air condition CHRYSLER VOYAGER 1996 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 746 of 1938

7C2

POWER

DISTRIBUTION

CENTER

40A

FUSE

21

85

87

3086FRONT

BLOWER

MOTOR

RELAY

5C2

3C1 C42

BLOCK JUNCTION

12FUSE10A

BATT A0

RUN A22

F20

20

WT

1

2

MOTOR BLOWER

FRONT B23

P18

C71

12

DB

Z1

18

BK

C28

5 0

123

4

A/C

HEATER

CONTROL

3C27C2C24C2210C2

C7

12

BK/TN

B35

10 1356

FRONT

BLOWER

MOTOR

RESISTOR

BLOCK

B31B23

P18B30 B33 B34B32C4

16

TN

C5

16

LGC6

14

LBC104

12

RD/WTC107

12

TN/BK

TN/BK12 C107

RD/WT12 C104

LB14 C6

LG16 C5

TN16 C4

HVAC

CONTROL FRONT

BLOWER

OFF GROUND

G300

BK12Z1

C26

G201

7

10

SWITCH CONTROL

FRONT

BLOWER

REAR

Z1

12

BK

4 M3 2 M1

3 M2 1 LOW 0 OFF

5 HIGH

35

32 34 33 30 31

GROUND M

(8W-10-8)

(8W-10-18) (8W-12-2)

(8W-12-12)

(8W-10-8) (8W-10-14)

(8W-15-7)

(8W-15-4)(8W-42-6)

