service indicator CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 683 of 1938

POWERTRAIN

CONTROL

MODULE C1

35

K22

18

OR/DB

OR/DB18 K22

ES08MODULE CONTROL

TRANSMISSION

12

SIGNAL SENSOR POSITION THROTTLE THROTTLE

POSITION

SENSOR

SIGNAL SIGNAL SENSOR POSITION CRANKSHAFT

CRANKSHAFT

POSITION

SENSOR

SIGNAL

6

ES05

K24

18

GY/BK GY/BK18 K24

32C1

BK/YL18 T41

76C2

10

P/N

TRANSMISSION

RANGE

SENSOR

SERVO CONTROL

SPEED

VEHICLE

13

4

STOP

LAMP

SWITCH

V30

18

DB/RD

213

C280

VENT

SOLENOID SOLENOIDVACUUM

56C2

V35

18

LG/RD

TN/RD18 V36

3E43

B707

E43 B706 YL/RD18 V32

5C1C262

K29

18

WT/PK

SPEED

CONTROL

VACUUM

SOLENOID

CONTROL CONTROL SOLENOIDVENT CONTROLSPEED

WT/PK20 K29 V32

20

YL/RD STOP LAMP

SWITCH

SENSESPEED

CONTROL

ON/OFF

SWITCH SENSE

2

6

G300

BK20Z1

DB/RD20 V30

GENERATOR

FIELD DRIVER

K20

18

DG

8C1

2

GENERATOR

TRANSMISSION

RANGE

SWITCH

T41

SENSE

10

YL/DG18 T10

SENSE REQUEST MANAGEMENTTORQUE

TORQUE

MANAGEMENT

REQUIREMENT

SENSE 63

C2

7

ST-RUN V23

CENTER MESSAGESERVICE

ENGINE

SOON

LAMP

C122

INDICATOR SERVICE ENGINE SOON5

B70

E43

P34

B232

A2G3

20

BK/PK

BK/PK20 G3

BK/PK18 G3 *13

* RHD

RHD LHD

JUNCTION

BLOCK

TOGENERATOR

FIELD

DRIVER

LAMP DRIVER (8W-70-8) (8W-70-8)

(8W-31-5)

(8W-33-3) (8W-33-3)

(8W-15-7)(8W-20-2) (8W-31-4)

(8W-31-8)(8W-12-9)

(8W-46-3)

(8W-12-19)

