engine oil CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1547 of 1938

CAUTION: Some clutch packs appear similar, but

they are not the same. Do not interchange clutch

components, as they might fail.

HYDRAULICS

The hydraulics of the transaxle provide:

²Manual shift lever select function

²Main line pressure regulation

²Torque converter and cooler flow control

Oil flow to the friction elements is controlled

directly by four solenoid valves. The hydraulics also

include a unique logic- controlled solenoid torque con-

verter clutch control valve. This valve locks out the

1st gear reaction element with the application of 2nd,

direct, or overdrive gear elements. It also redirects

the 1st gear solenoid output so that it can control

torque converter clutch operation. To regain access to

1st gear, a sequence of commands must be used to

move the solenoid TCC control valve. This precludes

any application of the 1st gear reaction element with

other elements applied. It also allows one solenoid to

control two friction elements.

Small, high-rate accumulators are provided in each

controlled friction element circuit. These serve to

absorb the pressure responses, and allow the controls

to read and respond to changes that are occurring.

SOLENOIDS

The solenoid valves perform most control functions,

these valves must be extremely durable and tolerant

of dirt. For that reason hardened-steel poppet and

ball valves are used. These are free from any close

operating clearances. The solenoids operate the

valves directly without any intermediate element.

Direct operation means that these units must have

very high output. They must close against the size-

able flow areas and high line pressures. Fast

response is also required to meet the control require-

ments.

Two of the solenoids are normally-venting and two

are normally-applying; this was done to provide a

default mode of operation. With no electrical power,

the transmission provides 2nd gear in (OD), (3), or

(L) shift lever positions. All other transmission lever

positions will operate normally. The choice of 2nd

gear was made to provide adequate breakaway per-

formance while still accommodating highway speeds.

SENSORS

There are three pressure switches to identify sole-

noid application. There are two speed sensors to read

input (torque converter turbine) and output (parking

sprag) speeds. There is also a transmission range

sensor to indicate the manual shift lever position.

The pressure switches are incorporated in an assem-

bly with the solenoids. Engine speed, throttle posi-tion, temperature, etc., are also observed. Some of

these signals are read directly from the engine con-

trol sensors; others are read from a multiplex circuit

with the powertrain control module.

ELECTRONICS

The 41TE Transmission Control Module (TCM) is

located underhood in a potted, die-cast aluminum

housing. The module used is a new controller called

EATX III. The TCM has a sealed, 60-way connector.

ADAPTIVE CONTROLS

These controls function by reading the input and

output speeds over 140 times a second and respond-

ing to each new reading. This provides the precise

and sophisticated friction element control needed to

make smooth clutch-to-clutch shifts for all gear

changes. The use of overrunning clutches or other

shift quality aids are not required. As with most

automatic transaxles, all shifts involve releasing one

element and applying a different element. In simpli-

fied terms, the upshift logic allows the releasing ele-

ment to slip backwards slightly. This ensures that it

does not have excess capacity. The apply element is

filled until it begins to make the speed change to the

higher gear. The apply pressure is then controlled to

maintain the desired rate of speed change. This con-

tinues until the shift is made. The key to providing

excellent shift quality is precision. For example, the

release element for upshifts is allowed to slip back-

wards slightly. The amount of that slip is typically

less than a total of 20 degrees. To achieve that pre-

cision, the TCM learns the traits of the transaxle

that it is controlling. It learns the release rate of the

releasing element and the apply time of the applying

element. It also learns the rate at which the apply

element builds pressure sufficient to begin making

the speed change. This method achieves more preci-

sion than would be possible with exacting tolerances.

It can also adapt to any changes that occur with age

or environment.

For kickdown shifts, the control logic allows the

releasing element to slip. Then controls the rate at

which the input (and engine) accelerate. When the

lower gear speed is achieved, the releasing element

reapplies to maintain that speed until the apply ele-

ment is filled. This provides quick response since the

engine begins to accelerate immediately. This also

provides a smooth torque exchange since the release

element can control the rate of torque increase. This

control can make any powertrain feel more respon-

sive without increasing harshness.

Adaptive controls respond to input speed changes.

They compensate for changes in engine or friction

element torque and provide good, consistent shift

quality for the life of the transaxle.

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 73

DESCRIPTION AND OPERATION (Continued)

Page 1552 of 1938

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4

piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

LOW/REVERSE CLUTCH

Apply air pressure to the low/reverse clutch feed

hole (rear of case, between 2 bolt holes). Then, look

in the area where the low/reverse piston contacts thefirst separator plate. Watch carefully for the piston to

move forward. The piston should return to its origi-

nal position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks the

output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not

rotate with hand torque. Release the air pressure

and confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

(2) Fluid leakage at or around the torque converter

area may originate from an engine oil leak. The area

should be examined closely. Factory fill fluid is red

and, therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the manual shaft. If the fluid level is high,

adjust to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the following

operation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside

(peripheral) weld.

²Torque converter hub weld.