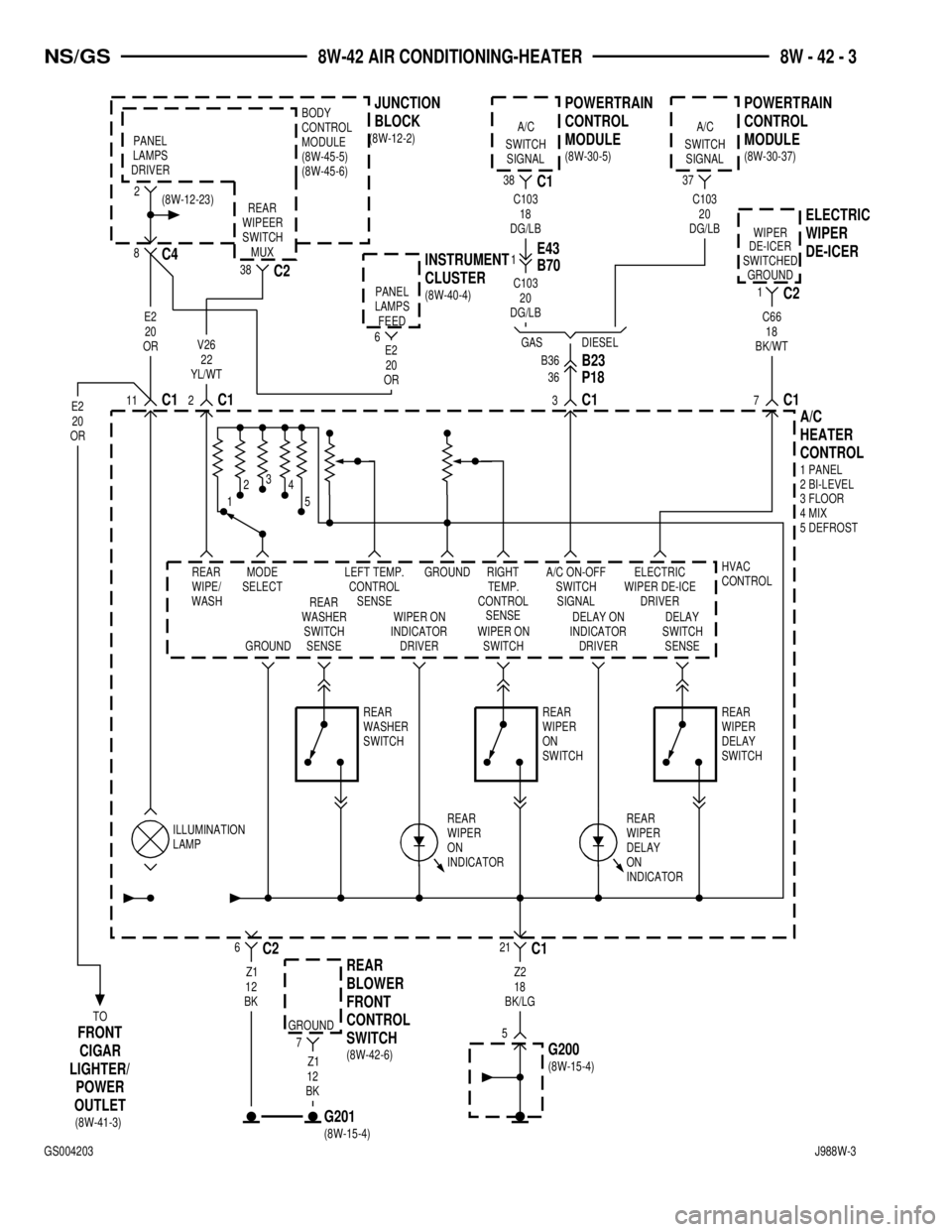

8W - 42 - 2 8W-42 AIR CONDITIONING-HEATERNS/GS

J988W-3GS004202

Page 747 of 1938

A/C

HEATER

CONTROL

HVAC

CONTROL MODE

SELECTGROUND

4 3

2

15

SENSE CONTROL LEFT TEMP.REAR

WASHER

SWITCH

SENSE

11C1

6C221C1

G201

7SWITCH CONTROL

FRONT

BLOWER

REAR

Z1

12

BK

Z1

12

BK

SENSE SWITCHDELAY

LAMP

ILLUMINATIONREAR

WIPER

DELAY

SWITCH

DELAY ON

INDICATOR

DRIVER

ON DELAY

WIPER

REAR

SWITCH

ON

WIPER

REAR

SWITCH WIPER ON

INDICATOR

REAR

WIPER

ON

INDICATOR DRIVER INDICATORWIPER ON

REAR

WASHER

SWITCH

RIGHT

TEMP.

CONTROL

GROUND

BK/LG18Z2

G200

5

2

PANEL

LAMPS

DRIVERBODY

CONTROL

MODULE

C48

BLOCK JUNCTION

6

CLUSTER

INSTRUMENT

E2

20

OR

E2

20

OR

WASHWIPE/ REAR

C12

38C2

SWITCH WIPEERREAR

V26

22

YL/WT

37

SIGNAL SWITCHA/C

POWERTRAIN

CONTROL

MODULE

SIGNAL SWITCH A/C ON-OFF

C13

C103

20

DG/LB

P18

B23B36

SENSEDRIVER WIPER DE-ICEELECTRIC

ELECTRIC

WIPER

DE-ICER

C17

C66

18

BK/WT

MODULE CONTROL

POWERTRAINA/C

SWITCH

SIGNAL

38C1

1

DG/LB18 C103

E43

B70

GAS DIESEL

C103

20

DG/LB

36

1 PANEL

2 BI-LEVEL

4 MIX 3 FLOOR

5 DEFROST

E2

20

OR

FRONT

CIGAR

LIGHTER/

POWER

OUTLET

TO

1C2

MUX

FEED LAMPSPANELWIPER

DE-ICER

SWITCHED

GROUND

GROUND

(8W-15-4)(8W-42-6)

(8W-15-4) (8W-45-5)

(8W-45-6)(8W-12-2)

(8W-40-4)(8W-30-37) (8W-30-5)

(8W-41-3)(8W-12-23)

