power steering CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 18 of 1938

ENGINE OIL

SAE VISCOSITY RATING INDICATES ENGINE OIL VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 30 specifies a single viscos-

ity engine oil. Engine oils also have multiple

viscosities. These are specified with a dual SAE vis-

cosity grade which indicates the cold-to-hot tempera-

ture viscosity range.

²SAE 30 = single grade engine oil.

²SAE 10W-30 = multiple grade engine oil.

API QUALITY CLASSIFICATION

The API Service Grade specifies the type of perfor-

mance the engine oil is intended to provide. The API

Service Grade specifications also apply to energy con-

serving engine oils.

Use engine oils that are API Service Certified.

5W-30 and 10W-30 MOPAR engine oils conform to

specifications.

Refer to Group 9, Engine for engine oil specifica-

tion.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear

lubricants. In addition, API classification defines the

lubricants usage.LUBRICANTS AND GREASES

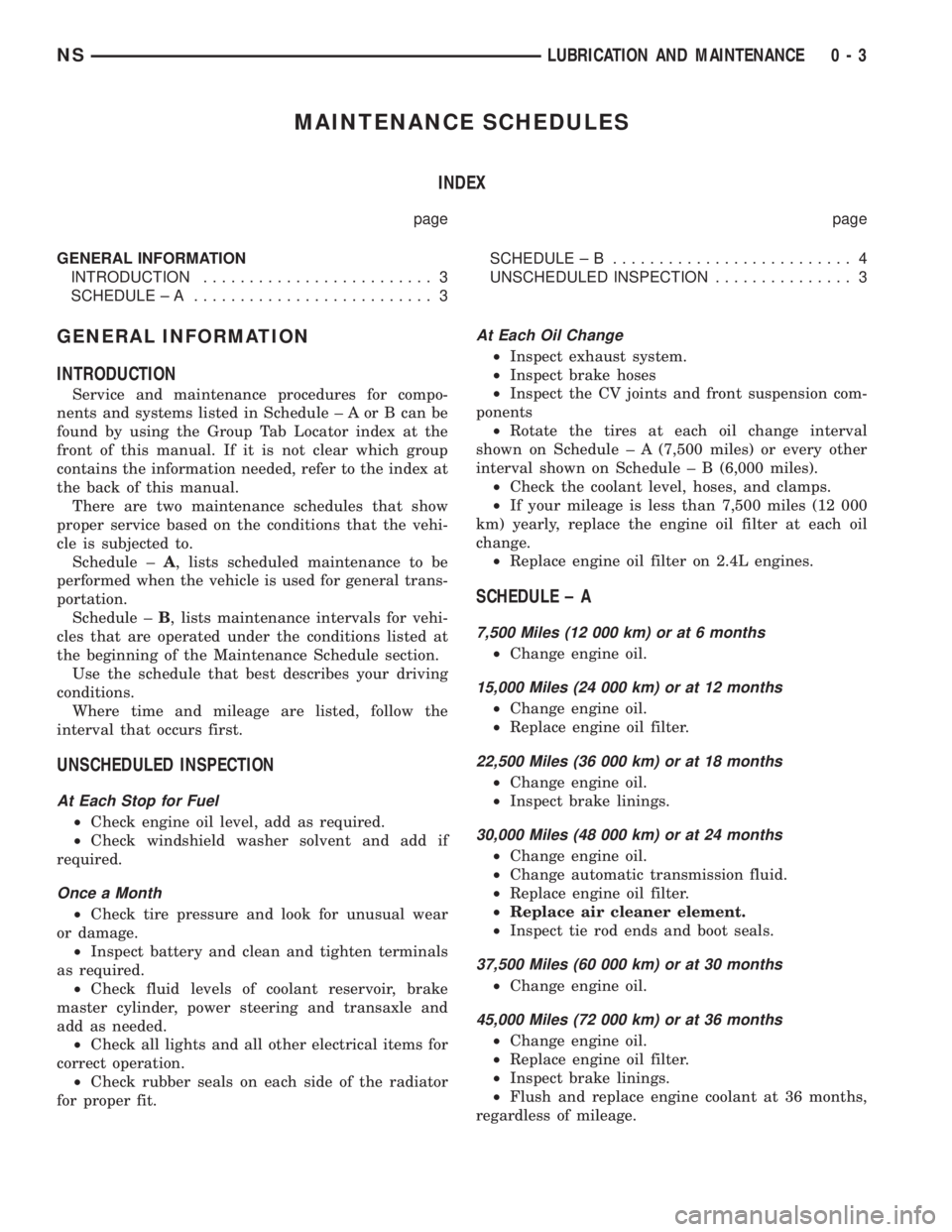

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 3) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

FLUID CAPACITIES

Fuel Tank.......................76L(20gal.)

Engine Oil, With Filter............4.3 L (4.5 qts.)

Engine Oil, W/O Filter.............3.8 L (4.0 qts.)

Cooling System 2.4L Engine........9.0 L (9.5 qts.)

Cooling System 3.OL Engine.......9.5 L (10.5 qts.)

Cooling System 3.3 or 3.8L Engine . .9.5 L (10.5 qts.)

Automatic Transaxle Service Fill.....3.8 L (4.0 qts.)

