battery CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1911 of 1938

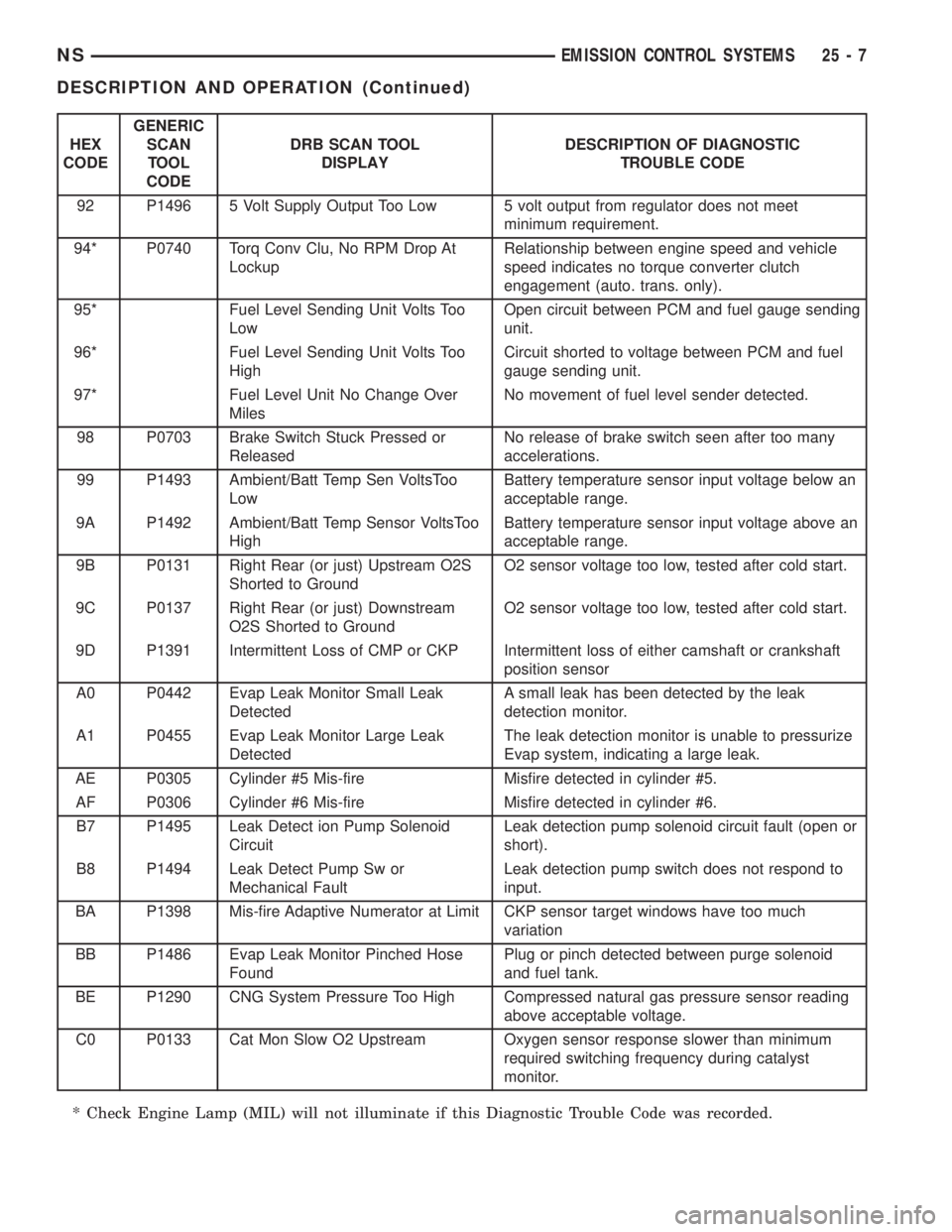

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC

TROUBLE CODE

92 P1496 5 Volt Supply Output Too Low 5 volt output from regulator does not meet

minimum requirement.

94* P0740 Torq Conv Clu, No RPM Drop At

LockupRelationship between engine speed and vehicle

speed indicates no torque converter clutch

engagement (auto. trans. only).