NS/GS8W-42 AIR CONDITIONING-HEATER 8W - 42 - 3

GS004203J988W-3

Page 748 of 1938

A/C

HEATER

CONTROL

HVAC

CONTROL

A/C

ON/OFF

SWITCH

SENSE

21C1

REAR

WINDOW

DEFOGGER

SWITCH

ON DEFOGGER

REAR

SWITCH

MODE

RECIRCULATE

SWITCH SENSEMODEINDICATOR

A/C

ON

INDICATOR DRIVER INDICATORA/C ON

A/C

SWITCH

BK/LG18Z2

G200

5

BLOCK JUNCTION

INDICATOR

MODE

RECIRCULATE

REAR WINDOW

DEFOGGER

RELAY CONTROL

10C1C11

(RUN) IGNITIONFUSED

14C4

BR/PK18 V23

20A

FUSE

6

ST-RUN A21

C14

22

WT/RD

C432

DRIVER INDICATORMODE RECIRCULATE

SWITCH SENSEDEFOGGERWINDOWREAR

10

CENTER

MESSAGE

V23

18

BR/PK

REAR

WINDOW

DEFOGGER

RELAY

8586

RECIRCULATE

(8W-15-4)(8W-12-2)

(8W-12-9)(8W-10-16)

(8W-46-2)

(8W-48-2)

