coolant CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 235 of 1938

INSTALLATION

(1) Place a new gasket (dipped in water) on the

thermostat housing surface, center thermostat into

opening in the intake manifold water box.

(2) Place housing and gasket over the thermostat,

making sure thermostat is in the recess provided

(Fig. 28).

(3) Bolt housing to intake manifold, tighten bolts

to 28 N´m (250 in. lbs.).

(4) Refill the cooling system to the proper level.

Refer to Cooling System Refilling outlined in this sec-

tion for procedure.

RADIATOR

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section.

(3) Remove air intake resonator.

(4) Remove coolant reserve system tank to filler

neck tube hose.

(5) Disconnect fans from the connector located on

the left side of the fan module.

(6) Remove the Coolant Recovery System (CRS)

tank retaining screw from the upper radiator closure

panel crossmember.

(7) Disconnect the upper radiator mounting

screws from the crossmember. Disconnect the engine

block heater wire if equipped.

(8) Remove the upper radiator closure panel

crossmember. Refer to Group 23 Body for procedure.

(9) Remove air cleaner assembly.

(10) Disconnect automatic transmission oil cooler

lines at radiator and plug.

(11) Disconnect inlet and outlet hoses from the

radiator. Remove the lower hose clip from the fan

module.

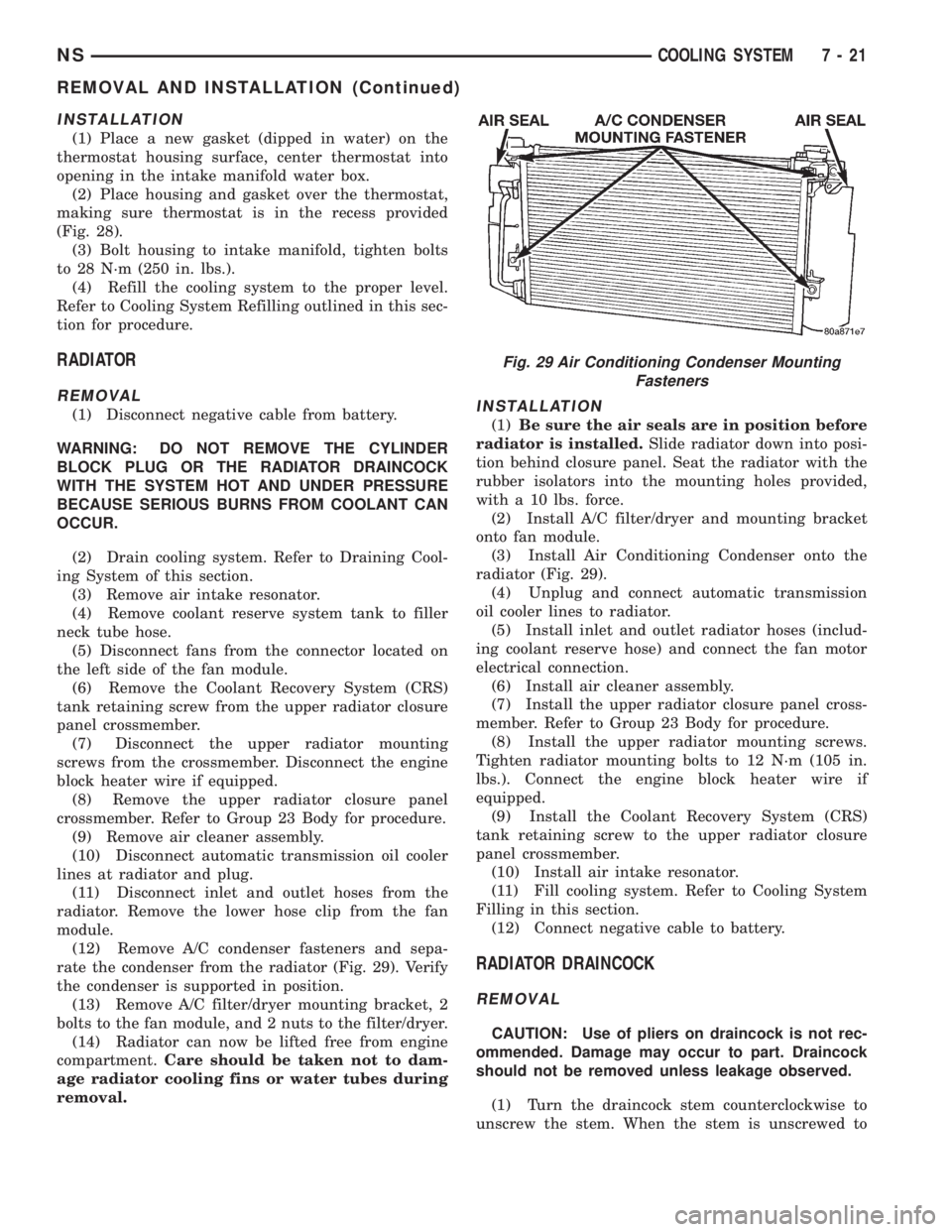

(12) Remove A/C condenser fasteners and sepa-

rate the condenser from the radiator (Fig. 29). Verify

the condenser is supported in position.

(13) Remove A/C filter/dryer mounting bracket, 2

bolts to the fan module, and 2 nuts to the filter/dryer.

(14) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.INSTALLATION

(1)Be sure the air seals are in position before

radiator is installed.Slide radiator down into posi-

tion behind closure panel. Seat the radiator with the

rubber isolators into the mounting holes provided,

with a 10 lbs. force.

(2) Install A/C filter/dryer and mounting bracket

onto fan module.

(3) Install Air Conditioning Condenser onto the

radiator (Fig. 29).

(4) Unplug and connect automatic transmission

oil cooler lines to radiator.

(5) Install inlet and outlet radiator hoses (includ-

ing coolant reserve hose) and connect the fan motor

electrical connection.

(6) Install air cleaner assembly.

(7) Install the upper radiator closure panel cross-

member. Refer to Group 23 Body for procedure.

(8) Install the upper radiator mounting screws.

Tighten radiator mounting bolts to 12 N´m (105 in.

lbs.). Connect the engine block heater wire if

equipped.

