servo CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 713 of 1938

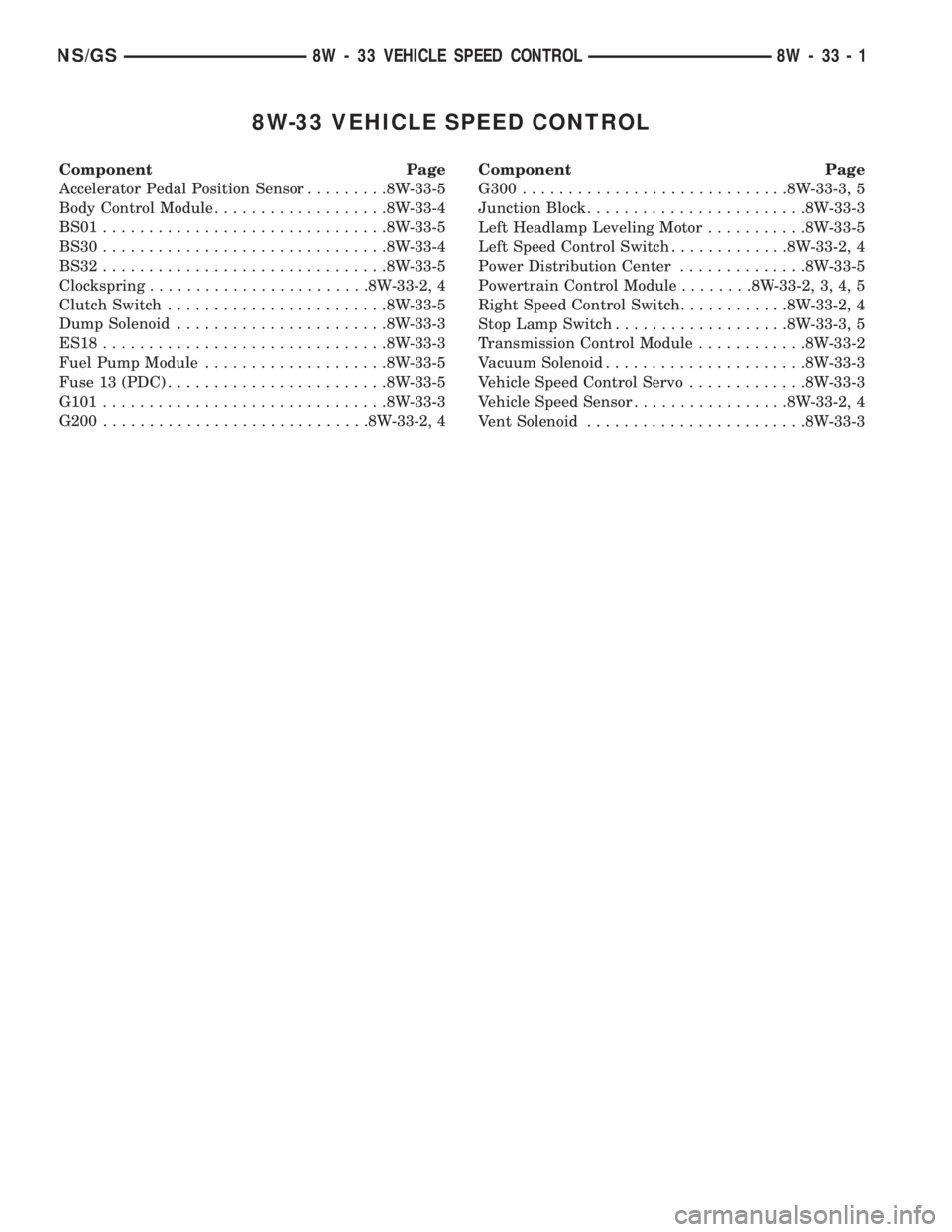

8W-33 VEHICLE SPEED CONTROL

Component Page

Accelerator Pedal Position Sensor.........8W-33-5

Body Control Module...................8W-33-4

BS01...............................8W-33-5

BS30...............................8W-33-4

BS32...............................8W-33-5

Clockspring........................8W-33-2, 4

Clutch Switch........................8W-33-5

Dump Solenoid.......................8W-33-3

ES18...............................8W-33-3

Fuel Pump Module....................8W-33-5

Fuse 13 (PDC)........................8W-33-5

G101...............................8W-33-3

G200.............................8W-33-2, 4Component Page

G300.............................8W-33-3, 5

Junction Block........................8W-33-3

Left Headlamp Leveling Motor...........8W-33-5

Left Speed Control Switch.............8W-33-2, 4

Power Distribution Center..............8W-33-5

Powertrain Control Module........8W-33-2, 3, 4, 5