Automatic Transaxle

31TH/O-haul Fill...............8.0 L (8.5 qts.)

Automatic Transaxle

41TE/O-haul Fill...............8.6 L (9.1 qts.)

Power Steering.................0.81 L (1.7 pts.)

Fig. 2 API Symbol

Fig. 3 NLGI Symbol

0 - 2 LUBRICATION AND MAINTENANCENS

GENERAL INFORMATION (Continued)

Page 19 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to.

Schedule ±A, lists scheduled maintenance to be

performed when the vehicle is used for general trans-

portation.

Schedule ±B, lists maintenance intervals for vehi-

cles that are operated under the conditions listed at

the beginning of the Maintenance Schedule section.

Use the schedule that best describes your driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on Schedule ± B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter on 2.4L engines.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Change automatic transmission fluid.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect tie rod ends and boot seals.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

45,000 Miles (72 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

NSLUBRICATION AND MAINTENANCE 0 - 3

Page 28 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

MAINTENANCE SCHEDULE............... 2

MAINTENANCE SCHEDULEÐ

DIESEL ENGINE....................... 2SCHEDULEÐA (DIESEL).................. 2

SCHEDULEÐB (DIESEL).................. 3

UNSCHEDULED INSPECTION.............. 2

GENERAL INFORMATION

MAINTENANCE SCHEDULE

Refer to the 1998 GS Service Manual for Gasoline

Engine and non-engine related Maintenance Sched-

ules.

MAINTENANCE SCHEDULEÐDIESEL ENGINE

The following are engine related Maintenance

items which are unique to Diesel engine-equipped

vehicles. Refer to the 1998 GS Service Manual for

Gasoline Engine and non-engine related Maintenance

Schedules.

The service intervals are based on odometer read-

ings in kilometers. There are two maintenance sched-

ules that show proper service intervals. Use the

schedule that best describes the conditions the vehi-

cle is operated under.Schedule-Alists all the sched-

uled maintenance to be performed under normal

operating conditions.Schedule-Bis the schedule for

vehicles that are operated under one or more of the

following conditions:

²Day and night temperatures are below freezing.

²Stop and go driving.

²Long periods of engine idling.

²Driving in dusty conditions.

²Short trips of less than 5 miles.

²Operation at sustained high speeds during hot

weather above 32ÉC (90ÉF).

²Taxi, police or delivery service.

²Trailer towing.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on ScheduleÐA (7,500 miles) or every other

interval shown on ScheduleÐ B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter.

SCHEDULEÐA (DIESEL)