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

SHIFT POSITION INDICATOR

The transmission range sensor (on the valve body)

sends a signal to the TCM on the position of the

transaxle manual valve lever. The TCM receives the

switch signal and processes the data. The TCM sends

the Shift Lever Position (SLP) information to the

BCM via the CCD bus. The BCM then outlines with

a box the appropriate shifter position indicator in the

instrument cluster.

Fig. 3 Air Pressure Test Plate

Fig. 4 Testing Reverse Clutch

21 - 78 TRANSAXLE AND POWER TRANSFER UNITNS

DIAGNOSIS AND TESTING (Continued)

Page 1554 of 1938

DIPSTICK TUBE FLUID SUCTION METHOD

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vaculay

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Add 4 Quarts of Mopar ATF Plus 3 Type 7176

transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range.

TRANSAXLE OIL PAN DROP METHOD

This procedure involves removing the transaxle oil

pan to drain the transaxle fluid.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N²m (165 in. lbs.).

(6) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid levelto 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range. Drive the vehicle a minimum of 10

miles.

(10) Raise the vehicle on the hoist.

(11) Check for leaks around the transaxle oil pan

sealing surfaces.

(12) Recheck the fluid level. The level should be in

the HOT range.

SEVERE USAGE SERVICE

If the vehicle exhibits any of the following symp-

toms, it is recommended that the transaxle oil and

filter be replaced.

²Transaxle oil discolored

²Transaxle oil has high mileage

²Oil feels grimy when rubbed between fingertips

²Poor shift quality

²Delayed gear engagement

²Vehicle shudder between shifts

TRANSAXLE OIL AND FILTER REPLACEMENT

This procedure involves changing the transaxle

fluid and filter, driving the vehicle for 10 miles and

changing the transaxle fluid a second time.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Separate the filter and O-ring from the valve

body. Inspect the O-ring for cuts or improper instal-

lation. This could lead to delayed garage shifts.

(6) Install a new filter. Replace the O-ring as nec-

essary.

(7) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N´m (165 in. lbs.).

(8) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(9) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(10) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

21 - 80 TRANSAXLE AND POWER TRANSFER UNITNS

SERVICE PROCEDURES (Continued)

Page 1555 of 1938

(11) Recheck the fluid level after the transaxle is

at normal operating temperature. The level should be

in the HOT range. Drive the vehicle a minimum of

10 miles.

(12) Raise the vehicle on the hoist.

(13) Remove the pan and clean all sealant from

the pan and transaxle mating surfaces. Clean the

magnet and the inside of the pan.

(14) Separate the filter from the valve body to

allow additional fluid to drain from the transaxle.

Inspect the filter O-ring for any damage and replace

as necessary.

(15) After the transaxle has stopped draining,

reinstall the filter and O-ring.

(16) Apply a 1/8 inch bead of Mopar RTV Sealant

to the mounting flange of the transaxle oil pan.

Apply RTV Sealant to the underside of the attaching

bolts. Attach the oil pan to the transaxle. Tighten the

bolts to 19 N´m (165 in. lbs.).

(17) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(18) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(19) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(20) Recheck the fluid level after the transaxle is

at normal operating temperature. The level should be

in the HOT range.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Group 0, Lubrica-

tion). Place a drain container with a large opening,

under transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Install a new filter and O-ring on bottom of the

valve body.

(4) Clean the oil pan and magnet. Reinstall pan

using new MOPARtRTV sealant. Tighten oil pan

bolts to 19 N´m (165 in. lbs.).

