transmission oil CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 215 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 1

AUTOMATIC TRANSMISSION OIL COOLERÐ

2.4L................................. 3

COOLANT RECOVERY SYSTEM (CRS)....... 3

COOLANT.............................. 3

COOLING SYSTEM....................... 2

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 3

RADIATOR PRESSURE CAP................ 4

RADIATOR............................. 3

WATER PUMPS......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 6

RADIATOR HOSES AND CLAMPS........... 6

WATER PIPESÐ3.0L ENGINE.............. 6

WATER PUMPÐ3.3/3.8L ENGINES.......... 7

WATER PUMPÐ2.4L ENGINE.............. 6

WATER PUMPÐ3.0L ENGINE.............. 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVE BELT.................. 7

COOLING SYSTEM DIAGNOSIS............. 8

DEAERATION.......................... 16

ELECTRIC FAN MOTOR TEST.............. 14

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE TESTING RADIATOR CAP....... 15

RADIATOR CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

RADIATOR COOLANT FLOW TEST.......... 14

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVEL SERVICE................ 16COOLANTÐADDING ADDITIONAL.......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 16

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTSÐ2.4L.......... 23

ACCESSORY DRIVE BELTSÐ3.0L.......... 24

ACCESSORY DRIVE BELTÐ3.3/3.8L........ 24

ENGINE BLOCK HEATER................. 23

FAN MODULE.......................... 22

RADIATOR DRAINCOCK.................. 21

RADIATOR............................ 21

THERMOSTATÐ2.4L ENGINE............. 19

THERMOSTATÐ3.0L ENGINE............. 20

THERMOSTATÐ3.3/3.8L ENGINES......... 20

WATER PUMP INLET TUBEÐ2.4L ENGINE . . . 17

WATER PUMPÐ3.3/3.8L ENGINES......... 19

WATER PUMPÐ2.4L ENGINE............ 17

WATER PUMPÐ3.0L ENGINE............. 18

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT................. 25

CHEMICAL CLEANING................... 25

COOLING SYSTEM CLEANING............. 25

RADIATOR PRESSURE CAP............... 25

REVERSE FLUSHING THE ENGINE......... 25

REVERSE FLUSHING THE RADIATOR....... 25

WATER PUMP......................... 24

ADJUSTMENTS

BELT TENSION CHART................... 26

BELT TENSION GAUGE METHOD........... 26

PROPER BELT TENSION................. 25

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 26

TORQUE CHART........................ 26

SPECIAL TOOLS

COOLING............................. 26

GENERAL INFORMATION

ACCESSORY DRIVE BELTS

The accessory drive system utilizes two different

style of drive belts. The conventional V-belt and the

Poly-V belt are used to drive the generator, air con-

ditioning compressor, power steering pump and waterpump. Satisfactory performance of these belts

depends on belt condition and proper belt tension.

Belt tensioning should be performed with the aid of a

Burroughs gauge Special Tool C-4162. Because of

space limitations in the engine compartment, the use

of the gauge may be restricted. Raise the vehicle on a

hoist and then remove the splash shield to gain

access to the drive belts.

NSCOOLING SYSTEM 7 - 1

Page 216 of 1938

COOLING SYSTEM

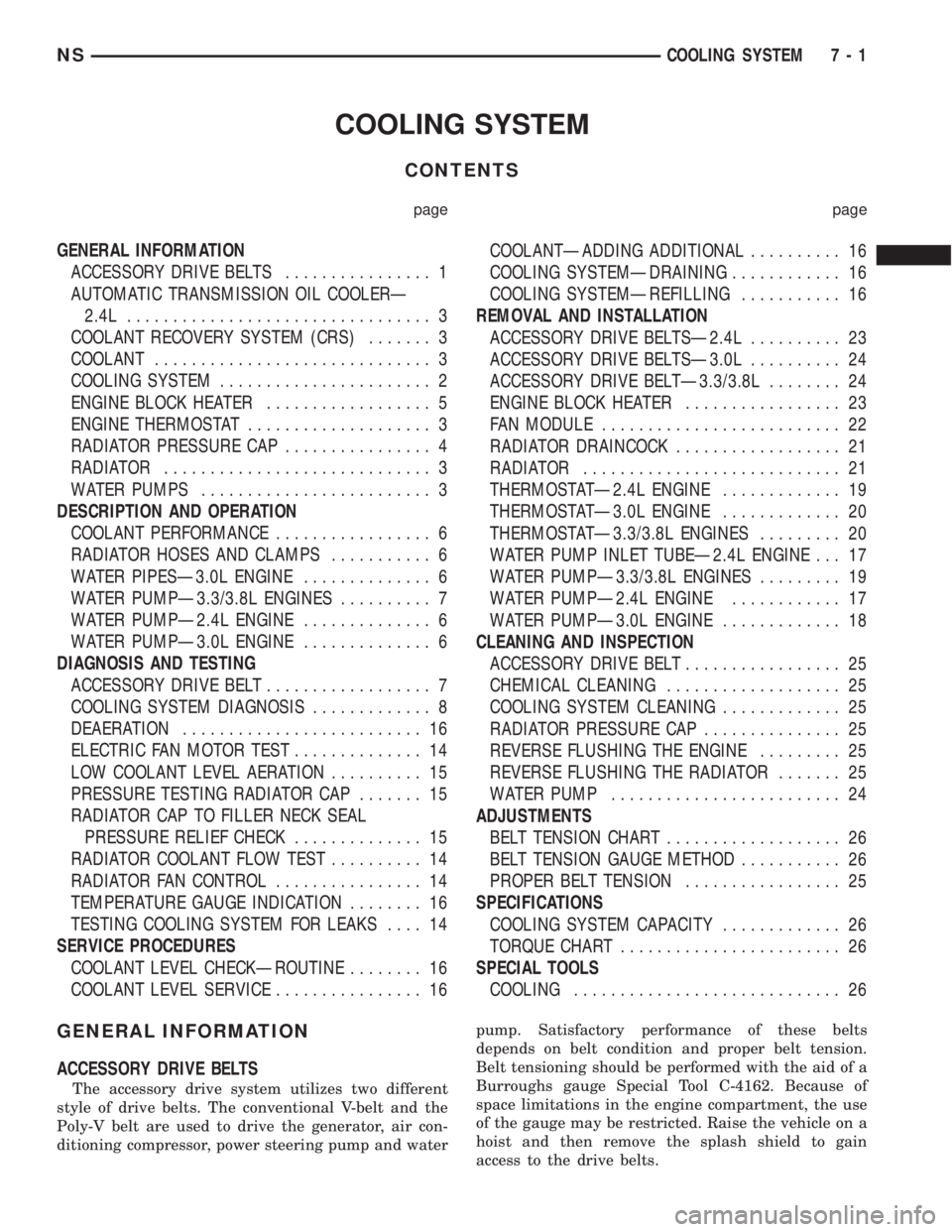

The cooling system has a radiator, coolant, electric fan

motor, shroud, pressure cap, thermostat, coolant reserve

system, transmission oil cooler, a water pump to circulate

the coolant, hoses, and clamps to complete the circuit.

²When Engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²

When Engine is warm: thermostat is open, cooling

system has bypass flow and coolant flow through radia-

tor.

Its primary purpose is to maintain engine temper-

ature in a range that will provide satisfactory engine

performance and emission levels under all expected

driving conditions. It also provides hot water (cool-

ant) for heater performance and cooling for automatic

transmission oil. It does this by transferring heat

from engine metal to coolant, moving this heated

coolant to the radiator, and then transferring this

heat to the ambient air.