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

10 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

0 - 2 LUBRICATION AND MAINTENANCENS/GS

Page 36 of 1938

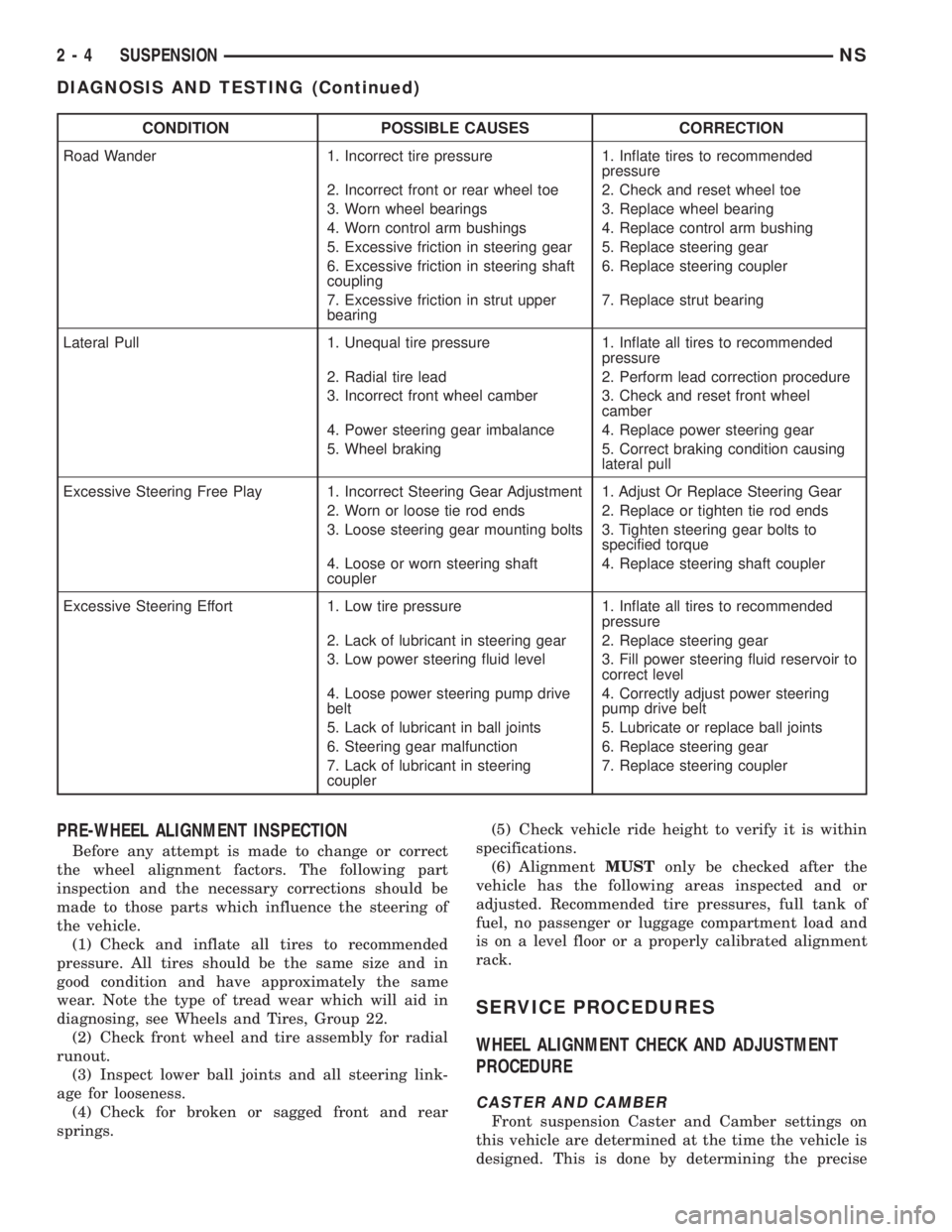

CONDITION POSSIBLE CAUSES CORRECTION

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended

pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel

camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free Play 1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to

specified torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering

pump drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering

coupler7. Replace steering coupler

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.(5) Check vehicle ride height to verify it is within

specifications.

(6) AlignmentMUSTonly be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER AND CAMBER

Front suspension Caster and Camber settings on

this vehicle are determined at the time the vehicle is

designed. This is done by determining the precise

2 - 4 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

Page 41 of 1938

FRONT SUSPENSION

INDEX

page page

DESCRIPTION AND OPERATION

BALL JOINT............................ 11

COIL SPRING........................... 11

FRONT SUSPENSION DESCRIPTION......... 9

HUB AND BEARING ASSEMBLY............ 10

LOWER CONTROL ARM.................. 10

Mc PHERSON STRUT ASSEMBLY........... 10

STABILIZER BAR ATTACHING LINK.......... 10

STABILIZER BAR........................ 10

STEERING KNUCKLE.................... 10

SUSPENSION CRADLE (CROSSMEMBER)..... 9

WHEEL MOUNTING STUDS................ 11

DIAGNOSIS AND TESTING

BALL JOINT (LOWER).................... 12

HUB AND BEARING ASSEMBLY............ 12

LOWER CONTROL ARM.................. 12

Mc PHERSON STRUT.................... 11

STABILIZER BAR........................ 12

STEERING KNUCKLE.................... 12SERVICE PROCEDURES

SUSPENSION CRADLE THREAD REPAIR

PROCEDURE......................... 12

REMOVAL AND INSTALLATION

BALL JOINT............................ 22

FRONT WHEEL MOUNTING STUDS......... 28

HUB AND BEARING ASSEMBLY............ 25

LOWER CONTROL ARM.................. 19

Mc PHERSON STRUT.................... 13

REAR WHEEL MOUNTING STUDS.......... 29

STABILIZER BAR........................ 23

STEERING KNUCKLE.................... 14

DISASSEMBLY AND ASSEMBLY

BALL JOINT SEAL BOOT.................. 33

LOWER CONTROL ARM FRONT BUSHING.... 34

LOWER CONTROL ARM REAR BUSHING..... 35

Mc PHERSON STRUT.................... 30

STABILIZER BAR BUSHING................ 35

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUES . . 36

SPECIAL TOOLS

FRONT SUSPENSION.................... 37

DESCRIPTION AND OPERATION

FRONT SUSPENSION DESCRIPTION

An independent Mc Pherson Strut type front sus-

pension is used on these vehicles. Vertical shock

absorbing Mc Pherson Struts attach to the top of the

steering knuckle and to the front strut tower. This

interconnection between the steering knuckle and the

body of the vehicle, provides for the correct steering

knuckle position. This steering knuckle position pro-

vides for the correct front Caster and Camber set-

tings for the vehicle, at the time the vehicle is

designed.

Lower control arms are attached inboard to the

cast aluminum front suspension cradle and outboard

to the bottom of the steering knuckle. Attachment of

the lower control arm to the steering knuckle is done

through a ball joint in the lower control arm.

During steering maneuvers, the strut and the

steering knuckle (through the ball joint and a pivot

bearing in the strut's upper retainer) turn as an

assembly.

SUSPENSION CRADLE (CROSSMEMBER)

This vehicle uses a one piece cast aluminum cradle

for the front suspension. The cradle is used as theattaching points for the lower control arms, stabilizer

bar and steering gear. The cradle also has the power

steering hoses and the chassis brake tubes attached

to it.

The cradle is mounted to the front frame rails at

four points, two on each side of the vehicle. The cra-

dle is isolated from the body of the vehicle using four

isolators, one located at each mounting bolt location.

WARNING: If a threaded hole in the suspension

cradle needs to be repaired, only use the type of

thread insert and installation procedure specified

for this application.

