oil temperature CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 892 of 1938

X3 20BK/RD

HORN RELAY CONTROL L110 22BK/YL

AUTO HEADLAMP SWITCH SENSE

BA

BLACK

40 30 20 10

31 21 11 NATURAL

1

Z1 20BK G9 20GY/BK

B A CAV GROUND RED BRAKE WARNING LAMP DRIVER CIRCUIT

FUNCTION

L308 20LG/WT V26 22YL/WT D9 22GY/BK D2 20WT/BK G6 22GY G19 20LG/OR G69 22BK/OR Z2 20BK/LG L307 20LG/OR E17 20YL/BK Z2 20BK/LG Z20 20BK/WT** E92 22OR/BK

V52 20DG/YL G2 22VT G26 20LB D1 20VT/BR M32 22BK/LB

G96 20LG/RD

40 39

38 37 36

35 34 33

32 31 30

29 28 27

26 25 24 23 22 21

20 19 18

17 16 15

14 13 12

11 10 9

8 7 6

5 4 3

2 1 CAV PARK LAMP SWITCH SENSE REAR WIPER SWITCH MUX RKE MODULE PROGRAM ENABLE CCD BUS(-) ENGINE OIL PRESSURE SWITCH SENSE ABS WARNING LAMP DRIVER VTSS LAMP DRIVER GROUND HEADLAMP SWITCH SENSE STEP DIMMER SWITCH SENSE GROUND GROUND DIMMER SWITCH SIGNAL

FRONT WIPER SWITCH MUX ENGINE TEMPERATURE WARNING LAMP DRIVER KEY-IN IGNITION SWITCH SENSE CCD BUS(+) COURTESY LAMP SWITCH SENSE RKE INTERFACE