95* Fuel Level Sending Unit Volts Too

LowOpen circuit between PCM and fuel gauge sending

unit.

96* Fuel Level Sending Unit Volts Too

HighCircuit shorted to voltage between PCM and fuel

gauge sending unit.

97* Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

98 P0703 Brake Switch Stuck Pressed or

ReleasedNo release of brake switch seen after too many

accelerations.

99 P1493 Ambient/Batt Temp Sen VoltsToo

LowBattery temperature sensor input voltage below an

acceptable range.

9A P1492 Ambient/Batt Temp Sensor VoltsToo

HighBattery temperature sensor input voltage above an

acceptable range.

9B P0131 Right Rear (or just) Upstream O2S

Shorted to GroundO2 sensor voltage too low, tested after cold start.

9C P0137 Right Rear (or just) Downstream

O2S Shorted to GroundO2 sensor voltage too low, tested after cold start.

9D P1391 Intermittent Loss of CMP or CKP Intermittent loss of either camshaft or crankshaft

position sensor

A0 P0442 Evap Leak Monitor Small Leak

DetectedA small leak has been detected by the leak

detection monitor.

A1 P0455 Evap Leak Monitor Large Leak

DetectedThe leak detection monitor is unable to pressurize

Evap system, indicating a large leak.

AE P0305 Cylinder #5 Mis-fire Misfire detected in cylinder #5.

AF P0306 Cylinder #6 Mis-fire Misfire detected in cylinder #6.

B7 P1495 Leak Detect ion Pump Solenoid

CircuitLeak detection pump solenoid circuit fault (open or

short).

B8 P1494 Leak Detect Pump Sw or

Mechanical FaultLeak detection pump switch does not respond to

input.

BA P1398 Mis-fire Adaptive Numerator at Limit CKP sensor target windows have too much

variation

BB P1486 Evap Leak Monitor Pinched Hose

FoundPlug or pinch detected between purge solenoid

and fuel tank.

BE P1290 CNG System Pressure Too High Compressed natural gas pressure sensor reading

above acceptable voltage.

C0 P0133 Cat Mon Slow O2 Upstream Oxygen sensor response slower than minimum

required switching frequency during catalyst

monitor.

* Check Engine Lamp (MIL) will not illuminate if this Diagnostic Trouble Code was recorded.

NSEMISSION CONTROL SYSTEMS 25 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1923 of 1938