(9) Install the Coolant Recovery System (CRS)

tank retaining screw to the upper radiator closure

panel crossmember.

(10) Install air intake resonator.

(11) Fill cooling system. Refer to Cooling System

Filling in this section.

(12) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not rec-

ommended. Damage may occur to part. Draincock

should not be removed unless leakage observed.

(1) Turn the draincock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

Fig. 29 Air Conditioning Condenser Mounting

Fasteners

NSCOOLING SYSTEM 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 236 of 1938

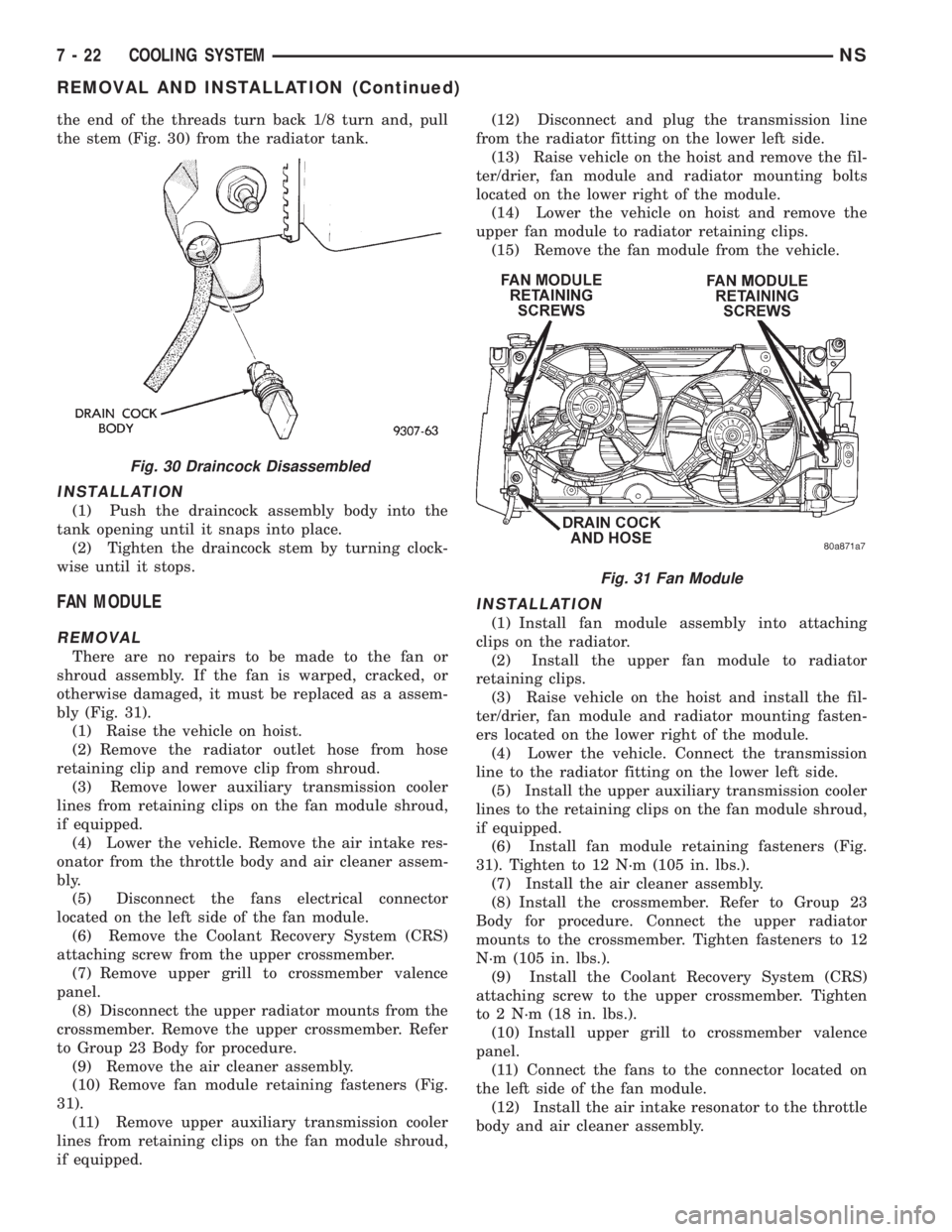

the end of the threads turn back 1/8 turn and, pull

the stem (Fig. 30) from the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening until it snaps into place.

(2) Tighten the draincock stem by turning clock-

wise until it stops.

FAN MODULE

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as a assem-

bly (Fig. 31).

(1) Raise the vehicle on hoist.

(2) Remove the radiator outlet hose from hose

retaining clip and remove clip from shroud.

(3) Remove lower auxiliary transmission cooler

lines from retaining clips on the fan module shroud,

if equipped.

(4) Lower the vehicle. Remove the air intake res-

onator from the throttle body and air cleaner assem-

bly.

(5) Disconnect the fans electrical connector

located on the left side of the fan module.

(6) Remove the Coolant Recovery System (CRS)

attaching screw from the upper crossmember.

(7) Remove upper grill to crossmember valence

panel.

(8) Disconnect the upper radiator mounts from the

crossmember. Remove the upper crossmember. Refer

to Group 23 Body for procedure.

(9) Remove the air cleaner assembly.

(10) Remove fan module retaining fasteners (Fig.

31).

(11) Remove upper auxiliary transmission cooler

lines from retaining clips on the fan module shroud,

if equipped.(12) Disconnect and plug the transmission line

from the radiator fitting on the lower left side.

(13) Raise vehicle on the hoist and remove the fil-

ter/drier, fan module and radiator mounting bolts

located on the lower right of the module.

(14) Lower the vehicle on hoist and remove the

upper fan module to radiator retaining clips.

(15) Remove the fan module from the vehicle.

INSTALLATION

(1) Install fan module assembly into attaching

clips on the radiator.

(2) Install the upper fan module to radiator

retaining clips.

(3) Raise vehicle on the hoist and install the fil-

ter/drier, fan module and radiator mounting fasten-

ers located on the lower right of the module.

(4) Lower the vehicle. Connect the transmission

line to the radiator fitting on the lower left side.

