power steering CHRYSLER VOYAGER 1996 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1231 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect the battery.

(2) Remove the air cleaner assembly and inlet

hose.

(3) Remove both hoses at intercooler and engine.

(4) Disconnect EGR vacuum hose.

(5) Disconnect brake booster vacuum hose.

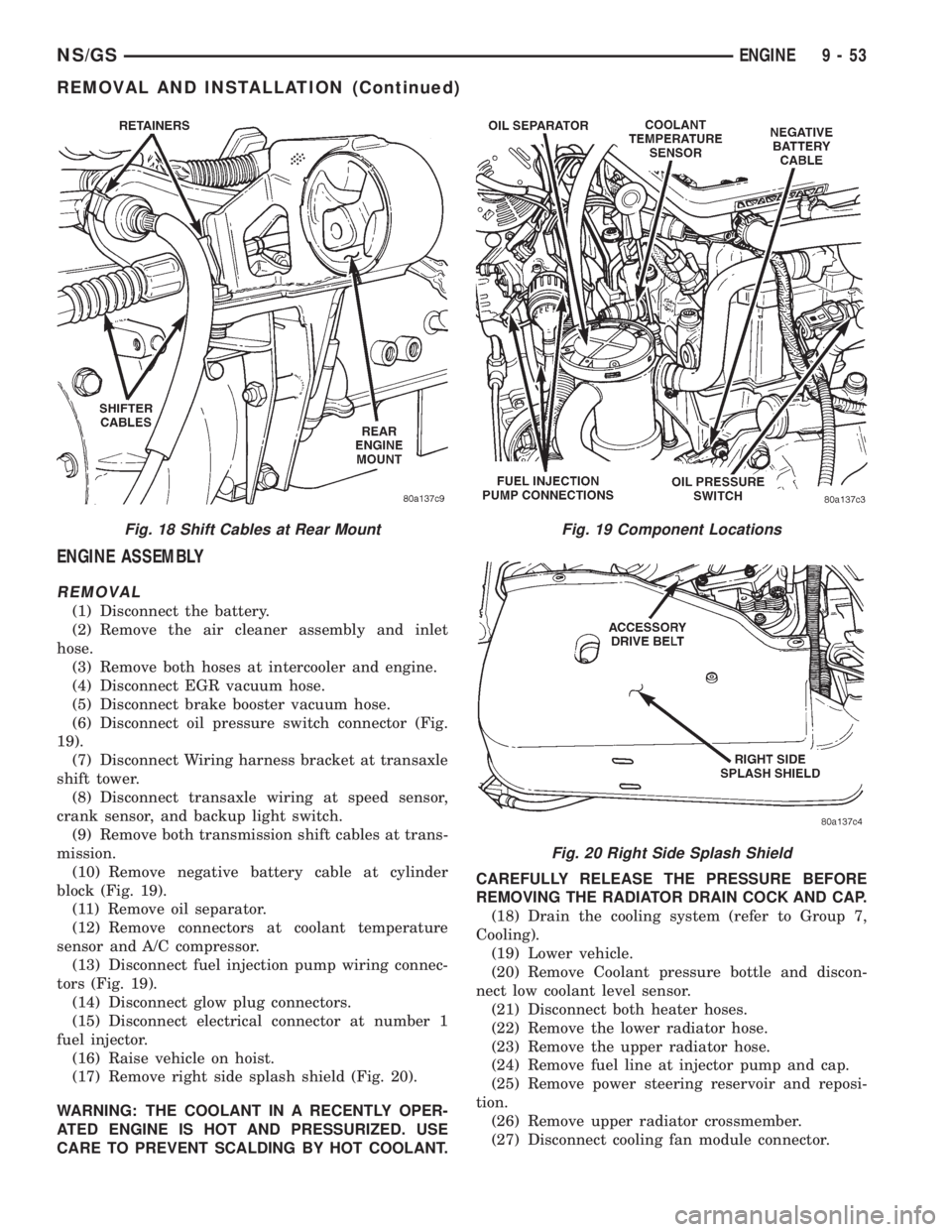

(6) Disconnect oil pressure switch connector (Fig.

19).

(7) Disconnect Wiring harness bracket at transaxle

shift tower.

(8) Disconnect transaxle wiring at speed sensor,

crank sensor, and backup light switch.

(9) Remove both transmission shift cables at trans-

mission.

(10) Remove negative battery cable at cylinder

block (Fig. 19).

(11) Remove oil separator.

(12) Remove connectors at coolant temperature

sensor and A/C compressor.

(13) Disconnect fuel injection pump wiring connec-

tors (Fig. 19).

(14) Disconnect glow plug connectors.

(15) Disconnect electrical connector at number 1

fuel injector.

(16) Raise vehicle on hoist.

(17) Remove right side splash shield (Fig. 20).

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND CAP.

(18) Drain the cooling system (refer to Group 7,

Cooling).

(19) Lower vehicle.

(20) Remove Coolant pressure bottle and discon-

nect low coolant level sensor.

(21) Disconnect both heater hoses.

(22) Remove the lower radiator hose.

(23) Remove the upper radiator hose.

(24) Remove fuel line at injector pump and cap.

(25) Remove power steering reservoir and reposi-

tion.

(26) Remove upper radiator crossmember.

(27) Disconnect cooling fan module connector.

Fig. 18 Shift Cables at Rear MountFig. 19 Component Locations

Fig. 20 Right Side Splash Shield

NS/GSENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1232 of 1938

(28) Remove radiator support bolts.It is neces-

sary to loosen the receiver/dryer to gain access

to the radiator bolts.

(29) Remove radiator and fans as an assembly.

(30) Remove accessory drive belt generator/power

steering. Refer to Group 7, for procedure.

(31) Remove both power steering lines at pump,

and cap both lines.

NOTE: It is not necessary to discharge A/C system

for engine removal.

(32) Remove A/C compressor. Secure compressor

away from engine for clearance during engine

removal.

(33) Remove Generator and adjusting bracket.

NOTE: Do not remove the mounting base from the

generator. It is aligned at the factory and cannot be

realigned in the field.

(34) Hoist vehicle.

(35) Remove exhaust pipe at turbo outlet.

(36) Remove connections at starter.

(37) Remove power steering high pressure line

bracket at rear of oil pan.

(38) Remove both driveshafts from transaxle. Refer

to Group 2, Suspension and Driveshafts.

(39) Disconnect clutch cable at transaxle.

(40) Remove reinforcement plate on lower cross-

member.

(41) Remove front and rear engine mounts. Refer

to procedure outlined in this section.

(42) Drain engine oil and remove oil filter if neces-

sary.