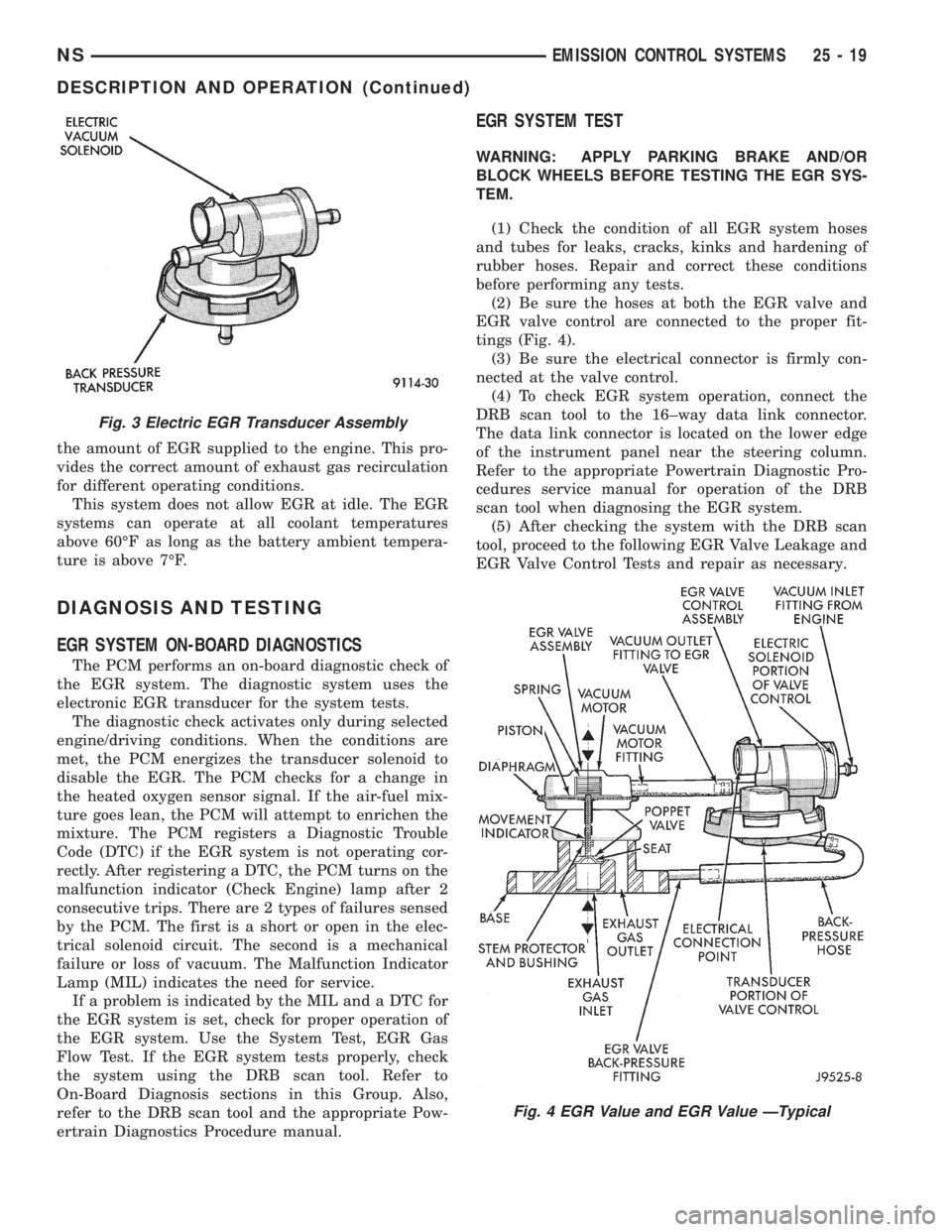

the amount of EGR supplied to the engine. This pro-

vides the correct amount of exhaust gas recirculation

for different operating conditions.

This system does not allow EGR at idle. The EGR

systems can operate at all coolant temperatures

above 60ÉF as long as the battery ambient tempera-

ture is above 7ÉF.

DIAGNOSIS AND TESTING

EGR SYSTEM ON-BOARD DIAGNOSTICS

The PCM performs an on-board diagnostic check of

the EGR system. The diagnostic system uses the

electronic EGR transducer for the system tests.

The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in

the heated oxygen sensor signal. If the air-fuel mix-

ture goes lean, the PCM will attempt to enrichen the

mixture. The PCM registers a Diagnostic Trouble

Code (DTC) if the EGR system is not operating cor-

rectly. After registering a DTC, the PCM turns on the

malfunction indicator (Check Engine) lamp after 2

consecutive trips. There are 2 types of failures sensed

by the PCM. The first is a short or open in the elec-

trical solenoid circuit. The second is a mechanical

failure or loss of vacuum. The Malfunction Indicator

Lamp (MIL) indicates the need for service.

If a problem is indicated by the MIL and a DTC for

the EGR system is set, check for proper operation of

the EGR system. Use the System Test, EGR Gas

Flow Test. If the EGR system tests properly, check

the system using the DRB scan tool. Refer to

On-Board Diagnosis sections in this Group. Also,

refer to the DRB scan tool and the appropriate Pow-

ertrain Diagnostics Procedure manual.

EGR SYSTEM TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE TESTING THE EGR SYS-

TEM.