(5) Install the upper auxiliary transmission cooler

lines to the retaining clips on the fan module shroud,

if equipped.

(6) Install fan module retaining fasteners (Fig.

31). Tighten to 12 N´m (105 in. lbs.).

(7) Install the air cleaner assembly.

(8) Install the crossmember. Refer to Group 23

Body for procedure. Connect the upper radiator

mounts to the crossmember. Tighten fasteners to 12

N´m (105 in. lbs.).

(9) Install the Coolant Recovery System (CRS)

attaching screw to the upper crossmember. Tighten

to 2 N´m (18 in. lbs.).

(10) Install upper grill to crossmember valence

panel.

(11) Connect the fans to the connector located on

the left side of the fan module.

(12) Install the air intake resonator to the throttle

body and air cleaner assembly.

Fig. 30 Draincock Disassembled

Fig. 31 Fan Module

7 - 22 COOLING SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 237 of 1938

(13) Raise the vehicle. Install the lower auxiliary

transmission cooler lines to the retaining clips on the

fan module shroud, if equipped.

(14) Install outlet hose retainer clip to the shroud.

Install the radiator outlet hose to the retaining clip.

(15) Lower the vehicle.

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Drain, Clean, Flush and

Refill of this section for procedure.

(2) Remove power cord plug from heater.

(3) Loosen screw in center of heater. Remove

heater assembly.

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward.

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks. Pressurize sys-

tem with Radiator Pressure Tool before looking for

leaks.

(5) Install power cord plug to heater.

ACCESSORY DRIVE BELTSÐ2.4L

REMOVAL/INSTALLATION-ADJUST

GENERATOR AND AIR CONDITIONING

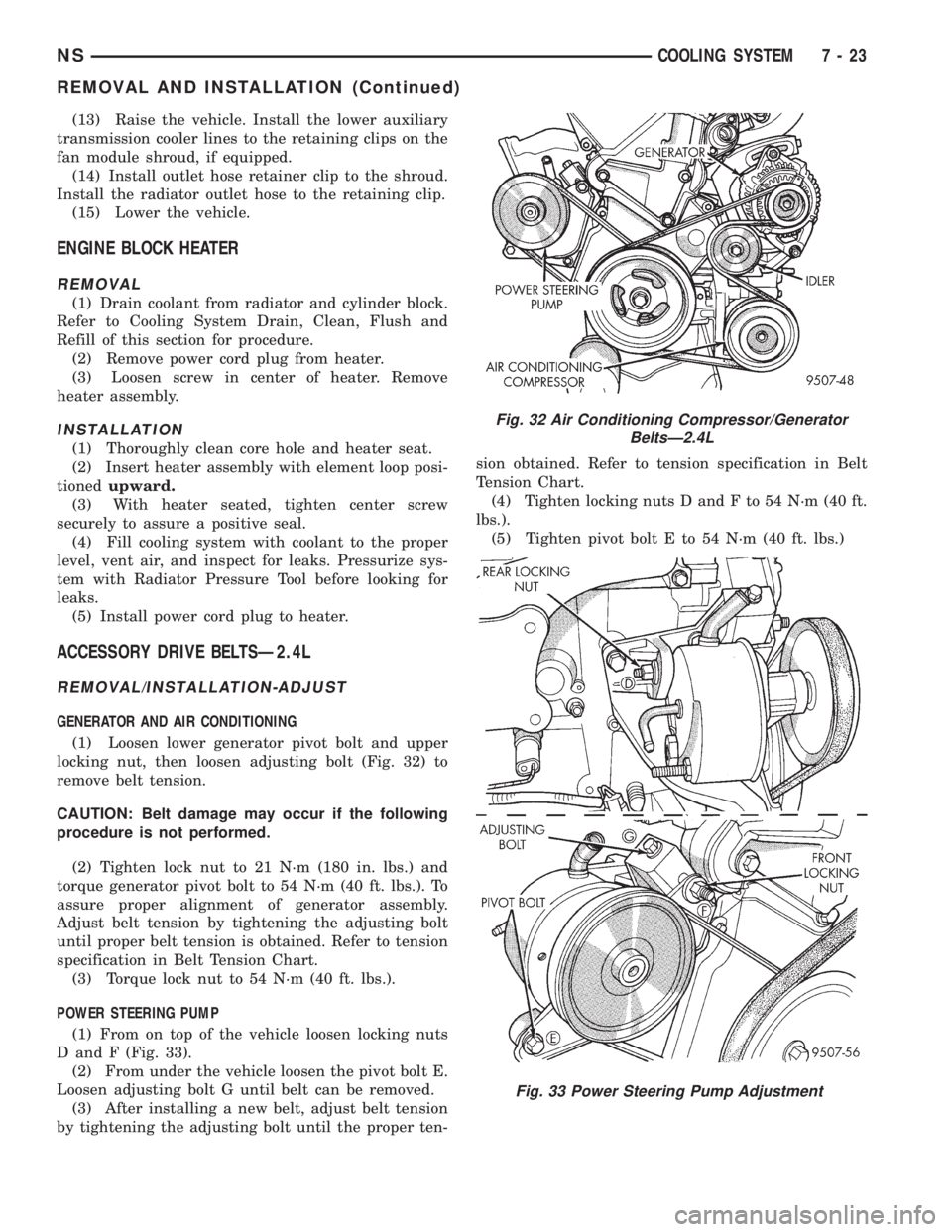

(1) Loosen lower generator pivot bolt and upper

locking nut, then loosen adjusting bolt (Fig. 32) to

remove belt tension.

CAUTION: Belt damage may occur if the following

procedure is not performed.

(2) Tighten lock nut to 21 N´m (180 in. lbs.) and

torque generator pivot bolt to 54 N´m (40 ft. lbs.). To

assure proper alignment of generator assembly.

Adjust belt tension by tightening the adjusting bolt

until proper belt tension is obtained. Refer to tension

specification in Belt Tension Chart.

(3) Torque lock nut to 54 N´m (40 ft. lbs.).

POWER STEERING PUMP

(1) From on top of the vehicle loosen locking nuts

D and F (Fig. 33).

(2) From under the vehicle loosen the pivot bolt E.