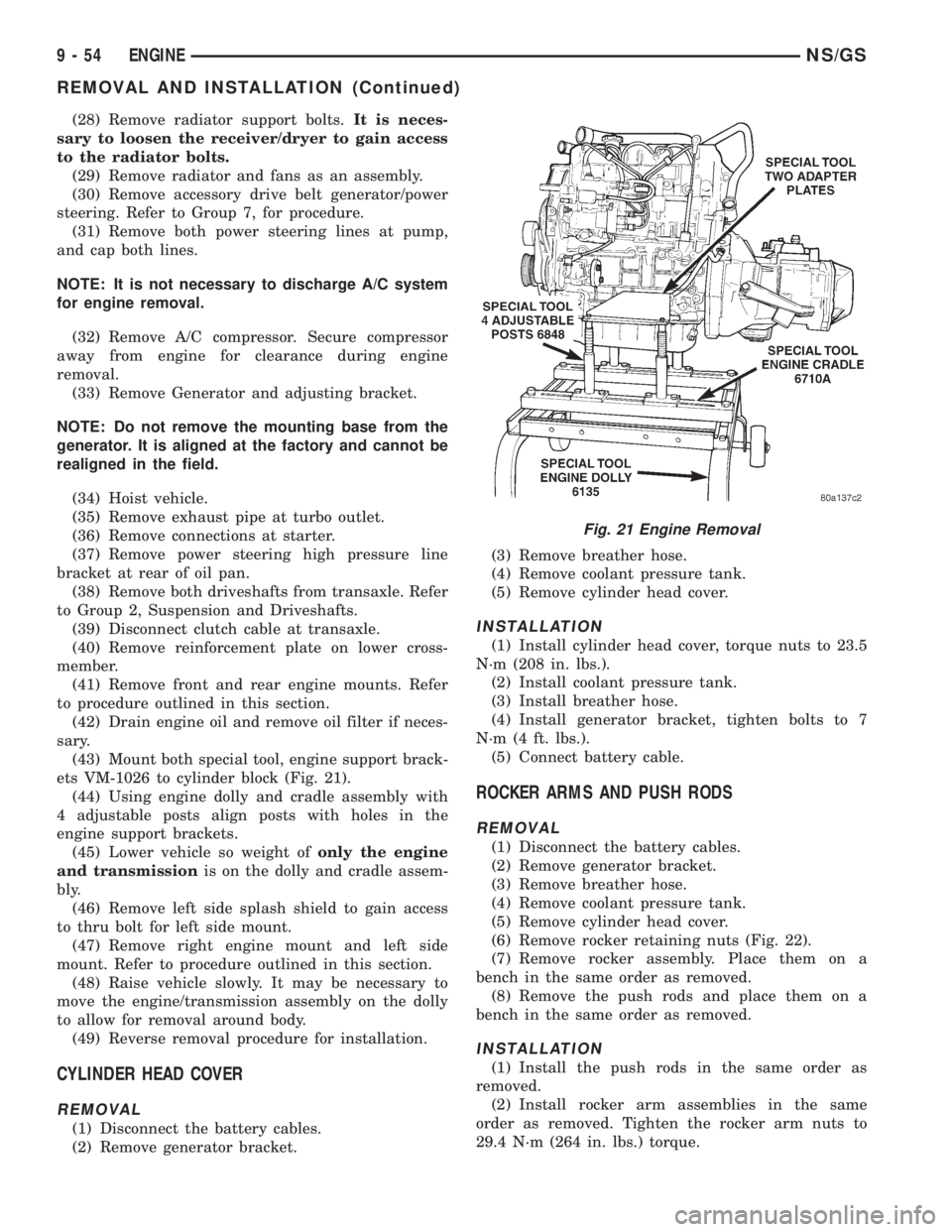

(43) Mount both special tool, engine support brack-

ets VM-1026 to cylinder block (Fig. 21).

(44) Using engine dolly and cradle assembly with

4 adjustable posts align posts with holes in the

engine support brackets.

(45) Lower vehicle so weight ofonly the engine

and transmissionis on the dolly and cradle assem-

bly.

(46) Remove left side splash shield to gain access

to thru bolt for left side mount.

(47) Remove right engine mount and left side

mount. Refer to procedure outlined in this section.

(48) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the dolly

to allow for removal around body.

(49) Reverse removal procedure for installation.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect the battery cables.

(2) Remove generator bracket.(3) Remove breather hose.

(4) Remove coolant pressure tank.

(5) Remove cylinder head cover.

INSTALLATION

(1) Install cylinder head cover, torque nuts to 23.5

N´m (208 in. lbs.).

(2) Install coolant pressure tank.

(3) Install breather hose.

(4) Install generator bracket, tighten bolts to 7

N´m (4 ft. lbs.).

(5) Connect battery cable.

ROCKER ARMS AND PUSH RODS

REMOVAL

(1) Disconnect the battery cables.

(2) Remove generator bracket.

(3) Remove breather hose.

(4) Remove coolant pressure tank.

(5) Remove cylinder head cover.

(6) Remove rocker retaining nuts (Fig. 22).

(7) Remove rocker assembly. Place them on a

bench in the same order as removed.

(8) Remove the push rods and place them on a

bench in the same order as removed.

INSTALLATION

(1) Install the push rods in the same order as

removed.

(2) Install rocker arm assemblies in the same

order as removed. Tighten the rocker arm nuts to

29.4 N´m (264 in. lbs.) torque.

Fig. 21 Engine Removal

9 - 54 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1239 of 1938

(3) Install cylinder head, intake manifold, and

exhaust manifold. Refer to cylinder head installation

in this section.

(4) Install push rods in original positions.

(5) Install rocker arms in original positions.

(6) Install cylinder head cover. Refer to cylinder

valve cover installation in this section.

(7) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery cable.

(2) Raise vehicle on hoist.

(3) Remove right side lower splash shield.

(4) Remove generator, power steering belt. Refer to

Group 7, Cooling.

(5) Remove water pump belt. Refer to Group 7,

Cooling.

(6) Remove engine starter. Refer to Group, 8B for

procedure

(7) Install flywheel locking tool VM.1014 to pre-

vent engine rotation.

NOTE: Crankshaft damper nut is left handed

thread.

(8) Remove vibration damper nut.

(9) Remove vibration damper. No special tool is

needed for removal.

CAUTION: If thread sealant is used it is important

to remove all the old thread sealant from the

threads on the crankshaft.

INSTALLATION

NOTE: Before installing damper be sure the O-ring

inside the center of the damper is in its grove.

(1) Install vibration damper.

CAUTION: Correct torque on the vibration damper

nut is important or engine damage can occur.

(2) Install vibration damper nut and tighten to 441

N´m (325 ft. lbs.).

(3) Remove flywheel locking tool, and install

engine starter.(4) Install both accessary drive belts. Refer to

Group 7, Cooling.

(5) Install right splash shield.

(6) Lower vehicle.

(7) Connect the battery cable.

