttle cable bracket.

(14) Install the wiring harness connectors on the

throttle position sensor and the AIS motor on throttle

body (Fig. 121).(15) Install the wiring harness connector (Fig. 120)

on the EGR valve transducer.

(16) Install the battery tray. Install the 2 bolts and

the nut (Fig. 119) attaching the battery tray to the

vehicle. Tighten the 2 bolts and the nut to a torque of

14 N´m (125 in lbs.).

(17) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(18) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(19) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 118). Securely tighten hose clamp at air

cleaner housing and throttle body.

(20) Install the battery and the battery thermal

guard.

(21) Install the battery cables on the battery.

(22) Check the operation of the stop lamp switch

and adjust if necessary.

JUNCTION BLOCK

REMOVE

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication And Mainte-

nance Group of this service manual.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hudraulic system.

(3) Remove the 6 chassis brake tubes (Fig. 129)

from the junction block.

(4) Remove the bolt (Fig. 130) attaching the junc-

tion block mounting braket to the front suspension

cradle.

INSTALL

(1) Install the junction block and mounting bracket

(Fig. 130) on the front suspension cradle. Install the

attaching bolt and tighten to a torque of 28 N´m (250

in. lbs.).

(2) Install the 6 chassis brake tubes (Fig. 131) into

the inlet and outlet ports of the junction block.

Fig. 128 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 55

REMOVAL AND INSTALLATION (Continued)

Page 152 of 1938

(7) Road test vehicle to ensure proper operation of

the vehicle's power brake system.