Loosen adjusting bolt G until belt can be removed.

(3) After installing a new belt, adjust belt tension

by tightening the adjusting bolt until the proper ten-sion obtained. Refer to tension specification in Belt

Tension Chart.

(4) Tighten locking nuts D and F to 54 N´m (40 ft.

lbs.).

(5) Tighten pivot bolt E to 54 N´m (40 ft. lbs.)

Fig. 32 Air Conditioning Compressor/Generator

BeltsÐ2.4L

Fig. 33 Power Steering Pump Adjustment

NSCOOLING SYSTEM 7 - 23

REMOVAL AND INSTALLATION (Continued)

Page 238 of 1938

ACCESSORY DRIVE BELTSÐ3.0L

GENERATOR/POWER STEERING PUMP BELT

REMOVAL/INSTALLATION

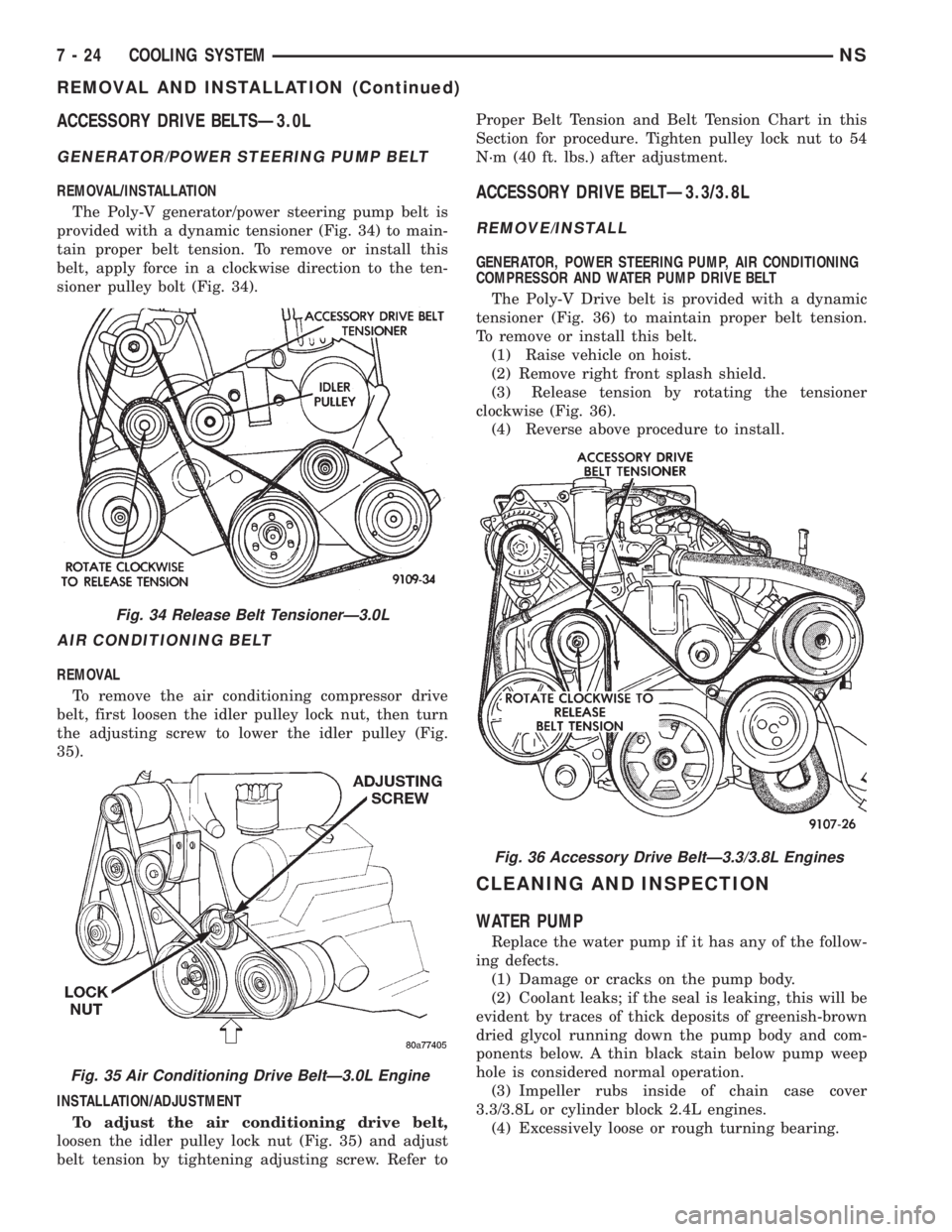

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 34) to main-

tain proper belt tension. To remove or install this

belt, apply force in a clockwise direction to the ten-

sioner pulley bolt (Fig. 34).

AIR CONDITIONING BELT

REMOVAL

To remove the air conditioning compressor drive

belt, first loosen the idler pulley lock nut, then turn

the adjusting screw to lower the idler pulley (Fig.

35).

INSTALLATION/ADJUSTMENT

To adjust the air conditioning drive belt,

loosen the idler pulley lock nut (Fig. 35) and adjust

belt tension by tightening adjusting screw. Refer toProper Belt Tension and Belt Tension Chart in this

Section for procedure. Tighten pulley lock nut to 54

N´m (40 ft. lbs.) after adjustment.

ACCESSORY DRIVE BELTÐ3.3/3.8L

REMOVE/INSTALL

GENERATOR, POWER STEERING PUMP, AIR CONDITIONING

COMPRESSOR AND WATER PUMP DRIVE BELT

The Poly-V Drive belt is provided with a dynamic

tensioner (Fig. 36) to maintain proper belt tension.

To remove or install this belt.

(1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner

clockwise (Fig. 36).

(4) Reverse above procedure to install.

CLEANING AND INSPECTION

WATER PUMP

Replace the water pump if it has any of the follow-

ing defects.

(1) Damage or cracks on the pump body.

(2) Coolant leaks; if the seal is leaking, this will be

evident by traces of thick deposits of greenish-brown

dried glycol running down the pump body and com-

ponents below. A thin black stain below pump weep

hole is considered normal operation.

(3) Impeller rubs inside of chain case cover

3.3/3.8L or cylinder block 2.4L engines.