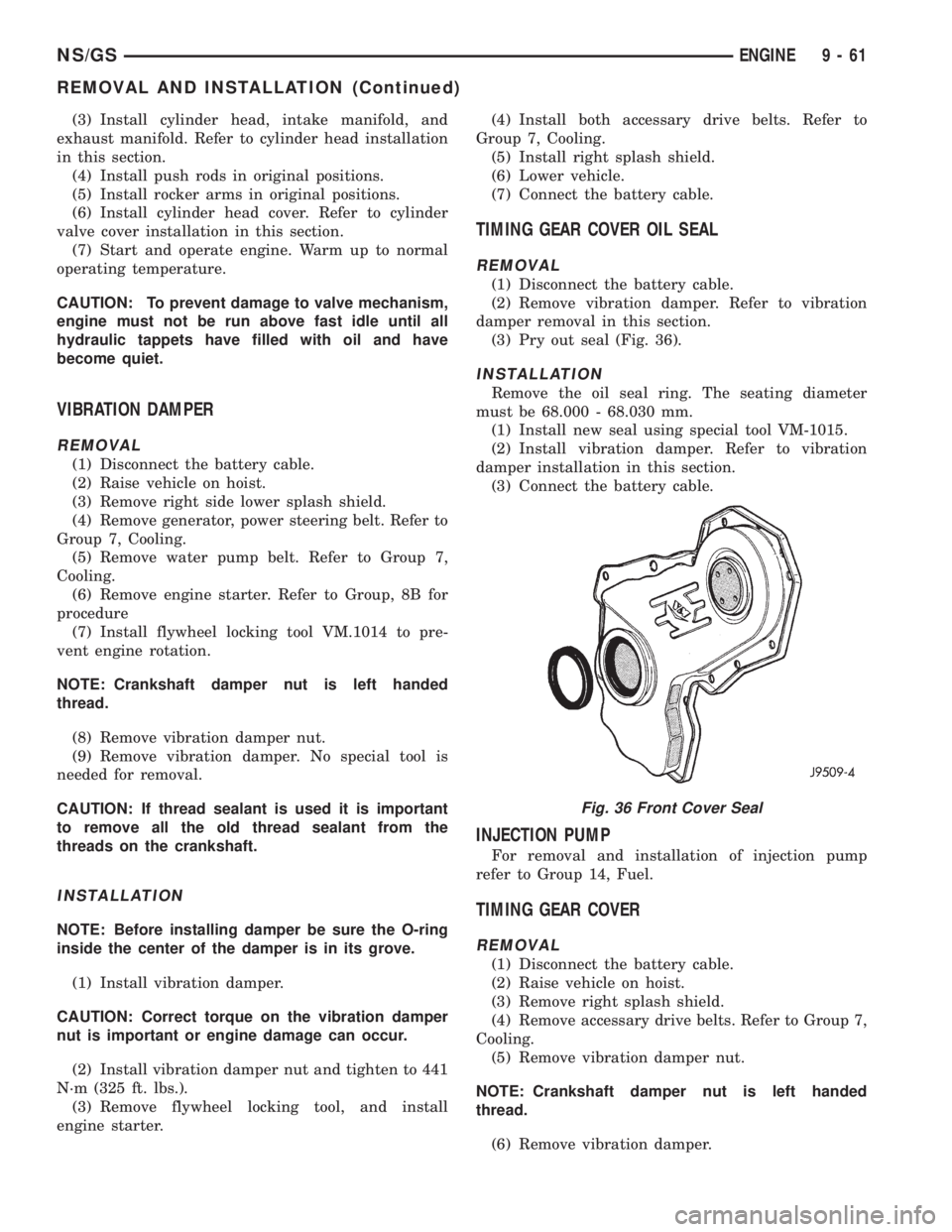

TIMING GEAR COVER OIL SEAL

REMOVAL

(1) Disconnect the battery cable.

(2) Remove vibration damper. Refer to vibration

damper removal in this section.

(3) Pry out seal (Fig. 36).

INSTALLATION

Remove the oil seal ring. The seating diameter

must be 68.000 - 68.030 mm.

(1) Install new seal using special tool VM-1015.

(2) Install vibration damper. Refer to vibration

damper installation in this section.

(3) Connect the battery cable.

INJECTION PUMP

For removal and installation of injection pump

refer to Group 14, Fuel.

TIMING GEAR COVER

REMOVAL

(1) Disconnect the battery cable.

(2) Raise vehicle on hoist.

(3) Remove right splash shield.

(4) Remove accessary drive belts. Refer to Group 7,

Cooling.

(5) Remove vibration damper nut.

NOTE: Crankshaft damper nut is left handed

thread.

(6) Remove vibration damper.

Fig. 36 Front Cover Seal

NS/GSENGINE 9 - 61

REMOVAL AND INSTALLATION (Continued)

Page 1240 of 1938

(7) Remove power steering/air conditioning pulley

nut. Remove pulley.

CAUTION: Remove old loctite from threads on

pump.

(8) Remove pump shaft support bracket assembly.

(9) Disconnect the water drain pipe hose at the

timing cover.

CAUTION: When separating the timing geat cover

from the block take care not to damage the mating

surface of the timing gear cover or block. Also take

care not to damage the timing gears or components

located inside the timing gear cover near the edge.

(10) Remove timing gear cover.