(5) Pour four quarts of MOPARtATF PLUS 3

(Automatic Transmission Fluid) Type 7176 through

the fill tube.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

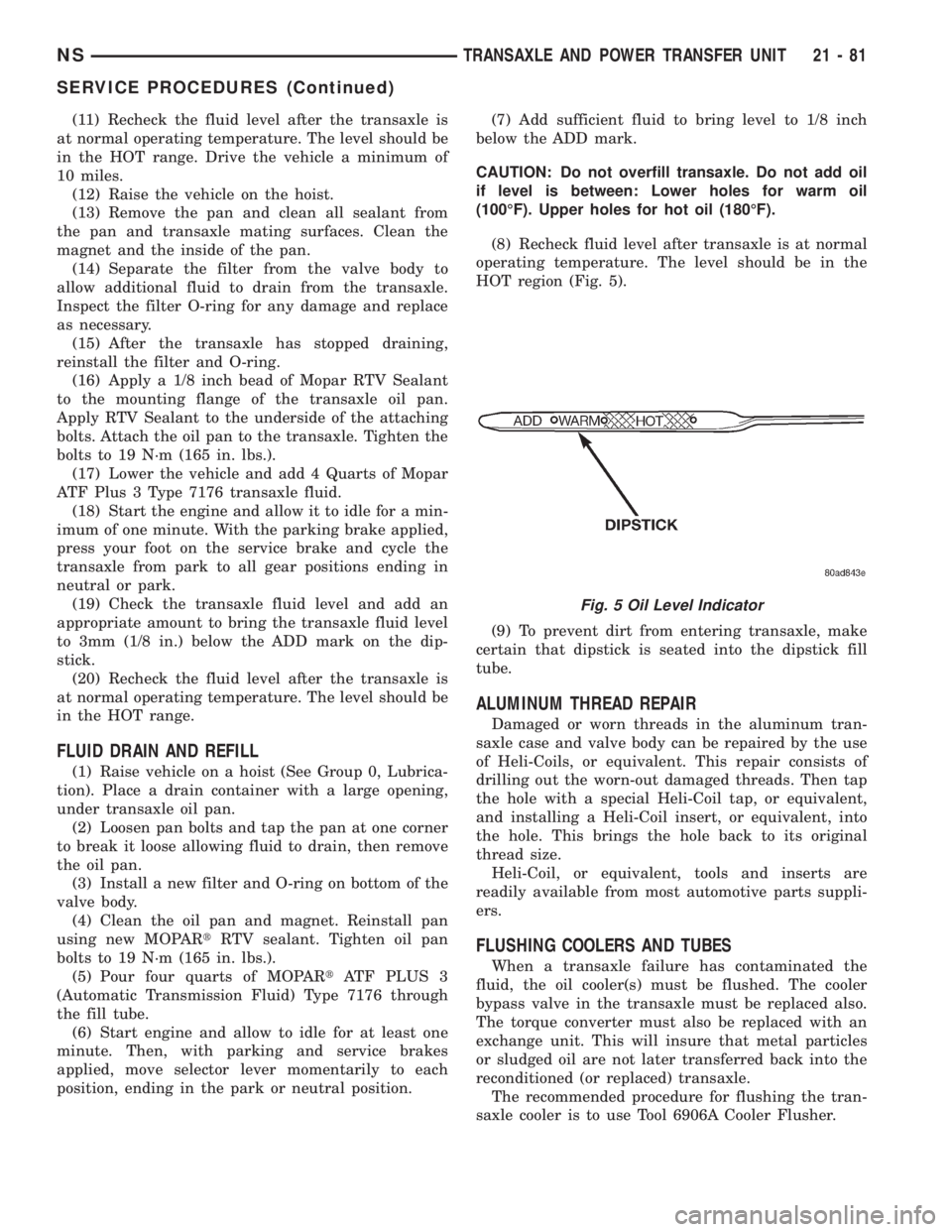

position, ending in the park or neutral position.(7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark.

CAUTION: Do not overfill transaxle. Do not add oil

if level is between: Lower holes for warm oil

(100ÉF). Upper holes for hot oil (180ÉF).

(8) Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the

HOT region (Fig. 5).

(9) To prevent dirt from entering transaxle, make

certain that dipstick is seated into the dipstick fill

tube.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils, or equivalent. This repair consists of

drilling out the worn-out damaged threads. Then tap

the hole with a special Heli-Coil tap, or equivalent,

and installing a Heli-Coil insert, or equivalent, into

the hole. This brings the hole back to its original

thread size.

Heli-Coil, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the oil cooler(s) must be flushed. The cooler

bypass valve in the transaxle must be replaced also.

The torque converter must also be replaced with an

exchange unit. This will insure that metal particles

or sludged oil are not later transferred back into the

reconditioned (or replaced) transaxle.

The recommended procedure for flushing the tran-

saxle cooler is to use Tool 6906A Cooler Flusher.

Fig. 5 Oil Level Indicator

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 81

SERVICE PROCEDURES (Continued)

Page 1556 of 1938

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readings

and clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF PLUS 3 Type 7176 auto-

matic transmission fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. Thispurges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with Mopar ATF

PLUS 3 (Type 7176) automatic transmission fluid.

The volume should be checked using the following

procedure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF, discon-

nect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using Mopar ATF PLUS 3 (Type 7176)

automatic transmission fluid.

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

(7) Check the cooler for debris on the external sur-

faces. Clean as necessary.

TRANSAXLE QUICK LEARN PROCEDURE

The quick learn procedure requires the use of the

DRBIII scan tool.

This program allows the electronic transaxle sys-

tem to recalibrate itself. This will provide the best

possible transaxle operation. The quick learn proce-

dure should be performed if any of the following pro-

cedures are performed:

²Transaxle Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

21 - 82 TRANSAXLE AND POWER TRANSFER UNITNS

SERVICE PROCEDURES (Continued)