(4) Excessively loose or rough turning bearing.

Fig. 34 Release Belt TensionerÐ3.0L

Fig. 35 Air Conditioning Drive BeltÐ3.0L Engine

Fig. 36 Accessory Drive BeltÐ3.3/3.8L Engines

7 - 24 COOLING SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 239 of 1938

NOTE: It is normal for the water pump to weep a

small amount of coolant from the weep hole (black

stain on water pump body). Do not replace the

water pump if this condition exists. Replace the

water pump if a heavy deposit or a steady flow of

green/brown engine coolant is evident on water

pump body from the weep hole (shaft seal failure).

Be sure to perform a thorough analysis before

replacing water pump.

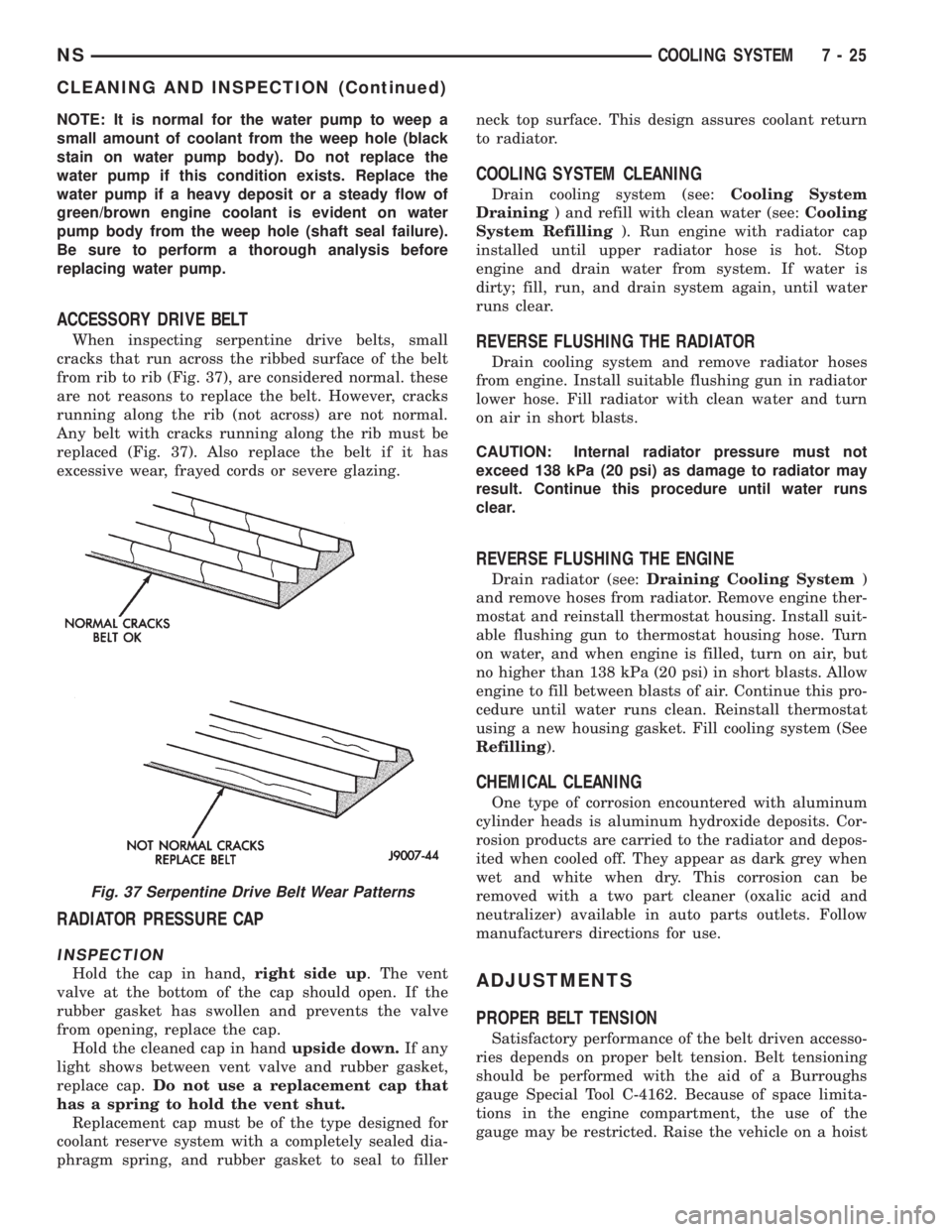

ACCESSORY DRIVE BELT

When inspecting serpentine drive belts, small

cracks that run across the ribbed surface of the belt

from rib to rib (Fig. 37), are considered normal. these

are not reasons to replace the belt. However, cracks

running along the rib (not across) are not normal.

Any belt with cracks running along the rib must be

replaced (Fig. 37). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

RADIATOR PRESSURE CAP

INSPECTION

Hold the cap in hand,right side up. The vent

valve at the bottom of the cap should open. If the

rubber gasket has swollen and prevents the valve

from opening, replace the cap.

Hold the cleaned cap in handupside down.If any

light shows between vent valve and rubber gasket,

replace cap.Do not use a replacement cap that

has a spring to hold the vent shut.

Replacement cap must be of the type designed for

coolant reserve system with a completely sealed dia-

phragm spring, and rubber gasket to seal to fillerneck top surface. This design assures coolant return

to radiator.

COOLING SYSTEM CLEANING

Drain cooling system (see:Cooling System

Draining) and refill with clean water (see:Cooling

System Refilling). Run engine with radiator cap

installed until upper radiator hose is hot. Stop

engine and drain water from system. If water is

dirty; fill, run, and drain system again, until water

runs clear.

REVERSE FLUSHING THE RADIATOR

Drain cooling system and remove radiator hoses

from engine. Install suitable flushing gun in radiator

lower hose. Fill radiator with clean water and turn

on air in short blasts.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result. Continue this procedure until water runs

clear.

