gas type CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1257 of 1938

DESCRIPTION...........SPECIFICATIONS

Nominal.................63.005±63.020 mm

±0.25....................62.755±62.770 mm

±0.125...................62.880±62.895 mm

Center Bearing Diameter...................

Nominal.................63.050±63.093 mm

±0.25....................62.800±62.843 mm

±0.125...................62.925±62.968 mm

Clearance Between Journal and Bearing:

0.030±0.088 mm..........................

Rear Journal Diameter.....................

Nominal.................79.980±80.000 mm

±0.25....................79.730±79.750 mm

±0.125...................79.855±79.875 mm

Rear Bearing Diameter.....................

Nominal.................80.045±80.070 mm

±0.25....................79.795±79.820 mm

±0.125...................79.920±79.945 mm

Clearance Between Journal and Bearing:

0.045±0.090 mm (Wear Limit: 0.200 mm).......

Connecting Rod Journal....................

Nominal.................53.940±53.955 mm

±0.25....................53.690±53.705 mm

±0.125...................53.815±53.830 mm

Connecting Rod Bearing....................

Nominal.................53.977±54.016 mm

±0.25....................53.727±53.766 mm

±0.125...................53.852±53.891 mm

Clearance Between Journal and Bearing:

0.022±0.076 mm (Wear Limit: 0.200 mm).......

Crankshaft End Play

End Play.....................0.08±0.21 mm

Adjustment.................Thrust Washers

Thrust Washers Available........2.31±2.36 mm

Thrust Washers Available........2.41±2.46 mm

Thrust Washers Available........2.51±2.56 mm

Main Bearing Carriers

Front....................67.025±67.050 mm

Center...................66.670±66.690 mm

Rear....................85.985±86.005 mm

Liners

Internal Diameter..........92.000±92.010 mm

Protrusion....................0.01±0.06 mm

Adjustment.........................Shims

Available Shims:...................0.15 mm

Available Shims:...................0.17 mm

Available Shims:...................0.20 mm

Available Shims:...................0.23 mm

Available Shims:...................0.25 mm

Cylinder Head

Minimum Thickness..........89.95±90.05 mm

Gasket.............................Steel

Gasket thickness:.......1.4260.1 mm 0 Holes

Gasket thickness:.......1.6260.1 mm 1 HolesDESCRIPTION...........SPECIFICATIONS

Gasket thickness:.......1.5260.1 mm 2 Holes

End Plates

Height.....................89.02±90.00 mm

Connecting Rods

Weight (Without the crank

bearing)..................1129±1195 grams

Small End Bearing Internal Diameter

Minimum.......................30.035 mm

Maximum......................30.050 mm

Crankshaft Bearings Standard Internal

Diameter.................53.997±54.016 mm

Pistons

Skirt Diameter............91.935±91.945 mm

(Measured at approximately 15 mm above the

bottom of the skirt)

Piston Clearance.............0.055±0.075 mm

Top of Piston to Cylinder Head....0.80±0.89 mm

Piston Protrusion.....0.53±0.62 mm Fit Gasket

(1.42), 0 Holes

Piston Protrusion.....0.73±0.82 mm Fit Gasket

(1.62), 1 Hole

Piston Protrusion.....0.63±0.72 mm Fit Gasket

(1.52), 2 Holes

Piston Pins

Type .........................Full Floating

Pin Diameter..............29.990±29.996 mm

Clearance..................0.004±0.014 mm

Piston Rings (Clearance in Groove)

Top .......................0.080±0.130 mm

Second.....................0.070±0.102 mm

Oil Control.................0.040±0.072 mm

Piston Rings (Fitted Gap)

Top .........................0.25±0.50 mm

Second......................0.20±0.35 mm

Oil Control...................0.25±0.58 mm

Camshaft

Journal Diameter Front.....53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Journal Diameter Center....53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Journal Diameter Rear......53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Tappets

Outside Diameter..........22.195±22.212 mm

Rocker Gear

Shaft Diameter.............21.979±22.00 mm

Bushing internal diameter . . . 22.020±22.041 mm

Assembly Clearance..........0.020±0.062 mm

Valves (Intake)

Opens........................26ÉB.T.D.C.

Closes........................58ÉA.B.D.C.

Valves (Exhaust)

Opens........................64ÉB.B.D.C.

Closes........................38ÉA.T.D.C.

NS/GSENGINE 9 - 79

SPECIFICATIONS (Continued)

Page 1265 of 1938

CAUTION: When servicing, care must be exercised

not to dent or bend the bellows of the flex-joint.

Should this occur, the flex-joint will eventually fail

and require the catalytic converter be replaced.

DESCRIPTION AND OPERATION

INTAKE/EXHAUST MANIFOLDÐ2.4L ENGINE

The intake manifold is a tuned two-piece alumi-

num casting with individual primary runners leading

from a plenum to the cylinders. The manifold is

designed to boost torque which is desired for excel-

lent engine response and usable power output.

The exhaust manifold is made of nodular cast iron

for strength and high temperatures.

INTAKE/EXHAUST MANIFOLDÐ3.0L ENGINE

The aluminum alloy manifold is a cross type with

long runners to improve air flow. The runners,

attaching below at the cylinder head, also attach

above and support an air plenum. The air plenum

chamber absorbs air pulsations created during the

suction phase of each cylinder.Both exhaust manifolds are a log style made of

ductile cast iron. Exhaust gasses, collected from the

front cylinder bank, leave the front manifold through

an end outlet and are fed through an upper crossover

tube to the rear manifold. The collected exhaust from

both manifolds are combined at the exhaust outlet, to

the exhaust pipe.

INTAKE/EXHAUST MANIFOLDÐ3.3/3.8L ENGINES

The intake manifold is a tuned two-piece semi-per-

manent mold aluminum casting with individual pri-

mary runners leading from a plenum to the

cylinders. The manifold is designed to boost torque in

the 3600 rpm range and contributes to the engine's

broad, flat torque curve, which was desired for excel-

lent engine tractability, response and usable power

output.

The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution.

The exhaust manifolds are log type with a cross-

over and are attached directly to the cylinder heads.

They are made from nodular cast iron.

DIAGNOSIS AND TESTING

EXHAUST SYSTEM

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST

NOISE (UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. EGR Valve to manifold gasket leakage. 3. Tighten fasteners or replace gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace gasket.

5. EGR tube to manifold tube leakage. 5. Tighten tube nut.

6. Exhaust flex-joint to manifold leak. 6. Tighten joint fasteners and/or replace

gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter assembly.