Page 1559 of 1938

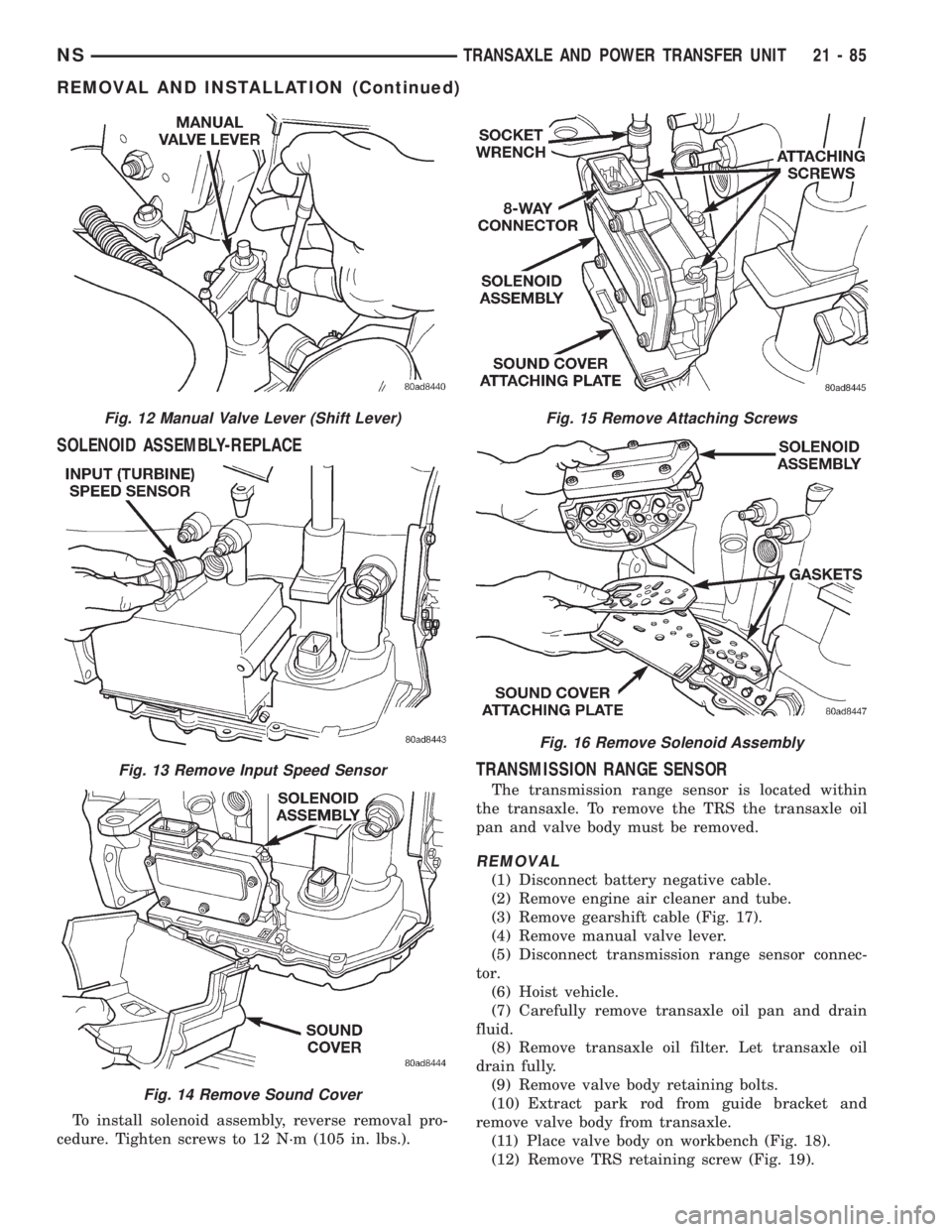

SOLENOID ASSEMBLY-REPLACE

To install solenoid assembly, reverse removal pro-

cedure. Tighten screws to 12 N´m (105 in. lbs.).

TRANSMISSION RANGE SENSOR

The transmission range sensor is located within

the transaxle. To remove the TRS the transaxle oil

pan and valve body must be removed.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove engine air cleaner and tube.

(3) Remove gearshift cable (Fig. 17).

(4) Remove manual valve lever.

(5) Disconnect transmission range sensor connec-

tor.

(6) Hoist vehicle.

(7) Carefully remove transaxle oil pan and drain

fluid.

(8) Remove transaxle oil filter. Let transaxle oil

drain fully.

(9) Remove valve body retaining bolts.

(10) Extract park rod from guide bracket and

remove valve body from transaxle.

(11) Place valve body on workbench (Fig. 18).

(12) Remove TRS retaining screw (Fig. 19).

Fig. 12 Manual Valve Lever (Shift Lever)

Fig. 13 Remove Input Speed Sensor

Fig. 14 Remove Sound Cover

Fig. 15 Remove Attaching Screws

Fig. 16 Remove Solenoid Assembly

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 85

REMOVAL AND INSTALLATION (Continued)