REVERSE FLUSHING THE ENGINE

Drain radiator (see:Draining Cooling System)

and remove hoses from radiator. Remove engine ther-

mostat and reinstall thermostat housing. Install suit-

able flushing gun to thermostat housing hose. Turn

on water, and when engine is filled, turn on air, but

no higher than 138 kPa (20 psi) in short blasts. Allow

engine to fill between blasts of air. Continue this pro-

cedure until water runs clean. Reinstall thermostat

using a new housing gasket. Fill cooling system (See

Refilling).

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be

removed with a two part cleaner (oxalic acid and

neutralizer) available in auto parts outlets. Follow

manufacturers directions for use.

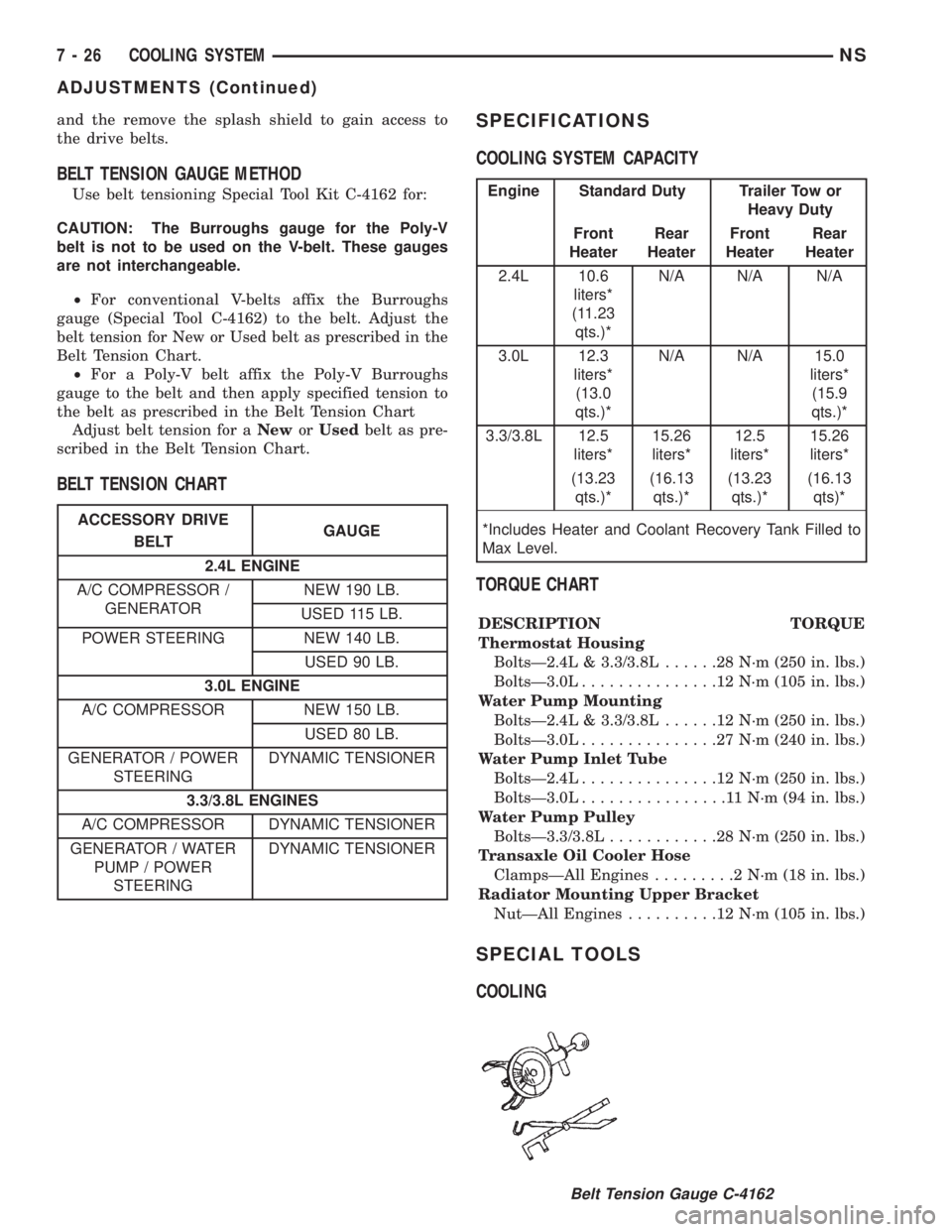

ADJUSTMENTS

PROPER BELT TENSION

Satisfactory performance of the belt driven accesso-

ries depends on proper belt tension. Belt tensioning

should be performed with the aid of a Burroughs

gauge Special Tool C-4162. Because of space limita-

tions in the engine compartment, the use of the

gauge may be restricted. Raise the vehicle on a hoist

Fig. 37 Serpentine Drive Belt Wear Patterns

NSCOOLING SYSTEM 7 - 25

CLEANING AND INSPECTION (Continued)

Page 240 of 1938

and the remove the splash shield to gain access to

the drive belts.

BELT TENSION GAUGE METHOD

Use belt tensioning Special Tool Kit C-4162 for:

CAUTION: The Burroughs gauge for the Poly-V

belt is not to be used on the V-belt. These gauges

are not interchangeable.

²For conventional V-belts affix the Burroughs

gauge (Special Tool C-4162) to the belt. Adjust the

belt tension for New or Used belt as prescribed in the

Belt Tension Chart.

²For a Poly-V belt affix the Poly-V Burroughs

gauge to the belt and then apply specified tension to

the belt as prescribed in the Belt Tension Chart

Adjust belt tension for aNeworUsedbelt as pre-

scribed in the Belt Tension Chart.

BELT TENSION CHARTSPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE CHART

DESCRIPTION TORQUE

Thermostat Housing

BoltsÐ2.4L & 3.3/3.8L......28N´m(250 in. lbs.)

BoltsÐ3.0L...............12N´m(105 in. lbs.)

Water Pump Mounting

BoltsÐ2.4L & 3.3/3.8L......12N´m(250 in. lbs.)

BoltsÐ3.0L...............27N´m(240 in. lbs.)

Water Pump Inlet Tube

BoltsÐ2.4L...............12N´m(250 in. lbs.)

BoltsÐ3.0L................11N´m(94in.lbs.)

Water Pump Pulley

BoltsÐ3.3/3.8L............28N´m(250 in. lbs.)