The threaded holes in the cradle that are

used for attachment of the lower control arm

rear bushing retainer, power steering hose and

chassis brake tubes can be repaired. The repair

is done by the installation of a Heli-Coilt

thread insert which has been specifically devel-

oped for this application. Refer to the Mopar

Parts Catalog for the specified Heli-Coil thread

insert to be used for this application. The pro-

cedure for installing the Heli-Coiltthread

insert is detailed in the Service Procedures sec-

tion in this group of the service manual.

NSSUSPENSION 2 - 9

Page 44 of 1938

STEERING KNUCKLE

The front suspension knuckle is not a repairable

component of the vehicles front suspensionIT MUST

BE REPLACED.If bent, broken or damaged in any

way, do not attempt to straighten or repair the steer-

ing knuckle.

Service replacement of the front hub/bearing

assembly can be done with the front steering knuckle

remaining on the vehicle.

LOWER CONTROL ARM

If damaged, the lower control arm casting is ser-

viced only as a complete component. Inspect lower

control arm for signs of damage from contact with

the ground or road debris. If lower control arm shows

any sign of damage, inspect lower control arm for

distortion.Do not attempt to repair or straighten

a broken or bent lower control arm.

The serviceable components of the lower control

arm are: the ball joint assembly, ball joint assembly

grease seal and control arm bushings. Inspect both

control arm bushings for severe deterioration, and

replace if required. Inspect ball joint per inspection

procedure in this section of the service manual and

replace if required. Service procedures to replace

these components are detailed in the specific compo-

nent removal and installation sections in this group

of the service manual.

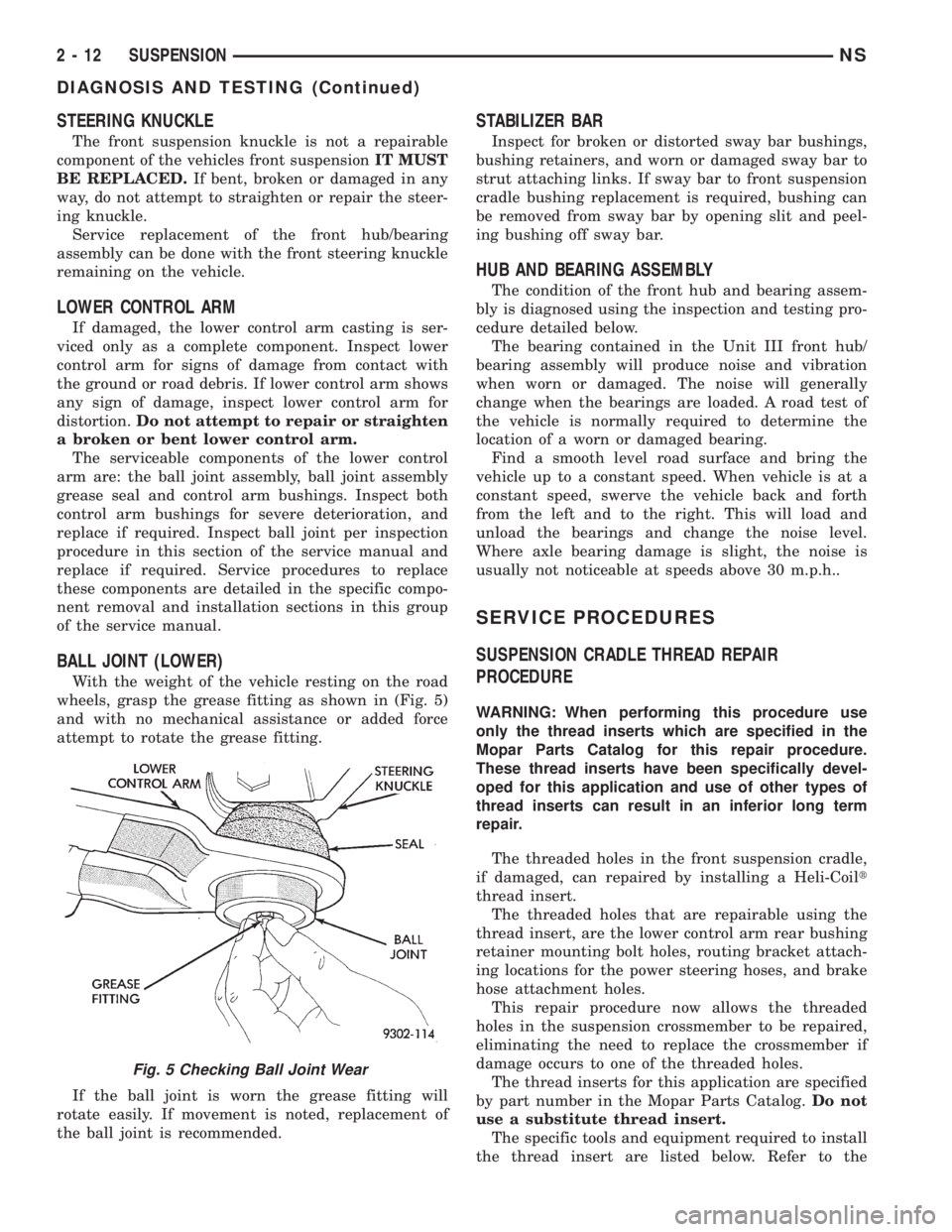

BALL JOINT (LOWER)

With the weight of the vehicle resting on the road

wheels, grasp the grease fitting as shown in (Fig. 5)

and with no mechanical assistance or added force

attempt to rotate the grease fitting.