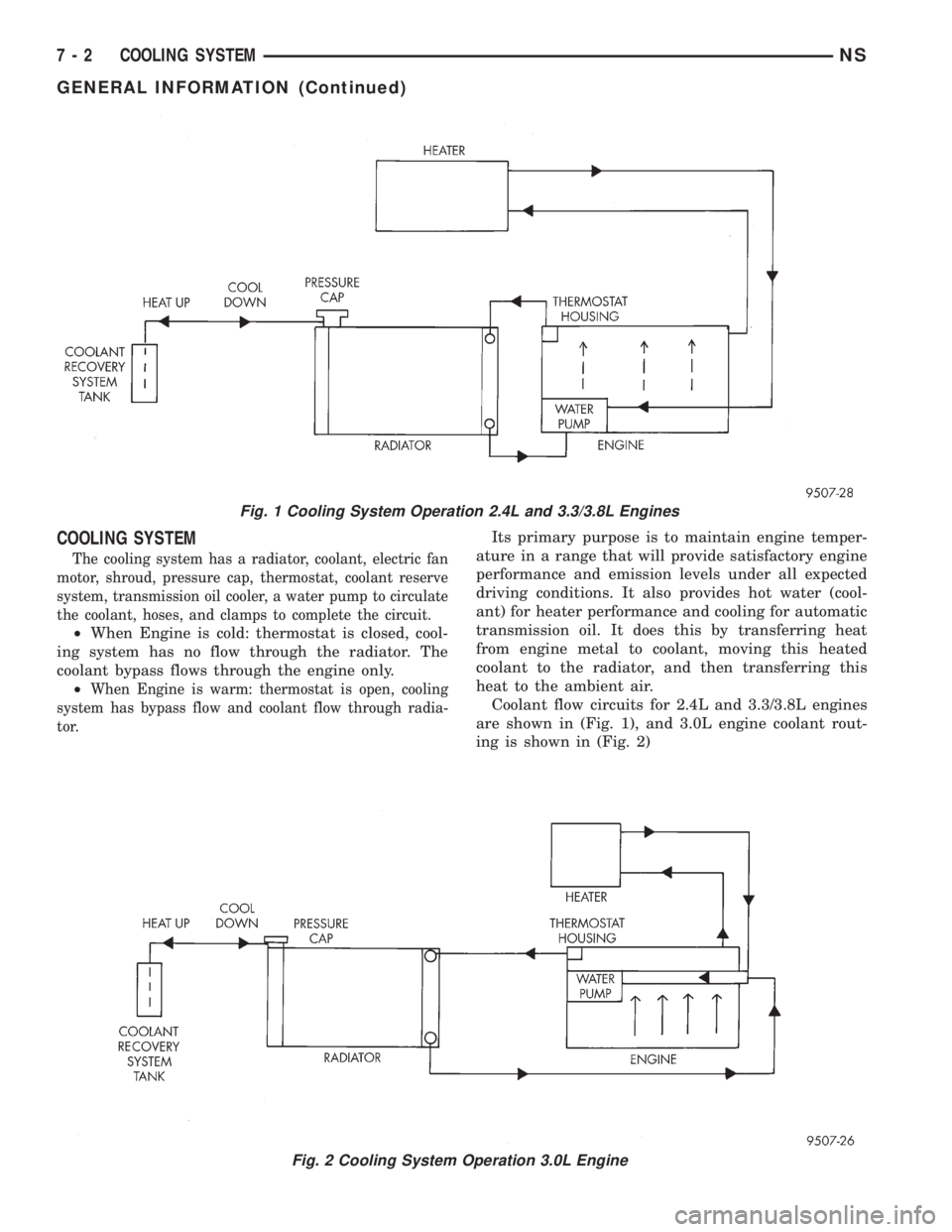

Coolant flow circuits for 2.4L and 3.3/3.8L engines

are shown in (Fig. 1), and 3.0L engine coolant rout-

ing is shown in (Fig. 2)

Fig. 1 Cooling System Operation 2.4L and 3.3/3.8L Engines

Fig. 2 Cooling System Operation 3.0L Engine

7 - 2 COOLING SYSTEMNS

GENERAL INFORMATION (Continued)

Page 217 of 1938

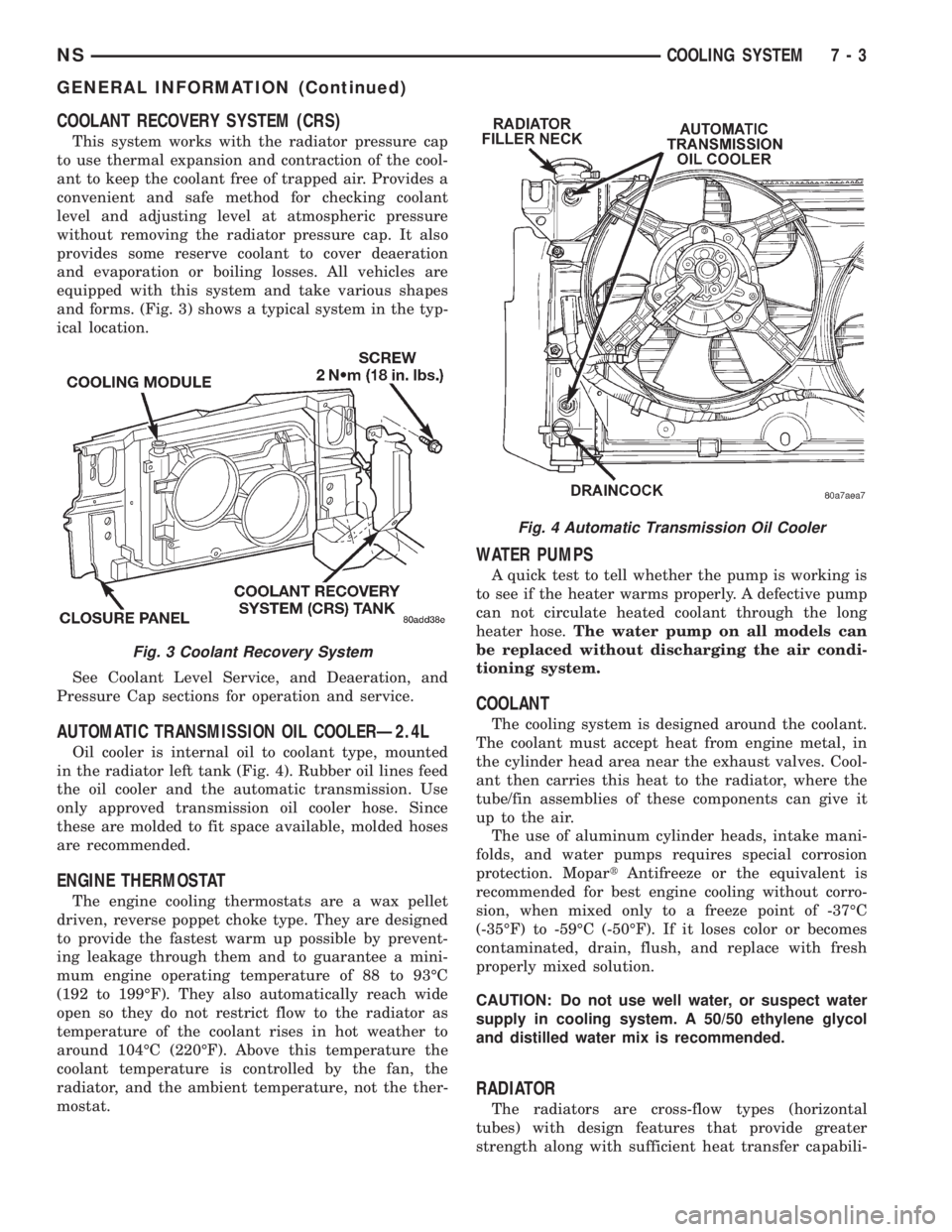

COOLANT RECOVERY SYSTEM (CRS)

This system works with the radiator pressure cap

to use thermal expansion and contraction of the cool-

ant to keep the coolant free of trapped air. Provides a

convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure

without removing the radiator pressure cap. It also

provides some reserve coolant to cover deaeration

and evaporation or boiling losses. All vehicles are

equipped with this system and take various shapes

and forms. (Fig. 3) shows a typical system in the typ-

ical location.

See Coolant Level Service, and Deaeration, and

Pressure Cap sections for operation and service.

AUTOMATIC TRANSMISSION OIL COOLERÐ2.4L

Oil cooler is internal oil to coolant type, mounted

in the radiator left tank (Fig. 4). Rubber oil lines feed

the oil cooler and the automatic transmission. Use

only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended.

ENGINE THERMOSTAT

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the fan, the

radiator, and the ambient temperature, not the ther-

mostat.