8W - 42 - 4 8W-42 AIR CONDITIONING-HEATERNS/GS

J988W-3GS004204

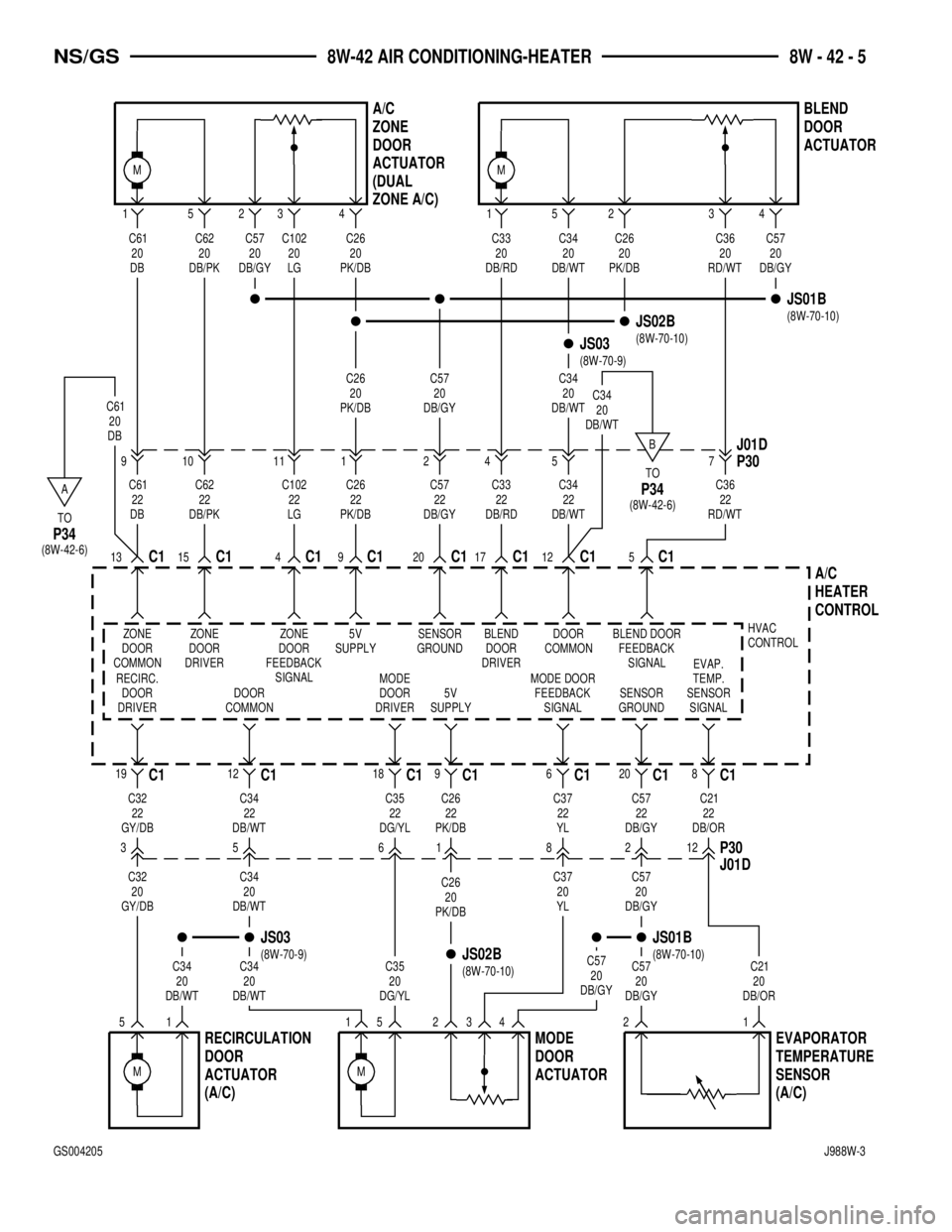

Page 749 of 1938

A/C

HEATER

CONTROL

HVAC

CONTROL

19C1

13C1

COMMONDOORZONE

15

ZONE

DOOR

DRIVER

C115

910

ACTUATOR DOOR

ZONE

234

C61

20

DB

C61

22

DB

P30 J01D

C62

20

DB/PK

C62

22

DB/PK

432

BLEND

DOOR

ACTUATOR

51

LG22 C102

11

4

C1

FEEDBACKDOORZONE

LG20 C102

JS01B

JS02B

4

C33

20

DB/RD

C117C33

22

DB/RD

BLEND

DOOR

DRIVER

SIGNALCOMMONDOOR

12C1

DB/WT22 C34

5

DB/WT20 C34

15 15

ACTUATOR DOOR

RECIRCULATION

24312

ACTUATOR

DOOR

MODE

SENSOR TEMPERATURE

EVAPORATOR

RECIRC.

DOOR

DRIVER

COMMONDOOR

C112

DRIVERDOOR MODE

C118

JS03

8C1

TEMP.

SENSOR

SIGNALEVAP.

C120SENSOR

GROUND

JS01B

6C1

SIGNAL FEEDBACK MODE DOOR

9C1

SUPPLY5V

JS02B

C15

BLEND DOOR

FEEDBACK

SIGNAL

C120

SENSOR

GROUNDSUPPLY5V

C19

C57

20

DB/GYC57

20

DB/GY

C57

20

DB/GY

C57

22

DB/GY

21

C26

22

PK/DB

C26

20

PK/DBC26

20

PK/DB

C26

20

PK/DB

7

C36

22

RD/WT

C36

20

RD/WT

12P30

J01D281653

C32

22

GY/DB

C32

20

GY/DBC34

20

DB/WT

C34

20

DB/WTC34

20

DB/WT

C34

22

DB/WTC26

22

PK/DBC57

22

DB/GY

C57

20

DB/GY

C57

20

DB/GY

C35

22

DG/YL

C35

20

DG/YL

C21

22

DB/OR

C21

20

DB/OR

C37

22

YL

C37

20

YL

JS03

C34

20

DB/WT

(DUAL

ZONE A/C)

(A/C)(A/C)

MM

MM

A/C

B

(8W-42-6)TO

P34A

(8W-42-6)TO

P34

C34

20

DB/WTC61

20

DB

C26

20

PK/DB

C57

20

DB/GY

(8W-70-10)

(8W-70-10)

(8W-70-9)(8W-70-10)

(8W-70-10)(8W-70-9)