8. Pipe and shell noise from front exhaust

pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST

NOISE1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler assembly

or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with catalytic

converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Remove restriction, if possible, or

replace as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper operation.

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

GENERAL INFORMATION (Continued)

Page 1296 of 1938

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

carbon monoxide emissions. The type and amount of

oxygenate used in the blend is important.

The following are generally used in gasoline

blends:

Ethanol- (Ethyl or Grain Alcohol) properly

blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with etha-

nol may be used in your vehicle.

MTBE/ETBE- Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline and up to 15 percent MTBE. Gasoline and

ETBE (Ethyl Tertiary Butyl Ether) are blends of gas-

oline and up to 17 percent ETBE. Gasoline blended

with MTBE or ETBE may be used in your vehicle.

Methanol- Methanol (Methyl or Wood Alcohol) is

used in a variety of concentrations blended with

unleaded gasoline. You may encounter fuels contain-

ing 3 percent or more methanol along with other

alcohols called cosolvents.

DO NOT USE GASOLINES CONTAINING

METHANOL.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components.

Problems that are the result of using methanol/

gasoline blends are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty.

Reformulated Gasoline

Many areas of the country are requiring the use of

cleaner-burning fuel referred to asReformulated

Gasoline. Reformulated gasolines are specially

blended to reduce vehicle emissions and improve air

quality.

Chrysler Corporation strongly supports the use of

reformulated gasolines whenever available. Although

your vehicle was designed to provide optimum perfor-

mance and lowest emissions operating on high qual-

ity unleaded gasoline, it will perform equally well

and produce even lower emissions when operating on

reformulated gasoline.

Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

E-85 GENERAL INFORMATION

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

Your vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in driv-

ability during warm up.

NOTE: When the ambient temperature is above

90ÉF, you may experience hard starting and rough

idle following start up even if the above recommen-

dations are followed.

STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in drivability (sags and/or hesita-

tions) until the engine is fully warmed up.

14 - 2 FUEL SYSTEMNS

GENERAL INFORMATION (Continued)

Page 1300 of 1938

hydrocarbons. Vapors from the fuel tank are collected

in a charcoal filled canister. The vapors are held in

the canister until the engine is operating. When the

engine is running, the vapors are drawn through the

intake manifold into the combustion chambers.

PRESSURE-VACUUM FILLER CAP

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 0.97 and 2.0 kPa

(0.14 and 0.29 psi). The cap must be replaced by a

similar unit if replacement is necessary.

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

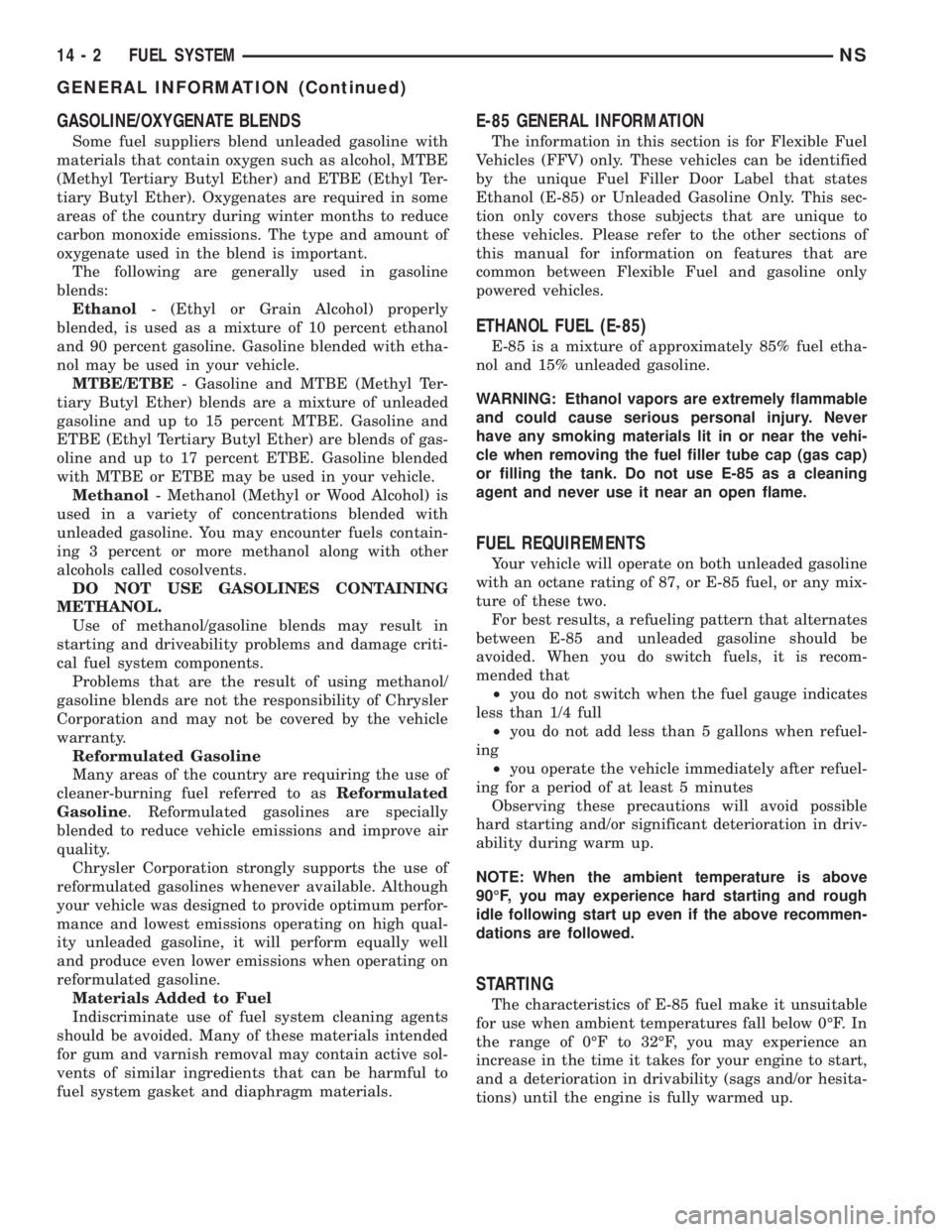

QUICK-CONNECT FITTINGS

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 4).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 4). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

