wheel torque CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 59 of 1938

INSTALL

CAUTION: Hub and bearing assembly mounting

surfaces on the steering knuckle and halfshaft (Fig.

60) must be smooth and completely free of foreign

material or nicks prior to installing hub and bearing

assembly.

CAUTION: When installing hub and bearing

assembly into steering knuckle, be careful not to

damage the bearing seal (Fig. 60) on the outer C/V

joint.

(1) Install hub/bearing assembly onto stub axle

and into steering knuckle until squarely seated on

the face of the steering knuckle.

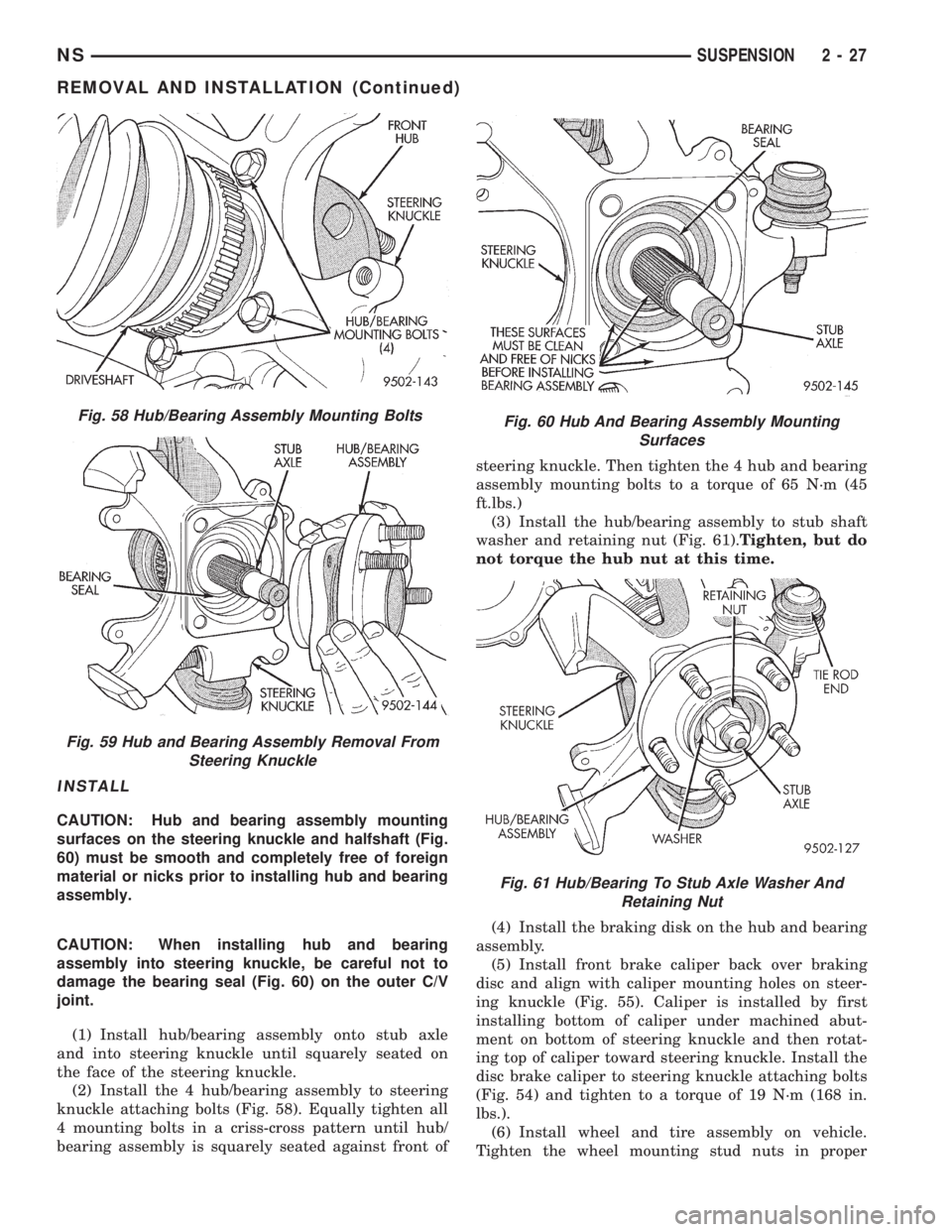

(2) Install the 4 hub/bearing assembly to steering

knuckle attaching bolts (Fig. 58). Equally tighten all

4 mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front ofsteering knuckle. Then tighten the 4 hub and bearing

assembly mounting bolts to a torque of 65 N´m (45

ft.lbs.)

(3) Install the hub/bearing assembly to stub shaft

washer and retaining nut (Fig. 61).Tighten, but do

not torque the hub nut at this time.

(4) Install the braking disk on the hub and bearing

assembly.

(5) Install front brake caliper back over braking

disc and align with caliper mounting holes on steer-

ing knuckle (Fig. 55). Caliper is installed by first

installing bottom of caliper under machined abut-

ment on bottom of steering knuckle and then rotat-

ing top of caliper toward steering knuckle. Install the

disc brake caliper to steering knuckle attaching bolts

(Fig. 54) and tighten to a torque of 19 N´m (168 in.

lbs.).

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

Fig. 58 Hub/Bearing Assembly Mounting Bolts

Fig. 59 Hub and Bearing Assembly Removal From

Steering Knuckle

Fig. 60 Hub And Bearing Assembly Mounting

Surfaces

Fig. 61 Hub/Bearing To Stub Axle Washer And

Retaining Nut

NSSUSPENSION 2 - 27

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1938

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(7) Lower vehicle to the ground.

CAUTION: When tightening hub/bearing assembly

to stub shaft retaining nut, do not exceed the max-

imum torque of 244 N´m (180 ft. lbs.).

(8) With vehicle brakes applied to keep vehicle

from moving, torque stub shaft to hub/bearing assem-

bly retaining nut to 244 N´m (180 ft. lbs.).

(9) Check the Toe setting on the vehicle and reset

if not within specifications.

FRONT WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature bearing failure.

The following procedure and special tools shown

MUST BEused when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire assembly from

the vehicle.