NS/GS8W-30 FUEL/IGNITION SYSTEM

2.4L8W - 30 - 19

GS003019J988W-3

Page 691 of 1938

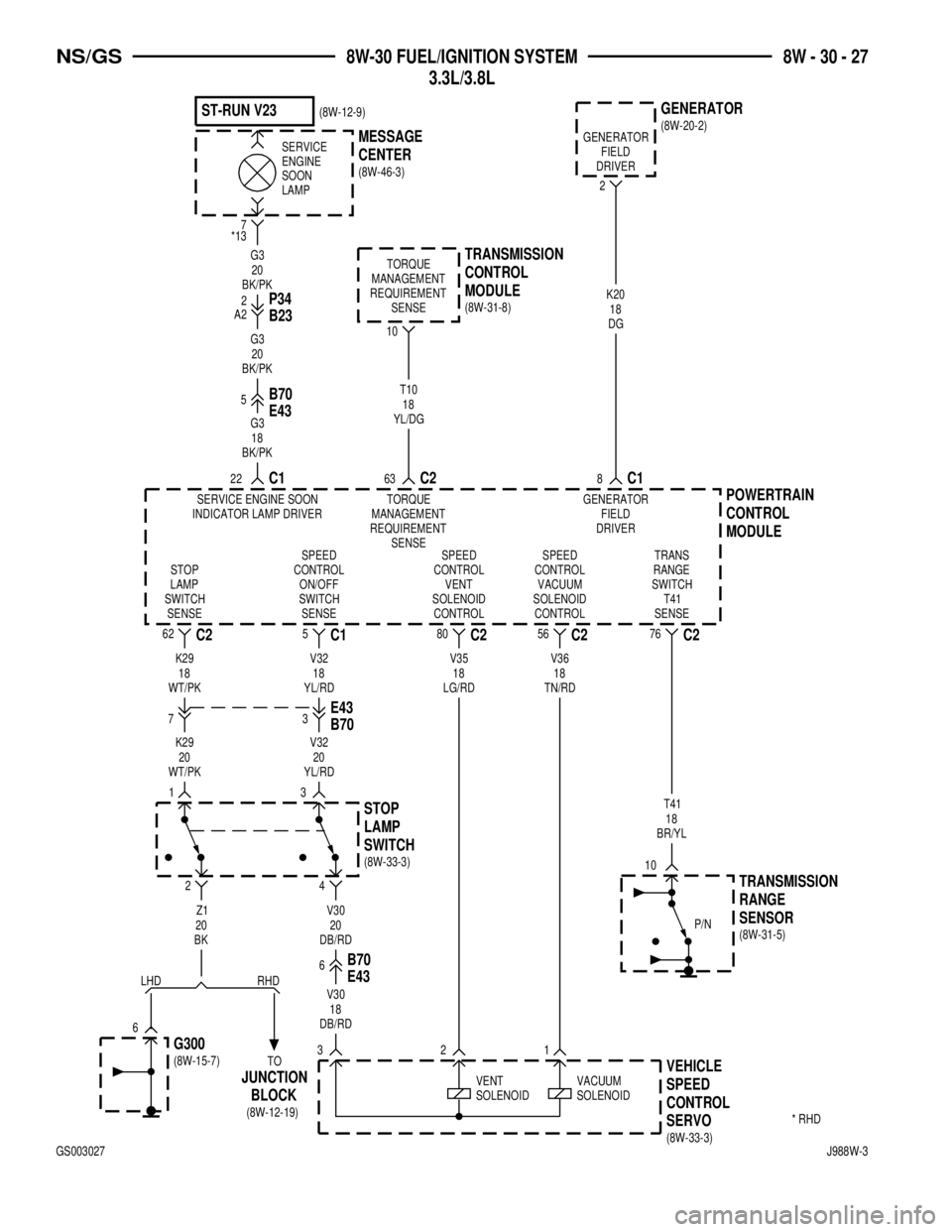

POWERTRAIN

CONTROL

MODULE

BR/YL18 T41

76C2

TRANS

RANGE

SWITCH

T41

SENSE

P/N

10

SERVO CONTROL

SPEED

VEHICLE

13

4

STOP

LAMP

SWITCH

V30

18

DB/RD

213

C280

VENT

SOLENOID SOLENOIDVACUUM

56C2

V35

18

LG/RD

TN/RD18 V36

3E43

B707

E43 B706 YL/RD18 V32

5C1C262

K29

18

WT/PK

SPEED

CONTROL

VACUUM

SOLENOID

CONTROL CONTROL SOLENOIDVENT CONTROLSPEED

WT/PK20 K29 V32

20

YL/RD STOP

LAMP

SWITCH

SENSESPEED

CONTROL

ON/OFF

SWITCH

SENSE

2

6

G300

BK20Z1DB/RD20 V30

TRANSMISSION

RANGE

SENSOR

2

8C1

K20

18

DG

DRIVERFIELD GENERATOR

GENERATOR

7

ST-RUN V23

CENTER

MESSAGESERVICE

ENGINE

SOON

LAMP

C122

INDICATOR LAMP DRIVERSERVICE ENGINE SOON5

B70

E43

P34

B232

A2G3

20

BK/PK

BK/PK20 G3

BK/PK18 G3 *13

RHD LHD

JUNCTION

BLOCK

TO

* RHD GENERATOR

FIELD

DRIVER

10

TRANSMISSION

CONTROL

MODULE

C2

63

T10

18

YL/DG

TORQUE

MANAGEMENT

REQUIREMENT

SENSE SENSE REQUIREMENTMANAGEMENTTORQUE

(8W-33-3) (8W-33-3)

(8W-15-7)(8W-31-5) (8W-20-2) (8W-12-9)

(8W-46-3)

(8W-12-19)(8W-31-8)