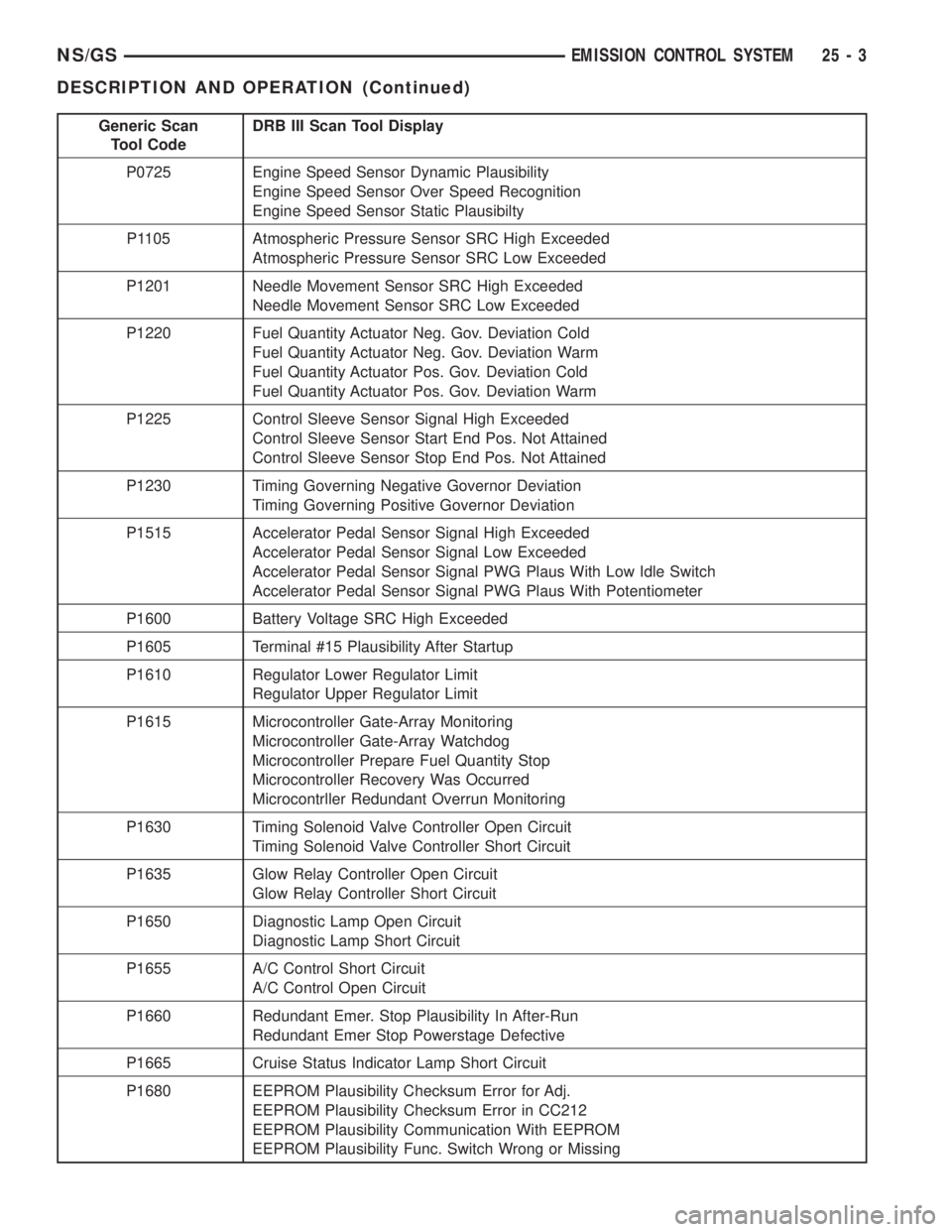

(1) Check the condition of all EGR system hoses

and tubes for leaks, cracks, kinks and hardening of

rubber hoses. Repair and correct these conditions

before performing any tests.

(2) Be sure the hoses at both the EGR valve and

EGR valve control are connected to the proper fit-

tings (Fig. 4).

(3) Be sure the electrical connector is firmly con-

nected at the valve control.

(4) To check EGR system operation, connect the

DRB scan tool to the 16±way data link connector.

The data link connector is located on the lower edge

of the instrument panel near the steering column.

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool when diagnosing the EGR system.