- - - -

- - -

- - - - - -

- - - - - CIRCUIT

- - - -

- - -

- - - - - -

- - - - - FUNCTION

P136 20YL

POWER FOLDING MIRROR SWITCH SIGNAL

* BUILT-UP-EXPORT

** EXCEPT BUILT-UP-EXPORT

GAS

BODY

CONTROL

MODULE - C2

BRAKE PRESSURE

SWITCH

8W - 80 - 16 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8016

Page 905 of 1938

12

- -

2

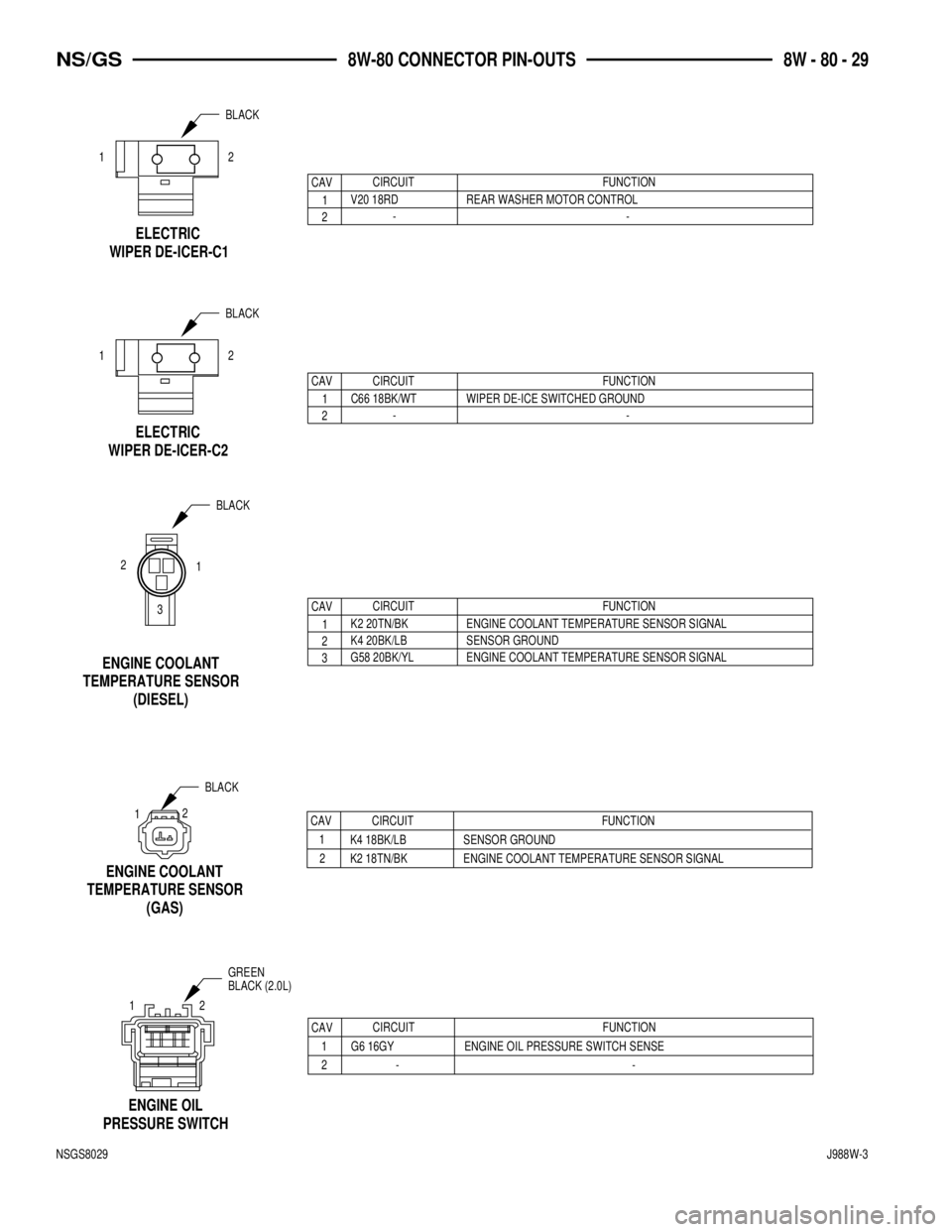

1V20 18RD CAV FUNCTION CIRCUIT

REAR WASHER MOTOR CONTROL BLACK

WIPER DE-ICER-C1ELECTRIC

ELECTRIC

WIPER DE-ICER-C2

BLACK

WIPER DE-ICE SWITCHED GROUND CIRCUIT FUNCTION

CAV

C66 18BK/WT

1

2--

2 1

SENSOR GROUND K4 20BK/LB

2

1K2 20TN/BK CAV FUNCTION CIRCUIT

ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

ENGINE COOLANT TEMPERATURE SENSOR SIGNAL G58 20BK/YL

3ENGINE COOLANT

TEMPERATURE SENSOR

(DIESEL)

1 2

3

BLACK

(GAS) TEMPERATURE SENSORENGINE COOLANT

12BLACK

K2 18TN/BK K4 18BK/LB

2 1 CAV ENGINE COOLANT TEMPERATURE SENSOR SIGNAL SENSOR GROUND CIRCUIT

FUNCTION

PRESSURE SWITCHENGINE OIL

BLACK (2.0L)

1GREEN

2

G6 16GY

2 1 CAV ENGINE OIL PRESSURE SWITCH SENSE

- CIRCUIT

- FUNCTION

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 29

NSGS8029J988W-3

Page 934 of 1938

(LHD) MESSAGE CENTER

* DIESEL WAIT-TO START WARNING LAMP DRIVER G85 20OR/BK * 7

BLUE

7 1

136

G69 22BK/OR M1 20PK

R41 18BK/TN V23 18BR/PK G9 20GY/BK

G6 22GY G3 20BK/PK G2 22VT

G19 20LG/OR L62 18BR/RD Z1 20BK

L63 18DG/RD L34 20RD/OR

13 12 11 10 9 8 7 6 5 4

3 2 1 CAV VTSS INDICATOR LAMP DRIVER

FUSED B (+)