Right Speed Control Switch............8W-33-2, 4

Stop Lamp Switch...................8W-33-3, 5

Transmission Control Module............8W-33-2

Vacuum Solenoid......................8W-33-3

Vehicle Speed Control Servo.............8W-33-3

Vehicle Speed Sensor.................8W-33-2, 4

Vent Solenoid........................8W-33-3

NS/GS8W - 33 VEHICLE SPEED CONTROL 8W - 33 - 1

Page 715 of 1938

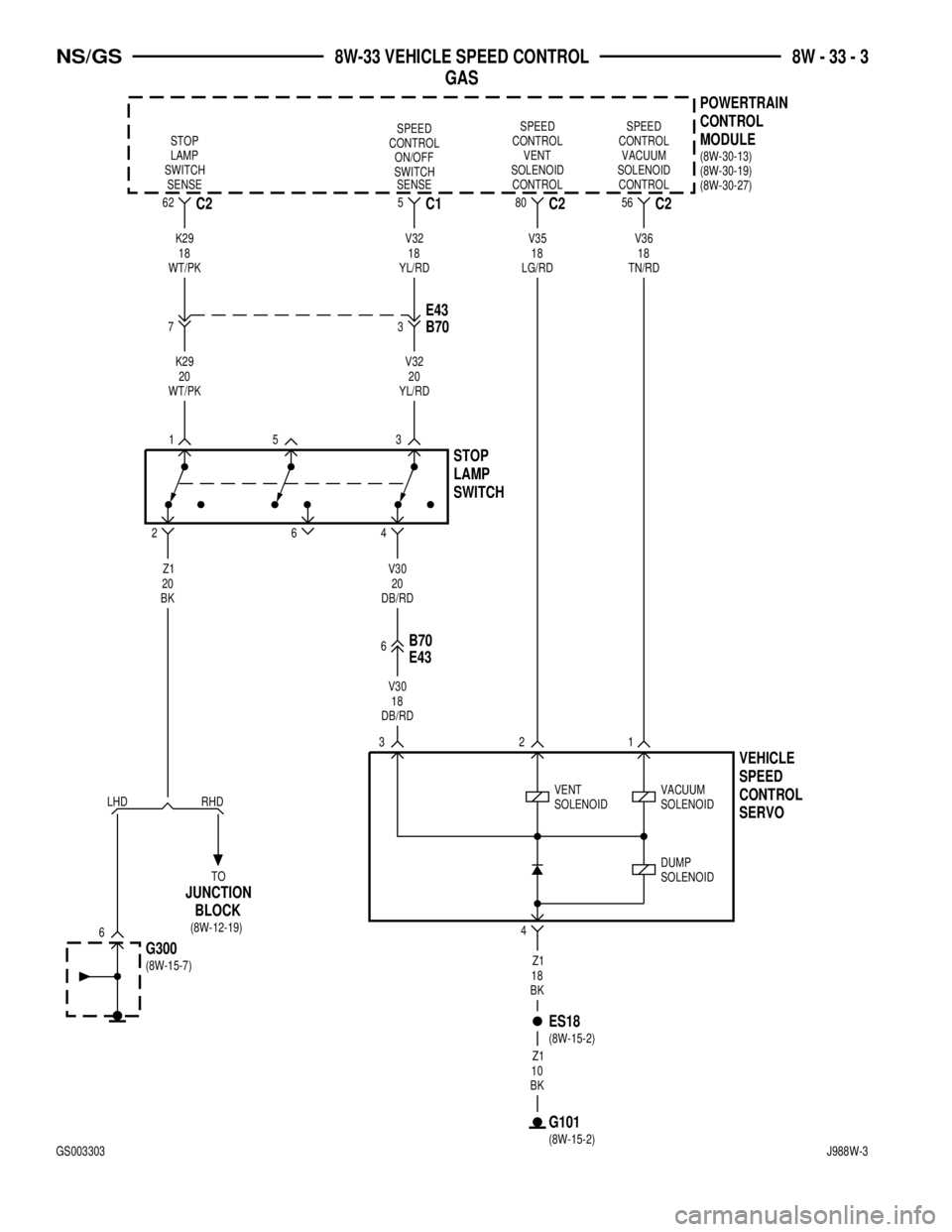

56C280C2

CONTROL SOLENOIDVACUUM CONTROLSPEED SPEED

CONTROL

VENT

SOLENOID

CONTROL

41

2

V36

18

TN/RDV35

18

LG/RD

SERVO CONTROL

SPEED

VEHICLE

Z1

18

BK

Z1

10

BK

ES18

G101

STOP

LAMP

SWITCH

4

SPEED

CONTROL

ON/OFF

SWITCH

POWERTRAIN

CONTROL

MODULE

C1

5

DB/RD20 V30

3

VACUUM

SOLENOID

SOLENOID DUMP SOLENOID VENT

3

62C2

SENSE SWITCHLAMPSTOP

YL/RD18 V32

YL/RD20 V32

E43

B70

3

6B70

E43

V30

18

DB/RD

7K29

18

WT/PK

1

Z1

20

BK

2

WT/PK20 K29

G300

6

RHD LHD

JUNCTION

BLOCK

TO5

6SENSE

(8W-15-2)

(8W-15-2)(8W-30-13)

(8W-30-19)

(8W-30-27)

(8W-15-7)(8W-12-19)