NS/GS8W-30 FUEL/IGNITION SYSTEM

3.3L/3.8L8W - 30 - 27

GS003027J988W-3

Page 779 of 1938

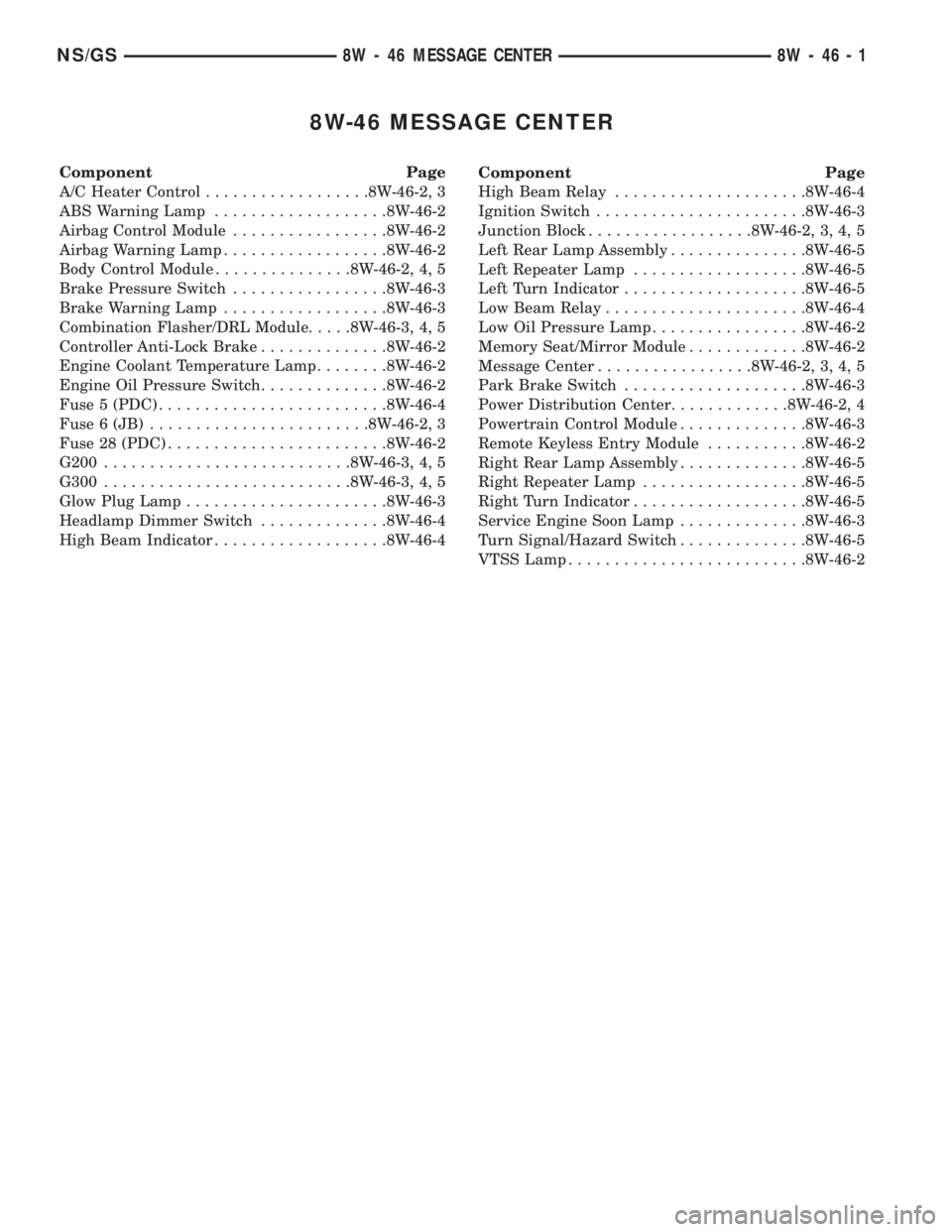

8W-46 MESSAGE CENTER

Component Page

A/C Heater Control..................8W-46-2, 3

ABS Warning Lamp...................8W-46-2

Airbag Control Module.................8W-46-2

Airbag Warning Lamp..................8W-46-2

Body Control Module...............8W-46-2, 4, 5

Brake Pressure Switch.................8W-46-3

Brake Warning Lamp..................8W-46-3

Combination Flasher/DRL Module.....8W-46-3, 4, 5

Controller Anti-Lock Brake..............8W-46-2

Engine Coolant Temperature Lamp........8W-46-2

Engine Oil Pressure Switch..............8W-46-2

Fuse 5 (PDC).........................8W-46-4

Fuse 6 (JB)........................8W-46-2, 3

Fuse 28 (PDC)........................8W-46-2

G200...........................8W-46-3, 4, 5

G300...........................8W-46-3, 4, 5

Glow Plug Lamp......................8W-46-3

Headlamp Dimmer Switch..............8W-46-4

High Beam Indicator...................8W-46-4Component Page

High Beam Relay.....................8W-46-4

Ignition Switch.......................8W-46-3

Junction Block..................8W-46-2, 3, 4, 5

Left Rear Lamp Assembly...............8W-46-5

Left Repeater Lamp...................8W-46-5

Left Turn Indicator....................8W-46-5

Low Beam Relay......................8W-46-4

Low Oil Pressure Lamp.................8W-46-2

Memory Seat/Mirror Module.............8W-46-2

Message Center.................8W-46-2, 3, 4, 5

Park Brake Switch....................8W-46-3

Power Distribution Center.............8W-46-2, 4

Powertrain Control Module..............8W-46-3

Remote Keyless Entry Module...........8W-46-2