AIRBAG WARNING LAMP DRIVER FUSED IGNITION (ST-RUN) RED BRAKE WARNING LAMP DRIVER

ENGINE OIL PRESSURE SWITCH SENSE SERVICE ENGINE SOON INDICATOR LAMP DRIVER ENGINE TEMPERATURE WARNING LAMP DRIVER

ABS WARNING LAMP DRIVER RIGHT TURN SIGNAL GROUND

LEFT TURN SIGNAL FUSED HIGH BEAM RELAY OUTPUT CIRCUIT

FUNCTION

SWITCH MEMORY SET

BLUE564

1 2 3

P23 20PK/RD P22 20PK/BK P24 20PK/WT Z1 20BK

6 5 4 3 2

1 CAV MEMORY NO. 2 MEMORY SET MEMORY NO. 1 GROUND - - CIRCUIT

- - FUNCTION

MODULE - C3 MEMORY SEAT/MIRROR

21 10

11 NATURAL

1

P29 20BR/WT P25 22VT/RD P47 22LB P40 22GY/LB P15 22YL/LB

P11 22YL/WT P19 22YL/LG P9 20RD

P28 20BR/RD P26 22BR P27 22LB/RD P48 22GY/WT P17 22RD/LB P13 22RD/WT

P21 22RD/LG

21 20 19

18 17 16

15 14 13

12 11 10 9 8 7

6

5 4 3

2 1 CAV 6 VOLT SUPPLY SEAT HORIZONTAL POSITION SENSE SEAT RECLINER POSITION SENSE SEAT RECLINER (FORWARD) SEAT HORIZONTAL (FORWARD) SEAT REAR VERTICAL (UP) SEAT FRONT VERTICAL (UP)

FUSED B (+) SEAT POSITION SENSE COMMON SEAT FRONT VERTICAL POSITION SENSE SEAT REAR VERTICAL POSITION SENSE SEAT RECLINER (REARWARD) SEAT HORIZONTAL (REARWARD)

SEAT REAR VERTICAL (DOWN)

SEAT FRONT VERTICAL (DOWN)

- - - - - - CIRCUIT

- - - - - - - FUNCTION

8W - 80 - 58 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8058

Page 935 of 1938

SWITCH MULTI-FUNCTION

8 127BLACK

1

L324 22WT/LG V10 20BR

L94 20OR/WT L93 22PK Z1 18BK

F1 20DB V52 20DG//YL V16 20WT

L305 22LB/WT L302 22LB/YL L91 22DB/PK

12 11 10 9 8 7

6

5 4 3 2 1 CAV HIGH BEAM RELAY CONTROL

FRONT WASHER MOTOR CONTROL LOW BEAM RELAY CONTROL HIGH/LOW BEAM RELAY CONTROL

GROUND FUSED B(+) WIPER MUX SIGNAL

HIGH SPEED RELAY DRIVER RIGHT TURN SIGNAL SENSE LEFT TURN SIGNAL SENSE COMBO FLASHER SWITCHED GROUND

- CIRCUIT

- FUNCTION

ACTUATOR MODE DOOR

5BLACK1

C35 20DG/YL C57 20DB/GY C37 20YL

C26 20PK/DB

C34 20DB/WT

5 4

3 2 1 CAV MODE DOOR DRIVER SENSOR GROUND MODE DOOR FEEDBACK SIGNAL

5 VOLT SUPPLY DOOR COMMON CIRCUIT

FUNCTION

FUSED RIGHT HIGH BEAM OUTPUT L34 20RD/OR7 131 6ENGINE TEMPERATURE WARNING LAMP DRIVER CIRCUIT FUNCTION

CAV

G2 22VT

1

2G19 20LG/OR

3L63 18DG/RD LEFT TURN SIGNAL

6L62 18BR/RD RIGHT TURN SIGNALSGROUND Z1 20BK

54

G69 22BK/OR

7

8M1 20PK

9R41 18BK/OR

V23 18BR/PK

10

13G3 20BK/PKENGINE OIL PRESSURE SWITCH SENSE G6 22GY

12G9 20GY/BK RED BRAKE WARNING LAMP DRIVER

11ABS WARNING LAMP DRIVER

FUSED B(+)

FUSED IGNITION (ST-RUN)