NS/GS8W-33 VEHICLE SPEED CONTROL

GAS8W - 33 - 3

GS003303J988W-3

Page 880 of 1938

Component Page

Seat Belt Switch.....................8W-80-83

Sentry Key Immobilizer Module.........8W-80-83

Speed Control Dimming Module.........8W-80-83

Stop Lamp Switch....................8W-80-83

Throttle Position Sensor (2.0L)..........8W-80-84

Throttle Position Sensor (Except 2.0L). . . .8W-80-84

Traction Control Switch................8W-80-84

Trailer Tow Connector.................8W-80-84

Transmission Control Module...........8W-80-85Component Page

Transmission Control Solenoids..........8W-80-86

Transmission Range Sensor.............8W-80-86

Turbine Speed Sensor.................8W-80-87

Turbo Boost Pressure Sensor............8W-80-87

Upstream Heated Oxygen Sensor........8W-80-87

Vehicle Speed Control Servo............8W-80-87

Vehicle Speed Sensor..................8W-80-88

Wiper Module (Built-Up-Export).........8W-80-88

Wiper Module (Except Built-Up-Export) . . .8W-80-88

8W - 80 - 4 8W - 80 CONNECTOR PIN-OUTSNS/GS

Page 963 of 1938

CONTROL SERVOVEHICLE SPEED

41BLACK

Z1 18BK V30 18DB/RD V35 18LG/RD

V36 18TN/RD

4 3

2 1 CAV GROUND STOP LAMP SWITCH OUTPUT SPEED CONTROL VENT SOLENOID CONTROL

SPEED CONTROL VACUM SOLENOID CONTROL CIRCUIT

FUNCTION

OXYGEN SENSOR UPSTREAM HEATED

4 32

K41 18BK/DG K4 18BK/LB A142 18DG/OR

Z1 18BK

4 3

2 1 CAV UPSTREAM HEATED OXYGEN SENSOR SIGNAL SENSOR GROUND ASD RELAY OUTPUT

GROUND CIRCUIT

FUNCTION GRAY

1BOOST PRESSURE SIGNAL K1 18DG/RD

4

4 1

TURBO BOOST

PRESSURE SENSOR

(DIESEL)