Page 1563 of 1938

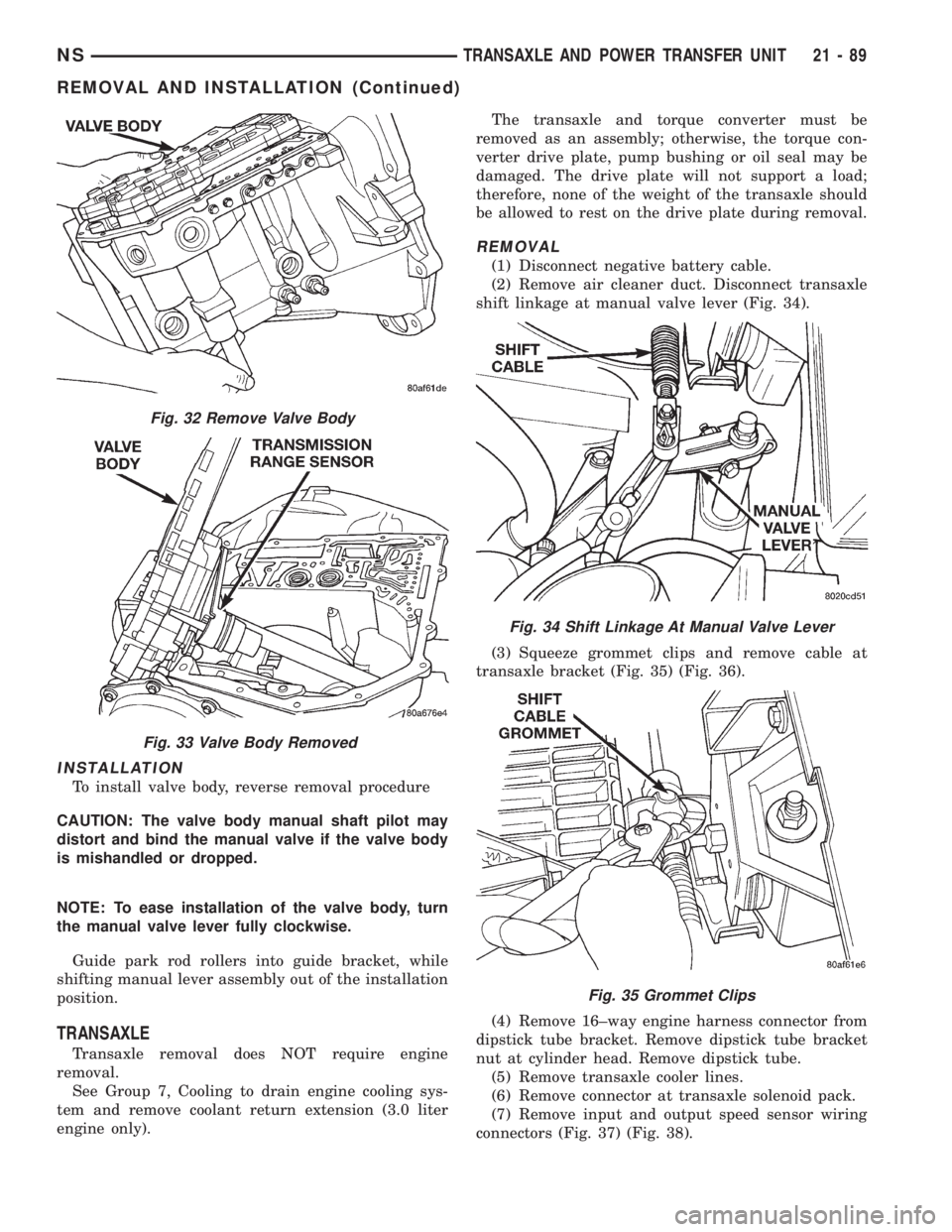

INSTALLATION

To install valve body, reverse removal procedure

CAUTION: The valve body manual shaft pilot may

distort and bind the manual valve if the valve body

is mishandled or dropped.

NOTE: To ease installation of the valve body, turn

the manual valve lever fully clockwise.

Guide park rod rollers into guide bracket, while

shifting manual lever assembly out of the installation

position.

TRANSAXLE

Transaxle removal does NOT require engine

removal.

See Group 7, Cooling to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only).The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner duct. Disconnect transaxle

shift linkage at manual valve lever (Fig. 34).

(3) Squeeze grommet clips and remove cable at

transaxle bracket (Fig. 35) (Fig. 36).

(4) Remove 16±way engine harness connector from

dipstick tube bracket. Remove dipstick tube bracket

nut at cylinder head. Remove dipstick tube.

(5) Remove transaxle cooler lines.

(6) Remove connector at transaxle solenoid pack.

(7) Remove input and output speed sensor wiring

connectors (Fig. 37) (Fig. 38).

Fig. 32 Remove Valve Body

Fig. 33 Valve Body Removed

Fig. 34 Shift Linkage At Manual Valve Lever

Fig. 35 Grommet Clips

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 89

REMOVAL AND INSTALLATION (Continued)