(RHD) MESSAGE CENTER

VTSS INDICATOR LAMP DRIVER

AIRBAG WARNING LAMP DRIVER

SERVICE ENGINE SOON INDICATOR LAMP DRIVER

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 59

NSGS8059J988W-3

Page 947 of 1938

MODULE - C1CONTROL POWERTRAIN

- -

K90 18TN ENGINE STARTER MOTOR RELAY CONTROL

C103 18DG/LB A/C SWITCH SIGNALKNOCK SENSOR SIGNAL K42 18DB/LG- - BLACK

10 20 30 40

1 11 21 31

K35 18GY/YL K1 18DG/RD K22 18OR/DB K44 18TN/YL K24 18GY/BK K41 18BK/DG K2 18TN/BK G3 18BK/PK F87 18WT/BK K12 18TN/WT K14 18LB/BR

K38 18GY K58 18BR/DB K11 18WT/DB K19 18GY/RD Z12 18BK/TN K20 18DG K13 18YL/WT

A142 18DG/OR V32 18YL/RD K17 18DB/TN K18 18RD/YL

40 39 38

37 36 35

34 33 32

31

30 29 28

27 26 25 24 23

22 21 20

19 18 17

16 15 14

13 12 11

10 9 8

7 6 5

4 3 2

1 CAV EGR SOLENOID CONTROL MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL THROTTLE POSITION SENSOR SIGNAL CAMSHAFT POSITION SENSOR SIGNAL CRANKSHAFT POSITION SENSOR SIGNAL HEATED OXYGEN SENSOR SIGNAL ENGINE COOLANT TEMPERATURE SENSOR SIGNAL SERVICE ENGINE SOON INDICATOR LAMP DRIVER FUSED IGNITION SWITCH OUTPUT (ST-RUN) INJECTOR NO. 2 DRIVER INJECTOR NO. 4 DRIVER

INJECTOR NO. 5 DRIVER (3.3L/3.8L) INJECTOR NO. 6 DRIVER (3.3L/3.8L) INJECTOR NO. 1 DRIVER IGNITION COIL NO. 1 DRIVER GROUND GENERATOR FIELD DRIVER INJECTOR NO. 3 DRIVER

AUTOMATIC SHUT DOWN RELAY OUTPUT SPEED CONTROL ON/OFF SWITCH SENSE IGNITION COIL NO. 2 DRIVER IGNITION COIL NO. 3 DRIVER (3.3L/3.8L)