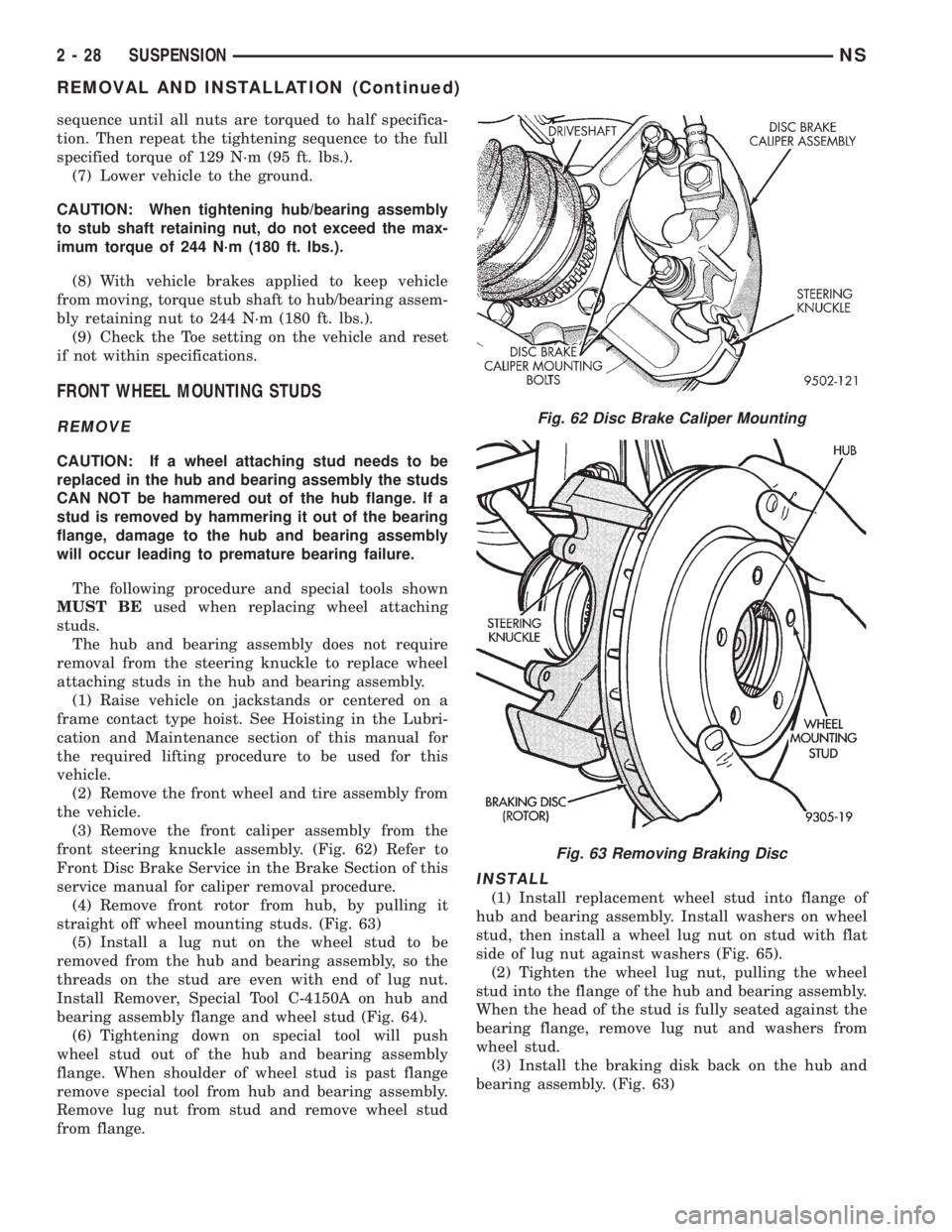

(3) Remove the front caliper assembly from the

front steering knuckle assembly. (Fig. 62) Refer to

Front Disc Brake Service in the Brake Section of this

service manual for caliper removal procedure.

(4) Remove front rotor from hub, by pulling it

straight off wheel mounting studs. (Fig. 63)

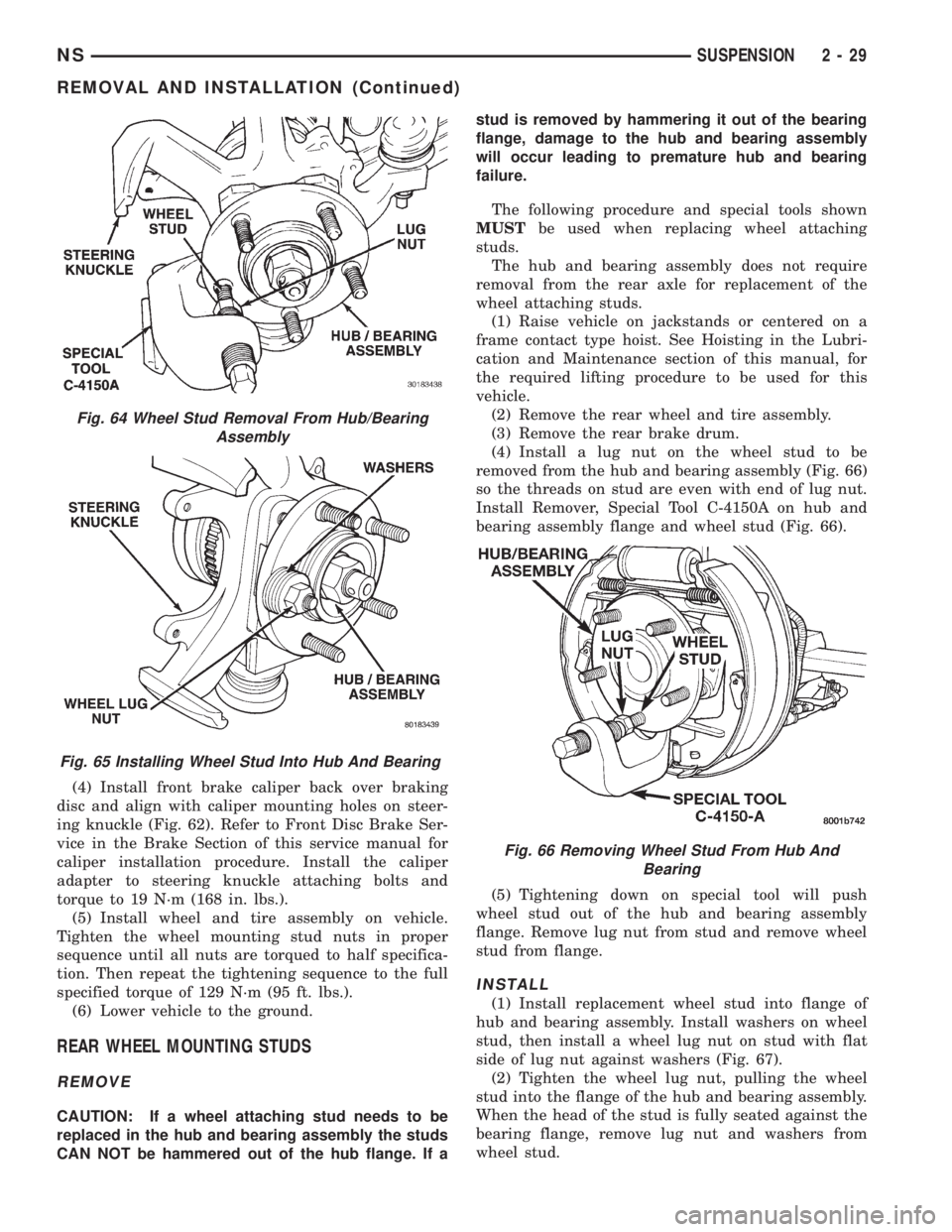

(5) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly, so the

threads on the stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 64).