Right Rear Lamp Assembly..............8W-46-5

Right Repeater Lamp..................8W-46-5

Right Turn Indicator...................8W-46-5

Service Engine Soon Lamp..............8W-46-3

Turn Signal/Hazard Switch..............8W-46-5

VTSS Lamp..........................8W-46-2

NS/GS8W - 46 MESSAGE CENTER 8W - 46 - 1

Page 781 of 1938

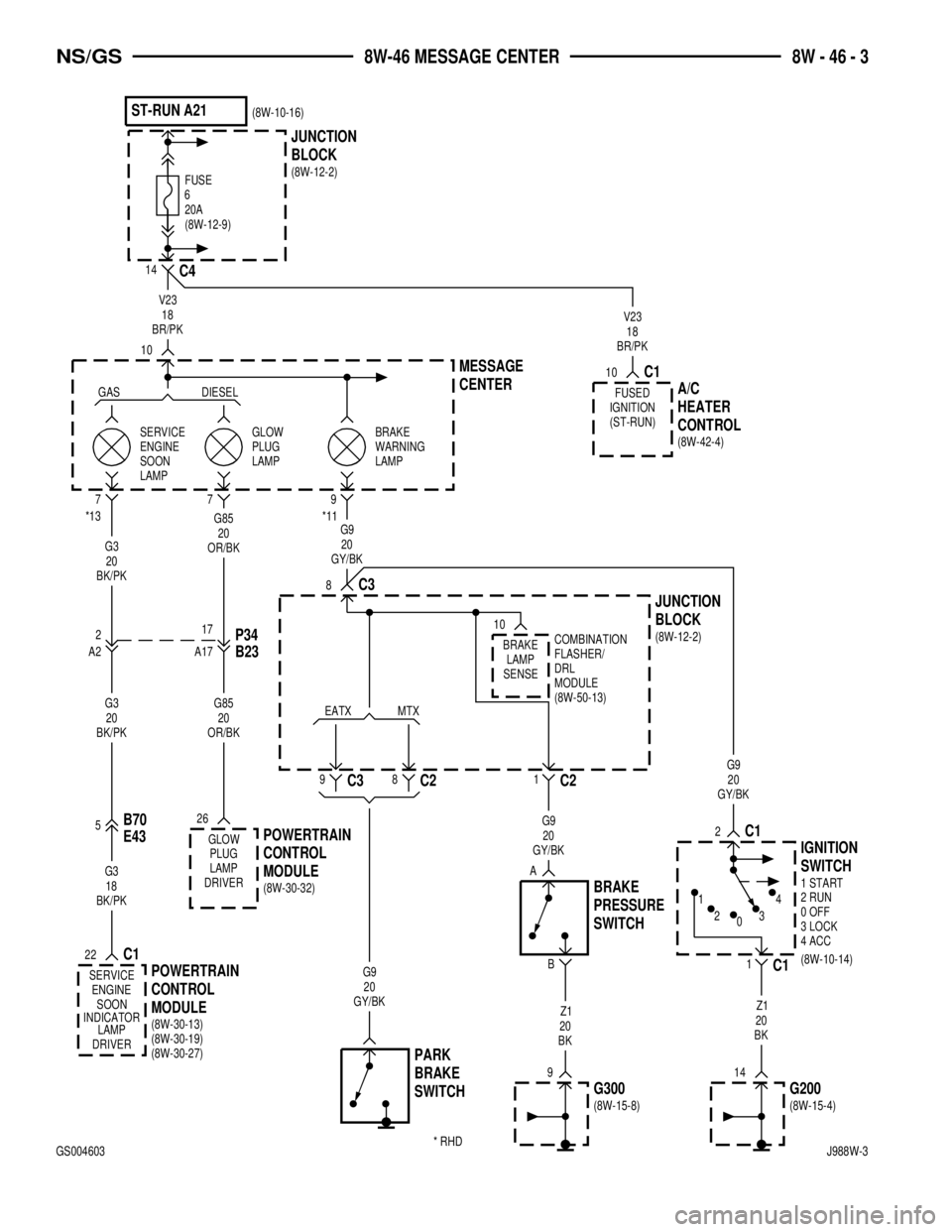

(ST-RUN) IGNITIONFUSED

GY/BK20 G9

Z1

20

BK

14

G200

IGNITION

SWITCH

4 1

2

03

2C1

1C1

BK20Z1

G300

9

SWITCH PRESSURE

BRAKE

B

1C2

A

G9

20

GY/BK

GY/BK20 G9

PARK

BRAKE

SWITCH

C39

C38

G9

20

GY/BK

JUNCTION

BLOCK

9

BRAKE

WARNING

LAMP

BK/PK20 G3

BK/PK20 G3

5B70

E43

2

DRIVERLAMP 22

SERVICE

ENGINE

SOON

MODULE CONTROL

POWERTRAIN

C1

LAMP

SOON

ENGINE

SERVICE

7

CENTER

MESSAGE

10

ST-RUN A21

20A

FUSE

6

BLOCK JUNCTION

14C4

BR/PK18 V23

C110

A/C

CONTROL

V23

18

BR/PK

A2

HEATER

GLOW

PLUG

LAMP

7

G85

20

OR/BK

POWERTRAIN

CONTROL

MODULE

26

GLOW

PLUG

LAMP

DRIVER GAS DIESEL

A17

17P34

B23

OR/BK20 G85

10

MODULE DRL

FLASHER/

COMBINATION

BRAKE

LAMP

SENSE

MTX

1 START

2 RUN

3 LOCK 0 OFF

4 ACC *13 *11

G3

18

BK/PK

EATX

8C2

* RHD

INDICATOR

(8W-15-4) (8W-15-8)(8W-12-2)

(8W-30-13)

(8W-30-19)

(8W-30-27)(8W-12-9)(8W-10-16)

(8W-12-2)

(8W-42-4)

(8W-30-32)(8W-50-13)

(8W-10-14)

NS/GS8W-46 MESSAGE CENTER 8W - 46 - 3

GS004603J988W-3

Page 934 of 1938

(LHD) MESSAGE CENTER

* DIESEL WAIT-TO START WARNING LAMP DRIVER G85 20OR/BK * 7

BLUE

7 1

136

G69 22BK/OR M1 20PK

R41 18BK/TN V23 18BR/PK G9 20GY/BK

G6 22GY G3 20BK/PK G2 22VT

G19 20LG/OR L62 18BR/RD Z1 20BK

L63 18DG/RD L34 20RD/OR

13 12 11 10 9 8 7 6 5 4

3 2 1 CAV VTSS INDICATOR LAMP DRIVER

FUSED B (+)