DIAGNOSIS AND TESTING

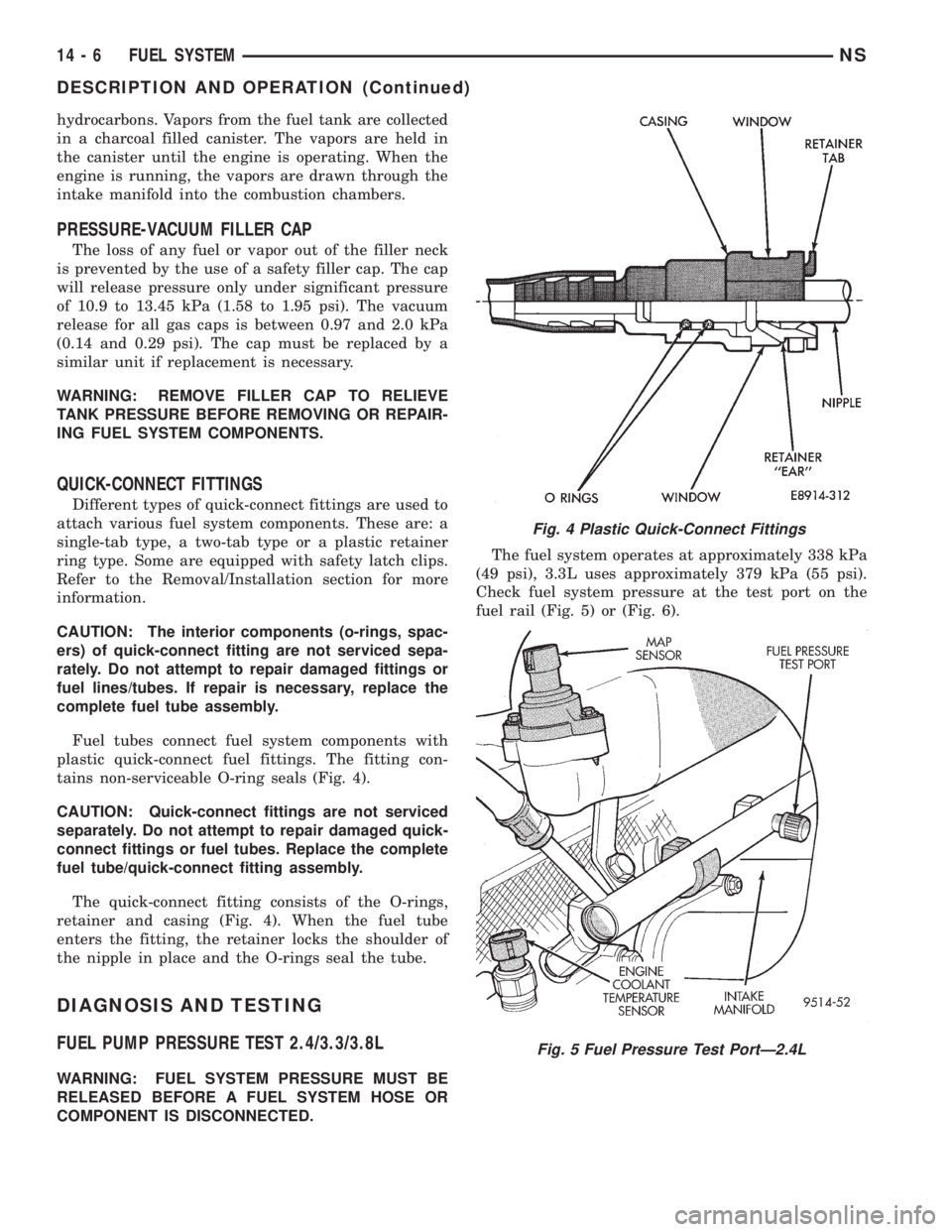

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L

WARNING: FUEL SYSTEM PRESSURE MUST BE

RELEASED BEFORE A FUEL SYSTEM HOSE OR

COMPONENT IS DISCONNECTED.The fuel system operates at approximately 338 kPa

(49 psi), 3.3L uses approximately 379 kPa (55 psi).

Check fuel system pressure at the test port on the

fuel rail (Fig. 5) or (Fig. 6).

Fig. 4 Plastic Quick-Connect Fittings

Fig. 5 Fuel Pressure Test PortÐ2.4L

14 - 6 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1371 of 1938

FUEL DELIVERY SYSTEMÐ2.5L DIESEL ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

FUEL DRAIN TUBES..................... 7

FUEL FILTER/WATER SEPARATOR.......... 4

FUEL GAUGE SENDING UNIT.............. 4

FUEL HEATER RELAY.................... 8

FUEL HEATER.......................... 8

FUEL INJECTION PUMP.................. 5

FUEL INJECTORS....................... 6

FUEL SHUTDOWN SOLENOID............. 5

FUEL SYSTEM PRESSURE WARNING....... 3

FUEL TANK MODULE.................... 4

FUEL TANK............................ 3

FUEL TUBES/LINES/HOSES AND CLAMPSÐ

LOW-PRESSURE TYPE................. 6

HIGH-PRESSURE FUEL LINES............. 7

INTRODUCTION........................ 3

QUICK-CONNECT FITTINGSÐLOW PRESSURE

TYPE............................... 7

WASTEGATE (TURBOCHARGER)........... 8

DIAGNOSIS AND TESTING

AIR IN FUEL SYSTEM................... 11

FUEL HEATER RELAY TEST.............. 12

FUEL INJECTION PUMP TEST............. 12

FUEL INJECTOR SENSOR TEST........... 12

FUEL INJECTOR TEST.................. 12

FUEL SHUTDOWN SOLENOID TEST........ 13

FUEL SUPPLY RESTRICTIONS............ 13GENERAL INFORMATION................. 9

HIGH-PRESSURE FUEL LINE LEAK TEST.... 14

VISUAL INSPECTION..................... 9

WASTEGATE (TURBOCHARGER).......... 14

SERVICE PROCEDURES

AIR BLEED PROCEDURES............... 14

FUEL INJECTION PUMP TIMING........... 15

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL.................. 16

AIR CLEANER ELEMENT................. 16

FUEL DRAIN TUBES.................... 16

FUEL FILTER/WATER SEPARATOR......... 16

FUEL HEATER RELAY................... 17

FUEL HEATER......................... 17

FUEL INJECTION PUMP................. 19

FUEL INJECTORS...................... 22

FUEL LEVEL SENSOR................... 18

FUEL RESERVOIR MODULE.............. 25

FUEL SHUTDOWN SOLENOID............ 23

FUEL TANK........................... 23

HIGH-PRESSURE LINES................. 26

SPECIFICATIONS

FUEL INJECTOR FIRING SEQUENCE....... 27

FUEL SYSTEM PRESSURE............... 27

FUEL TANK CAPACITY.................. 27

IDLE SPEED.......................... 27

DESCRIPTION AND OPERATION

INTRODUCTION

This Fuel Delivery section will cover components

not controlled by the PCM. For components con-

trolled by the PCM, refer to the Fuel Injection Sys-

temÐ2.5L Diesel Engine section of this group.