- - - - - - -

- - - - - CIRCUIT

- - - - - - -

- - - - - FUNCTION

K21 18BK/RD* INTAKE AIR TEMPERATURE SENSOR SIGNAL

* 2.0L

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 71

NSGS8071J988W-3

Page 966 of 1938

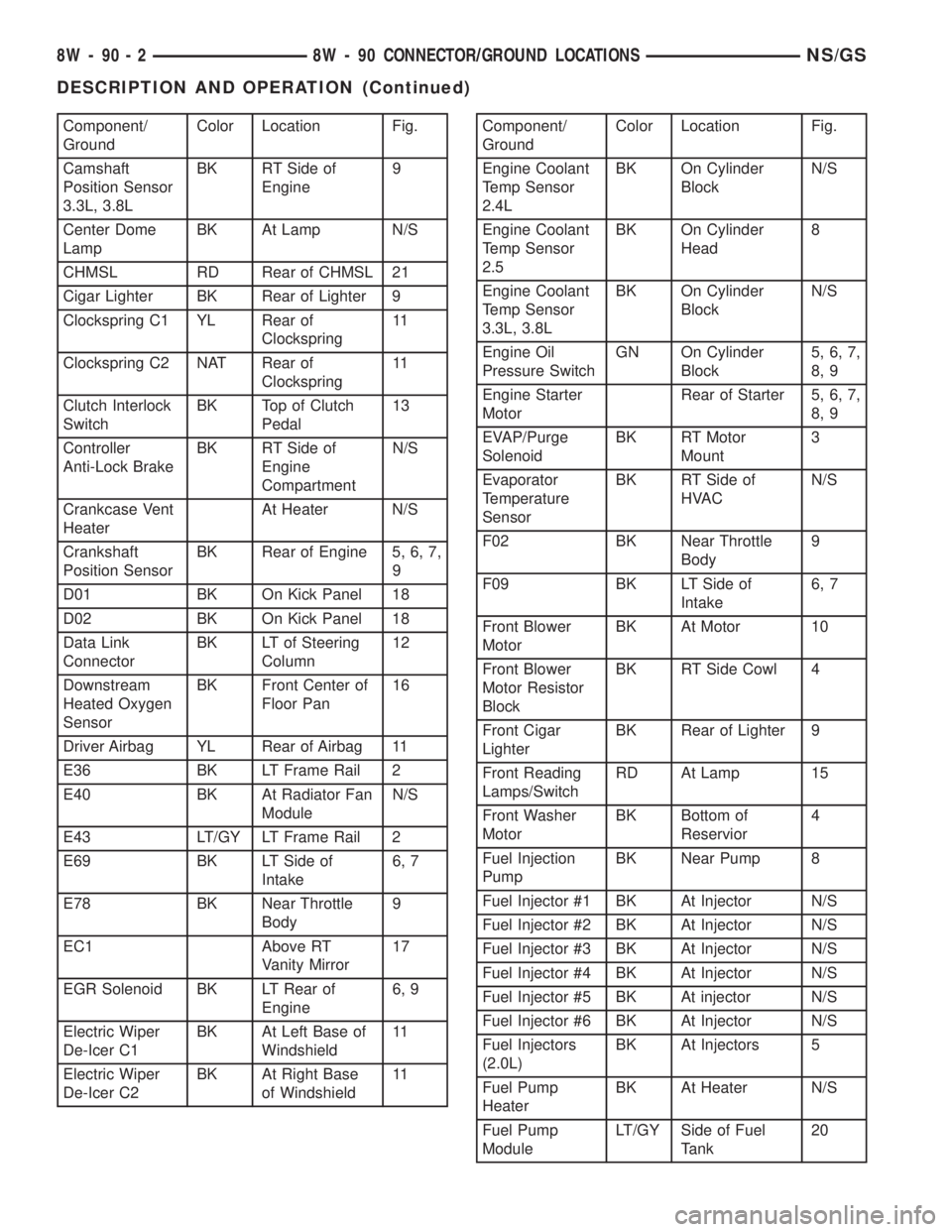

Component/

GroundColor Location Fig.

Camshaft

Position Sensor

3.3L, 3.8LBK RT Side of

Engine9

Center Dome

LampBK At Lamp N/S

CHMSL RD Rear of CHMSL 21

Cigar Lighter BK Rear of Lighter 9

Clockspring C1 YL Rear of

Clockspring11

Clockspring C2 NAT Rear of

Clockspring11

Clutch Interlock

SwitchBK Top of Clutch

Pedal13

Controller

Anti-Lock BrakeBK RT Side of

Engine

CompartmentN/S

Crankcase Vent

HeaterAt Heater N/S

Crankshaft

Position SensorBK Rear of Engine 5, 6, 7,

9

D01 BK On Kick Panel 18

D02 BK On Kick Panel 18

Data Link

ConnectorBK LT of Steering

Column12

Downstream

Heated Oxygen

SensorBK Front Center of

Floor Pan16

Driver Airbag YL Rear of Airbag 11

E36 BK LT Frame Rail 2

E40 BK At Radiator Fan

ModuleN/S

E43 LT/GY LT Frame Rail 2

E69 BK LT Side of

Intake6, 7

E78 BK Near Throttle

Body9

EC1 Above RT

Vanity Mirror17

EGR Solenoid BK LT Rear of

Engine6, 9

Electric Wiper

De-Icer C1BK At Left Base of

Windshield11

Electric Wiper

De-Icer C2BK At Right Base

of Windshield11Component/

GroundColor Location Fig.