AIRBAG WARNING LAMP DRIVER FUSED IGNITION (ST-RUN) RED BRAKE WARNING LAMP DRIVER

ENGINE OIL PRESSURE SWITCH SENSE SERVICE ENGINE SOON INDICATOR LAMP DRIVER ENGINE TEMPERATURE WARNING LAMP DRIVER

ABS WARNING LAMP DRIVER RIGHT TURN SIGNAL GROUND

LEFT TURN SIGNAL FUSED HIGH BEAM RELAY OUTPUT CIRCUIT

FUNCTION

SWITCH MEMORY SET

BLUE564

1 2 3

P23 20PK/RD P22 20PK/BK P24 20PK/WT Z1 20BK

6 5 4 3 2

1 CAV MEMORY NO. 2 MEMORY SET MEMORY NO. 1 GROUND - - CIRCUIT

- - FUNCTION

MODULE - C3 MEMORY SEAT/MIRROR

21 10

11 NATURAL

1

P29 20BR/WT P25 22VT/RD P47 22LB P40 22GY/LB P15 22YL/LB

P11 22YL/WT P19 22YL/LG P9 20RD

P28 20BR/RD P26 22BR P27 22LB/RD P48 22GY/WT P17 22RD/LB P13 22RD/WT

P21 22RD/LG

21 20 19

18 17 16

15 14 13

12 11 10 9 8 7

6

5 4 3

2 1 CAV 6 VOLT SUPPLY SEAT HORIZONTAL POSITION SENSE SEAT RECLINER POSITION SENSE SEAT RECLINER (FORWARD) SEAT HORIZONTAL (FORWARD) SEAT REAR VERTICAL (UP) SEAT FRONT VERTICAL (UP)

FUSED B (+) SEAT POSITION SENSE COMMON SEAT FRONT VERTICAL POSITION SENSE SEAT REAR VERTICAL POSITION SENSE SEAT RECLINER (REARWARD) SEAT HORIZONTAL (REARWARD)

SEAT REAR VERTICAL (DOWN)

SEAT FRONT VERTICAL (DOWN)

- - - - - - CIRCUIT

- - - - - - - FUNCTION

8W - 80 - 58 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8058

Page 935 of 1938

SWITCH MULTI-FUNCTION

8 127BLACK

1

L324 22WT/LG V10 20BR

L94 20OR/WT L93 22PK Z1 18BK

F1 20DB V52 20DG//YL V16 20WT

L305 22LB/WT L302 22LB/YL L91 22DB/PK

12 11 10 9 8 7

6

5 4 3 2 1 CAV HIGH BEAM RELAY CONTROL

FRONT WASHER MOTOR CONTROL LOW BEAM RELAY CONTROL HIGH/LOW BEAM RELAY CONTROL

GROUND FUSED B(+) WIPER MUX SIGNAL

HIGH SPEED RELAY DRIVER RIGHT TURN SIGNAL SENSE LEFT TURN SIGNAL SENSE COMBO FLASHER SWITCHED GROUND

- CIRCUIT

- FUNCTION

ACTUATOR MODE DOOR

5BLACK1

C35 20DG/YL C57 20DB/GY C37 20YL

C26 20PK/DB

C34 20DB/WT

5 4

3 2 1 CAV MODE DOOR DRIVER SENSOR GROUND MODE DOOR FEEDBACK SIGNAL

5 VOLT SUPPLY DOOR COMMON CIRCUIT

FUNCTION

FUSED RIGHT HIGH BEAM OUTPUT L34 20RD/OR7 131 6ENGINE TEMPERATURE WARNING LAMP DRIVER CIRCUIT FUNCTION

CAV

G2 22VT

1

2G19 20LG/OR

3L63 18DG/RD LEFT TURN SIGNAL

6L62 18BR/RD RIGHT TURN SIGNALSGROUND Z1 20BK

54

G69 22BK/OR

7

8M1 20PK

9R41 18BK/OR

V23 18BR/PK

10

13G3 20BK/PKENGINE OIL PRESSURE SWITCH SENSE G6 22GY

12G9 20GY/BK RED BRAKE WARNING LAMP DRIVER

11ABS WARNING LAMP DRIVER

FUSED B(+)

FUSED IGNITION (ST-RUN)

(RHD) MESSAGE CENTER

VTSS INDICATOR LAMP DRIVER

AIRBAG WARNING LAMP DRIVER

SERVICE ENGINE SOON INDICATOR LAMP DRIVER

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 59

NSGS8059J988W-3

Page 947 of 1938

MODULE - C1CONTROL POWERTRAIN

- -

K90 18TN ENGINE STARTER MOTOR RELAY CONTROL

C103 18DG/LB A/C SWITCH SIGNALKNOCK SENSOR SIGNAL K42 18DB/LG- - BLACK

10 20 30 40

1 11 21 31

K35 18GY/YL K1 18DG/RD K22 18OR/DB K44 18TN/YL K24 18GY/BK K41 18BK/DG K2 18TN/BK G3 18BK/PK F87 18WT/BK K12 18TN/WT K14 18LB/BR

K38 18GY K58 18BR/DB K11 18WT/DB K19 18GY/RD Z12 18BK/TN K20 18DG K13 18YL/WT

A142 18DG/OR V32 18YL/RD K17 18DB/TN K18 18RD/YL

40 39 38

37 36 35

34 33 32

31

30 29 28

27 26 25 24 23

22 21 20

19 18 17

16 15 14

13 12 11

10 9 8

7 6 5

4 3 2

1 CAV EGR SOLENOID CONTROL MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL THROTTLE POSITION SENSOR SIGNAL CAMSHAFT POSITION SENSOR SIGNAL CRANKSHAFT POSITION SENSOR SIGNAL HEATED OXYGEN SENSOR SIGNAL ENGINE COOLANT TEMPERATURE SENSOR SIGNAL SERVICE ENGINE SOON INDICATOR LAMP DRIVER FUSED IGNITION SWITCH OUTPUT (ST-RUN) INJECTOR NO. 2 DRIVER INJECTOR NO. 4 DRIVER