The fuel heater relay, fuel heater and fuel gauge

are not operated by the PCM. These components are

controlled by the ignition (key) switch. All other fuel

system electrical components necessary to operate

the engine are controlled or regulated by the PCM.

FUEL SYSTEM PRESSURE WARNING

WARNING: HIGH±PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 45,000 KPA (6526 PSI).

USE EXTREME CAUTION WHEN INSPECTING FORHIGH±PRESSURE FUEL LEAKS. INSPECT FOR

HIGH±PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD (Fig. 1). HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

FUEL TANK

The fuel tank and tank mounting used with the

diesel powered engine is the same as used with gas-

oline powered models, although the fuel tank module

is different.

The fuel tank contains the fuel tank module and

two rollover valves. Two fuel lines are routed to the

fuel tank module. One line is used for fuel supply to

the fuel filter/water separator. The other is used to

return excess fuel back to the fuel tank.

The fuel tank module contains the fuel gauge elec-

trical sending unit.An electrical fuel pump is not

used with the diesel engine.

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 3

Page 1373 of 1938

For periodic draining of water from the bowl, refer

to Fuel Filter/Water Separator Removal/Installation

in this group.

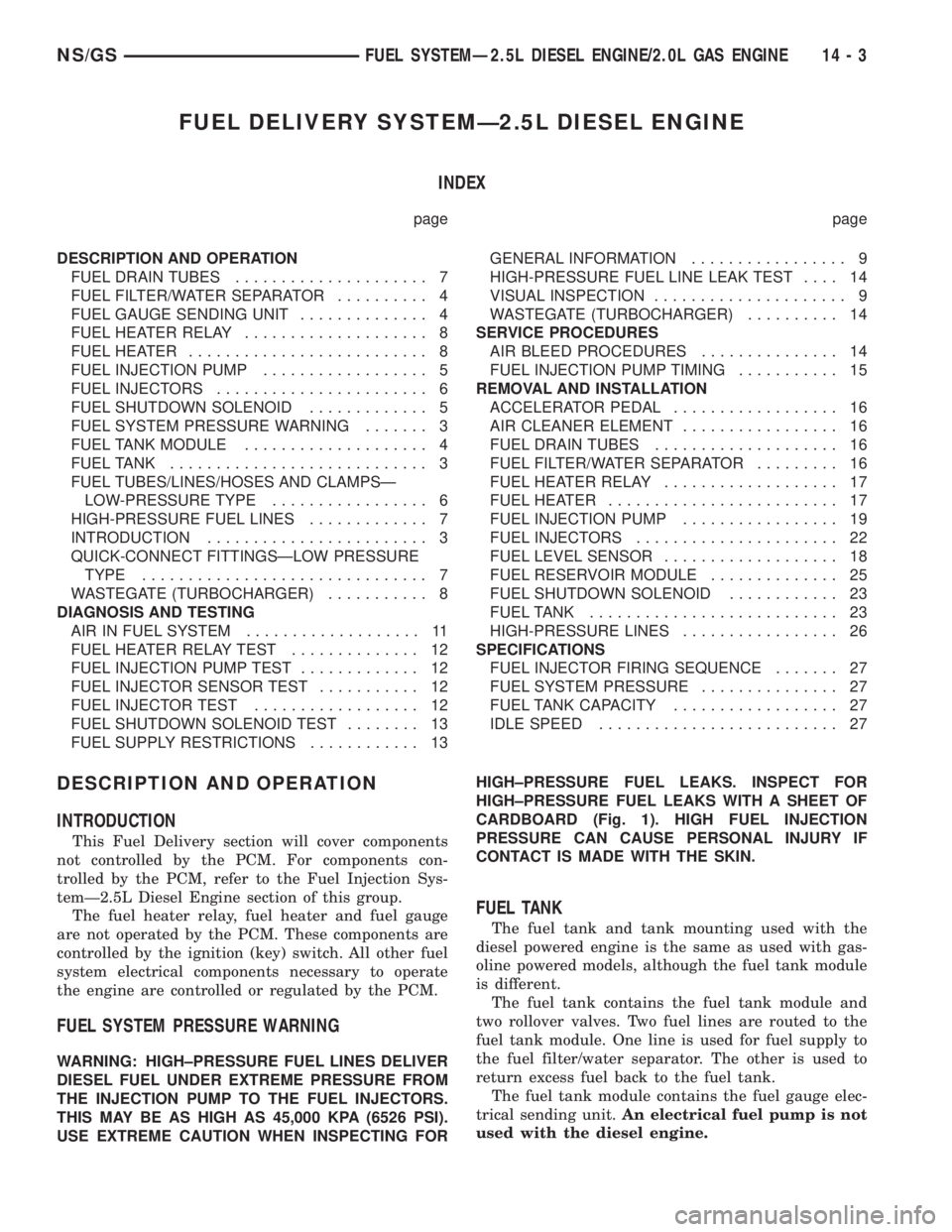

FUEL SHUTDOWN SOLENOID

The fuel shutdown solenoid is controlled and

operated by the PCM.

The fuel shutdown (shut-off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

pressure fuel injection pump. The solenoid is

mounted to the rear of the injection pump (Fig. 4).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the

solenoid is shut off and fuel flow is not allowed to the

fuel injection pump. When the key is placed in the

ON or START positions, fuel supply is allowed at the

injection pump.