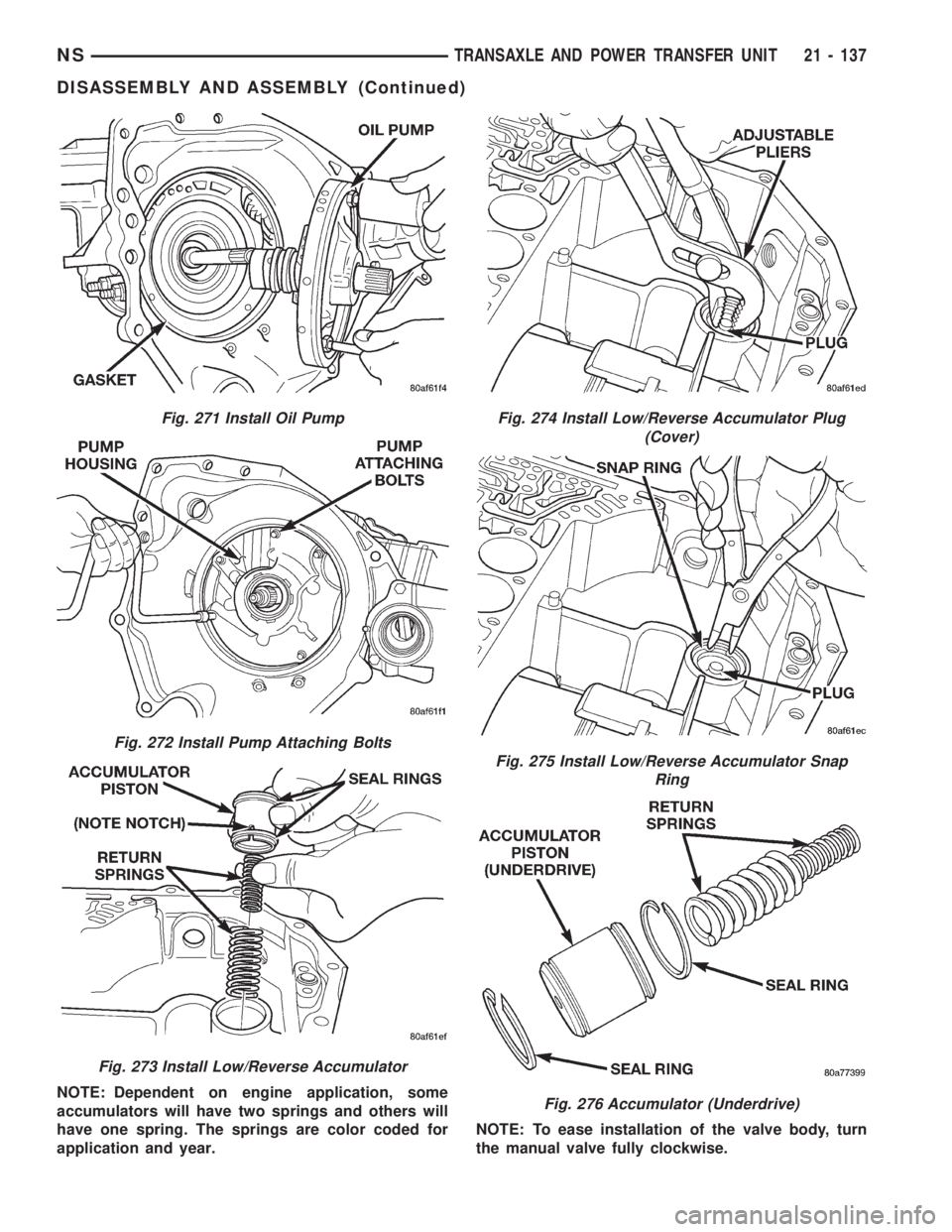

Page 1611 of 1938

NOTE: Dependent on engine application, some

accumulators will have two springs and others will

have one spring. The springs are color coded for

application and year.NOTE: To ease installation of the valve body, turn

the manual valve fully clockwise.

Fig. 271 Install Oil Pump

Fig. 272 Install Pump Attaching Bolts

Fig. 273 Install Low/Reverse Accumulator

Fig. 274 Install Low/Reverse Accumulator Plug

(Cover)

Fig. 275 Install Low/Reverse Accumulator Snap

Ring

Fig. 276 Accumulator (Underdrive)