(6) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. When shoulder of wheel stud is past flange

remove special tool from hub and bearing assembly.

Remove lug nut from stud and remove wheel stud

from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 65).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the braking disk back on the hub and

bearing assembly. (Fig. 63)

Fig. 62 Disc Brake Caliper Mounting

Fig. 63 Removing Braking Disc

2 - 28 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 61 of 1938

(4) Install front brake caliper back over braking

disc and align with caliper mounting holes on steer-

ing knuckle (Fig. 62). Refer to Front Disc Brake Ser-

vice in the Brake Section of this service manual for

caliper installation procedure. Install the caliper

adapter to steering knuckle attaching bolts and

torque to 19 N´m (168 in. lbs.).

(5) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(6) Lower vehicle to the ground.

REAR WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If astud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

The following procedure and special tools shown

MUSTbe used when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the rear axle for replacement of the

wheel attaching studs.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly.

(3) Remove the rear brake drum.

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 66)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 66).

(5) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. Remove lug nut from stud and remove wheel

stud from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 67).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

Fig. 64 Wheel Stud Removal From Hub/Bearing

Assembly

Fig. 65 Installing Wheel Stud Into Hub And Bearing

Fig. 66 Removing Wheel Stud From Hub And

Bearing

NSSUSPENSION 2 - 29

REMOVAL AND INSTALLATION (Continued)

Page 62 of 1938

(3) Install the rear brake drum on the hub and

bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(5) Lower vehicle to the ground.

DISASSEMBLY AND ASSEMBLY

Mc PHERSON STRUT

DISASSEMBLY

The Mc Pherson Strut must be remove from the

vehicle for it to be disassembled and assembled.

Refer to Mc Pherson Strut in the Removal And

Installation Section in this group of the service man-

ual for the required procedure to remove and install

the Mc Pherson Strut.

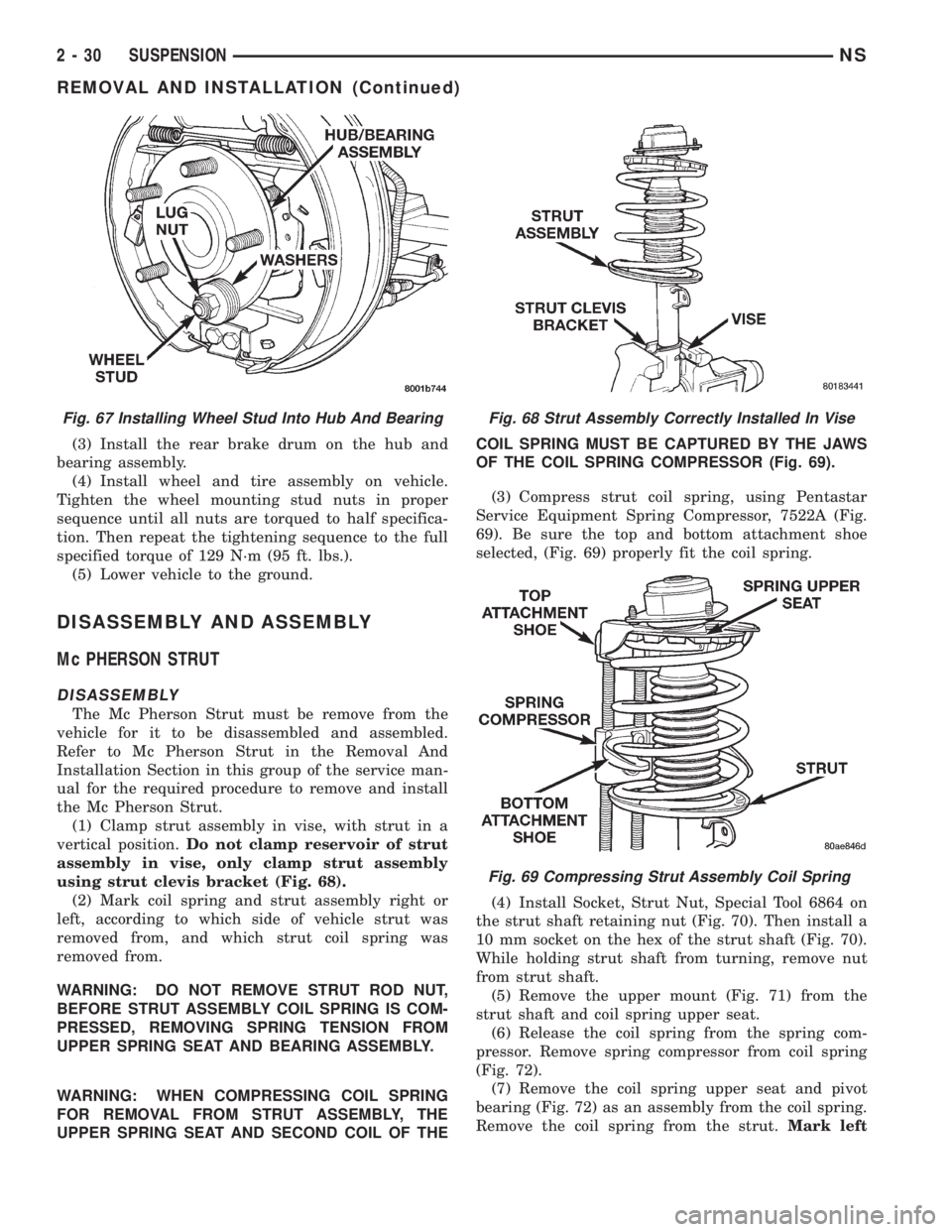

(1) Clamp strut assembly in vise, with strut in a

vertical position.Do not clamp reservoir of strut

assembly in vise, only clamp strut assembly

using strut clevis bracket (Fig. 68).

(2) Mark coil spring and strut assembly right or

left, according to which side of vehicle strut was

removed from, and which strut coil spring was

removed from.

WARNING: DO NOT REMOVE STRUT ROD NUT,

BEFORE STRUT ASSEMBLY COIL SPRING IS COM-

PRESSED, REMOVING SPRING TENSION FROM

UPPER SPRING SEAT AND BEARING ASSEMBLY.

WARNING: WHEN COMPRESSING COIL SPRING

FOR REMOVAL FROM STRUT ASSEMBLY, THE

UPPER SPRING SEAT AND SECOND COIL OF THECOIL SPRING MUST BE CAPTURED BY THE JAWS

OF THE COIL SPRING COMPRESSOR (Fig. 69).