(5) After checking the system with the DRB scan

tool, proceed to the following EGR Valve Leakage and

EGR Valve Control Tests and repair as necessary.

Fig. 3 Electric EGR Transducer Assembly

Fig. 4 EGR Value and EGR Value ÐTypical

NSEMISSION CONTROL SYSTEMS 25 - 19

DESCRIPTION AND OPERATION (Continued)

Page 1931 of 1938

Generic Scan

Tool CodeDRB III Scan Tool Display

P0725 Engine Speed Sensor Dynamic Plausibility

Engine Speed Sensor Over Speed Recognition

Engine Speed Sensor Static Plausibilty

P1105 Atmospheric Pressure Sensor SRC High Exceeded

Atmospheric Pressure Sensor SRC Low Exceeded

P1201 Needle Movement Sensor SRC High Exceeded

Needle Movement Sensor SRC Low Exceeded

P1220 Fuel Quantity Actuator Neg. Gov. Deviation Cold

Fuel Quantity Actuator Neg. Gov. Deviation Warm

Fuel Quantity Actuator Pos. Gov. Deviation Cold

Fuel Quantity Actuator Pos. Gov. Deviation Warm

P1225 Control Sleeve Sensor Signal High Exceeded

Control Sleeve Sensor Start End Pos. Not Attained

Control Sleeve Sensor Stop End Pos. Not Attained

P1230 Timing Governing Negative Governor Deviation

Timing Governing Positive Governor Deviation

P1515 Accelerator Pedal Sensor Signal High Exceeded

Accelerator Pedal Sensor Signal Low Exceeded

Accelerator Pedal Sensor Signal PWG Plaus With Low Idle Switch

Accelerator Pedal Sensor Signal PWG Plaus With Potentiometer

P1600 Battery Voltage SRC High Exceeded

P1605 Terminal #15 Plausibility After Startup

P1610 Regulator Lower Regulator Limit

Regulator Upper Regulator Limit

P1615 Microcontroller Gate-Array Monitoring

Microcontroller Gate-Array Watchdog

Microcontroller Prepare Fuel Quantity Stop

Microcontroller Recovery Was Occurred

Microcontrller Redundant Overrun Monitoring

P1630 Timing Solenoid Valve Controller Open Circuit

Timing Solenoid Valve Controller Short Circuit

P1635 Glow Relay Controller Open Circuit

Glow Relay Controller Short Circuit

P1650 Diagnostic Lamp Open Circuit

Diagnostic Lamp Short Circuit

P1655 A/C Control Short Circuit

A/C Control Open Circuit

P1660 Redundant Emer. Stop Plausibility In After-Run

Redundant Emer Stop Powerstage Defective

P1665 Cruise Status Indicator Lamp Short Circuit

P1680 EEPROM Plausibility Checksum Error for Adj.

EEPROM Plausibility Checksum Error in CC212

EEPROM Plausibility Communication With EEPROM

EEPROM Plausibility Func. Switch Wrong or Missing

NS/GSEMISSION CONTROL SYSTEM 25 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1936 of 1938