INJECTOR NO. 5 DRIVER (3.3L/3.8L) INJECTOR NO. 6 DRIVER (3.3L/3.8L) INJECTOR NO. 1 DRIVER IGNITION COIL NO. 1 DRIVER GROUND GENERATOR FIELD DRIVER INJECTOR NO. 3 DRIVER

AUTOMATIC SHUT DOWN RELAY OUTPUT SPEED CONTROL ON/OFF SWITCH SENSE IGNITION COIL NO. 2 DRIVER IGNITION COIL NO. 3 DRIVER (3.3L/3.8L)

- - - - - - -

- - - - - CIRCUIT

- - - - - - -

- - - - - FUNCTION

K21 18BK/RD* INTAKE AIR TEMPERATURE SENSOR SIGNAL

* 2.0L

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 71

NSGS8071J988W-3

Page 1057 of 1938

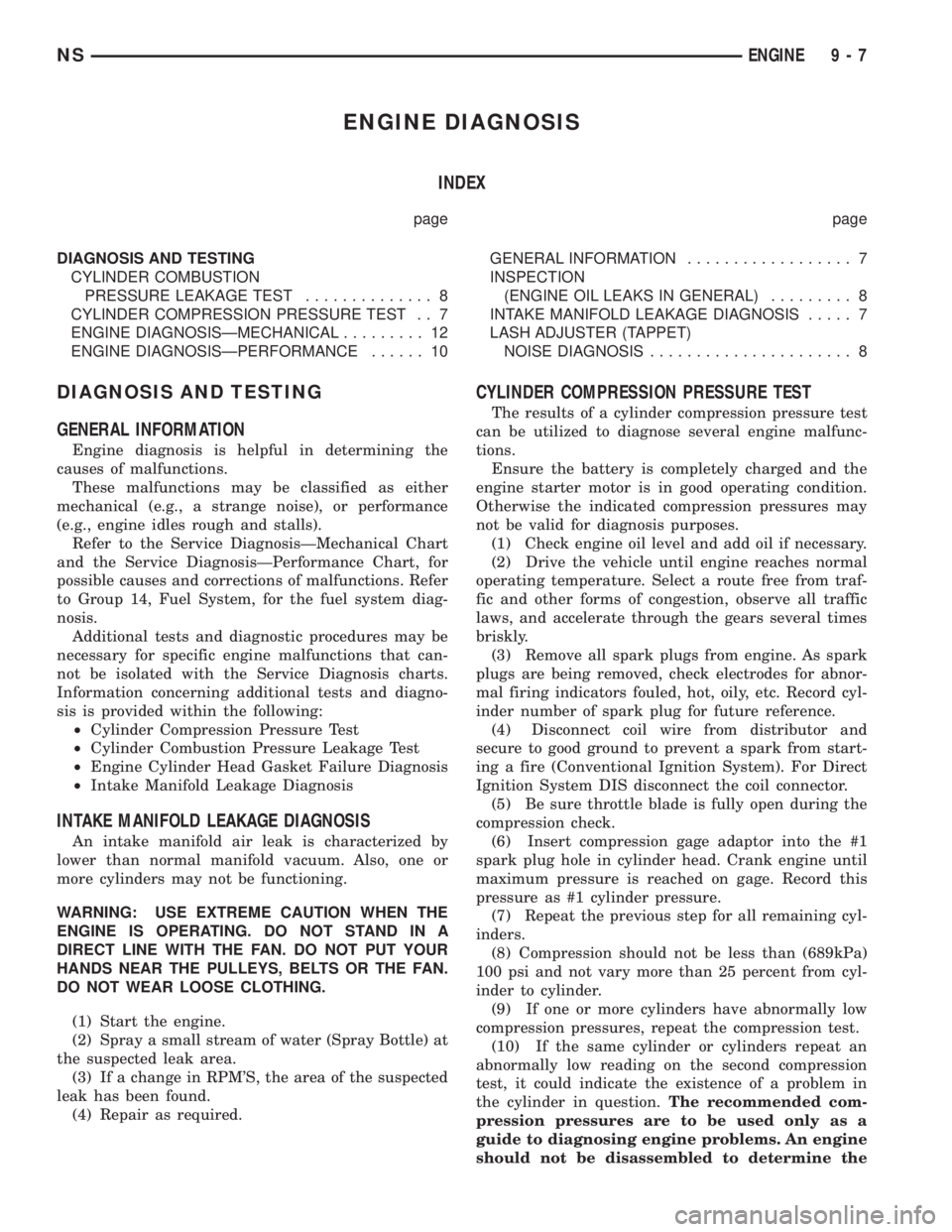

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST.............. 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 12

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION

(ENGINE OIL LEAKS IN GENERAL)......... 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS...................... 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