(3) Compress strut coil spring, using Pentastar

Service Equipment Spring Compressor, 7522A (Fig.

69). Be sure the top and bottom attachment shoe

selected, (Fig. 69) properly fit the coil spring.

(4) Install Socket, Strut Nut, Special Tool 6864 on

the strut shaft retaining nut (Fig. 70). Then install a

10 mm socket on the hex of the strut shaft (Fig. 70).

While holding strut shaft from turning, remove nut

from strut shaft.

(5) Remove the upper mount (Fig. 71) from the

strut shaft and coil spring upper seat.

(6) Release the coil spring from the spring com-

pressor. Remove spring compressor from coil spring

(Fig. 72).

(7) Remove the coil spring upper seat and pivot

bearing (Fig. 72) as an assembly from the coil spring.

Remove the coil spring from the strut.Mark left

Fig. 67 Installing Wheel Stud Into Hub And BearingFig. 68 Strut Assembly Correctly Installed In Vise

Fig. 69 Compressing Strut Assembly Coil Spring

2 - 30 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 68 of 1938

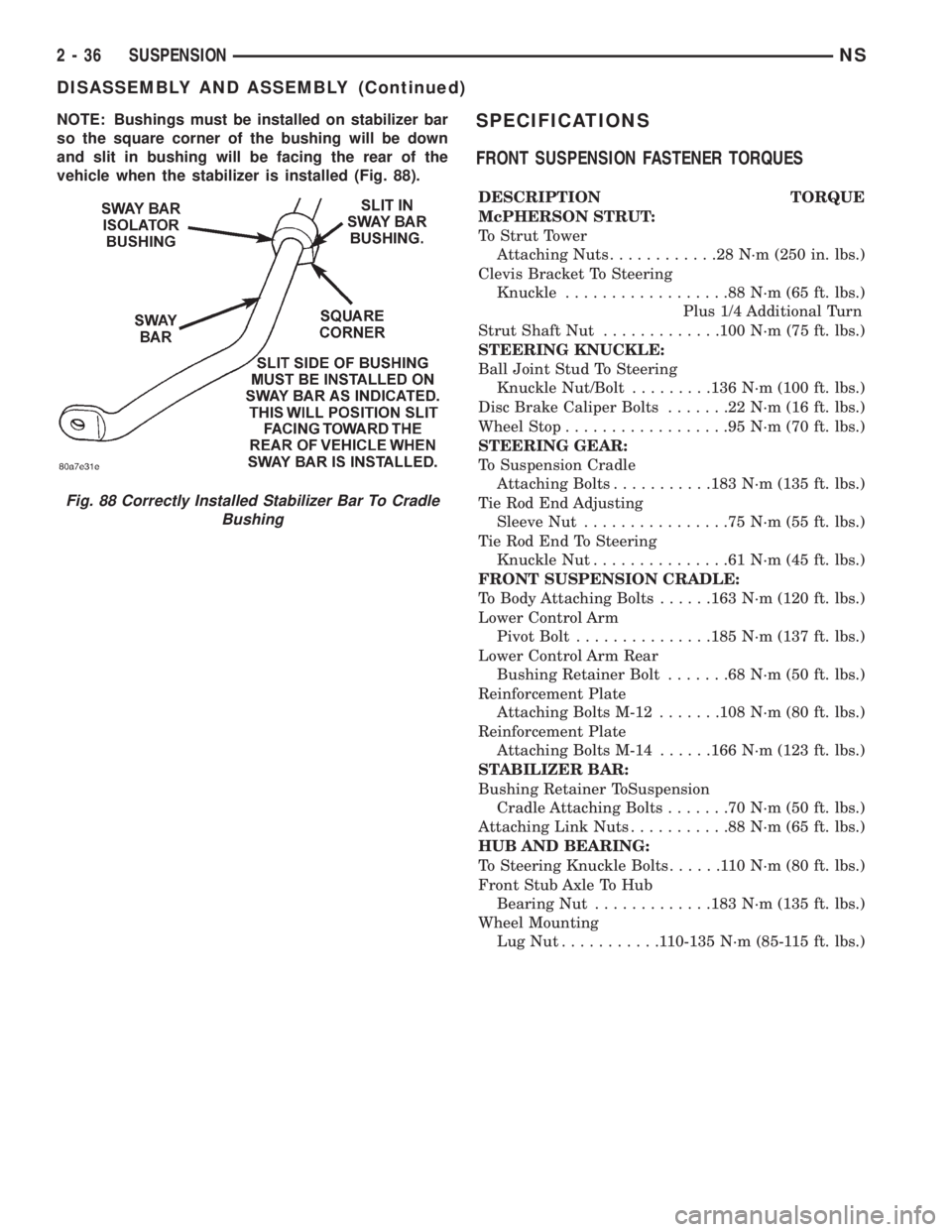

NOTE: Bushings must be installed on stabilizer bar

so the square corner of the bushing will be down

and slit in bushing will be facing the rear of the

vehicle when the stabilizer is installed (Fig. 88).SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUES

DESCRIPTION TORQUE

McPHERSON STRUT:

To Strut Tower

Attaching Nuts............28N´m(250 in. lbs.)

Clevis Bracket To Steering

Knuckle..................88N´m(65ft.lbs.)

Plus 1/4 Additional Turn

Strut Shaft Nut.............100 N´m (75 ft. lbs.)

STEERING KNUCKLE:

Ball Joint Stud To Steering

Knuckle Nut/Bolt.........136 N´m (100 ft. lbs.)

Disc Brake Caliper Bolts.......22N´m(16ft.lbs.)

Wheel Stop..................95N´m(70ft.lbs.)

STEERING GEAR:

To Suspension Cradle

Attaching Bolts...........183 N´m (135 ft. lbs.)

Tie Rod End Adjusting

Sleeve Nut................75N´m(55ft.lbs.)

Tie Rod End To Steering

Knuckle Nut...............61N´m(45ft.lbs.)

FRONT SUSPENSION CRADLE:

To Body Attaching Bolts......163 N´m (120 ft. lbs.)

Lower Control Arm

Pivot Bolt...............185 N´m (137 ft. lbs.)

Lower Control Arm Rear

Bushing Retainer Bolt.......68N´m(50ft.lbs.)

Reinforcement Plate

Attaching Bolts M-12.......108 N´m (80 ft. lbs.)

Reinforcement Plate

Attaching Bolts M-14......166 N´m (123 ft. lbs.)

STABILIZER BAR:

Bushing Retainer ToSuspension

Cradle Attaching Bolts.......70N´m(50ft.lbs.)

Attaching Link Nuts...........88N´m(65ft.lbs.)