K9 18LB

3K21 18BK/RD INTAKE AIR TEMPERATURE SIGNALSENSOR GROUND K4 18BK/LB

21

CAV FUNCTION CIRCUIT FUNCTION

CIRCUIT

SPEED SENSOR GROUND

INPUT SPEED SENSOR SIGNALCAV

1

2T13 18DB/BK

T52 18RD/BK

GRAY

1 2

TURBINE

SPEED SENSOR

5 VOLT SUPPLY

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 87

NSGS8087J988W-3

Page 971 of 1938

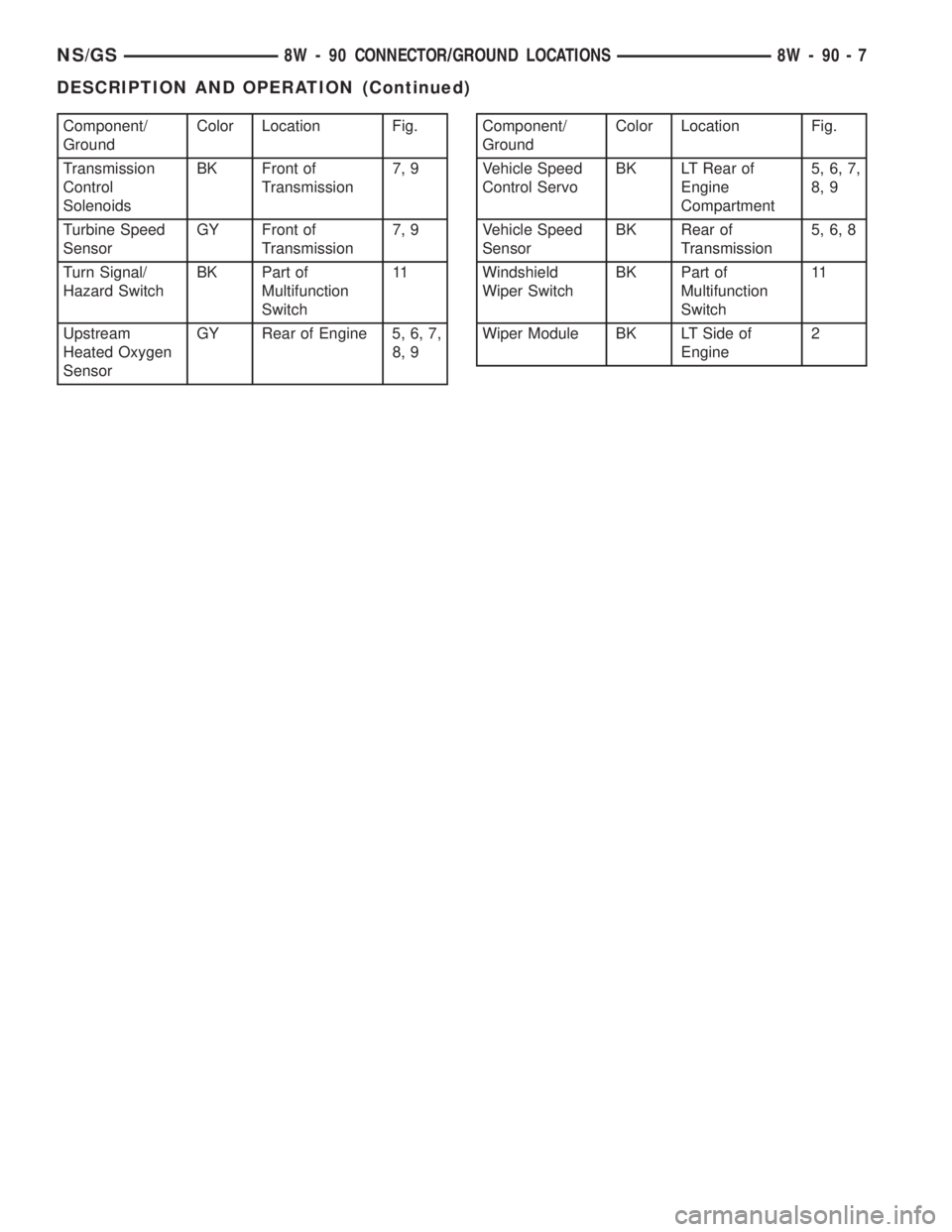

Component/

GroundColor Location Fig.

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9Component/

GroundColor Location Fig.