Engine Coolant

Temp Sensor

2.4LBK On Cylinder

BlockN/S

Engine Coolant

Temp Sensor

2.5BK On Cylinder

Head8

Engine Coolant

Temp Sensor

3.3L, 3.8LBK On Cylinder

BlockN/S

Engine Oil

Pressure SwitchGN On Cylinder

Block5, 6, 7,

8, 9

Engine Starter

MotorRear of Starter 5, 6, 7,

8, 9

EVAP/Purge

SolenoidBK RT Motor

Mount3

Evaporator

Temperature

SensorBK RT Side of

HVACN/S

F02 BK Near Throttle

Body9

F09 BK LT Side of

Intake6, 7

Front Blower

MotorBK At Motor 10

Front Blower

Motor Resistor

BlockBK RT Side Cowl 4

Front Cigar

LighterBK Rear of Lighter 9

Front Reading

Lamps/SwitchRD At Lamp 15

Front Washer

MotorBK Bottom of

Reservior4

Fuel Injection

PumpBK Near Pump 8

Fuel Injector #1 BK At Injector N/S

Fuel Injector #2 BK At Injector N/S

Fuel Injector #3 BK At Injector N/S

Fuel Injector #4 BK At Injector N/S

Fuel Injector #5 BK At injector N/S

Fuel Injector #6 BK At Injector N/S

Fuel Injectors

(2.0L)BK At Injectors 5

Fuel Pump

HeaterBK At Heater N/S

Fuel Pump

ModuleLT/GY Side of Fuel

Tank20

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 996 of 1938

Component/

GroundColor Location Fig.

Downstream

Heated Oxygen

SensorBK Front Center of

Floor Pan16

Driver Airbag YL Rear of Airbag 11

E36 BK LT Frame Rail 2

E40 BK At Radiator Fan

ModuleN/S

E43 LT/GY LT Frame Rail 2

E69 BK LT Side of

Intake6, 7

E78 BK Near Throttle

Body9

EC1 At Top Center

of Windshield17

EGR Solenoid BK LT Rear of

Engine6, 9

Electric Wiper

De-Icer C1BK At Right Base

of Windshield11

Electric Wiper

De-Icer C2BK At Left Base of

Windshield11

Engine Coolant

Temp Sensor

2.4LBK On Cylinder

BlockN/S

Engine Coolant

Temp Sensor

3.3L, 3.8LBK On Cylinder

BlockN/S

Engine Oil

Pressure SwitchGN On Cylinder

Block5, 6, 7,

8, 9

Engine Starter

MotorRear of Starter 5, 6, 7,

8, 9

EVAP/Purge

SolenoidBK RT Motor

Mount3

Evaporator

Temperature

SensorBK RT Side of

HVACN/S

F02 BK Near Throttle

Body9

F09 BK LT Side of

Intake6, 7

Front Blower

MotorBK At Motor 10

Front Blower

Motor Resistor

BlockBK LT Side of

Engine2

Front Cigar

LighterBK Rear of Lighter 11Component/

GroundColor Location Fig.

Front Reading

Lamps/SwitchBL At Lamp 17

Front Washer

MotorBK Bottom of

Reservior4

Fuel Injector #1 BK At Injector N/S

Fuel Injector #2 BK At Injector N/S

Fuel Injector #3 BK At Injector N/S

Fuel Injector #4 BK At Injector N/S

Fuel Injector #5 BK At Injector N/S

Fuel Injector #6 BK At Injector N/S

Fuel Pump

ModuleGY Side of Fuel

Tank20

G100 LT Frame Rail 3

G101 2.4L Rear of

Cylinder Head6, 7

G101 3.3L, 3.8L Rear of

Cylinder Block9

G102 LT Frame Rail 3

G103 2.4L Rear of

Cylinder Head6, 7

G103 3.3L, 3.8L Rear of

Cylinder Block9

G104 Near T/O for

RT HeadlampN/S

G200 Left of I.P.

Center Stack10

G201 I.P. Center

Support10

G202 I.P. Center

Support10

G204 I.P. Center

Support10

G300 BK LT Kick Panel 13

G301 RT Kick Panel 13, 14

G302 BK LT Quarter

Panel21

G400 BK In Liftgate 23

Generator BK Rear of

Generator5, 6, 7,

8, 9

Glove Box

LampBL Rear of Glove

Box11

Headlamp

Dimmer SwitchBK Part of

Multifunction

Switch11

8W - 90 - 32 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1056 of 1938

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 5).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either

ENERGY CONSERVING or ENERGY CONSERV-

ING II.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 6).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