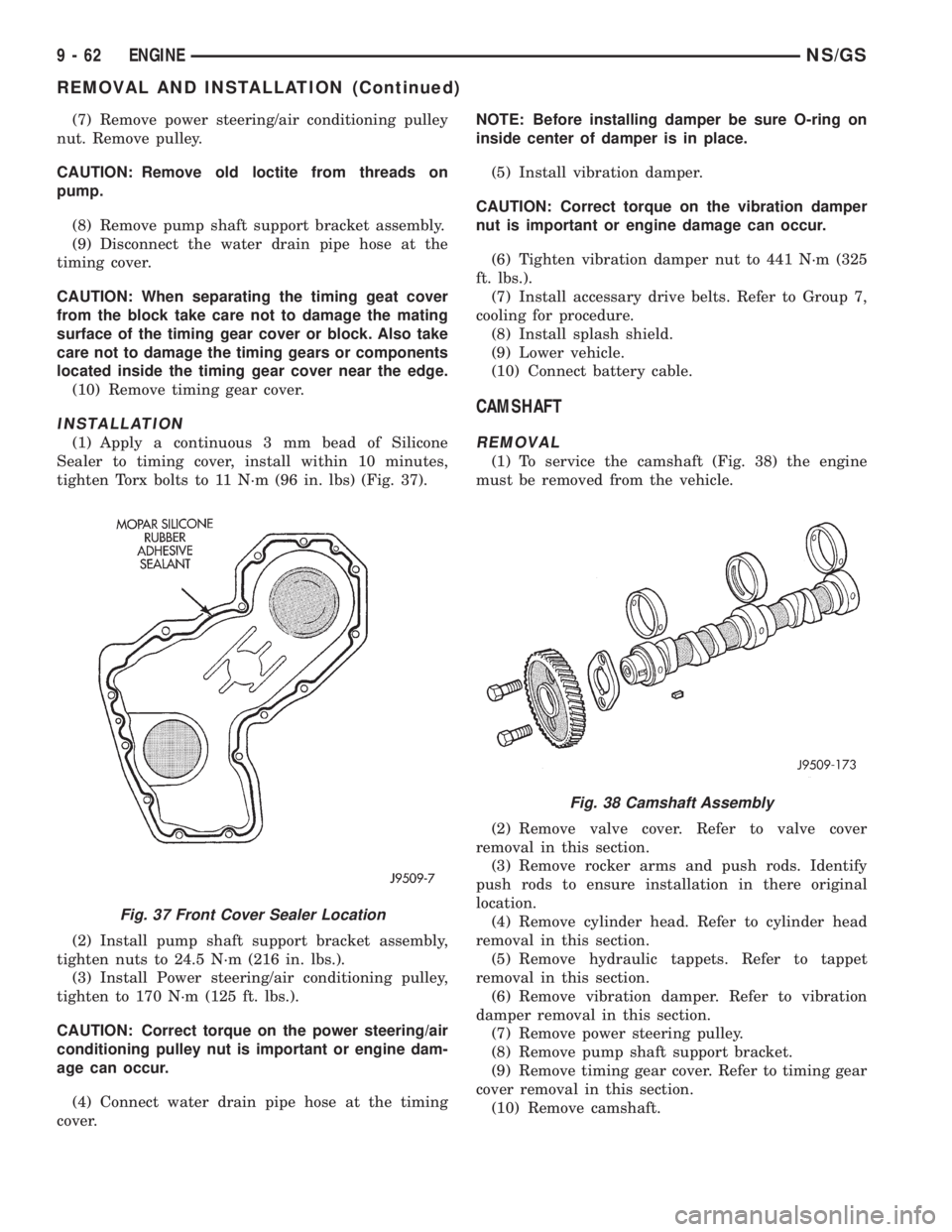

INSTALLATION

(1) Apply a continuous 3 mm bead of Silicone

Sealer to timing cover, install within 10 minutes,

tighten Torx bolts to 11 N´m (96 in. lbs) (Fig. 37).

(2) Install pump shaft support bracket assembly,

tighten nuts to 24.5 N´m (216 in. lbs.).

(3) Install Power steering/air conditioning pulley,

tighten to 170 N´m (125 ft. lbs.).

CAUTION: Correct torque on the power steering/air

conditioning pulley nut is important or engine dam-

age can occur.

(4) Connect water drain pipe hose at the timing

cover.NOTE: Before installing damper be sure O-ring on

inside center of damper is in place.

(5) Install vibration damper.

CAUTION: Correct torque on the vibration damper

nut is important or engine damage can occur.

(6) Tighten vibration damper nut to 441 N´m (325

ft. lbs.).

(7) Install accessary drive belts. Refer to Group 7,

cooling for procedure.

(8) Install splash shield.

(9) Lower vehicle.

(10) Connect battery cable.

CAMSHAFT

REMOVAL

(1) To service the camshaft (Fig. 38) the engine

must be removed from the vehicle.

(2) Remove valve cover. Refer to valve cover

removal in this section.

(3) Remove rocker arms and push rods. Identify

push rods to ensure installation in there original

location.

(4) Remove cylinder head. Refer to cylinder head

removal in this section.

(5) Remove hydraulic tappets. Refer to tappet

removal in this section.

(6) Remove vibration damper. Refer to vibration

damper removal in this section.

(7) Remove power steering pulley.

(8) Remove pump shaft support bracket.

(9) Remove timing gear cover. Refer to timing gear

cover removal in this section.

(10) Remove camshaft.

Fig. 37 Front Cover Sealer Location

Fig. 38 Camshaft Assembly

9 - 62 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1259 of 1938

DESCRIPTION...................TORQUE

Injector

Tighten to................65N´m(48ft.lbs.)

Intake Manifold Mounting

Nuts...................30N´m(264 in. lbs.)

Main Bearing Oil Delivery Union

Bolts....................54N´m(40ft.lbs.)

Oil Feed Line To Rocker Arms

Bolts.................12.7 N´m (108 in. lbs.)

Oil Feed Line to Block

Bolts.................12.7 N´m (108 in. lbs.)

Oil Feel Line to Vacuum Pump

Bolts.................16.7 N´m (145 in. lbs.)

Oil Filter

Tighten to...............9.8N´m(85in.lbs.)

Oil Filter Adaptor

Fastener.................49N´m(36ft.lbs.)

Oil Filter Base

Fastener.................49N´m(36ft.lbs.)

Oil Pan Mounting

Bolts...................12N´m(108 in. lbs.)

Oil Pickup Tube

Bolts..................11.3N´m(100 in. lbs.)

Oil Pump Mounting

Bolts.................27.5 N´m (240 in. lbs.)

Oil Pan Drain

Plug.....................54N´m(40ft.lbs.)

Power Steering Pressure Hose

Fastener................28N´m(240 in. lbs.)

Power Steering Pulley

Nut ...................170N´m(125 ft. lbs.)

Rear Crankshaft Bearing Carrier

Bolts..................10.8 N´m (95 in. lbs.)

Rocker Arm Cover

Bolts.................14.7 N´m (132 in. lbs.)

Rocker Arm Mounting

Nuts..................29.4 N´m (264 in. lbs.)

Power Steering Pump Mounting

Nuts..................24.5 N´m (216 in. lbs.)

Turbocharger Mounting

Nuts...................32N´m(288 in. lbs.)

Turbocharger Oil Delivery

Bolt..................27.5 N´m (240 in. lbs.)

Turbocharger Oil Drain

Bolts..................10.8 N´m (95 in. lbs.)

Vacuum Pump Mounting

Bolts..................10.8 N´m (95 in. lbs.)

Water Manifold Mounting

Bolts..................11.8N´m(108 in. lbs.)