WATER PUMPS

A quick test to tell whether the pump is working is

to see if the heater warms properly. A defective pump

can not circulate heated coolant through the long

heater hose.The water pump on all models can

be replaced without discharging the air condi-

tioning system.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves. Cool-

ant then carries this heat to the radiator, where the

tube/fin assemblies of these components can give it

up to the air.

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

protection. MopartAntifreeze or the equivalent is

recommended for best engine cooling without corro-

sion, when mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it loses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

RADIATOR

The radiators are cross-flow types (horizontal

tubes) with design features that provide greater

strength along with sufficient heat transfer capabili-

Fig. 3 Coolant Recovery System

Fig. 4 Automatic Transmission Oil Cooler

NSCOOLING SYSTEM 7 - 3

GENERAL INFORMATION (Continued)

Page 230 of 1938

at running operating temperature the high pressure

inlet tank runs full and the low pressure outlet tank

drops:

²Transmission oil will become hotter.

²High reading shown on the temperature gauge.

²Air in the coolant can cause loss of flow through

the heater.

²Exhaust gas leaks into the coolant also can

cause the same problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It then

escapes to the atmosphere in the CRS tank and is

replaced with solid coolant on cool down.

TEMPERATURE GAUGE INDICATION

At idle with Air Conditioning off the temperature

gauge will rise slowly to about 5/8 gauge travel, the

fan will come on and the gauge will quickly drop to

about 1/2 gauge travel. This is normal.

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE

Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the reserve tank (Fig. 3). The coolant level

should be between the minimum and maximum

marks.

COOLANTÐADDING ADDITIONAL

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant reserve tank.

Use only 50/50 mix of ethylene glycol type antifreeze

and water.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

COOLANT LEVEL SERVICE

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator.

When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator draincock while observing the CoolantRecovery System (CRS) Tank. Coolant level in the

CRS tank should drop slightly. Then remove the radi-

ator cap. The radiator should be full to the top. If

not, and the coolant level in the CRS tank is at the

MIN mark there is an air leak in the CRS system.

Check hose or hose connections to the CRS tank,

radiator filler neck or the pressure cap seal to the

radiator filler neck for leaks.

COOLING SYSTEMÐDRAINING

Without removing radiator pressure cap and

with system not under pressure,shut engine off

and open draincock. The coolant reserve tank should

empty first, then remove radiator pressure cap. (if

not, see Testing Cooling System for leaks). To vent

2.4L engine remove the coolant temperature sensor

located above water outlet housing (Fig. 15). The 3.0/

3.3/3.8L engines have an air bleed vent on the ther-

mostat.

Removal of a sensor is required because the ther-

mostat does not have an air vent. Sensor removal

allows an air bleed for coolant to drain from the

engine block.

COOLING SYSTEMÐREFILLING

First clean system to remove old coolant, see Cool-

ing System Cleaning.

Fill the system, using the correct antifreeze as

described in the Coolant Section. Fill the system to

50 percent of its capacity with 100 percent glycol.

Then complete filling system with water. The 2.4L

engine requires venting by removal of the coolant

sensor on top of the water outlet connector (Fig. 15).

When coolant reaches this hole:

²Install coolant sensor and tighten to 7 N´m (60

in. lbs.) for 2.4L Engines.

Fig. 15 Coolant Temperature SensorÐ2.4L Engine

Drain/Fill

7 - 16 COOLING SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 235 of 1938

INSTALLATION

(1) Place a new gasket (dipped in water) on the

thermostat housing surface, center thermostat into

opening in the intake manifold water box.

(2) Place housing and gasket over the thermostat,

making sure thermostat is in the recess provided

(Fig. 28).

(3) Bolt housing to intake manifold, tighten bolts

to 28 N´m (250 in. lbs.).

(4) Refill the cooling system to the proper level.

Refer to Cooling System Refilling outlined in this sec-

tion for procedure.

RADIATOR

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section.

(3) Remove air intake resonator.

(4) Remove coolant reserve system tank to filler

neck tube hose.

(5) Disconnect fans from the connector located on

the left side of the fan module.

(6) Remove the Coolant Recovery System (CRS)

tank retaining screw from the upper radiator closure

panel crossmember.

(7) Disconnect the upper radiator mounting

screws from the crossmember. Disconnect the engine

block heater wire if equipped.

(8) Remove the upper radiator closure panel

crossmember. Refer to Group 23 Body for procedure.

(9) Remove air cleaner assembly.

(10) Disconnect automatic transmission oil cooler

lines at radiator and plug.

(11) Disconnect inlet and outlet hoses from the

radiator. Remove the lower hose clip from the fan

module.

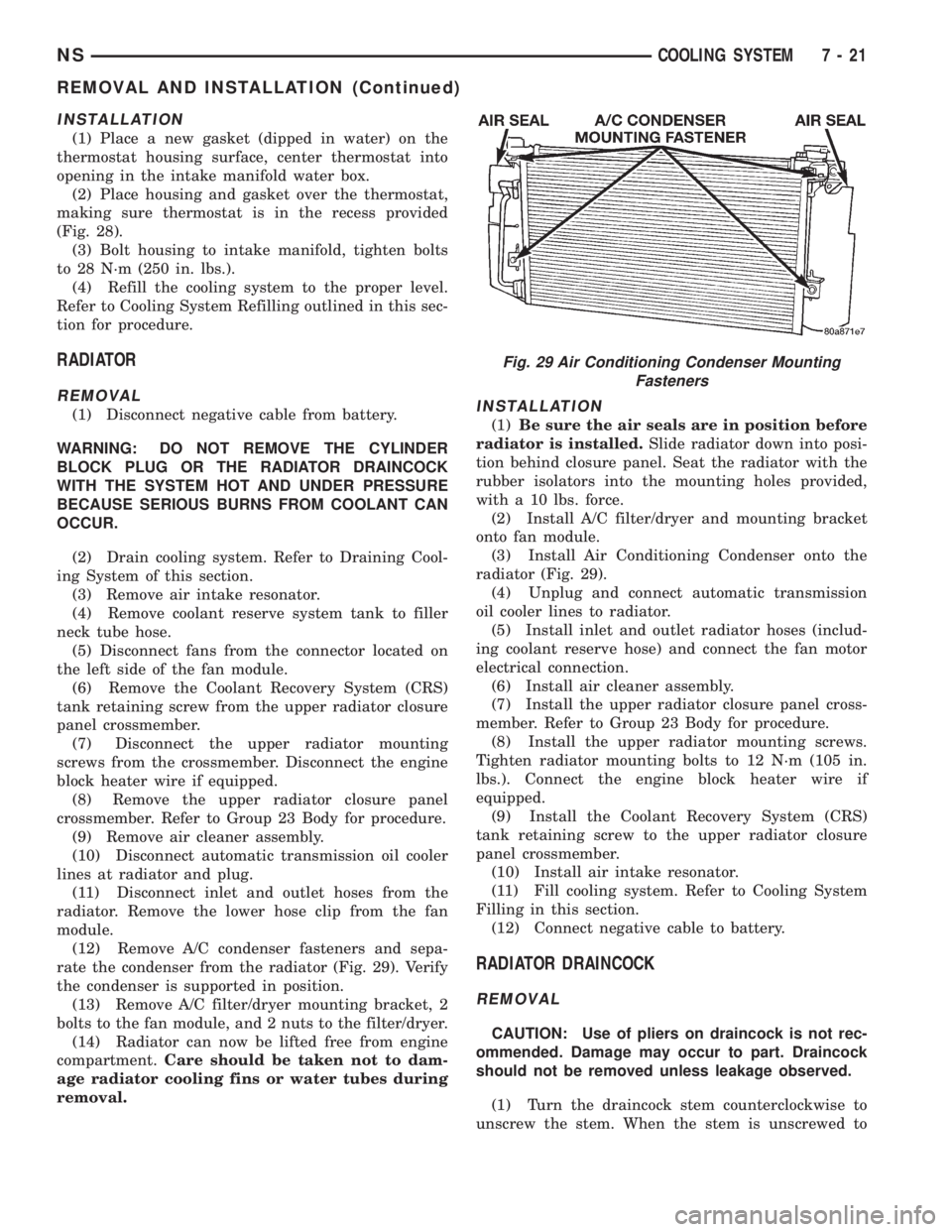

(12) Remove A/C condenser fasteners and sepa-

rate the condenser from the radiator (Fig. 29). Verify

the condenser is supported in position.