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1064 of 1938

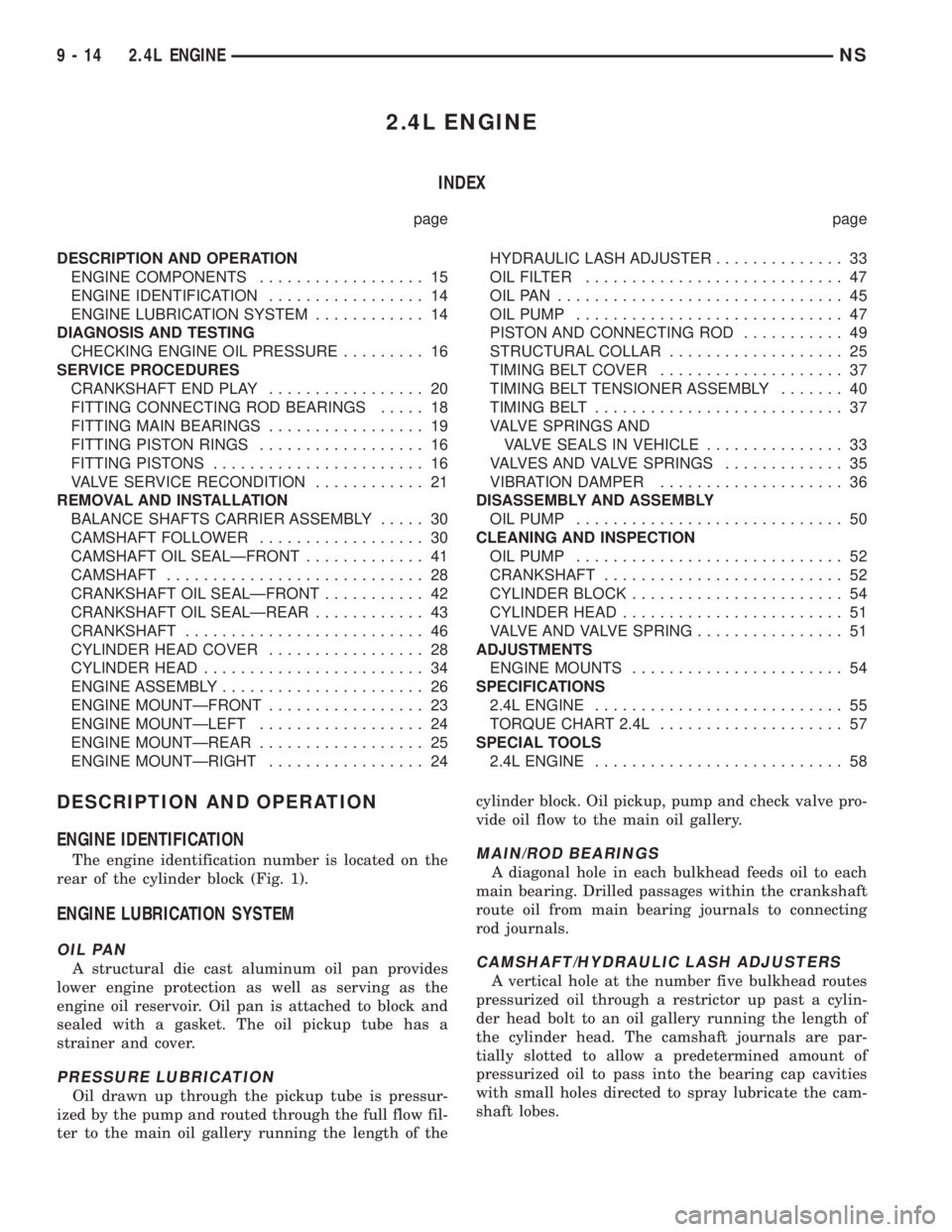

2.4L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 15

ENGINE IDENTIFICATION................. 14

ENGINE LUBRICATION SYSTEM............ 14

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 16

SERVICE PROCEDURES

CRANKSHAFT END PLAY................. 20

FITTING CONNECTING ROD BEARINGS..... 18

FITTING MAIN BEARINGS................. 19

FITTING PISTON RINGS.................. 16

FITTING PISTONS....................... 16

VALVE SERVICE RECONDITION............ 21

REMOVAL AND INSTALLATION

BALANCE SHAFTS CARRIER ASSEMBLY..... 30

CAMSHAFT FOLLOWER.................. 30

CAMSHAFT OIL SEALÐFRONT............. 41

CAMSHAFT............................ 28

CRANKSHAFT OIL SEALÐFRONT........... 42

CRANKSHAFT OIL SEALÐREAR............ 43

CRANKSHAFT.......................... 46

CYLINDER HEAD COVER................. 28

CYLINDER HEAD........................ 34

ENGINE ASSEMBLY...................... 26

ENGINE MOUNTÐFRONT................. 23

ENGINE MOUNTÐLEFT.................. 24

ENGINE MOUNTÐREAR.................. 25

ENGINE MOUNTÐRIGHT................. 24HYDRAULIC LASH ADJUSTER.............. 33

OILFILTER ............................ 47

OILPAN ............................... 45

OIL PUMP............................. 47

PISTON AND CONNECTING ROD........... 49

STRUCTURAL COLLAR................... 25

TIMING BELT COVER.................... 37

TIMING BELT TENSIONER ASSEMBLY....... 40

TIMING BELT........................... 37

VALVE SPRINGS AND

VALVE SEALS IN VEHICLE............... 33

VALVES AND VALVE SPRINGS............. 35

VIBRATION DAMPER.................... 36

DISASSEMBLY AND ASSEMBLY

OIL PUMP............................. 50

CLEANING AND INSPECTION

OIL PUMP............................. 52

CRANKSHAFT.......................... 52

CYLINDER BLOCK....................... 54

CYLINDER HEAD........................ 51

VALVE AND VALVE SPRING................ 51

ADJUSTMENTS

ENGINE MOUNTS....................... 54

SPECIFICATIONS

2.4L ENGINE........................... 55

TORQUE CHART 2.4L.................... 57

SPECIAL TOOLS

2.4L ENGINE........................... 58

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

ENGINE LUBRICATION SYSTEM

OIL PAN

A structural die cast aluminum oil pan provides

lower engine protection as well as serving as the

engine oil reservoir. Oil pan is attached to block and

sealed with a gasket. The oil pickup tube has a

strainer and cover.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full flow fil-

ter to the main oil gallery running the length of thecylinder block. Oil pickup, pump and check valve pro-

vide oil flow to the main oil gallery.

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up past a cylin-

der head bolt to an oil gallery running the length of

the cylinder head. The camshaft journals are par-

tially slotted to allow a predetermined amount of

pressurized oil to pass into the bearing cap cavities

with small holes directed to spray lubricate the cam-

shaft lobes.