Water Pump Pulley

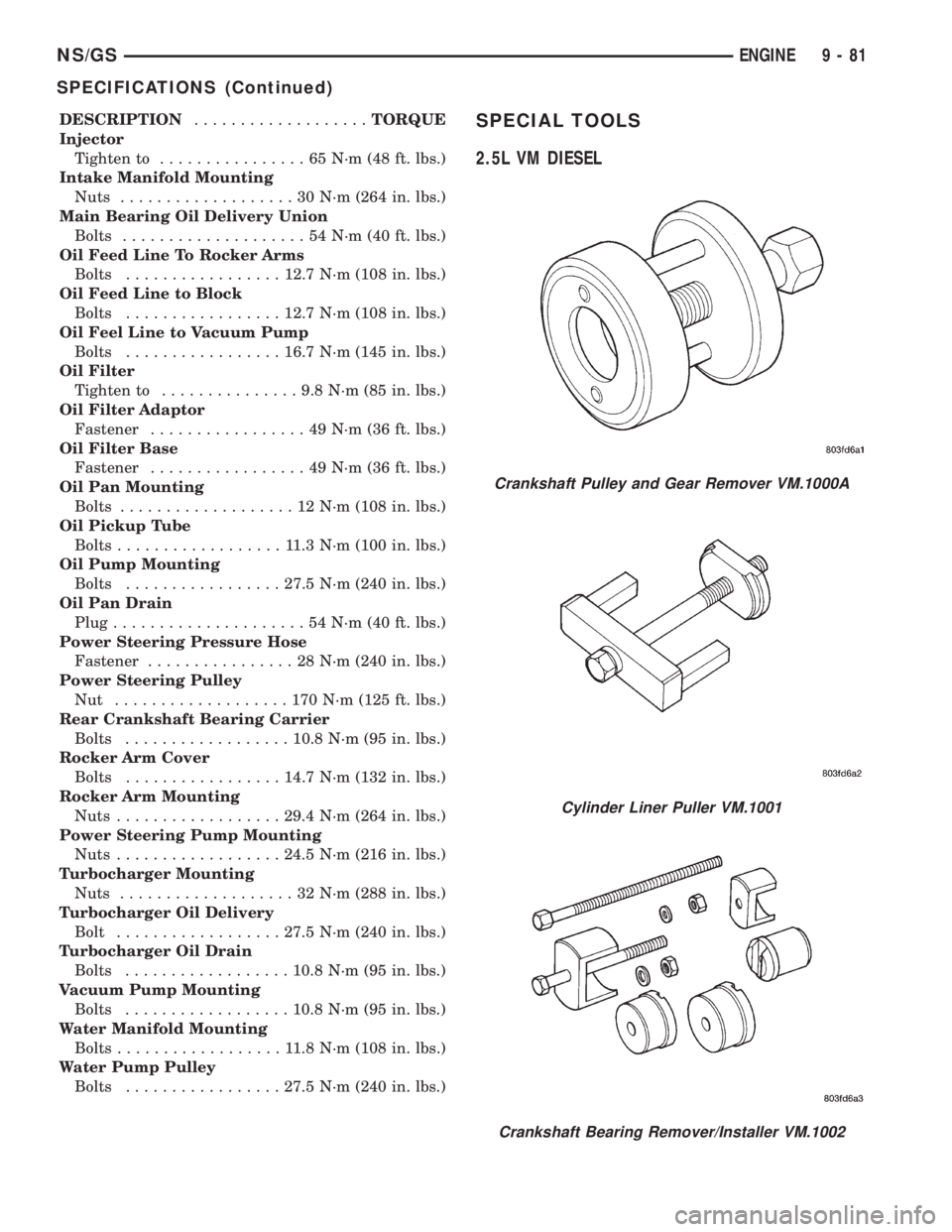

Bolts.................27.5 N´m (240 in. lbs.)SPECIAL TOOLS

2.5L VM DIESEL

Crankshaft Pulley and Gear Remover VM.1000A

Cylinder Liner Puller VM.1001

Crankshaft Bearing Remover/Installer VM.1002

NS/GSENGINE 9 - 81

SPECIFICATIONS (Continued)

Page 1278 of 1938

CAUTION: When using the ASD Fuel System Test,

The Auto Shutdown (ASD) Relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLDSÐ3.3/3.8L ENGINE

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove accessory drive belt. Refer to Accessory

Drive section located in Group 7 Cooling System for

procedure.

(3) Remove generator.

(4) Raise vehicle and disconnect exhaust pipe

from rear (cowl side) exhaust manifold at flex-joint.

(5) Disconnect down stream oxygen sensor connec-

tor.

(6) Lower exhaust system to gain access to rear

manifold.

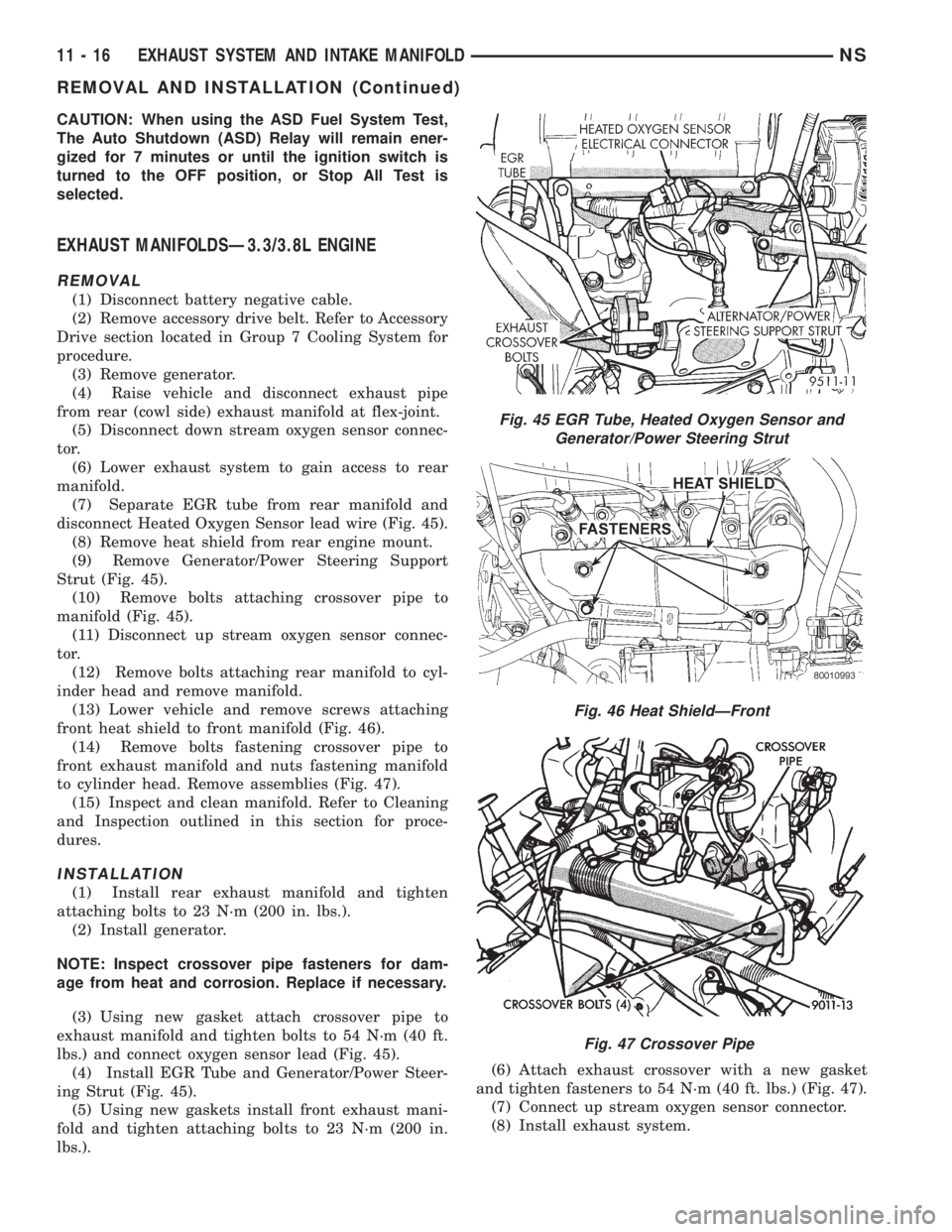

(7) Separate EGR tube from rear manifold and

disconnect Heated Oxygen Sensor lead wire (Fig. 45).

(8) Remove heat shield from rear engine mount.

(9) Remove Generator/Power Steering Support

Strut (Fig. 45).

(10) Remove bolts attaching crossover pipe to

manifold (Fig. 45).

(11) Disconnect up stream oxygen sensor connec-

tor.

(12) Remove bolts attaching rear manifold to cyl-

inder head and remove manifold.

(13) Lower vehicle and remove screws attaching

front heat shield to front manifold (Fig. 46).

(14) Remove bolts fastening crossover pipe to

front exhaust manifold and nuts fastening manifold

to cylinder head. Remove assemblies (Fig. 47).