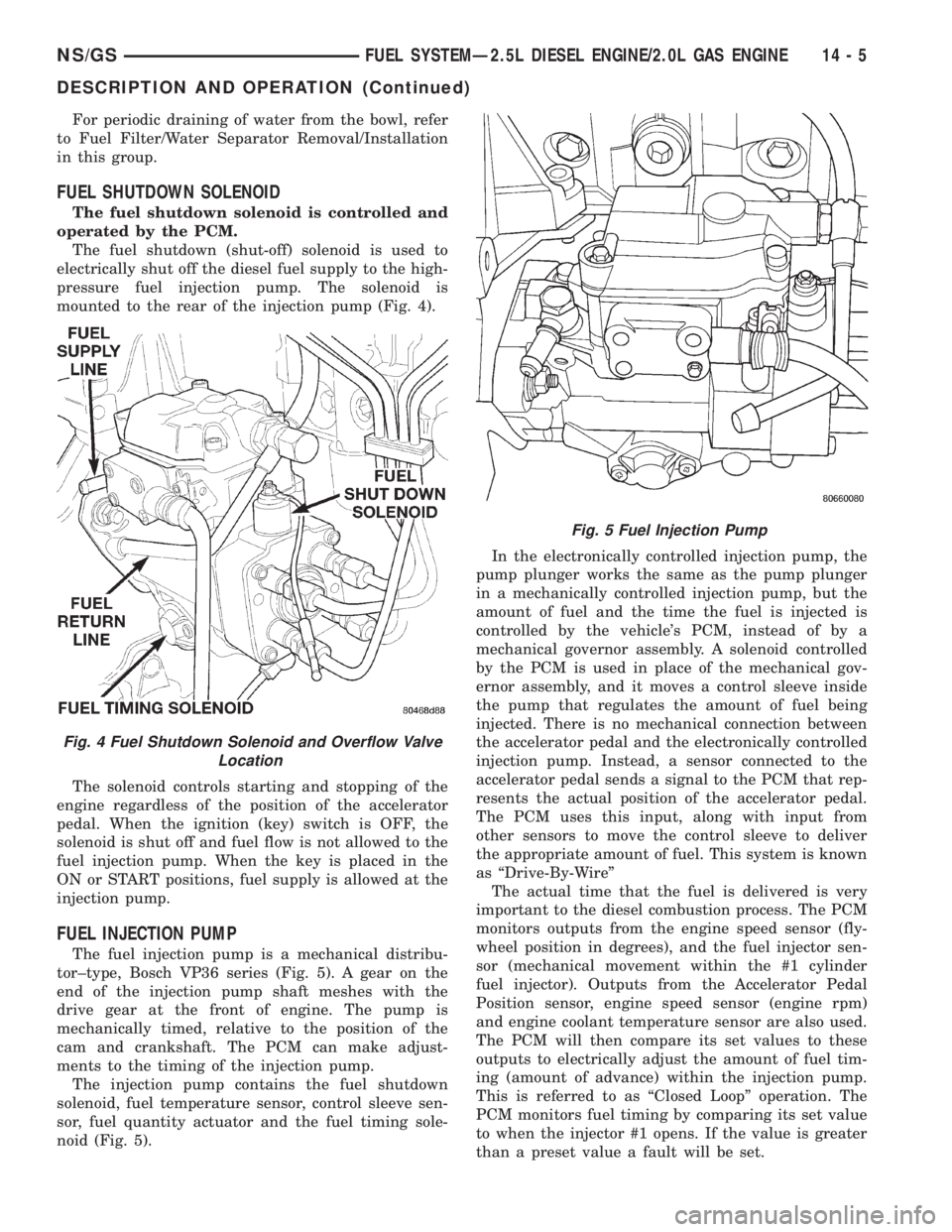

FUEL INJECTION PUMP

The fuel injection pump is a mechanical distribu-

tor±type, Bosch VP36 series (Fig. 5). A gear on the

end of the injection pump shaft meshes with the

drive gear at the front of engine. The pump is

mechanically timed, relative to the position of the

cam and crankshaft. The PCM can make adjust-

ments to the timing of the injection pump.

The injection pump contains the fuel shutdown

solenoid, fuel temperature sensor, control sleeve sen-

sor, fuel quantity actuator and the fuel timing sole-

noid (Fig. 5).In the electronically controlled injection pump, the

pump plunger works the same as the pump plunger

in a mechanically controlled injection pump, but the

amount of fuel and the time the fuel is injected is

controlled by the vehicle's PCM, instead of by a

mechanical governor assembly. A solenoid controlled

by the PCM is used in place of the mechanical gov-

ernor assembly, and it moves a control sleeve inside

the pump that regulates the amount of fuel being

injected. There is no mechanical connection between

the accelerator pedal and the electronically controlled

injection pump. Instead, a sensor connected to the

accelerator pedal sends a signal to the PCM that rep-

resents the actual position of the accelerator pedal.

The PCM uses this input, along with input from

other sensors to move the control sleeve to deliver

the appropriate amount of fuel. This system is known

as ªDrive-By-Wireº

The actual time that the fuel is delivered is very

important to the diesel combustion process. The PCM

monitors outputs from the engine speed sensor (fly-

wheel position in degrees), and the fuel injector sen-

sor (mechanical movement within the #1 cylinder

fuel injector). Outputs from the Accelerator Pedal

Position sensor, engine speed sensor (engine rpm)

and engine coolant temperature sensor are also used.

The PCM will then compare its set values to these

outputs to electrically adjust the amount of fuel tim-

ing (amount of advance) within the injection pump.

This is referred to as ªClosed Loopº operation. The

PCM monitors fuel timing by comparing its set value

to when the injector #1 opens. If the value is greater

than a preset value a fault will be set.

Fig. 4 Fuel Shutdown Solenoid and Overflow Valve

Location

Fig. 5 Fuel Injection Pump

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1374 of 1938

Actual electric fuel timing (amount of advance) is

accomplished by the fuel timing solenoid mounted to

the bottom of the injection pump (Fig. 5). Fuel timing

will be adjusted by the PCM, which controls the fuel

timing solenoid.

An overflow valve is attached into the fuel return

line at the rear of the fuel injection pump (Fig. 4).

This valve serves two purposes. One is to ensure that

a certain amount of residual pressure is maintained

within the pump when the engine is switched off.

This will prevent the fuel timing mechanism within

the injection pump from returning to its zero posi-

tion. The other purpose is to allow excess fuel to be

returned to the fuel tank through the fuel return

line. The pressure values within this valve are preset

and can not be adjusted.

The fuel injection pump supplies high±pressure

fuel of approximately 45,000 kPa (6526 psi) to each

injector in precise metered amounts at the correct

time.

For mechanical injection pump timing, refer to

Fuel Injection Pump Timing in the Service Proce-

dures section of this group.