9 - 14 2.4L ENGINENS

Page 1119 of 1938

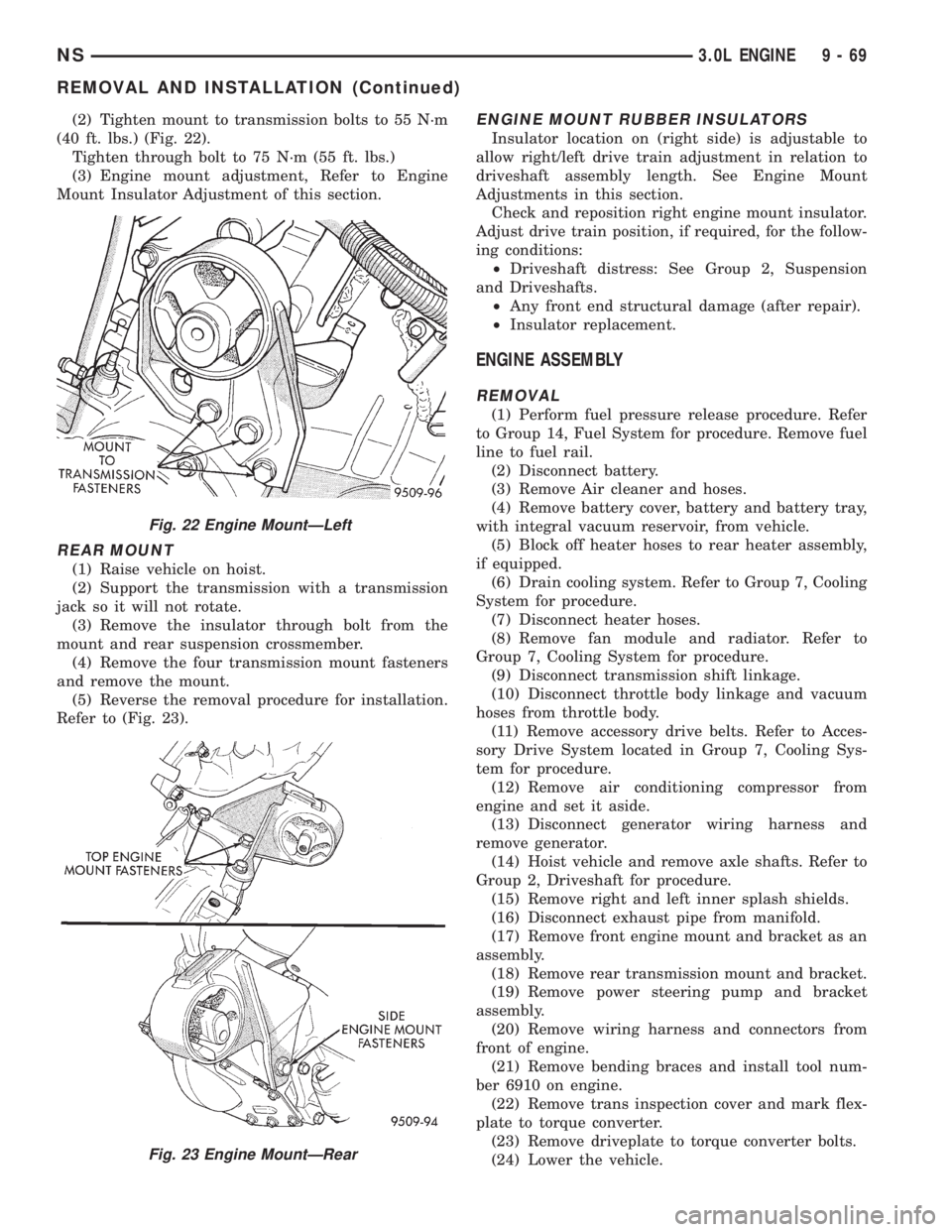

(2) Tighten mount to transmission bolts to 55 N´m

(40 ft. lbs.) (Fig. 22).

Tighten through bolt to 75 N´m (55 ft. lbs.)

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

REAR MOUNT

(1) Raise vehicle on hoist.

(2) Support the transmission with a transmission

jack so it will not rotate.

(3) Remove the insulator through bolt from the

mount and rear suspension crossmember.

(4) Remove the four transmission mount fasteners

and remove the mount.

(5) Reverse the removal procedure for installation.

Refer to (Fig. 23).

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) is adjustable to

allow right/left drive train adjustment in relation to

driveshaft assembly length. See Engine Mount

Adjustments in this section.

Check and reposition right engine mount insulator.

Adjust drive train position, if required, for the follow-

ing conditions:

²Driveshaft distress: See Group 2, Suspension

and Driveshafts.

²Any front end structural damage (after repair).

²Insulator replacement.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Remove battery cover, battery and battery tray,

with integral vacuum reservoir, from vehicle.

(5) Block off heater hoses to rear heater assembly,

if equipped.

(6) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(7) Disconnect heater hoses.

(8) Remove fan module and radiator. Refer to

Group 7, Cooling System for procedure.

(9) Disconnect transmission shift linkage.

(10) Disconnect throttle body linkage and vacuum

hoses from throttle body.

(11) Remove accessory drive belts. Refer to Acces-

sory Drive System located in Group 7, Cooling Sys-

tem for procedure.

(12) Remove air conditioning compressor from

engine and set it aside.

(13) Disconnect generator wiring harness and

remove generator.

(14) Hoist vehicle and remove axle shafts. Refer to

Group 2, Driveshaft for procedure.

(15) Remove right and left inner splash shields.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front engine mount and bracket as an

assembly.

(18) Remove rear transmission mount and bracket.

(19) Remove power steering pump and bracket

assembly.

(20) Remove wiring harness and connectors from

front of engine.

(21) Remove bending braces and install tool num-

ber 6910 on engine.

(22) Remove trans inspection cover and mark flex-

plate to torque converter.

(23) Remove driveplate to torque converter bolts.

(24) Lower the vehicle.