(15) Inspect and clean manifold. Refer to Cleaning

and Inspection outlined in this section for proce-

dures.

INSTALLATION

(1) Install rear exhaust manifold and tighten

attaching bolts to 23 N´m (200 in. lbs.).

(2) Install generator.

NOTE: Inspect crossover pipe fasteners for dam-

age from heat and corrosion. Replace if necessary.

(3) Using new gasket attach crossover pipe to

exhaust manifold and tighten bolts to 54 N´m (40 ft.

lbs.) and connect oxygen sensor lead (Fig. 45).

(4) Install EGR Tube and Generator/Power Steer-

ing Strut (Fig. 45).

(5) Using new gaskets install front exhaust mani-

fold and tighten attaching bolts to 23 N´m (200 in.

lbs.).(6) Attach exhaust crossover with a new gasket

and tighten fasteners to 54 N´m (40 ft. lbs.) (Fig. 47).

(7) Connect up stream oxygen sensor connector.

(8) Install exhaust system.

Fig. 45 EGR Tube, Heated Oxygen Sensor and

Generator/Power Steering Strut

Fig. 46 Heat ShieldÐFront

Fig. 47 Crossover Pipe

11 - 16 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

REMOVAL AND INSTALLATION (Continued)

Page 1283 of 1938

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER MOUNT BUSHINGS . . . 5

FRONT CROSSMEMBER................... 3SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS.... 5

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER

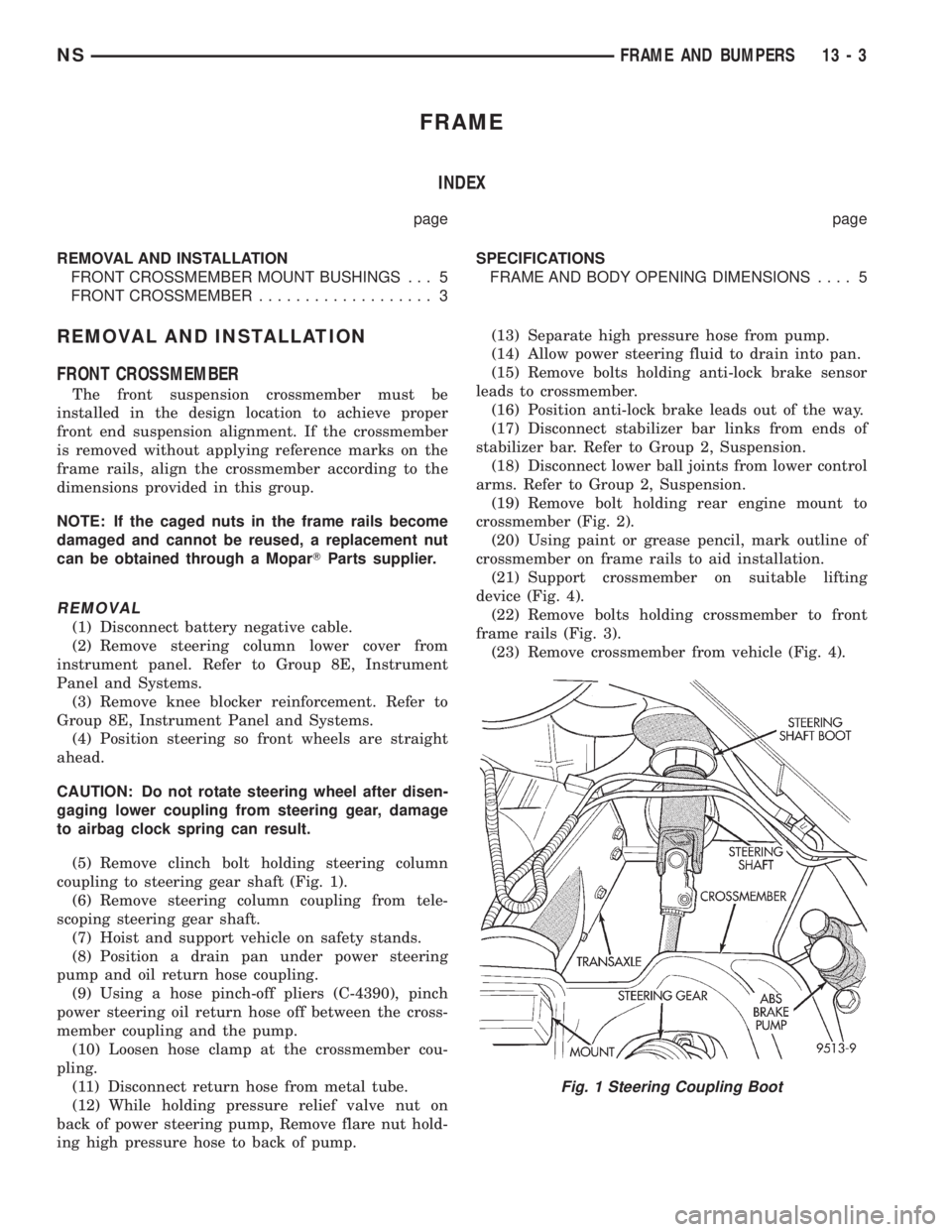

The front suspension crossmember must be

installed in the design location to achieve proper

front end suspension alignment. If the crossmember

is removed without applying reference marks on the

frame rails, align the crossmember according to the

dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through a MoparTParts supplier.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(3) Remove knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to airbag clock spring can result.

(5) Remove clinch bolt holding steering column

coupling to steering gear shaft (Fig. 1).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.

(7) Hoist and support vehicle on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the crossmember cou-

pling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut hold-

ing high pressure hose to back of pump.(13) Separate high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts holding anti-lock brake sensor

leads to crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar. Refer to Group 2, Suspension.

(18) Disconnect lower ball joints from lower control

arms. Refer to Group 2, Suspension.

(19) Remove bolt holding rear engine mount to

crossmember (Fig. 2).

(20) Using paint or grease pencil, mark outline of

crossmember on frame rails to aid installation.

(21) Support crossmember on suitable lifting

device (Fig. 4).

(22) Remove bolts holding crossmember to front

frame rails (Fig. 3).

(23) Remove crossmember from vehicle (Fig. 4).