If the ball joint is worn the grease fitting will

rotate easily. If movement is noted, replacement of

the ball joint is recommended.

STABILIZER BAR

Inspect for broken or distorted sway bar bushings,

bushing retainers, and worn or damaged sway bar to

strut attaching links. If sway bar to front suspension

cradle bushing replacement is required, bushing can

be removed from sway bar by opening slit and peel-

ing bushing off sway bar.

HUB AND BEARING ASSEMBLY

The condition of the front hub and bearing assem-

bly is diagnosed using the inspection and testing pro-

cedure detailed below.

The bearing contained in the Unit III front hub/

bearing assembly will produce noise and vibration

when worn or damaged. The noise will generally

change when the bearings are loaded. A road test of

the vehicle is normally required to determine the

location of a worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

unload the bearings and change the noise level.

Where axle bearing damage is slight, the noise is

usually not noticeable at speeds above 30 m.p.h..

SERVICE PROCEDURES

SUSPENSION CRADLE THREAD REPAIR

PROCEDURE

WARNING: When performing this procedure use

only the thread inserts which are specified in the

Mopar Parts Catalog for this repair procedure.

These thread inserts have been specifically devel-

oped for this application and use of other types of

thread inserts can result in an inferior long term

repair.

The threaded holes in the front suspension cradle,

if damaged, can repaired by installing a Heli-Coilt

thread insert.

The threaded holes that are repairable using the

thread insert, are the lower control arm rear bushing

retainer mounting bolt holes, routing bracket attach-

ing locations for the power steering hoses, and brake

hose attachment holes.

This repair procedure now allows the threaded

holes in the suspension crossmember to be repaired,

eliminating the need to replace the crossmember if

damage occurs to one of the threaded holes.

The thread inserts for this application are specified

by part number in the Mopar Parts Catalog.Do not

use a substitute thread insert.