NSENGINE 9 - 7

Page 1070 of 1938

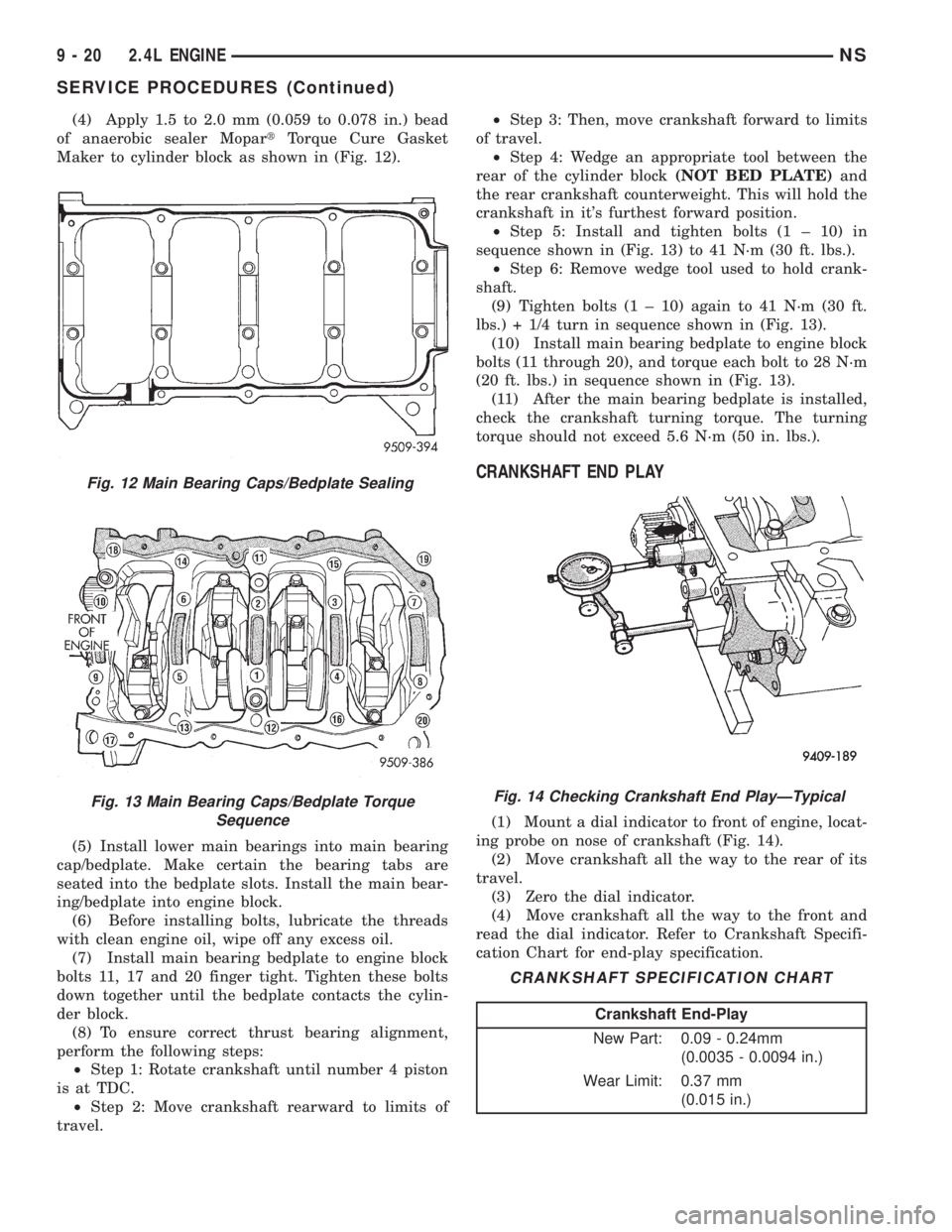

(4) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead

of anaerobic sealer MopartTorque Cure Gasket

Maker to cylinder block as shown in (Fig. 12).

(5) Install lower main bearings into main bearing

cap/bedplate. Make certain the bearing tabs are

seated into the bedplate slots. Install the main bear-

ing/bedplate into engine block.

(6) Before installing bolts, lubricate the threads

with clean engine oil, wipe off any excess oil.

(7) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block.

(8) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1 ± 10) in

sequence shown in (Fig. 13) to 41 N´m (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(9) Tighten bolts (1 ± 10) again to 41 N´m (30 ft.

lbs.) + 1/4 turn in sequence shown in (Fig. 13).

(10) Install main bearing bedplate to engine block

bolts (11 through 20), and torque each bolt to 28 N´m

(20 ft. lbs.) in sequence shown in (Fig. 13).

(11) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 14).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Crankshaft Specifi-

cation Chart for end-play specification.

Fig. 12 Main Bearing Caps/Bedplate Sealing

Fig. 13 Main Bearing Caps/Bedplate Torque

SequenceFig. 14 Checking Crankshaft End PlayÐTypical

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-Play

New Part: 0.09 - 0.24mm

(0.0035 - 0.0094 in.)

Wear Limit: 0.37 mm

(0.015 in.)