NS/GS8W-42 AIR CONDITIONING-HEATER 8W - 42 - 5

GS004205J988W-3

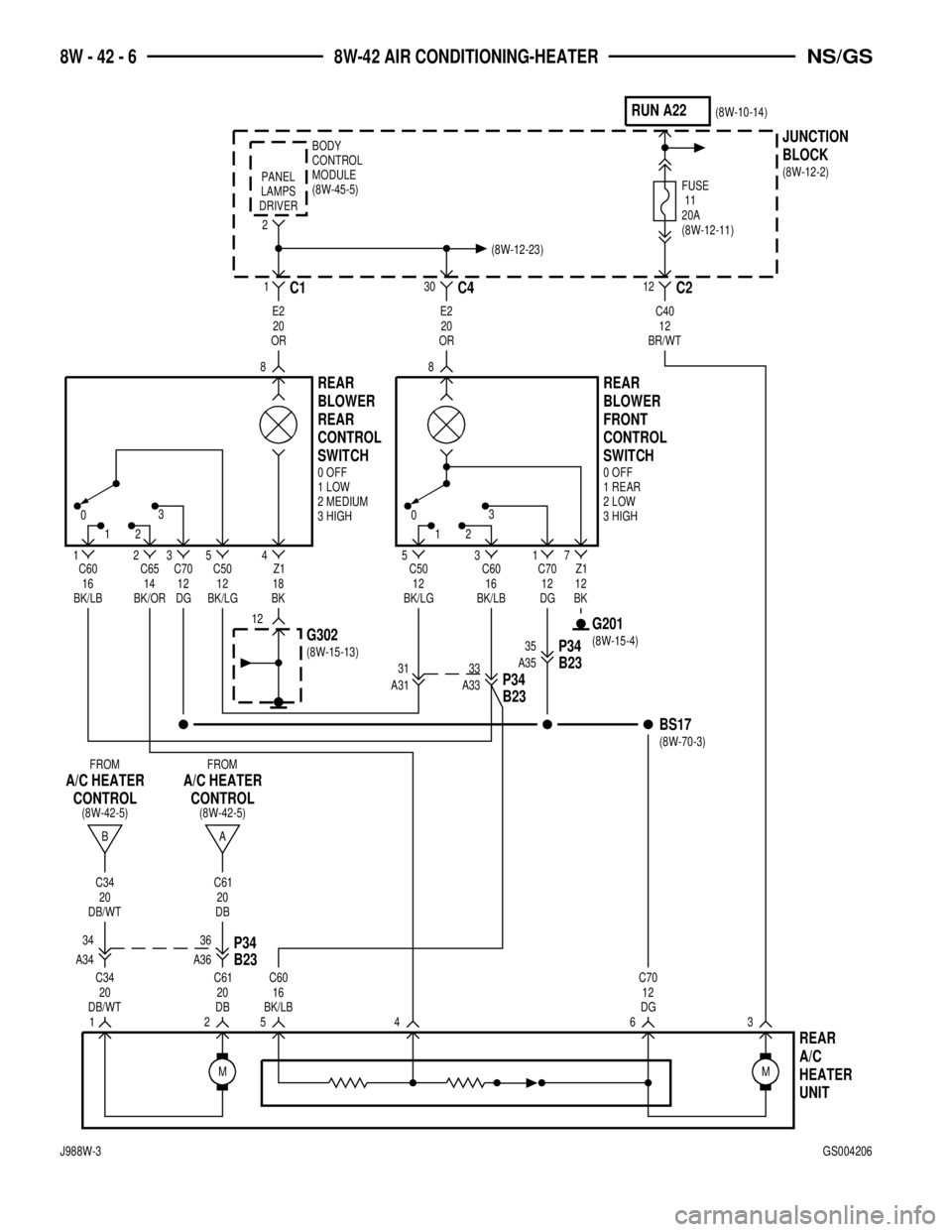

Page 750 of 1938

8

1

REAR

BLOWER

REAR

CONTROL

SWITCH SWITCHCONTROL

FRONT

BLOWER

REAR

8

3

3

2 1 00

123

C11

2

BODY

CONTROL

MODULE

PANEL

LAMPS

DRIVERBLOCK JUNCTION

30C4

741523

546

UNIT

HEATER

A/C

REAR

3

C212

20A

FUSE

11

RUN A22

C40

12

BR/WT

BS17

5

12

E2

20

ORE2

20

OR

G201G302

12

A36

P34

B23

A34

C61

20

DBC34

20

DB/WT

Z1

18

BK

33P34

B23

Z1

12

BK

31

C50

12

BK/LGC50

12

BK/LGC60

16

BK/LBC60

16

BK/LB

C60

16

BK/LB

C65

14

BK/ORC70

12

DG

C70

12

DG

C70

12

DG

A35B23 P34

34 36

A31 A3335

M

M

0 OFF

1 LOW

2 MEDIUM

3 HIGH 3 HIGH2 LOW

1 REAR

0 OFF

A (8W-42-5)B (8W-42-5)

A/C HEATER

CONTROL

FROM

CONTROL A/C HEATER

FROM

C34

20

DB/WT

C61

20

DB

(8W-45-5)(8W-12-2)

(8W-12-11)(8W-10-14)

(8W-70-3) (8W-15-4)

(8W-15-13)(8W-12-23)

8W - 42 - 6 8W-42 AIR CONDITIONING-HEATERNS/GS

J988W-3GS004206

Page 751 of 1938

C62

POWER

DISTRIBUTION

CENTER

8587

3086A/C

COMPRESSOR

CLUTCH

RELAY

15A

FUSE

11

BATT A0

7C6

1PTC

9A

C130

BLOCK JUNCTION

ST-RUN A21

6C2

F87

18

WT/BK

C261

POWERTRAIN

CONTROL

MODULE5V

SUPPLY

1

2