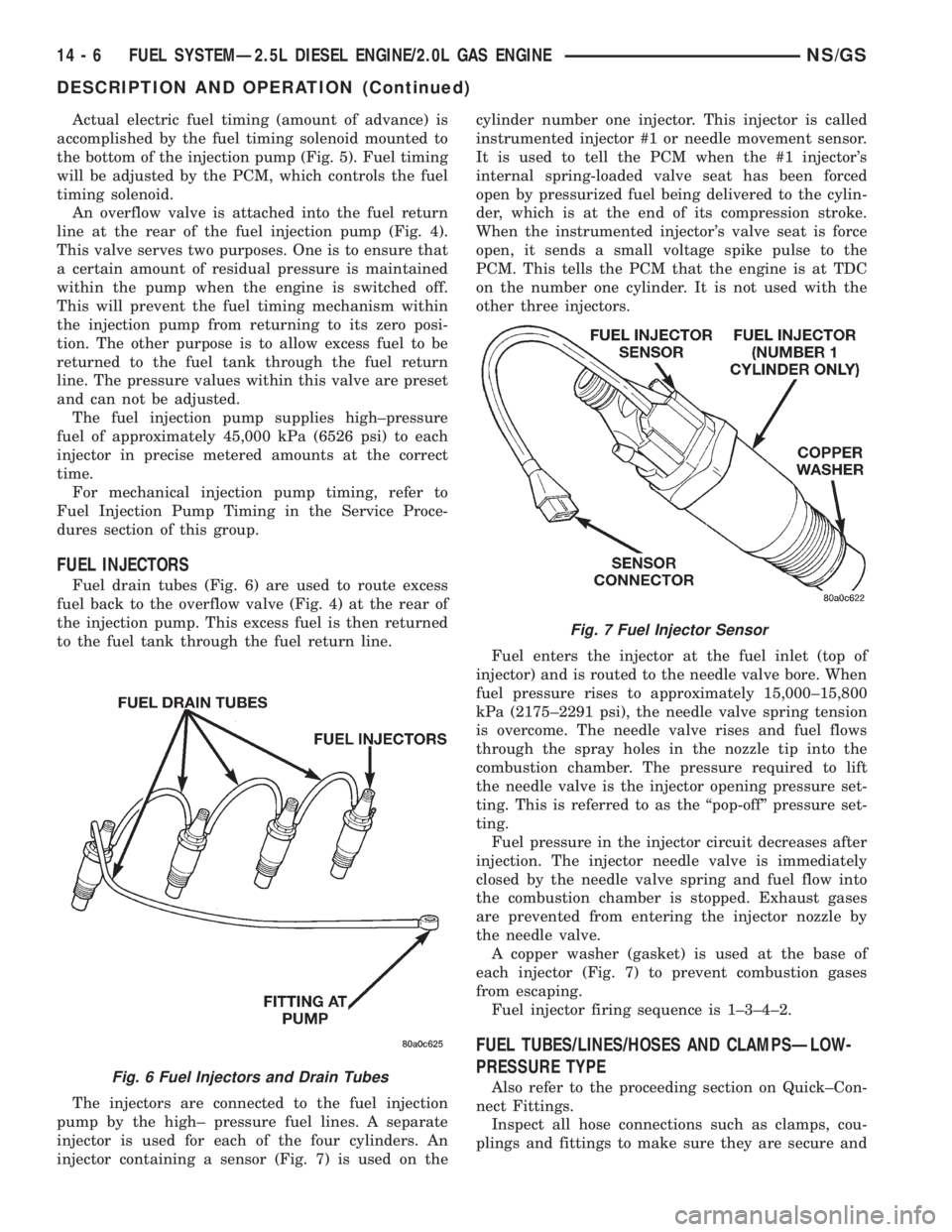

FUEL INJECTORS

Fuel drain tubes (Fig. 6) are used to route excess

fuel back to the overflow valve (Fig. 4) at the rear of

the injection pump. This excess fuel is then returned

to the fuel tank through the fuel return line.

The injectors are connected to the fuel injection

pump by the high± pressure fuel lines. A separate

injector is used for each of the four cylinders. An

injector containing a sensor (Fig. 7) is used on thecylinder number one injector. This injector is called

instrumented injector #1 or needle movement sensor.

It is used to tell the PCM when the #1 injector's

internal spring-loaded valve seat has been forced

open by pressurized fuel being delivered to the cylin-

der, which is at the end of its compression stroke.

When the instrumented injector's valve seat is force

open, it sends a small voltage spike pulse to the

PCM. This tells the PCM that the engine is at TDC

on the number one cylinder. It is not used with the

other three injectors.

Fuel enters the injector at the fuel inlet (top of

injector) and is routed to the needle valve bore. When

fuel pressure rises to approximately 15,000±15,800

kPa (2175±2291 psi), the needle valve spring tension

is overcome. The needle valve rises and fuel flows

through the spray holes in the nozzle tip into the

combustion chamber. The pressure required to lift

the needle valve is the injector opening pressure set-

ting. This is referred to as the ªpop-offº pressure set-

ting.

Fuel pressure in the injector circuit decreases after

injection. The injector needle valve is immediately

closed by the needle valve spring and fuel flow into

the combustion chamber is stopped. Exhaust gases

are prevented from entering the injector nozzle by

the needle valve.

A copper washer (gasket) is used at the base of

each injector (Fig. 7) to prevent combustion gases

from escaping.

Fuel injector firing sequence is 1±3±4±2.

FUEL TUBES/LINES/HOSES AND CLAMPSÐLOW-

PRESSURE TYPE

Also refer to the proceeding section on Quick±Con-

nect Fittings.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure andFig. 6 Fuel Injectors and Drain Tubes

Fig. 7 Fuel Injector Sensor

14 - 6 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1375 of 1938

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube or a

quick±connect fitting. Replace complete line/tube as

necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the fuel lines/tubes are prop-

erly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses are of a special construction.

If it is necessary to replace these lines/tubes/hoses,

use only original equipment type.

The hose clamps used to secure the rubber hoses

are of a special rolled edge construction. This con-

struction is used to prevent the edge of the clamp

from cutting into the hose. Only these rolled edge

type clamps may be used in this system. All other

types of clamps may cut into the hoses and cause

fuel leaks.

Where a rubber hose is joined to a metal tube

(staked), do not attempt to repair. Replace entire

line/tube assembly.

Use new original equipment type hose clamps.

Tighten hose clamps to 2 N´m (20 in. lbs.) torque.