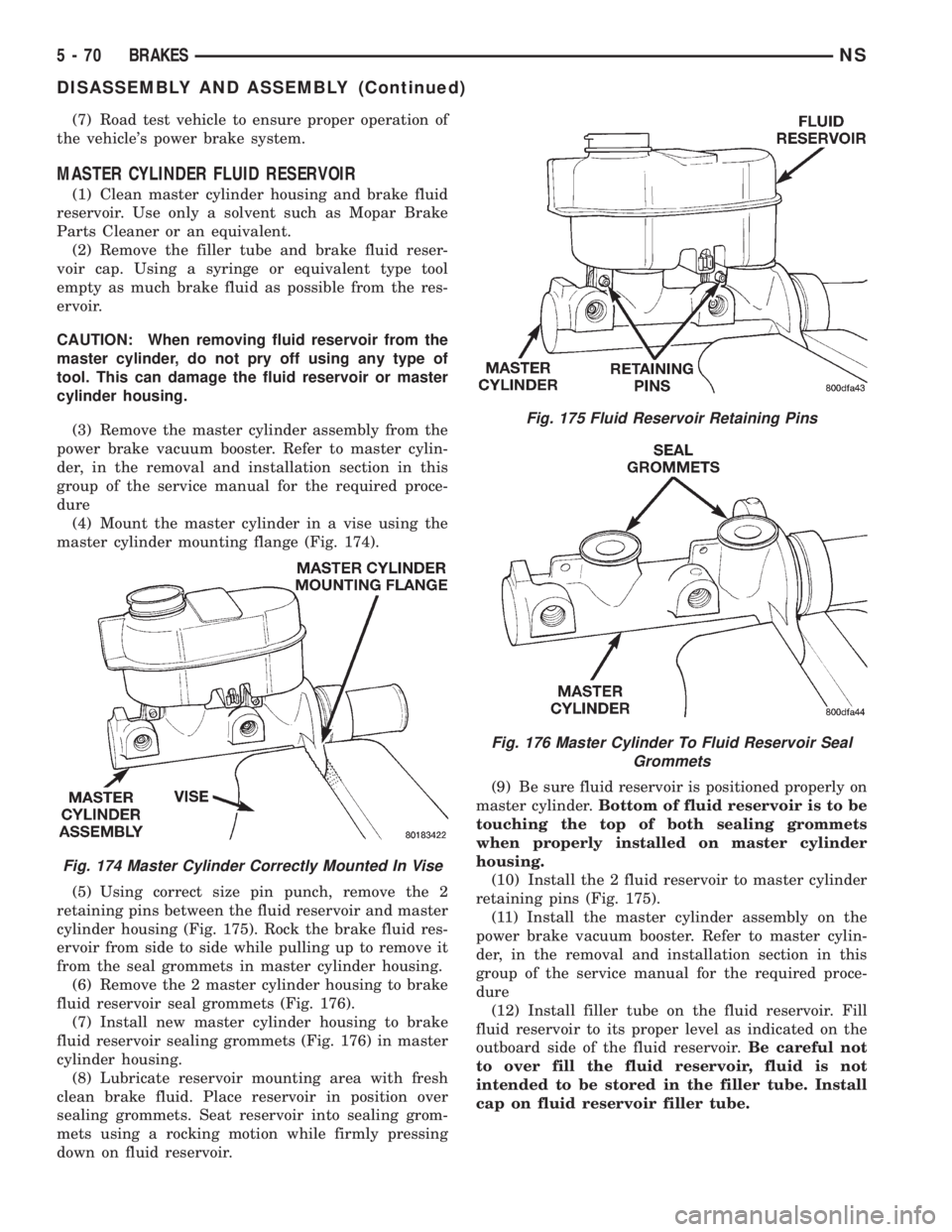

MASTER CYLINDER FLUID RESERVOIR

(1) Clean master cylinder housing and brake fluid

reservoir. Use only a solvent such as Mopar Brake

Parts Cleaner or an equivalent.

(2) Remove the filler tube and brake fluid reser-

voir cap. Using a syringe or equivalent type tool

empty as much brake fluid as possible from the res-

ervoir.

CAUTION: When removing fluid reservoir from the

master cylinder, do not pry off using any type of

tool. This can damage the fluid reservoir or master

cylinder housing.

(3) Remove the master cylinder assembly from the

power brake vacuum booster. Refer to master cylin-

der, in the removal and installation section in this

group of the service manual for the required proce-

dure

(4) Mount the master cylinder in a vise using the

master cylinder mounting flange (Fig. 174).

(5) Using correct size pin punch, remove the 2

retaining pins between the fluid reservoir and master

cylinder housing (Fig. 175). Rock the brake fluid res-

ervoir from side to side while pulling up to remove it

from the seal grommets in master cylinder housing.

(6) Remove the 2 master cylinder housing to brake

fluid reservoir seal grommets (Fig. 176).

(7) Install new master cylinder housing to brake

fluid reservoir sealing grommets (Fig. 176) in master

cylinder housing.

(8) Lubricate reservoir mounting area with fresh

clean brake fluid. Place reservoir in position over

sealing grommets. Seat reservoir into sealing grom-

mets using a rocking motion while firmly pressing

down on fluid reservoir.(9) Be sure fluid reservoir is positioned properly on

master cylinder.Bottom of fluid reservoir is to be

touching the top of both sealing grommets

when properly installed on master cylinder

housing.

(10) Install the 2 fluid reservoir to master cylinder

retaining pins (Fig. 175).

(11) Install the master cylinder assembly on the

power brake vacuum booster. Refer to master cylin-

der, in the removal and installation section in this

group of the service manual for the required proce-

dure

(12) Install filler tube on the fluid reservoir. Fill

fluid reservoir to its proper level as indicated on the

outboard side of the fluid reservoir.Be careful not

to over fill the fluid reservoir, fluid is not

intended to be stored in the filler tube. Install

cap on fluid reservoir filler tube.