(13) Remove A/C filter/dryer mounting bracket, 2

bolts to the fan module, and 2 nuts to the filter/dryer.

(14) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.INSTALLATION

(1)Be sure the air seals are in position before

radiator is installed.Slide radiator down into posi-

tion behind closure panel. Seat the radiator with the

rubber isolators into the mounting holes provided,

with a 10 lbs. force.

(2) Install A/C filter/dryer and mounting bracket

onto fan module.

(3) Install Air Conditioning Condenser onto the

radiator (Fig. 29).

(4) Unplug and connect automatic transmission

oil cooler lines to radiator.

(5) Install inlet and outlet radiator hoses (includ-

ing coolant reserve hose) and connect the fan motor

electrical connection.

(6) Install air cleaner assembly.

(7) Install the upper radiator closure panel cross-

member. Refer to Group 23 Body for procedure.

(8) Install the upper radiator mounting screws.

Tighten radiator mounting bolts to 12 N´m (105 in.

lbs.). Connect the engine block heater wire if

equipped.

(9) Install the Coolant Recovery System (CRS)

tank retaining screw to the upper radiator closure

panel crossmember.

(10) Install air intake resonator.

(11) Fill cooling system. Refer to Cooling System

Filling in this section.

(12) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not rec-

ommended. Damage may occur to part. Draincock

should not be removed unless leakage observed.

(1) Turn the draincock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

Fig. 29 Air Conditioning Condenser Mounting

Fasteners

NSCOOLING SYSTEM 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 273 of 1938

STARTER

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT.... 1

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST.................. 1

FEED CIRCUIT RESISTANCE TEST........... 3

FEED CIRCUIT TEST...................... 4REMOVAL AND INSTALLATION

STARTERÐ2.4L ENGINE.................. 5

STARTERÐ3.0L ENGINE.................. 6

STARTERÐ3.3/3.8L ENGINE............... 6

SPECIFICATIONS

STARTER .............................. 7

TORQUE............................... 7

GENERAL INFORMATION

INTRODUCTION

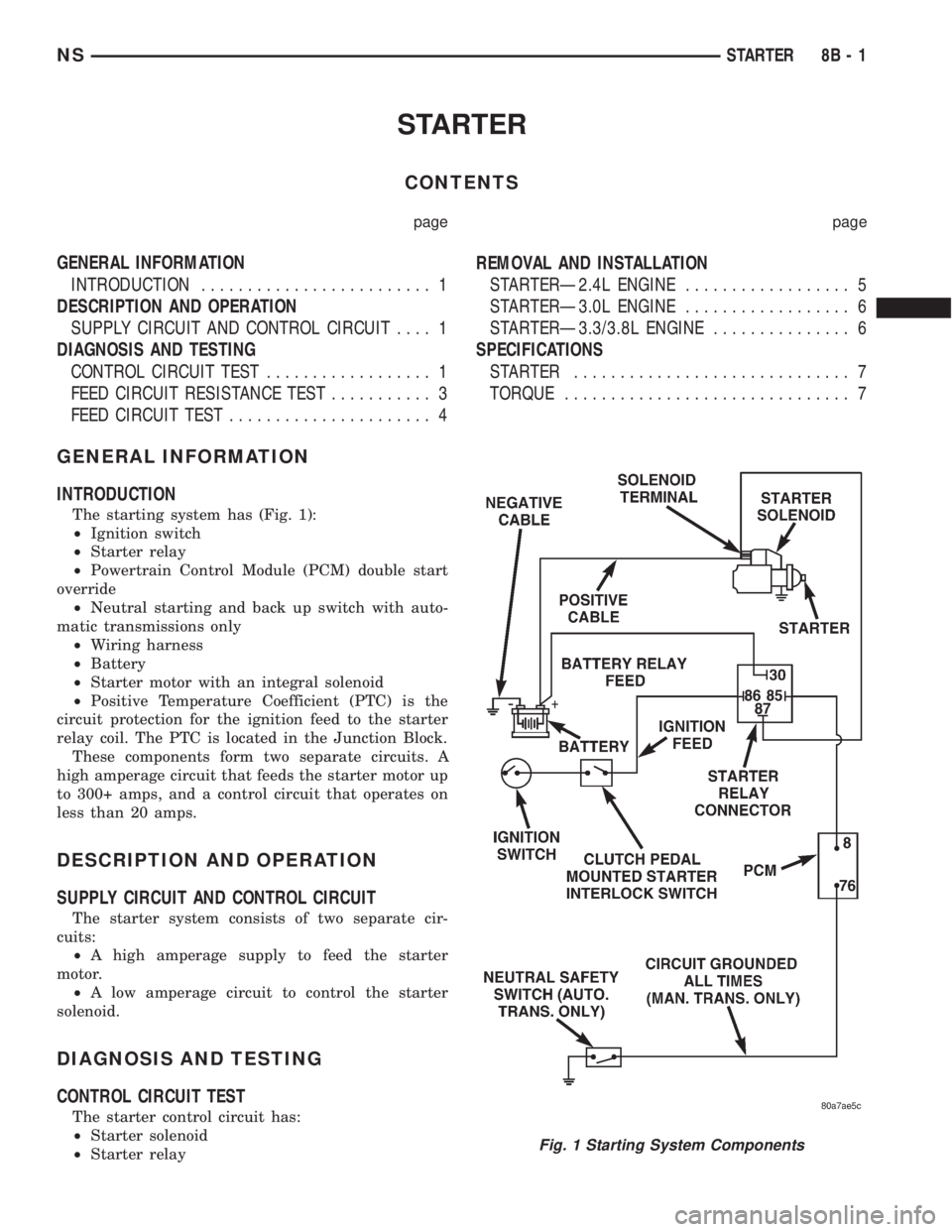

The starting system has (Fig. 1):

²Ignition switch

²Starter relay

²Powertrain Control Module (PCM) double start

override

²Neutral starting and back up switch with auto-

matic transmissions only

²Wiring harness

²Battery

²Starter motor with an integral solenoid

²Positive Temperature Coefficient (PTC) is the

circuit protection for the ignition feed to the starter

relay coil. The PTC is located in the Junction Block.

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST

The starter control circuit has:

²Starter solenoid

²Starter relay

Fig. 1 Starting System Components

NSSTARTER 8B - 1

Page 274 of 1938

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Clutch Pedal Position Switch with manual

transmissions

²Ignition switch

²Battery

²All related wiring and connections

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the in the Power Distribution Center

(PDC). Refer to the PDC cover for the proper relay

location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

(3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(5) Lower the vehicle.

(6) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(7) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not or solenoid chatters, check