HUB AND BEARING:

To Steering Knuckle Bolts......110N´m(80ft.lbs.)

Front Stub Axle To Hub

Bearing Nut.............183 N´m (135 ft. lbs.)

Wheel Mounting

LugNut...........110-135 N´m (85-115 ft. lbs.)

Fig. 88 Correctly Installed Stabilizer Bar To Cradle

Bushing

2 - 36 SUSPENSIONNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 70 of 1938

REAR SUSPENSION

INDEX

page page

GENERAL INFORMATION

REAR SUSPENSION..................... 38

DESCRIPTION AND OPERATION

REAR TRACK BAR....................... 39

REAR WHEEL ALIGNMENT................ 39

SHOCK ABSORBERS (REAR LOAD LEVELING) . 40

STABILIZER BAR........................ 39

REMOVAL AND INSTALLATION

JOUNCE BUMPER....................... 46

LEAF SPRING FRONT MOUNT............. 47LEAF SPRING REAR MOUNT.............. 47

REAR SPRINGS (AWD)................... 43

REAR SPRINGS (FWD)................... 40

REAR TRACK BAR....................... 45

SHOCK ABSORBER...................... 45

STABILIZER BAR........................ 46

TRACK BAR MOUNT..................... 45

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUES . . . 48

GENERAL INFORMATION

REAR SUSPENSION

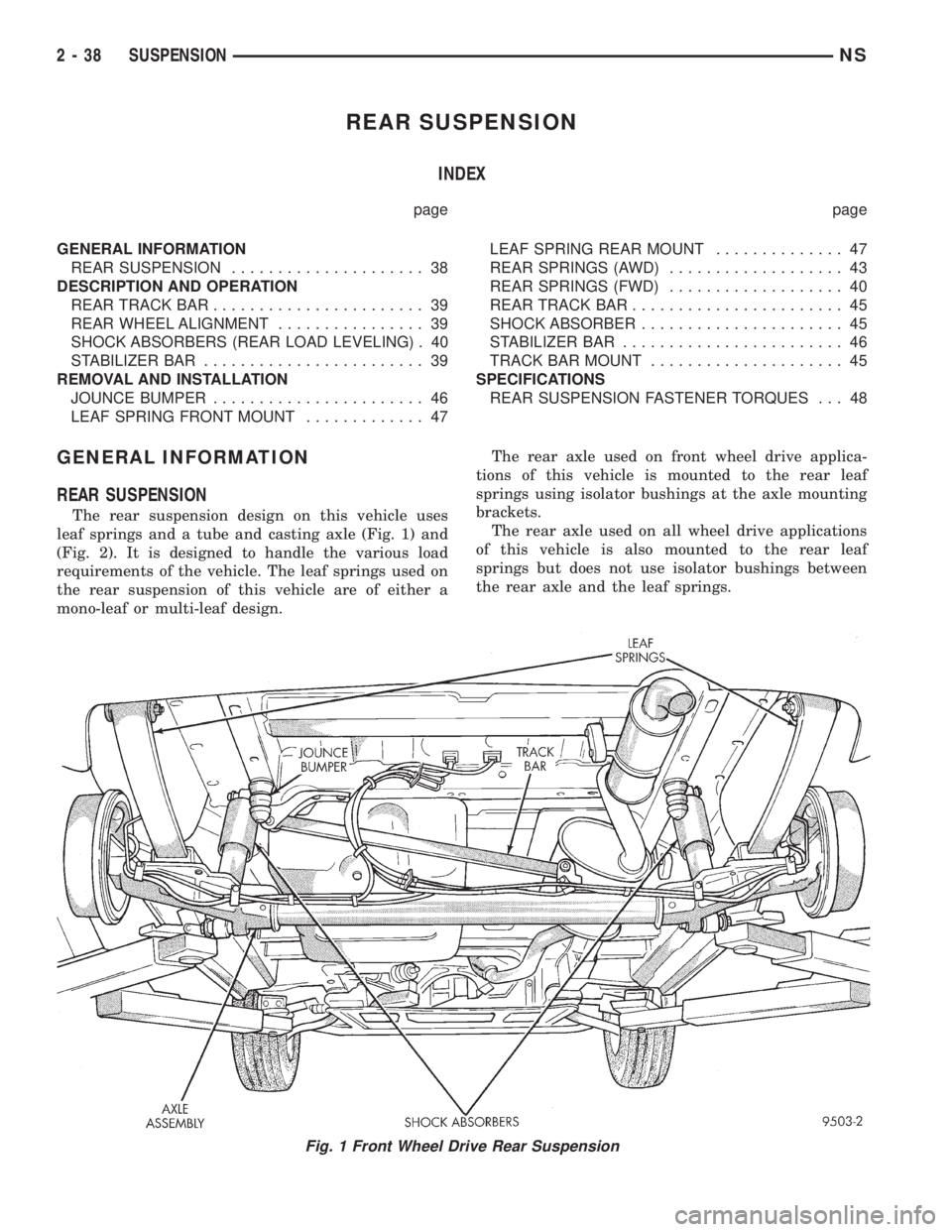

The rear suspension design on this vehicle uses

leaf springs and a tube and casting axle (Fig. 1) and

(Fig. 2). It is designed to handle the various load

requirements of the vehicle. The leaf springs used on

the rear suspension of this vehicle are of either a

mono-leaf or multi-leaf design.The rear axle used on front wheel drive applica-

tions of this vehicle is mounted to the rear leaf

springs using isolator bushings at the axle mounting

brackets.

The rear axle used on all wheel drive applications

of this vehicle is also mounted to the rear leaf

springs but does not use isolator bushings between

the rear axle and the leaf springs.