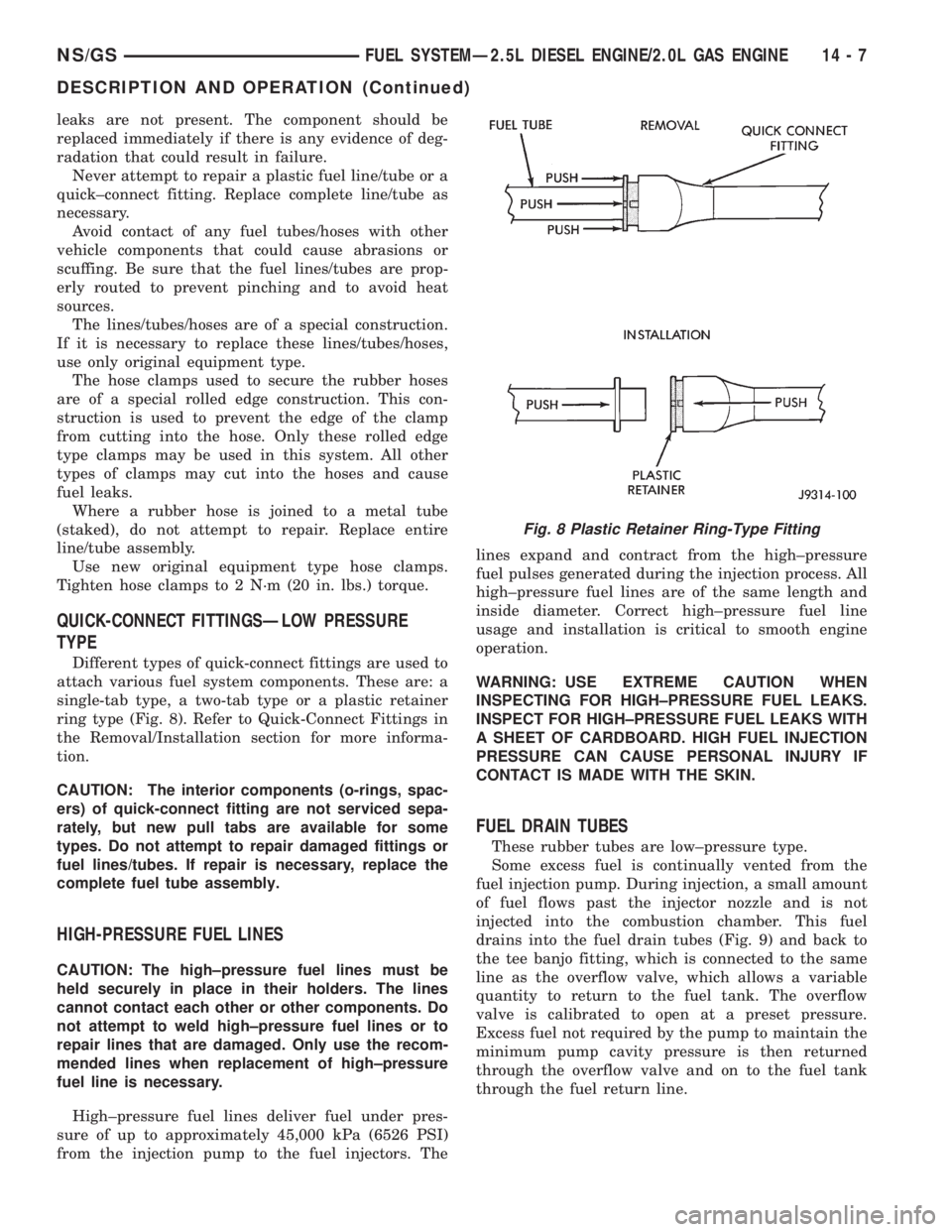

QUICK-CONNECT FITTINGSÐLOW PRESSURE

TYPE

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type (Fig. 8). Refer to Quick-Connect Fittings in

the Removal/Installation section for more informa-

tion.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately, but new pull tabs are available for some

types. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

HIGH-PRESSURE FUEL LINES

CAUTION: The high±pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high±pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high±pressure

fuel line is necessary.

High±pressure fuel lines deliver fuel under pres-

sure of up to approximately 45,000 kPa (6526 PSI)

from the injection pump to the fuel injectors. Thelines expand and contract from the high±pressure

fuel pulses generated during the injection process. All

high±pressure fuel lines are of the same length and

inside diameter. Correct high±pressure fuel line

usage and installation is critical to smooth engine

operation.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH±PRESSURE FUEL LEAKS.

INSPECT FOR HIGH±PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

FUEL DRAIN TUBES

These rubber tubes are low±pressure type.

Some excess fuel is continually vented from the

fuel injection pump. During injection, a small amount

of fuel flows past the injector nozzle and is not

injected into the combustion chamber. This fuel

drains into the fuel drain tubes (Fig. 9) and back to

the tee banjo fitting, which is connected to the same

line as the overflow valve, which allows a variable

quantity to return to the fuel tank. The overflow

valve is calibrated to open at a preset pressure.

Excess fuel not required by the pump to maintain the

minimum pump cavity pressure is then returned

through the overflow valve and on to the fuel tank

through the fuel return line.

Fig. 8 Plastic Retainer Ring-Type Fitting

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1384 of 1938

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing the accelerator pedal or throttle cable.

REMOVAL

(1) Disconnect electrical connector.

(2) Remove accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

(1) Place accelerator pedal assembly over studs

protruding from floor pan. Tighten mounting nuts to

5 N´m (46 in. lbs.) torque.

(2) Connect electrical connector.

(3) Before starting the engine, operate the acceler-

ator pedal to check for any binding.

AIR CLEANER ELEMENT

REMOVAL

(1) Remove hose clamp at Mass Air Flow Sensor.

(2) Remove hose from Mass Air Flow Sensor.(3) Loosen 2 clamps holding air cleaner housing

halves together.

(4) Remove left side of air cleaner housing.

(5) Remove element from air cleaner housing.

INSTALLATION

(1) Install a new element in housing.

(2) Position left side of housing.

(3) Snap clamps into place.

(4) Install hoses and clamps.