Fig. 1 Steering Coupling Boot

NSFRAME AND BUMPERS 13 - 3

Page 1369 of 1938

FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE

CONTENTS

page page

FUEL DELIVERY SYSTEMÐ2.0L ENGINE.... 28

FUEL DELIVERY SYSTEMÐ2.5L DIESEL

ENGINE.............................. 3

FUEL INJECTION SYSTEMÐ2.0L ENGINE . . . 32FUEL INJECTION SYSTEMÐ2.5L DIESEL

ENGINE............................. 43

GENERAL INFORMATION.................. 1

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

FUEL REQUIREMENTSÐ2.0L ENGINE....... 2

FUEL REQUIREMENTSÐ2.5L DIESEL........ 2GASOLINE/OXYGENATE BLENDS........... 2

INTRODUCTIONÐ2.0L ENGINE............. 2

INTRODUCTIONÐ2.5L DIESEL............. 1

GENERAL INFORMATION

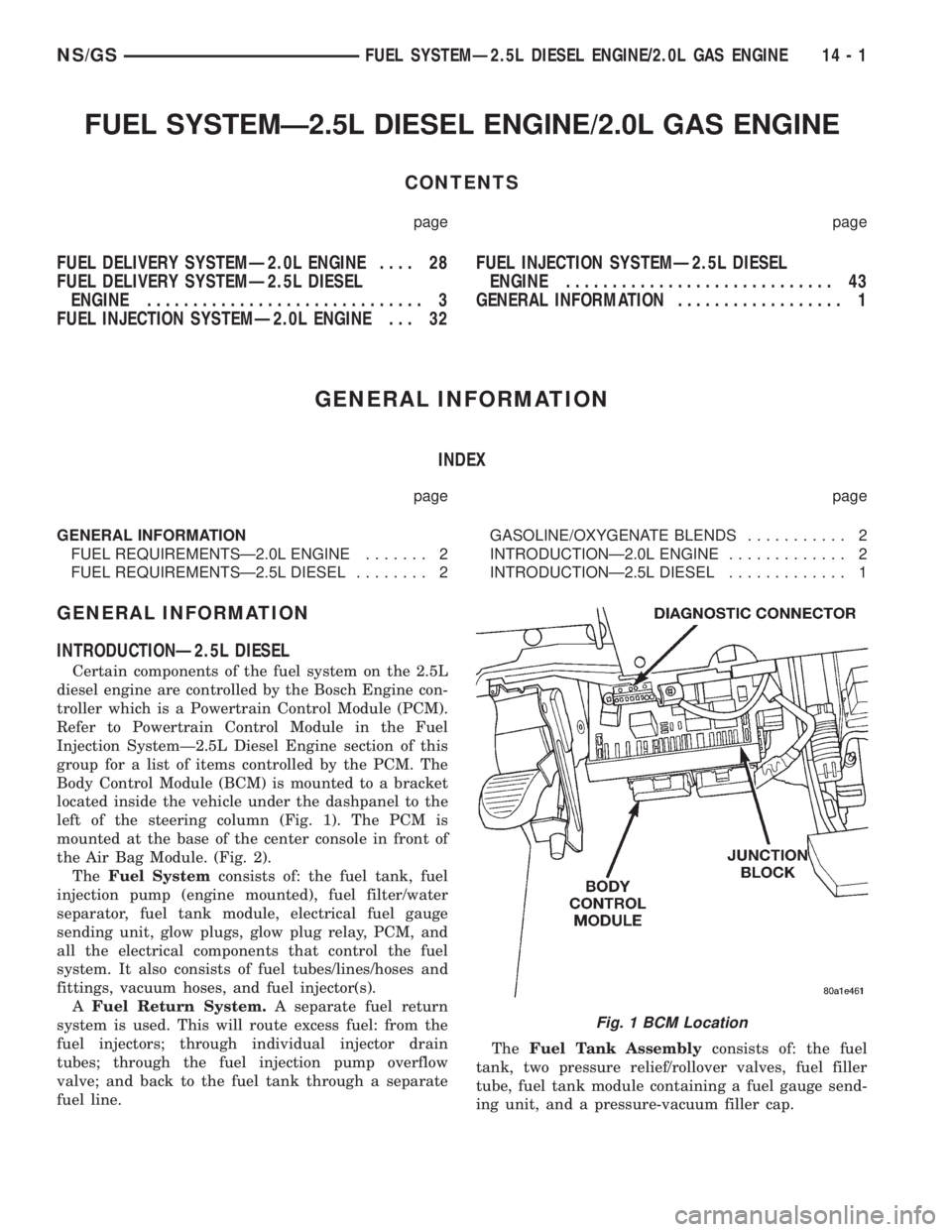

INTRODUCTIONÐ2.5L DIESEL

Certain components of the fuel system on the 2.5L

diesel engine are controlled by the Bosch Engine con-

troller which is a Powertrain Control Module (PCM).

Refer to Powertrain Control Module in the Fuel

Injection SystemÐ2.5L Diesel Engine section of this

group for a list of items controlled by the PCM. The

Body Control Module (BCM) is mounted to a bracket

located inside the vehicle under the dashpanel to the

left of the steering column (Fig. 1). The PCM is

mounted at the base of the center console in front of

the Air Bag Module. (Fig. 2).

TheFuel Systemconsists of: the fuel tank, fuel

injection pump (engine mounted), fuel filter/water

separator, fuel tank module, electrical fuel gauge

sending unit, glow plugs, glow plug relay, PCM, and

all the electrical components that control the fuel

system. It also consists of fuel tubes/lines/hoses and

fittings, vacuum hoses, and fuel injector(s).

AFuel Return System.A separate fuel return

system is used. This will route excess fuel: from the

fuel injectors; through individual injector drain

tubes; through the fuel injection pump overflow

valve; and back to the fuel tank through a separate

fuel line.TheFuel Tank Assemblyconsists of: the fuel

tank, two pressure relief/rollover valves, fuel filler

tube, fuel tank module containing a fuel gauge send-

ing unit, and a pressure-vacuum filler cap.