Transaxle Oil Cooler Hose

ClampsÐAll Engines.........2N´m(18in.lbs.)

Radiator Mounting Upper Bracket

NutÐAll Engines..........12N´m(105 in. lbs.)

SPECIAL TOOLS

COOLING

ACCESSORY DRIVE

BELTGAUGE

2.4L ENGINE

A/C COMPRESSOR /

GENERATORNEW 190 LB.

USED 115 LB.

POWER STEERING NEW 140 LB.

USED 90 LB.

3.0L ENGINE

A/C COMPRESSOR NEW 150 LB.

USED 80 LB.

GENERATOR / POWER

STEERINGDYNAMIC TENSIONER

3.3/3.8L ENGINES

A/C COMPRESSOR DYNAMIC TENSIONER

GENERATOR / WATER

PUMP / POWER

STEERINGDYNAMIC TENSIONER

Engine Standard Duty Trailer Tow or

Heavy Duty

Front

HeaterRear

HeaterFront

HeaterRear

Heater

2.4L 10.6

liters*

(11.23

qts.)*N/A N/A N/A

3.0L 12.3

liters*

(13.0

qts.)*N/A N/A 15.0

liters*

(15.9

qts.)*

3.3/3.8L 12.5

liters*15.26

liters*12.5

liters*15.26

liters*

(13.23

qts.)*(16.13

qts.)*(13.23

qts.)*(16.13

qts)*

*Includes Heater and Coolant Recovery Tank Filled to

Max Level.

Belt Tension Gauge C-4162

7 - 26 COOLING SYSTEMNS

ADJUSTMENTS (Continued)

Page 241 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

COOLANT PRESSURE BOTTLE............ 1

COOLING SYSTEM Ð 2.0L GASOLINE...... 1

COOLING SYSTEM Ð 2.5L VM DIESEL..... 1

LOW COOLANT LEVEL SENSOR........... 1

RADIATOR............................ 2

DESCRIPTION AND OPERATION

AUTOMATIC BELT TENSIONER............ 6

BELT TENSION......................... 5

COOLANT PERFORMANCE............... 5

PRESSURE/VENT CAP................... 4

THERMOSTAT OPERATION............... 4

THERMOSTAT......................... 6

WATER PUMP......................... 3

SERVICE PROCEDURES

ADDING ADDITIONAL COOLANT........... 7

DRAINING COOLING SYSTEM............. 7

REFILLING COOLING SYSTEM............ 7

REMOVAL AND INSTALLATION

ENGINE THERMOSTATÐ 2.0L GASOLINE . . . 9GENERATOR/POWER STEERING BELT Ð 2.5L

VM DIESEL......................... 10

RADIATOR Ð 2.5L VM DIESEL........... 9

THERMOSTAT Ð 2.5L VM DIESEL......... 9

WATER PUMP BELT Ð 2.5L VM DIESEL . . . 10

WATER PUMP Ð 2.0L GASOLINE......... 7

WATER PUMP Ð 2.5L VM DIESEL........ 8

CLEANING AND INSPECTION

WATER PUMP........................ 10

ADJUSTMENTS

BELT TENSION CHART................. 11

BELT TENSION GAUGE METHOD......... 11

SPECIFICATIONS

COOLING SYSTEM CAPACITY............ 12

TORQUE CHART...................... 12

SPECIAL TOOLS

COOLING............................ 12

GENERAL INFORMATION

COOLING SYSTEM Ð 2.0L GASOLINE

The 2.0L gasoline engine cooling system consists of

an engine cooling module, thermostat, coolant, a

water pump to circulate the coolant. The engine cool-

ing module may consist of a radiator, electric fan

motors, fan, shroud, coolant reserve system, hoses,

clamps, air condition condenser.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

COOLING SYSTEM Ð 2.5L VM DIESEL

The cooling system has a radiator, coolant, electric

fan motors, shroud, pressure cap, thermostat, coolant

pressure bottle, hoses, a water pump to circulate the

coolant, to complete the circuit. Coolant flow for the

VM diesel engine is shown in (Fig. 1).

COOLANT PRESSURE BOTTLE

2.5L VM DIESEL

This system works with the pressure cap to use

thermal expansion and contraction of the coolant to

keep the coolant free of trapped air. It provides some

reserve coolant to cover minor leaks and evaporation

or boiling losses. The coolant pressure bottle location

for 2.5L diesel is above the cylinder head cover (Fig.

2).

LOW COOLANT LEVEL SENSOR

The low coolant level sensor checks for low coolant

level in the coolant tank. A signal will be sent from

this sensor to the Body Control Module (BCM). When

the BCM determines low coolant level for 30 contin-

uous seconds, the instrument panel mounted low

coolant level warning lamp will be illuminated. The

sensor is located on the front side of the coolant tank

(Fig. 4). For information, refer to Group 8E, Instru-

ment Panel and Gauges.

If this lamp is illuminated, it indicates the need to

fill the coolant tank and check for leaks.

NS/GSCOOLING SYSTEM 7 - 1

Page 242 of 1938

RADIATOR

The radiators are cross-flow types (horizontal

tubes) with design features that provide greater

strength along with sufficient heat transfer capabili-

Fig. 1 Cooling System Operation ± 2.5L VM Diesel

Fig. 2 Coolant Pressure Bottle ± 2.5L VM Diesel

Fig. 3 Low Coolant Warning Sensor Connector ±

2.5L VM Diesel

7 - 2 COOLING SYSTEMNS/GS

GENERAL INFORMATION (Continued)

Page 243 of 1938

ties to keep the engine satisfactorily cooled (Fig. 5)

and (Fig. 6).

CAUTION: Plastic tanks, while stronger then brass

are subject to damage by impact, such as wrenches

etc., or by excessive torque on hose clamps.

If the plastic tank is damaged, replace the radia-

tor.

DESCRIPTION AND OPERATION

WATER PUMP

2.0L GASOLINE

The water has a diecast aluminum body and hous-

ing with a stamped steel impeller. The water pumpbolts directly to the block (Fig. 7). Cylinder block to

water pump sealing is provided by a rubber O-ring.