Fig. 174 Master Cylinder Correctly Mounted In Vise

Fig. 175 Fluid Reservoir Retaining Pins

Fig. 176 Master Cylinder To Fluid Reservoir Seal

Grommets

5 - 70 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 153 of 1938

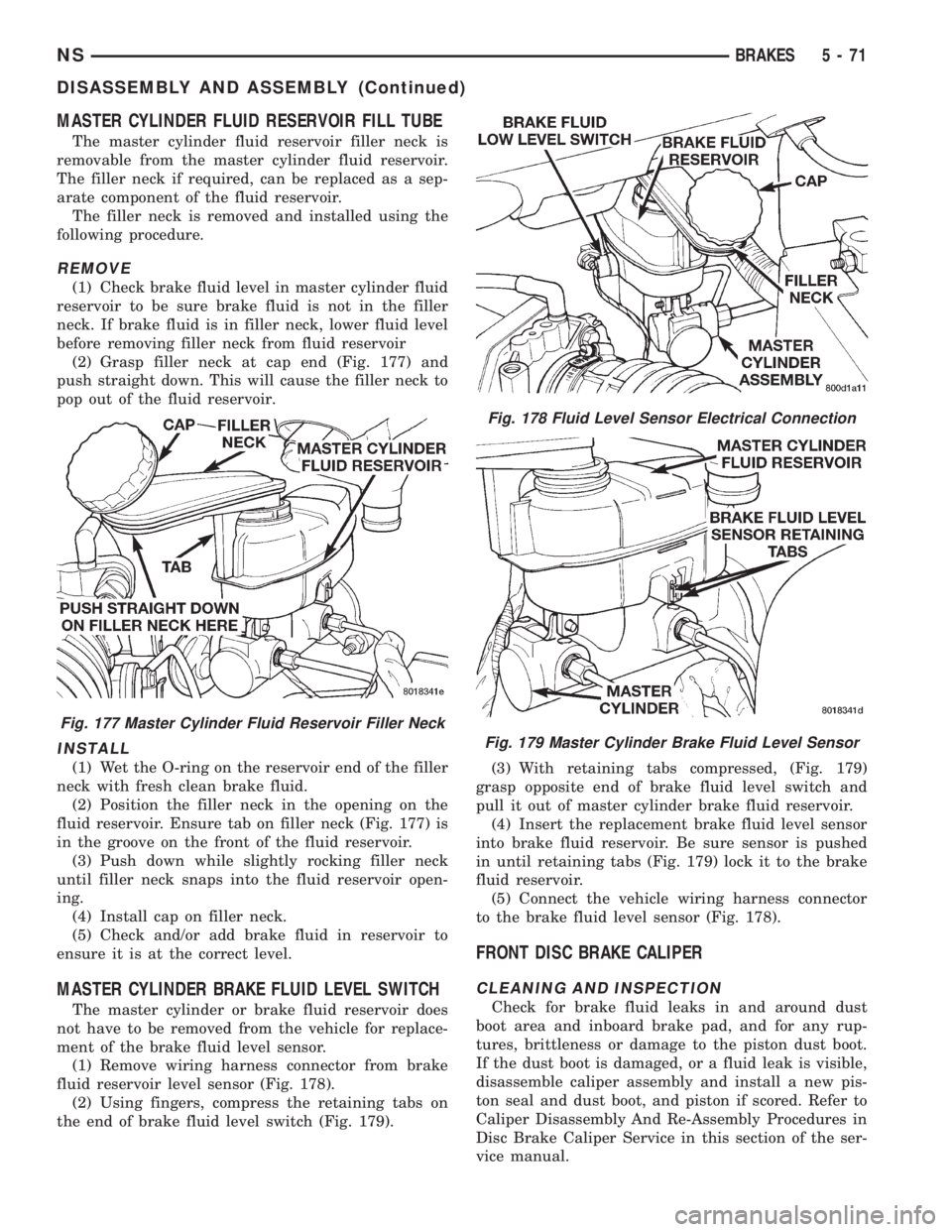

MASTER CYLINDER FLUID RESERVOIR FILL TUBE

The master cylinder fluid reservoir filler neck is

removable from the master cylinder fluid reservoir.

The filler neck if required, can be replaced as a sep-

arate component of the fluid reservoir.

The filler neck is removed and installed using the

following procedure.

REMOVE

(1) Check brake fluid level in master cylinder fluid

reservoir to be sure brake fluid is not in the filler

neck. If brake fluid is in filler neck, lower fluid level

before removing filler neck from fluid reservoir

(2) Grasp filler neck at cap end (Fig. 177) and

push straight down. This will cause the filler neck to

pop out of the fluid reservoir.

INSTALL

(1) Wet the O-ring on the reservoir end of the filler

neck with fresh clean brake fluid.

(2) Position the filler neck in the opening on the

fluid reservoir. Ensure tab on filler neck (Fig. 177) is

in the groove on the front of the fluid reservoir.

(3) Push down while slightly rocking filler neck

until filler neck snaps into the fluid reservoir open-

ing.

(4) Install cap on filler neck.

(5) Check and/or add brake fluid in reservoir to

ensure it is at the correct level.

MASTER CYLINDER BRAKE FLUID LEVEL SWITCH

The master cylinder or brake fluid reservoir does

not have to be removed from the vehicle for replace-

ment of the brake fluid level sensor.

(1) Remove wiring harness connector from brake

fluid reservoir level sensor (Fig. 178).

(2) Using fingers, compress the retaining tabs on

the end of brake fluid level switch (Fig. 179).(3) With retaining tabs compressed, (Fig. 179)

grasp opposite end of brake fluid level switch and

pull it out of master cylinder brake fluid reservoir.

(4) Insert the replacement brake fluid level sensor

into brake fluid reservoir. Be sure sensor is pushed

in until retaining tabs (Fig. 179) lock it to the brake

fluid reservoir.

(5) Connect the vehicle wiring harness connector

to the brake fluid level sensor (Fig. 178).

FRONT DISC BRAKE CALIPER

CLEANING AND INSPECTION

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Fig. 177 Master Cylinder Fluid Reservoir Filler Neck

Fig. 178 Fluid Level Sensor Electrical Connection

Fig. 179 Master Cylinder Brake Fluid Level Sensor

NSBRAKES 5 - 71

DISASSEMBLY AND ASSEMBLY (Continued)