Fig. 22 Engine MountÐLeft

Fig. 23 Engine MountÐRear

NS3.0L ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 1154 of 1938

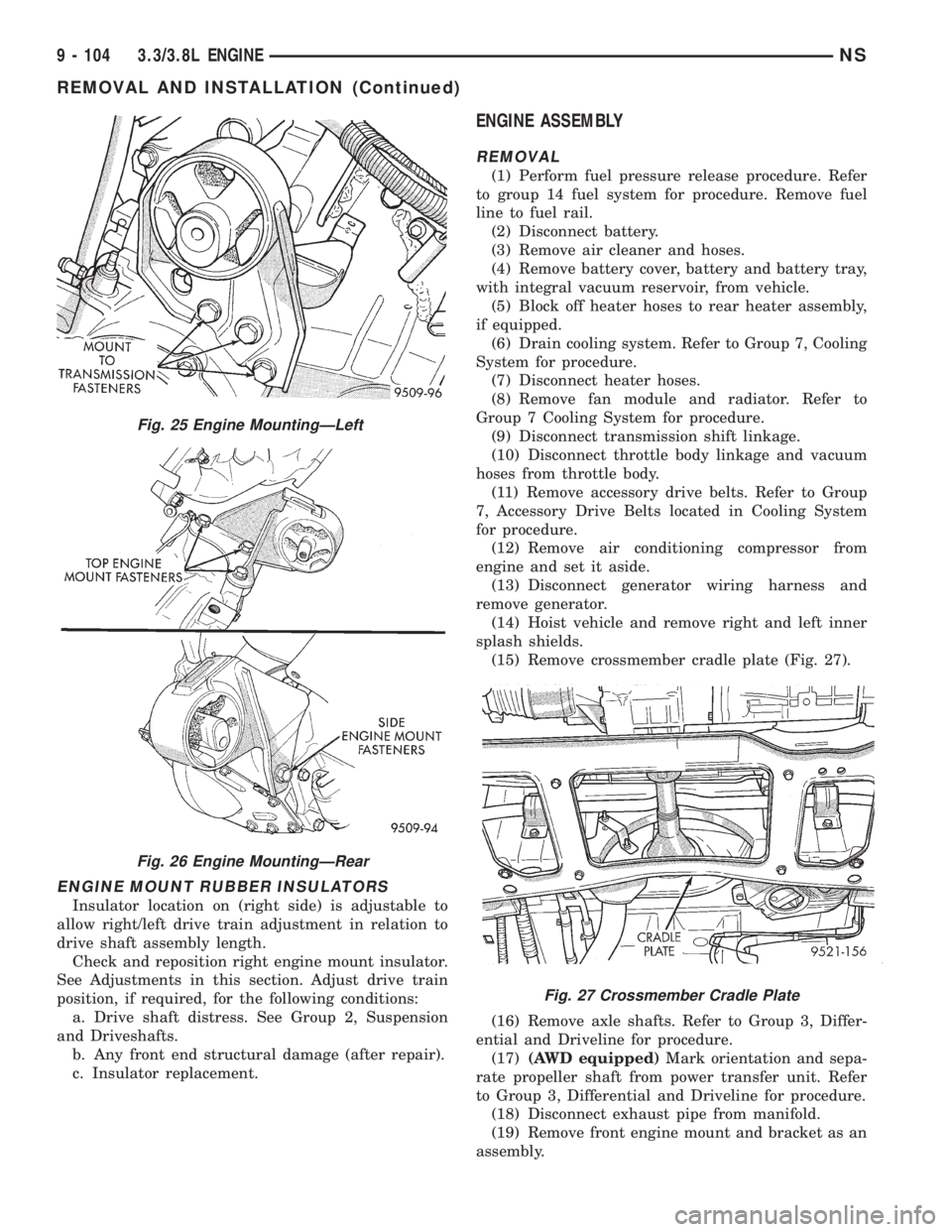

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) is adjustable to

allow right/left drive train adjustment in relation to

drive shaft assembly length.

Check and reposition right engine mount insulator.

See Adjustments in this section. Adjust drive train

position, if required, for the following conditions:

a. Drive shaft distress. See Group 2, Suspension

and Driveshafts.

b. Any front end structural damage (after repair).

c. Insulator replacement.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to group 14 fuel system for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove air cleaner and hoses.

(4) Remove battery cover, battery and battery tray,

with integral vacuum reservoir, from vehicle.

(5) Block off heater hoses to rear heater assembly,

if equipped.

(6) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(7) Disconnect heater hoses.

(8) Remove fan module and radiator. Refer to

Group 7 Cooling System for procedure.

(9) Disconnect transmission shift linkage.

(10) Disconnect throttle body linkage and vacuum

hoses from throttle body.

(11) Remove accessory drive belts. Refer to Group

7, Accessory Drive Belts located in Cooling System

for procedure.

(12) Remove air conditioning compressor from

engine and set it aside.

(13) Disconnect generator wiring harness and

remove generator.

(14) Hoist vehicle and remove right and left inner

splash shields.

(15) Remove crossmember cradle plate (Fig. 27).

(16) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(17)(AWD equipped)Mark orientation and sepa-

rate propeller shaft from power transfer unit. Refer

to Group 3, Differential and Driveline for procedure.

(18) Disconnect exhaust pipe from manifold.

(19) Remove front engine mount and bracket as an

assembly.