CLUTCH COMPRESSOR

A/C

G102 ES23

C3

18

DB/BK

Z1

18

BK

Z1

12

BK

64C2

CONTROL CLUTCH RELAYCOMPRESSORA/C

213

TRANSDUCER

PRESSURE

A/C

SIGNAL SWITCH PRESSUREA/C

42C2

SENSOR

GROUND

C243

C13

18

DB/ORES03

K6

18

VT/WT

K6

18

VT/WT

C18

18

DB

6C61C6

ES07

F87

18

WT/BKF87

18

BK/WT

3.3L/3.8L 2.0L

K4

18

BK/LB

ES02

ES21

ES21 FS01

BK/LB18 K4

K4

18

BK/LB

ES21

ES02

2.4L

5E69 F09

ES02

(8W-10-10)

(8W-10-29)(8W-10-8) (8W-12-13)(8W-12-2) (8W-10-16)

(8W-30-5) (8W-15-2) (8W-15-2)(8W-70-7) (8W-12-13)

(8W-70-4)

(8W-70-4)

(8W-70-5) (8W-70-5) (8W-70-6)

(8W-70-6)

(8W-70-5) (8W-12-13)

NS/GS8W-42 AIR CONDITIONING-HEATER

GAS8W - 42 - 7

GS004207J988W-3

Page 752 of 1938

POWER

DISTRIBUTION

CENTER

C2

73

POWERTRAIN

CONTROL

MODULERADIATOR

FAN

RELAY

CONTROL

1

2

NO. 1 FAN

RADIATOR RADIATOR

FAN

NO. 2

2 1

4

3

RELAY FAN

RADIATOR

24FUSE40A

BATT A0

C76

G102RFS2

FUSED

B (+)

FAN

RELAY

CONTROLRELAY

2

RFS1

1E40

RF3

C23

12

DG

C23

12

DG

C23

12

DGC23

12

DG

1 GROUND

ES23

Z1

14

BK

Z1

12

BKZ1

12

BK

Z1

12

BK

E40 RF32

Z1

12

BK

Z1

12

BK

A16

12

GY

MM

LG/DB14 K173

RADIATOR

OUTPUTRADIATOR

FAN

(8W-10-8)

(8W-30-5) (8W-10-15)(8W-10-8)

(8W-15-2)(8W-15-2)