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 137

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1641 of 1938

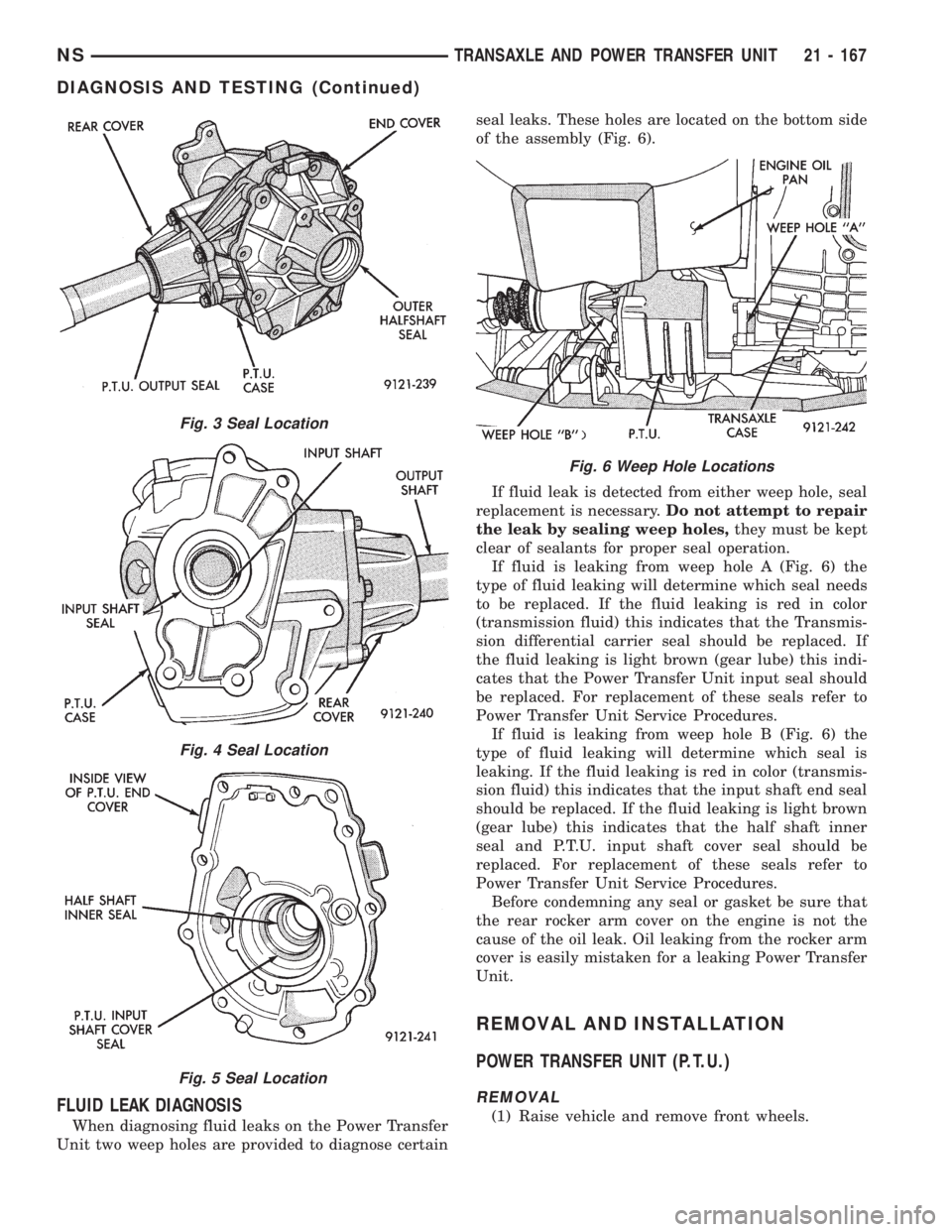

FLUID LEAK DIAGNOSIS

When diagnosing fluid leaks on the Power Transfer

Unit two weep holes are provided to diagnose certainseal leaks. These holes are located on the bottom side

of the assembly (Fig. 6).

If fluid leak is detected from either weep hole, seal

replacement is necessary.Do not attempt to repair

the leak by sealing weep holes,they must be kept

clear of sealants for proper seal operation.

If fluid is leaking from weep hole A (Fig. 6) the

type of fluid leaking will determine which seal needs

to be replaced. If the fluid leaking is red in color

(transmission fluid) this indicates that the Transmis-

sion differential carrier seal should be replaced. If

the fluid leaking is light brown (gear lube) this indi-

cates that the Power Transfer Unit input seal should

be replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

If fluid is leaking from weep hole B (Fig. 6) the

type of fluid leaking will determine which seal is

leaking. If the fluid leaking is red in color (transmis-

sion fluid) this indicates that the input shaft end seal

should be replaced. If the fluid leaking is light brown

(gear lube) this indicates that the half shaft inner

seal and P.T.U. input shaft cover seal should be

replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

Before condemning any seal or gasket be sure that

the rear rocker arm cover on the engine is not the

cause of the oil leak. Oil leaking from the rocker arm

cover is easily mistaken for a leaking Power Transfer

Unit.

REMOVAL AND INSTALLATION

POWER TRANSFER UNIT (P.T.U.)

REMOVAL

(1) Raise vehicle and remove front wheels.

Fig. 3 Seal Location

Fig. 4 Seal Location

Fig. 5 Seal Location

Fig. 6 Weep Hole Locations

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 167

DIAGNOSIS AND TESTING (Continued)

Page 1658 of 1938

GENERAL INFORMATION

A-598 MANUAL TRANSAXLE

Safety goggles should be worn at all times

when working on these transaxles.The A-598

manual transaxle uses SAE 5W-30 engine oil, meet-

ing SG and/or SG-CD qualifications, as the factory

fill lubricant. SAE G5 10W-40 engine oil is a suitable

service fill alternative.

This transaxle combines gear reduction, ratio selec-

tion, and differential functions in one unit. It is

housed in a die-cast aluminum case.

A-558 MANUAL TRANSAXLEÐRHD VEHICLES

Safety goggles should be worn at all times

when working on these transaxles.The A-558

manual transaxle uses SAE 5W-30 engine oil, meet-

ing SG and/or SG-CD qualifications, as the factory

fill lubricant. SAE G5 10W-40 engine oil is a suitable

service fill alternative.

This transaxle combines gear reduction, ratio selec-

tion, and differential functions in one unit. It is

housed in a die-cast aluminum case.