Fig. 25 Engine MountingÐLeft

Fig. 26 Engine MountingÐRear

Fig. 27 Crossmember Cradle Plate

9 - 104 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1231 of 1938

ENGINE ASSEMBLY

REMOVAL

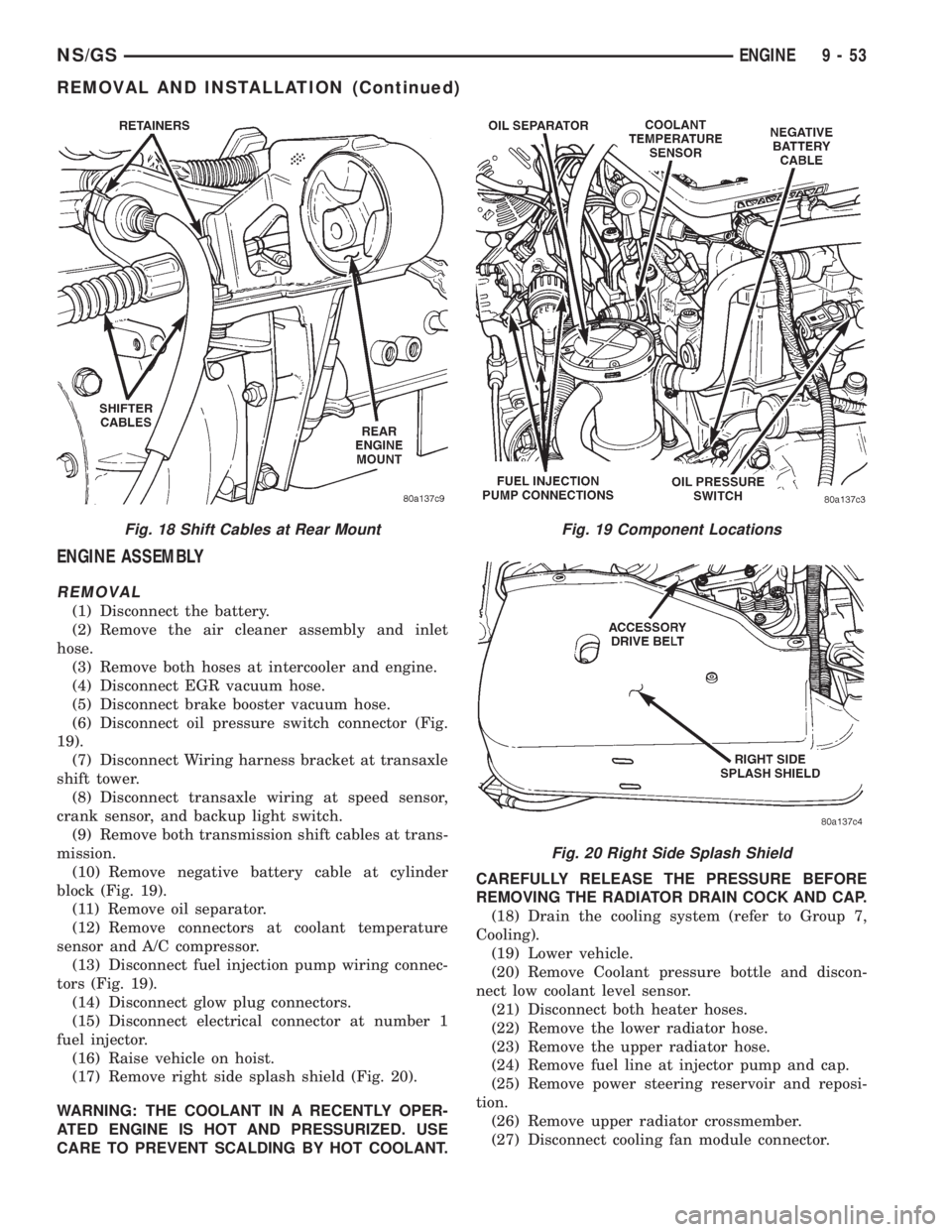

(1) Disconnect the battery.

(2) Remove the air cleaner assembly and inlet

hose.

(3) Remove both hoses at intercooler and engine.

(4) Disconnect EGR vacuum hose.

(5) Disconnect brake booster vacuum hose.

(6) Disconnect oil pressure switch connector (Fig.

19).

(7) Disconnect Wiring harness bracket at transaxle

shift tower.

(8) Disconnect transaxle wiring at speed sensor,

crank sensor, and backup light switch.

(9) Remove both transmission shift cables at trans-

mission.

(10) Remove negative battery cable at cylinder

block (Fig. 19).

(11) Remove oil separator.

(12) Remove connectors at coolant temperature

sensor and A/C compressor.

(13) Disconnect fuel injection pump wiring connec-

tors (Fig. 19).

(14) Disconnect glow plug connectors.

(15) Disconnect electrical connector at number 1

fuel injector.

(16) Raise vehicle on hoist.

(17) Remove right side splash shield (Fig. 20).

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND CAP.

(18) Drain the cooling system (refer to Group 7,

Cooling).

(19) Lower vehicle.

(20) Remove Coolant pressure bottle and discon-

nect low coolant level sensor.

(21) Disconnect both heater hoses.

(22) Remove the lower radiator hose.

(23) Remove the upper radiator hose.

(24) Remove fuel line at injector pump and cap.

(25) Remove power steering reservoir and reposi-

tion.

(26) Remove upper radiator crossmember.

(27) Disconnect cooling fan module connector.

Fig. 18 Shift Cables at Rear MountFig. 19 Component Locations

Fig. 20 Right Side Splash Shield

NS/GSENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)