Fig. 5 Temperature/Engine Oil Viscosity

Fig. 6 Engine Oil Container Standard Notations

9 - 6 ENGINENS

GENERAL INFORMATION (Continued)

Page 1057 of 1938

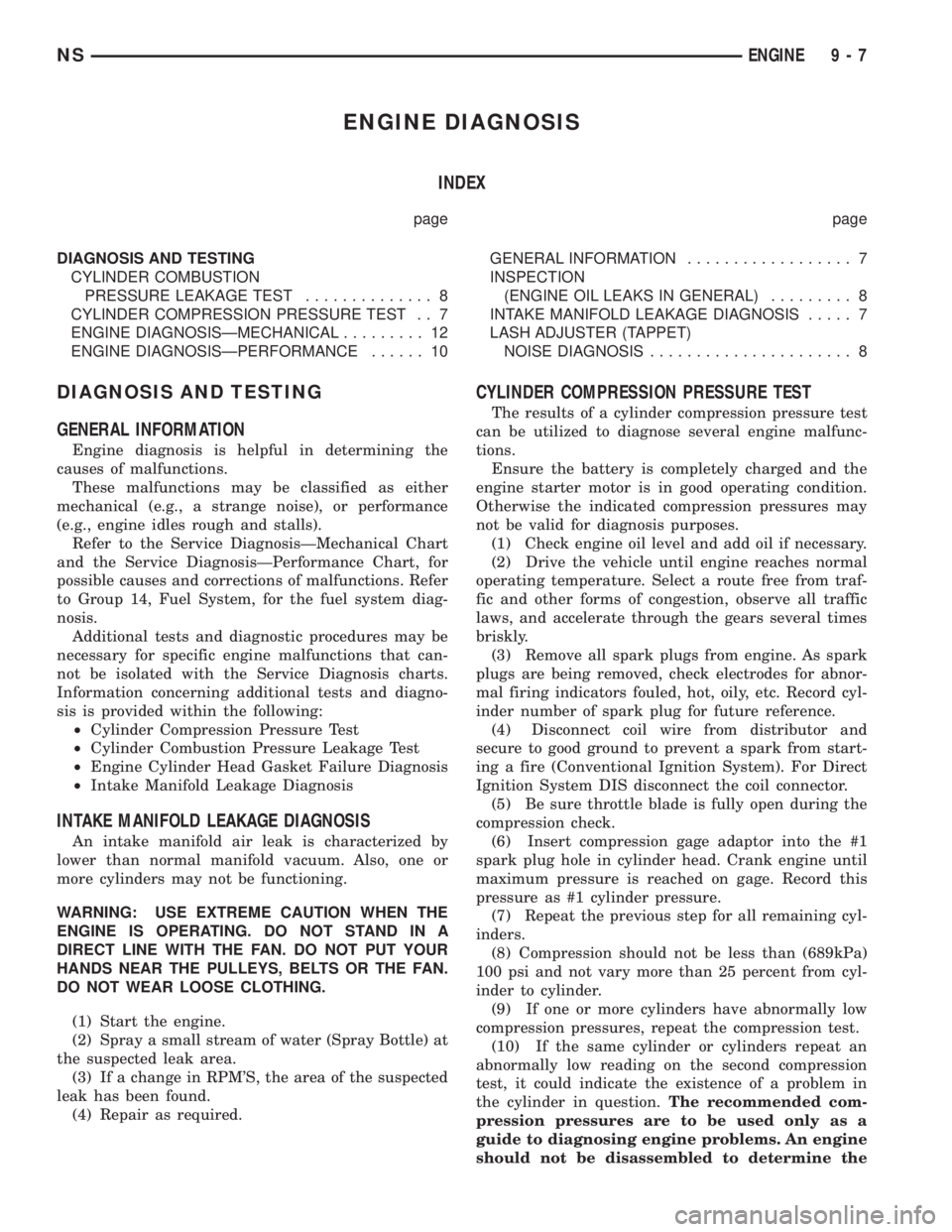

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST.............. 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 12

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION

(ENGINE OIL LEAKS IN GENERAL)......... 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS...................... 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