8W - 42 - 8 8W-42 AIR CONDITIONING-HEATER

GASNS/GS

J988W-3GS004208

Page 753 of 1938

C62

POWER

DISTRIBUTION

CENTER

8587

3086A/C

COMPRESSOR

CLUTCH

RELAY

15A

FUSE

11

BATT A0

7C6

1C6

19

POWERTRAIN

CONTROL

MODULE5V

SUPPLY

CLUTCH COMPRESSOR

A/C

C3

18

DB/BK

28

CONTROL CLUTCH RELAYCOMPRESSORA/C

213

TRANSDUCER

PRESSURE

A/C

SIGNAL SWITCH PRESSUREA/C

13

SENSOR

GROUND 33

C13

20

DB/OR

K7

20

ORC18

20

DBK4

20

BK/LB

2

Z2

18

BK

Z1

16

BK

Z0

10

BK

ES01 ES02Z0

6

BK

G100

Z0

2

BK

G103

BATTERY

30

87

DIESEL

POWER

RELAY

20A

FUSE

17

BATT A0C65

ES29ES06

A142

18

DG/OR

A142

18

DG/OR

A142

18

DG/OR

9E97

B106

C13

20

DB/OR

BS34

1(8W-10-9)

(8W-10-29)(8W-10-8)

(8W-30-38) (8W-20-3)

(8W-15-3)

(8W-15-3)(8W-30-28) (8W-10-25)(8W-10-8) (8W-10-25)(8W-10-25)

(8W-70-11)

NS/GS8W-42 AIR CONDITIONING-HEATER

DIESEL8W - 42 - 9

GS004209J988W-3

Page 754 of 1938

POWER

DISTRIBUTION

CENTER

6

POWERTRAIN

CONTROL

MODULE

24FUSE40A

BATT A0

C76

A16

12

GY

NO. 1 RELAY

FAN

RADIATOR

6

RADIATOR

FAN

RELAY

NO. 2

48

2662

4

NO. 3 RELAY

FAN

RADIATOR

4

312

ES07

C25

12

YL

LOW

SPEED

RADIATOR

RELAY NO. 2

CONTROLC24

20

DB/PK

CONTROL NO.1 & NO.3RADIATORSPEEDHIGH

48

ES09

1E95

B10710B106 E97ES29

C24

20

DB/PK

C137

20

YLC137

20

YL

C137

20

YL

A142

18

DG/ORA142

18

DG/ORA142

18

DG/OR

C27

12

DB/PKC27

12

DB/PK

C27

12

DB/PK

BATT A17

ES12

G102

Z1

12

BK

Z1

12

BK

Z1

12

BK

C116

12

LG/WT

DRIVER'S

SIDE

RADIATOR

FAN FANRADIATOR

SIDE

PASSENGER'S

MMDISCONNECT

FAN

RADIATOR

48

258A17

12

RD/BK

(8W-10-8)

(8W-30-37)(8W-10-15)(8W-10-8)

(8W-10-25)

(8W-15-3)

(8W-15-3)(8W-10-19)

8W - 42 - 10 8W-42 AIR CONDITIONING-HEATER

DIESELNS/GS

J988W-3GS004210

Page 1053 of 1938

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, Tool C-3501,

equipped with 280 grit stones, if the cylinder bore is

straight and round. 20-60 strokes depending on the

bore condition, will be sufficient to provide a satisfac-

tory surface. Inspect cylinder walls after each 20

strokes, using a light honing oil.Do not use engine

or transmission oil, mineral spirits or kerosene.