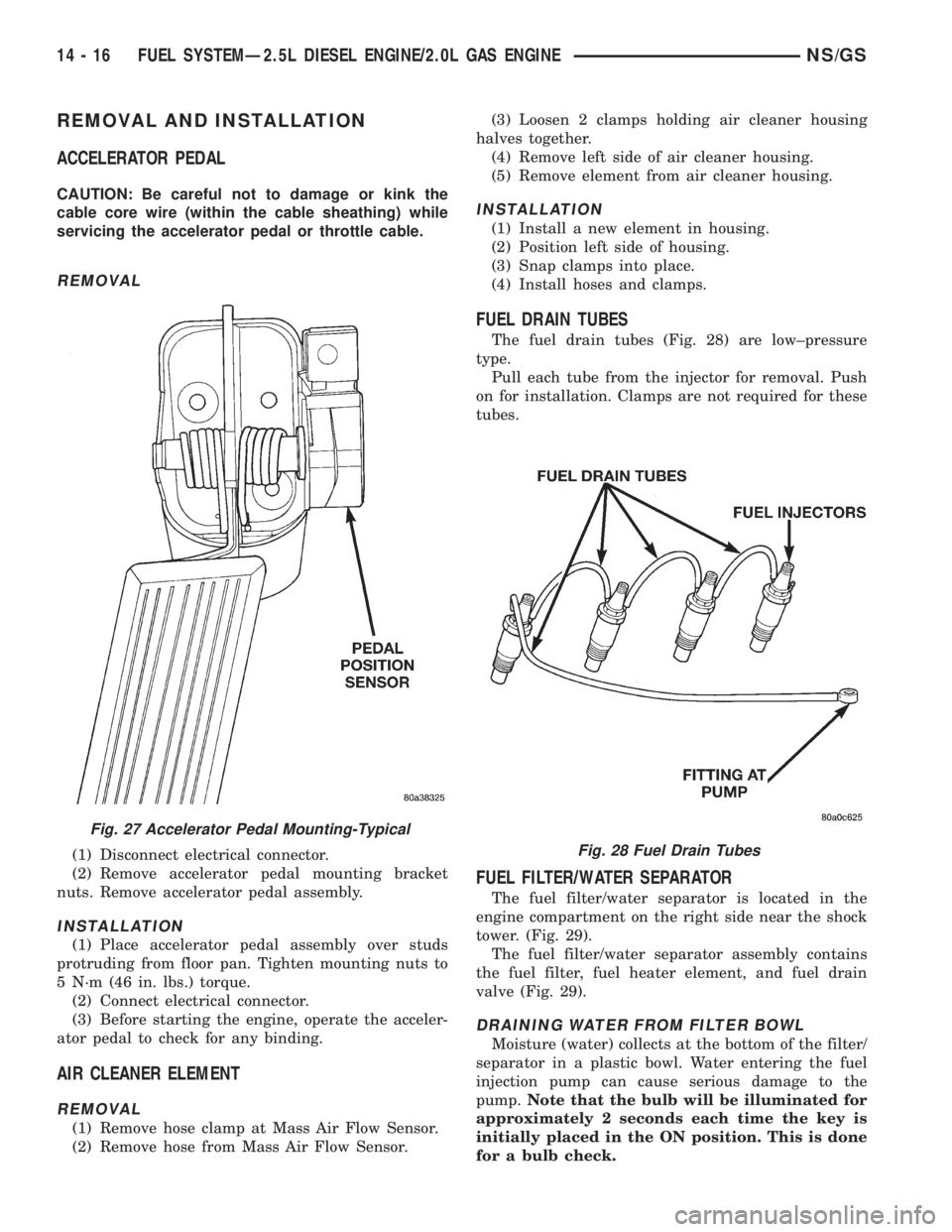

FUEL DRAIN TUBES

The fuel drain tubes (Fig. 28) are low±pressure

type.

Pull each tube from the injector for removal. Push

on for installation. Clamps are not required for these

tubes.

FUEL FILTER/WATER SEPARATOR

The fuel filter/water separator is located in the

engine compartment on the right side near the shock

tower. (Fig. 29).

The fuel filter/water separator assembly contains

the fuel filter, fuel heater element, and fuel drain

valve (Fig. 29).

DRAINING WATER FROM FILTER BOWL

Moisture (water) collects at the bottom of the filter/

separator in a plastic bowl. Water entering the fuel

injection pump can cause serious damage to the

pump.Note that the bulb will be illuminated for

approximately 2 seconds each time the key is

initially placed in the ON position. This is done

for a bulb check.

Fig. 27 Accelerator Pedal Mounting-Typical

Fig. 28 Fuel Drain Tubes

14 - 16 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

Page 1390 of 1938

(14) Gauge reading should be at 0.60 mm. If not,

the pump must be rotated for adjustment:

(a) Loosen the three injection pump mounting

nuts at the mounting flanges. These flanges are

equipped with slotted holes. The slotted holes are

used to rotate and position the injection pump for

fuel timing. Loosen the three nuts just enough to

rotate the pump.

(b) Rotate the pumpclockwise(as viewed from

front) until .60 mm is indicated on the dial indica-

tor gauge.

(c) Tighten the three pump mounting nuts to 30

N´m (22 ft. lbs.) torque.

(d) Recheck the dial indicator after tightening

the pump mounting nuts. Gauge should still be

reading 0.60 mm. Loosen pump mounting nuts and

readjust if necessary.

(15) Remove dial indicator and adapter tools.

(16) Install access plug and washer to rear of

injection pump.

(17) Install plug at timing gear cover.

(18) Remove dial indicator from valve stem.

(19) Install valve spring and keepers.

(20) Install rocker arm assembly and tighten nuts.

(21) Install and connect the four high±pressure

fuel lines to the fuel injection pump. Also connect

fuel lines at the fuel injectors. For procedures, refer

to High±Pressure Fuel Lines in this group.

(22) Install electrical connector at engine coolant

temperature sensor.

(23) Connect electrical connector at fuel shutdown

solenoid.(24) Connect the main engine wiring harness to

the glow plugs.

(25) Connect the fuel timing solenoid pigtail har-

ness to the engine wiring harness.

(26) Connect the overflow valve/banjo fitting (fuel

return line assembly). Replace copper gaskets before

installing.

(27) Connect the rubber fuel return and supply

hoses to metal lines at pump. Tighten hose clamps to

2 N´m (20 in. lbs.) torque.

(28) Install generator assembly.

(29) Install engine accessory drive belt. Refer to

Group 7, Cooling System for procedures.

(30) Install negative battery cable to battery.

(31) Start the engine and bring to normal operat-

ing temperature.

(32) Check for fuel leaks.

FUEL INJECTORS

Four fuel injectors are used on each engine. Of these

four, two different types are used. The fuel injector used

on cylinder number one is equipped with a fuel injector

sensor (Fig. 47). The other three fuel injectors are iden-

tical.

Do not place the fuel injector equipped with

the fuel injector sensor into any other location

except the cylinder number one position.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Thoroughly clean the area around the injector

with compressed air.

(3) Remove the fuel drain hoses (tubes) at each

injector (Fig. 48) being serviced. Each of these hoses

is slip±fit to the fitting on injector.

(4) Remove the high±pressure fuel line at injector

being removed. Refer to High±Pressure Fuel Lines in

this group for procedures.

(5) Remove the injector using special socket tool

number VM.1012A. When removing cylinder number

Fig. 46 Installing Dial Indicator and Special Adapter

Tools

Fig. 47 Fuel Injector SensorÐNumber±1 Cylinder

14 - 22 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)