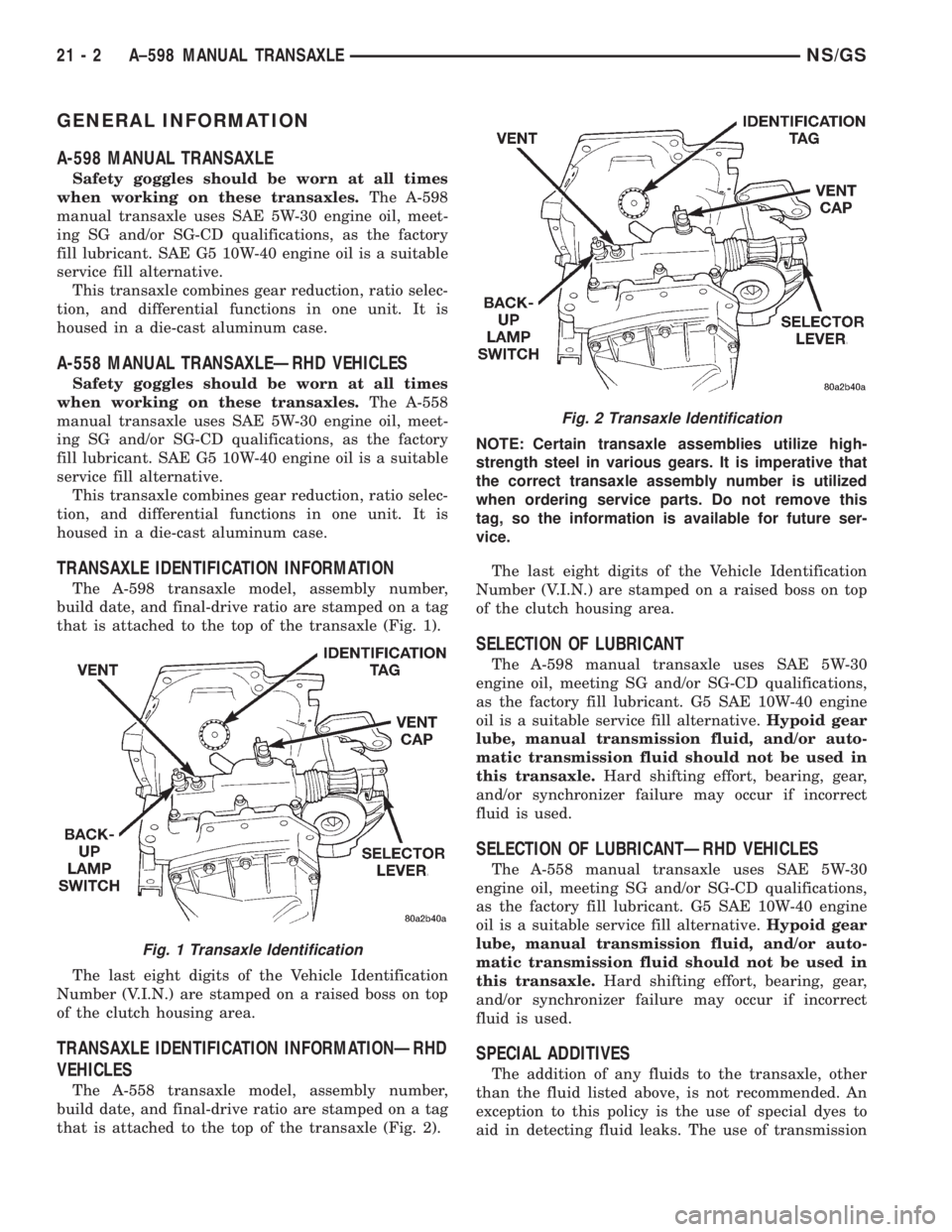

TRANSAXLE IDENTIFICATION INFORMATION

The A-598 transaxle model, assembly number,

build date, and final-drive ratio are stamped on a tag

that is attached to the top of the transaxle (Fig. 1).

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

TRANSAXLE IDENTIFICATION INFORMATIONÐRHD

VEHICLES

The A-558 transaxle model, assembly number,

build date, and final-drive ratio are stamped on a tag

that is attached to the top of the transaxle (Fig. 2).NOTE: Certain transaxle assemblies utilize high-

strength steel in various gears. It is imperative that

the correct transaxle assembly number is utilized

when ordering service parts. Do not remove this

tag, so the information is available for future ser-

vice.

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on a raised boss on top

of the clutch housing area.

SELECTION OF LUBRICANT

The A-598 manual transaxle uses SAE 5W-30

engine oil, meeting SG and/or SG-CD qualifications,

as the factory fill lubricant. G5 SAE 10W-40 engine

oil is a suitable service fill alternative.Hypoid gear

lube, manual transmission fluid, and/or auto-

matic transmission fluid should not be used in

this transaxle.Hard shifting effort, bearing, gear,

and/or synchronizer failure may occur if incorrect

fluid is used.

SELECTION OF LUBRICANTÐRHD VEHICLES

The A-558 manual transaxle uses SAE 5W-30

engine oil, meeting SG and/or SG-CD qualifications,

as the factory fill lubricant. G5 SAE 10W-40 engine

oil is a suitable service fill alternative.Hypoid gear

lube, manual transmission fluid, and/or auto-

matic transmission fluid should not be used in

this transaxle.Hard shifting effort, bearing, gear,

and/or synchronizer failure may occur if incorrect

fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

Fig. 1 Transaxle Identification

Fig. 2 Transaxle Identification

21 - 2 A±598 MANUAL TRANSAXLENS/GS