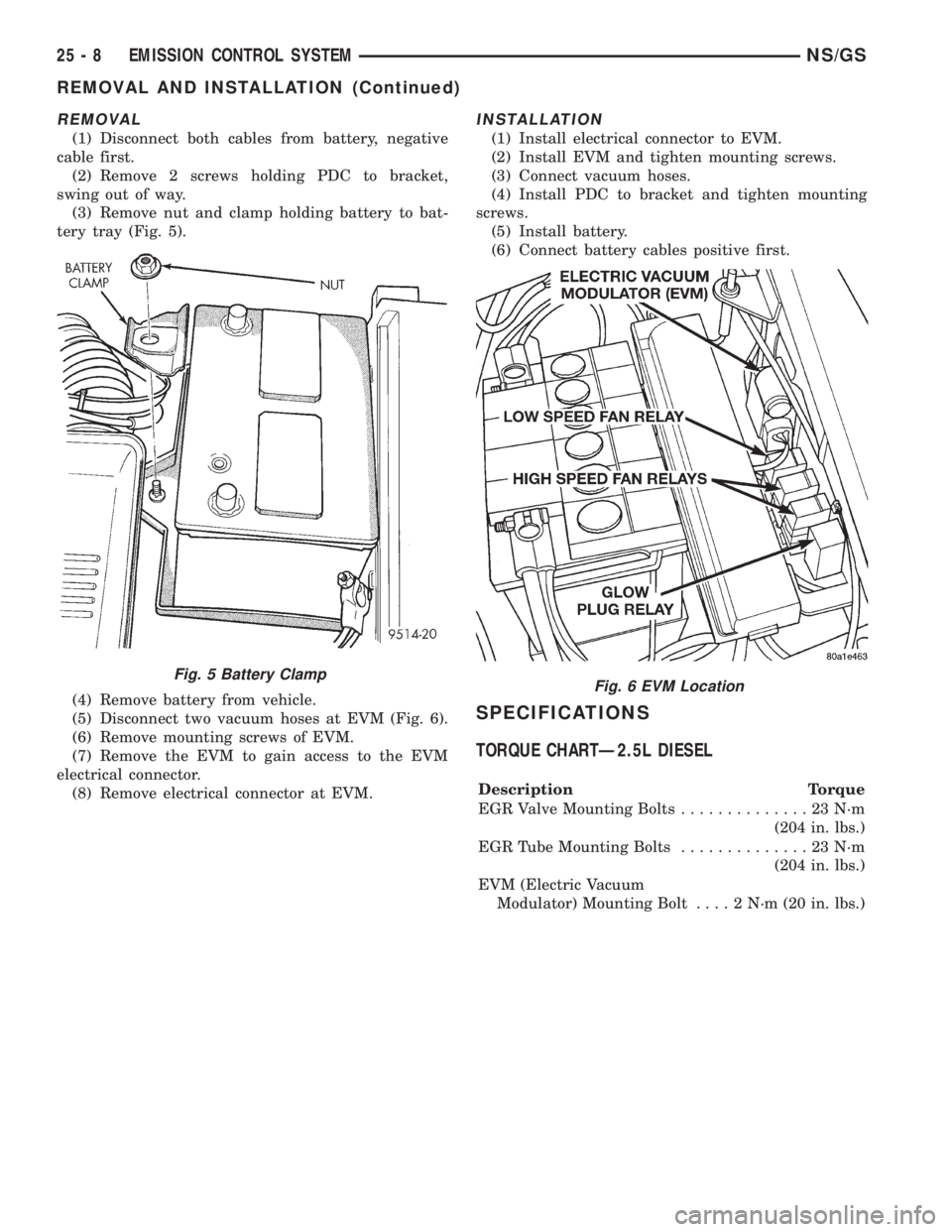

REMOVAL

(1) Disconnect both cables from battery, negative

cable first.

(2) Remove 2 screws holding PDC to bracket,

swing out of way.

(3) Remove nut and clamp holding battery to bat-

tery tray (Fig. 5).

(4) Remove battery from vehicle.

(5) Disconnect two vacuum hoses at EVM (Fig. 6).

(6) Remove mounting screws of EVM.

(7) Remove the EVM to gain access to the EVM

electrical connector.

(8) Remove electrical connector at EVM.

INSTALLATION

(1) Install electrical connector to EVM.

(2) Install EVM and tighten mounting screws.

(3) Connect vacuum hoses.

(4) Install PDC to bracket and tighten mounting

screws.

(5) Install battery.

(6) Connect battery cables positive first.

SPECIFICATIONS

TORQUE CHARTÐ2.5L DIESEL

Description Torque

EGR Valve Mounting Bolts..............23N´m

(204 in. lbs.)

EGR Tube Mounting Bolts..............23N´m

(204 in. lbs.)

EVM (Electric Vacuum

Modulator) Mounting Bolt. . . . 2 N´m (20 in. lbs.)

Fig. 5 Battery ClampFig. 6 EVM Location

25 - 8 EMISSION CONTROL SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)