wiring and connectors from starter relay to starter

solenoid for loose or corroded connections. Particu-

larly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION/NEUTRAL

WITH THE PARKING BRAKE APPLIED

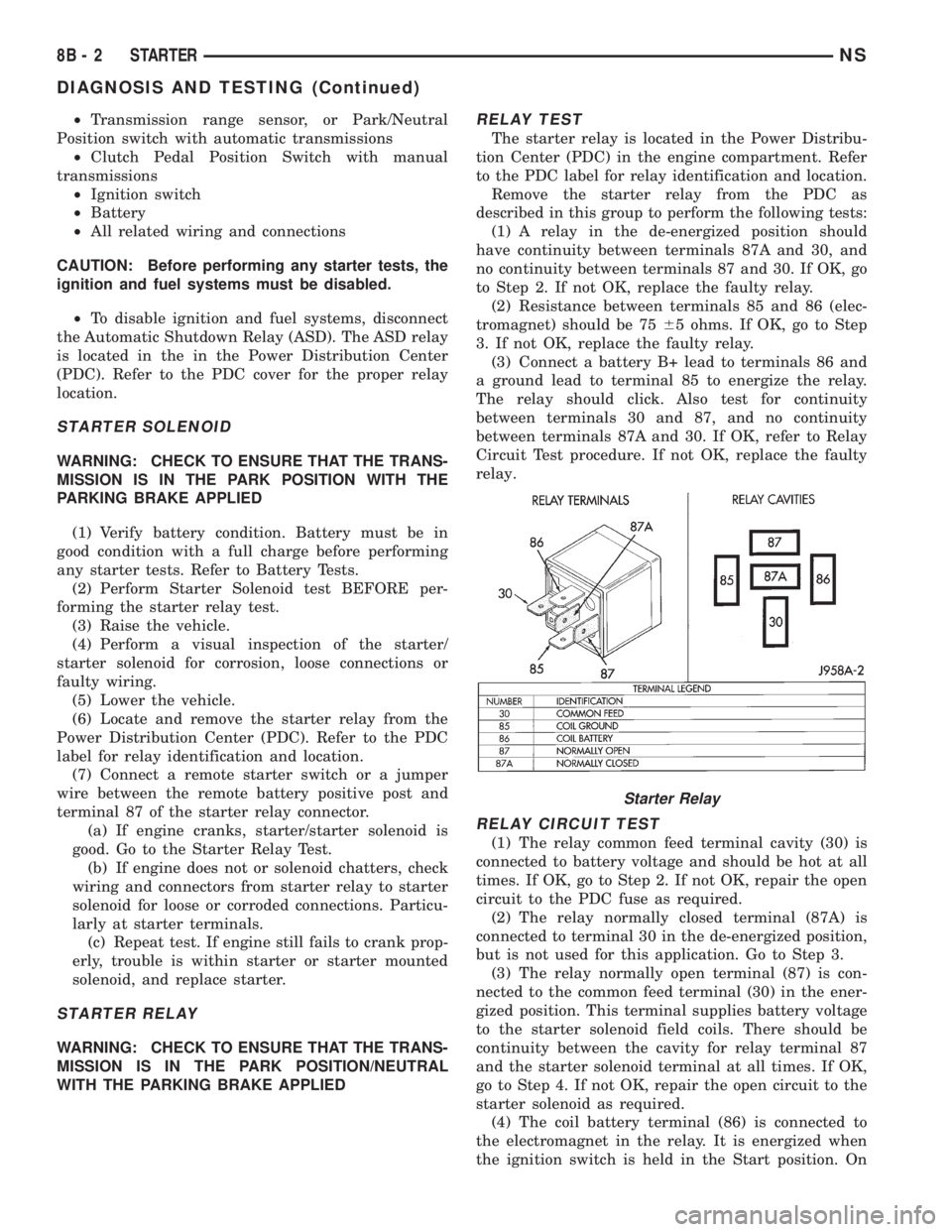

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 86 and

a ground lead to terminal 85 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position. On

Starter Relay

8B - 2 STARTERNS

DIAGNOSIS AND TESTING (Continued)

Page 275 of 1938

vehicles with a manual transmission, the clutch

pedal must be fully depressed for this test. Check for

battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position, and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short

circuit to the ignition switch and repair, if required.

If the circuit to the ignition switch is OK, see the

Ignition Switch Test procedure in this group. If not

OK with a manual transmission, check the circuit

between the relay and the clutch pedal position

switch for an open or a short. If the circuit is OK, see

the Clutch Pedal Position Switch Test procedure in

this group.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with an

automatic transmission, it is grounded through the

park/neutral position switch only when the gearshift

selector lever is in the Park or Neutral positions. On

vehicles with a manual transmission, it is grounded

at all times. Check for continuity to ground at the

cavity for relay terminal 85. If not OK with an auto-

matic transmission, check for an open or short circuit

to the park/neutral position switch and repair, if

required. If the circuit is OK, see the Park/Neutral

Position Switch Test procedure in this group. If not

OK with a manual transmission, repair the circuit to

ground as required.

SAFETY SWITCHES

For diagnostics,

²Clutch Pedal Position Switch, refer to Group 6,

Clutch.

²Park/Neutral Position Switch, refer to Group 21,

Transaxle

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to Group 8D, Ignition

Systems or Group 8W, Wiring Diagrams. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

Refer to Group 8A, Battery for proper procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Group 8W, Wiring Diagrams,

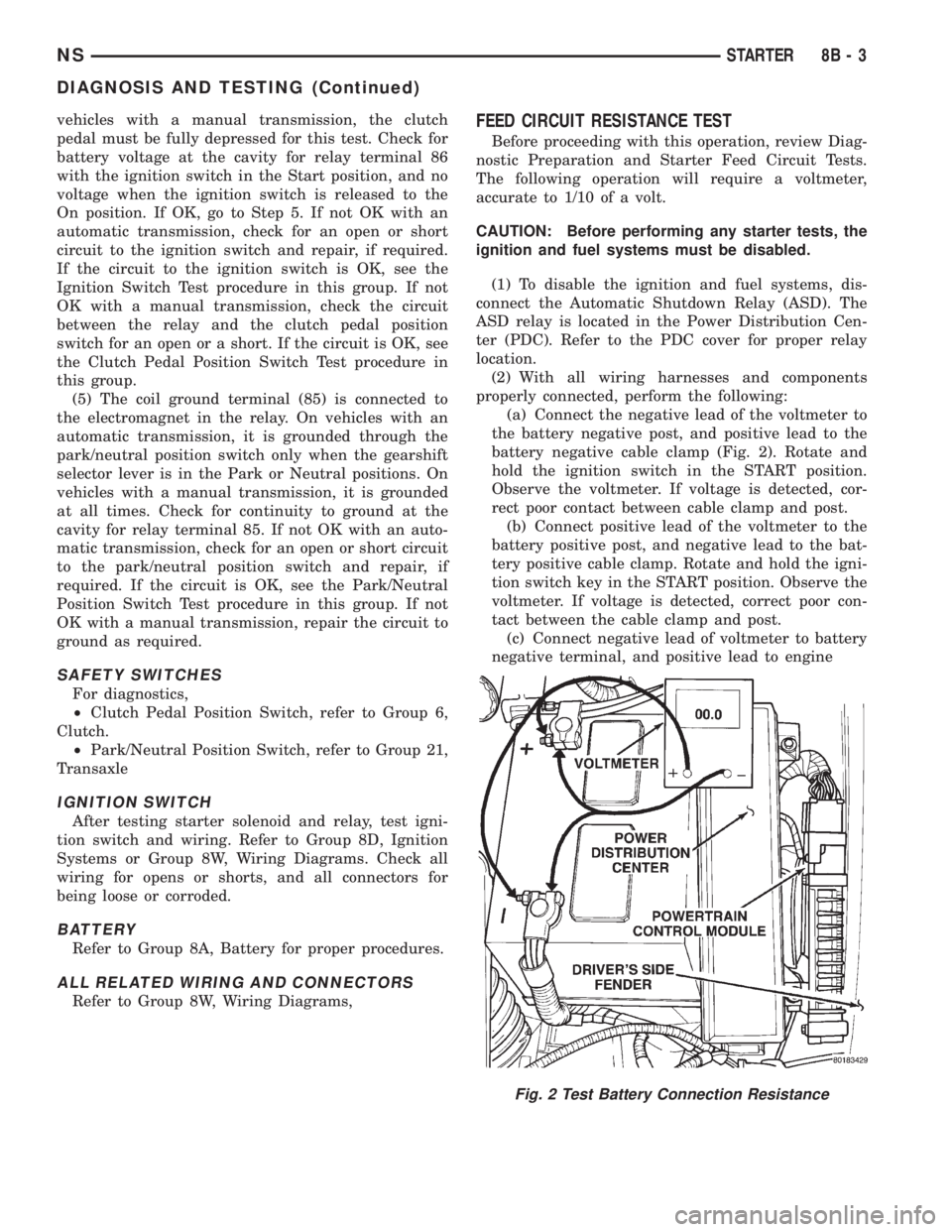

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp (Fig. 2). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