The water pump is driven by the timing belt. Refer

to Group 9, Engine section for component removal to

access the water pump.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

2.5L VM DIESEL

The Diesel engine water pump has an aluminum

body and housing with a stamped steel impeller. The

pump uses an O-ring gasket between body and hous-

ing. The water pump is driven by the accessory drive

belt, and the pump housing is bolted to the cylinder

block (Fig. 9).

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

Fig. 4 Low Coolant Level Sensor

Fig. 5 Cooling Module Ð2.0LGasoline

Fig. 6 Cooling Module ÐVM Diesel

NS/GSCOOLING SYSTEM 7 - 3

GENERAL INFORMATION (Continued)

Page 244 of 1938

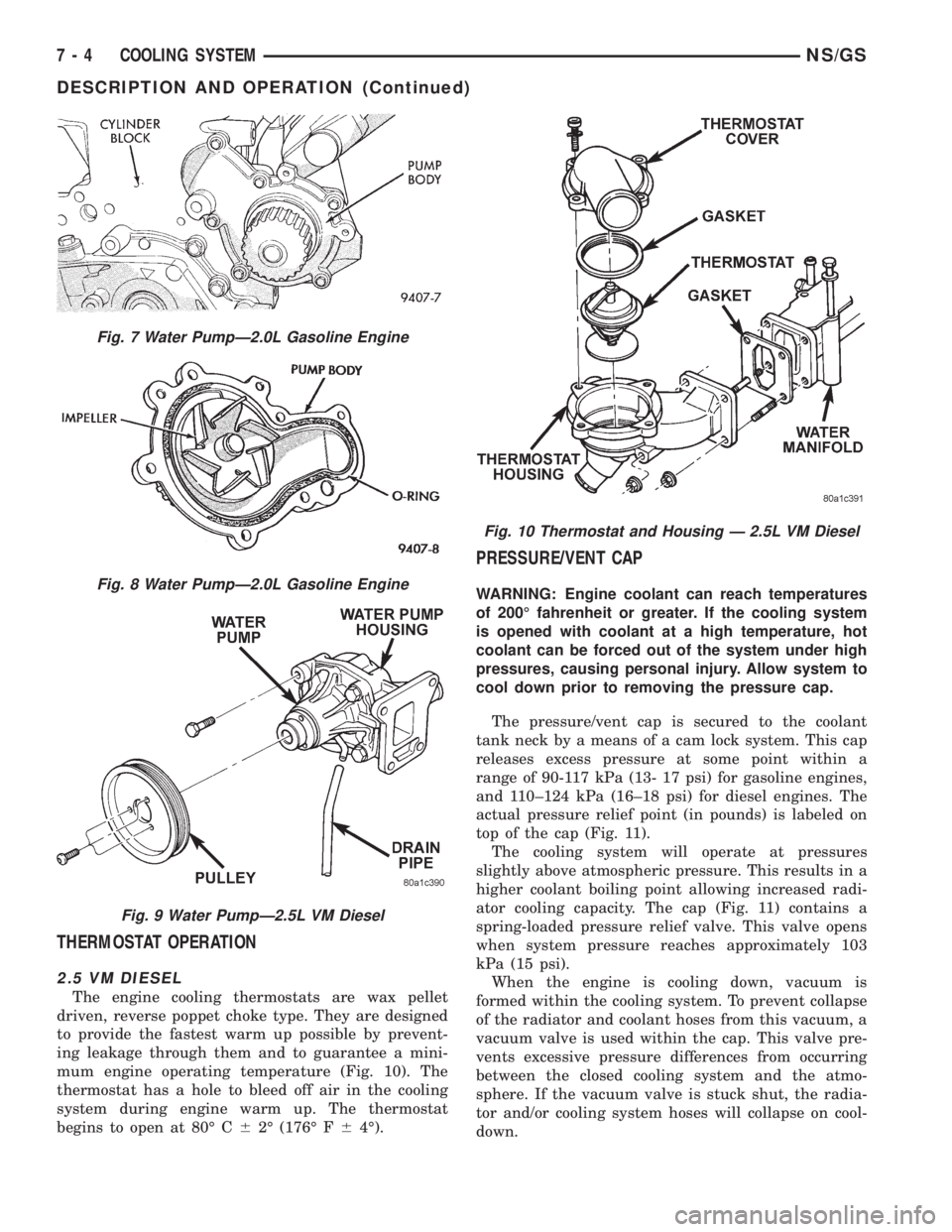

THERMOSTAT OPERATION

2.5 VM DIESEL

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature (Fig. 10). The

thermostat has a hole to bleed off air in the cooling

system during engine warm up. The thermostat

begins to open at 80É C62É (176É F64É).

PRESSURE/VENT CAP

WARNING: Engine coolant can reach temperatures

of 200É fahrenheit or greater. If the cooling system

is opened with coolant at a high temperature, hot

coolant can be forced out of the system under high

pressures, causing personal injury. Allow system to

cool down prior to removing the pressure cap.

The pressure/vent cap is secured to the coolant

tank neck by a means of a cam lock system. This cap

releases excess pressure at some point within a

range of 90-117 kPa (13- 17 psi) for gasoline engines,

and 110±124 kPa (16±18 psi) for diesel engines. The

actual pressure relief point (in pounds) is labeled on

top of the cap (Fig. 11).

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap (Fig. 11) contains a

spring-loaded pressure relief valve. This valve opens

when system pressure reaches approximately 103

kPa (15 psi).

When the engine is cooling down, vacuum is

formed within the cooling system. To prevent collapse

of the radiator and coolant hoses from this vacuum, a

vacuum valve is used within the cap. This valve pre-

vents excessive pressure differences from occurring

between the closed cooling system and the atmo-

sphere. If the vacuum valve is stuck shut, the radia-

tor and/or cooling system hoses will collapse on cool-

down.

Fig. 7 Water PumpÐ2.0L Gasoline Engine

Fig. 8 Water PumpÐ2.0L Gasoline Engine

Fig. 9 Water PumpÐ2.5L VM Diesel

Fig. 10 Thermostat and Housing Ð 2.5L VM Diesel

7 - 4 COOLING SYSTEMNS/GS

DESCRIPTION AND OPERATION (Continued)