Fig. 1 Front Wheel Drive Rear Suspension

2 - 38 SUSPENSIONNS

Page 76 of 1938

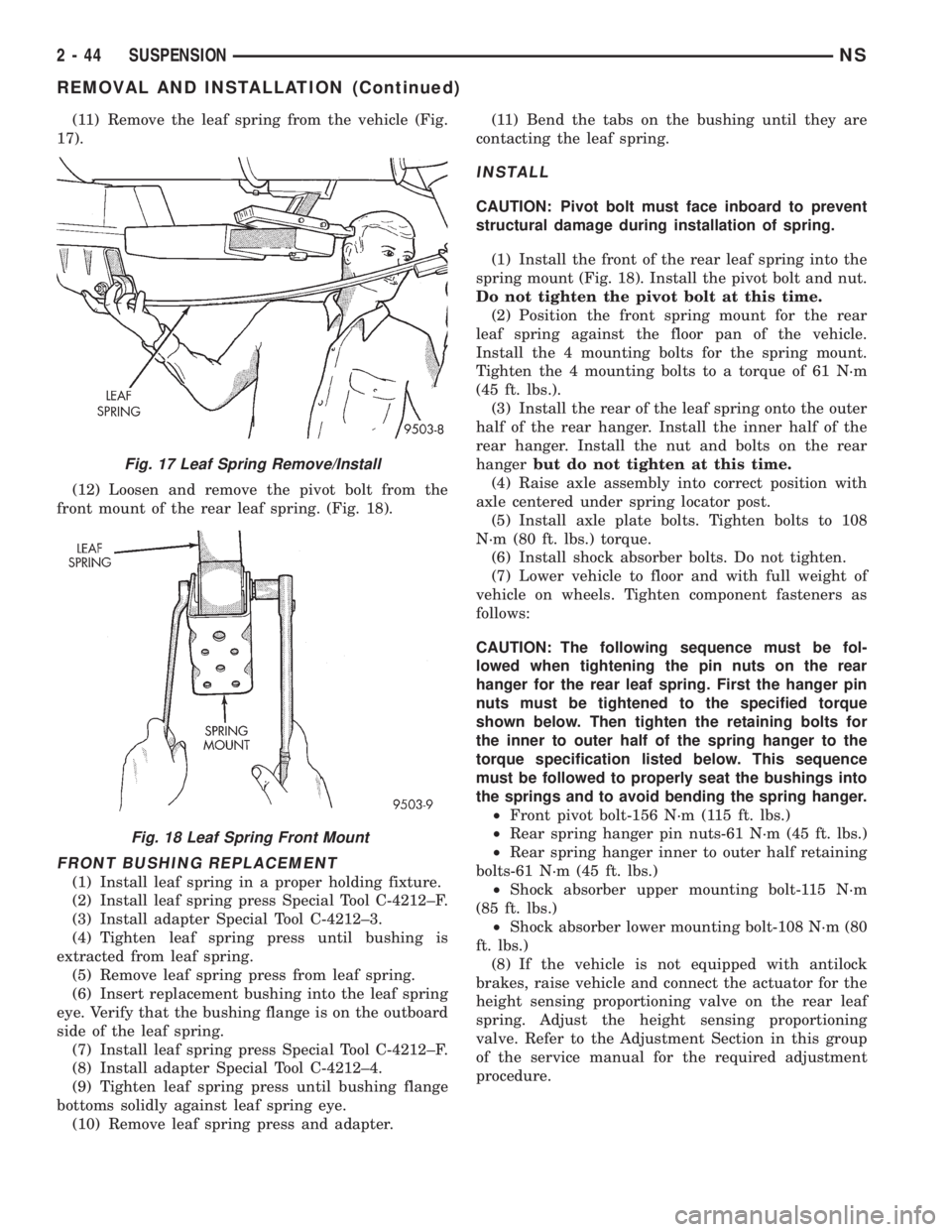

(11) Remove the leaf spring from the vehicle (Fig.

17).

(12) Loosen and remove the pivot bolt from the

front mount of the rear leaf spring. (Fig. 18).

FRONT BUSHING REPLACEMENT

(1) Install leaf spring in a proper holding fixture.

(2) Install leaf spring press Special Tool C-4212±F.

(3) Install adapter Special Tool C-4212±3.

(4) Tighten leaf spring press until bushing is

extracted from leaf spring.

(5) Remove leaf spring press from leaf spring.

(6) Insert replacement bushing into the leaf spring

eye. Verify that the bushing flange is on the outboard

side of the leaf spring.

(7) Install leaf spring press Special Tool C-4212±F.

(8) Install adapter Special Tool C-4212±4.

(9) Tighten leaf spring press until bushing flange

bottoms solidly against leaf spring eye.

(10) Remove leaf spring press and adapter.(11) Bend the tabs on the bushing until they are

contacting the leaf spring.

INSTALL

CAUTION: Pivot bolt must face inboard to prevent

structural damage during installation of spring.

(1) Install the front of the rear leaf spring into the

spring mount (Fig. 18). Install the pivot bolt and nut.

Do not tighten the pivot bolt at this time.

(2) Position the front spring mount for the rear

leaf spring against the floor pan of the vehicle.

Install the 4 mounting bolts for the spring mount.

Tighten the 4 mounting bolts to a torque of 61 N´m

(45 ft. lbs.).

(3) Install the rear of the leaf spring onto the outer

half of the rear hanger. Install the inner half of the

rear hanger. Install the nut and bolts on the rear

hangerbut do not tighten at this time.

(4) Raise axle assembly into correct position with

axle centered under spring locator post.

(5) Install axle plate bolts. Tighten bolts to 108

N´m (80 ft. lbs.) torque.

(6) Install shock absorber bolts. Do not tighten.

(7) Lower vehicle to floor and with full weight of

vehicle on wheels. Tighten component fasteners as

follows:

CAUTION: The following sequence must be fol-

lowed when tightening the pin nuts on the rear

hanger for the rear leaf spring. First the hanger pin

nuts must be tightened to the specified torque

shown below. Then tighten the retaining bolts for

the inner to outer half of the spring hanger to the

torque specification listed below. This sequence

must be followed to properly seat the bushings into

the springs and to avoid bending the spring hanger.

²Front pivot bolt-156 N´m (115 ft. lbs.)

²Rear spring hanger pin nuts-61 N´m (45 ft. lbs.)

²Rear spring hanger inner to outer half retaining

bolts-61 N´m (45 ft. lbs.)

²Shock absorber upper mounting bolt-115 N´m

(85 ft. lbs.)

²Shock absorber lower mounting bolt-108 N´m (80

ft. lbs.)

(8) If the vehicle is not equipped with antilock

brakes, raise vehicle and connect the actuator for the

height sensing proportioning valve on the rear leaf

spring. Adjust the height sensing proportioning

valve. Refer to the Adjustment Section in this group

of the service manual for the required adjustment

procedure.

Fig. 17 Leaf Spring Remove/Install

Fig. 18 Leaf Spring Front Mount

2 - 44 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 77 of 1938

SHOCK ABSORBER

REMOVE/INSTALL

(1) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

hoist. See Hoisting in the Lubrication And Mainte-

nance section of this service manual.

(2) Support the rear axle of the vehicle using 2

jackstands positioned at the outer ends of the axle.

NOTE: If the shock absorber lower mounting bolt

deflects upward during removal, raise axle by

adjusting the support jack. If the lower shock

absorber bolt deflects downward during removal,

lower the axle by adjusting the support jack.

(3) Remove the shock absorber lower mounting

bolt.

(4) While holding shock absorber, remove the

shock absorber upper mounting bolt.

(5) To install the shock absorber use the reverse

sequence of its removal.

(6) Lower the vehicle to the ground so the full

weight of the vehicle is supported by the suspension.