Fig. 1 BCM Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 1

Page 1406 of 1938

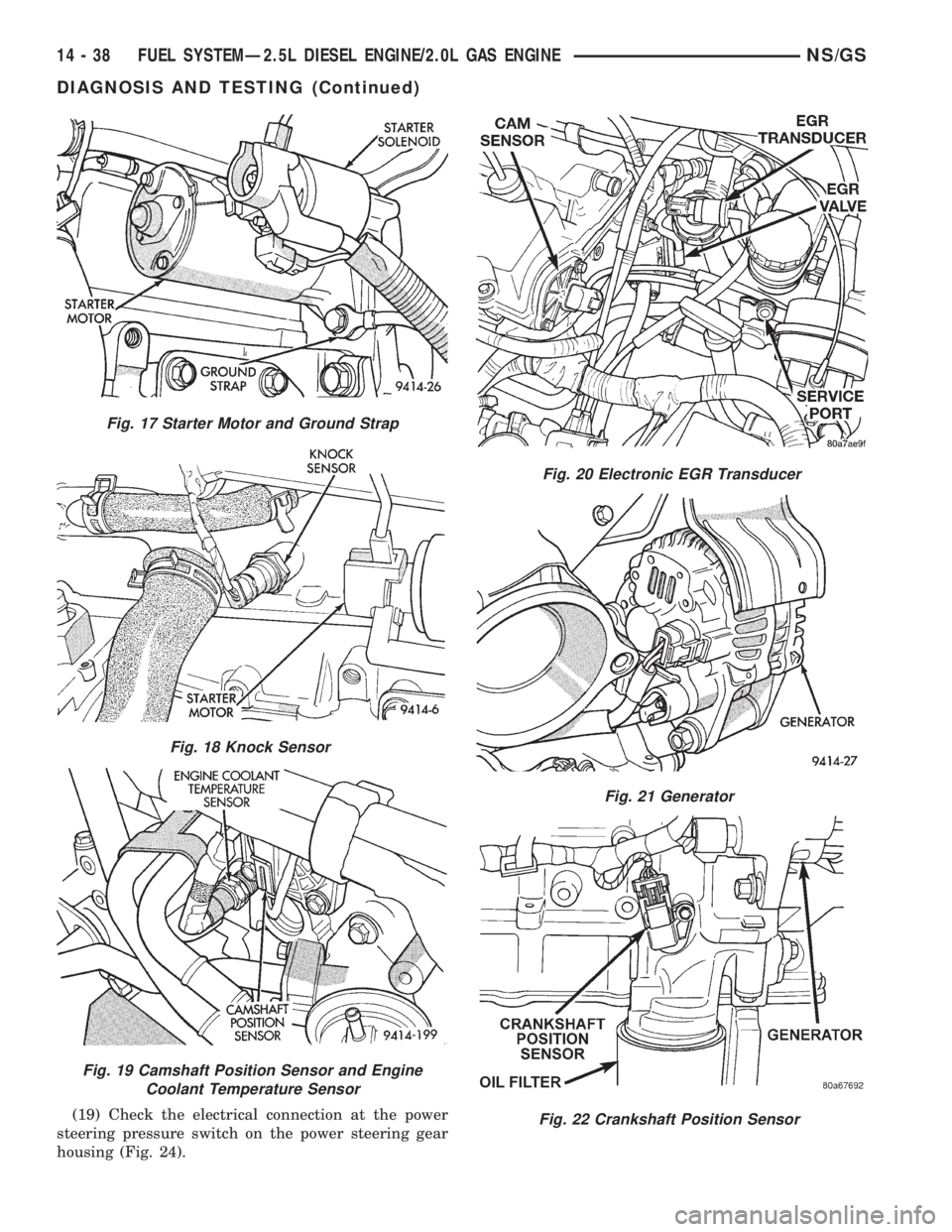

(19) Check the electrical connection at the power

steering pressure switch on the power steering gear

housing (Fig. 24).

Fig. 17 Starter Motor and Ground Strap

Fig. 18 Knock Sensor

Fig. 19 Camshaft Position Sensor and Engine

Coolant Temperature Sensor

Fig. 20 Electronic EGR Transducer

Fig. 21 Generator

Fig. 22 Crankshaft Position Sensor

14 - 38 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1407 of 1938

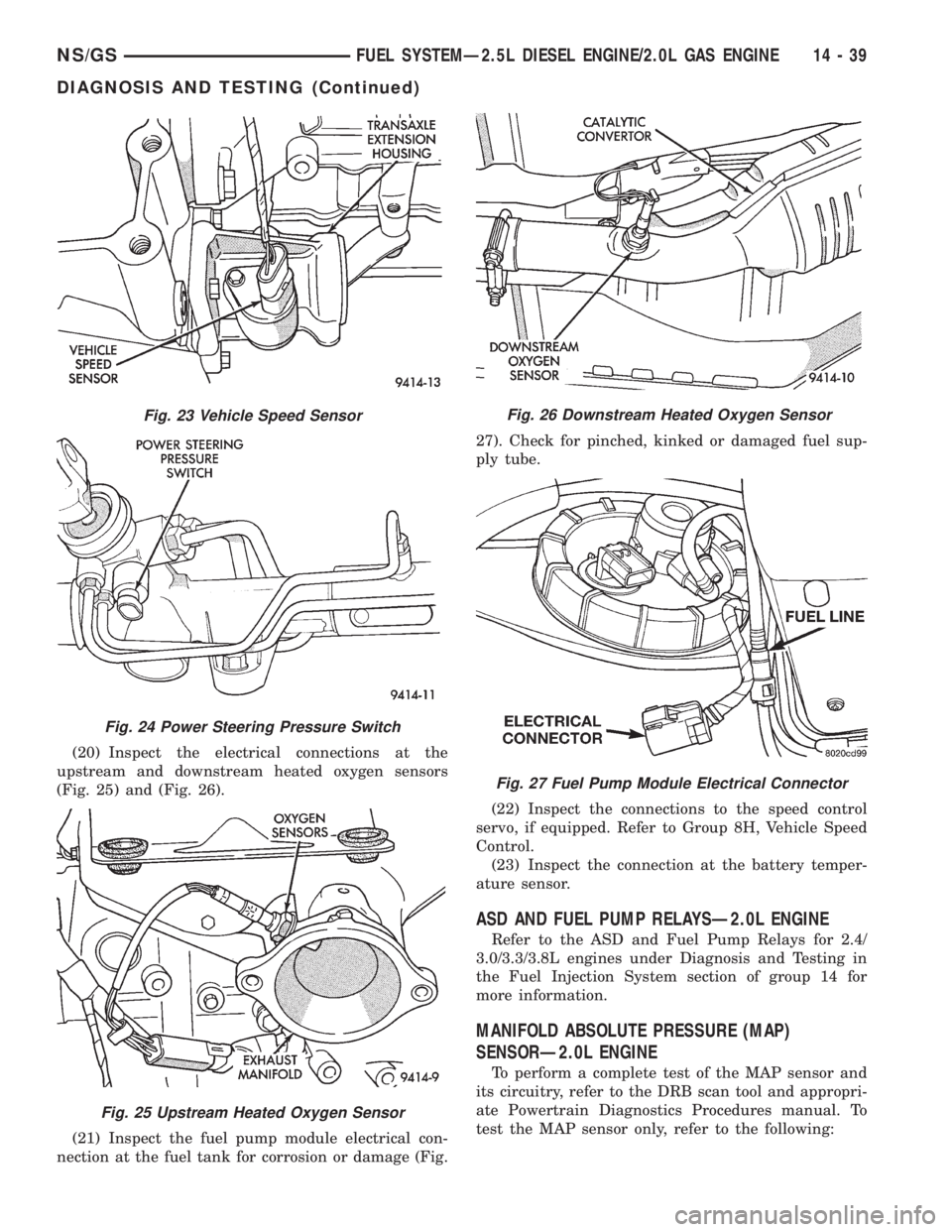

(20) Inspect the electrical connections at the

upstream and downstream heated oxygen sensors

(Fig. 25) and (Fig. 26).

(21) Inspect the fuel pump module electrical con-

nection at the fuel tank for corrosion or damage (Fig.27). Check for pinched, kinked or damaged fuel sup-

ply tube.

(22) Inspect the connections to the speed control

servo, if equipped. Refer to Group 8H, Vehicle Speed

Control.

(23) Inspect the connection at the battery temper-

ature sensor.

ASD AND FUEL PUMP RELAYSÐ2.0L ENGINE

Refer to the ASD and Fuel Pump Relays for 2.4/

3.0/3.3/3.8L engines under Diagnosis and Testing in

the Fuel Injection System section of group 14 for

more information.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.0L ENGINE

To perform a complete test of the MAP sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the MAP sensor only, refer to the following:

Fig. 23 Vehicle Speed Sensor

Fig. 24 Power Steering Pressure Switch

Fig. 25 Upstream Heated Oxygen Sensor

Fig. 26 Downstream Heated Oxygen Sensor

Fig. 27 Fuel Pump Module Electrical Connector

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 39

DIAGNOSIS AND TESTING (Continued)