Fig. 2 Test Battery Connection Resistance

NSSTARTER 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 581 of 1938

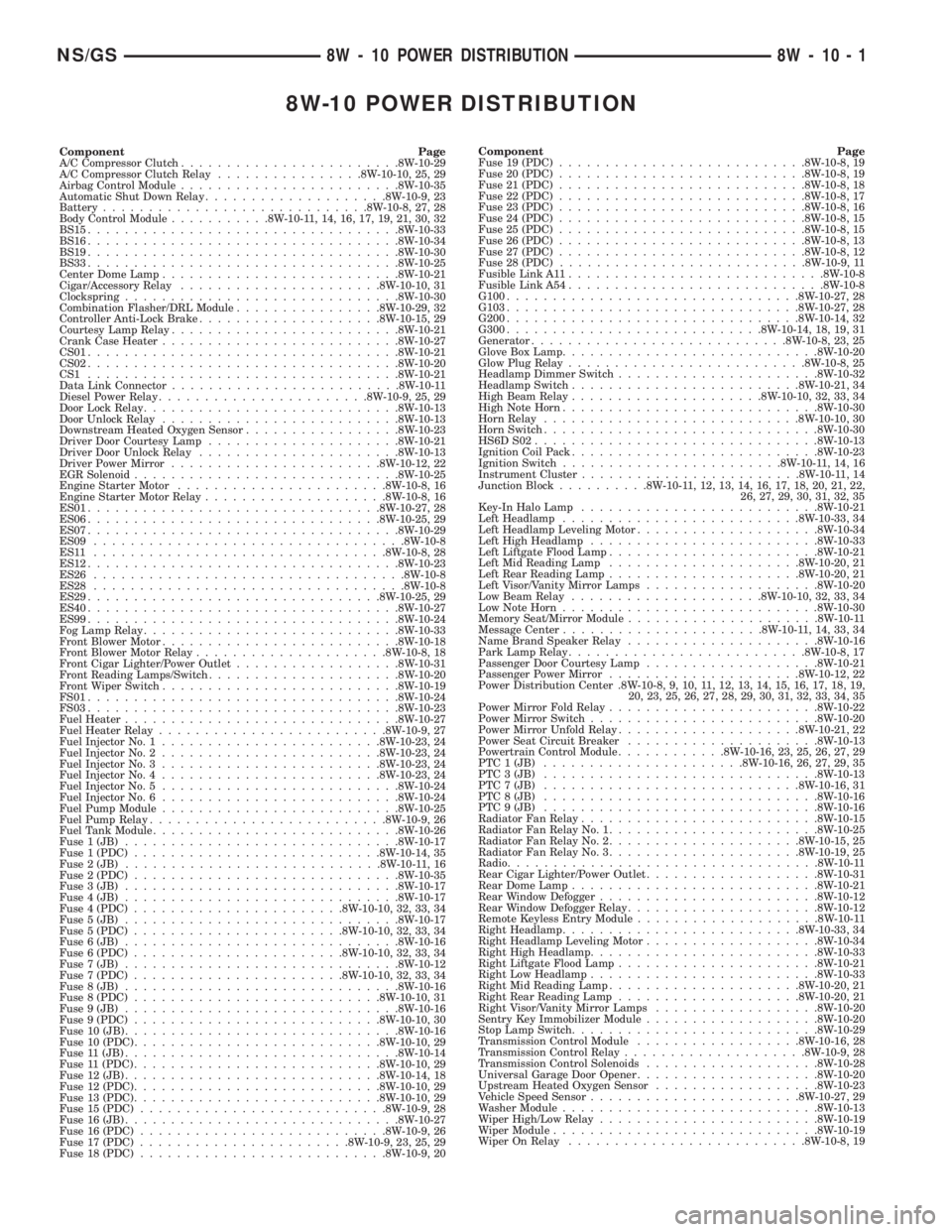

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch........................8W-10-29