(7) Tighten the upper and lower shock absorber

mounting bolt to their specified torques.

REAR TRACK BAR

REMOVE

(1) Remove the nut and bolt mounting the track

bar to the rear axle (Fig. 19).

(2) Remove the nut and bolt attaching the track

bar to the track bar mount on the body of the vehicle.

Remove the track bar from the track bar mount.

INSTALL

(1) Install the track bar first into the body mount

for the track bar (Fig. 20). Install the track bar boltwith the head of the bolt facing toward the rear of

the vehicle (Fig. 21). Do not tighten.

(2) Install the track bar into its mounting bracket

on the rear axle (Fig. 19). Install the track bar bolt

with the head of the bolt facing toward the rear of

the vehicle. Do not tighten.

(3) Lower the vehicle to the ground until the full

weight of the vehicle is supported by the wheels.

Tighten both track bar attaching bolts to a torque of

95 N´m (70 ft. lbs.).

TRACK BAR MOUNT

REMOVE

(1) Remove the track bar from the track bar

mount.

(2) Remove the three bolts attaching the track bar

mount to the body (Fig. 22).

Fig. 19 Track Bar Mounting To Axle

Fig. 20 Track Bar Installation

Fig. 21 Track Bar Bolt Installation

NSSUSPENSION 2 - 45

REMOVAL AND INSTALLATION (Continued)

Page 79 of 1938

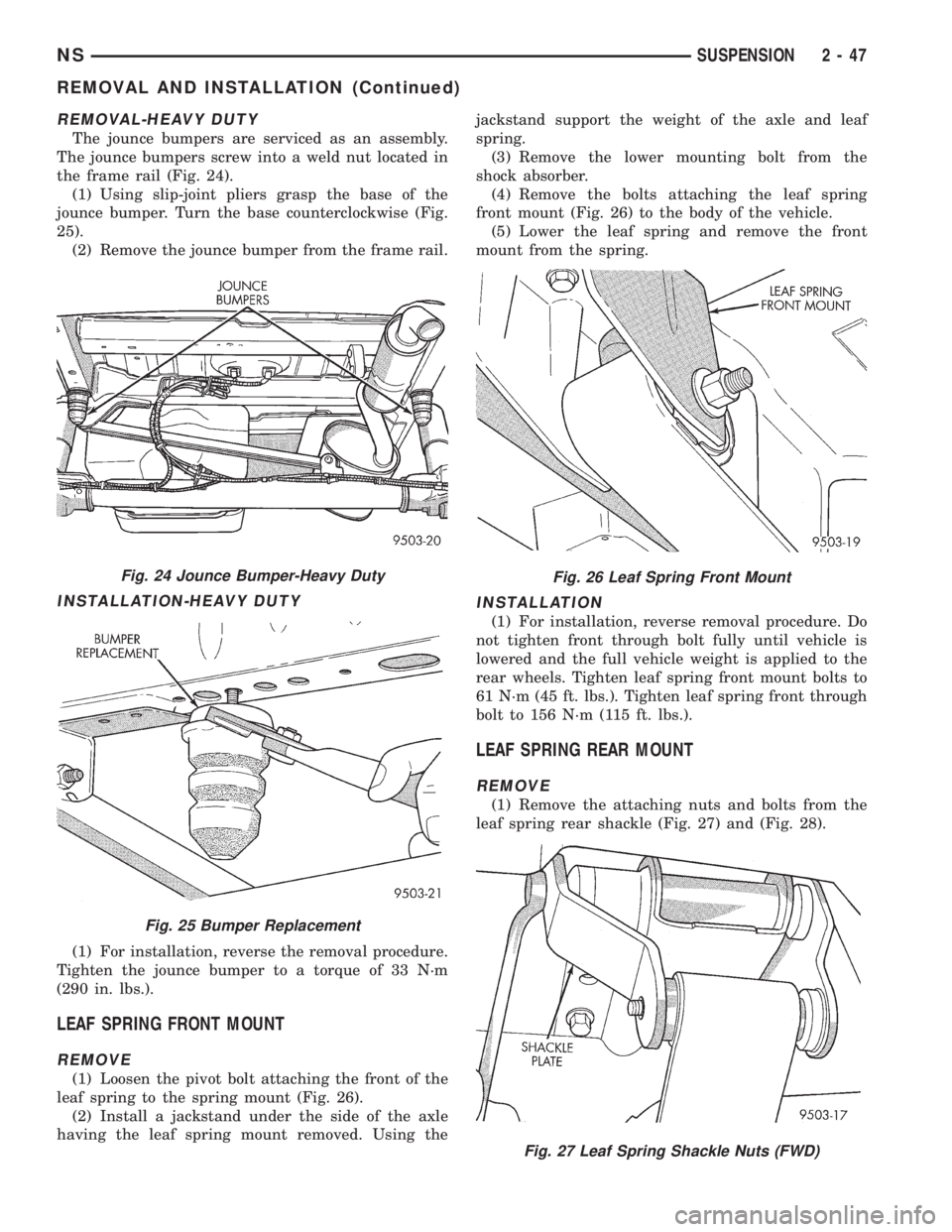

REMOVAL-HEAVY DUTY

The jounce bumpers are serviced as an assembly.

The jounce bumpers screw into a weld nut located in

the frame rail (Fig. 24).

(1) Using slip-joint pliers grasp the base of the

jounce bumper. Turn the base counterclockwise (Fig.

25).

(2) Remove the jounce bumper from the frame rail.

INSTALLATION-HEAVY DUTY

(1) For installation, reverse the removal procedure.

Tighten the jounce bumper to a torque of 33 N´m

(290 in. lbs.).

LEAF SPRING FRONT MOUNT

REMOVE

(1) Loosen the pivot bolt attaching the front of the

leaf spring to the spring mount (Fig. 26).

(2) Install a jackstand under the side of the axle

having the leaf spring mount removed. Using thejackstand support the weight of the axle and leaf

spring.

(3) Remove the lower mounting bolt from the

shock absorber.

(4) Remove the bolts attaching the leaf spring

front mount (Fig. 26) to the body of the vehicle.

(5) Lower the leaf spring and remove the front

mount from the spring.

INSTALLATION

(1) For installation, reverse removal procedure. Do

not tighten front through bolt fully until vehicle is

lowered and the full vehicle weight is applied to the

rear wheels. Tighten leaf spring front mount bolts to

61 N´m (45 ft. lbs.). Tighten leaf spring front through

bolt to 156 N´m (115 ft. lbs.).