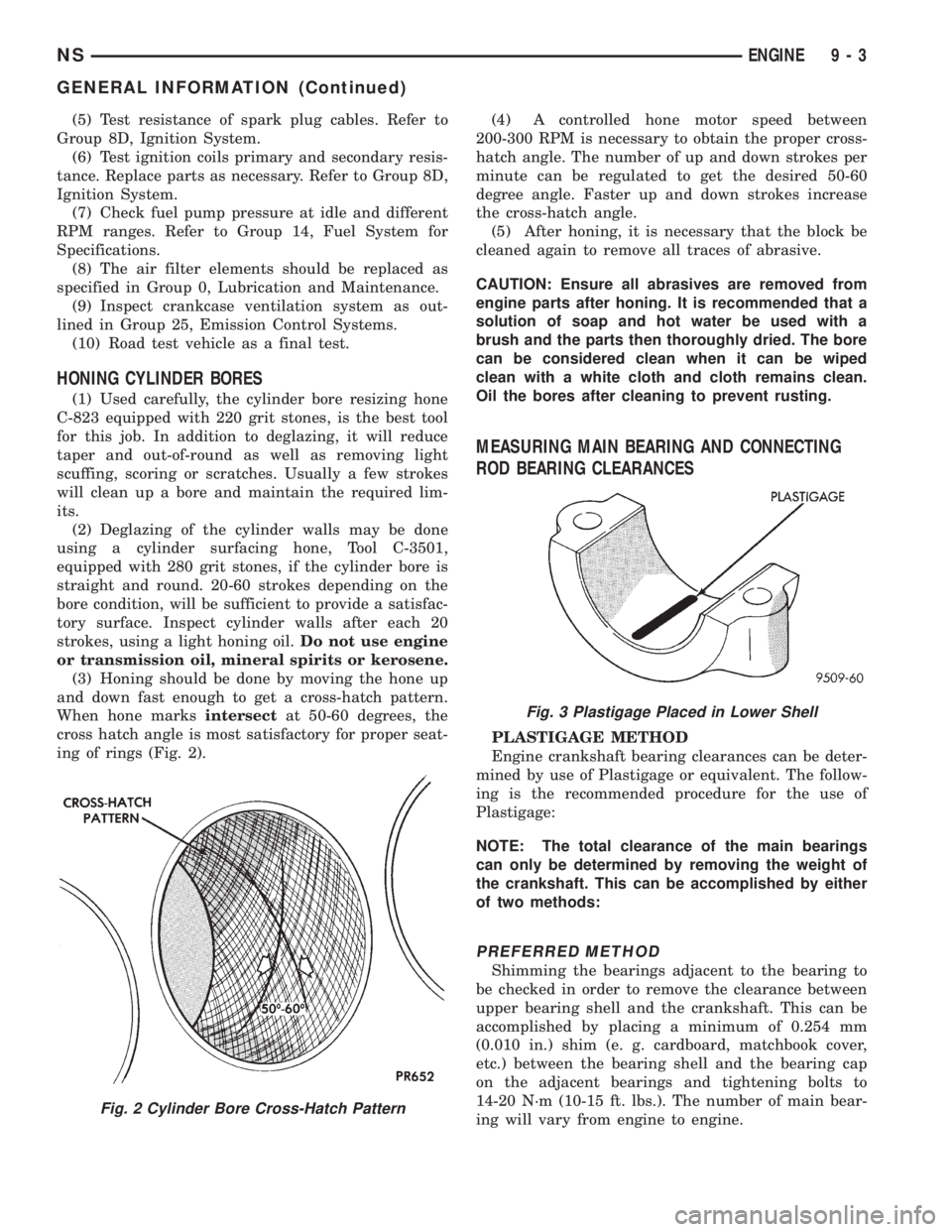

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 2).(4) A controlled hone motor speed between

200-300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50-60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

MEASURING MAIN BEARING AND CONNECTING

ROD BEARING CLEARANCES

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings

can only be determined by removing the weight of

the crankshaft. This can be accomplished by either

of two methods:

PREFERRED METHOD

Shimming the bearings adjacent to the bearing to

be checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N´m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

Fig. 2 Cylinder Bore Cross-Hatch Pattern

Fig. 3 Plastigage Placed in Lower Shell

NSENGINE 9 - 3

GENERAL INFORMATION (Continued)