NSENGINE 9 - 7

Page 1058 of 1938

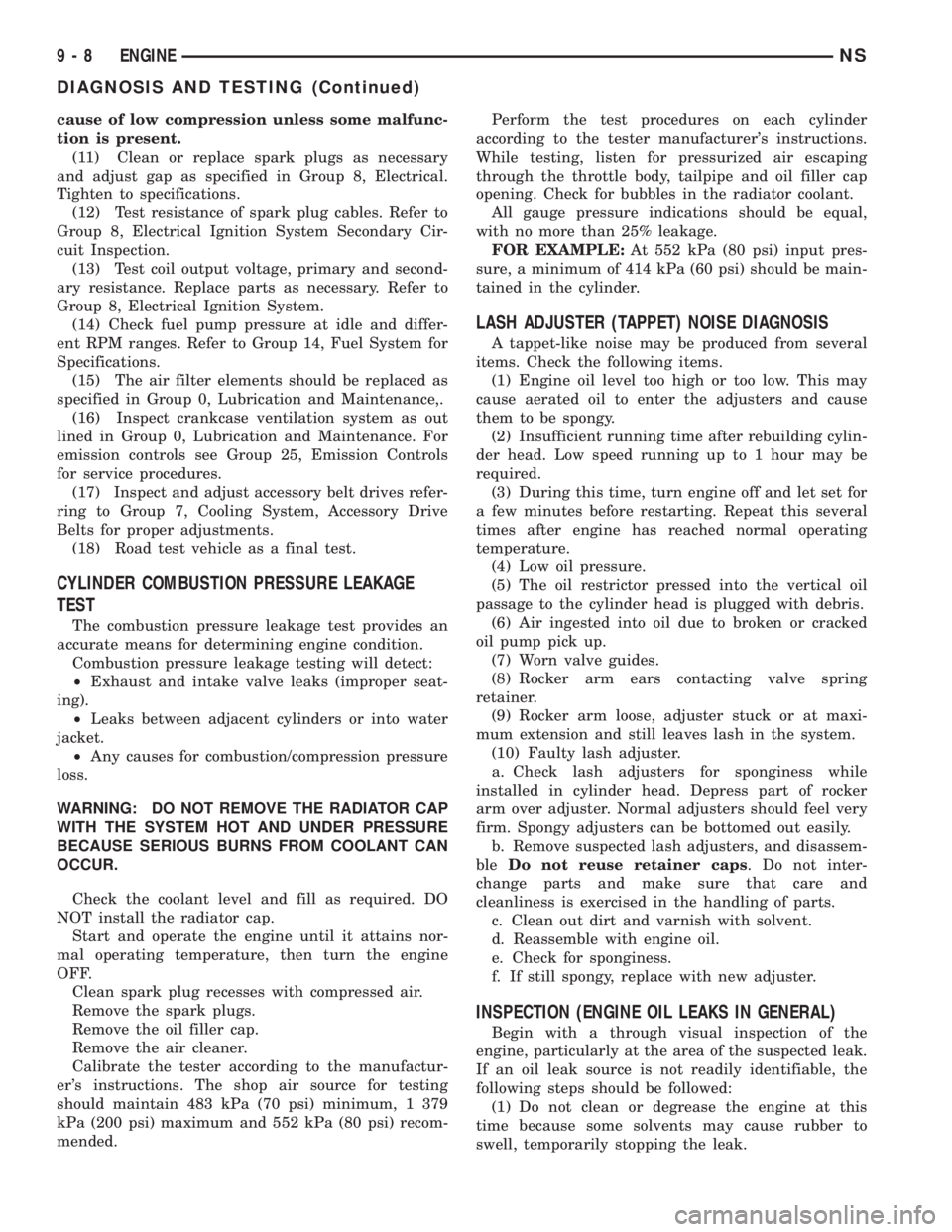

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and disassem-

bleDo not reuse retainer caps. Do not inter-

change parts and make sure that care and

cleanliness is exercised in the handling of parts.

c. Clean out dirt and varnish with solvent.

d. Reassemble with engine oil.

e. Check for sponginess.

f. If still spongy, replace with new adjuster.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

9 - 8 ENGINENS

DIAGNOSIS AND TESTING (Continued)