9 - 20 2.4L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1072 of 1938

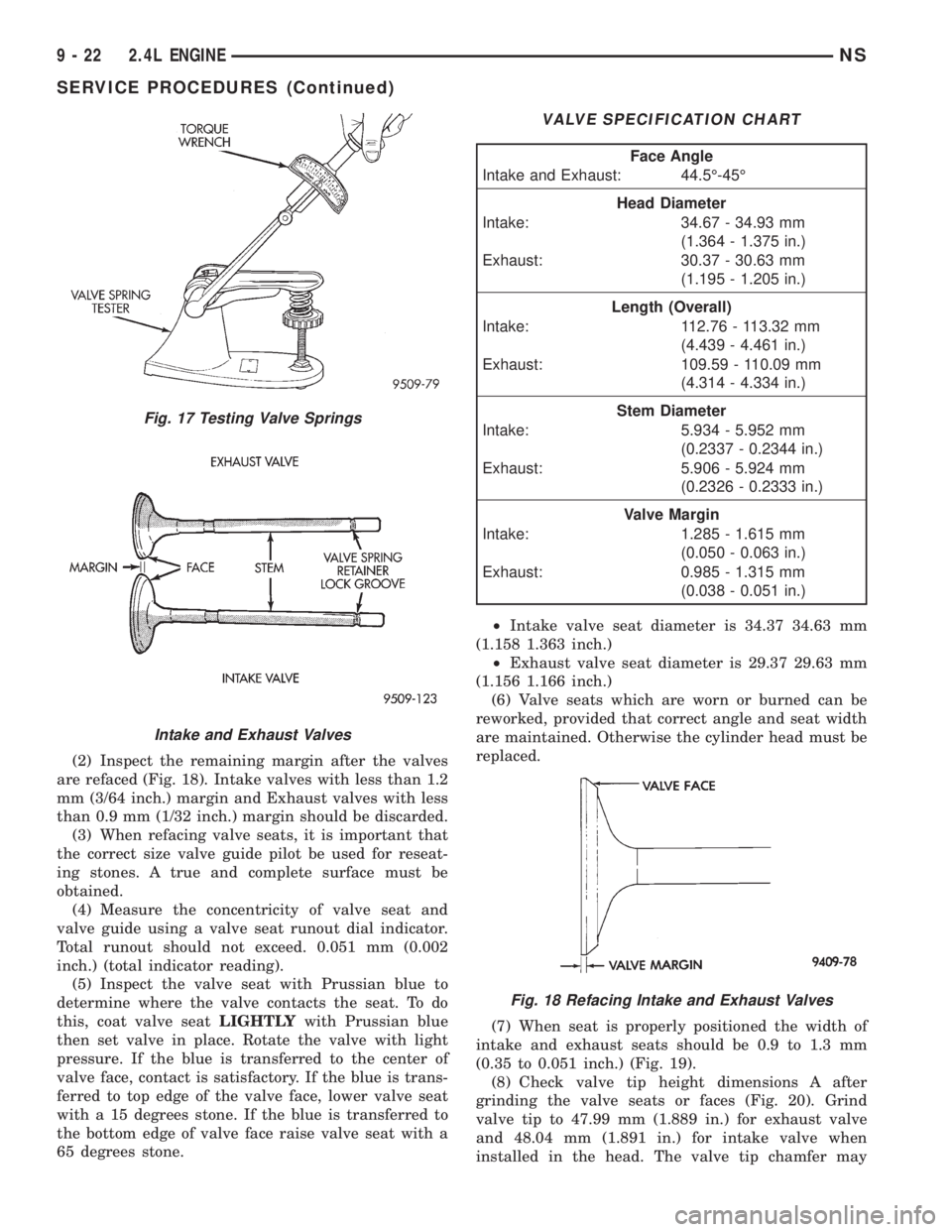

(2) Inspect the remaining margin after the valves

are refaced (Fig. 18). Intake valves with less than 1.2

mm (3/64 inch.) margin and Exhaust valves with less

than 0.9 mm (1/32 inch.) margin should be discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.²Intake valve seat diameter is 34.37 34.63 mm

(1.158 1.363 inch.)

²Exhaust valve seat diameter is 29.37 29.63 mm

(1.156 1.166 inch.)

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.9 to 1.3 mm

(0.35 to 0.051 inch.) (Fig. 19).

(8) Check valve tip height dimensions A after

grinding the valve seats or faces (Fig. 20). Grind

valve tip to 47.99 mm (1.889 in.) for exhaust valve

and 48.04 mm (1.891 in.) for intake valve when

installed in the head. The valve tip chamfer may

Fig. 17 Testing Valve Springs

Intake and Exhaust Valves

VALVE SPECIFICATION CHART

Face Angle

Intake and Exhaust: 44.5É-45É

Head Diameter

Intake: 34.67 - 34.93 mm

(1.364 - 1.375 in.)

Exhaust: 30.37 - 30.63 mm

(1.195 - 1.205 in.)

Length (Overall)

Intake: 112.76 - 113.32 mm

(4.439 - 4.461 in.)

Exhaust: 109.59 - 110.09 mm

(4.314 - 4.334 in.)

Stem Diameter

Intake: 5.934 - 5.952 mm

(0.2337 - 0.2344 in.)

Exhaust: 5.906 - 5.924 mm

(0.2326 - 0.2333 in.)

Valve Margin

Intake: 1.285 - 1.615 mm

(0.050 - 0.063 in.)

Exhaust: 0.985 - 1.315 mm

(0.038 - 0.051 in.)

Fig. 18 Refacing Intake and Exhaust Valves

9 - 22 2.4L ENGINENS

SERVICE PROCEDURES (Continued)