LEAF SPRING REAR MOUNT

REMOVE

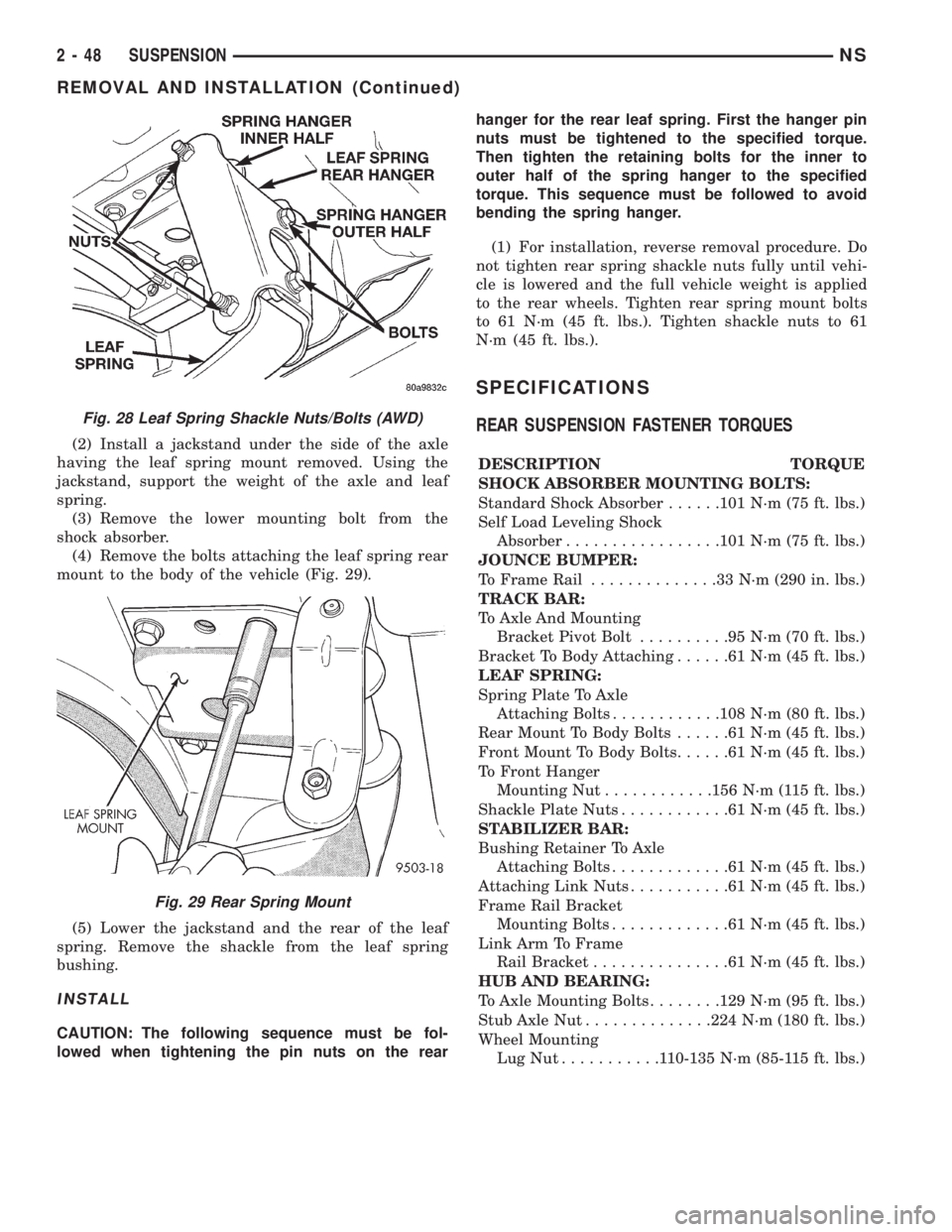

(1) Remove the attaching nuts and bolts from the

leaf spring rear shackle (Fig. 27) and (Fig. 28).

Fig. 24 Jounce Bumper-Heavy Duty

Fig. 25 Bumper Replacement

Fig. 26 Leaf Spring Front Mount

Fig. 27 Leaf Spring Shackle Nuts (FWD)

NSSUSPENSION 2 - 47

REMOVAL AND INSTALLATION (Continued)

Page 80 of 1938

(2) Install a jackstand under the side of the axle

having the leaf spring mount removed. Using the

jackstand, support the weight of the axle and leaf

spring.

(3) Remove the lower mounting bolt from the

shock absorber.

(4) Remove the bolts attaching the leaf spring rear

mount to the body of the vehicle (Fig. 29).

(5) Lower the jackstand and the rear of the leaf

spring. Remove the shackle from the leaf spring

bushing.

INSTALL

CAUTION: The following sequence must be fol-

lowed when tightening the pin nuts on the rearhanger for the rear leaf spring. First the hanger pin

nuts must be tightened to the specified torque.

Then tighten the retaining bolts for the inner to

outer half of the spring hanger to the specified

torque. This sequence must be followed to avoid

bending the spring hanger.

(1) For installation, reverse removal procedure. Do

not tighten rear spring shackle nuts fully until vehi-

cle is lowered and the full vehicle weight is applied

to the rear wheels. Tighten rear spring mount bolts

to 61 N´m (45 ft. lbs.). Tighten shackle nuts to 61

N´m (45 ft. lbs.).

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUES

DESCRIPTION TORQUE

SHOCK ABSORBER MOUNTING BOLTS:

Standard Shock Absorber......101 N´m (75 ft. lbs.)

Self Load Leveling Shock

Absorber.................101 N´m (75 ft. lbs.)

JOUNCE BUMPER:

To Frame Rail..............33N´m(290 in. lbs.)

TRACK BAR:

To Axle And Mounting

Bracket Pivot Bolt..........95N´m(70ft.lbs.)

Bracket To Body Attaching......61N´m(45ft.lbs.)

LEAF SPRING:

Spring Plate To Axle

Attaching Bolts............108 N´m (80 ft. lbs.)

Rear Mount To Body Bolts......61N´m(45ft.lbs.)

Front Mount To Body Bolts......61N´m(45ft.lbs.)

To Front Hanger

Mounting Nut............156 N´m (115 ft. lbs.)

Shackle Plate Nuts............61N´m(45ft.lbs.)

STABILIZER BAR:

Bushing Retainer To Axle

Attaching Bolts.............61N´m(45ft.lbs.)

Attaching Link Nuts...........61N´m(45ft.lbs.)

Frame Rail Bracket

Mounting Bolts.............61N´m(45ft.lbs.)

Link Arm To Frame

Rail Bracket...............61N´m(45ft.lbs.)

HUB AND BEARING:

To Axle Mounting Bolts........129 N´m (95 ft. lbs.)

Stub Axle Nut..............224 N´m (180 ft. lbs.)

Wheel Mounting

LugNut...........110-135 N´m (85-115 ft. lbs.)

Fig. 28 Leaf Spring Shackle Nuts/Bolts (AWD)

Fig. 29 Rear Spring Mount

2 - 48 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)