A/C Compressor Clutch Relay................8W-10-10, 25, 29

Airbag Control Module........................8W-10-35

Automatic Shut Down Relay....................8W-10-9, 23

Battery.............................8W-10-8, 27, 28

Body Control Module...........8W-10-11, 14, 16, 17, 19, 21, 30, 32

BS15..................................8W-10-33

BS16..................................8W-10-34

BS19..................................8W-10-30

BS33..................................8W-10-25

Center Dome Lamp..........................8W-10-21

Cigar/Accessory Relay......................8W-10-10, 31

Clockspring..............................8W-10-30

Combination Flasher/DRL Module................8W-10-29, 32

Controller Anti-Lock Brake....................8W-10-15, 29

Courtesy Lamp Relay.........................8W-10-21

Crank Case Heater..........................8W-10-27

CS01..................................8W-10-21

CS02..................................8W-10-20

CS1 ..................................8W-10-21

Data Link Connector.........................8W-10-11

Diesel Power Relay.......................8W-10-9, 25, 29

Door Lock Relay............................8W-10-13

Door Unlock Relay..........................8W-10-13

Downstream Heated Oxygen Sensor.................8W-10-23

Driver Door Courtesy Lamp.....................8W-10-21

Driver Door Unlock Relay......................8W-10-13

Driver Power Mirror.......................8W-10-12, 22

EGR Solenoid.............................8W-10-25

Engine Starter Motor.......................8W-10-8, 16

Engine Starter Motor Relay....................8W-10-8, 16

ES01................................8W-10-27, 28

ES06................................8W-10-25, 29

ES07..................................8W-10-29

ES09..................................8W-10-8

ES11 ................................8W-10-8, 28

ES12..................................8W-10-23

ES26..................................8W-10-8

ES28..................................8W-10-8

ES29................................8W-10-25, 29

ES40..................................8W-10-27

ES99..................................8W-10-24

Fog Lamp Relay............................8W-10-33

Front Blower Motor..........................8W-10-18

Front Blower Motor Relay.....................8W-10-8, 18

Front Cigar Lighter/Power Outlet..................8W-10-31

Front Reading Lamps/Switch.....................8W-10-20

Front Wiper Switch..........................8W-10-19

FS01..................................8W-10-24

FS03..................................8W-10-23

Fuel Heater..............................8W-10-27

Fuel Heater Relay.........................8W-10-9, 27

Fuel Injector No. 1........................8W-10-23, 24

Fuel Injector No. 2........................8W-10-23, 24

Fuel Injector No. 3........................8W-10-23, 24

Fuel Injector No. 4........................8W-10-23, 24

Fuel Injector No. 5..........................8W-10-24

Fuel Injector No. 6..........................8W-10-24

Fuel Pump Module..........................8W-10-25

Fuel Pump Relay..........................8W-10-9, 26

Fuel Tank Module...........................8W-10-26

Fuse 1 (JB)..............................8W-10-17

Fuse 1 (PDC)...........................8W-10-14, 35

Fuse 2 (JB)............................8W-10-11, 16

Fuse 2 (PDC).............................8W-10-35

Fuse 3 (JB)..............................8W-10-17

Fuse 4 (JB)..............................8W-10-17

Fuse 4 (PDC).......................8W-10-10, 32, 33, 34

Fuse 5 (JB)..............................8W-10-17

Fuse 5 (PDC).......................8W-10-10, 32, 33, 34

Fuse 6 (JB)..............................8W-10-16

Fuse 6 (PDC).......................8W-10-10, 32, 33, 34

Fuse 7 (JB)..............................8W-10-12

Fuse 7 (PDC).......................8W-10-10, 32, 33, 34

Fuse 8 (JB)..............................8W-10-16

Fuse 8 (PDC)...........................8W-10-10, 31

Fuse 9 (JB)..............................8W-10-16

Fuse 9 (PDC)...........................8W-10-10, 30

Fuse 10 (JB)..............................8W-10-16

Fuse 10 (PDC)...........................8W-10-10, 29

Fuse 11 (JB)..............................8W-10-14

Fuse 11 (PDC)...........................8W-10-10, 29

Fuse 12 (JB)............................8W-10-14, 18

Fuse 12 (PDC)...........................8W-10-10, 29

Fuse 13 (PDC)...........................8W-10-10, 29

Fuse 15 (PDC)...........................8W-10-9, 28

Fuse 16 (JB)..............................8W-10-27

Fuse 16 (PDC)...........................8W-10-9, 26

Fuse 17 (PDC).......................8W-10-9, 23, 25, 29

Fuse 18 (PDC)...........................8W-10-9, 20Component Page

Fuse 19 (PDC)...........................8W-10-8, 19

Fuse 20 (PDC)...........................8W-10-8, 19

Fuse 21 (PDC)...........................8W-10-8, 18

Fuse 22 (PDC)...........................8W-10-8, 17

Fuse 23 (PDC)...........................8W-10-8, 16

Fuse 24 (PDC)...........................8W-10-8, 15

Fuse 25 (PDC)...........................8W-10-8, 15

Fuse 26 (PDC)...........................8W-10-8, 13

Fuse 27 (PDC)...........................8W-10-8, 12

Fuse 28 (PDC)...........................8W-10-9, 11

Fusible Link A11............................8W-10-8

Fusible Link A54............................8W-10-8

G100................................8W-10-27, 28

G103................................8W-10-27, 28

G200................................8W-10-14, 32

G300............................8W-10-14, 18, 19, 31

Generator............................8W-10-8, 23, 25

Glove Box Lamp............................8W-10-20

Glow Plug Relay..........................8W-10-8, 25

Headlamp Dimmer Switch......................8W-10-32

Headlamp Switch.........................8W-10-21, 34

High Beam Relay.....................8W-10-10, 32, 33, 34

High Note Horn............................8W-10-30

Horn Relay............................8W-10-10, 30

Horn Switch..............................8W-10-30

HS6D S02...............................8W-10-13

Ignition Coil Pack...........................8W-10-23

Ignition Switch........................8W-10-11, 14, 16

Instrument Cluster........................8W-10-11, 14

Junction Block..........8W-10-11, 12, 13, 14, 16, 17, 18, 20, 21, 22,

26, 27, 29, 30, 31, 32, 35

Key-In Halo Lamp..........................8W-10-21

Left Headlamp..........................8W-10-33, 34

Left Headlamp Leveling Motor....................8W-10-34

Left High Headlamp.........................8W-10-33

Left Liftgate Flood Lamp.......................8W-10-21

Left Mid Reading Lamp.....................8W-10-20, 21

Left Rear Reading Lamp.....................8W-10-20, 21

Left Visor/Vanity Mirror Lamps...................8W-10-20

Low Beam Relay.....................8W-10-10, 32, 33, 34

Low Note Horn............................8W-10-30

Memory Seat/Mirror Module.....................8W-10-11

Message Center......................8W-10-11, 14, 33, 34

Name Brand Speaker Relay.....................8W-10-16

Park Lamp Relay..........................8W-10-8, 17

Passenger Door Courtesy Lamp...................8W-10-21

Passenger Power Mirror.....................8W-10-12, 22

Power Distribution Center .8W-10-8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19,

20, 23, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35

Power Mirror Fold Relay.......................8W-10-22

Power Mirror Switch.........................8W-10-20

Power Mirror Unfold Relay....................8W-10-21, 22

Power Seat Circuit Breaker.....................8W-10-13

Powertrain Control Module............8W-10-16, 23, 25, 26, 27, 29

PTC 1 (JB)......................8W-10-16, 26, 27, 29, 35

PTC 3 (JB)..............................8W-10-13

PTC 7 (JB)............................8W-10-16, 31

PTC 8 (JB)..............................8W-10-16

PTC 9 (JB)..............................8W-10-16

Radiator Fan Relay..........................8W-10-15

Radiator Fan Relay No. 1.......................8W-10-25

Radiator Fan Relay No. 2.....................8W-10-15, 25

Radiator Fan Relay No. 3.....................8W-10-19, 25

Radio..................................8W-10-11

Rear Cigar Lighter/Power Outlet...................8W-10-31

Rear Dome Lamp...........................8W-10-21

Rear Window Defogger........................8W-10-12

Rear Window Defogger Relay.....................8W-10-12

Remote Keyless Entry Module....................8W-10-11

Right Headlamp..........................8W-10-33, 34

Right Headlamp Leveling Motor...................8W-10-34

Right High Headlamp.........................8W-10-33

Right Liftgate Flood Lamp......................8W-10-21

Right Low Headlamp.........................8W-10-33

Right Mid Reading Lamp.....................8W-10-20, 21

Right Rear Reading Lamp....................8W-10-20, 21

Right Visor/Vanity Mirror Lamps..................8W-10-20

Sentry Key Immobilizer Module...................8W-10-20

Stop Lamp Switch...........................8W-10-29

Transmission Control Module..................8W-10-16, 28

Transmission Control Relay....................8W-10-9, 28

Transmission Control Solenoids...................8W-10-28

Universal Garage Door Opener....................8W-10-20

Upstream Heated Oxygen Sensor..................8W-10-23

Vehicle Speed Sensor.......................8W-10-27, 29

Washer Module............................8W-10-13

Wiper High/Low Relay........................8W-10-19

Wiper Module.............................8W-10-19

Wiper On Relay..........................8W-10-8, 19

NS/GS8W - 10 POWER DISTRIBUTION 8W - 10 - 1

Page 665 of 1938

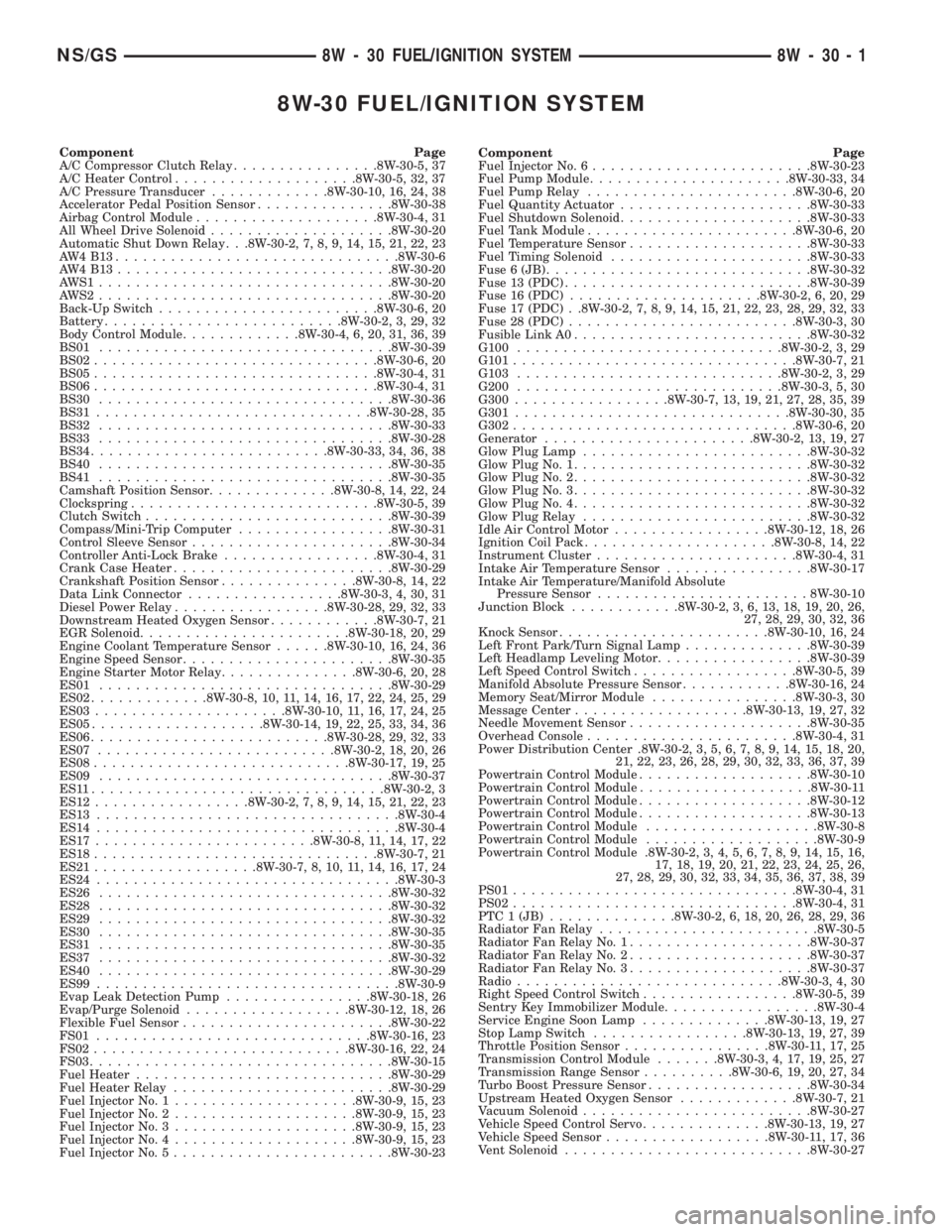

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay................8W-30-5, 37