The specific tools and equipment required to install

the thread insert are listed below. Refer to the

Fig. 5 Checking Ball Joint Wear

2 - 12 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

Page 102 of 1938

SERVICE PROCEDURES

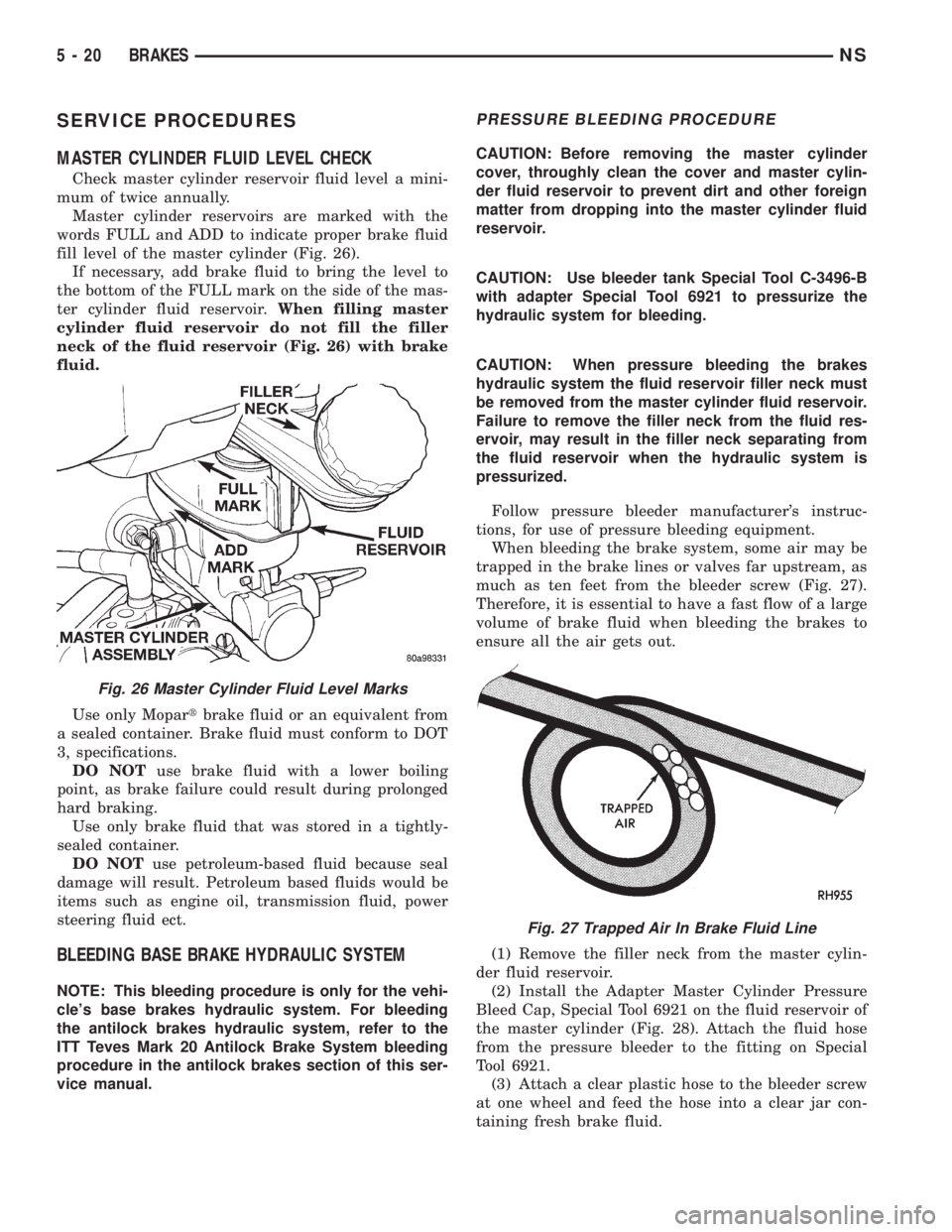

MASTER CYLINDER FLUID LEVEL CHECK

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Master cylinder reservoirs are marked with the

words FULL and ADD to indicate proper brake fluid

fill level of the master cylinder (Fig. 26).

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.When filling master

cylinder fluid reservoir do not fill the filler

neck of the fluid reservoir (Fig. 26) with brake

fluid.

Use only Mopartbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications.

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid ect.

BLEEDING BASE BRAKE HYDRAULIC SYSTEM

NOTE: This bleeding procedure is only for the vehi-

cle's base brakes hydraulic system. For bleeding

the antilock brakes hydraulic system, refer to the

ITT Teves Mark 20 Antilock Brake System bleeding

procedure in the antilock brakes section of this ser-

vice manual.

PRESSURE BLEEDING PROCEDURE

CAUTION: Before removing the master cylinder

cover, throughly clean the cover and master cylin-

der fluid reservoir to prevent dirt and other foreign

matter from dropping into the master cylinder fluid

reservoir.

CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool 6921 to pressurize the

hydraulic system for bleeding.

CAUTION: When pressure bleeding the brakes

hydraulic system the fluid reservoir filler neck must

be removed from the master cylinder fluid reservoir.

Failure to remove the filler neck from the fluid res-

ervoir, may result in the filler neck separating from

the fluid reservoir when the hydraulic system is

pressurized.

Follow pressure bleeder manufacturer's instruc-

tions, for use of pressure bleeding equipment.

When bleeding the brake system, some air may be

trapped in the brake lines or valves far upstream, as

much as ten feet from the bleeder screw (Fig. 27).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

(1) Remove the filler neck from the master cylin-

der fluid reservoir.

(2) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 28). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(3) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

Fig. 26 Master Cylinder Fluid Level Marks

Fig. 27 Trapped Air In Brake Fluid Line

5 - 20 BRAKESNS

Page 130 of 1938

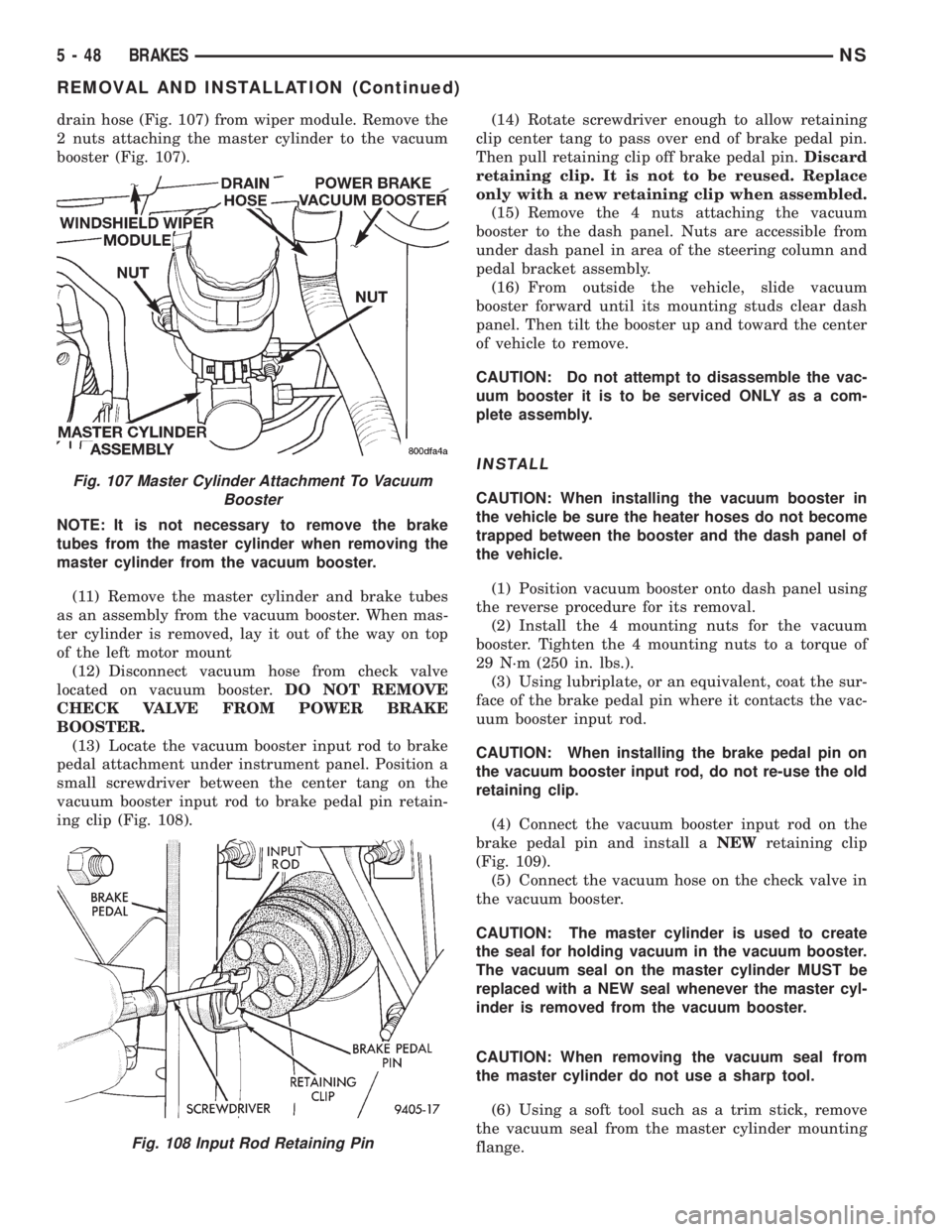

drain hose (Fig. 107) from wiper module. Remove the

2 nuts attaching the master cylinder to the vacuum

booster (Fig. 107).

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(11) Remove the master cylinder and brake tubes

as an assembly from the vacuum booster. When mas-

ter cylinder is removed, lay it out of the way on top

of the left motor mount

(12) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

(13) Locate the vacuum booster input rod to brake

pedal attachment under instrument panel. Position a

small screwdriver between the center tang on the

vacuum booster input rod to brake pedal pin retain-

ing clip (Fig. 108).(14) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assembled.

(15) Remove the 4 nuts attaching the vacuum

booster to the dash panel. Nuts are accessible from

under dash panel in area of the steering column and

pedal bracket assembly.

(16) From outside the vehicle, slide vacuum

booster forward until its mounting studs clear dash

panel. Then tilt the booster up and toward the center

of vehicle to remove.

CAUTION: Do not attempt to disassemble the vac-

uum booster it is to be serviced ONLY as a com-

plete assembly.

INSTALL

CAUTION: When installing the vacuum booster in

the vehicle be sure the heater hoses do not become

trapped between the booster and the dash panel of

the vehicle.

(1) Position vacuum booster onto dash panel using

the reverse procedure for its removal.

(2) Install the 4 mounting nuts for the vacuum

booster. Tighten the 4 mounting nuts to a torque of

29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the vacuum booster input rod, do not re-use the old

retaining clip.

(4) Connect the vacuum booster input rod on the

brake pedal pin and install aNEWretaining clip

(Fig. 109).

(5) Connect the vacuum hose on the check valve in

the vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the vacuum booster.

The vacuum seal on the master cylinder MUST be

replaced with a NEW seal whenever the master cyl-

inder is removed from the vacuum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(6) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

Fig. 107 Master Cylinder Attachment To Vacuum

Booster

Fig. 108 Input Rod Retaining Pin

5 - 48 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 132 of 1938

(10) Remove clip attaching drain hose to brake

tube at master cylinder. Remove drain hose (Fig. 114)

from wiper module. Remove the 2 nuts attaching the

master cylinder assembly to the power brake vacuum

booster (Fig. 114).

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the power brake vacuum

booster.

(11) Remove the master cylinder and the brake

tubes as an assembly from power brake vacuum

booster. When master cylinder is removed, lay it out

of the way on top of the left motor mount(12) Disconnect vacuum hose from check valve

located on power brake vacuum booster.DO NOT

REMOVE CHECK VALVE FROM POWER

BRAKE BOOSTER.

(13) Locate the power brake vacuum booster input

rod to brake pedal attachment under instrument

panel. Position a small screwdriver between the cen-

ter tang on the power brake booster input rod to

brake pedal pin retaining clip (Fig. 115).

(14) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assembled.

(15) Remove the 4 nuts attaching the vacuum

booster to the dash panel. Nuts are accessible from

under dash panel in area of the steering column and

pedal bracket assembly.