A/C Heater Control....................8W-30-5, 32, 37

A/C Pressure Transducer.............8W-30-10, 16, 24, 38

Accelerator Pedal Position Sensor...............8W-30-38

Airbag Control Module....................8W-30-4, 31

All Wheel Drive Solenoid....................8W-30-20

Automatic Shut Down Relay . . .8W-30-2, 7, 8, 9, 14, 15, 21, 22, 23

AW4B13...............................8W-30-6

AW4B13..............................8W-30-20

AWS1................................8W-30-20

AWS2................................8W-30-20

Back-Up Switch........................8W-30-6, 20

Battery..........................8W-30-2, 3, 29, 32

Body Control Module.............8W-30-4, 6, 20, 31, 36, 39

BS01................................8W-30-39

BS02...............................8W-30-6, 20

BS05...............................8W-30-4, 31

BS06...............................8W-30-4, 31

BS30................................8W-30-36

BS31..............................8W-30-28, 35

BS32................................8W-30-33

BS33................................8W-30-28

BS34..........................8W-30-33, 34, 36, 38

BS40................................8W-30-35

BS41................................8W-30-35

Camshaft Position Sensor..............8W-30-8, 14, 22, 24

Clockspring...........................8W-30-5, 39

Clutch Switch...........................8W-30-39

Compass/Mini-Trip Computer.................8W-30-31

Control Sleeve Sensor......................8W-30-34

Controller Anti-Lock Brake.................8W-30-4, 31

Crank Case Heater........................8W-30-29

Crankshaft Position Sensor...............8W-30-8, 14, 22

Data Link Connector.................8W-30-3, 4, 30, 31

Diesel Power Relay.................8W-30-28, 29, 32, 33

Downstream Heated Oxygen Sensor............8W-30-7, 21

EGR Solenoid.......................8W-30-18, 20, 29

Engine Coolant Temperature Sensor......8W-30-10, 16, 24, 36

Engine Speed Sensor.......................8W-30-35

Engine Starter Motor Relay...............8W-30-6, 20, 28

ES01................................8W-30-29

ES02.............8W-30-8, 10, 11, 14, 16, 17, 22, 24, 25, 29

ES03.....................8W-30-10, 11, 16, 17, 24, 25

ES05...................8W-30-14, 19, 22, 25, 33, 34, 36

ES06..........................8W-30-28, 29, 32, 33

ES07..........................8W-30-2, 18, 20, 26

ES08............................8W-30-17, 19, 25

ES09................................8W-30-37

ES11................................8W-30-2, 3

ES12.................8W-30-2, 7, 8, 9, 14, 15, 21, 22, 23

ES13.................................8W-30-4

ES14.................................8W-30-4

ES17........................8W-30-8, 11, 14, 17, 22

ES18...............................8W-30-7, 21

ES21..................8W-30-7, 8, 10, 11, 14, 16, 17, 24

ES24.................................8W-30-3

ES26................................8W-30-32

ES28................................8W-30-32

ES29................................8W-30-32

ES30................................8W-30-35

ES31................................8W-30-35

ES37................................8W-30-32

ES40................................8W-30-29

ES99.................................8W-30-9

Evap Leak Detection Pump................8W-30-18, 26

Evap/Purge Solenoid..................8W-30-12, 18, 26

Flexible Fuel Sensor.......................8W-30-22

FS01..............................8W-30-16, 23

FS02............................8W-30-16, 22, 24

FS03.................................8W-30-15

Fuel Heater............................8W-30-29

Fuel Heater Relay........................8W-30-29

Fuel Injector No. 1....................8W-30-9, 15, 23

Fuel Injector No. 2....................8W-30-9, 15, 23

Fuel Injector No. 3....................8W-30-9, 15, 23

Fuel Injector No. 4....................8W-30-9, 15, 23

Fuel Injector No. 5........................8W-30-23Component Page

Fuel Injector No. 6........................8W-30-23

Fuel Pump Module......................8W-30-33, 34

Fuel Pump Relay.......................8W-30-6, 20

Fuel Quantity Actuator.....................8W-30-33

Fuel Shutdown Solenoid.....................8W-30-33

Fuel Tank Module.......................8W-30-6, 20

Fuel Temperature Sensor....................8W-30-33

Fuel Timing Solenoid......................8W-30-33

Fuse 6 (JB).............................8W-30-32

Fuse 13 (PDC)...........................8W-30-39

Fuse 16 (PDC).....................8W-30-2, 6, 20, 29

Fuse 17 (PDC) . .8W-30-2, 7, 8, 9, 14, 15, 21, 22, 23, 28, 29, 32, 33

Fuse 28 (PDC).........................8W-30-3, 30

Fusible Link A0..........................8W-30-32

G100.............................8W-30-2, 3, 29

G101...............................8W-30-7, 21

G103.............................8W-30-2, 3, 29

G200.............................8W-30-3, 5, 30

G300.................8W-30-7, 13, 19, 21, 27, 28, 35, 39

G301..............................8W-30-30, 35

G302...............................8W-30-6, 20

Generator.......................8W-30-2, 13, 19, 27

Glow Plug Lamp.........................8W-30-32

Glow Plug No. 1..........................8W-30-32

Glow Plug No. 2..........................8W-30-32

Glow Plug No. 3..........................8W-30-32

Glow Plug No. 4..........................8W-30-32

Glow Plug Relay.........................8W-30-32

Idle Air Control Motor.................8W-30-12, 18, 26

Ignition Coil Pack.....................8W-30-8, 14, 22

Instrument Cluster......................8W-30-4, 31

Intake Air Temperature Sensor................8W-30-17

Intake Air Temperature/Manifold Absolute

Pressure Sensor.......................8W-30-10

Junction Block............8W-30-2, 3, 6, 13, 18, 19, 20, 26,

27, 28, 29, 30, 32, 36

Knock Sensor.......................8W-30-10, 16, 24

Left Front Park/Turn Signal Lamp..............8W-30-39

Left Headlamp Leveling Motor.................8W-30-39

Left Speed Control Switch..................8W-30-5, 39

Manifold Absolute Pressure Sensor............8W-30-16, 24

Memory Seat/Mirror Module................8W-30-3, 30

Message Center...................8W-30-13, 19, 27, 32

Needle Movement Sensor....................8W-30-35

Overhead Console.......................8W-30-4, 31

Power Distribution Center .8W-30-2, 3, 5, 6, 7, 8, 9, 14, 15, 18, 20,

21, 22, 23, 26, 28, 29, 30, 32, 33, 36, 37, 39

Powertrain Control Module...................8W-30-10

Powertrain Control Module...................8W-30-11

Powertrain Control Module...................8W-30-12

Powertrain Control Module...................8W-30-13

Powertrain Control Module...................8W-30-8

Powertrain Control Module...................8W-30-9

Powertrain Control Module .8W-30-2, 3, 4, 5, 6, 7, 8, 9, 14, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25, 26,

27, 28, 29, 30, 32, 33, 34, 35, 36, 37, 38, 39

PS01...............................8W-30-4, 31

PS02...............................8W-30-4, 31

PTC 1 (JB)..............8W-30-2, 6, 18, 20, 26, 28, 29, 36

Radiator Fan Relay........................8W-30-5

Radiator Fan Relay No. 1....................8W-30-37

Radiator Fan Relay No. 2....................8W-30-37

Radiator Fan Relay No. 3....................8W-30-37

Radio.............................8W-30-3, 4, 30

Right Speed Control Switch.................8W-30-5, 39

Sentry Key Immobilizer Module.................8W-30-4

Service Engine Soon Lamp..............8W-30-13, 19, 27

Stop Lamp Switch.................8W-30-13, 19, 27, 39

Throttle Position Sensor................8W-30-11, 17, 25

Transmission Control Module.......8W-30-3, 4, 17, 19, 25, 27

Transmission Range Sensor..........8W-30-6, 19, 20, 27, 34

Turbo Boost Pressure Sensor..................8W-30-34

Upstream Heated Oxygen Sensor.............8W-30-7, 21

Vacuum Solenoid.........................8W-30-27

Vehicle Speed Control Servo..............8W-30-13, 19, 27

Vehicle Speed Sensor..................8W-30-11, 17, 36

Vent Solenoid...........................8W-30-27

NS/GS8W - 30 FUEL/IGNITION SYSTEM 8W - 30 - 1