(16) From outside the vehicle, slide power brake

vacuum booster forward until its mounting studs

Fig. 111 Air Inlet Resonator

Fig. 112 Battery Tray Mounting Locations

Fig. 113 Electrical Connection To Fluid Level Sensor

Fig. 114 Master Cylinder Attachment To Power

Brake Vacuum Booster

5 - 50 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 136 of 1938

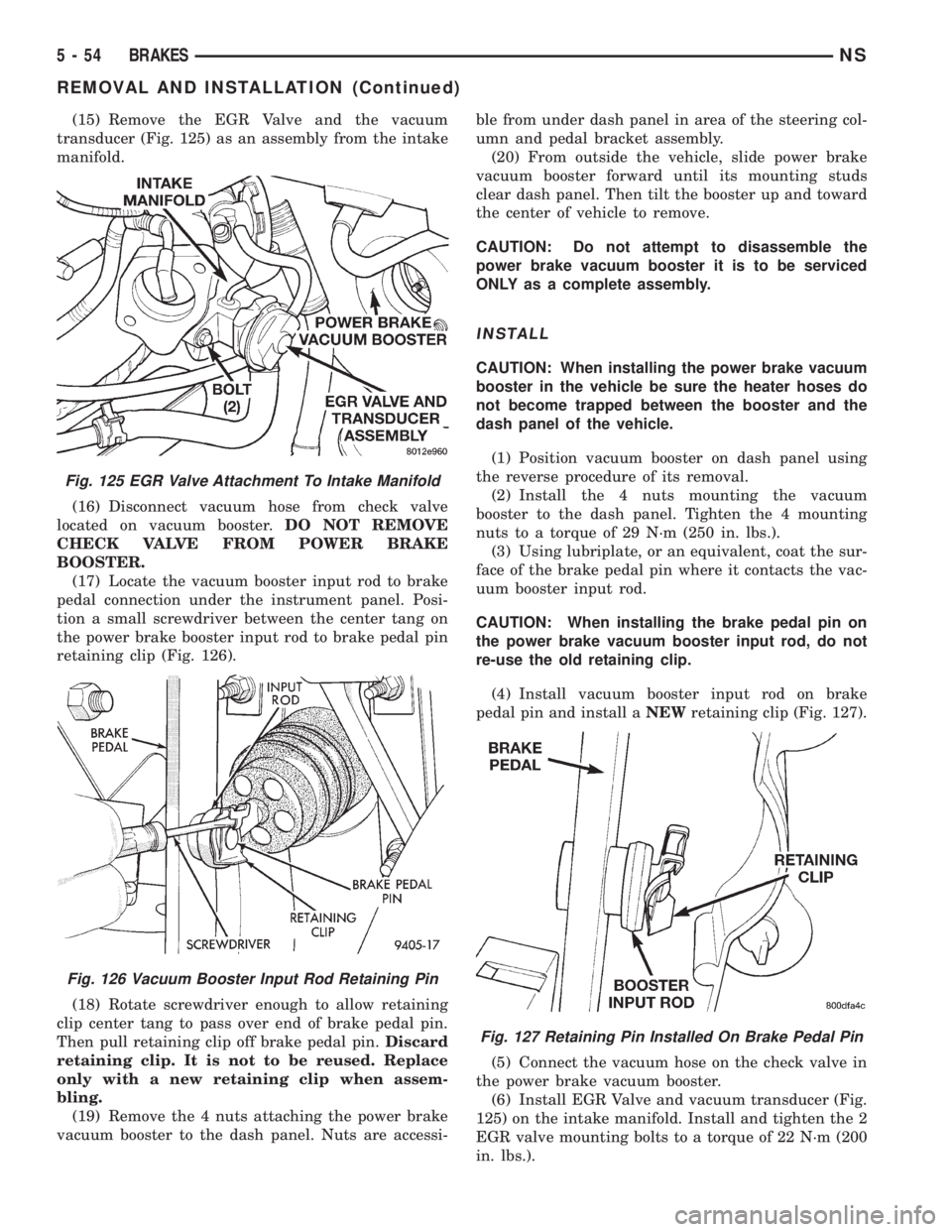

(15) Remove the EGR Valve and the vacuum

transducer (Fig. 125) as an assembly from the intake

manifold.

(16) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

(17) Locate the vacuum booster input rod to brake

pedal connection under the instrument panel. Posi-

tion a small screwdriver between the center tang on

the power brake booster input rod to brake pedal pin

retaining clip (Fig. 126).

(18) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assem-

bling.

(19) Remove the 4 nuts attaching the power brake

vacuum booster to the dash panel. Nuts are accessi-ble from under dash panel in area of the steering col-

umn and pedal bracket assembly.

(20) From outside the vehicle, slide power brake

vacuum booster forward until its mounting studs

clear dash panel. Then tilt the booster up and toward

the center of vehicle to remove.

CAUTION: Do not attempt to disassemble the

power brake vacuum booster it is to be serviced

ONLY as a complete assembly.

INSTALL

CAUTION: When installing the power brake vacuum

booster in the vehicle be sure the heater hoses do

not become trapped between the booster and the

dash panel of the vehicle.

(1) Position vacuum booster on dash panel using

the reverse procedure of its removal.

(2) Install the 4 nuts mounting the vacuum

booster to the dash panel. Tighten the 4 mounting

nuts to a torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake vacuum booster input rod, do not

re-use the old retaining clip.

(4) Install vacuum booster input rod on brake

pedal pin and install aNEWretaining clip (Fig. 127).

(5) Connect the vacuum hose on the check valve in

the power brake vacuum booster.

(6) Install EGR Valve and vacuum transducer (Fig.

125) on the intake manifold. Install and tighten the 2

EGR valve mounting bolts to a torque of 22 N´m (200

in. lbs.).

Fig. 125 EGR Valve Attachment To Intake Manifold

Fig. 126 Vacuum Booster Input Rod Retaining Pin

Fig. 127 Retaining Pin Installed On Brake Pedal Pin

5 - 54 BRAKESNS

REMOVAL AND INSTALLATION (Continued)